Omron C200HG-CPU33, C200HG-CPU63, C200HG-CPU43, C200HG-CPU53, C200HE-CPU32 Installation Manual

...Page 1

C200HX-CPUjj-E/-ZE

C200HG-CPUjj-E/-ZE

C200HE-CPUjj-E/-ZE

Programmable Controllers

Installation Guide

Revised November 2001

Page 2

iv

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

!

WARNING Indicates information that, if not heeded, could possibly result in loss of life or serious injury.

!

Caution Indicates information that, if not heeded, could result in relatively serious or minor injury, dam-

!

age to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

vi

Page 5

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 What is a Control System? 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

System Configuration and Units 9. . . . . . . . . . . . . . . . . . . .

2-1 Basic Configuration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Units 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Peripheral Devices 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Expanded System Configurations 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Installation and Wiring 49. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Installation Environment 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Wiring 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Programming Console Operation 79. . . . . . . . . . . . . . . . . . .

4-1 Using the Programming Console 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Checking Initial Operation 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Troubleshooting, Inspections, and Maintenance 83. . . . . . .

5-1 Troubleshooting 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Inspection and Maintenance 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Inspections 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Standard Models 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Unit Current and Power Consumption 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Dimensions and Mounting Methods 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 6

About this Manual:

This manual describes the installation of C200HX, C200HG, and C200HE Programmable Controllers,

and it includes the sections described below. Programming and operating information is provided in the

C200HX/C200HG/C200HE Operation Manual.

Please read this manual completely and be sure you understand the information provided before attempting to install a C200HX/C200HG/C200HE PC. Be sure to read the precautions in the following sec-

tion.

Section 1 is an introduction to Programmable Controllers (or PCs). General information is provided on

PCs and how they work.

Section 2 provides a description of all the components of the C200HX/C200HG/C200HE. The names of

the parts of each Unit are given. Expanded systems, including networks and Special I/O Units are also

introduced.

Section 3 describes how to install and wire a PC System.

Section 4 provides general information about the Programming Console.

Section 5 provides information on hardware and software errors that occur during PC operation. It also

covers maintenance and inspection, and explains how to replace consumable components such as

fuses, relays, and batteries.

Appendix A provides tables of standard models.

Appendix B provides tables of Unit specifications.

Appendix C provides the current/power consumptions for the Units and calculations of the total con-

sumption of a PC.

Appendix D provides Unit dimensions and mounting information.

A Glossary, and an Index are also provided.

WARNING Failure to read and understand the information provided in this manual may result in

!

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the PC. You must read

this section and understand the information contained before attempting to set up or operate a PC system.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 8

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON PCs.

Be sure to read this manual before attempting to use the software and keep this

manual close at hand for reference during operation.

5Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the abovementioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

WARNING Do not touch the Power Supply Unit while power is being supplied or

!

immediately after power has been turned OFF. Doing so may result in electric

shock.

xii

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

Page 9

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, the input signals may not be readable.

Caution Confirm safety at the destination node before transferring a program to another

!

node or changing contents of the I/O memory area. Doing either of these without

confirming safety may result in injury.

4Operating Environment Precautions

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

!

torque specified in the operation manual. The loose screws may result in burning

or malfunction.

Caution When using the C200HW-PA209R Power Supply Unit with an 8-slot or 10-slot

!

CPU Backplane or Expansion I/O Backplane, be sure to use only Backplanes

with “-V1” at the end of the model number. Using an 8-slot or 10-slot Backplane

without “-V1” at the end of the model number may result in malfunction due to

deterioration of the base or pattern burnout. The 3-slot and 5-slot Backplanes do

not come in “-V1” models, and models without “-V1” can be used.

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

xiii

Page 10

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Cassettes, Power

Supply Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

5Application Precautions

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

xiv

Page 11

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

6Conformance to EC Directives

6 Conformance to EC Directives

Observe the following precautions when installing the C200HX/HG/HE PCs that

conform to the EC Directives.

1, 2, 3... 1. Since the C200HX/HG/HE PC is defined as an open type, be sure to install it

inside a panel.

2. Provide reinforced insulation or double insulation for the DC power source

connected to the DC I/O Unit and for a CPU Unit with a DC Power Supply

Unit.

3. The C200HX/HG/HE PC that conforms to the EC Directives also conforms,

as an individual unit, to the Common Emission Standard (EN50081-2) of the

EC Directives. When incorporated into a device, however, the C200HX/HG/

HE PC may not satisfy this Standard due to the noise produced by the contact output when it switches on and off. In such a case, it will be necessary to

take countermeasures such as connecting a surge or arc killer, or providing

an external means of protection for the PC. The countermeasures taken to

satisfy the Standard vary depending on the load devices, wiring, machinery

configuration, etc. Described on page 137 are examples of countermeasures to be taken to reduce the noise.

xv

Page 12

Criteria for Taking Countermeasures

(Refer to EN50081-2 for details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the PC included is less than 5 times per minute.

Countermeasures are not required if the frequency of load switching for the

whole system with the PC included is more than 5 times per minute.

6Conformance to EC Directives

xvi

Page 13

SECTION 1

Introduction

This section provides general information about Programmable Controllers (PCs) and how they fit into a Control System.

1-1 What is a Control System? 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Input Devices 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Output Devices 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 14

What is a Control System? Section 1-1

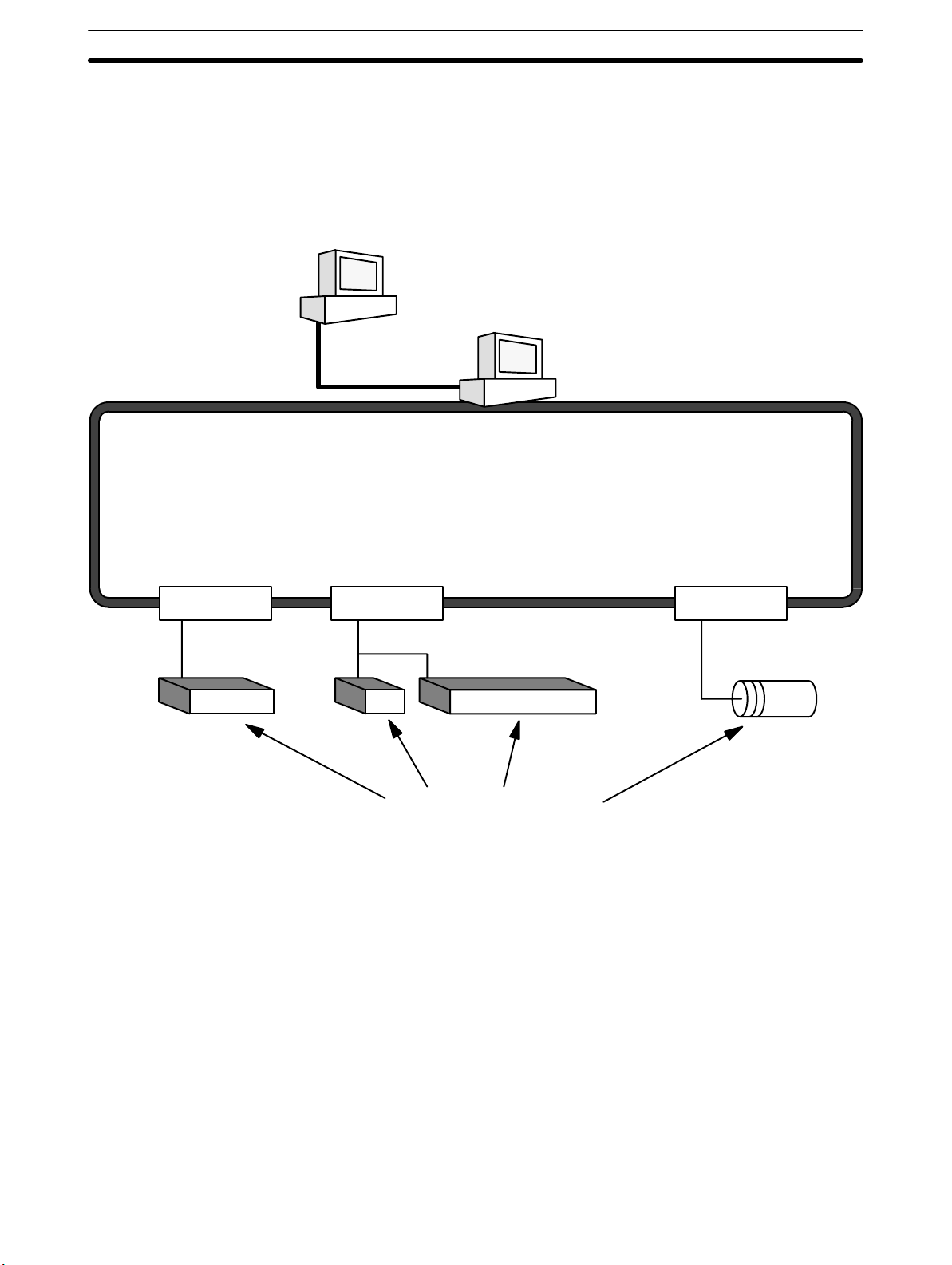

1-1 What is a Control System?

A Control System is the electronic equipment needed to control a particular process. It may include everything from a process control computer, if one is used,

to the factory computer, down through the PCs (and there may be many of them

networked together) and then on down through the network to the control components: the switches, stepping motors, solenoids, and sensors which monitor

and control the mechanical operations.

Process Control Computer

Factory Computer

PCs

PC PC PC

Control Components

A Control System can involve very large applications where many different models of PC are networked together or it could be an application as small as a single

PC controlling a single output device.

2

Page 15

What is a Control System? Section 1-1

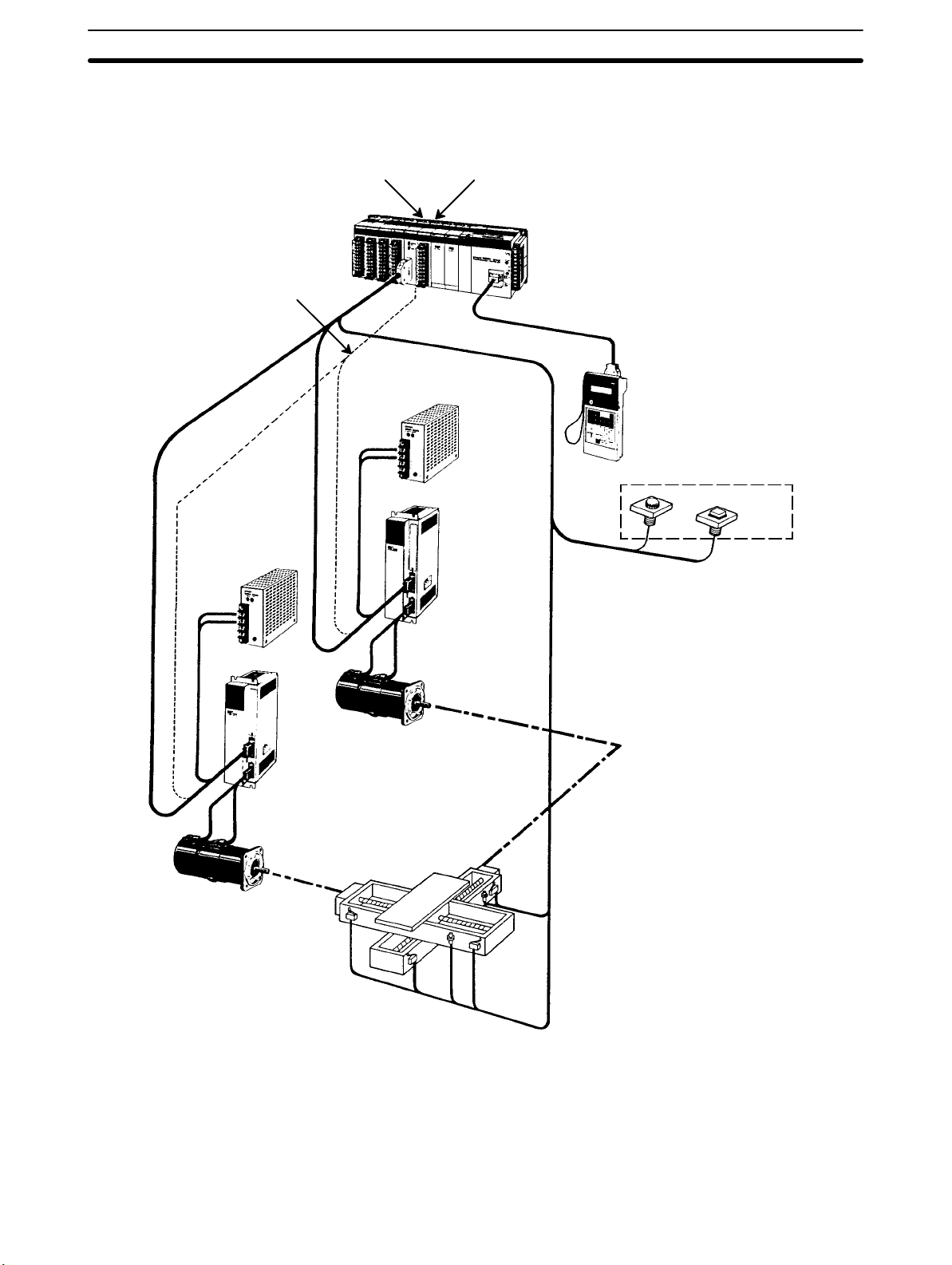

A Position Control System

Position Control Unit

Signal line for

Servomotor

driver control

Power

source

Input Unit

Power

source

DC Servomotor

Driver

PC

Hand-held Programming

Console

Control panel

Control switch

DC Servomotor Driver

DC Servomotor

In the typical Control System example shown above, a PC controls the movement of the workpiece bed across two horizontal axes using Limit Switches and

