Page 1

Section 7

25mm min.

25mm min.

Chemical Resistance

IDタ グ取 り 付け時の注意事項

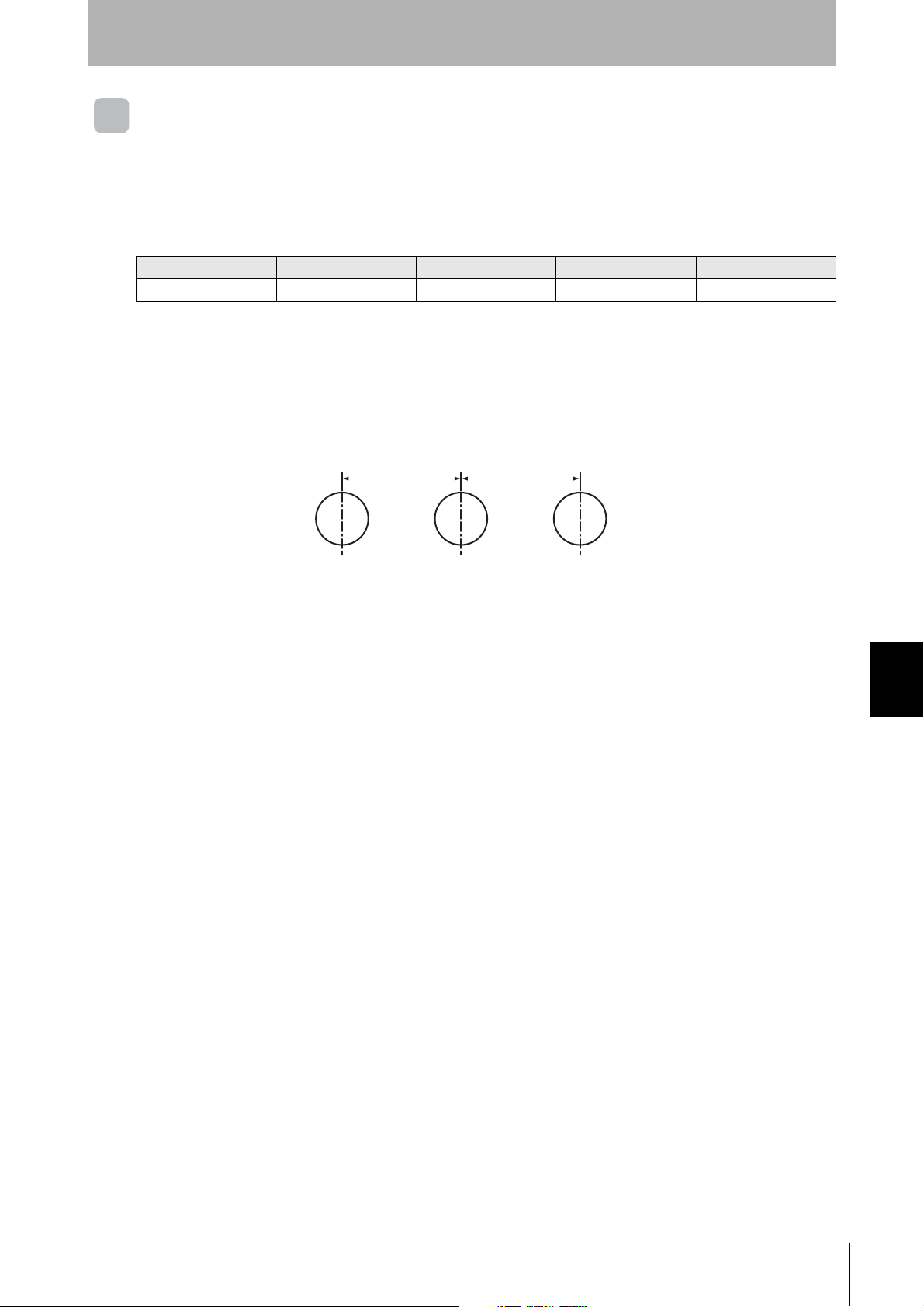

V680-D1KP52MT

Differences in Surrounding Metals (Reference)

Communications distances are affected by the type of metal in back of or surrounding the Tag, as

shown in the following table.

鉄 SUS 黄銅 アルミ ニウム

形V680-D1KP52MT 100% 85~90% 80~85% 80~85%

注. 周囲/背面金属が鉄の場合を100% と し て います。

Mutual Interference with Tags (Reference)

Provide the mounting distances indicated below to prevent malfunctions due to mutual interference

when using more than one Tag.

Section 7 Reference Data

RFID System

User's Manual

149

Page 2

Section 7

ID Tag

3.5mm min.

Metal

Embedded

ID Tag

Metal

Surface-mounted

金属

IDタ グ

xx

• V680-HS52 &V680-D1KP66MT

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS63 &V680-D1KP66MT

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS65 &V680-D1KP66MT

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

60

100mm min.

