Page 1

AutoVISION Software

Quick Start Guide

Z434-E-02 (84-9100005-02)

Page 2

AutoVISION Quick Start Guide

Table of Contents

Introduction .......................................................................................................... 4

1. Install and Start AutoVISION ............................................................................ 6

2. AutoVISION Display and Basic Operation ......................................................... 7

3. Connect to the Camera .................................................................................... 9

4. Capture an Image ........................................................................................... 11

5. Edit Vision Job ................................................................................................ 12

5.1. Set Camera Parameters ............................................................................... 12

5.2. Use Locate Tool ............................................................................................ 14

5.3. Use Decode Tool, Show Only the ROI of the Selected Tool, Adjust ROI by

Checking Coordinate, Rotate ROI Automatically ................................................ 16

5.4. Use OCR Tool ............................................................................................... 19

5.5. Use Count Tool ............................................................................................ 21

5.6. Use Presence/Absence Tool, Use Zoom Options ........................................ 22

5.7. Use Measure Tool ........................................................................................ 24

5.8. Try All Tools ................................................................................................. 26

5.9. Set Inspection Outputs ................................................................................ 27

5.9.1. Digital Outputs ....................................................................................... 27

5.9.2.TCP/IP and Serial Output String .............................................................. 29

5.9.3.Opening Telnet Client to View Results .................................................... 31

6. Save Job ......................................................................................................... 32

7. Run the Job .................................................................................................... 32

8. Saving Setup or Runtime Images .................................................................... 33

OMRON

Microscan Systems, Inc. ©2020

Page 3

AutoVISION Quick Start Guide December 2020

9. Save Job to Flash Memory on Camera ........................................................... 34

10. Switch Job Saved on Camera ........................................................................ 35

11. Edit Which Job is Saved on Camera ............................................................. 35

Appendix A – Quick Start Samples ...................................................................... 36

Appendix B – Use Omron Microscan Link ........................................................... 37

Appendix C – Use FTP Image Output .................................................................. 39

Appendix D – Correlation Table with Omron FH/FQ Series ................................ 40

Page 4

AutoVISION Quick Start Guide December 2020

Introduction

Thank you for purchasing your MicroHawk smart camera. This document is designed as a quick overview

on how to use the AutoVISION software to set up a simple vision application.

This document will guide you through software installation, and then through the 5 simple steps to

deploy your vison application which are Connect to the camera, create “new” job, get a good Image,

program and Edit your job, and then finally to Run it.

AutoVISION Help

Full details for the operation of AutoVISION can be found in Help. You can access the HELP from the UI

two ways, either through the menu or by clicking on the help icon .

Additional Material for the purchase, setup and operation of your Omron Vision System can be found on

your local Omron Website. These include:

Name of Manual

Camera specific Datasheets

Quickstart Guides

Camera specific Hardware User’s manual

Communication and Industrial protocol manual

Page 5

AutoVISION Quick Start Guide December 2020

The symbols used in this manual have the following meanings

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Page 6

AutoVISION Quick Start Guide December 2020

1. Ins

Minimum PC Requirements

tall and Start Au

a. Download the latest version of AutoVISION software from the Omron website.

b. Double cli

(File name example:

c. Double cli

(*)

Intel® Core™

Internet

2GB RAM (Windows 7 SP1 / Windows 7 Embedded St

64GB hard

32-bit color display, 1366 x 768 or 1280 x 960

4.0 Windows Experience Index (particularly for graphi

1 USB 2

ck (run) the downloaded installer.

ck (run) the AutoVISION icon(*) on your desktop

Explorer 11 / Google Chrome

drive space

.0 port and 1 Netw

toVISION

SetupAutoVISION_522_3016.exe)

i3 Processor @1.6GHz

andard SP1)

cs)

