Page 1

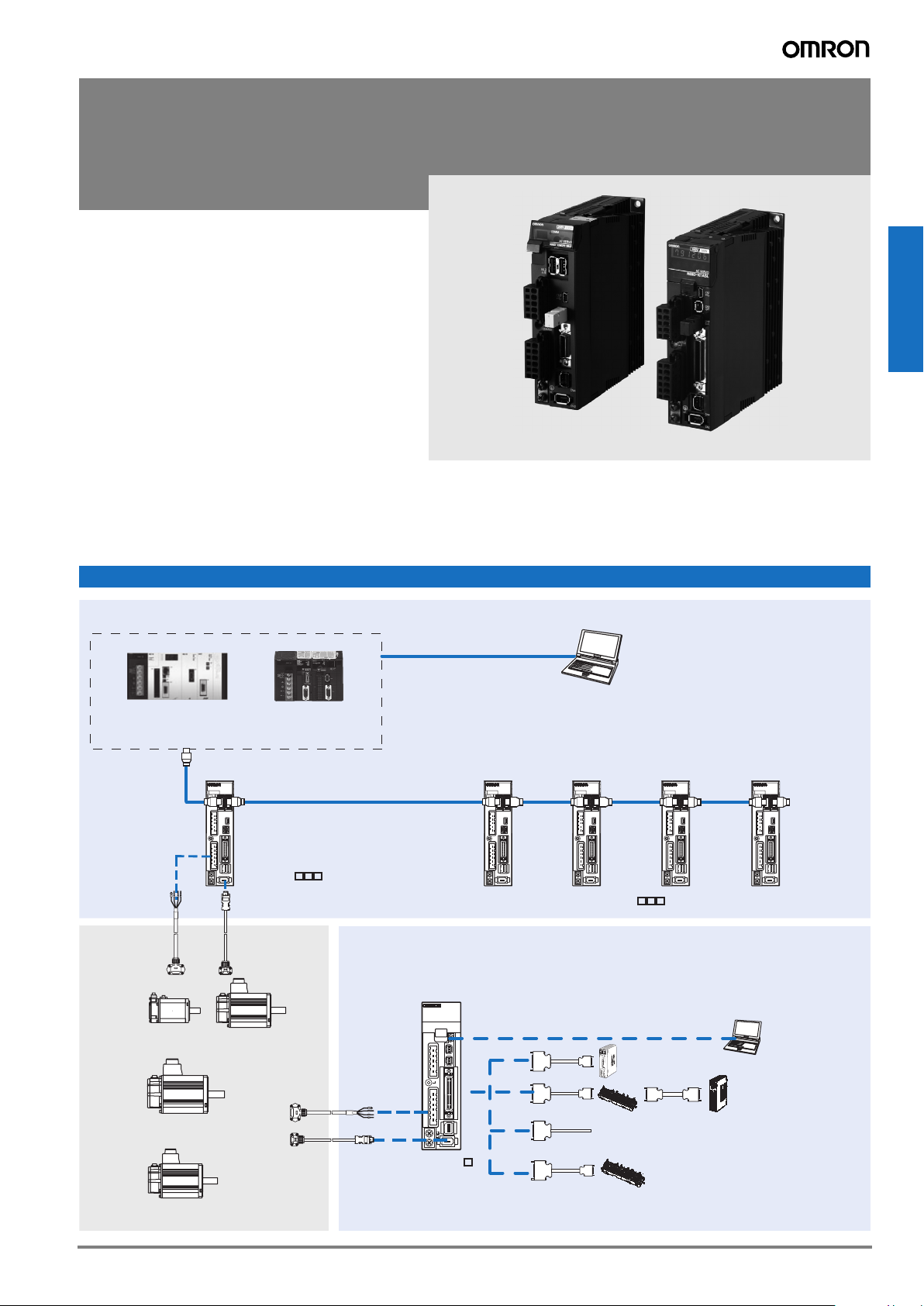

R88D-KN@@@-ML2, R88D-KT@

Accurax G5 servo drive

Accurate motion control in a compact size

servo drive family. MECHATROLINK-II

motion bus and safety built-in.

• MECHATROLINK-II and Analog/ Pulse servo drive

models

• Safety conforming ISO13849-1 Performance Level

D

• High-response frequency of 2 kHz

• High resolution serial encoder for greater accuracy

provided by 20 bits encoder

• External encoder input for full close loop

• Real time auto-tuning

• Advanced tuning algorithms (Anti-vibration function,

torque feedforward, disturbance observer)

Ratings

• 230 VAC Single-phase 100 W to 1.5 kW (8.59 Nm)

• 400 VAC three-phase 600 W to 5 kW (28.7 Nm)

AC Servo systems

System configuration

MECHATROLINK-II control

TJ1-MC04/16

R88D-KN -ML2

Power cable

Encoder cable

CJ1W-MCH72

CJ1W-NCF71

MECHATROLINK-II

Open Analog/pulse control

Accurax G5 Analog/pulse

Servo Drive

Personal computer

software: CX-One

Accurax G5 ML-II Servo Drives

Terminator

R88D-KN -ML2

Servo Motor

3000 rpm (50 W-5 kW)

Servo Motor

2000 rpm (400 W-5 kW)

Servo Motor

1000 rpm (900 W-3 kW)

Power cable

Encoder cable

R88D-KT

Motion control unit

General purpose cable

Te rm i n al block

for Ser vo drive I/O

general purpose

signals

Unit

Personal computer :

Software CX-One

Position control unit

61Accurax G5 servo drive

Page 2

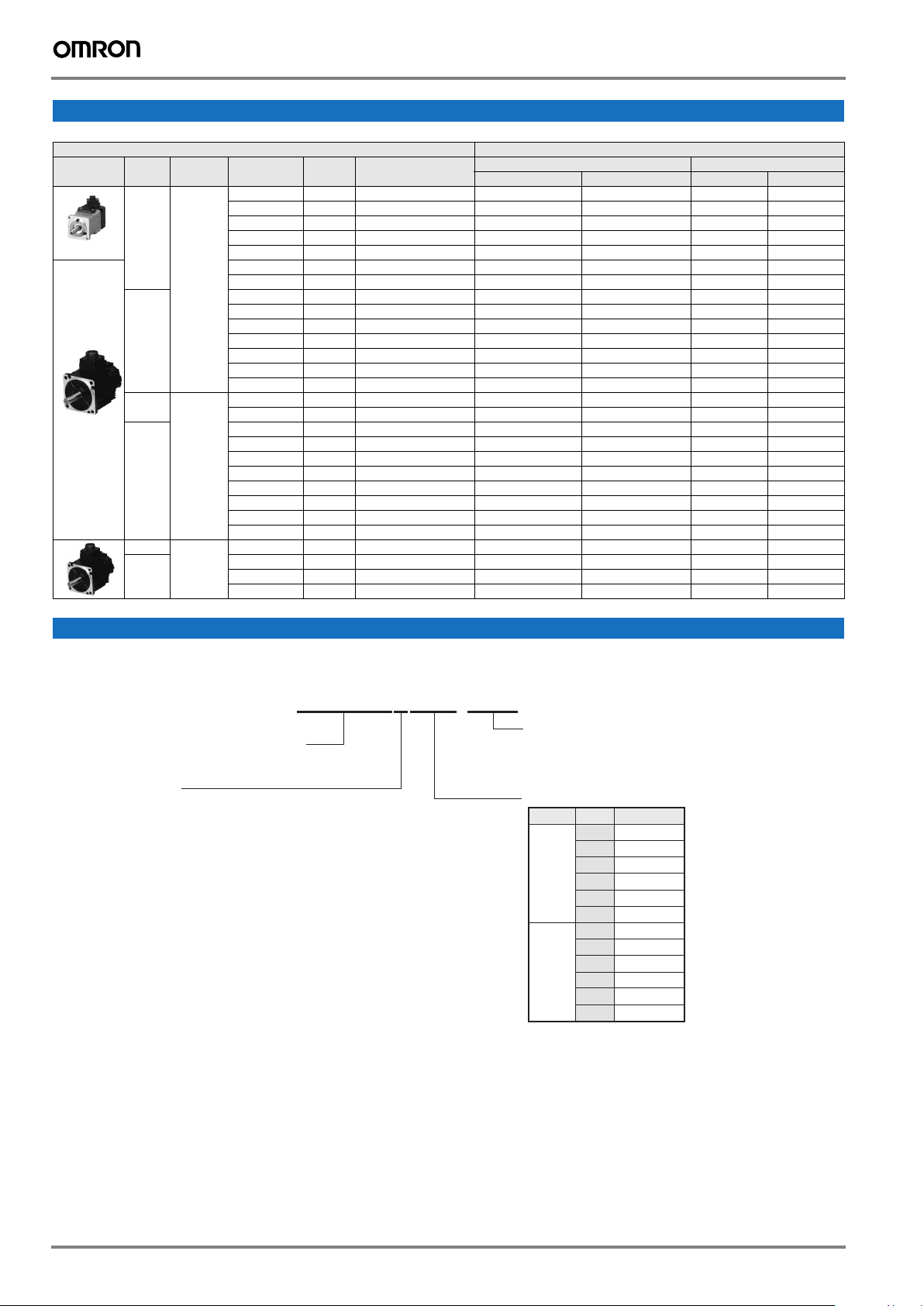

Servo motor supported

Voltage Speed Rated torque Capacity Model MECHATROLINK-II model Analog/Pulse model