Servomotors to monitor and control movement.

DC Servomotor

3

Page 16

The Role of the PC Section 1-2

1-2 The Role of the PC

The Programmable Controller, or PC, is the part of the Control System that

directly controls the manufacturing process. According to the program stored in

its memory, the PC accepts data from the input devices connected to it, and uses

this data to monitor the controlled system. When the program calls for some

action to take place, the PC sends data to the output devices connected to it, to

cause that action to take place. The PC may be used to control a simple, repetitive task, or it may be connected to other PCs, or to a host computer in order to

integrate the control of a complex process.

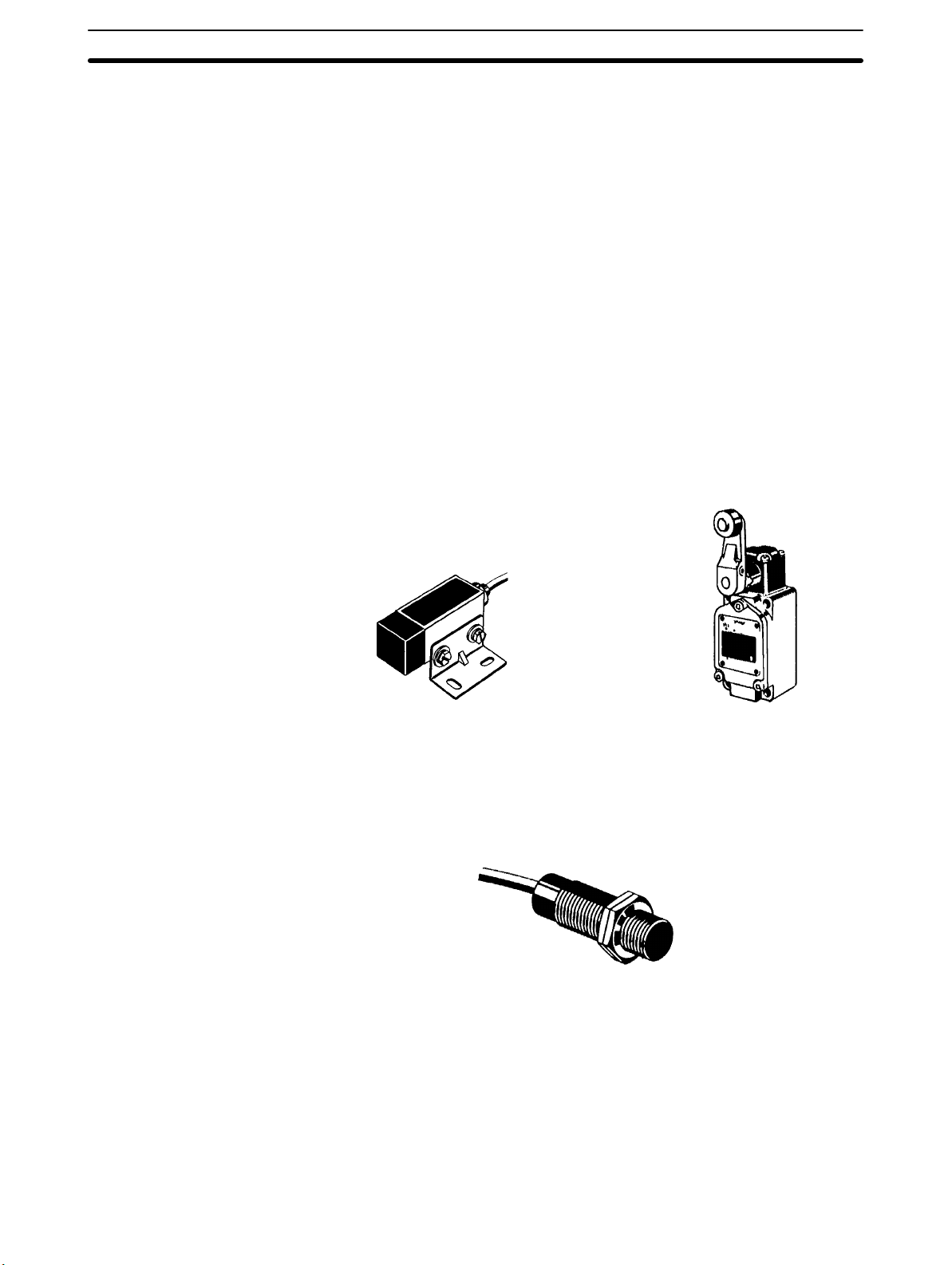

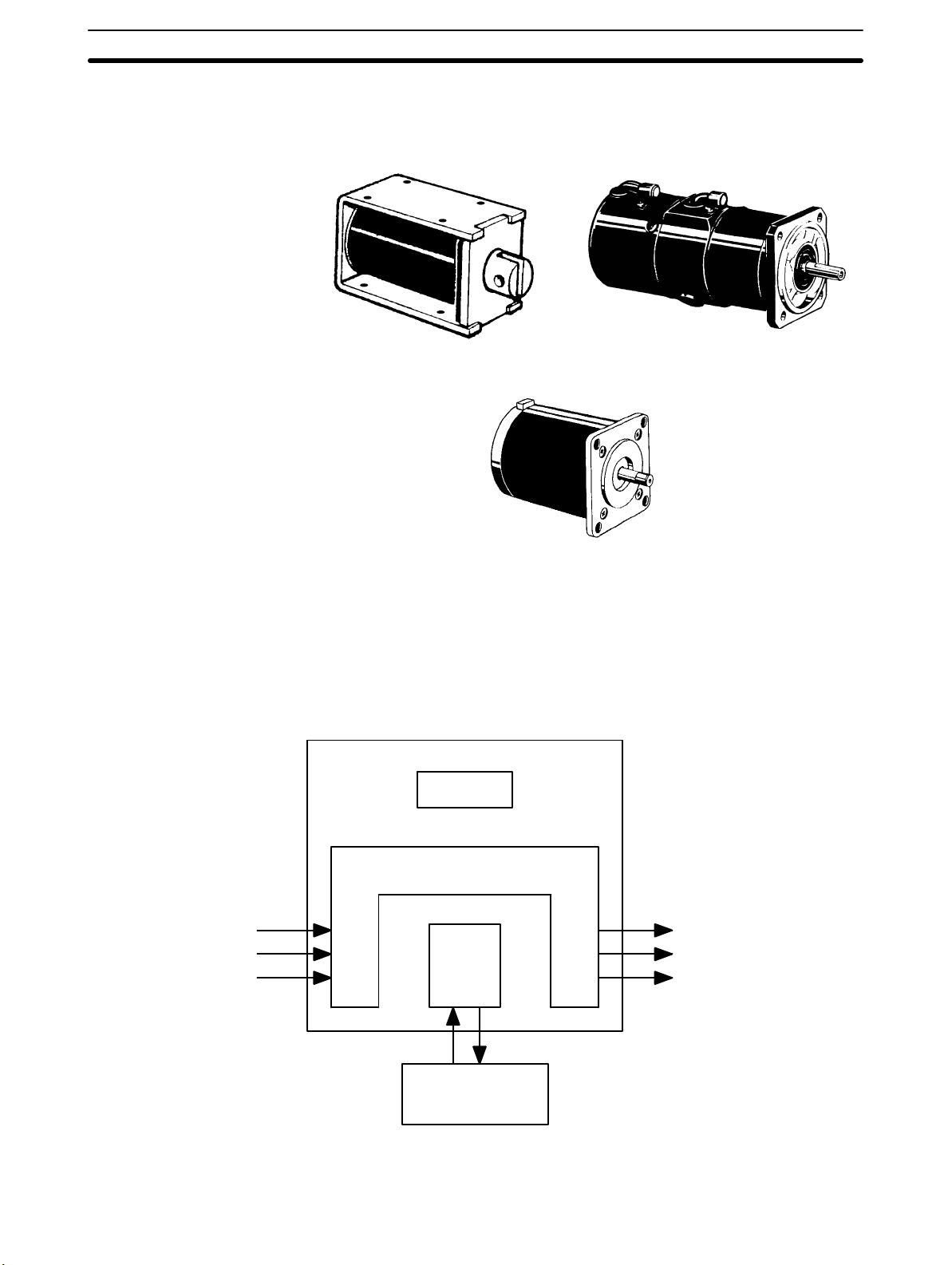

1-2-1 Input Devices

PCs can receive input from either automated or manual devices. The PC could

receive data from the user via a pushbutton switch, keyboard, or similar device.

Automated input could come from a variety of devices: microswitches, timers,

encoders, photosensors, and so on. Some devices, like the Limit Switch shown

below, turn ON or OFF when the equipment actually makes contact with it. Other

devices, like the Photoelectric Switch and Proximity Switch shown below, use

other means, such as light or inductance, in order to get information about the

equipment being monitored.

1-2-2 Output Devices

Photoelectric switch Limit switch

Proximity switch

A PC can output to a myriad of devices for use in automated control. Almost anything that you can think of could be controlled (perhaps indirectly) by a PC. Some

of the most common devices are motors, Solenoids, Servomotors, Stepping

Motors, valves, switches, indicator lights, buzzers, and alarms. Some of these

output devices; such as the motors, Solenoids, Servomotors, Stepping Motors,

4

Page 17

How Does a PC Work? Section 1-3

and valves; affect the controlled system directly. Others; such as the indicator

lights, buzzers, and alarms; provide output to notify personnel.

Solenoid

1-3 How Does a PC Work?

PCs operate by monitoring input signals and providing output signals. When

changes are detected in the signals, the PC reacts, through the user-programmed internal logic, to produce output signals. The PC continually scans the

program in its memory to achieve this control.

Block Diagram of PC

Servomotor

Stepping motor

Power Supply

Signals

from

switches,

sensors,

etc.

Memory

Signals to

Input Output

CPU

Programming

Device

Solenoids,

motors,

etc.

A program for your applications must be designed, and stored in the PC. This

program is then executed as part of the cycle of internal operations of the PC.