ork port

Page 7

AutoVISION Quick Start Guide December 2020

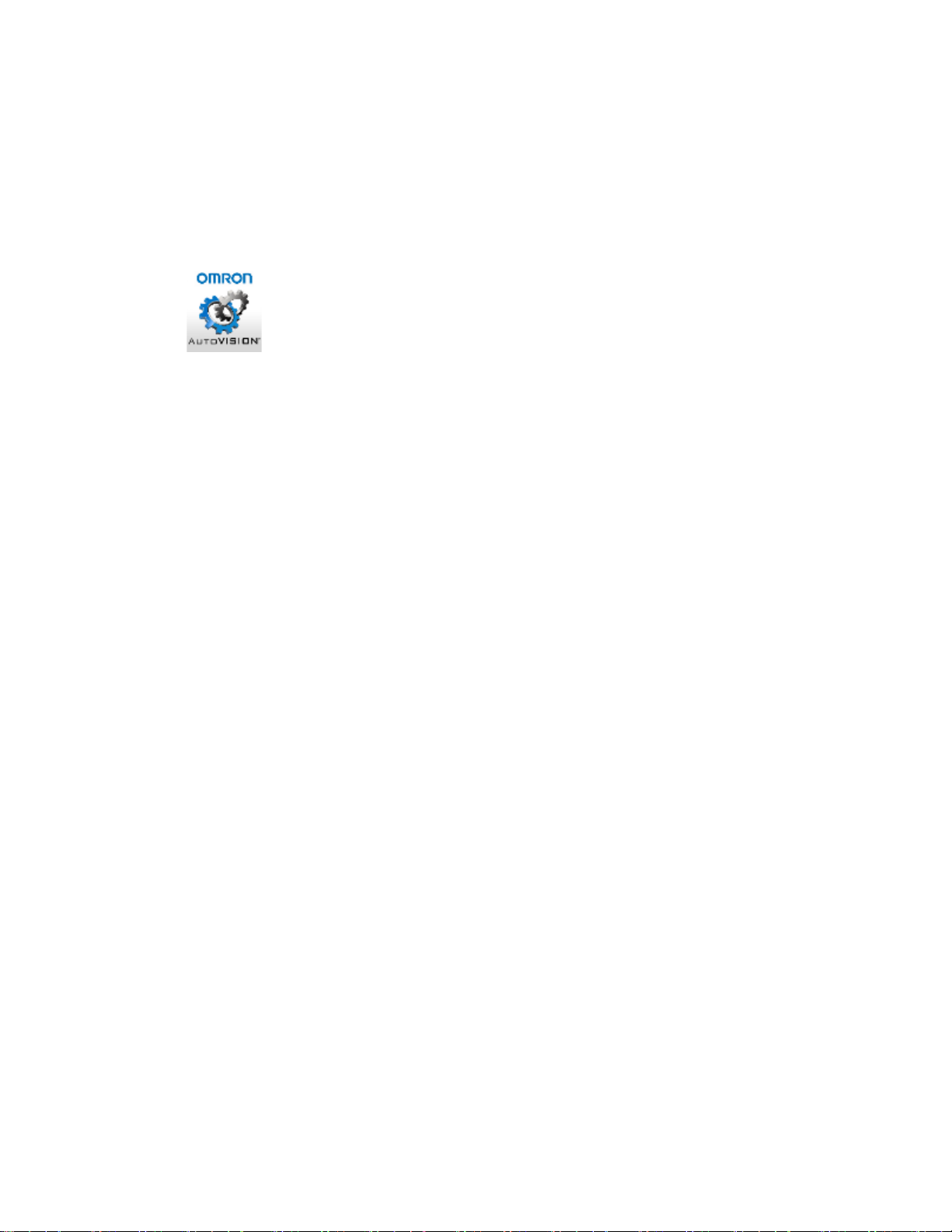

2. AutoVISION Display and basic operation

a. Edit mode

Job(setting data) name Advanced Parameters menu Help menu

Create new job

/Save job to PC・

Camera

Display option

/Delete selected

job/Tryout

Tool list view

・Camera mode:Camera MAC address/IP

address/camera model name

・Emulator mode:load image file name

b. Run

mode

Acquire Single image

Zoom options

Intensity on mouse

pointer (0~255)

Tools

Data navigator menu (Check

the detail in HELP)

Rotation option of ROI

(Region of Interest)

Tool parameters view

Pixel coordinate on

mouse pointer

(Unit:pixel)

Run/Stop/Trigger

button

Image Display Options/Image

Saving Options/Job Switching

Counter reset

button

Inspection Statistics

view

Result of each tool view

Page 8

AutoVISION Quick Start Guide December 2020

Basic operation

c.

ck

・

Left cli

:

Select

Drag with r

・

Upper scro

・

Lower scroll/Pinch i

・

ight click:Repositi

ll/Pinch out/Swipe down with 2 fingers/Double tap

on image

n/Swipe up with 2 fingers

Zoom out

:

Zoom in

:

