查询A6S-4102供应商

DIP Switch

Low-cost DIP Switch with Slide Pins

Allows automatic mounting with DIP IC insertion

machines.

Washable models with seal tape are available.

SMT (surface-mounted terminal) models are

available.

Ordering Information

No.

poles

of

Standard W

DIP terminal DIP terminal DIP terminal

Flat actuated

Raised actuator

ith seal tape

A6T/A6S

Flat actuated

Standard W

SMT terminal SMT terminal SMT terminal

ith seal tape

Raised actuator

1 A6T-1101 A6T-1102 A6T-1104 --- --- --2 A6T-2101 A6T-2102 A6T-2104 A6S-2101 A6S-2102 A6S-2104

3 --- --- --- A6S-3101 A6S-3102 A6S-3104

4 A6T-4101 A6T-4102 A6T-4104 A6S-4101 A6S-4102 A6S-4104

5 --- --- --- A6S-5101 A6S-5102 A6S-5105

6 A6T-6101 A6T-6102 A6T-6104 A6S-6101 A6S-6102 A6S-6104

7 --- --- --- A6S-7101 A6S-7102 A6S-7104

8 A6T-8101 A6T-8102 A6T-8104 A6S-8101 A6S-8102 A6S-8104

9 --- --- --- A6S-9101 A6S-9102 A6S-9104

10 A6T-0101 A6T-0102 A6T-0104 A6S-0101 A6S-0102 A6S-0104

1

A6T/A6S

Specifications

Ratings/Characteristics

Switching

Insulation resistance

Contact resistance

Dielectric strength

V

ibration resistance

Shock resistance

Life expectancy

Ambient temperature

Ambient humidity

Operating force

Flammability rating

capacity

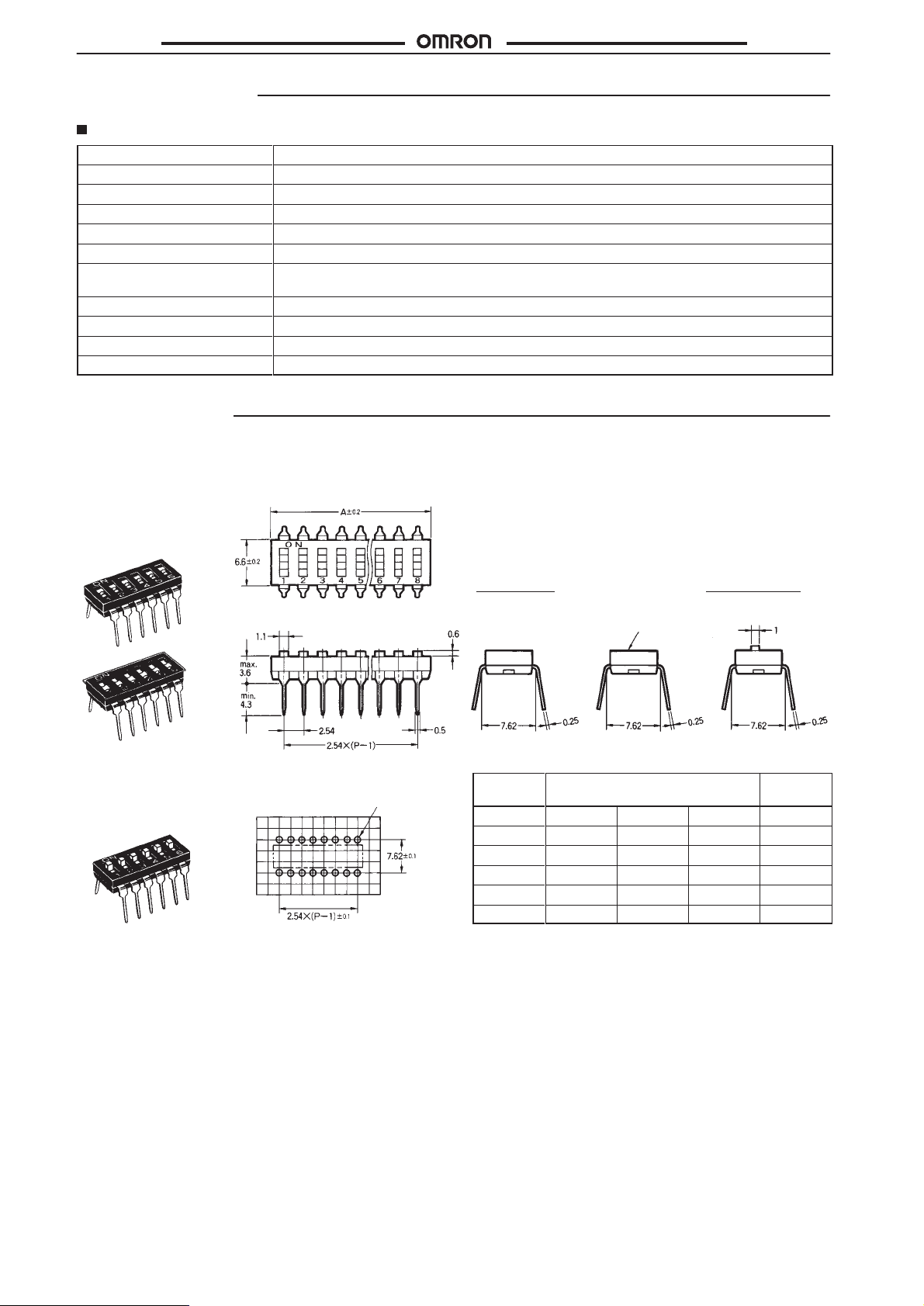

Dimensions

Note: 1.

Flat Actuated with DIP Terminal

Standard/With Seal Tape

A6T-j101

A6T-j102

All units are in millimeters unless otherwise indicated.

2.

Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

25 mA at 24 VDC

100 MΩ min. (at 250 VDC)

200 mΩ max. (initial value)

500 V

AC for 1 min between terminals of same polarity