5

Page 18

How Does a PC Work? Section 1-3

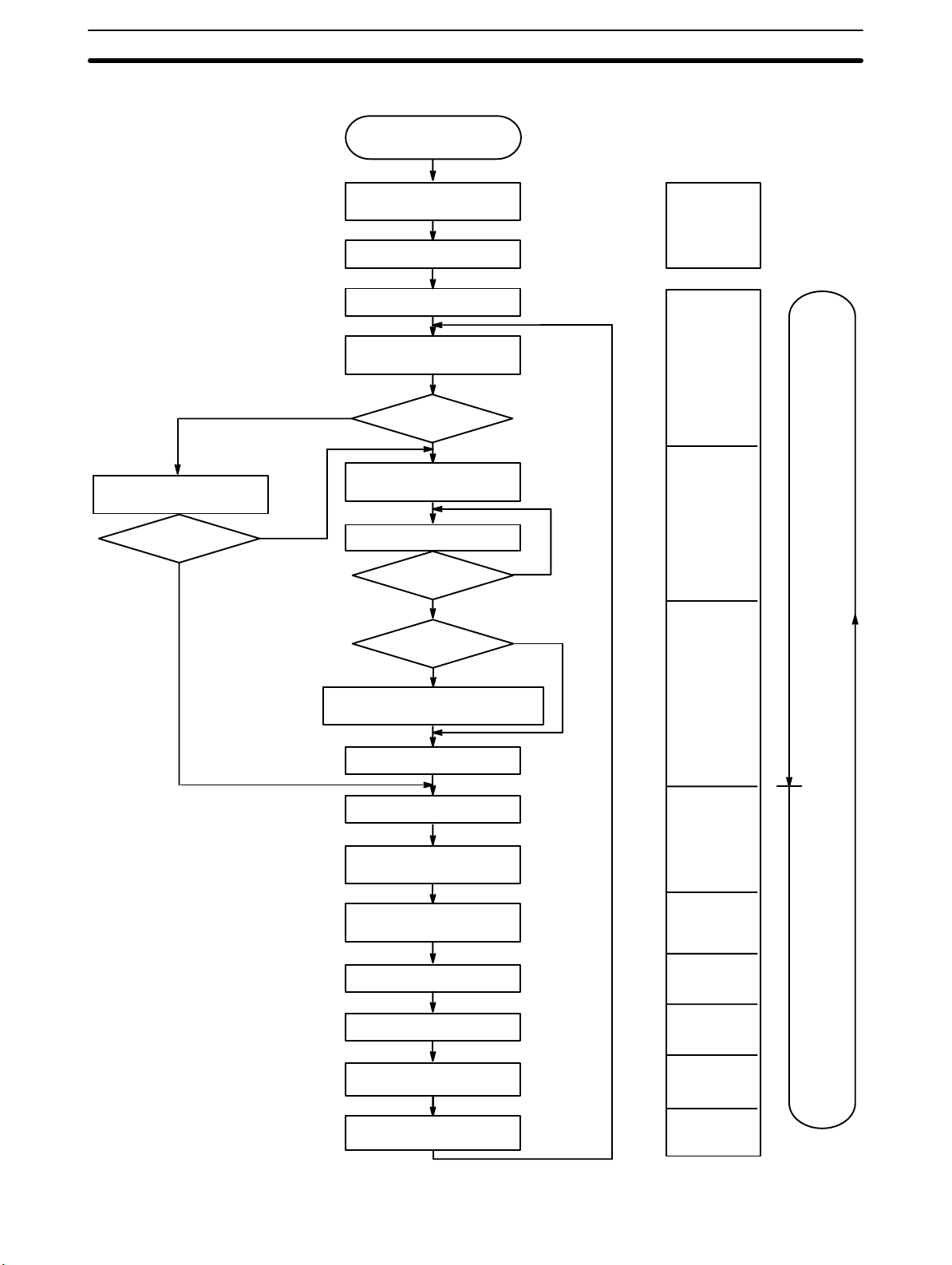

Cycle When a PC operates, that is, when it executes its program to control an external

system, a series of operations are performed inside the PC. These internal

operations can be broadly classified into the following four categories:

1, 2, 3... 1. Common (or overseeing) processes, such as watchdog timer operation and

testing the program memory.

2. Data input and output.

3. Instruction execution.

4. Peripheral device servicing.

Cycle Time The total time required for a PC to perform all these internal operations is called

the cycle time. The flowchart and diagram on the following page illustrate these

internal operations for a typical PC.

Timing is one of the most important factors in designing a Control System. For

accurate operations, it is necessary to have answers to such questions as these:

• How long does it take for the PC to execute all the instructions in its memory?

• How long does it take for the PC to produce a control output in response to a

given input signal?

The cycle time of the PC can be automatically calculated and monitored, but it is

necessary to have an understanding of the timing relationships within the PC for

effective system design and programming.

6

Page 19

How Does a PC Work? Section 1-3

Flowchart of CPU Operation

Sets error flags and turns

ON or flashes indicator

ALARM/ERROR

ERROR

(Solid ON)

ALARM

(Flashing)

Power application

Clears IR area and

resets all timers

Checks I/O Unit connections

Resets watchdog timer

Checks hardware and

Program Memory

NO

Check OK?

Resets watchdog timer and

program address counter

Executes program

End of program?

Initialization on

power-up

Overseeing

processes

YES

Program

execution

NO

YES

SCAN(18)

executed?

NO

YES

Resets watchdog timer and waits

until the set cycle time has elapsed

Calculates cycle time

Resets watchdog timer

Refreshes input bits

and output signals

Services RS-232C

connector

Services Host Link Units

Services Peripheral devices

Services Communications

Boards

Services SYSMAC LINK and

SYSMAC NET Link Units

Cycle time

calculation

I/O refreshing

RS-232C

connector

servicing

Host Link Unit

servicing

Peripheral

device

servicing

Communicatio

ns Board

servicing

SYSMAC LINK

and SYSMAC

NET servicing

PC

cycle

time

7

Page 20

Page 21

SECTION 2

System Configuration and Units

This section describes the system configuration used for the C200HX/C200HG/C200HE PCs and the individual Units used in

the system configuration.

2-1 Basic Configuration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 CPU Rack 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Expansion I/O Racks 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 I/O Connecting Cable 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Units 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 CPU Units 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Memory Cassettes 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Communications Boards 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Power Supply Units 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 Backplanes 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-6 Standard I/O Units 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-7 Group-2 High-density I/O Units 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-8 High-density I/O Units Classified as Special I/O Units 30. . . . . . . . . . . . . . . . . . . .

2-3 Peripheral Devices 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Programming Consoles 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Ladder Support Software (LSS) 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 SYSMAC Support Software (SSS) 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 SYSMAC-CPT Support Software 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Expanded System Configurations 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-1 Required Mounting Conditions 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-2 Special I/O Units 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-3 Link Systems and Networks 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Page 22

Basic Configuration Section 2-1

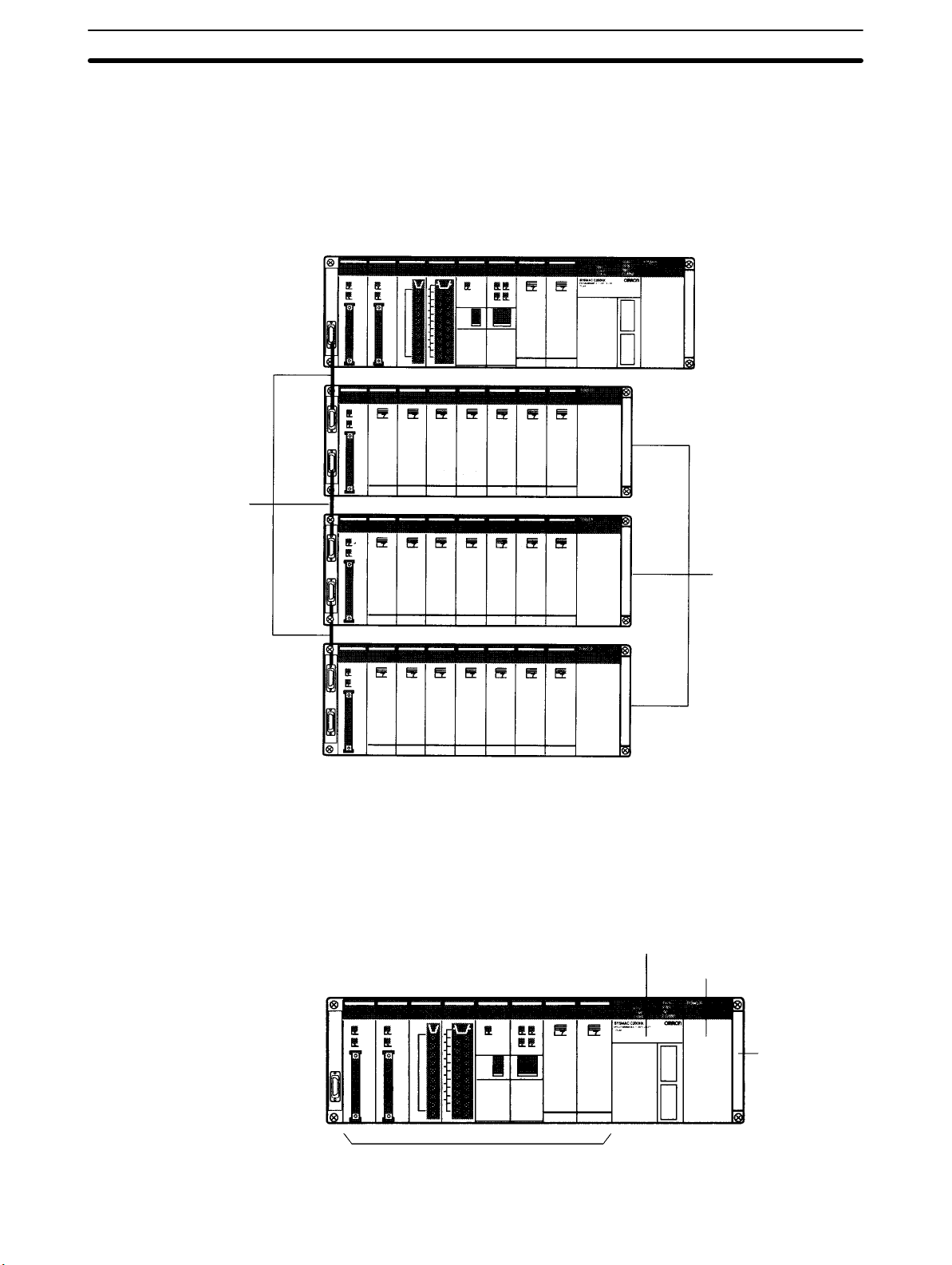

2-1 Basic Configuration

The basic configuration of the PC is shown below. With the C200HX/

C200HG/C200HE, up to two or up to three Expansion I/O Racks (depending on

the CPU Unit) can be connected to the CPU Rack, depending on the number of

I/O points required in the system.