100mm min.

Chemical Resistance

V680-D1KP66MT

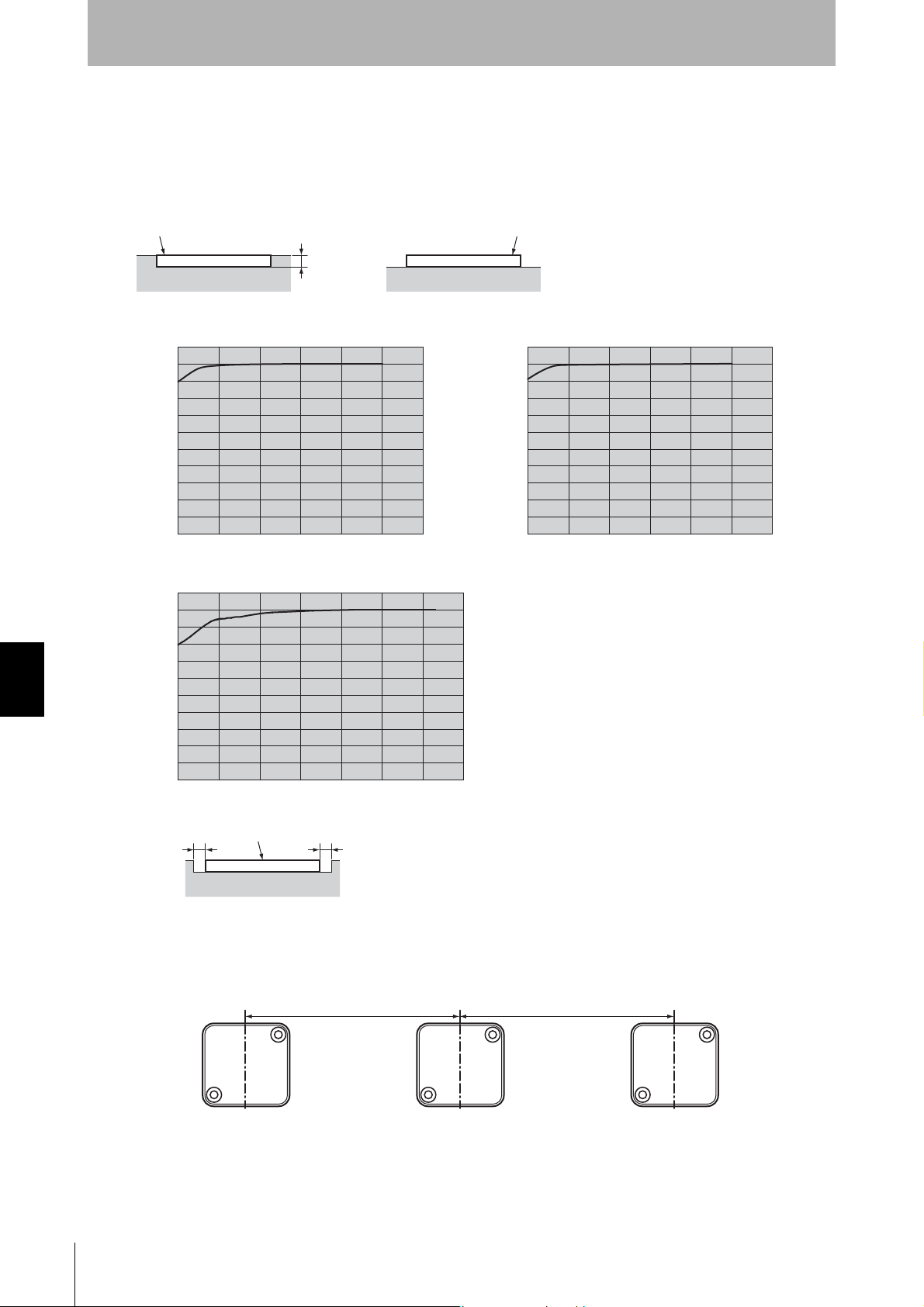

Effect of Metal behind Tags (Reference)

The V680-D1KP66MT can be surface-mounted or it can be embedded in metal. If it is embedded in

metal, the height of the metal casing must not exceed that of the Tag.

Section 7 Reference Data

Mutual Interference with Tags (Reference)

Provide the mounting distances indicated below to prevent malfunctions due to mutual interference

when using more than one Tag.

150

RFID System

User's Manual

Page 3

Section 7

25mm min.

25mm min.