230 V 3000 min

400 V 2.39 Nm 750 W R88M-K75030(F/C)-@ - R88D-KN10F-ML2 - R88D-KT10F

230 V 2000 min

400 V 1.91 Nm 400 W R88M-K40020(F/C)-@ - R88D-KN06F-ML2 - R88D-KT06F

230 V 1000 min

400 V 8.59 Nm 900 W R88M-K90010(F/C)-@ R88D-KN15F-ML2 - R88D-KT15F

Accurax G5 rotary servo motor Accurax G5 servodrive

-1

0.16 Nm 50 W R88M-K05030(H/T)-@ R88D-KN01H-ML2 - R88D-KT01H -

0.32 Nm 100 W R88M-K10030(H/T)-@ R88D-KN01H-ML2 - R88D-KT01H -

0.64 Nm 200 W R88M-K20030(H/T)-@ R88D-KN02H-ML2 - R88D-KT02H -

1.3 Nm 400 W R88M-K40030(H/T)-@ R88D-KN04H-ML2 - R88D-KT04H -

2.4 Nm 750 W R88M-K75030(H/T)-@ R88D-KN08H-ML2 - R88D-KT08H -

3.18 Nm 1000 W R88M-K1K030(H/T)-@ R88D-KN15H-ML2 - R88D-KT15H -

4.77 Nm 1500 W R88M-K1K530(H/T)-@ R88D-KN15H-ML2 - R88D-KT15H -

3.18 Nm 1000 W R88M-K1K030(F/C)-@ - R88D-KN15F-ML2 - R88D-KT15F

4.77 Nm 1500 W R88M-K1K530(F/C)-@ - R88D-KN15F-ML2 - R88D-KT15F

6.37 Nm 2000 W R88M-K2K030(F/C)-@ - R88D-KN20F-ML2 - R88D-KT20F

9.55 Nm 3000 W R88M-K3K030(F/C)-@ - R88D-KN30F-ML2 - R88D-KT30F

12.7 Nm 4000 W R88M-K4K030(F/C)-@ - R88D-KN50F-ML2 - R88D-KT50F

15.9 Nm 5000 W R88M-K5K030(F/C)-@ - R88D-KN50F-ML2 - R88D-KT50F

-1

4.77 Nm 1000 W R88M-K1K020(H/T)-@ R88D-KN10H-ML2 - R88D-KT10H -

7.16 Nm 1500 W R88M-K1K520(H/T)-@ R88D-KN15H-ML2 - R88D-KT15H -

2.86 Nm 600 W R88M-K60020(F/C)-@ - R88D-KN06F-ML2 - R88D-KT06F

4.77 Nm 1000 W R88M-K1K020(F/C)-@ - R88D-KN10F-ML2 - R88D-KT10F

7.16 Nm 1500 W R88M-K1K520(F/C)-@ - R88D-KN15F-ML2 - R88D-KT15F

9.55 Nm 2000 W R88M-K2K020(F/C)-@ - R88D-KN20F-ML2 - R88D-KT20F

14.3 Nm 3000 W R88M-K3K020(F/C)-@ - R88D-KN30F-ML2 - R88D-KT30F

19.1 Nm 4000 W R88M-K4K020(F/C)-@ - R88D-KN50F-ML2 - R88D-KT50F

23.9 Nm 5000 W R88M-K5K020(F/C)-@ - R88D-KN50F-ML2 - R88D-KT50F

-1

8.59 Nm 900 W R88M-K90010(H/T)-@ R88D-KN15H-ML2 - R88D-KT15H -

19.1 Nm 2000 W R88M-K2K010(F/C)-@ R88D-KN30F-ML2 - R88D-KT30F

28.7 Nm 3000 W R88M-K3K010(F/C)-@ R88D-KN50F-ML2 - R88D-KT50F

230V 400V 230V 400V

Type designation

Servo drive

Accurax G5 Series servo drive

Drive Type

T: Analog/pulse type

N: Network type

R88D-KN01H-ML2

Model

Blank: Analog/pulse type

ML2: MECHATROLINK-II comms

Capacity and Voltage

Vol tage Code

01H

02H

04H

230 V

08H

10H

15H

06F

10F

15F

400 V

20F

30F

50F

Output

100 W

200 W

400 W

750 W

1 kW

1.5 kW

600 W

1.0 kW

1.5 kW

2.0 kW

3.0 kW

5.0 kW

62 AC servo systems

Page 3

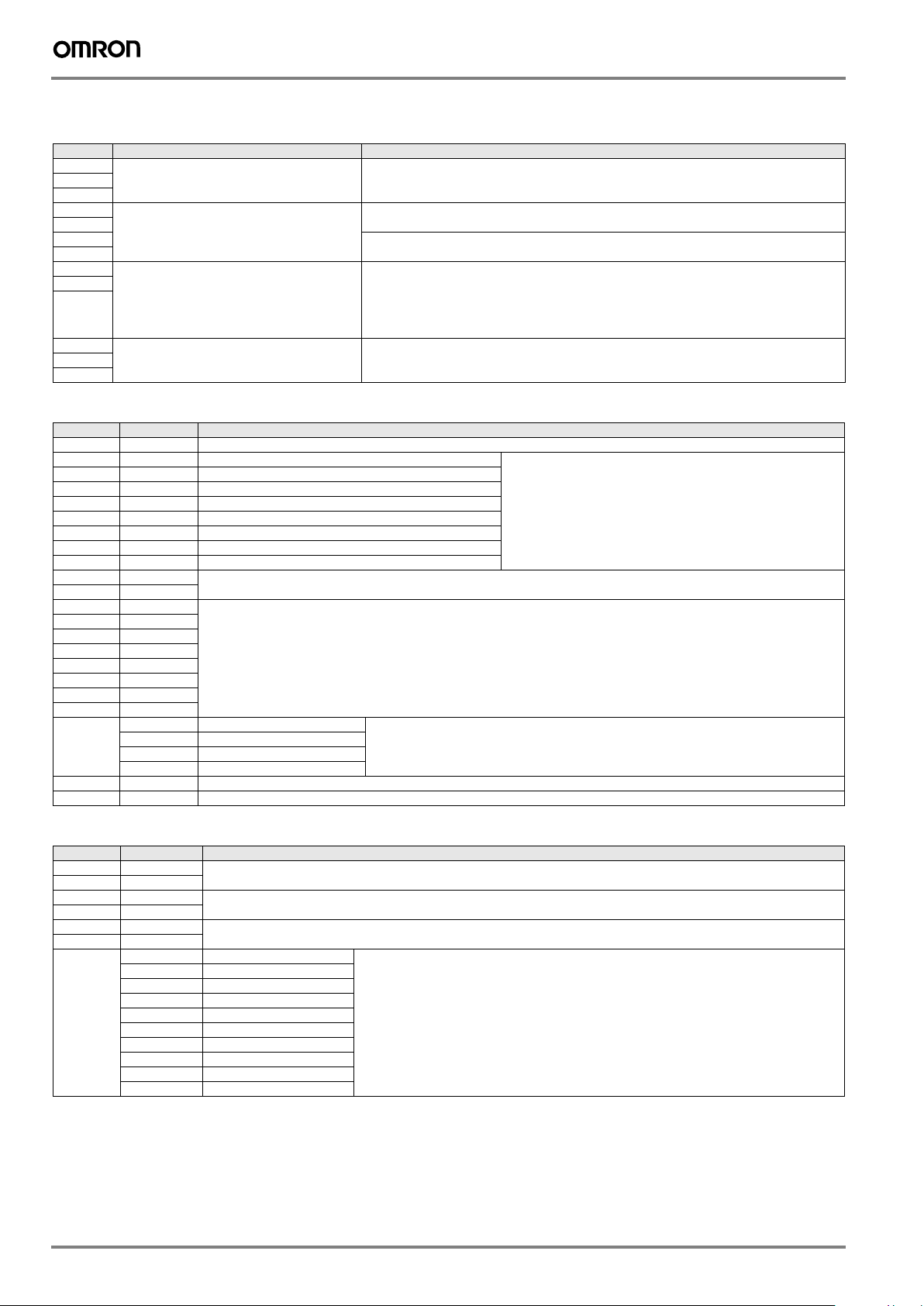

Servo drive specifications

Single-phase, 230 V

Servo drive type R88D-K@ 01H@ 02H@ 04H@ 08H@ 10H@ 15H@

Applicable

servo motor

Max. applicable motor capacity W 100 200 400 750 1000 1500

Continuous output current Arms 1.2 1.6 2.6 4.1 5.9 9.4

Input power Main circuit Single-phase/3-phase, 200 to 240 VAC + 10 to -15% (50/60 Hz)

Supply Control circuit Single-phase, 200 to 240 VAC + 10 to -15% (50/60 Hz)

Control method IGBT-driven PWM method, sinusoidal drive

Feedback Serial encoder (incremental/absolute value)

Usage/storage temperature 0 to +55°C / -20 to 65°C

Usage/storage humidity 90% RH or less (non-condensing)

Altitude 1000m or less above sea level

Basic specifications

Vibration /shock re sista nce (max. ) 5.88 m /s

Conditions

Configuration Base mounted

Appr ox. weight Kg 0.8 1.1 1.6 1.8

R88M-K@ 05030(H/T)@ 20030(H/T)@ 40030(H/T)@ 75030(H/T)@ 1K020(H/T)@ 1K030(H/T)@

10030(H/T)@ - - - - 1K530(H/T)@

- - - - - 1K520(H/T)@

- - - - - 90010(H/T)@

2

10-60 Hz (Continuous operation at resonance point is not allowed) / 19.6 m/s

2

AC Servo systems

Three-phase, 400 V

Servo drive type R88D-K@ 06F-@ 10F-@ 15F-@ 20F-@ 30F-@ 50F-@

Applicable

servo motor

Max. applicable motor capacity kW 0.6 1.0 1.5 2.0 3.0 5.0

Continuous output current Arms 2.9 4.7 6.7 9.4 16.5

Input power Main circuit 3-phase, 380 to 480 VAC + 10 to -15% (50/60Hz)

Supply Control circuit 24 VDC ±15%

Control method IGBT-driven PWM method, sinusoidal drive

Feedback Serial encoder (incremental/absolute value)

Usage/storage temperature 0 to +55°C / -20 to +65°C

Usage/storage humidity 90% RH or less (non-condensing)

Altitude 1000 m or less above sea level

Basic specifications

Vibration/shock resistance 5.88 m/s

Conditions

Configuration Base mounted

Ap prox. wei ght Kg 1. 9 2. 7 4. 7

R88M-K@ 40020(F/C)-@ 75030(F/C)-@ 1K030(F/C)-@ 2K030(F/C)-@ 3K030(F/C)-@ 4K030(F/C)-@

60020(F/C)-@ 1K020(F/C)-@ 1K530(F/C)-@ 2K020(F/C)-@ 3K020(F/C)-@ 5K030(F/C)-@

- - 1K520(F/C)-@ - 2K010(F/C)-@ 4K020(F/C)-@

- - 90010(F/C)-@ - - 5K020(F/C)-@

- - - - - 3K010(F/C)-@

2

10-60 Hz (Continuous operation at resonance point is not allowed) / 19.6 m/s

2

Accurax G5 servo drive 63

Page 4

General specifications (for MECHATROLINK-II servo drives)

Control mode Position control, velocity control, torque control, full-closed control.