Page 9

AutoVISION Quick Start Guide December 2020

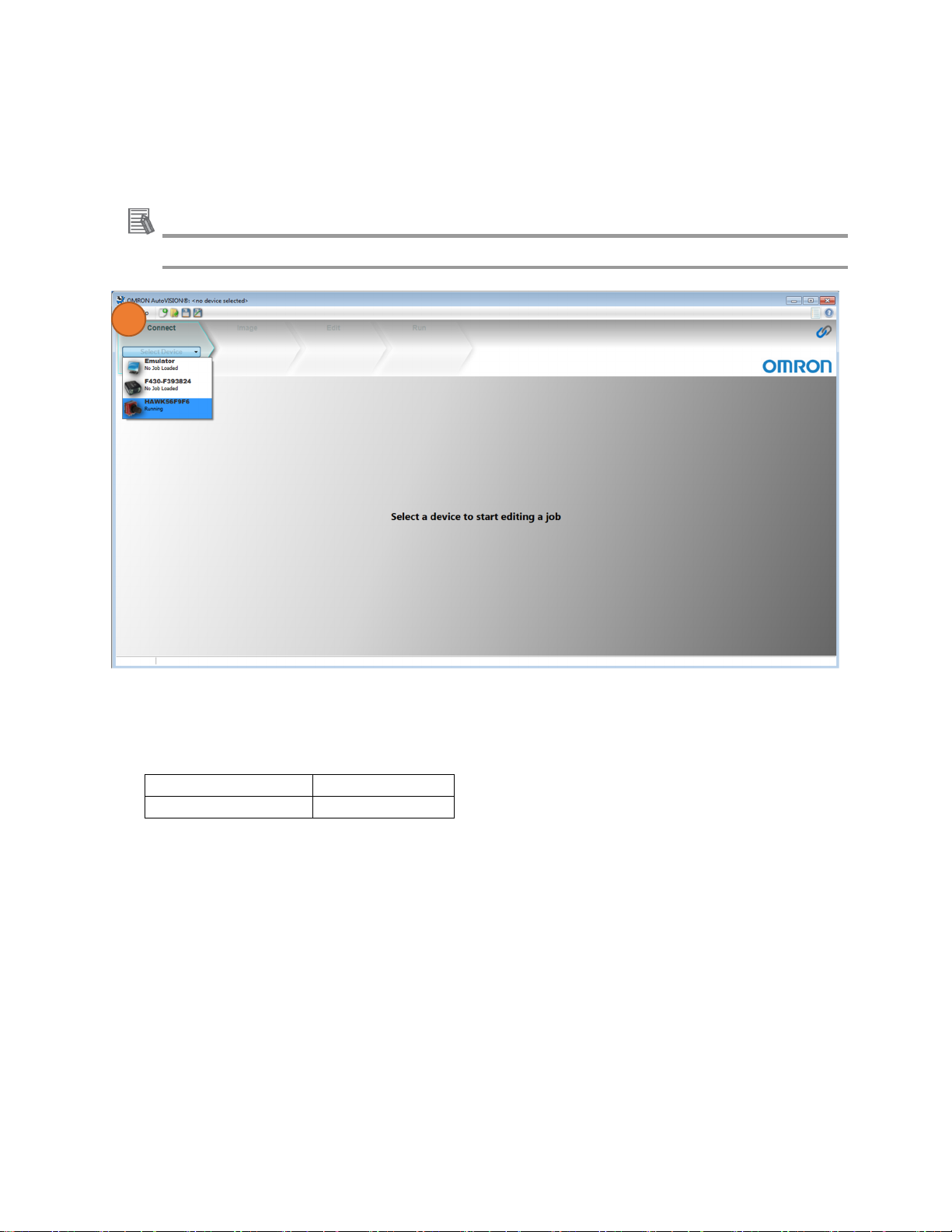

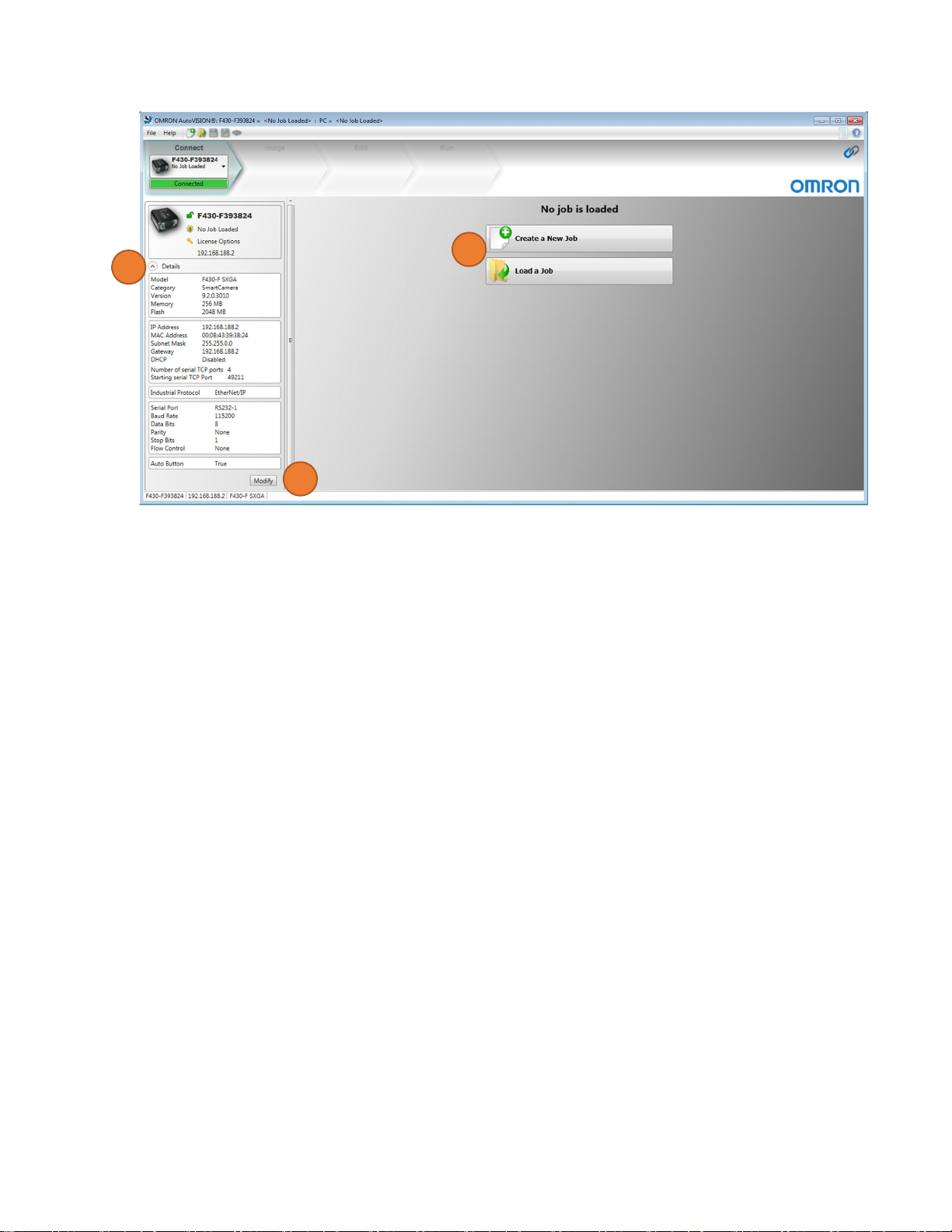

3. Connect to the Camera

Select the device to be used with AutoVISION.

a. Select the camera in the drop-down box.

Additional Information

Select [Emulator] if you want to verify by saved images

a

b. The F430-F camera is set by default as below. Set your computer to a compatible address or if the

network parameters need to be changed.

IP address 192.168.188.2

Subnet mask 255.255.0.0

i. Click [Details] button to see the IP Address

ii. Click [Modify] to make changes. This may request to reboot your camera. Modification is

reflected when reconnection is completed.

c. Select [Create a New Job].