Chemical Resistance

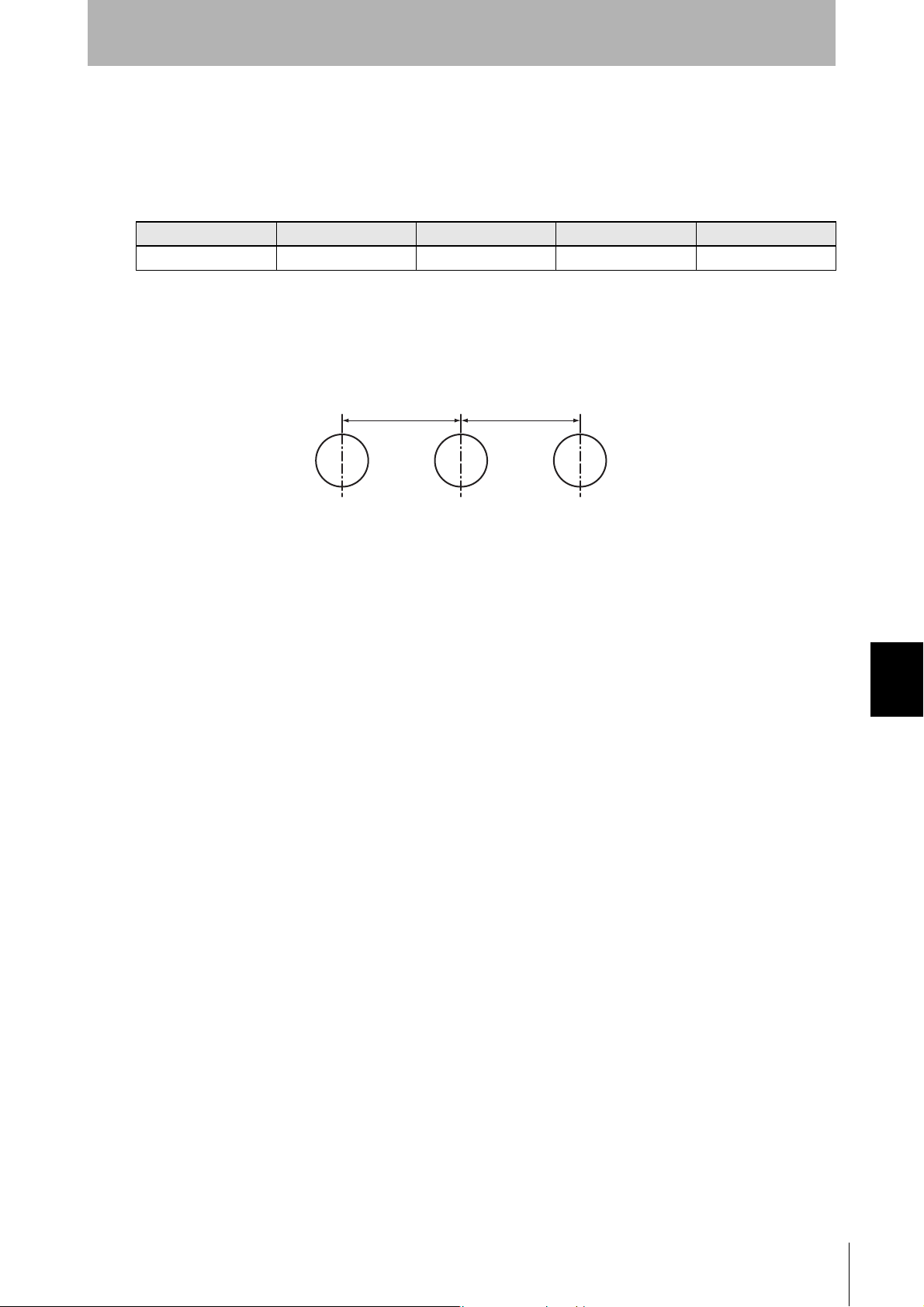

V680-D2KF52M

Differences in Surrounding Metals (Reference)

Communications distances are affected by the type of metal in back of or surrounding the Tag, as

shown in the following table.

Steel SUS Brass Aluminum

V680-D2KF52M 100% 80% to 85% 80% to 85% 75% to 80%

The values for steel are set to 100%

Mutual Interference with Tags (Reference)

Provide the mounting distances indicated below to prevent malfunctions due to mutual interference

when using more than one Tag.

Section 7 Reference Data

RFID System

User's Manual

151

Page 4

Section 7

ID Tag

4.5mm min.

Metal

Embedded

ID Tag

Metal

Surface-mounted

• V680-HS52 &V680-D2KF67M

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS63 & V680-D2KF67M

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS65 & V680-D2KF67M

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

ID Tag

X

X

120mm min.

120mm min.