CPU Rack

I/O Connecting Cables

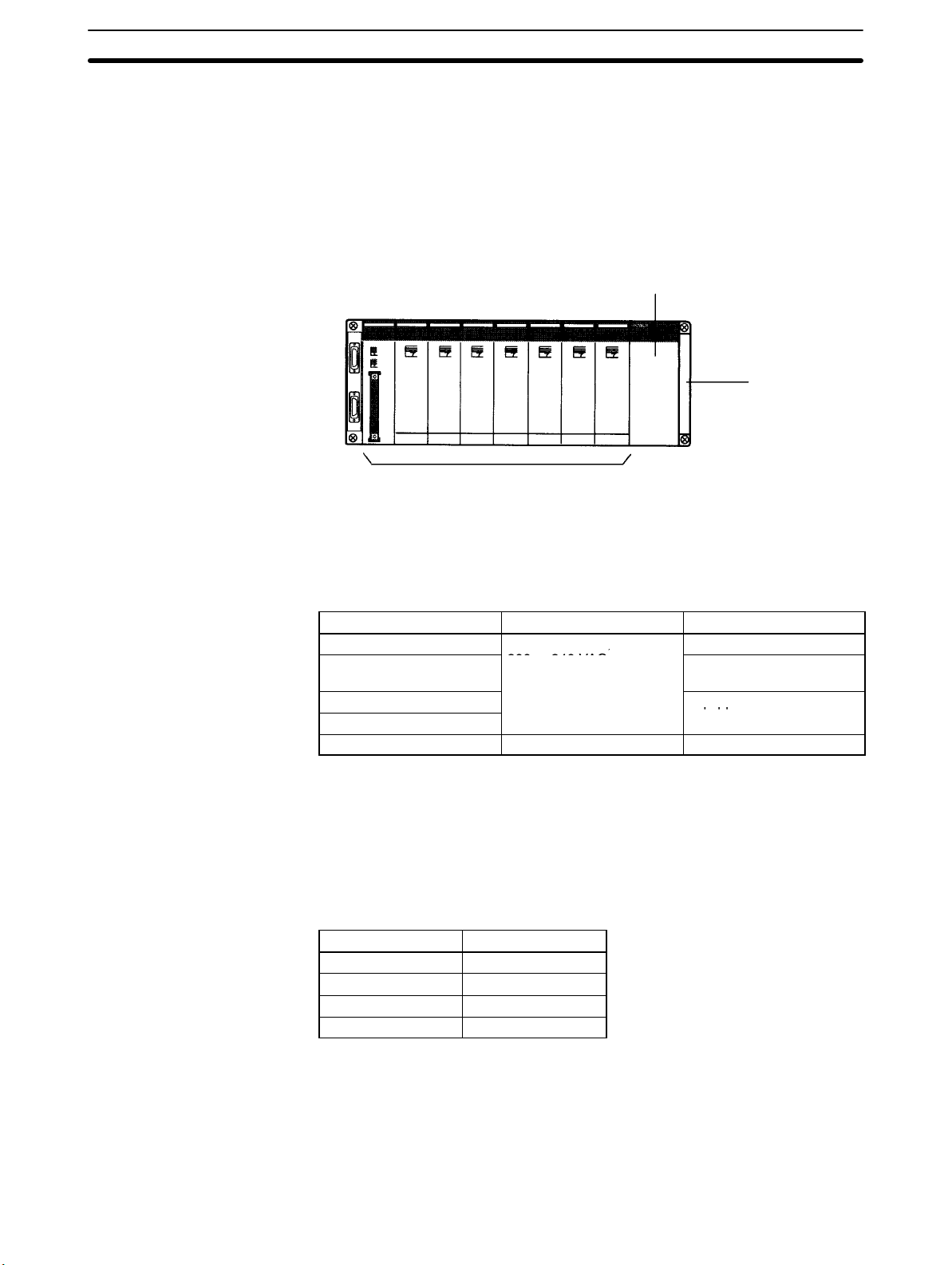

2-1-1 CPU Rack

Expansion I/O Racks

An example of a CPU Rack is shown below. The CPU Rack consists of a CPU

Backplane, CPU Unit, Power Supply Unit, I/O Units, and other special Units.

CPU Unit

Power Supply Unit

10

CPU Backplane

Other Units

Page 23

,

Basic Configuration Section 2-1

Power Supply Units The Power Supply Unit supplies power to the CPU Rack. The Power Supply

Units listed in the following table are available. Refer to 2-2-4 Power Supply

Units for further details.

Model Supply voltage Remarks

C200HW-PA204

C200HW-PA204S

C200HW-PA204R/PA209R

(See note.)

C200HW-PD024 24 VDC ---

Note The C200HW-PA204R/PA209R cannot be used with all combinations of CPU

Units and Backplanes. Refer to page 23, Restrictions for the C200HW-PA204R/

PA209R, for details.

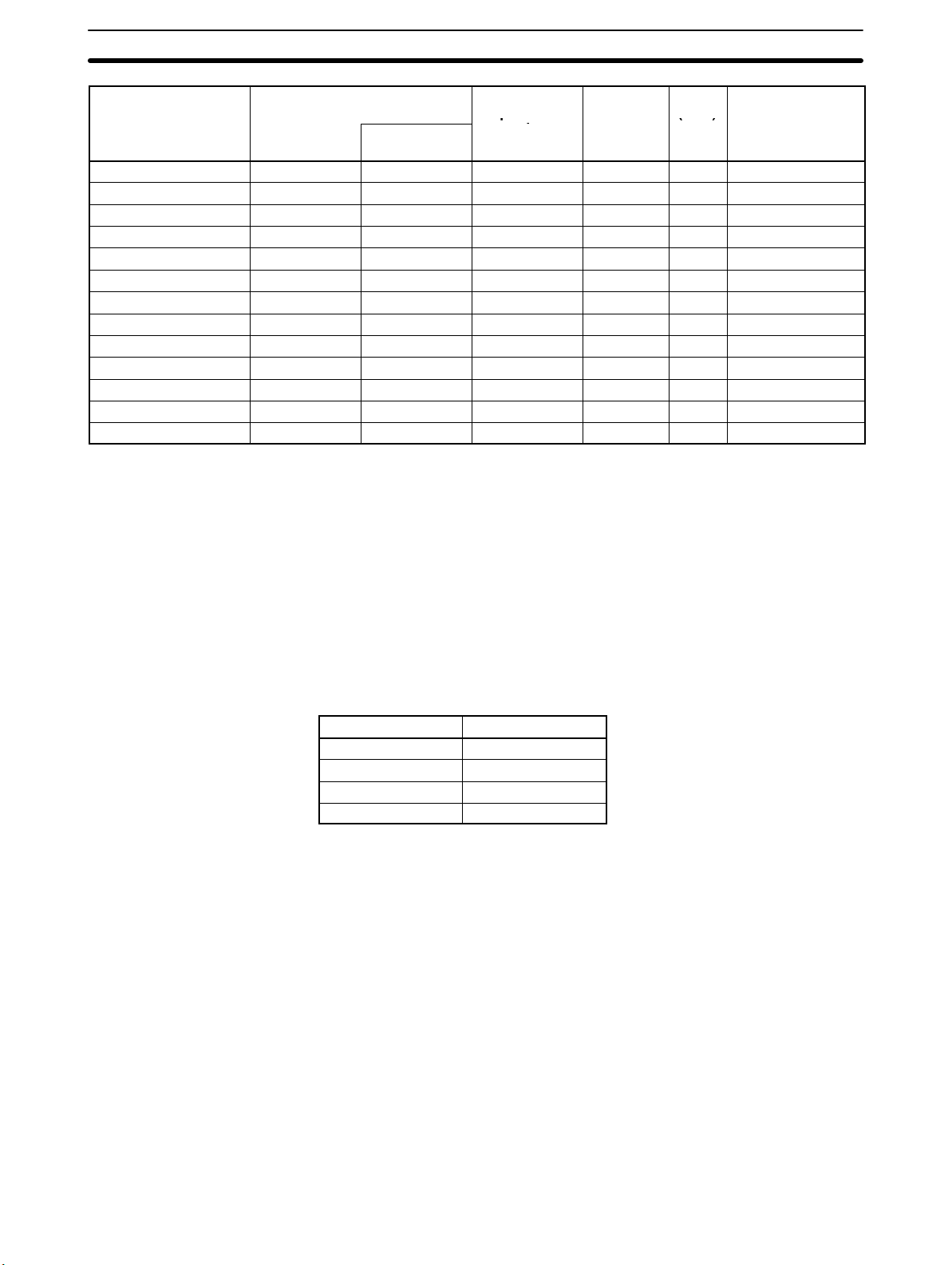

CPU Units The CPU Units listed in the following tables are available. Refer to 2-2-1 CPU

Units for further details on the CPU Units.

100 to 120 VAC,

200 to 240 VAC

---

Provides 24-VDC output

terminals.

Equipped with RUN output

contacts.

Model User

program

memory

C200HE-CPU11-E/ZE 3.2K words 4K words --- 0.3 µs min. 640 points 2 Racks

C200HE-CPU32-E/ZE 7.2K words 6K words --- 0.3 µs min. 880 points 2 Racks

C200HE-CPU42-E/ZE 7.2K words 6K words --- 0.3 µs min. 880 points 2 Racks

C200HG-CPU33-E/ZE 15.2K words 6K words 6K words 0.15 µs min. 880 points 2 Racks

C200HG-CPU43-E/ZE 15.2K words 6K words 6K words 0.15 µs min. 880 points 2 Racks

C200HG-CPU53-E/ZE 15.2K words 6K words 6K words 0.15 µs min. 1,184 points 3 Racks

C200HG-CPU63-E/ZE 15.2K words 6K words 6K words 0.15 µs min. 1,184 points 3 Racks

C200HX-CPU34-E/ZE 31.2K words 6K words 6K words x 3

C200HX-CPU44-E/ZE 31.2K words 6K words 6K words x 3

C200HX-CPU54-E/ZE 31.2K words 6K words 6K words x 3

C200HX-CPU64-E/ZE 31.2K words 6K words 6K words x 3

C200HX-CPU65-ZE 63.2K words 6K words 6K words x 8

C200HX-CPU85-ZE 63.2K words 6K words 6K words x 16

Data

memory

Extended

data memory

(EM)

(18K words)

(18K words)

(18K words)

(18K words)

(48K words)

(96K words)

Instruction

processing

time (basic

instructions)

0.1 µs min. 880 points 2 Racks

0.1 µs min. 880 points 2 Racks

0.1 µs min. 1,184 points 3 Racks

0.1 µs min. 1,184 points 3 Racks

0.1 µs min. 1,184 points 3 Racks

0.1 µs min. 1,184 points 3 Racks

Max. real I/O

points

supported

Max. No. of

Expansion

I/O Racks

11

Page 24

Spec a /O

(C)

oa d

Basic Configuration Section 2-1

Model

C200HE-CPU11-E/ZE Not supported Not supported 10 Units No No No

C200HE-CPU32-E/ZE 10 Units 5 Units 10 Units No Yes Ye s

C200HE-CPU42-E/ZE 10 Units 5 Units 10 Units Yes Yes Yes

C200HG-CPU33-E/ZE 10 Units 5 Units 10 Units No Ye s Yes

C200HG-CPU43-E/ZE 10 Units 5 Units 10 Units Ye s Yes Ye s

C200HG-CPU53-E/ZE 16 Units 8 Units 16 Units No Ye s Yes

C200HG-CPU63-E/ZE 16 Units 8 Units 16 Units Ye s Yes Ye s

C200HX-CPU34-E/ZE 10 Units 5 Units 10 Units No Yes Ye s

C200HX-CPU44-E/ZE 10 Units 5 Units 10 Units Yes Yes Yes

C200HX-CPU54-E/ZE 16 Units 8 Units 16 Units No Yes Ye s

C200HX-CPU64-E/ZE 16 Units 8 Units 16 Units Yes Yes Yes

C200HX-CPU65-ZE 16 Units 8 Units 16 Units Ye s Yes Ye s

C200HX-CPU85-ZE 16 Units 8 Units 16 Units Ye s Yes Ye s

Max. No. of Group-2

High-density I/O Units

64-point Units

(see note 1)

Max. No. of

Special I/O

Units

(see note 2)

RS-232C Clock

(RTC)

Communications

Note 1. Each 64 I/O Unit is treated as two Units.

2. Special I/O Units like the C200H-NC211 that are allocated the words for two

Units are treated as two Units.

3. Unit number settings for Group-2 Units for the following CPU Units must be

between 0 and 9:

C200HE-CPU32/42-E/ZE

C200HG-CPU33/43-E/ZE

C200HX-CPU34/44-E/ZE

Board

CPU Backplane The CPU Backplane is required to mount the CPU Unit and other Units compos-

ing the CPU Rack. The following CPU Backplanes are available depending on

the number of slot required for Units. Refer to 2-2-5 Backplanes for further

details.

Model Number of slots

C200HW-BC031 3

C200HW-BC051 5

C200HW-BC081-V1 8

C200HW-BC101-V1 10

Note When using the C200HW-PA209R Power Supply Unit with an 8-slot or 10-slot

CPU Backplane or Expansion I/O Backplane, be sure to use the C200HWBC081-V1 or C200HW-BC101-V1.

Other Units The other Units that can be mounted to the CPU Rack include the Standard I/O

Units, High-density I/O Units, and Special I/O Units.