Performance Frequency characteristics 2 kHz

Command input MECHATROLINK-II

Sequence input signal - Multi-function input x 8 by parameter setting (forward/reverse drive prohibition, emergency stop, external latch,

Sequence output signal It is possible to output three types of signal form incl.: brake release, servo ready, servo alarm, positioning com-

I/O signal

USB

communications

MECHATROLINKII communications

Automatic load inertia detection Automatic motor parameter setting. One parameter rigidity setting.

Dynamic brake (DB) Built-in. Operates during main power OFF, servo alarm, servo OFF or overtravel.

Regenerative processing Internal resistor included in models from 600 W to 5 kW. Regenerative resistor externally mounted (option).

Overtravel (OT) prevention function DB stop, deceleration stop or coast to stop during P-OT, N-OT operation

Encoder divider function Optional division possible

Protective functions Overcurrent, overvoltage, undervoltage, overspeed, overload, encoder error, overheat...

Analog monitor functions for supervision Analog monitor of motor speed, speed reference, torque reference, command following error, analog input...

Integrated functions

Panel operator Display functions 2-digit 7-segment LED display shows the drive status, alarm codes, parameters...

CHARGE lamp Lits when the main circuit power supply is turned ON.

Safety terminal Functions Safety Torque OFF function to cut off the motor current and stop the motor. Output signal for failure monitoring

External encoder feedback Serial signal and line-driver A-B-Z encoder for full-close control

Speed zero clamp Preset velocity command can be clamped to zero by the speed zero clamp input.

soft start time setting 0 to 10 s (acceleration, deceleration can be set separately).

communication

Interface Personal computer/ Connector mini-USB

Communications standard Compliant with USB 2.0 standard

Function Parameter setting and status monitoring

Communications protocol MECHATROLINK-II

Station address 41H to 51 FH (max. number of slaves: 30)

Tranmission speed 10 Mbps

Transmission cycle 1, 2 & 4 ms

Data length 32 bytes

Switches 2 x rotary switches for setting the MECHATROLINK-II node address

Conformed standards EN ISO13849-1:2008 (PL- d, Performance Level d), IEC61800-5 -2:2007 (function STO, Safe Torque OFF),

MECHATROLINK-II commands (for sequence, motion, data setting/reference, monitor, adjustment and other

commands)

origin proximity, forward/reverse torque limit, general purpose monitor input).

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection,

warning, position command status, speed limit detection, alarm ouput, speed command status.

The monitoring signals to output and their scaling can be specified with parameters.

Number of channels: 2 (Output voltage: ±10V DC)

MECHATROLINK-II communications status LED indicator (COM)

function.

EN61508:2001 (Safety Integrity Level 2, SIL2), EN954-1:1996 (CAT3).

General specifications (for analog/pulse servo drives)

Control mode 7 modes selectables by parameter: (1) position control, (2) velocity control, (3) torque control, (4) position/velocity

Performance Frequency characteristics 2 kHz

Speed control Speed reference voltage 6 VDC at rated speed: set at delivery (the scale and polarity can be set by parameters)

Torque control Torque reference voltage 3 VDC at rated torque: set at delivery (the scale and polarity can be set by parameters).

Input signal

Speed/torque control

Command

pulse

Input signal

Position control

Command

pulse

Input signal

External encoder scaling Applicable scaling ratio: 1/20 - 160

Full-closed control

Position signal output A-phase, B.phase, Z-phase line driver output and Z-phase open-collector output.

Sequence input signal - Multi-function input x 10 by parameter setting (servo ON, control mode switching, forward/reverse drive prohi-

I/O signal

Sequence output signal It is possible to output four types of signal form incl.: brake release, servo ready, servo alarm, positioning com-

Speed zero clamp Preset velocity command can be clamped to zero by the speed zero clamp input.

Soft start time setting 0 to 10 s (acceleration, deceleration can be set separately). S-curve acceleration/deceleration is also available.

Torque limit 3 VDC at rated torque (torque can be limited separately in positive/negative direction).

Preset speed control Preset speed is selectable from 8 internal settings by digital inputs.

Speed limit Speed limit can be set by parameter.

Input pulse type Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train

Input pulse frequency 4 Mpps max. (200 Kpps max. at open collector).

Command pulse scaling

(Electronic Gear)

Input pulse type Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train

Input pulse frequency 4 Mpps max. (200 Kpps max. at open collector).

Command pulse scaling

(Electronic Gear)

control, (5) position/torque control, (6) velocity/torque control and (7) full-closed control.

Applicable scaling ratio: 1/1000 - 1000

Any value of 1-2

per motor revolution). The combination has to be within the range shown above.

Applicable scaling ratio: 1/1000 - 1000

Any value of 1-2

The combination has to be within the range shown above.

Any value of 1-2

per motor revolution). The combination has to be within the range shown above.

bition, vibration filter switching, gain switching, electronic gear switching, error counter reset, pulse prohibition,

alarm reset, internal speed selection, torque limit switching, zero speed, emergency stop, inertia ratio switching,

velocity/torque command sign).

- Dedicated input x 1 (SEN: sensor ON, ABS data request).

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection,

warning, position command status, speed limit detection, speed command status.

30

can be set for numerator (encoder resolution) and denominator (command pulse resolution

30

can be set for numerator (encoder resolution) and denominator (command pulse resolution).

30

can be set for numerator (encoder resolution) and denominator (external encoder resolution

64 AC servo systems

Page 5

USB

Communications

Interface Personal computer/ Connector mini-USB

Communications standard Compliant with USB 2.0 standard

Function Parameter setting and status monitoring

Automatic load inertia detection Automatic motor parameter setting. One parameter rigidity setting.

Dynamic brake (DB) Built-in. Operates during main power OFF, servo alarm, servo OFF or overtravel.

Regenerative processing Internal resistor included in models from 600 W to 5 kW. Regenerative resistor externally mounted (option).

Overtravel (OT) prevention function DB stop, deceleration stop or coast to stop during P-OT, N-OT operation

Encoder divider function Optional division possible

Electronic gearing (Numerator/Denominator) Up to 4 electronic gear numerators by combining with inputs.

Internal speed setting function 8 speeds may be set internally

Protective functions Overcurrent, overvoltage, undervoltage, overspeed, overload, encoder error, overheat...

Analog monitor functions for supervision Analog monitor of motor speed, speed reference, torque reference, command following error, analog input...

The monitoring signals to output and their scaling can be specified by parameters.

Number of channels: 2 (Output voltage: ±10V DC)

Panel operator Display functions 6-digit 7-segment LED display shows the drive status, alarm codes, parameters...

Integrated functions

Panel operator keys Used to set/monitor parameters and drive condition (5 key switches).

CHARGE lamp Lits when the main circuit power supply is turned ON.

Safety terminal Functions Safety torque OFF function to cut off the motor current and stop the motor. Output signal for failure monitoring

Conformed standards EN ISO13849-1:2008 (PL- d, Performance Level d), IEC61800-5 -2:2007 (function STO, Safe Torque OFF),

function.

EN61508:2001 (Safety Integrity Level 2, SIL2), EN954-1:1996 (CAT3).

External encoder feedback Serial signal and line-driver A-B-Z encoder for full-close control