Malfunction:

Malfunction:

Mechanical:

Electrical:

Operating: –20°

Operating:

0.29 N min. (30 gf)

UL 94-0

10 to 55 Hz, 1.5-mm double amplitude

300 m/s2 min. (approx. 30G min.)

1,000 operations min.

1,000 operations min.

C to 70°C (with no icing)

35% to 90%

, and between terminals of dif

A6T/A6S

ferent polarity

Raised Actuator

with DIP Terminal

A6T-j104

Dimensions

PCB

(T

op V

iew)

1.0±0.05 dia.

P: pole numbers

Flat

Actuated

W

Standard

No.

of

poles

1 A6T-1101 A6T-1102 A6T-1104 3.48

2 A6T-2101 A6T-2102 A6T-2104 6.02

4 A6T-4101 A6T-4102 A6T-4104 11.10

6 A6T-6101 A6T-6102 A6T-6104 16.18

8 A6T-8101 A6T-8102 A6T-8104 21.26

10 A6T-0101 A6T-0102 A6T-0104 26.34

ith Seal T

Seal

tape (t = 0.06)

ape

Model A

Raised Actuator

2

A6T/A6S

Flat Actuated with SMT Terminal

Standard/With Seal Tape

A6S-j101

A6S-j102

A6T/A6S

Raised Actuator

with SMT Terminal

A6S-j104

Dimensions

PCB

(T

op V

iew)

P: pole numbers

Installation

Internal Connections (Top View)

Actuated

Flat

W

Standard

No.

of

poles

2 A6S-2101 A6S-2102 A6S-2104 6.02

3 A6S-3101 A6S-3102 A6S-3104 8.56

4 A6S-4101 A6S-4102 A6S-4104 11.10

5 A6S-5101 A6S-5102 A6S-5104 13.64

6 A6S-6101 A6S-6102 A6S-6104 16.18

7 A6S-7101 A6S-7102 A6S-7104 18.72

8 A6S-8101 A6S-8102 A6S-8104 21.26

9 A6S-9101 A6S-9102 A6S-9104 23.80

10 A6S-0101 A6S-0102 A6S-0104 26.34

ith Seal T

Seal

ape

tape (t = 0.06)

Model A

Raised Actuator

Precautions

Circuit Design

Use the DIP Switch within the rated voltage and current ranges,

otherwise the DIP Switch may have a shortened life expectancy,

radiate

heat, or burn out.