Chemical Resistance

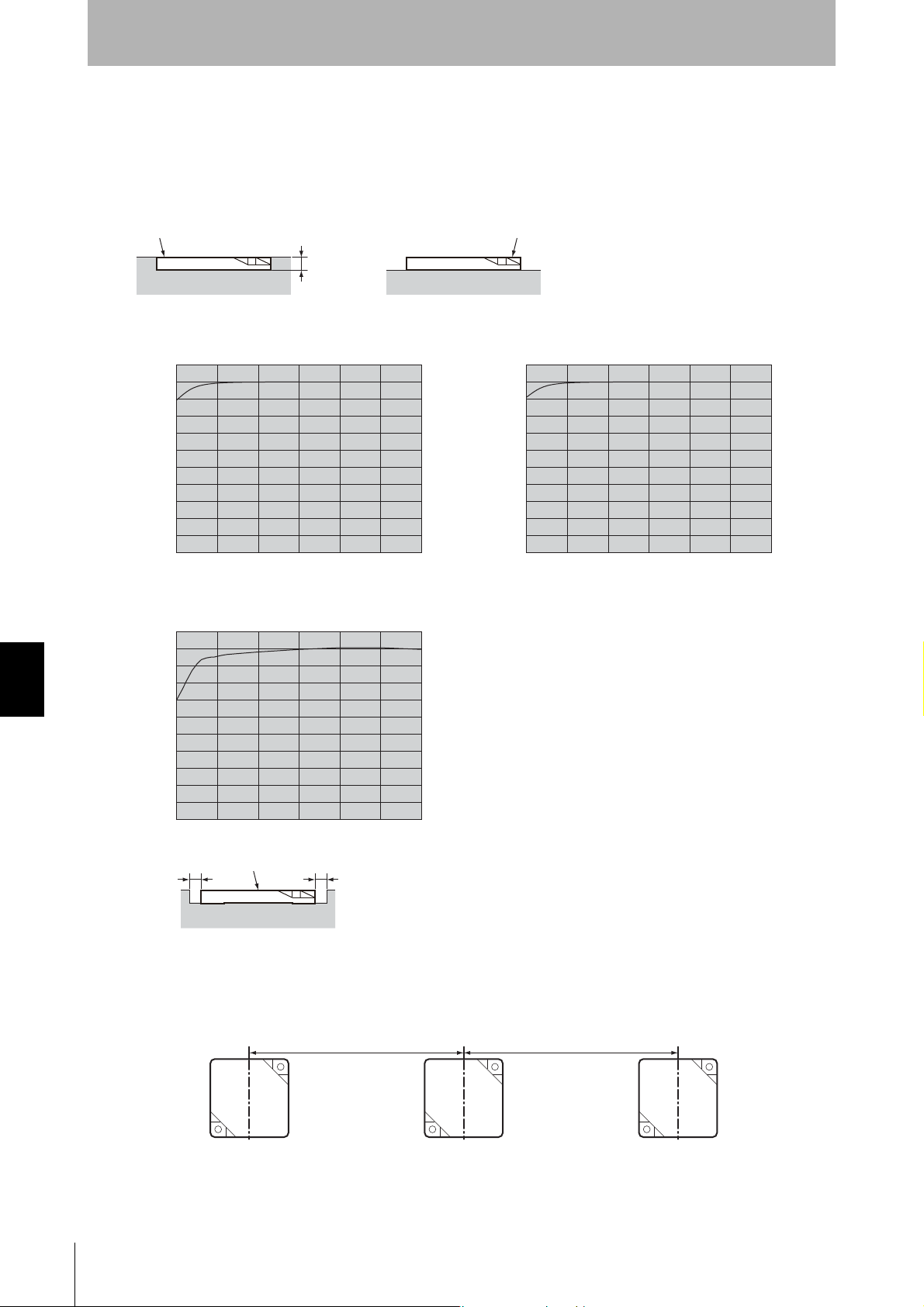

V680-D2KF67M

Effect of Surrounding Metals (Reference)

The V680-D2KF67M can be surface-mounted or it can be embedded in metal. If it is embedded in

metal, the height of the metal casing must not exceed that of the Tag.

Section 7 Reference Data

152

Mutual Interference with Tag (Reference)

To prevent malfunctioning due to mutual interference when using more than one Tag,

leave sufficient space between them as shown in the following diagram.