12

Page 25

,

qpp

Basic Configuration Section 2-1

2-1-2 Expansion I/O Racks

An example of an Expansion I/O Rack is shown in the following diagram. Expansion I/O Racks consist of and I/O Backplane, Power Supply Unit, I/O Units, and

other Units. Expansion I/O Racks are connected to the CPU Rack to increase

the number of I/O Units and other Units that can be used by the PC. You can

connect up to 2 or up to 3 Expansion I/O Racks to a CPU Rack, the number

depending on the CPU Unit that is used.

Power Supply Unit

I/O Backplane

Other Units

Power Supply Unit The Power Supply Unit supplies power to the Expansion I/O Rack. The Power

Supply Units listed in the following table are available. Refer to 2-2-4 Power Sup-

ply Units for further details.

Model Supply voltage Remarks

C200HW-PA204

C200HW-PA204S

C200HW-PD204R

C200HW-PD209R

C200HW-PD024 24 VDC

100 to 120 VAC,

200 to 240 VAC

---

Provides 24-VDC output

terminals.

Equipped with RUN

output contacts.

Note RUN output contacts cannot be used with Expansion I/O Racks.

I/O Backplane The I/O Backplane is required to mount the Power Supply Unit and other Units

composing the Expansion I/O Rack. The following I/O Backplanes are available

depending on the number of slot required for Units. Refer to 2-2-5 Backplanes

for further details.

Model Number of slots

C200HW-BI031 3

C200HW-BI051 5

C200HW-BI081-V1 8

C200HW-BI101-V1 10

Note When using the C200HW-PA209R Power Supply Unit with an 8 or 10-slot Back-

plane, be sure to use the C200HW-BC081-V1 or C200HW-BC101-V1.

Other Units The other Units that can be mounted to an Expansion I/O Rack include the Stan-

dard I/O Units, High-density I/O Units, and Special I/O Units.

13

Page 26

Units

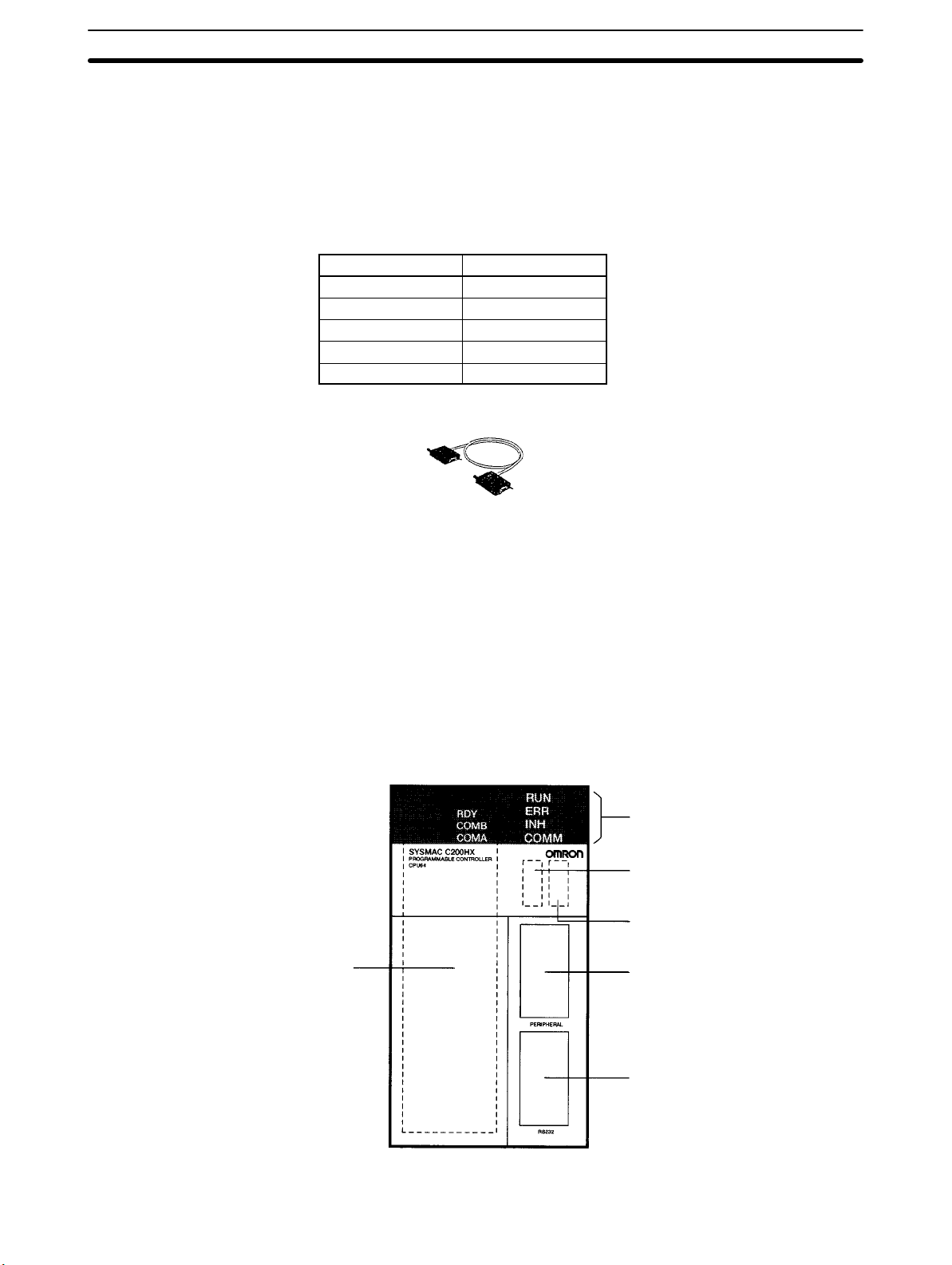

2-1-3 I/O Connecting Cable

The first Expansion I/O Rack is connected to the CPU Rack, and the second and

third Expansion I/O Racks are connected to the previous Expansion I/O Rack

through I/O Connecting Cable. There are five different lengths of cable available, which can be used as desired to provide the desired distance between

each Rack. The sum of the lengths of all the I/O Connecting Cables connected

within one PC, however, but be 12 m or less.

Model Cable length

C200H-CN311 30 cm

C200H-CN711 70 cm

C200H-CN221 2 m

C200H-CN521 5 m

C200H-CN131 10 m

Section 2-2

2-2 Units

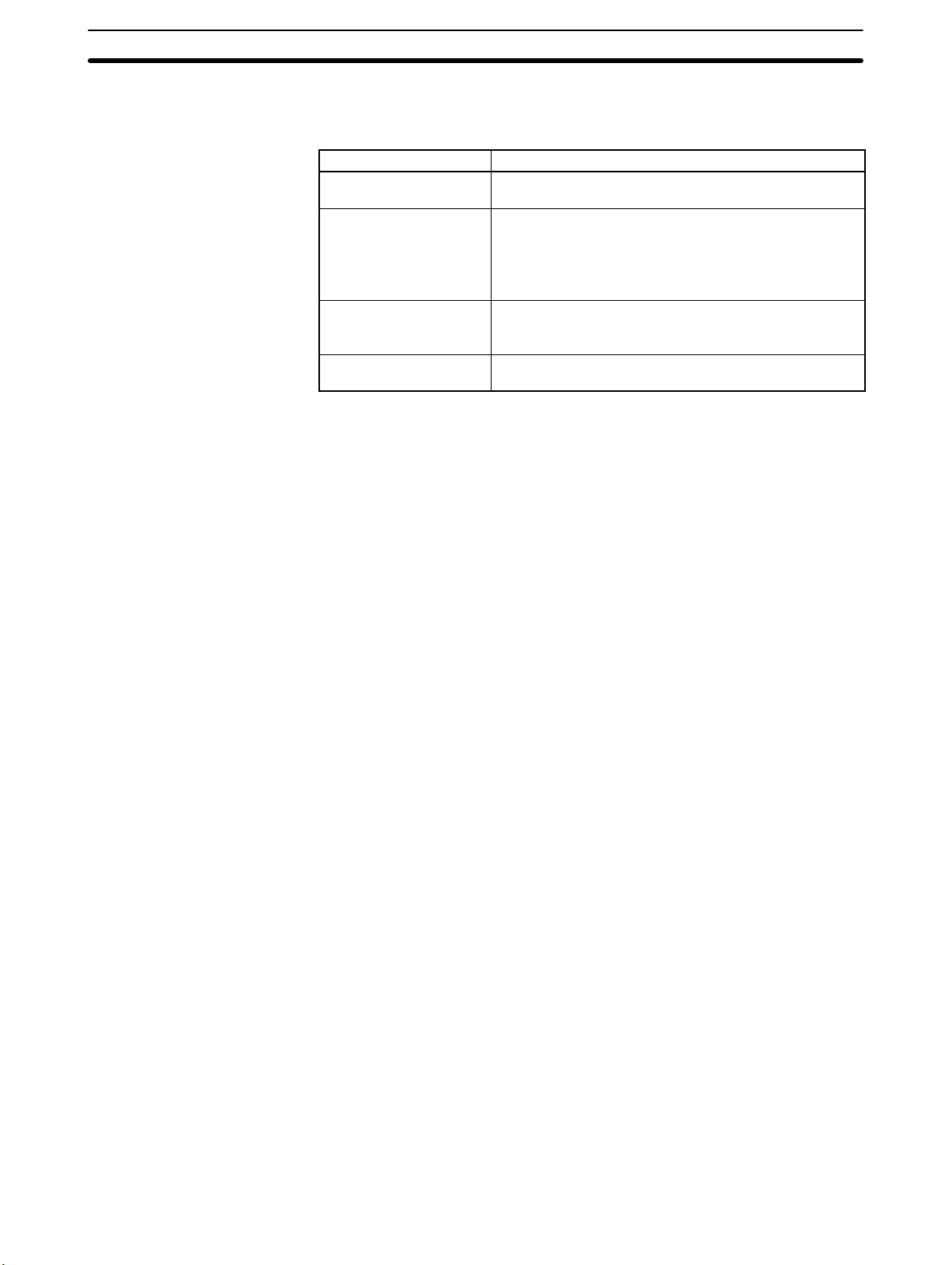

2-2-1 CPU Units

6. Communications Board

compartment

The following diagram shows the components of the CPU Unit as viewed from

the front cover. The numbers in the diagram correspond to the numbers of the

following items in the description.

1. Indicators

2. Memory Casette

compartment

3. DIP Switch

4. Peripheral port

14

5. RS-232C port

Page 27

Units

Section 2-2

1, 2, 3... 1. Indicators

The indicators (LEDs) on the front cover of the CPU Unit operate as

described in the following table.

LED Contents

RUN (green) Lights when the PC is operating normally in MONITOR

or RUN mode.

ERR (red) Flashes if an error occurs that does not stop the CPU

Unit (a non-fatal error).

Lights if an error occurs that stops the CPU Unit (a fatal

error). If a fatal error occurs, the RUN indicator will turn

OFF and the outputs from all Output Units will turn OFF.

INH (orange) Lights when the Load OFF Bit (SR 25215) turns ON. If

the Load OFF Bit is turned ON, the outputs from all

Output Units will turn OFF.

COMM (orange) Lights when the CPU Unit is communicating via the

peripheral or RS-232C port.

2. Memory Casette Compartment

The Memory Cassette compartment contains the built-in RAM and can be

used to mount an optional Memory Cassette. Refer to 3-1-8 Mounting

Memory Cassettes for the mounting methods.

15

Page 28

Units

3. DIP Switch

The DIP switch is used to make various settings that determine who the PC

will operate. The C200HX/C200HG/C200HE CPU Unit has a 6-pin DIP

switch, as shown in the following diagram. The settings of these pins are

listed in the following table.

Pin no. Setting Function

1

ON Writing disabled for user memory.

OFF Writing enabled for user memory.

2

ON Contents of the Memory Cassette automatically read when power is turned on.

OFF Contents of the Memory Cassette not automatically read when power is turned on.

3

ON Programming Console messages displayed in English.

OFF Programming Console messages displayed in the language stored in system ROM. (Messages

displayed in Japanese with the Japanese version of system ROM.)