Expansion connector Serial bus for option board

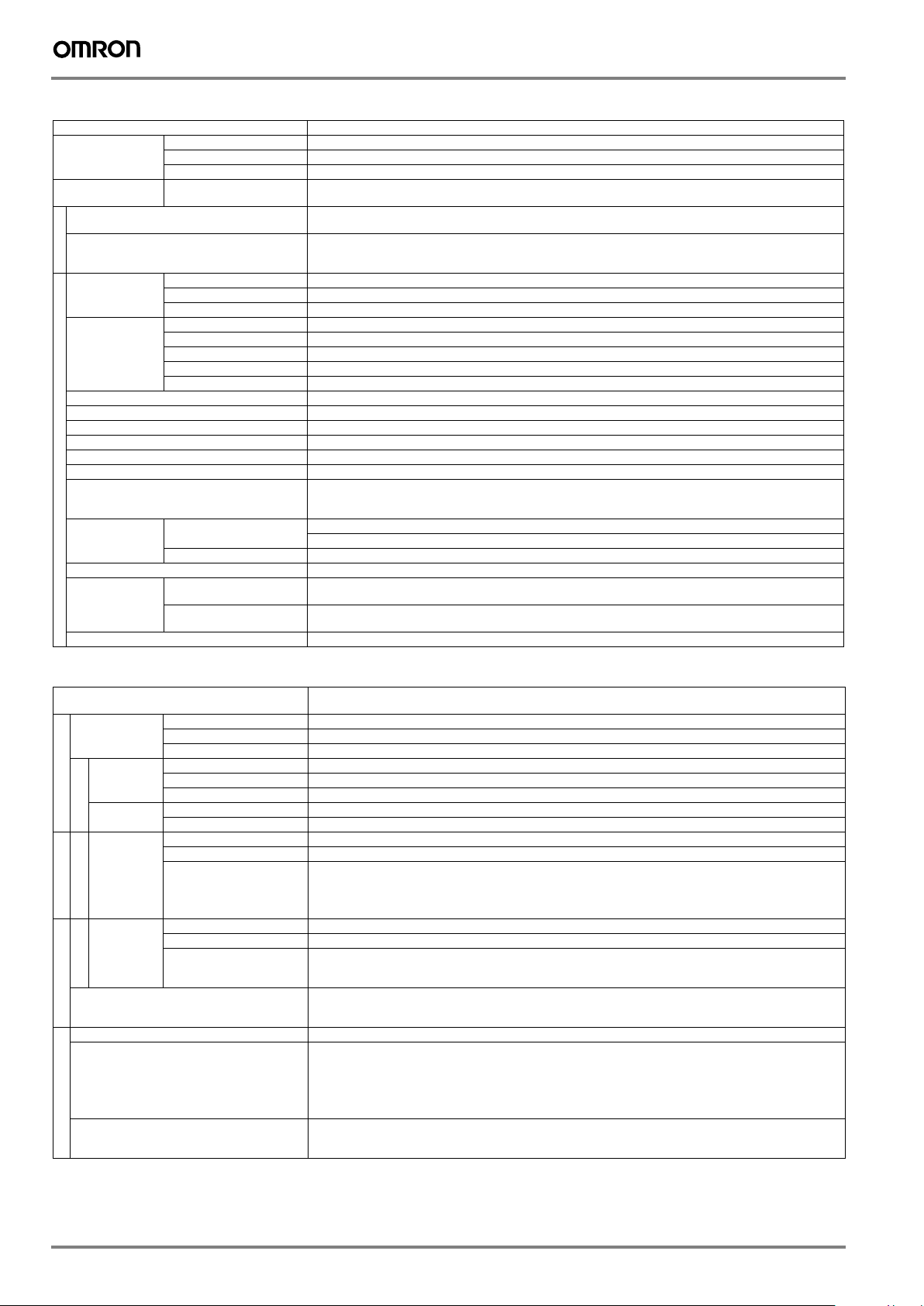

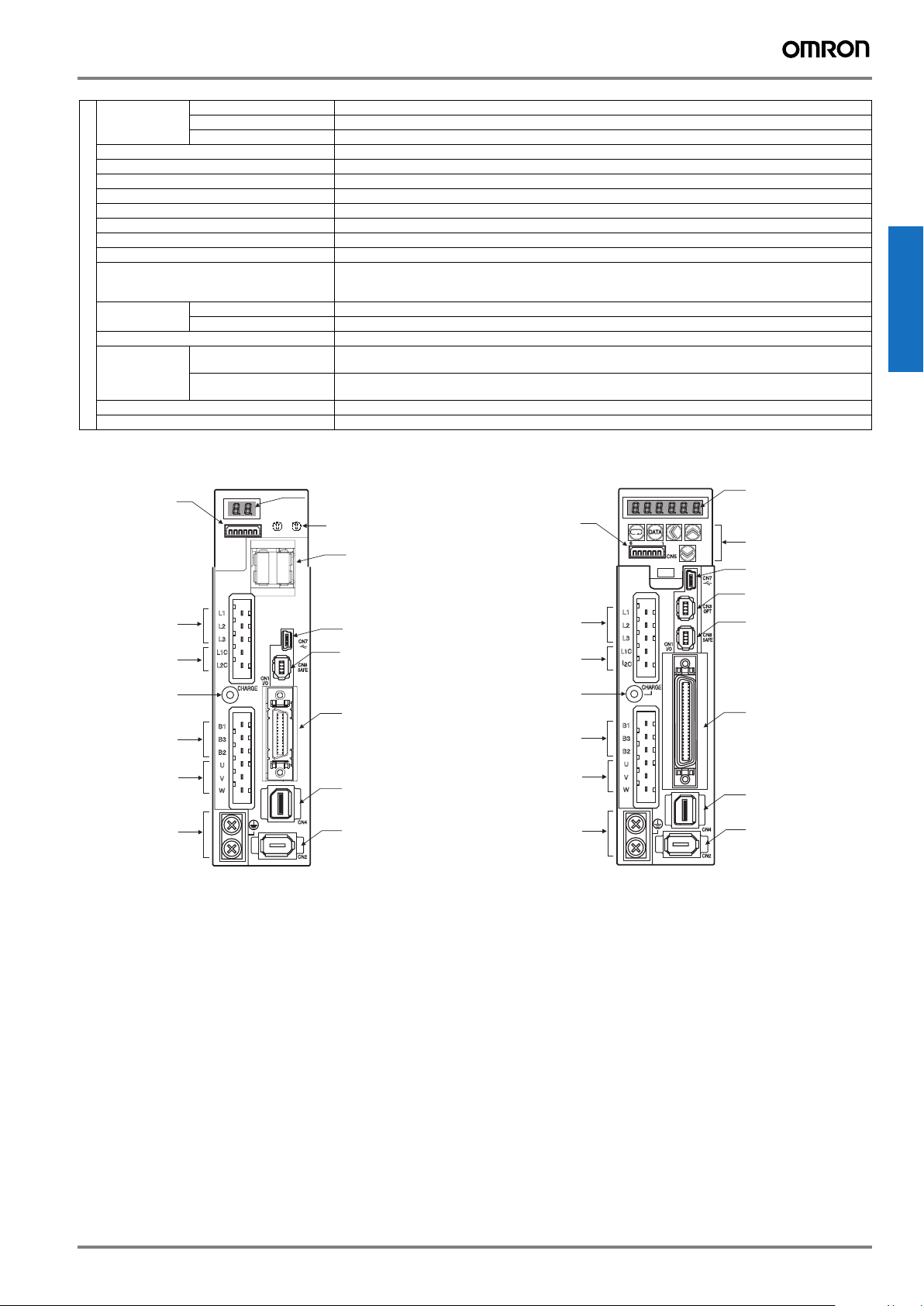

Servo drive part names

AC Servo systems

Monitor connector (CN5)

Main circuit

power supply terminals

(L1, L2, and L3)

Control circuit

power supply terminals

(L1C and L2C)

Charge lamp

External Regeneration

Resistor connection

terminals (B1, B2 and B3)

Motor connection

terminals (U, V and W)

Protective ground terminals

Display area

Address number switches

MECHATROLINK-II connector (CN6)

USB connector (CN7)

Safety connector (CN8)

Control I/O connector (CN1)

- 26 pins-

External encoder connector (CN4)

Encoder connector (CN2)

Monitor connector (CN5)

Main circuit

power supply terminals

(L1, L2, and L3)

Control circuit

power supply terminals

(L1C and L2C)

Charge lamp

External Regeneration

Resistor connection

terminals (B1, B2 and B3)

Motor connection

terminals (U, V and W)

Protective ground terminals

MECHATROLINK-II servo drives Analog/pulse servo drives

Display area

Operation area

USB connector (CN7)

Expansion connector (CN3)

Safety connector (CN8)

Control I/O connector (CN1)

- 50 pins -

External encoder connector (CN4)

Encoder connector (CN2)

Note: the above pictures show 230 V servo drives models only. The 400 V servo drives have 24 VDC power input terminals for control circuit

instead of L1C and L2C terminals.

Accurax G5 servo drive 65

Page 6

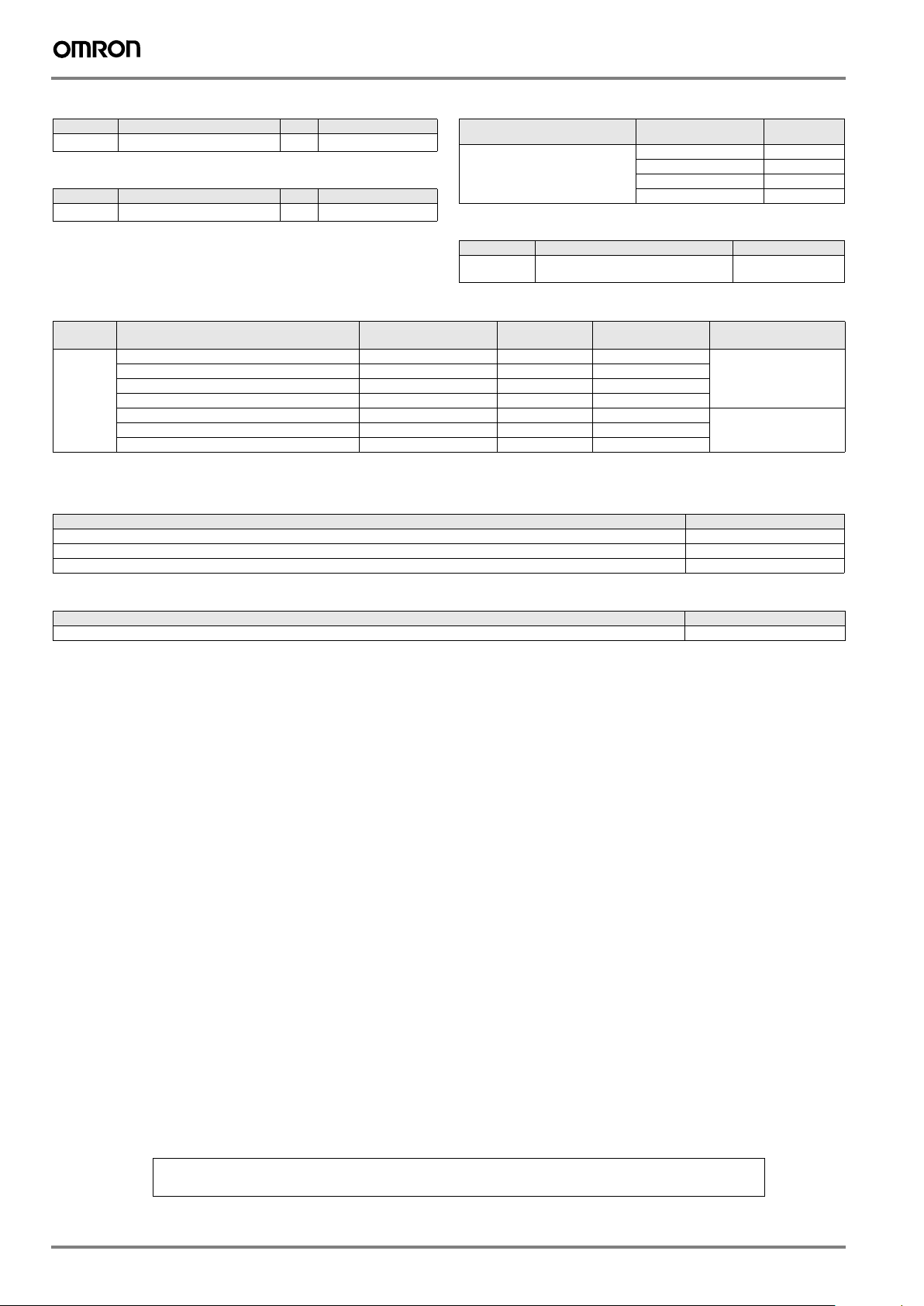

I/O specifications

Terminals specifications (for all drives)

Symbol Name Function

L1 Main power supply input terminal AC power input terminals for the main circuit

L2

L3

L1C Control power supply input terminal AC power input terminals for the control circuit

L2C

24 V DC power input terminals for the control circuit

0 V

B1 External regeneration resistor connection terminals Servo drives below 750W: no internal resistor is connected. Leave B2 and B3 open.

B2

B3

U Servo motor connection terminals Terminals for outputs to the servomotor.

V

W

Note: for single-phase servo drives connect the power supply input to L1 and L3.

(for 200V single/three-phase servo drives only).

(for 400V three-phase servo drives only).

Connect an external regenerative resistor between B1 and B2.