RFID System

User's Manual

Page 5

Section 7

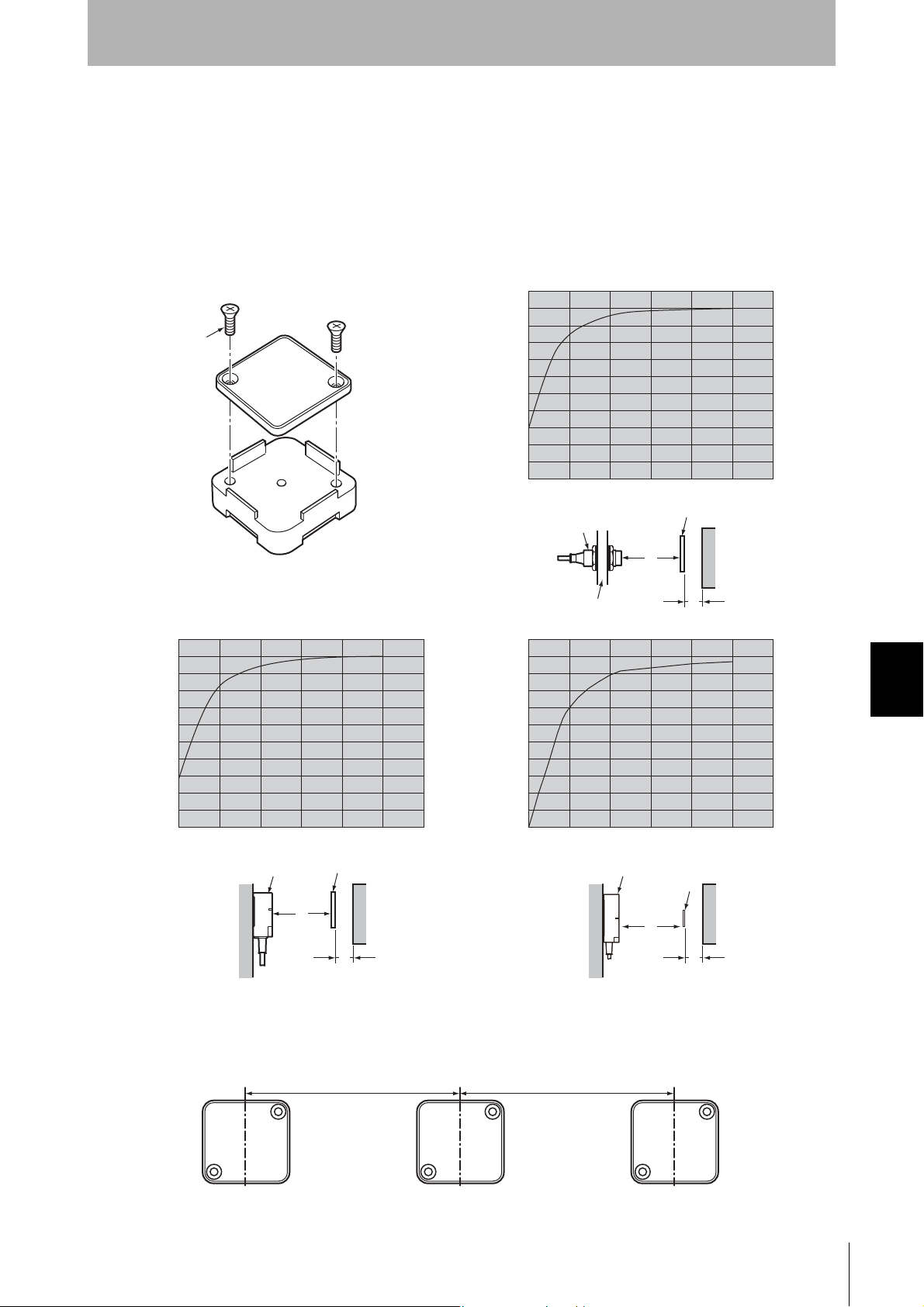

M3 countersunk screw

V600-A86 Attachment Installation

Install so that the mounting holes are aligned.

• V680-HS52 &V680-D1KP66T

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

ID Tag

Metal on back

Antenna

Communications

distance

Y

X

Metal

• V680-HS63 &V680-D1KP66T

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS65 &V680-D1KP66T

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

Antenna

ID Tag

Metal on back

Metal

Y

X

Communications

distance

Antenna

ID Tag

Metal on back

Metal

Y

X

Communications

distance

100mm min.

100mm min.

Chemical Resistance

V680-D1KP66T

Effect of Metal behind Tags (Reference)

The V680-D1KP66T communications distance is reduced if there is any met al material behind the Tag.

If the Tag is to be mounted to metal, then either use a V600-A86 Attachment (sold sep ar ately) or insert

a non-metal spacer (such as plastic or resin). The relationship between the distance from the Tag to

the metal surface and the communications dista nce is shown below.

The Attachment is 10 mm thick, and more than one Attachment can be stacked.

Mutual Interference with Tag (Reference)

To prevent malfunctioning due to mutual interference when using more than one Tag, leave sufficient

space between them as shown in the following diagram.

RFID System

User's Manual

Section 7 Reference Data

153

Page 6

Section 7

• V680-HS52 &V680-D1KP66T-SP

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS63 &V680-D1KP66T-SP

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS65 &V680-D1KP66T-SP

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

ID Tag

Metal on back

Antenna

Y

X

Metal

Communications

distance

Antenna

ID Tag

Metal on back

Metal

Y

X

Communications

distance

Y

X

Communications

distance

Metal

Antenna

ID Tag

Metal on back

Chemical Resistance

V680-D1KP66T-SP

Effect of Metal behind Tags (Reference)

Mounting ID T ags to met al workpieces or palettes will affect the communications capabilities. Place non-metallic parts (e.g., plastic or resin) between the metallic parts by referring to the following relationship between the

distance between the ID T a g and the metallic body versus the communications distance.