Page 10

AutoVISION Quick Start Guide December 2020

c

bi

bii

Page 11

AutoVISION Quick Start Guide December 2020

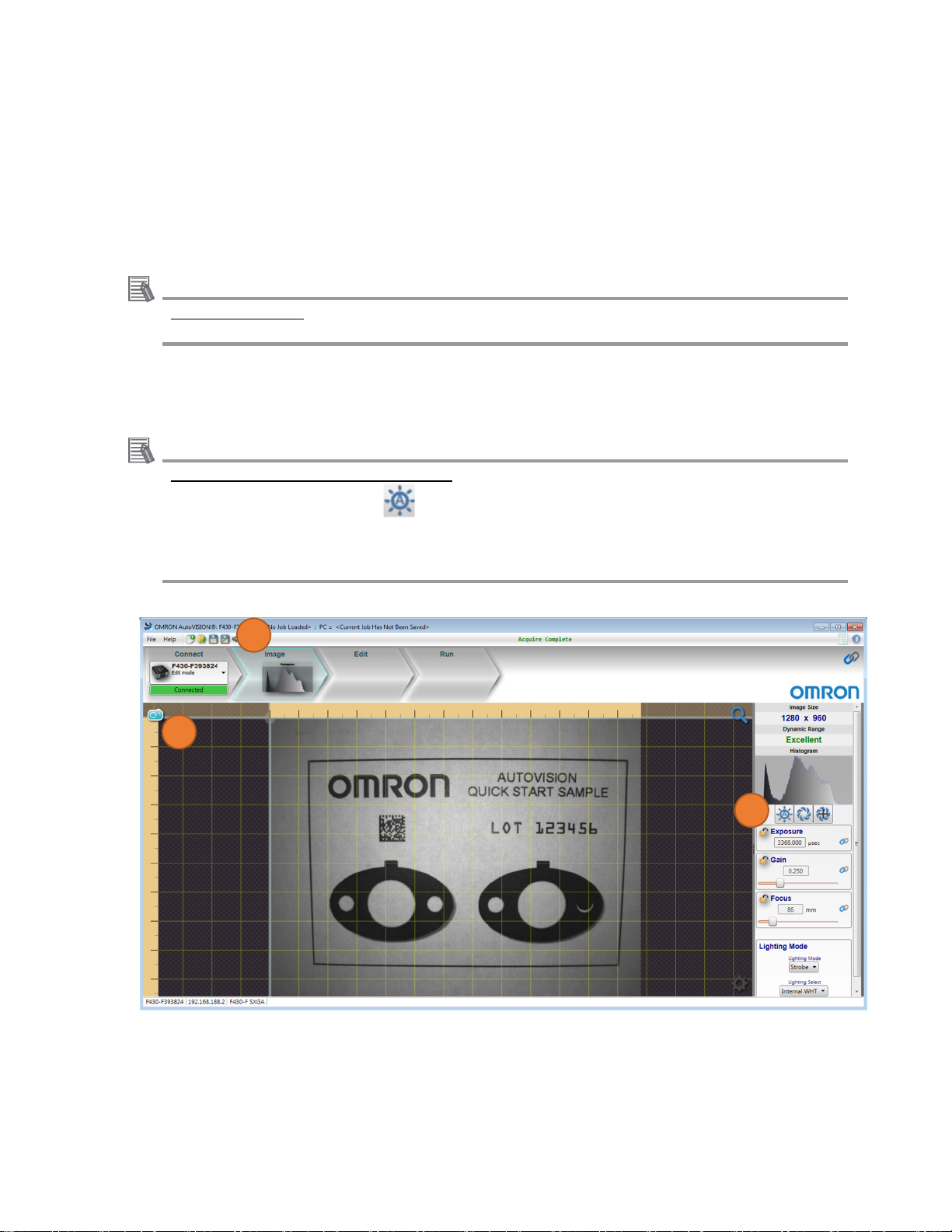

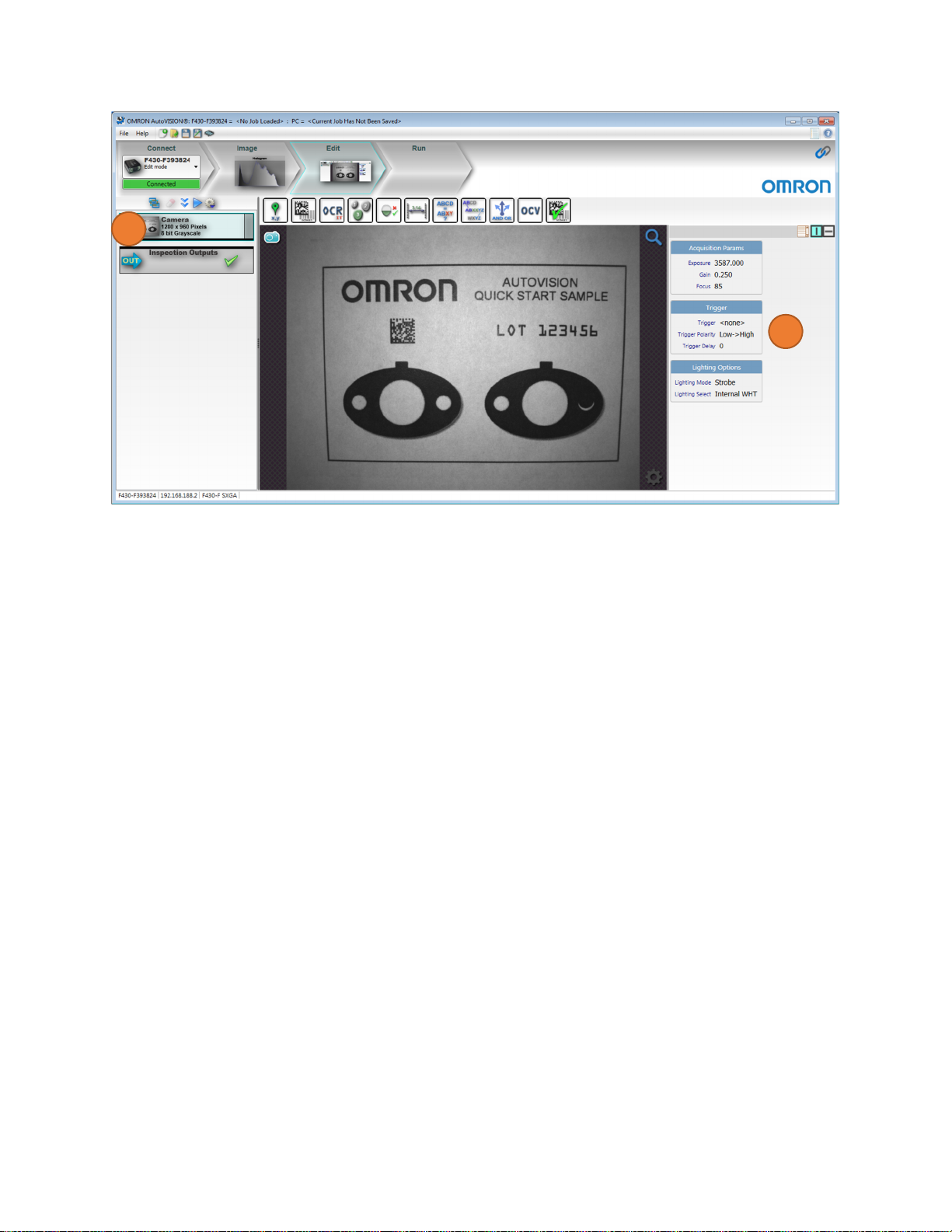

4. Capture an Image

Adjust the camera and lighting settings to produce the best image.

a. Select the Image view on Navigator bar to adjust your image for best performance. Creating a New

Job will move you automatically to Image view.

b. Capture images by clicking on the blue camera icon. If you have hardware connected, you will also

have live image icon.

Additional Information

Using the Emulator

p.10 describes how to load saved images into AutoVISION.

c. The camera and lighting settings are available on the right side. These settings include [Exposure],

[Gain], [Focus] and [Lighting] Modes.

Additional Information

About Exposure, Gain, Focus adjustment

Click the Auto Calibration icon for optimal camera parameters to be set automatically. This

feature works best if there are high contrast features in the center of the image. After Auto

Calibration has completed, click the blue camera icon to capture a new full screen image with

these settings.