Servo drives from 750W to 5 kW: short-circuit in B2 and B3 for internal regenerative resistor. If the

internal regenerative resistor is insufficient, connect an external regenerative resistor between B1 and

B2 and remove the wire between B2 and B3.

I/O signals (CN1) - Input signals (for MECHATROLINK-II servo drives)

Pin No. Signal name Function

6 I-COM ± pole of external DC power. The power must use 12V-24V (±5%)

5 E-STOP Emergency stop The signal name shows the factory setting. The function can be

7 P-OT Forward run prohibited

8 N-OT Reverse run prohibited

9 DEC Origin proximity

10 EXT3 External latch input 3

11 EXT2 External latch input 2

12 EXT1 External latch input 1

13 SI-MON0 General purpose monitor input 0

14

15

17 - Terminals not used. Do not connect.

18 19 20 21 22 23 24 -

- PCL Forward torque limit The function of input signals allocated to pins 5 and 7 to 13 can be changed with these options by

Shell FG Shield ground. Connected to frame ground if the shield wire of the I/O signal cable is connected to the connector shell.

16 GND Signal ground. It is insulated with power supply (I-COM) for the control signal in the servo drive.

BTP-I

BTN-I

NCL Reverse torque limit

SI-MON1 General-purpose monitor input 1

SI-MON2 General-purpose monitor input 2

Connecting pin for the absolute encoder backup battery. Do not connect when a battery is connected to the encoder cable (CN2

connector).

parameters settings.

changed by parameter setting.

I/O signals (CN1) - output signals (for MECHATROLINK-II servo drives)

Pin No. Signal name Function

1 BRK-OFF+ External brake release signal

2BRK-OFF

25 S-RDY+ Servo ready: ON when there is no servo alarm and control/main circuit power supply is ON

26 S-RDY3 ALM+ Servo alarm: Turns OFF when an error is detected

4ALM-

- INP1 Position complete output 1 The function of output signals allocated to pins 1,2, 25 and 26 can be changed with these options by

AT-SPEED Speed complete

T_LIM Torque limit

ZSP Zero speed

V-COIN Speed coincidence

INP2 Position complete output 2

WARN1 Warning 1

WARN2 Warning 2

DEN Origin proximity

V_LIM Speed limit

parameters settings

66 AC servo systems

Page 7

I/O signals (CN1) - Input signals (for analog/pulse servo drives)

Pin No. Control mode Signal name Function

1 Position/

3+CW

4-CW

2 +24 VCW

5+CCW

6 -CCW

44 +CWLD Reference pulse input for line driver only.

45 -CWLD

46 +CCWLD

47 -CCWLD

14 Speed REF Speed reference input: ±10 V/rated motor speed (input gain can be modified using a parameter).

15 - AGND1 Analog signal ground

16 Torque TREF2 Torque reference input: ±10 V/rated motor torque (input gain can be modified using a parameter).

18 NCL Reverse torque limit input: ±10 V/rated motor torque (input gain can be modified using a parameter).

17 - AGND1 Analog signal ground

7 Common +24 VIN Control power supply input for sequence signals: users must provide the +24 V power supply (12 to 24 V).

29 RUN Servo ON: this turn ON the servo.

26 Position/Full

27 Common GSEL Gain switching Enables gain value according parameter setting.

28 Position/Full

30 Position/Full

31 Common RESET Alarm reset input. Release the alarm status. The error counter is reset when the alarm is reset.

32 Position/

33 Position IPG Pulse prohibition input. Digital input to inhibit the position reference pulse.

8 Coomon NOT Reverse run prohibited

9 POT Forward run prohibited

20 Position/

13 SENGND Sensor ON signal ground.

42 Common BAT (+) Backup battery connection terminals when the absolute encoder power is interrupted. Do not connect when a absolute

43 BATGND (-)

50 FG Frame ground

- - TLSEL Torque limit switch The function of input signals allocated to pins 8,9 and 26 to 33 can be changed with

12 - Terminals not used. Do not connect.

40 41 -

Full close loop

Torque TREF1 Torque reference input: ±10 V/rated motor torque (input gain can be modified using a parameter).

Position/Speed

Full close loop

close loop

close loop

Speed VSEL3 Internal speed selection 3 Input to select the desired speed setting during internally speed operation.

close loop

Speed VSEL2 Internal speed selection 2 Input to select the desired speed setting during internally speed operation.

Speed/Torque

Speed VSEL1 Internal speed selection 1 Input to select the desired speed setting during internally speed operation.

Speed/Torque

+24 VCW Reference pulse input for line driver and open collector according to parameter setting.

Input mode:

Sign + pulse string

Reverse/forward pulse (CCW/CW pulse)

Two-phase pulse (90° phase differential)

Input mode:

Reverse/forward pulse (CCW/CW pulse)

VLIM Speed limit input: ±10 V/rated motor speed (input gain can be modified using a parameter).

PCL Forward torque limit input: ±10 V/rated motor torque (input gain can be modified using a parameter).

DFSEL1 Vibration filter switching 1 Enables vibration filter according parameter setting.

GESEL1 Electronic gear switching 1 Switches the numerator fro electronic gear ratio.

ECRST Error counter reset input. Resets the position error counter.

TVSEL Control mode switching

SEN Sensor ON input. Initial data request signal when using an absolute encoder.

encoder battery cable for backup is used.

DFSEL2 Vibration filter switching 2

GESEL2 Electronic gear switching 2

VZERO Zero speed

VSIGN Speed command signal

TSIGN Torque command signal

E-STOP Emergency stop

JSEL Inertia ratio switching

The speed selecton is combining this input with VSEL1 and VSEL2 inputs.

The speed selecton is combining this input with VSEL1 and VSEL3 inputs.

Position ↔ speed

↔

↔

torque

speed

Position

To rque

The speed selecton is combining this input with VSEL2 and VSEL3 inputs.

Overtravel prohibited: stops servomotor when movable part travels beyond the

allowable range of motion.

these options by parameters settings

Enables control mode switching

AC Servo systems

Accurax G5 servo drive 67

Page 8

I/O signals (CN1) - output signals (for analog/pulse servo drives)

Pin No. Control mode Signal name Function

21 Position/

Full close loop

22 -A Encoder phase A48 +B Encoder phase B+

49 -B Encoder phase B23 +Z Encoder phase Z+

24 -Z Encoder phase Z19 Z Encoder phase-Z output Phase Z is output for encoder signals (or external scale signals during full closing control).

25 ZCOM Encoder phase-Z common

11 Common BKIR Brake release signal output Timing signal for operating the electromagnetic brake on a motor.

10 BKIRCOM

35 READY Servo ready: ON if there is not servo alarm when the control/main circuit power supply is turned ON.

34 READYCOM

37 /ALM Servo alarm: turns OFF when an error is detected.

36 ALMCOM

39 Speed/torque TGON Motor rotation speed detection. This output turns ON when the motor rotation speed reaches the speed set in a parameter.

39 Position/

Full close loop

38 INP1COM

- - INP2 Position complete output 2 The function of output signals allocated to pins 11,10, 34 to 39 can be changed with these op-

+A Encoder phase A+ Encoder signals (or external scale signals during full closing control) are output according En-

INP1 Positioning complete output 1: turns ON when position error is equal to setting parameter.

P-CMD Position command status

ZSP Zero speed

WARN1 Warning 1

WARN2 Warning 2

ALM-ATB Alarm output

VCMP Speed conformity output

V-CMD Speed command status

V-LIMIT Speed limit detection

T-LIMIT Torque limit detection

coder Dividing Numerator parameter.

This is the line-driver output (equivalent to R422). The maximum output frequency is 4 Mbps.

Phase Z is output for encoder signals (or external scale signals during full closing control). This

is the line-driver output (equivalent to R422).

Open-collector output.

tions by parameters settings.

Encoder connector (CN2) - (for all servo drives)

Pin No. Signal name Function

1 E5V Encoder power supply + 5 V

2 E0V Encoder power supply ground

3 BAT+ Battery + (used only with absolute encoder)

4 BAT– Battery – (used only with absolute encoder)

5 PS+ Encoder serial signal input (+phase)

6 PS– Encoder serial signal input (-phase)

Shell FG Shield ground

External encoder connector (CN4) - (for all servo drives)

Pin No. Signal name Function

1 E5V External scale power supply output. Use at 5.2V +/-5% and at or below 250 mA.

2 E0V This is connected to the control circuit ground connected to connector CN1.

3 PS External scale signal I/O (serial signal).

4/PS

5 EXA External scale signal input (Phase A, B, and Z signals). Perfoms the input and output of phase A, B and Z signals.

6 /EXA

7EXB

8 /EXB

9EXZ

10 /EXZ

Shell FG Shield ground

Monitor connector (CN5) - (for all servo drives)

Pin No. Signal name Function

1 AM1 Analog monitor output 1. Outputs the analog signal for the monitor. Use the parameters setting to select the output

2 AM2 Analog monitor output 2. Outputs the analog signal for the monitor. Use the parameters setting to select the output

3 GND Ground for analog monitors 1,2.

4 - Terminals not used. Do not connect.

56-

to monitor.

Default setting: Motor rotation speed 1 V/(1000 r/min).

to monitor.

Default setting: Motor rotation speed 1 V/(1000 r/min).

USB connector (CN7) - (all servo drives)

Pin No. Signal name Function

1 VBUS USB signal terminal for computer comunication.

2D3 D+ Ground for analog monitors 1,2.

4 - Not used. Do not connect.

5 GND Signal ground.

68 AC servo systems

Page 9

Safety connector (CN8) - (all servo drives)

Pin No. Signal name Function

1 - Not used. Do not connect.

23 SF1- Safety input 1 & 2. This input turns OFF the power trransistor drive signals in the servo drive to cut off the current

4SF1+

output to the motor.

5SF26SF2+

7 EDM- A monitor signal is output to detect a safety function failure.

8EDM+

Shell FG Frame ground.