4

ON Setting function for special instructions enabled.

OFF Setting function for special instructions disabled (default).

5

ON Standard communications parameters (see note) will be set for the following serial communications

ports.

• Built-in RS-232C port

• Peripheral port (only when a CQM1-CIF01/-CIF02 Cable is connected. Does not apply to Program-

ming Console.)

Note 1. Standard communications parameters are as follows:

Serial communications mode: Host Link or peripheral bus; start bits: 1; data length: 7 bits;

parity: even; stop bits: 2; baud rate: 9,600 bps

2. The CX-Programmer running on a personal computer can be connected to the peripheral

port via the peripheral bus using the above standard communications parameters.

OFF The communications parameters for the following serial communications ports will be set in PC

Setup as follows:

• Built-in RS-232C port: DM 6645 and DM 6646

• Peripheral port: DM 6650 and DM 6651

Note When the CX-Programmer is connected to the peripheral port with the peripheral bus, either set

bits 00 to 03 of DM 6650 to 0 Hex (for standard parameters), or set bits 12 to 15 of DM 6650 to 0

Hex and bits 00 to 03 of DM 6650 to 1 Hex (for Host Link or peripheral bus) separately.

6

ON Expansion TERMINAL mode for the Programming Console; AR 0712: ON

OFF Console mode for the Programming Console; AR 0712: OFF

Section 2-2

16

Note All pins are set to OFF for the factory defaults.

4. Peripheral Port

The peripheral port is connected to peripheral devices, such as the Programming Console.

5. RS-232C Port

The RS-232C port is connected to external devices that support an

RS-232C interface, such as personal computers.

6. Communications Board Compartment

The Communications Board compartment is used to mount a Communica-

Page 29

Units

Section 2-2

tions Board. Refer to 3-1-9 Mounting a Communications Board for the

mounting methods.

2-2-2 Memory Cassettes

Memory Cassettes can be optionally mounted to increase memory capacity

over just the built-in RAM. There are two types of Memory Cassette available.

These are shown in the following diagram.

EEPROM Memory Cassette EPROM Memory Cassette

Notch

C200HW-ME

EEPROM Memory Cassette When an EEPROM Memory Cassette is installed in the CPU Unit, the user

memory (UM) and I/O data can be directly read and written. There is no need for

a backup power supply. The Memory Cassette can also be removed from the

CPU Unit and used for storing data.

Model Capacity

C200HW-ME04K 4K words

C200HW-ME08K 8K words

C200HW-ME16K 16K words

C200HW-ME32K 32K words

C200HW-ME64K 64K words

Note The C200HW-ME64K can be used with the C200HX-CPU65-ZE/CPU85-ZE

CPU Units only. It cannot be used with other CPU Units.

EPROM Memory Cassette With an EPROM Memory Cassette, the program is written using a PROM Writer.

The ROM is mounted to the Memory Casette and then installed in the CPU Unit.

I/O data cannot be stored.

Model Capacity

C200HS-MP16K 16K words/32K words

Memory Cassette Settings

EEPROM Memory Cassette Set the DIP switch. For an EEPROM Memory Cassette, set pin no. 1 (write pro-

tect) to either ON or OFF. Setting it to ON will protect the program in the memory

from being overwritten. Setting it to OFF will allow the program to be overwritten.

(The factory setting is OFF.)

EPROM Memory Cassette For an EPROM Memory Cassette, set pin no. 1 (ROM Type Selector) according

to the type of ROM that is mounted.

Pin no. 1 ROM type Model Capacity Access speed

OFF 27256 ROM-JD-B 16K words 150 ns

ON 27512 ROM-KD-B 32K words 150 ns

17

Page 30

Units

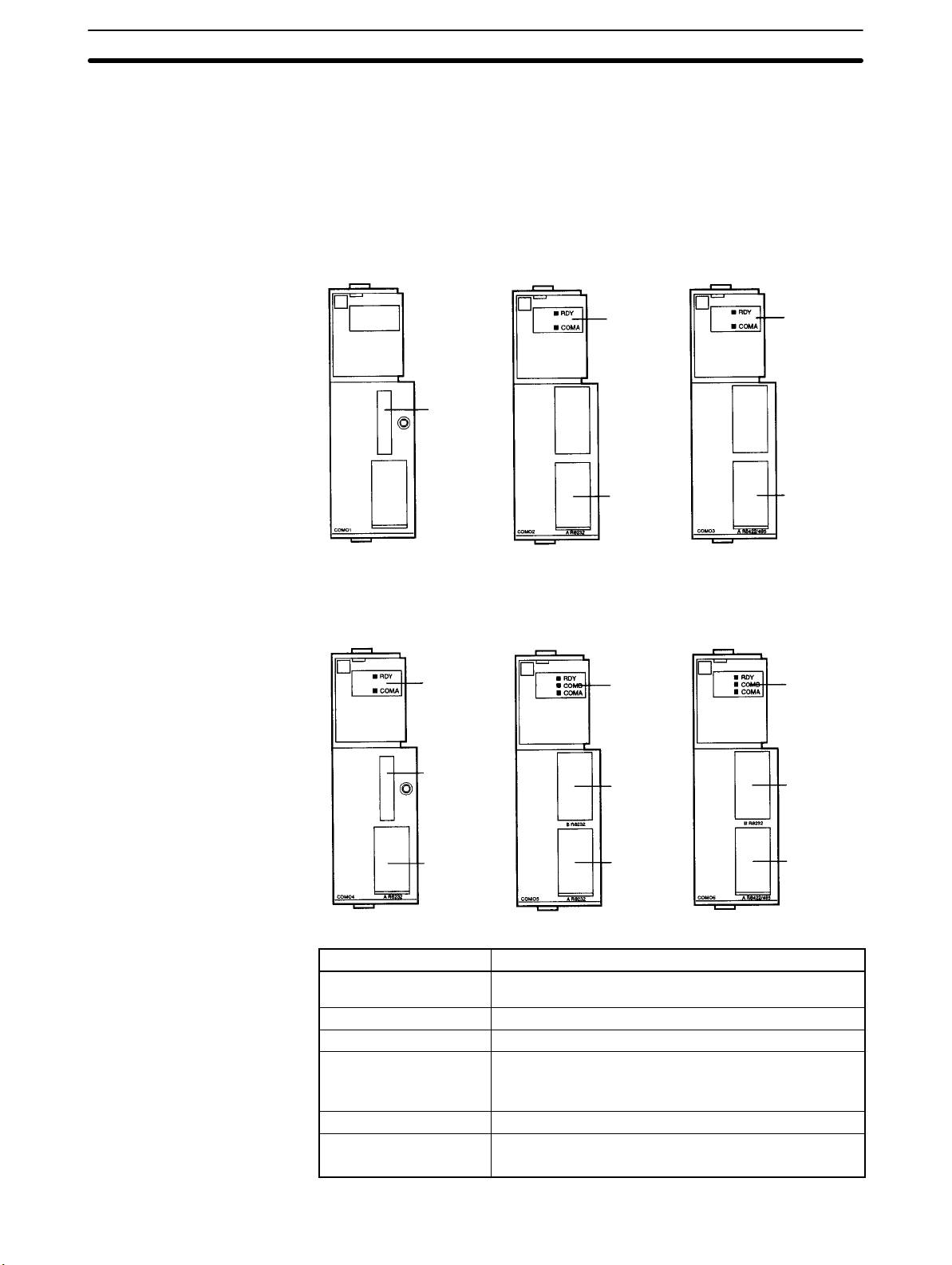

2-2-3 Communications Boards

An optional Communications Board can be mounted in the CPU Unit to provide

communications with the following types of devices/systems through the communications port: SYSMAC LINK Systems, SYSMAC NET Systems, personal

computers, Programmable Terminals (PTs), bar code readers, temperature

controllers, devices with RS-232C or RS-422 interfaces, etc.

The following Communications Boards are available.

C200HW-COM01 C200HW-COM02-V1 C200HW-COM03-V1

Section 2-2

Indicators Indicators

Bus

Connecting

Unit

connector

Port A

(RS-232C)

Port A

(RS-422/

RS-485)

C200HW-COM04-EV1 C200HW-COM05-EV1 C200HW-COM06-EV1

Indicators

Bus

Connecting

Unit

connector

Port A

(RS-232C)

Indicators Indicators

Port B

(RS-232C)

Port A

(RS-232C)

Port B

(RS-232C)

Port A

(RS-422/

RS-485)

18

Model

Specifications

C200HW-COM01 Connection port for SYSMAC LINK, SYSMAC NET, or

other Communications Units.

C200HW-COM02-V1 RS-232C port x 1

C200HW-COM03-V1 RS-422/485 port x 1

C200HW-COM04-EV1 Connection port for SYSMAC LINK, SYSMAC NET, or

other Communications Units.

RS-232C port x 1 (supports protocol macros)

C200HW-COM05-EV1 RS-232C port x 2 (supports protocol macros)

C200HW-COM06-EV1 RS-422/485 port x 1 (supports protocol macros)

RS-232C port x 1 (supports protocol macros)

Page 31

Units

Section 2-2

Note Use either the C200HW-COM01 or a V1 Communications Board for the ZE-ver-

sion C200HX/HG/HE CPU Units.

Indicators (LEDs) The Communications Board indicators on the front panel of the CPU Unit indi-

cate the status of the Board, as described in the following table.

Indicator Color Status Meaning

RDY Green

Not lit The Board cannot be used due to a hardware

error on the Board.

Flashing A setting error has been discovered in the PC

Setup or the protocol data.

Lit The Board is operating properly and

communications are possible.

COMB Orange Flashing Communications are in progress with the

device connected to port B.

COMA Orange Flashing Communications are in progress with the

device connected to port A.

2-2-4 Power Supply Units

Power Supply Units provide power to the CPU Rack and the Expansion I/O

Racks. Power Supply Units are available for either AC or DC power input. The

numbers in the diagram correspond to the numbers of the following items in the

description. (The following diagram shows the C200HW-PA204S.)

Part Names and Functions

/N

L

2

100 to 120 VAC/

200 to 240 VAC

L

1

100 to 120

200 to 240

+24 VDC 0.8 A

1. POWER indicator

2. Terminals for external

connections

Note The AC input terminals may

be indicated as L

L2/N

instead of L2/N and L1 on

some Units. However, there

is no difference in their functions or performance.

L

1

L1/N

/N and L

1

2

1, 2, 3... 1. POWER Indicator

The POWER indicator will be lit whenever the Power Supply Unit is outputting 5 V.

L

2

19

Page 32

short bar on

Units

Section 2-2

2. Terminals for External Connections

These terminals are connected as shown in the diagram below. The numbers in the diagram correspond to the numbers of the following items in the

description.

Supply

voltage

100 to

120 VAC or

200 to

240 VAC

(Select the

voltage using

the metal

short bar on

the voltage

selector

terminals.)

24 VDC 5 VDC, 4.6 A,

Output

capacity

5 VDC, 4.6 A,

30 W

5 VDC, 9 A,

45 W

30 W

Output

terminals

Without Without C200HW-PA204

24 VDC,

0.8 A

Without With C200HW-PA204R

Without With C200HW-PA209R

Without Without C200HW-PD024

RUN output Model

Without C200HW-PA204S

20

Page 33

Units

Terminal Connections

C200HW-PA204: AC Input C200HW-PA204S: AC Input

1. AC Input

2. Voltage selector

terminals

L2/N

100 to 120 VAC/

200 to 240 VAC

Input

L

1

100 to 120

Close

200 to 240

Open

1. AC Input

2. Voltage selector

terminals

Section 2-2

L2/N

100 to 120 VAC/

200 to 240 VAC

Input

L

1

100 to 120

Close

200 to 240

Open

3. LG

4. GR

C200HW-PA204R: AC Input

1. AC Input

2. Voltage selector

terminals

3. LG

4. GR

7. RUN output

5. 24 VDC output

C200HW-PA209R: DC Input

L2/N

100 to 120 VAC/

200 to 240 VAC

Input

L

1

100 to 120

Close

200 to 240

Open

RUN OUTPUT

250 VAC

24 VDC

2 A

1. AC Input

2. Voltage selector

terminals

3. LG

4. GR

7. RUN output

C200HW-PD024: DC Input

3. LG

4. GR

24 VDC 0.8 A

Output

L2/N

100 to 120 VAC/

200 to 240 VAC

Input

L

1

100 to 120

Close

200 to 240

Open

RUN OUTPUT

240 VAC

24 VDC

2 A Resistive

6. DC Input

3. LG

4. GR

1, 2, 3... 1. AC Input (C200HW-PA20jj Only)

Supply either 100 to 120 VAC or 200 to 240 VAC to the AC input terminals. If

one power supply phase of the equipment is grounded, connect the

grounded phase side to the L

/N (or L1/N if so indicated) terminal.