a

b

c

Page 12

AutoVISION Quick Start Guide December 2020

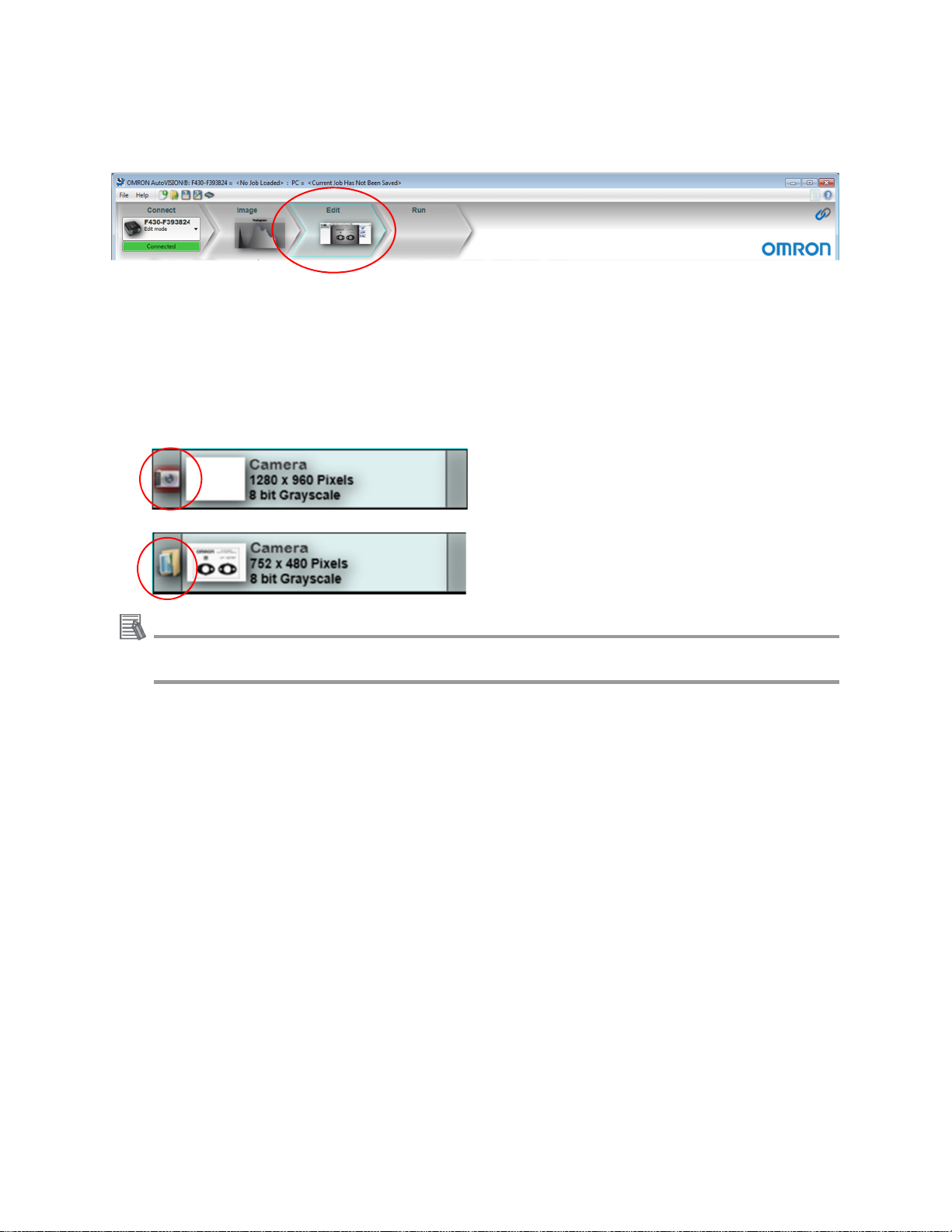

5. Edit Vision Job

Select the Edit view on Navigator bar to add or adjust the VISION Tools used in your job.

5.1 Set Camera Parameters

Adjust camera parameters, including the camera trigger. Load saved images if using an Emulator.

a. To the left of the image is the tool list with the Camera at the top. Select the Camera in the tool list.

The selected tool will turn light blue.

i. To use saved images, click the camera icon on the left side of the Camera tool. This will change

the icon to a folder and a dialog box will be displayed allowing your choose the folder that contains

the saved images.

ii. Clicking on the Folder will toggle back to taking images from the connected hardware.

Additional Information

The images for this AutoVISION quick tutorial are located at:

C:\Omron\AutoVision\TestImages\AV Quick Start

b. To the right of the image are the settings associated with the selected tool. Set the desired trigger

settings. In this example, leave this setting at [none] or [Virtual] for this job.

Page 13

AutoVISION Quick Start Guide December 2020

a

b

Page 14

AutoVISION Quick Start Guide December 2020

5.2. Use Locate tool

The Locate tool is used to detect a parts position and orientation. Locators can also be used compensate

for part movement and rotation by moving subsequent tools into place based on the found location

point.

In this example, set the tool up to locate “OMRON” logo position and rotation.

a. The available tools are shown in a toolbar just above the image. Click on the [Locate Tool] icon to

add this tool to the job.

b. This tool has two regions of interest (ROIs). The inner ROI (Template ROI) is the locate pattern

(“OMRON” log in this example) to learn. The outer ROI (Locate Shape ROI) is the search area for

this pattern. Adjust the regions as shown below.

a

b

c. Click the Red Train icon in the upper left of the Template ROI. After training the ROIs will

become green and a yellow outline should be seen around the learned pattern.

c

Page 15

AutoVISION Quick Start Guide December 2020

Precautions for Correct Use

Direction of adjust parameters

a.

To

reduce inspection time

t [Allowed Rotation] as small as

Adjus

Ex.) If

the work will not rotate, set from +\-180(Default) to 10 degree or less. Just enough fo

normal rotation.

possible

r

b.

To prevent fr

i. To preven

ii. To prevent from lack of detection: Set [Fit Quality] to [Relax

(*)[Accept Threshold]

[Show Advanced Parameters Window] and adjust other parameters. To check the detail, see

HELP.

om miss-dete

t from finding wrong parts: Set [Fit Quality] to [Precise]

and [Conformity Tolerance] are automatically set. If now solved, click

ction

ed] (*)

Page 16

AutoVISION Quick Start Guide December 2020

5.3. Use Decode Tool ,Enable Location and Rotation based on Locator

The Decode Tool is used for reading 1D/2D codes. In this example, read the Data Matrix symbol

Additional Information

To display only the selected tool’s ROI

You can see and control all the ROIs for multiple tools in default. Click [Show only the ROI of the

selected Tool] icon , then you can prevent from changing other ROI’s position. It is available

if the icon changes to .

a. Select the [Decode (bar

code) Tool] icon to add this tool to the job.

b. Resize the Decode tool ROI around the Data Matrix Symbol. This tool typically wo

default setti

ngs. No parameter changes are required in this exampl

a

b

e.

rks well with

Page 17

AutoVISION Quick Start Guide December 2020

c. Enable the [rotate option] in the Decode tool parameters. When enabled the icon will be lig

This will allow the tool to rotate based on the angle of the [Locate tool].

blue.

c

onal Information

Additi

ROI rotation option

The tool rotation can be adjusted by clicking on the blue round rotation handle seen on the

right side of the ROI and dragging to the desired rotation.

ht

Precautions for Correct Use

Direction of adjust parameters

a.

ROI

size

i. Make the Decode tool ROI 20 % larger than the 1D/2D code to allow for the quiet

To detect the

in bottom part of AutoVISI

code size, mouse over to code symbol and check the pixel coordinate shown

ON.

zone.

Page 18

AutoVISION Quick Start Guide December 2020

ii. If the 2D code is rectangular, enble both DataMatrix ECC200, and

the bottom of the code selection list. DRME is for rectangular codes and will enhance the

systems ability to find them.

b.

When faced with other diffiult to read applications, try to use [Custom features]. You can

use this in [Shown the Advanced Parametes Window]. See HELP for more detail.