Dimensions

Servo drives

R88D-KT01/02H, R88D-KN01/02H-ML2 (230 V, 100 - 200 W)

40

70

130 (for Analog/pulse model)

132 (for ML2 model)

φ5.2

AC Servo systems

150

R88D-KT04H, R88D-KN04H-ML2 (230 V, 400 W)

55

150

70

R88D-KT08H, R88D-KN08H-ML2 (230 V, 750 W)

65

70

130 (for Analog/pulse model)

132 (for ML2 model)

170 (for Analog/pulse model)

172 (for ML2 model)

±0.5

±0.5

±0.5

140

φ5.2

±0.5

140

φ5.2

(150)

6

28

(40)

(150)

6

43

(55)

4

±0.5

±0.5

140

150

(150)

7.5

50

(65)

Accurax G5 servo drive 69

Page 10

R88D-KT10/15H, R88D-KN10/15H-ML2 (230 V, 1 - 1.5 kW)

85 (for Analog/pulse model)

86 (for ML2 model)

70

170 (for Analog/pulse model)

172 (for ML2 model)

150

R88D-KT06/10/15F, R88D-KN06/10/15F-ML2 (400 V, 600 W - 1.5 kW)

170 (for Analog/pulse model)

172 (for ML2 model)

91 (for Analog/pulse model)

92 (for ML2 model)

70

150

4

(150)

8.5

(85)

±0.5

70

4

(150)

φ5.2

±0.5

140

φ5.2

±0.5

140

R88D-KT20F, R88D-KN20F-ML2 (400 V, 2 kW)

94

85

17.5

42.5

5.2

R2.6

5.2 5.2

17.5

50

φ5.2

5.2

168

188

198

R2.6

50

φ5.2

±0.5

(168)

70

±0.5

25

φ5.2

±0.5

188

±0.5

50

(94)

14.5

70

193.5 (for Analog/pulse model)

195 (for ML2 model)

1.5

70 AC servo systems

Page 11

R88D-KT30/50F, R88D-KN30/50F-ML2 (400 V, 3 - 5 kW)

R2.6

15

15

130

100

φ5.2

65

5.2 5.2

5.2

65

100

5.2

φ5.2

R2.6

220

240

70

250

212 (for Analog/pulse model)

213 (for ML2 model)

Filters

Filter model External dimensions Mount dimensions

R88A-FIK102-RE 190 42 44 180 20

R88A-FIK104-RE 190 57 30 180 30

R88A-FIK107-RE 190 64 35 180 40

R88A-FIK114-RE 190 86 35 180 60

R88A-FIK304-RE 190 86 40 180 60

R88A-FIK306-RE 245 94 40 235 60

R88A-FIK312-RE 290 130 45 280 100

H W D M1 M2

3

M1

(220)

15

H

±0.5

50

W

M2

drive

mounts

100

φ5.2

±0.5

240

AC Servo systems

±0.5

(130)

D

output

flexes

Accurax G5 servo drive 71

Page 12

Installation

Single-phase, 230 VAC (for MECHATROLINK-II servo drives)

L1

L2

L3

N

Thermal switch

Contactor

12 to 24 VDC

Noise filter

Single-Phase

200 to 230 VAC

Emergency stop

Forward run

prohibited

Reverse run

prohibited

Origin

proximity

External

latch 3

External

latch 2

External

latch 1

General-purpose

monitor input 0

I-COM

E-STOP

POT

NOT

DEC

EXT3

EXT2

EXT1

SI-MON0

L1

L3

CNA

L1C

L2C

4.7kΩ

6

1kΩ

5

4.7kΩ

1kΩ

7

4.7kΩ

1kΩ

8

4.7kΩ

1kΩ

9

4.7kΩ

1kΩ

10

4.7kΩ

1kΩ

11

4.7kΩ

1kΩ

12

4.7kΩ

1kΩ

13

*1

B1

B3

B2

CNB

Accurax G5

MECHATROLINK-II

Servo drive

CN1

CN2

U

V

W

1

2

25

26

3

4

BRK-OFF+

BRK-OFF-

S-RDY+

S-RDY-

ALM+

ALM-

Servo motor

Optical encoder

Brake release

signal output

Servo ready

completed output

Servo alarm output

External power supply 12 to 24 VDC

Maximum

service voltage: 30 VDC

Maximum

output current: 50 mADC

14

Backup battery

+24 V

+24 V

S1

+24 V +24 V

T11A1 T12 T21 T22 T31 T32 T33 Y1 T41 T42

+24 V

*1 For servo drives from 750 W, B2 and B3 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an

external regenerative resistor between B1 and B2.

*2 For use only with an absolute encoder. If a backup battery is connected to CN1 I/O connector, an encoder cable with a battery is not required.

*3 Wiring diagram example using the G9SX safety unit. If a safety unit is not used, keep the factory safety bypass connector installed in the CN8.

G9SX safety unit *3

S14A2S24 S34 S44 S54

(3.6 V)

L1 X1 X2

*2

BTP-I

BTN-I

Connect shield to

connector shell

SF1+

SF1-

SF2+

SF2-

15

16

FG

4kW

4

1kW

3

4kW

6

1kW

5

CN8

GND

Frame ground

10

EDM+

8

EDM output: Monitor signal to detect a safety function failure

(Maximum service voltage: 30 VDC or less

EDM-

7

Maximum output current: 50 mADC)

Note: The input function of pins 5 and 7 to 13, and output function of pins 1, 2, 25 and 26, can be changed via parameter settings.

72 AC servo systems

Page 13

Three-phase, 400 VAC (for MECHATROLINK-II servo drives)

Three-Phase

400 VAC

Thermal switch

Contactor

I-COM

E-STOP

POT

NOT

DEC

EXT3

EXT2

EXT1

SI-MON0

L1

L2

L3

24 V

0 V

6

5

7

8

9

10

11

12

13

CNA

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

4.7kΩ

1kΩ

Power supply

24 VDC +/-15%

12 to 24 VDC

Noise filter

Emergency stop

Forward run

prohibited

Reverse run

prohibited

Origin

proximity

External

latch 3

External

latch 2

External

latch 1

General-purpose

monitor input 0

*1

B1

B3

B2

CNB

Accurax G5

MECHATROLINK-II

Servo drive

CN1

CN2

U

V

W

1

2

25

26

3

4

BRK-OFF+

BRK-OFF-

S-RDY+

S-RDY-

ALM+

ALM-

Servo motor

Optical encoder

Brake release

signal output

Servo ready

completed output

Servo alarm output

External power supply 12 to 24 VDC

Maximum

service voltage: 30 VDC

Maximum

output current: 50 mADC

AC Servo systems

Backup battery

+24 V

+24 V

S1

+24 V +24 V

T11A1 T12 T21 T22 T31 T32 T33 Y1 T41 T42

+24 V

*1 Normally B2 and B3 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external regenerative

resistor between B1 and B2.

*2 For use only with an absolute encoder. If a backup battery is connected to CN1 I/O connector, an encoder cable with a battery is not required.

*3 Wiring diagram example using the G9SX safety unit. If a safety unit is not used, keep the factory safety bypass connector installed in the CN8.

G9SX safety unit *3

S14A2S24 S34 S44 S54

(3.6 V)

L1 X1 X2

*2

Connect shield to

connector shell

BTN-I

FG

SF1+

SF1-

SF2+

SF2-

15

16

GND

Frame ground

4kW

4

1kW

3

4kW

6

1kW

5

CN8

10

EDM+

8

EDM output: Monitor signal to detect a safety function failure

(Maximum service voltage: 30 VDC or less

EDM-

7

Maximum output current: 50 mADC)

14

BTP-I

Note: The input function of pins 5 and 7 to 13, and output function of pins 1, 2, 25 and 26, can be changed via parameter settings.

Accurax G5 servo drive 73

Page 14

Single-phase, 230 VAC(for analog/pulse servo drives)

L1

L2

L3

N

Thermal switch

Contactor

Noise filter

Single-Phase

200 to 230 VAC

+24 VCW

+CW

-CW

+24 VCCW

+CCW

-CCW

+CWLD

-CWLD

+CCWLD

-CCWLD

Position reference

Reverse pulse

500 kpps max.

Forward pulse

*3

Reverse pulse

2 Mpps max.

Forward pulse

12 to 24 VDC

L1

L3

L1C

L2C

1

3

4

2

5

6

44

45

46

47

7+24 VIN

2.2 kΩ

220 Ω

2.2 kΩ

220 Ω

3 kΩ

110 Ω

3k Ω

3k Ω

110 Ω

3 kΩ

4.7 k

CNA

43 kΩ

43 kΩ

43 kΩ

43 kΩ

Ω

*1

B1

B3

B2

Accurax G5

Analog/Pulse

Servo drive

CN1

CNB

CN2

U

V

W

11

BKIR

Brake release signal output

BKIRCOM

10

READY

35

Servo ready output

READYCOM

34

/ALM37

Alarm output

ALMCOM

36

INP39

Positioning completed output

INPCOM

38

19

Z

Phase-Z output

(open-collector output)

25

ZCOM

Servo motor

Optical encoder

External power supply 12 to 24 VDC

Maximum

service voltage: 30 VDC

Maximum

output current: 50 mADC

+24 V

+24 V

+24 V

S1

+24 V +24 V

T11A1 T12 T21 T22 T31 T32 T33 Y1 T41 T42

G9SX safety unit *5

S14A2S24 S34 S44 S54

L1 X1 X2

Servo ON

Vibration filter

switching

Gain switching

Electronic gear

switching

Deviation counter reset

Alarm reset

Control mode

switching

Pulse prohibition

Reverse run

prohibited

Forward run

prohibited

DFSEL1

GSEL

SF1+

SF1-

SF2+

SF2-

29RUN

Ω

4.7 k

26

Ω

4.7 k

27

Ω

4.7 k

28GESEL1

Ω

4.7 k

30ECRST

Ω

4.7 k

31RESET

Ω

4.7 k

32TVSEL

Ω

4.7 k

33IPG

Ω

4.7 k

8NOT

Ω

4.7 k

9POT

4kW

4

1kW

3

4kW

6

1kW

5

1 µF

3.83 kΩ

3.83 kΩ

3.83 kΩ

CN8

100Ω

4.7 kΩ

20 k

10 k

10 kΩ

10

Shell

+A

21

-A22

+B49

-B48

+Z23

-Z24

20

SEN

SENGND

13

42

BAT

43

BATGND

Ω

14

REF/TREF1/VLIM

15

AGND

Ω

16

PCL/TREF2

17

AGND1

18

NCL

50

FG

EDM+

8

EDM-

7

FG

Encoder phase-A output

Encoder phase-B output

Encoder phase-Z output

Reverse torque limit

Frame ground

Line-driver output corresponding

with the EIA RS-422A communications

method (load resistance 120 W min.)