Mounting

Do

not operate the DIP Switch while mounting, soldering, or wash

ing

the DIP Switch, otherwise the DIP

heat of the solder, the DIP Switch may malfunction due to the penetration of the washing agent, or the machine incorporating the

DIP

Switch may operate or be set incorrectly

An automatic insertion machine incorporating a body stopper is

available

sertion

Switch,

form

tion

for mounting the DIP Switch. When using an automatic in

machine incorporating a half-lead stopper to mount the DIP

make sure that the automatic insertion machine will not de

the terminals of

of the DIP Switch may result.

the DIP Switch, otherwise the improper inser

Switch may deform due the

.

-

-

-

-

3

A6T/A6S

A6T/A6S

Soldering

Observe the following conditions when soldering the DIP Switch.

Automatic Soldering Bath

Soldering temperature:

Soldering time:

Reflow Soldering

Soldering

temperature

(°C)

Manual

Soldering

Soldering temperature:

Soldering time:

Set the pins of the DIP Switch to OFF before soldering the DIP

Switch.

Before

soldering the DIP Switch on a PCB, make sure that there is

no

unnecessary space between the DIP Switch and PCB.

Before soldering the DIP Switch on a multilayer PCB, make sure

the DIP Switch will

that

pattern

or land of the multilayer PCB.

Do

not solder the DIP Switch more than twice including rectification

soldering. An interval of five minutes is required between the first

second solderings.

and

Make sure that there is no flux rise on the surface of the PCB.

260°C max.

5 s max. for a 1.6-mm thick,

single-side PCB

2 minutes

max.

350°

20 seconds

max.

C at the tip of the soldering iron.

Soldering time

3 s max. for a 1.6-mm thick,

single-side PCB

not be deformed by the soldering heat on the

Washing

Washable A6T

Not washable

Ultrasonic cleaning is unavailable to any A6T or A6S-series DIP

Switch

with a seal tape. It is possible to wipe or dip these models into

washing

agents for one minute maximum.

Apply

fluorocarbon or alcoholic solvents to clean washable

Do not apply any other solvents or water to clean any washable

because they may deteriorate the materials or performance

model

of

the model.

Washing

be

equipment incorporating more than one washing bath can

used to clean washable models provided that the washable mod

els are cleaned for one minute maximum per bath and the total

cleaning

time does not exceed three minutes.

Do

not impose any external force on washable models while

ing.

Do

not clean

at

least three minutes to clean washable models after soldering.

The

provided

washable models immediately after soldering. W

A6T or A6S-series DIP Switch with a seal tape can be washed

that the seal tape is not

the DIP Switch.

(with seal tape),

A6S (with seal tape)

A6T

(standard/raised actuator),

A6S (standard/raised actuator)

removed or pasted before washing

models.

wash

ait for

-

-

PCB surface

Flux

4

A6T/A6S

Handling

Do

not apply excessive operating force to the DIP Switch, otherwise

the DIP Switch may be damaged or deformed, thus causing the

switch mechanism to malfunction as a result. Apply an operating

force

not exceeding 200% of the maximum rated operating force to

the DIP Switch.

the DIP Switch incorporating slide pins with a tiny

Set

ject,

such as the tip

set

the DIP Switch using tweezers or any other sharp object, which

may damage the DIP Switch. Do not set the DIP Switch using the

point of a mechanical pencil, otherwise lead powder or fragments

may

fall into the DIP Switch and internal circuit board, causing the

DIP

Switch to malfunction and reducing the dielectric

circuit

board.

of a ball-point pen or small screwdriver

, rounded ob

. Do not

strength of the

A6T/A6S

-

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

o convert grams into ounces, multiply by 0.03527.

Cat. No. A102-E1-1 In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Control

Components Division H.Q.

28th Fl., Crystal T

1-2-27, Shiromi, Chuo-ku,

Osaka 540 Japan

Phone:

06-949-61

ower Bldg.

15 Fax: 06-949-6134

Printed

in Japan

0996-1M (0996)

a

5

Loading...

Loading...