DataMatrix DMRE at

Page 19

AutoVISION Quick Start Guide December 2020

5.4. Use OCR Tool

This tool is used to read expiration date and LOT numbers etc. Read “LOT 123456” string in this example.

a. Select the [OCR Tool] icon to add this tool to the job.

b. Resize the OCR tool ROI around the text, “LOT 12345

c. Enable

rotation for this

tool.

a

6”.

c

b

Page 20

AutoVISION Quick Start Guide December 2020

Precautions for Correct Use

Direction of parameter adjustment

To read correctly, click on character selection on the right side of the screen. The OCR algorithm

works in 2 steps: Segment characters→Recognize characters. Some keys for success are

described below. To check the detail for each parameter, see HELP.

a. Segment char

i. Adjust

ii. Set [Scaling factor] as “Character width” x “Scaling factor” = 30 pixel.

b.

Recognize characters

Adjust Confidence

same chara

the

correct character in the face of more variation

You can increase the recognition rate by adding

the

Font Library. Click on the character which should be added to library. The “A

sample” popset.

The rea

hovering ove

The

colors are defined as below in relationship to match score:

-Green:

acters

min/max character size according to actual size in AutoVISION image view

To detect the characeter size, mouse over to

coordinate sh

cter has different shapes. Even at 50% it will not tend to misread, but will

up will appear. Type in correct character and it will be added to the sample

d confidence for each character can also be seen as a value of 0 to

r a character and has a color associated with the read confid

81 – 100%

own in bottom part of AutoVISION.

below 0.8 (80%) to increase read rate. It is not uncommon

characters and

characters which are miss-classified into

.

check the pixel

that the

read

dd

1 when

ence.

-Orange: 51 – 80%

-Red: 0

– 50%

Page 21

AutoVISION Quick Start Guide December 2020

5.5. Use Count Tool

This tool detects the number of objects based on color or shape information. In this example, verify that

two small holes are in the gasket.

a. Select the [Count Tool] icon to add this tool to the jo

b. Resize

c. Change

the Count Blobs tool ROI around the left gasket. Enable rotation for this t

the Blob settings to find the desired objects. Each blob will have a yellow perimeter with a

b.

crosshair ( + ) in the center. In the parameter settings on right side of screen:

i. Set [Polarity] to [Light on Da

ii. Adjust [

iii. Change

passes if it fi

Additi

Min and Max blob size] to count the two smaller white circles on each ga

the max and min range of the [Tolerance] to 2 <–> 2 to make sure the

nds the correct number of holes, which is 2 in this

onal Information

rk]

To detect optimal maximum/minimum blob size

This tool does not provide you the number of pixels of each blob. You will easily detect the size

of each blob by using [Presence/Absence tool] stated in next section. You can also change the

Min and Max size to determine empirically the correct value.

a

ool.

sket.

tool only

case.

b

c

b

Page 22

AutoVISION Quick Start Guide December 2020

5.6. Use Presence/Absence Tool

Use Zoom options

This tool detects the presence of a feature based on pixel intensity or contrast. Verify that the tab is

present in the gasket in this example.

a. Select the [Presence Tool] icon to add this tool to the job. Enable rotation for this tool.

a

biv

b. Use the Zoom button to make it easier to position the tool

i. Move the mouse over the [Zoom] icon

ii. Click [Zoom

iii. Righ

t click and drag to reposition image

in

(+)]

to see the Zoom options

iv. Resize and position the ROI over the left gasket tab

bi

Page 23

AutoVISION Quick Start Guide December 2020

c. Change the Presence tool settings to pass when the gasket tab is present in the tool. The orange

pixels inside the tool are the pixels that are counted.

i.

Adjust the Upper/Lower Threshold, using the sliders, to make the gasket tab appear

orange.

ii.

Set the [Tolerance] so that the Presence tool will pass when a gasket tab is in the tool

but fails when the tool contains all light or dark pixels. Note the pixel count in the

[Presence1] tool on the left side of the screen. The lower and upper tolerance settings

should bracket this value to determine if the tab is present.

iii.

Enable the Rotate option.

d. Click [Zoom to Fit] to see the entire image

ciii

d

ci

cii

Page 24

AutoVISION Quick Start Guide December 2020

5.7. Use Measure Tool

This tool allows you to perform width or height measurements between two edges or circle radius etc.

Measure the width of the gasket tab in this example.

a. Select the [Measure Tool] icon to add this tool to the job. Width measure is default.

b. Resize and position the ROI over the right gasket tab. Zoom in if desired. Enable rotation in this tool.

c. Change the Measure tool settings to pass when the gasket tab is the correct width.

i.

Adjust the [Edge Strength] to find the desired edge.

ii.

Adjust the [Tolerance] so that the tab only passes when it is the correct width. The current

width is shown in [Measure1] in the tool list on left side of screen.

a

a

b

d. The [Measure tool] also has a calibration options. The first is Simple Calibrate You can convert

the measurement result from pixel to required unit. To use this feature:

i.

Click [Calibrate]

ii.

The current measurement in pixels is displayed in the [Measured Value] field (Default:

pixel to ich conversion value)

iii.

iv.

In the [Real World Value] field enter the current measurement

Enter the measurement units (Ex. In. to mm)

v.

Click [Calibrate]

e. AutoVISION also allows full non-linear calibration based on inputting data from a target. Use the

Omron Device Non-linear Calibration Utility in the start menu. This will create a calibration file

that you can load into your job through the AutoVISION File menu.

ci

Page 25

AutoVISION Quick Start Guide December 2020

d

Page 26

AutoVISION Quick Start Guide December 2020

5.8. Try All Tools

Try all the vision tools in the job to confirm that they are configured as desired.

a. [Tryout Once] button will capture a new image and run all tools, once on the PC. Look at status

indicators. A green check means the tool has passed. A red X means the tool has failed, for

reason such as wrong count, or out of tolerance.

b. Tryout Loop button will capture a new image and run all tools. Once completed it will repeat

this process continuously until the Stop Loop button is pressed.

Additional Information

In case of using Emulator mode

a.

Tryout the

b.

The available

TIFF/BMP/PNG image of same resolution

images in selected folder one by one.

image are the one acquired by MicroHawk smart camera series or

.

a

b

Page 27

AutoVISION Quick Start Guide December 2020

5.9. Set Inspection Outputs

This tool communicates inspection results to another device. Basic means are [Digital output] and

[TCP/IP and Serial Output String]. In addition, you can use some MSLink and industrial protocols. In this

example, see how to use [Digital output] and [TCP/IP and Serial Output String].