Sensor ON

Backup battery

(3.6 V)

Speed/Torque command or Speed limit

(±10 V/rated speed or torque)

Forward torque limit/Torque command

(±12 V/rated speed or torque)

Reverse torque limit

(±12 V/rated speed or torque)

EDM output: monitor signal to detect a safety

function failure

(Maximum service voltage: 30 VDC or less

Maximum output current: 50 mADC)

*2

*4

*4

*4

*1 For servo drives from 750 W, B2 and B3 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an

external regenerative resistor between B1 and B2.

*2 For use only with an absolute encoder. If a backup battery is connected to CN1 I/O connector, an encoder cable with a battery is not required.

*3 Only available in Position control mode.

*4 The input function depends on control mode used (Position, speed or torque control).

*5 Wiring diagram example using the G9SX safety unit. If a safety unit is not used, keep the factory safety bypass connector installed in the CN8.

Note: The input function of pins 8,9 and 26 to 33, and output function of pins 10, 11, 34, 35, 38 and 39, can be changed via parameter settings.

74 AC servo systems

Page 15

Three-phase, 400 VAC (for analog/pulse servo drives)

Three-Phase

400 VAC

Thermal switch

Contactor

Noise filter

Power supply

24 VDC +/-15%

+24 VCW

+CW

-CW

+24 VCCW

+CCW

-CCW

+CWLD

-CWLD

+CCWLD

-CCWLD

Position reference

Reverse pulse

500 kpps max.

Forward pulse

*3

Reverse pulse

2 Mpps max.

Forward pulse

12 to 24 VDC

L1

L2

L3

24 V

0 V

1

3

4

2

5

6

44

45

46

47

7+24 VIN

2.2 kΩ

220 Ω

2.2 kΩ

220 Ω

3 kΩ

110 Ω

3k Ω

3k Ω

110 Ω

3 kΩ

4.7 k

CNA

43 kΩ

43 kΩ

43 kΩ

43 kΩ

Ω

*1

B1

B3

B2

Accurax G5

Analog/Pulse

Servo drive

CN1

CNB

CN2

U

V

W

BKIR

11

Brake release signal output

BKIRCOM

10

READY

35

Servo ready output

READYCOM

34

/ALM37

Alarm output

ALMCOM

36

INP39

Positioning completed output

INPCOM

38

19

Z

Phase-Z output

(open-collector output)

25

ZCOM

Servo motor

Optical encoder

External power supply 12 to 24 VDC

Maximum

service voltage: 30 VDC

Maximum

output current: 50 mADC

AC Servo systems

+24 V

+24 V

+24 V

S1

+24 V +24 V

T11A1 T12 T21 T22 T31 T32 T33 Y1 T41 T42

G9SX safety unit *5

S14A2S24 S34 S44 S54

L1 X1 X2

Servo ON

Vibration filter

switching

Gain switching

Electronic gear

switching

Deviation counter reset

Alarm reset

Control mode

switching

Pulse prohibition

Reverse run

prohibited

Forward run

prohibited

DFSEL1

GSEL

SF1+

SF1-

SF2+

SF2-

29RUN

Ω

4.7 k

26

Ω

4.7 k

27

Ω

4.7 k

28GESEL1

Ω

4.7 k

30ECRST

Ω

4.7 k

31RESET

Ω

4.7 k

32TVSEL

Ω

4.7 k

33IPG

Ω

4.7 k

8NOT

Ω

4.7 k

9POT

4kW

4

1kW

3

4kW

6

1kW

5

1 µF

CN8

100Ω

3.83 kΩ

3.83 kΩ

3.83 kΩ

10

4.7 kΩ

20 k

10 k

10 kΩ

Shell

21

+A

-A22

+B49

-B48

+Z23

-Z24

20

SEN

SENGND

13

42

BAT

43

Ω

14

REF/TREF1/VLIM

15

AGND

Ω

16

PCL/TREF2

17

AGND1

18

NCL

50

FG

EDM+

8

EDM-

7

FG

Encoder phase-A output

Encoder phase-B output

Encoder phase-Z output

BATGND

Frame ground

Line-driver output corresponding

with the EIA RS-422A communications

method (load resistance 120 W min.)

Sensor ON

Backup battery

(3.6 V)

Speed/Torque command or Speed limit

(±10 V/rated speed or torque)

Forward torque limit/Torque command

(±12 V/rated speed or torque)

Reverse torque limit

(±12 V/rated speed or torque)

EDM output: monitor signal to detect a safety

function failure

(Maximum service voltage: 30 VDC or less

Maximum output current: 50 mADC)

*2

*4

*4

*4

*1 Normally B2 and B3 are short-circuited. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external regenerative

resistor between B1 and B2.

*2 For use only with an absolute encoder. If a backup battery is connected to CN1 I/O connector, an encoder cable with a battery is not required.

*3 Only available in Position control mode.

*4 The input function depends on control mode used (Position, speed or torque control).

*5 Wiring diagram example using the G9SX safety unit. If a safety unit is not used, keep the factory safety bypass connector installed in the CN8.

Note: The input function of pins 8,9 and 26 to 33, and output function of pins 10, 11, 34, 35, 38 and 39, can be changed via parameter settings.

Accurax G5 servo drive 75

Page 16

Ordering information

Accurax G5 series MECHATROLINK-II reference configuration

C

Accurax G5 series MECHATROLINK-II

Servo Drive

Servo M otor

A

300 0 rpm (50 W-5 k W)

Servo M otor

A

200 0 rpm (4 00 W- 5 kW)

Servo M otor

A

1000 rpm (900 W-3 kW)

Filter

CablesB

L

External

regenerative

resistor

K

R88D-KN@@@-ML2

CN5

CN6

CN7

CN8

CN1

CN4

CN2

G

H

I

USB mini connector cable

D

E

Analog monitor ca ble

MECHATROLINK-II cables

Personal computer:

Software CX-One

Servo d rive I/O signal s connector

F

Terminal block

for Servo drive I/ O

signals

Unit

Note: The symbols ABCDE... show the recommended sequence to select the components in Accurax G5 servo system

Servo motors, power & encoder cables

Note: AB Refer to the Accurax G5 servo motor chapter for servomotor, motor cables or connectors selection

J

MECHATROLINK-II

Motion controllers

TJ1-MC04/16

CJ1W-MCH72

CJ1W-NCF71

Servo drives

Symbol Specifications Servo drive model A Compatible G5 series rotary servo motors

C 1 phase 230 VAC 100 W R88D-KN01H-ML2 R88M-K05030(H/T)-@

R88M-K10030(H/T)-@

R88M-K1K530(H/T)-@

R88M-K1K520(H/T)-@

R88M-K90010(H/T)-@

R88M-K60020(F/C)-@

R88M-K1K020(F/C)-@

R88M-K1K530(F/C)-@

R88M-K1K520(F/C)-@

R88M-K90010(F/C)-@

R88M-K2K020(F/C)-@

R88M-K3K020(F/C)-@

R88M-K2K010(F/C)-@

R88M-K5K030(F/C)-@

R88M-K4K020(F/C)-@

R88M-K5K020(F/C)-@

R88M-K3K010(F/C)-@

3 phase 400 VAC

200 W R88D-KN02H-ML2 R88M-K20030(H/T)-@

400 W R88D-KN04H-ML2 R88M-K40030(H/T)-@

750 W R88D-KN08H-ML2 R88M-K75030(H/T)-@

1.0 kW R88D-KN10H-ML2 R88M-K1K020(H/T)-@

1.5 kW R88D-KN15H-ML2 R88M-K1K030(H/T)-@

600 W R88D-KN06F-ML2 R88M-K40020(F/C)-@

1.0 kW R88D-KN10F-ML2 R88M-K75030(F/C)-@

1.5 kW R88D-KN15F-ML2 R88M-K1K030(F/C)-@

2.0 kW R88D-KN20F-ML2 R88M-K2K030(F/C)-@

3.0 kW R88D-KN30F-ML2 R88M-K3K030(F/C)-@

5.0 kW R88D-KN50F-ML2 R88M-K4K030(F/C)-@

76 AC servo systems

Page 17

Control cables (for CN1)

Symbol Description Connect to Model

D I/O connector kit (26 pins) For I/O general purpose - R88A-CNW01C

E Terminal block cable For I/O general purpose 1 m XW2Z-100J-B34

General purpose cable 1 m R88A-CPKB001S-E

F Terminal block (M3 screw and for pin terminals) - XW2B-20G4

2 m XW2Z-200J-B34

Terminal block (M3.5 screw and for fork/round terminals) - XW2B-20G5

Terminal block (M3 screw and for fork/round terminals) - XW2D-20G6

Analog monitor (for CN5)

Symbol Name Model

G

Analog monitor cable 1m R88A-CMK001S

MECHATROLINK-II cables (for CN6)

Symbol Specifications Length Model

H

MECHATROLINK-II

Terminator resistor

MECHATROLINK-II cables 0.5 m JEPMC-W6003-A5-E

- JEPMC-W6022-E

1 m JEPMC-W6003-01-E

3 m JEPMC-W6003-03-E

5 m JEPMC-W6003-05-E

10 m JEPMC-W6003-10-E

20 m JEPMC-W6003-20-E

30 m JEPMC-W6003-30-E

USB personal computer cable (for CN7)

Symbol Name Model

I

USB mini-connector cable 2m AX-CUSBM002-E

MECHATROLINK-II Motion controllers

Symbol Name Model

J

Trajexia stand-alone motion controller TJ1-MC04 (4 axes)

TJ1-MC16 (16 axes)

Trajexia-PLC motion controller CJ1W-MCH72

Position Controller Unit for CJ1 PLC CJ1W-NCF71 (16 axes)

CJ1W-NC471 (4 axes)

CJ1W-NC271 (2 axes)

Position Controller Unit for CS1 PLC CS1W-NCF71 (16 axes)

CS1W-NC471 (4 axes)

CS1W-NC271 (2 axes)

External regenerative resistor

Symbol Regenerative resistor unit model Specifications

K

R88A-RR08050S 50 Ω, 80 W

R88A-RR080100S 100 Ω, 80 W

R88A-RR22047S 47 Ω, 220 W

R88A-RR50020S 20 Ω, 500 W

Cable for Safety Functions (for CN8)

Symbol Description Model

- Safety connector with 3 m cable

(with loose wires at one end)