Section 7 Reference Data

RFID System

154

User's Manual

Page 7

Section 7

100mm min.

100mm min.

100mm min.

100mm min.

Chemical Resistance

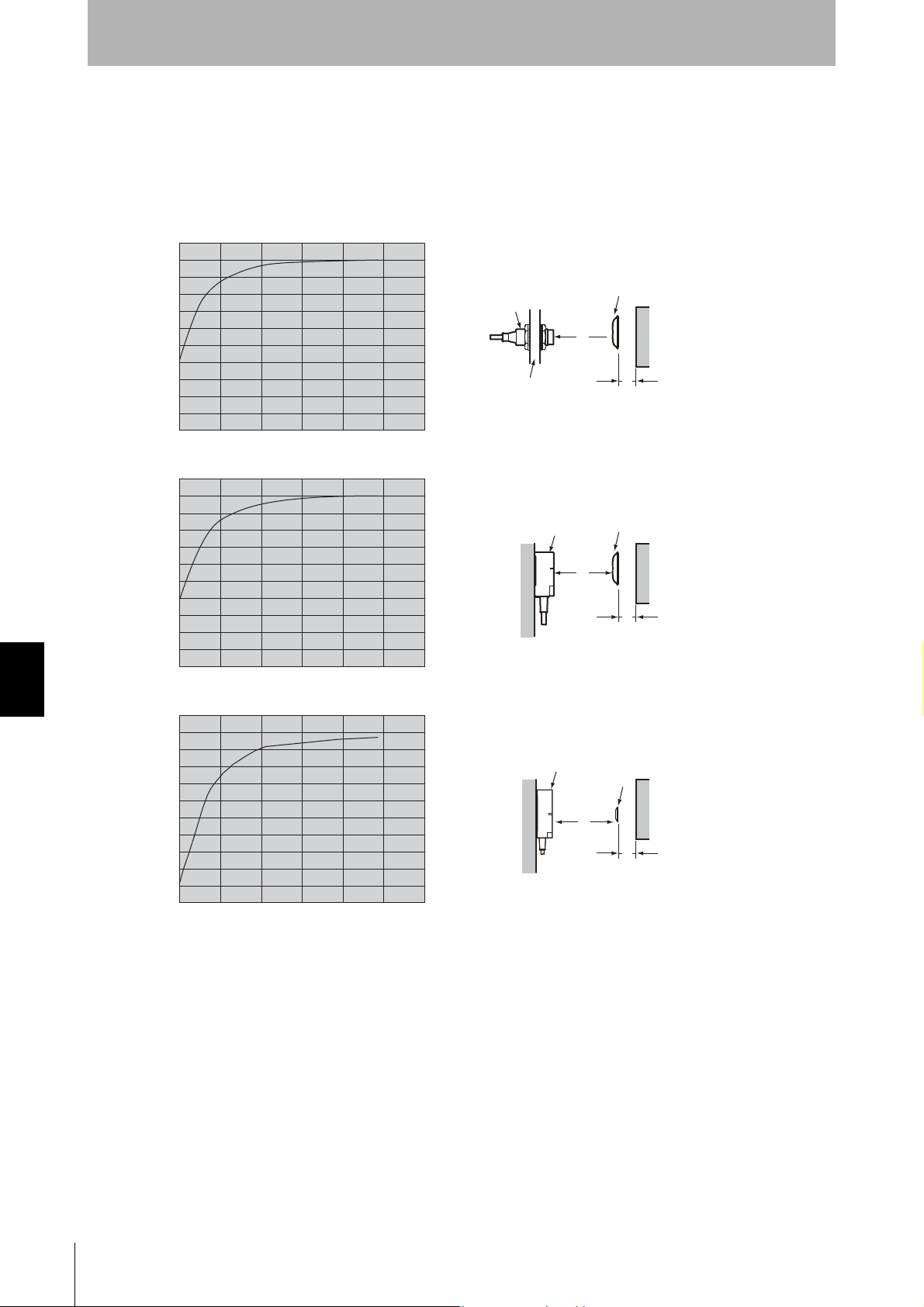

Mutual Interference with Tag (Reference)

To prevent malfunctioning due to mutual interference when using more than one Tag, leave sufficient

space between them as shown in the following diagram.

Section 7 Reference Data

RFID System

User's Manual

155

Page 8

Section 7

• V680-HS52 &V680-D2KF67

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS63 &V680-D2KF67

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

• V680-HS65 &V680-D2KF67

10 20 30 40 50 (mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

ID Tag

Metal on back

Antenna

Communications

distance

Y

X

ID Tag

Metal on back

Antenna

Communications

distance

Y

X

ID Tag

Metal on back

Antenna

Communications

distance

Y

X

Metal

200mm min.