5.9.1. Digital Outputs

Digital Outputs are a fast, easy method of indicating the inspection results to another device, like a PLC

or stack light.

a. Select the [Inspection Outputs] in the

b. Click

the [Digital Output

a

s]

tool list

b

c. Assign th

under Output 1/2/3 and select Inspection Done. Set the desired pulse width time, in

Click

make i

t 20 ms (milliseconds

e outputs in the Digital Outputs pop up wind

).

ow.

this job

Page 28

AutoVISION Quick Start Guide December 2020

c

Page 29

AutoVISION Quick Start Guide December 2020

5.9.2.TCP/IP and Serial Output String

TCP/IP or Serial output messages provide the ability to transmit inspection results like a barcode or

measurement to another device. In this example we will send the Decode1 tool string followed by CR LF

(Carriage Return + Line Feed) characters.

a. Select TCP/IP and Serial Ou

b. Select String

c. In t

he TCP/IP and Serial Out window we need to build the output string. Select the blue + sy

and sel

Output Port and choose TC

ect Tool Output Value. This will add a field to the Build Output String region that states

[Not Connected].

d. Select the blue + sy

to the

output string.

mbol

t

a

P1 (49211).

mbol

and select Text. This will enter a field to allow you to add characters

e. Click on

b

c

the [Not Connected] field, under [Decode1], select [Decoded

Text].

Page 30

AutoVISION Quick Start Guide December 2020

e

f. Click in the blank text field and enter: \r\n

f

g. The results can be seen in a telnet client window when an inspection is completed in Edit mode using

the [Try Once] or [Try Loop] buttons and in Run mode.

Page 31

AutoVISION Quick Start Guide December 2020

5.9.3. Opening Telnet Client to view results

Additional Information

Reason to test using Telnet Client

Quickly see the results that are output from your camera over a specific TCP/IP Socket and Port.

If the Telnet Client has not been enabled in Windows, please go to the link below and follow the

instructions to enable this Windows feature.

https://social.technet.microsoft.com/wiki/contents/articles/38433.windows-10-enabling-telnetclient.aspx

a. Click the Windows Start button, type cmd.exe and hit the Enter key.

b. In the cmd.exe window type the following command listed. Replace the 192.168.188.2 (Default

setting) with your camera IP address.

Precautions for Correct Use

Using Emulator

Your camera IP address can be found if you click on the word Connect in AutoVISION. If using

the Emulator use IP address: 127.0.0.1 (Loop back address).

Typical Example: Type telnet 192.168.188.2 49211

b

c. Click the [Try Once] button in AutoVISION. Each time the Inspection is run the decoded text is

shown in the Telnet window on a new line.

c

Page 32

AutoVISION Quick Start Guide December 2020

6. Save Job

Go to the [File] menu > [Save or click the Save] icon

Additional Information

About the [File] menu > [Archive Job] function

This will save the AutoVISION job and will make an additional Archive file that has an .AVZ

extension. The Archive file contains the AutoVISION job and all the additional support files (ex.

Font Library for the OCR Tool, Images, Locators, etc.) used by that job.

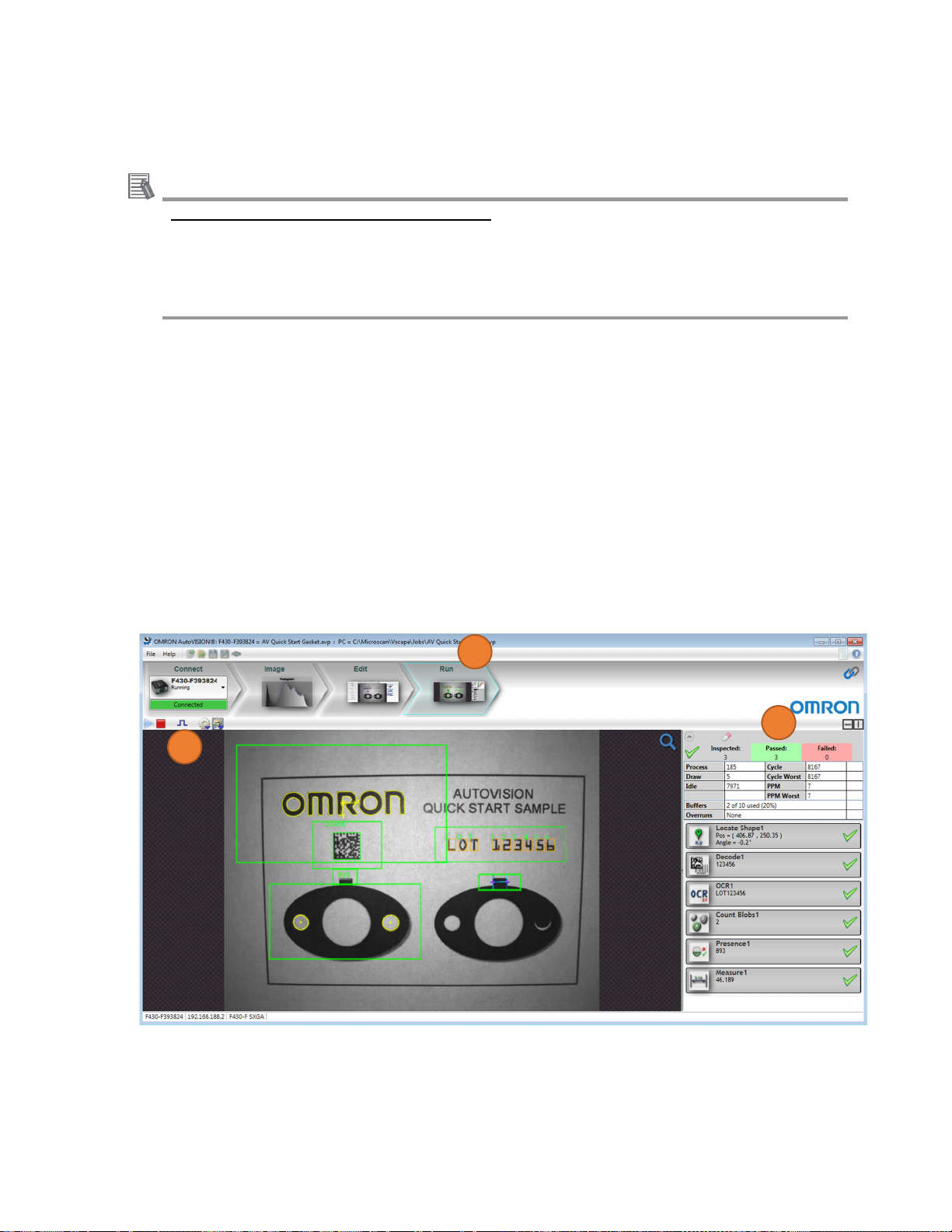

7. Run the Job

Download the job to the selected camera and run.

a. Select the [Run] view in Navigator bar.