R88A-CSK003S-E

Filters

Symbol Applicable servodrive Filter model Rated current Leakage current Rated voltage

L R88D-KN01H-ML2, R88D-KN02H-ML2 R88A-FIK102-RE 2.4 A 3.5 mA 250 VAC single-phase

R88D-KN04H-ML2 R88A-FIK104-RE 4.1 A 3.5 mA

R88D-KN08H-ML2 R88A-FIK107-RE 6.6 A 3.5 mA

R88D-KN10H-ML2, R88D-KN15H-ML2 R88A-FIK114-RE 14.2 A 3.5 mA

R88D-KN06F-ML2, R88D-KN10F-ML2, R88D-KN15F-ML2 R88A-FIK304-RE 4 A 0.3 mA / 32 mA

R88D-KN20F-ML2 R88A-FIK306-RE 6 A 0.3 mA / 32 mA

R88D-KN30F-ML2, R88D-KN50F-ML2 R88A-FIK312-RE 12.1 A 0.3 mA / 32 mA

1. Momentary peak leakage current for the filter at switch-on/off.

1

400 VAC three-phase

1

1

AC Servo systems

Connectors

Specifications Model

External encoder connector (for CN4) R88A-CNK41L

Safety I/O signal connector (for CN8) R88A-CNK81S

Computer software

Specifications Model

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.91 or higher) CX-drive

Accurax G5 servo drive 77

Page 18

Ordering information

Accurax G5 series Analog/pulse Reference configuration

C

Accurax G5 series

Analog/Pulse servo drive

Servo Motor

A

3000 rpm (50 W-5 k W)

Servo Motor

A

2000 rpm (400 W-5 kW)

A

Servo Motor

1000 rpm (900 W-3 kW)

B

Cables

Filter

Q

External

regenerative

resistor

P

CN5

CN7

CN8

CN1

CN4

CN2

R88D-KT@

N

Analog monitor ca ble

O

USB mini c onnec tor cable

D

E

H

K

I

General purpose ca ble

L

Motion control unit

Position control unit

-High-speed type-

J

M

Terminal block for Ser vo drive

I/O general purpose signal s

Personal computer:

Software CX-One

Terminal block

for external signals

F

Position control unit

G

Note: The symbols ABCDE... show the recommended sequence to select the components in Accurax G5 servo system

Servo motors, power & encoder cables

Note: AB Refer to the Accurax G5 servo motor chapter for servomotor, motor cables or connectors selection

Servo drives

Symbol Specifications Servo drive model A Compatible Accurax G5 series rotary servo motors

C 1 phase 230 VAC 100 W R88D-KT01H R88M-K05030(H/T)-@

R88M-K10030(H/T)-@

R88M-K1K530(H/T)-@

R88M-K1K520(H/T)-@

R88M-K90010(H/T)-@

R88M-K60020(F/C)-@

R88M-K1K020(F/C)-@

R88M-K1K530(F/C)-@

R88M-K1K520(F/C)-@

R88M-K90010(F/C)-@

R88M-K2K020(F/C)-@

R88M-K3K020(F/C)-@

R88M-K2K010(F/C)-@

R88M-K5K030(F/C)-@

R88M-K4K020(F/C)-@

R88M-K5K020(F/C)-@

R88M-K3K010(F/C)-@

3 phase 400 VAC

200 W R88D-KT02H R88M-K20030(H/T)-@

400 W R88D-KT04H R88M-K40030(H/T)-@

750 W R88D-KT08H R88M-K75030(H/T)-@

1.0 kW R88D-KT10H R88M-K1K020(H/T)-@

1.5 kW R88D-KT15H R88M-K1K030(H/T)-@

600 W R88D-KT06F R88M-K40020(F/C)-@

1.0 kW R88D-KT10F R88M-K75030(F/C)-@

1.5 kW R88D-KT15F R88M-K1K030(F/C)-@

2.0 kW R88D-KT20F R88M-K2K030(F/C)-@

3.0 kW R88D-KT30F R88M-K3K030(F/C)-@

5.0 kW R88D-KT50F R88M-K4K030(F/C)-@

78 AC servo systems

Page 19

Control cables (for CN1)

Symbol Description Connect to Model

D

E Control cable

F Terminal block cable for external signals

Control cable

(1 axis)

Control cable

(2 axis)

(line-driver output for 1 axis)

Control cable

(open-collector output for 1 axis)

Control cable

(line-driver output for 2 axis)

Control cable

(open-collector output for 2 axis)

(for input common, forward/reverse run prohibited inputs,

emergency stop input, origin proximity input and interrupt input)

Motion control units

CS1W-MC221

CS1W-MC421

Motion control units

CS1W-MC221

CS1W-MC421

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

Position control units (high-speed type)

CJ1W-NC214

CJ1W-NC414

Position control units (high-speed type)

CJ1W-NC234

CJ1W-NC434

CJ1W-NC214

CJ1W-NC414

1 m R88A-CPG001M1

2 m R88A-CPG002M1

3 m R88A-CPG003M1

5 m R88A-CPG005M1

1 m R88A-CPG001M2

2 m R88A-CPG002M2

3 m R88A-CPG003M2

5 m R88A-CPG005M2

1 m XW2Z-100J-G9

5 m XW2Z-500J-G9

10 m XW2Z-10MJ-G9

1 m XW2Z-100J-G13

3 m XW2Z-300J-G13

1 m XW2Z-100J-G1

5 m XW2Z-500J-G1

10 m XW2Z-10MJ-G1

1 m XW2Z-100J-G5

3 m XW2Z-300J-G5

0.5 m XW2Z-C50X

1 m XW2Z-100X

2 m XW2Z-200X

3 m XW2Z-300X

5 m XW2Z-500X

10 m XW2Z-010X

G Terminal block for external signals (M3 screw, pin terminals) - XW2B-20G4

Terminal block for ext. signals

Terminal block for ext. signals

H Cable from servo relay unit to servo drive CS1W-NC1@3, CJ1W-NC1@3, C200HW-NC113,

I

J

K

L

Servo relay unit Position control units

Position control unit

connecting cable

General purpose cable For general purpose controllers 1 m R88A-CPG001S

Terminal block cable For general purpose controllers 1 m XW2Z-100J-B24

(M3.5 screw, fork/round terminals) - XW2B-20G5

(M3 screw, fork/round terminals) - XW2D-20G6

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3,

C200HW-NC213/413, CQM1H-PLB21 or CQM1-CPU43

CJ1M-CPU21/22/23 1 m XW2Z-100J-B31

CS1W-NC1@3, CJ1W-NC1@3 or C200HW-NC113

P o s i ti o n c o n t r o l un i t s

CS1W-NC2@3/4@3, CJ1W-NC2@3/4@3 or

C200HW-NC213/413

CQM1H-PLB21 or CQM1-CPU43 - XW2B-20J6-3B (1 axis)

CJ1M-CPU21/22/23 - XW2B-20J6-8A (1 axis)

CQM1H-PLB21 0.5 m XW2Z-050J-A3

CS1W-NC113 or C200HW-NC113 0.5 m XW2Z-050J-A6

CS1W-NC213/413 or C200HW-NC213/413 0.5 m XW2Z-050J-A7

CS1W-NC133 0.5 m XW2Z-050J-A10

CS1W-NC233/433 0.5 m XW2Z-050J-A11

CJ1W-NC113 0.5 m XW2Z-050J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

CJ1W-NC133 0.5 m XW2Z-050J-A18

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A33

1 m XW2Z-100J-B25

2 m XW2Z-200J-B25

2 m XW2Z-200J-B31

- XW2B-20J6-1B (1 axis)

- XW2B-40J6-2B (2 axes)

XW2B-40J6-9A (2 axes)

1 m XW2Z-100J-A3

1 m XW2Z-100J-A6

1 m XW2Z-100J-A7

1 m XW2Z-100J-A10

1 m XW2Z-100J-A11

1 m XW2Z-100J-A14

1 m XW2Z-100J-A15

1 m XW2Z-100J-A18

1 m XW2Z-100J-A19

1 m XW2Z-100J-A33

2 m R88A-CPG002S

2 m XW2Z-200J-B24

M Terminal block (M3 screw and for pin terminals) - XW2B-50G4

Terminal block (M3.5 screw and for fork/round terminals) - XW2B-50G5

Terminal block (M3 screw and for fork/round terminals) - XW2D-50G6

AC Servo systems

Accurax G5 servo drive 79

Page 20

Analog monitor (for CN5)

Symbol Name Model

N

Analog monitor cable 1m R88A-CMK001S

USB personal computer cable (for CN7)

Symbol Name Model

O

USB mini-connector cable 2m AX-CUSBM002-E

External regenerative resistor

Symbol Regenerative resistor

P

unit model

R88A-RR08050S 50 Ω, 80 W

R88A-RR080100S 100 Ω, 80 W

R88A-RR22047S 47 Ω, 220 W

R88A-RR50020S 20 Ω, 500 W

Specifications

Cable for Safety Functions (for CN8)

Symbol Description Model

- Safety connector with 3 m cable

(with loose wires at one end)

R88A-CSK003S-E

Filters

Symbol Applicable servodrive Filter model Rated current Leakage current Rated

voltage

Q R88D-KT01H, R88D-KT02H R88A-FIK102-RE 2.4 A 3.5 mA 250 VAC single-phase

R88D-KT04H R88A-FIK104-RE 4.1 A 3.5 mA

R88D-KT08H R88A-FIK107-RE 6.6 A 3.5 mA

R88D-KT10H, R88D-KT15H R88A-FIK114-RE 14.2 A 3.5 mA

R88D-KT06F, R88D-KT10F, R88D-KT15F R88A-FIK304-RE 4 A 0.3 mA / 32 mA

R88D-KT20F R88A-FIK306-RE 6 A 0.3 mA / 32 mA

R88D-KT30F, R88D-KT50F R88A-FIK312-RE 12.1 A 0.3 mA / 32 mA

1. Momentary peak leakage current for the filter at switch-on/off.

Connectors

Specifications Model

I/O connector kit -50 pins-(for CN1) R88A-CNU11C

External encoder connector (for CN4) R88A-CNK41L

Safety I/O signal connector (for CN8) R88A-CNK81S

1

400 VAC three-phase

1

1

Computer software

Specifications Model

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.90 or higher) CX-drive

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I101E-EN-01A

In the interest of product improvement, specifications are subject to change without notice.

80 AC servo systems

Loading...

Loading...