200mm min.

Chemical Resistance

V680-D2KF67

Effect of Metal behind Tags (Reference)

The V680-D2KF67 communications distance is reduced if there is any metal material behind the Tag.

Section 7 Reference Data

Mutual Interference with Tag (Reference)

To prevent malfunctioning due to mutual interference when using more than one Tag, leave sufficient

space between them as shown in the following diagram.

156

RFID System

User's Manual

Page 9

V680-D8KF68/-D32KF68

The transmission distance will be reduced if there is metal in back of

a Tag. When mounting on a metal surface, use the special

Attachment (V680-A81) of another sales or insert a non-metallic

spacer (e.g., plastic, wood, etc.).

The following diagrams show the relationship between the distance

between a Tag and metal surface and the transmission distance. The

Attachment is 10 mm thick.

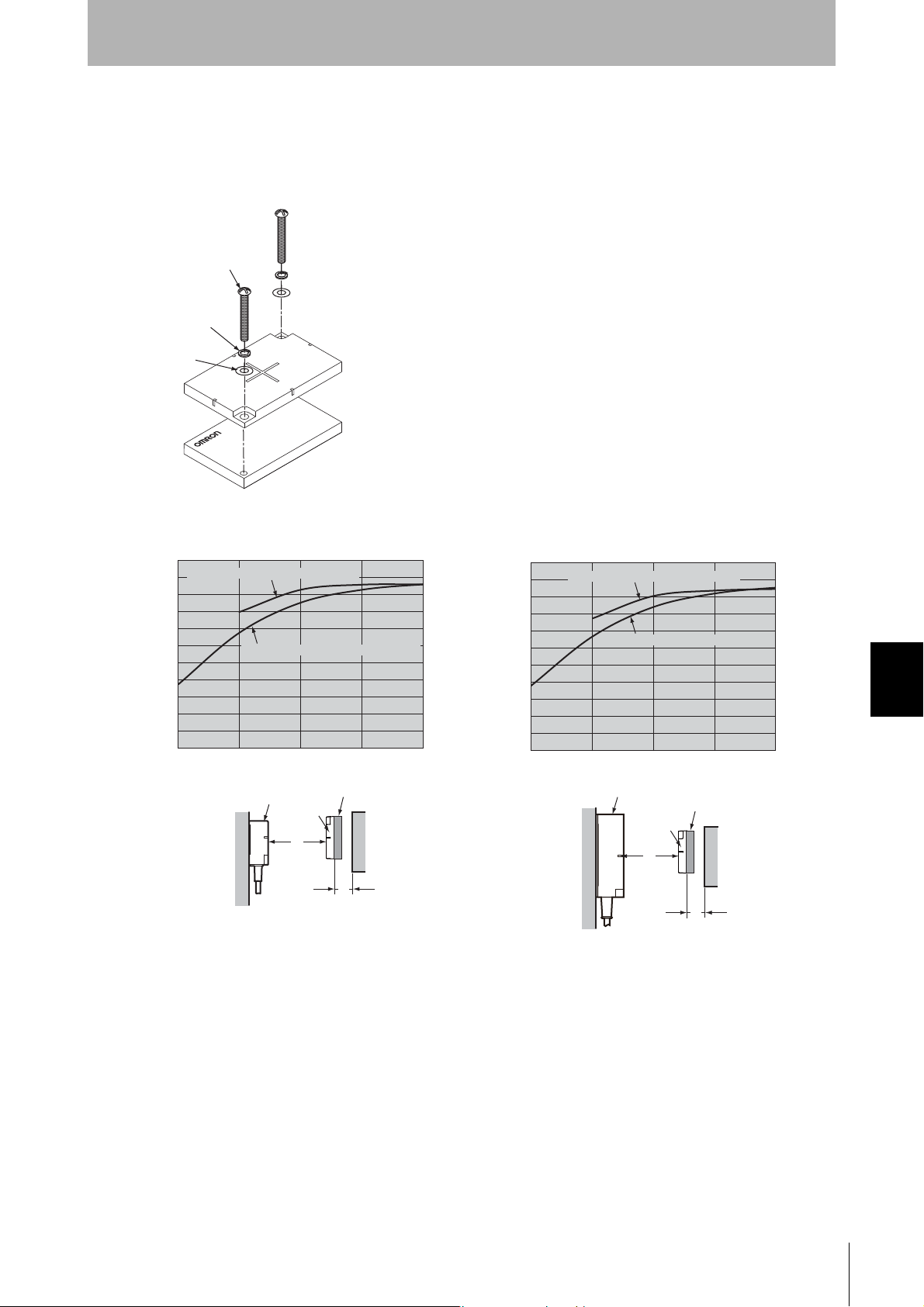

• Special Attachment (V680-A81) Installation Direction

M4 screw

Spring washer

Flat washer

• V680-HS63 &V680-D8KF68/-D32KF68

10 20 30 40

(mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

Antenna

When Attachment (V680-A81) is not used

When Attachment (V680-A81) is used

Atachment

Metal on back

Metal

Communications

distance

Y

X

ID Tag

• V680-HS63 &V680-D8KF68/-D32KF68

10 20 30 40

(mm)