2

2. Voltage Selector Terminals (C200HW-PA20jj Only)

Short these terminals with a metal short bar when 100 to 120 VAC is being

supplied to the AC input terminals.

3. LG

Ground the LG terminal to 100 Ω or less to increase resistance to noise and

protect against possible electrical shock.

24 VDC

21

Page 34

Units

Section 2-2

4. GR

Ground the GR terminal to 100 Ω or less to protect against possible electrical shock.

5. 24 VDC Output (C200HW-PA204S Only)

The 24 VDC output terminals can be used to supply power to DC Input Units.

The combined power consumption for both 5 V and 24 V must be 30 W or

less.

6. DC Input (C200HW-PD024 Only)

Supply 24 VDC to the DC input terminals.

7. RUN Output (C200HW-PA204R/PA209R Only)

The internal contact will turn ON when the CPU Unit is operating in RUN or

MONITOR mode. These terminals are available only on the C200HWPA204R.

22

Page 35

manufacturing

manufacturing

Units

Section 2-2

Restrictions for the

C200HW-PA204R/PA209R

Use the C200HW-PA204R/PA209R Power Supply Unit only with the following

CPU Units and Backplanes. CPU Units and Backplanes with manufacturing

numbers earlier than the ones given cannot be used.

CPU Units

Model

C200HX-CPU65-E 20Z6 or later

C200HX-CPU54-E 2817 or later

C200HX-CPU44-E 19Z6 or later

C200HX-CPU34-E 2417 or later

C200HG-CPU63-E 25Z6 or later

C200HG-CPU53-E 0817 or later

C200HG-CPU43-E 19Z6 or later

C200HG-CPU33-E 1017or later

C200HE-CPU42-E 20Z6 or later

C200HE-CPU32-E 19Z6 or later

C200HE-CPU11-E 20Z6 or later

C200HX/HG/HE-

CPUjj-ZE

All models

Manufacturing number (See below.)

Made in Japan Made in the Netherlands

0147 or later

Backplanes (with C200HW-PA204R)

Model

C200HW-BC031 0617 or later

C200HW-BC051 19Z6 or later

C200HW-BC081 24Z6 or later

C200HW-BC101 20Z6 or later

Manufacturing number (See below.)

Made in Japan Made in the Netherlands

0147 or later

Backplanes (with C200HW-PA209R)

CPU Backplanes I/O Backplanes

C200HW-BC031

C200HW-BC051

C200HW-BC081-V1 (-V1 or later) C200HW-BI081-V1 (-V1 or later)

C200HW-BC101-V1 (-V1 or later) C200HW-BI101-V1 (-V1 or later)

Caution When using the C200HW-PA209R Power Supply Unit, be sure to use only the

!

Same

manufacturing

number as for

C200HW-PA204R.

C200HW-BI031

C200HW-BI051

Same

manufacturing

number as for

C200HW-PA204R.

Backplanes listed in the above table. Using a different Backplane may result in

malfunction due to deterioration of the base or pattern burnout.

Note Manufacturing numbers are as shown in the following diagram.

j j j j

Year (Ex. 1997 = 7)

Month (1 to 9 = Jan to Sep, X/Y/Z = Oct/Nov/Dec

Day (01 to 31)

23

Page 36

Units

2-2-5 Backplanes

CPU Backplane

Section 2-2

There are two types of Backplane: the CPU Backplane, used for the CPU Rack,

and the I/O Backplane, used for Expansion I/O Racks. The Backplane serves to

hold and connect the following types of Unit: the CPU Unit, the Power Supply

Unit, I/O Units, Special I/O Units, etc.

The components of the Backplanes are shown in the following diagrams and

described following them. The numbers in the diagram correspond to the numbers of the following items in the description.

4. Unit mounting slots

1. Backplane

mounting

screw

2. Power Supply

Unit connector

6. Unit lock levers

7. I/O Connecting Cable connector

3. CPU Unit

connector

5. Unit connector

I/O Backplane

4. Unit mounting slots

1. Backplane

mounting

screw

2. Power Supply

Unit connector

5. Unit connector6. Unit lock levers

7. I/O Connecting Cable connector

1, 2, 3... 1. Backplane Mounting Screws

Mount the Backplane firmly using four M4 screws.

2. Power Supply Unit Connector

Connect the Power Supply Unit.

3. CPU Unit Connector

Connect the CPU Unit.

4. Unit Mounting Slots

Mount one Unit to each slot. There are 3, 5, 8, or 10 slots available on the

Backplane depending on the model of Backplane used.

5. Unit Connectors

Connect I/O Units, Special I/O Units, Interrupt Input Units, and/or Analog

Timer Units.

Note Attach a C500-COV01 Connector Cover to any slot that is not being used to pre-

vent dust and dirt from entering the unused connectors.

6. Unit Lock Levers

The lock levers hold the Units in place. Press down on the level and pull up

on the Unit to release the lock.

7. I/O Connecting Cable Connector

Connect the I/O Cable from the CPU Rack to the first Expansion I/O Rack or

between adjacent Expansion I/O Racks to this connector.

24

Page 37

p

p

Units

Section 2-2

2-2-6 Standard I/O Units

The following Standard I/O Units are available.

Input Units

Name Model number Specifications No. of

points

DC Input Unit

AC Input Unit C200H-IA121 100 to 120 VAC 8 pts

AC/DC Input Unit C200H-IM211 12 to 24 VAC/DC 8 pts

Output Units

Name Model number Specifications No. of

Contact Output Unit C200H-OC221 2 A, 250 VAC/24 VDC (For resistive loads) 8 pts

Transistor Output

Unit

Triac Output Unit C200H-OA221 1 A, 250 VAC 8 pts

C200H-ID211 12 to 24 VDC 8 pts

C200H-ID212 24 VDC 16 pts

C200H-IA122/IA122V 100 to 120 VAC 16 pts

C200H-IA221 200 to 240 VAC 8 pts

C200H-IA222/IA222V 200 to 240 VAC 16 pts

C200H-IM212 24 VAC/DC 16 pts

Note The C200H-ID001/002 cannot be used on the following Backplanes: C200HW-

BCjj1/BIjj1.

points

C200H-OC222 2 A, 250 VAC/24 VDC (For resistive loads) 12 pts

C200H-OC225 2 A, 250 VAC/24 VAC (For resistive loads) 16 pts

C200H-OC223 2 A, 250 VAC/24 VDC (For resistive loads)

Independent commons

C200H-OC224 2 A, 250 VAC/24 VDC (For resistive loads)

Independent commons

C200H-OC222V 2 A, 250 VAC/24 VDC (For resistive loads) 12 pts

C200H-OC226 2 A, 250 VAC/24 VDC (For resistive loads) 16 pts

C200H-OC224V 2 A, 250 VAC/24 VDC (For resistive loads)

Independent commons

C200H-OD411 1 A, 12 to 48 VDC 8 pts

C200H-OD211 0.3 A, 24 VDC 12 pts

C200H-OD212 0.3 A, 24 VDC 16 pts

C200H-OD213 2.1 A, 24 VDC 8 pts

C200H-OD214 0.8 A, 24 VDC; source type (PNP); with load short protection 8 pts

C200H-OD216 5 to 24 VDC; source type (PNP) 8 pts

C200H-OD217 5 to 24 VDC; source type (PNP) 12 pts

C200H-OD21A 1.0 A, 24 VDC; source type (PNP); with load short protection 16 pts

C200H-OA222V 0.3 A, 250 VAC 12 pts

C200H-OA223 1.2 A, 250 VAC 8 pts

C200H-OA224 0.5 A, 250 VAC 12 pts

5 pts

8 pts

8 pts

Optional Products

The following optional products are available for use with Standard I/O Units.

• I/O Unit Cover: C200H-COV11

Cover for 10-pin terminal block.

• Space Unit: C200H-SP001

Used for vacant slots.

25

Page 38

Units

Section 2-2

Components

The Standard I/O Units come in three shapes; A-shape, B-shape, and E-shape.

Refer to Appendix D Specifications for the dimensions of each Unit. The numbers in the diagram correspond to the numbers of the following items in the

description.

A-shape I/O Unit (10-terminal Terminal Block) B-shape I/O Unit (19-terminal Terminal Block)

1. I/O Unit lock notch

2. Nameplate

3. I/O indicators:

Indicate ON/OFF

status of points

4. 10-terminal terminal block

4. 19-terminal terminal block

E-shape I/O Unit (10-terminal Terminal Block)

I/O Unit lock notch

Nameplate

I/O indicators

Indicate ON/OFF

status of points

10-terminal terminal block

26

Note The C200H-OC226 is an extended B-shape I/O Unit and its dimensions are dif-

ferent from those of the B-shape I/O Unit shown above.

Page 39

Units

Section 2-2

1, 2, 3... 1. I/O Unit Lock Notch

The lock notch fits into the Backplane to hold the Unit in place.

2. Nameplate

The nameplate shows the model number of the I/O Unit.

3. I/O Indicators (LEDs)

The indicators show the ON/OFF status of the I/O points. The arrangement

of the indicators varies with the model of I/O Unit, as shown in the following

tables.

4. Terminal Block

The terminal block is used to wiring I/O. There terminals blocks are removable and consist of two parts.

Units with 10-terminal

Terminal Blocks

Units with 19-terminal

Terminal Blocks

Appearance Unit type Model numbers

8-point Units ID211, IM211, IA121,

IA221, OC221, and

OA216

8-point Units

F: Fuse burnt out

(with LED)

8-point Units

ALARM indictors

(with LEDs)

5-point Units OD223

Appearance Unit type Model numbers

16-point Units ID212, IA122, IA122V,

12-point Units OC222, OC222V, OD211,

OD213, OD411, OA221,

and OA223

OD214

IA222, IA222V, IM212,

OC225, OC226, OD212,

and OD21A

OD217, OA222V, and

OA224

2-2-7 Group-2 High-density I/O Units

Group-2 High-density I/O Units come in two varieties; C-shape and D-shape.

The shape of the two varieties is the same, but C-shape Units have only one connector, while the D-shape Units have two. C-shape Units have 32 I/O points and

D-shape Units have 64 I/O points.

Group-2 High-density I/O Units can be used with C200H-CPU21/22/23/31 CPU

Racks and Expansion I/O Racks. They cannot be used with Slave Racks.

8-point Units OC224 and OC224V

27

Page 40

Units

C-shape Units (32-point Units)

Section 2-2

Unit Specifications Shape Model

DC Input Unit 12 VDC; 64 pts D C200H-ID111

24 VDC; 32 pts

24 VDC; 64 pts D C200H-ID216

Transistor Output Unit 4.5 VDC,16 mA to

26.4 VDC,100 mA; 32 pts

4.5 VDC,16 mA to

26.4 VDC,100 mA; 64 pts

24 VDC, 0.5 A (5A/Unit); 32 pts C C200H-OD21B

1. I/O Unit lock notch

2. Nameplate

3. I/O indicators

4. I/O number setting switch

C C200H-ID217

C200H-ID218

C200H-ID219

C C200H-OD218

D C200H-OD219

D-shape Units (64-point Units)

5. 40-pin connector

1. I/O Unit lock notch

2. Nameplate

3. I/O indicators LED

4. I/O number setting switch

6. Indicator switch

28

5. 40-pin connectors

Page 41

Units

I/O Indicators

Units with One 40-pin

Connector

Section 2-2

1, 2, 3... 1. I/O Unit Lock Notch

The lock notch fits into the Backplane to hold the Unit in place.