The job is downloaded to the selected camera; once completed, the counters and tools are seen to

the right of the image area.

b. Counters and Tool results field. See HELP for details.

c. Trigger button

i.

If the trigger was set to none, the inspection will start running continuously.

ii.

If the camera was set to use a virtual trigger, click the Trigger icon to provide a trigger to the

camera.

a

cii

b

Page 33

AutoVISION Quick Start Guide December 2020

8. Saving setup or runtime images

a. Click [Image Saving Options] .

b. Click [Select Folder] and find the folder you would like to save images.

c. Select [Save as TIFF] or [Save as BMP].

d. Select the condition of saving images from: [Save All Images] [Save Failed Images] [Save Passed

Images].

e. Click [Run Job].

e

a

b

c

d

Page 34

AutoVISION Quick Start Guide December 2020

9. Save Job to flash memory on camera

Saving the job to flash memory on the camera is required to allow the camera to load and restart the job

on power up.

a. Select the [Edit] view in navigator bar.

b. Confirm that the job is correct and has been saved to the PC.

Additional Information

About file save type

It is recommended that you select File > Archive Job… This will save the job to the PC and

create an Archive file (*.avz) that contains the job and additional support files used by the job.

c. Select the camera flash memory icon

d. Select the memory slot to write

i.

Select [New Slot] to write this job to the camera.

ii.

If jobs exist on the camera, selecting an existing slot will overwrite that memory slot.

c

d

e. A pop-up window may appear which will allow you to overload the desired job to the camera.

e

Page 35

AutoVISION Quick Start Guide December 2020

10. Switch Job which is saved in camera

a. Select [Connect] view in navigator bar

b. Below the

[Load a Job] button is a listing of the jobs stored in flash memory on the ca

c. If multiple jobs are stored

camera powe

r up, and click [Make Current].

in flash memory, select the desired job slot that should be loaded

mera.

on

Additional Information

About management of job size

Click [Refresh the job list] , then you can see the list of file size for each job and free memory

size.

11. Edit job which is saved in camera

Select the job to be edit, click [Upload Current Job from

Device]

Click [Load a Job] and select target *avp/*avz file.

10.a

12

11

10.b

10.c

Refresh the job list

Page 36

AutoVISION Quick Start Guide December 2020

Appendix A – Quick Start Samples

The AutoVISION quick start images used in this document are located at:

C:\Omron\AutoVision\TestImages\AV Quick Start

There are another sample images and jobs in below folder. Use them for your reference located at:

C:\OMRON\AutoVision\TestImages

Good Sample

Bad Sample

Page 37

AutoVISION Quick Start Guide December 2020

Appendix B – Use Omron Microscan Link

AutoVISION allows you to link tool parameters to tags within the software's Global Data Service GDS .

This makes it possible to "set and get" the parameter values via any GDS-supported protocol, including

serial, TCP/IP, EtherNet/IP, and PROFINET I/O. Example of count tool setting is below. See HELP for

more detail.

a. Set up [Count tool].

b. Click the link button in [Count tool] in tool list.

c. Hovering the mouse over the link buttons identifies their associated parameter as shown below.

Clicking the link button displays the Link Menu populated with GDS tags of a compatible type.

d. Select the variable to be linked.

e. Once a parameter is linked, the background of the link button turns green.

f. There are other parameters to be linked which is not shown in tool list. To check all, click [Data

nacigator] . To check each parameter, see HELP.

Page 38

AutoVISION Quick Start Guide December 2020

Additional Information

Memory map of MicroHawk smart camera

The memory map for each type of variable is pre-defined as below. To check details, see

industrial protocol manual (*).

(*)C:\OMRON\Vscape\Documentation\industrialprotocolmanual.en.pdf

Ex.)Input assembly layout of Ethernet/IP

Page 39

AutoVISION Quick Start Guide December 2020

Appendix C – Use FTP Image Output

To save images to server via PLC, you can use FTP protocol by below step.

a. Click [Edit] in Navigator bar and click [Inspection Output] in left tool list.

b. Click [FTP Image Output] in right image view.

c. Fill each parameters of FTP server and other options.

Precautions for Correct Use

About File name format

There is a different in file name format between using AutoVISION soft trigger and PLC

command trigger.

Trigger from AutoVISION:”Characters set in Job”+yy-mm-dd-….tif

Trigger from PLC

Precautions for Correct Use

Specification of TimeStamp

There is a different in file name format between using AutoVISION soft trigger and PLC

command trigger.

TimeStamp is the time count[us] after booting.

Additional Information

How to change file name

You can change base file name from PLC by using Omron MicroScan Link Tag (stringN)

:

”Characters set in Job”+TimeStamp.tif

Ex). If the goal format is “ABC000-01_TIMESTAMP.tif”, the serial command is “SET stringN

ABC000-01”

Page 40

AutoVISION Quick Start Guide December 2020

Appendix D – Correlation table with Omron FH/FQ series

The definition of specific words is different between MicroHawk smart camera and Omron FH/FQ. This

section introduces the customer who is familiar with Omron FH/FQ series to understand the meanings

easier by showing the list of each word. Note that these are the explanation of similar functions. No

compatibility for them.

MicroHawk smart camera main

functions

Locate(Locate Shape mode)

Decode Barcode/2D code Can I change the match strings from external

OCR OCR

Count Labeling Can I check the number of pixel for each Blob?

Presence/Absence Gravity Can I output gravity coordinate?

Measure Edge Position/Scan Edge

Omron FH/FQ similar functions MicroHawk smart camera’s FAQ

Shape Search III Can I add or delete some of model edges to get

more stable result?

No

→

device?

Yes. Use OmronMicroScanLink.

→

No. But you can check Min/Max number of

→

Blobs in data navigator.

No. Use [Locate tool] and select [Locate Blob]

→

mode.

Can I calibrate using calibration plate?

Position/Circular Edge Position

Yes. See [Multi Dot Calibration Utility] in

→

HELP.。

Image Preprocessing Filtering Can I use multiple preprocessing unit?

No

→

Save Image Image logging Can I select any folders to save images (Ex. USB

folder)?

Yes

→

Job Scene How many jobs can I save in camera?

Until you use all the free memory.

→

Calibration(Exposure/Gain/Focus)

Calibration(Pixel→mm)

None

Same as left

Page 41

Authorized Distributor:

1220 (0520)

© OMRON Corporation 2020 All Rights Reserved.

In the interest of product improvement, specifications

are subject to change without notice.

Z434-E-02 (84-9100005-02)

OMRON Corporation Industrial Automation Company

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

Contact: www.ia.omron.com

Kyoto, JAPAN

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra T echnopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Loading...

Loading...