2. Nameplate

The nameplate shows the model number of the I/O Unit.

3. I/O Indicators (LED)

The indicators show the ON/OFF status of the I/O points. The arrangement

of the indicators varies with the model of I/O Unit, as shown in the following

tables.

4. I/O Number Setting Switch

This switch is used to set the I/O number for the Unit. Set the number to

between 0 and F for Units with one 40-pin connector and to between 0 and 8

or A and E for Units with two 40-pin connectors.

5. 40-pin Connectors

The number of connectors depends on the Unit.

6. Indicator Switch

Determines whether the status of connector 1 or connector 2 I/O points are

shown on the I/O indicators.

Appearance Unit type Model numbers

32 points Unit ID216 and ID218

Units with Two 40-pin

Connectors

32 points Unit

F: Fuse burnt out

(with LED)

Appearance Unit type Model numbers

64 points Unit ID111, ID217, and ID219

64 points Unit

F: Fuse burnt out

(with LED)

OD218 and OD21B

OD219

29

Page 42

pp

Units

2-2-8 High-density I/O Units Classified as Special I/O Units

Some High-density I/O Units are classified as Special I/O Units. Up to 10 or up to

16 Special I/O Units can be connected to a PC depending on the CPU Unit that is

used. These Units have two 24-pin connectors. In general, these Units control

32 I/O points, although some Units can control 128 I/O points when set for

dynamic operation.

Refer to Appendix B Specifications for detailed specifications and dimensions of

the Units.

Unit Model Number Specifications

TTL Input Unit C200H-ID501 5 VDC, 32 inputs

DC Input Unit C200H-ID215 24 VDC; 32 inputs

TTL Output Unit C200H-OD501 5 VDC, 32 outputs

Transistor Output Unit C200H-OD215 24 VDC; 32 outputs

TTL I/O Unit C200H-MD501 5 VDC, 16 inputs, 16 outputs

DC Input/Transistor Output Unit

C200H-MD115 12 VDC; 16 inputs, 16 outputs

C200H-MD215 24 VDC; 16 inputs, 16 outputs

1. I/O Unit lock notch

Section 2-2

1, 2, 3... 1. I/O Unit Lock Notch

The lock notch fits into the Backplane to hold the Unit in place.

2. Nameplate

The nameplate shows the model number of the Unit.

3. I/O Indicators (LED)

The indicators show the ON/OFF status of the I/O points.

4. Unit Number Setting Switch

Turn OFF the power supply to the PC and set the unit number to between 0

and F using a flat-blade screwdriver, being careful not to damage the slot or

leave the switch set half-way between two settings.

5. 24-pin Connectors

There are two 24-pin connectors.

2. Nameplate

3. I/O indicators LED

4. Unit number setting switch

5. 24-pin connectors

30

Page 43

Peripheral Devices

2-3 Peripheral Devices

There are various Peripheral Devices that can be use to support C200HX/

C200HG/C200HE operation. These Peripheral Devices are introduced in this

section.

2-3-1 Programming Consoles

There are two Programming Consoles that can be used with the C200HX/

C200HG/C200HE: the C200H-PRO27-E and the CQM1-PRO01-E. The following illustration shows the C200H-PRO27-E Programming Console.

Section 2-3

Connected to Peripheral Port on CPU Unit.

C200H-CN222 (2 m) or

C200H-CN422 (4 m), Connecting

Cable

As shown in the illustration, the C200H-PRO27-E Programming Console connects to the C200HX/C200HG/C200HE CPU Unit with C200H-CN222 or

C200H-CN422 Connecting Cable, which must be purchased separately.

The CQM1-PRO01-E Programming Console comes with 2 m of Connecting

Cable.

2-3-2 Ladder Support Software (LSS)

The LSS is a powerful support software package for the OMRON C-series Programmable Controllers (PCs). The LSS runs on an IBM PC/AT or compatible

personal computer, and can be use to program, monitor and control PCs. While

some PCs require a SYSMAC NET Link Unit, Host Link Unit, or Peripheral Interface Unit to connect the computer running LSS, the C200HX/C200HG/C200HE

can be connected directly to the LSS via it’s peripheral or RS-232C port.

The LSS provides displays of various useful lists when the computer is operated

offline and can be used to monitor operating conditions of the PC, and to read

and write PC data. PC programs can be developed in a mnemonic or ladder diagram form.

The LSS supports the C200HX/C200HG/C200HE only within the functions

available for the C200HS.

C200H-PRO27-E Programming Console

31

Page 44

Peripheral Devices

When working in ladder diagram form, not only the program is displayed but also

other information such as I/O, block, and instruction comments can be input and

displayed. Moreover, the LSS allows more than one PC to be connected to and

monitored using a single computer. The monitoring speed can be accelerated if

the optional S3200-NSB11-E SYSMAC NET NSB is used.

For details concerning LSS, refer to the Ladder Support Software Operation

Manual (W237).

2-3-3 SYSMAC Support Software (SSS)

The SSS is an advanced software application that runs on IBM PC/AT or compatibles and is used to program, monitor, and otherwise control OMRON SYSMAC

C-series PCs and SYSMAC CVM1 PCs. The C200HX/C200HG/C200HE can

be connected directly to a computer running the SSS in exactly the same way as

for the LSS.

The SSS can be used with any of the CVM1 PCs and with all of the many C-series PCs. The SSS automatically switches programming styles and other operations between the various PCs when a PC model is set in the SSS’s System

Setup.

All programs written on the Ladder Support Software or on the CV Support Software can be read and used by the SSS. Programs created for the C2000H or

C200HX/C200HG/C200HE families of PCs can be converted for use with CVM1

PCs so that existing programs can be used with the newer PCs.

The SSS naturally supports all of the functionality for C-series PCs as the LSS,

plus some new functions that facilitate fast, efficient programming and operation.

Section 2-3

2-3-4 SYSMAC-CPT Support Software

The SYSMAC-CPT Support Software is the only support software currently

compatible with the C200Hj-ZE PCs. This software is designed to run on IBM

PC/AT or compatibles and allows you to perform all the operations of the Programming Console as well as many additional ones. PC programs can be written on-screen in ladder-diagram form as well as in mnemonic form. As the program is written, it is displayed on a display, making confirmation and modification

quick and easy. Syntax checks may also be performed on the programs before

they are downloaded to the PC.

The SYSMAC-CPT Support Software does not support any of the original

C200HX/HG/HE CPU Units at present.

32

Page 45

Expanded System Configurations

2-4 Expanded System Configurations

2-4-1 Required Mounting Conditions

A maximum of 16 Special I/O Units including PC Link Units can be mounted to

any slot of CPU, Expansion I/O, and Slave Racks. I/O word numbers 100 to 199,

400 to 459, and DM 1000 to DM 2599 are allocated to each Special I/O Unit.

High-density I/O Units can be mounted Remote I/O Slave Units only when the

Remote I/O Slave Units are connected to C200H-RM001-PV1 or

C200H-RM201 Remote I/O Master Units.

The number of Special I/O Units used with a Slave Rack is limited by data transmission considerations, as shown in the table below. The numbers in the table

indicate the maximum number of Units of groups A, B, C, or D which can be used

with a single Slave Rack.

A B C D

High-speed Counter Units

Position Control Units

(C200H-NC111/112,

C200HW-NC113/213)

ASCII Units

Analog I/O Units

ID Sensor Units

Fuzzy Logic Units

4 units max. 8 units max. 6 units max. 2 units max.

High-density and Mixed I/O

Units

Temperature Control Units

Cam Positioner Units

Heat/Cool Temperature

Control Unit

PID Control Unit

Temperature Sensor Units

Voice Units

Position Control Units

(C200H-NC211,

C200HW-NC413)

Motion Control Units

Section 2-4

Note 1. When a combination of Units from groups A, B, C, and D is used, the number

2-4-2 Special I/O Units

It is possible to connect a variety of Special I/O Units to the C200HX/

C200HG/C200HE Racks.

High-density I/O Units

(Special I/O Units)

The TTL Input Unit, DC Input Unit, TTL Output Unit, Transistor Output Unit, TTL

I/O Unit, and DC Input/Transistor Output Unit are High-density I/O Units.

The C200H-ID501, C200H-OD501, and C200H-MD501 are I/O Units for the

TTL Unit.

Eight input points each of the C200H-ID501, C200H-ID215, C200H-MD501,

C200H-MD115, and C200H-MD215 can be set for pulse input.

A High-density I/O Unit can retrieve pulse input, which is shorter in length than

that of the High-density I/O Unit cycle time, as an input signal when the Highdensity I/O Unit is set for pulse input.

from each group must satisfy both the following equations:

3A + B + 2C + 6D ≤ 12

A + B + C + D ≤ 8

2. Other Units can be added until the total number of Units reaches ten. If PC

Link Units are used, the number of Units including the PC Link Units must

not exceed ten.

33

Page 46

Expanded System Configurations

Section 2-4

The C200H-MD501, C200H-MD115, and C200H-MD215 can each be set for

128 dynamic input points (64 points x two circuits) and the C200H-OD501 and

C200H-OD215 can each be set for 128 dynamic output points (64 points x two

circuits).

High-speed Counter Units The High-speed Counter Units have the following six operation modes.

Linear, circular, preset, gate, latch, and sampling operation modes

The High-speed Counter Units, which have a counting speed of 50 kcps, can be

used for phase-difference pulse input, adding and subtracting pulse input, and

pulse and direction input. The High-speed Counter Units have eight-point output

per single axis.

Rotary Encoder

Position Control Units The Position Control Units have pulse-train output, thus enabling connection to

stepping motor drivers or servomotor drivers.

The C200H-NC111 and C200H-NC112 are for a single axis, and the

C200H-NC211 is for two axes.

Stepping motor

driver or servomotor driver with

pulse-train input.

Stepping motor

or servomotor

34

5-V power supply

Page 47

Expanded System Configurations

Section 2-4

Analog I/O Units The Analog Input (A/D) Units retrieve analog inputs and the Analog Output (D/A)

Unit sends analog outputs.

The following Analog I/O Units are available:

C200H-AD001 with 4-point analog input, C200H-AD002 with 8-point analog

input, C200H-DA001 with 2-point analog output, and C200H-DA002 with

4-point analog output

The Analog Input (AD) Unit is used.

Analog input

Analog output

The Analog Output (DA) Unit is used.

Preamplifier

transducer

Servomotor controller

variable adjuster

Sensor

Motor

Temperature Sensor Units The following table lists Temperature Sensor Unit models and available temper-

ature sensors.

Only one kind of temperature sensor can be connected to the C200H-TS001 or

C200H-TS002. Each Temperature Sensor Unit connects to a maximum of four

temperature sensor inputs.

Model Connectable temperature sensor

C200H-TS001 K (CA)/K (IC)

C200H-TS002 K (CA)/L (Fe-CuNi) (available for DIN)

C200H-TS101 JPt 100 Ω

C200H-TS102 Pt 100 Ω (available for DIN/1989JIS)

Thermocouple: K (CA), J (IC), L (Fe-CuNi)

Platinum resistance thermometer: JPt100 Ω, Pt100 Ω

ASCII Unit BASIC programs can be input to the ASCII Unit via its port 1 from any personal

computer in terminal mode if the personal computer incorporates an RS-232C

interface.

It is possible to write BASIC programs with an IBM PC/AT or compatible.

Port 1

(RS-232C)

Port 1/2

BASIC Program:

Personal computer

Input: Bar code reader

Output: Printer and plasma display

35

Page 48

Expanded System Configurations

Section 2-4

Voice Unit Voice messages can be input from dynamic microphones or cassette tape

recorders and output from loudspeakers or headsets via the Voice Unit.

The Voice Unit incorporates a sentence function and word combination function,

either of which can be selected to record voice messages for 64 seconds maximum.

Voice can be saved on floppy disks with an IBM PC/AT or compatible.

Voice input

Voice output

Voice saving/Re-input