0

50

70

Distance to metal (x)

60

40

30

20

10

90

(%)

100

80

The communications distance without

metal is 100%

When Attachment (V680-A81) is not used

When Attachment (V680-A81) is used

Atachment

Antenna

Metal

Metal on back

Y

X

Communications

distance

ID Tag

Effect of Metal behind Tags (Reference)

Section 7

Chemical Resistance

RFID System

User's Manual

Section 7 Reference Data

157

Page 10

Section 7

120mm min.

120mm min.

120mm min.

120mm min.

150mm min.

150mm min.

150mm min.

150mm min.

Chemical Resistance

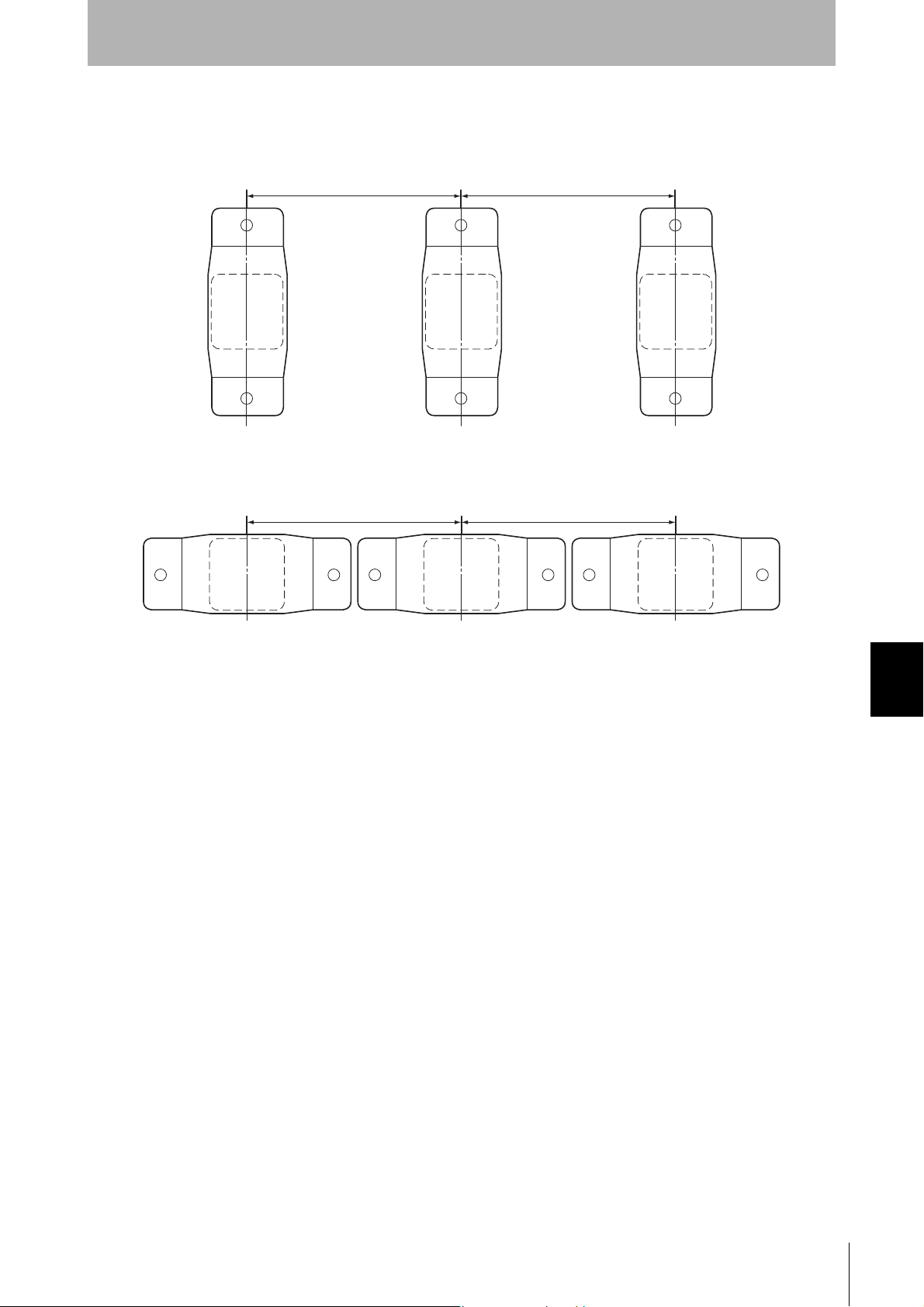

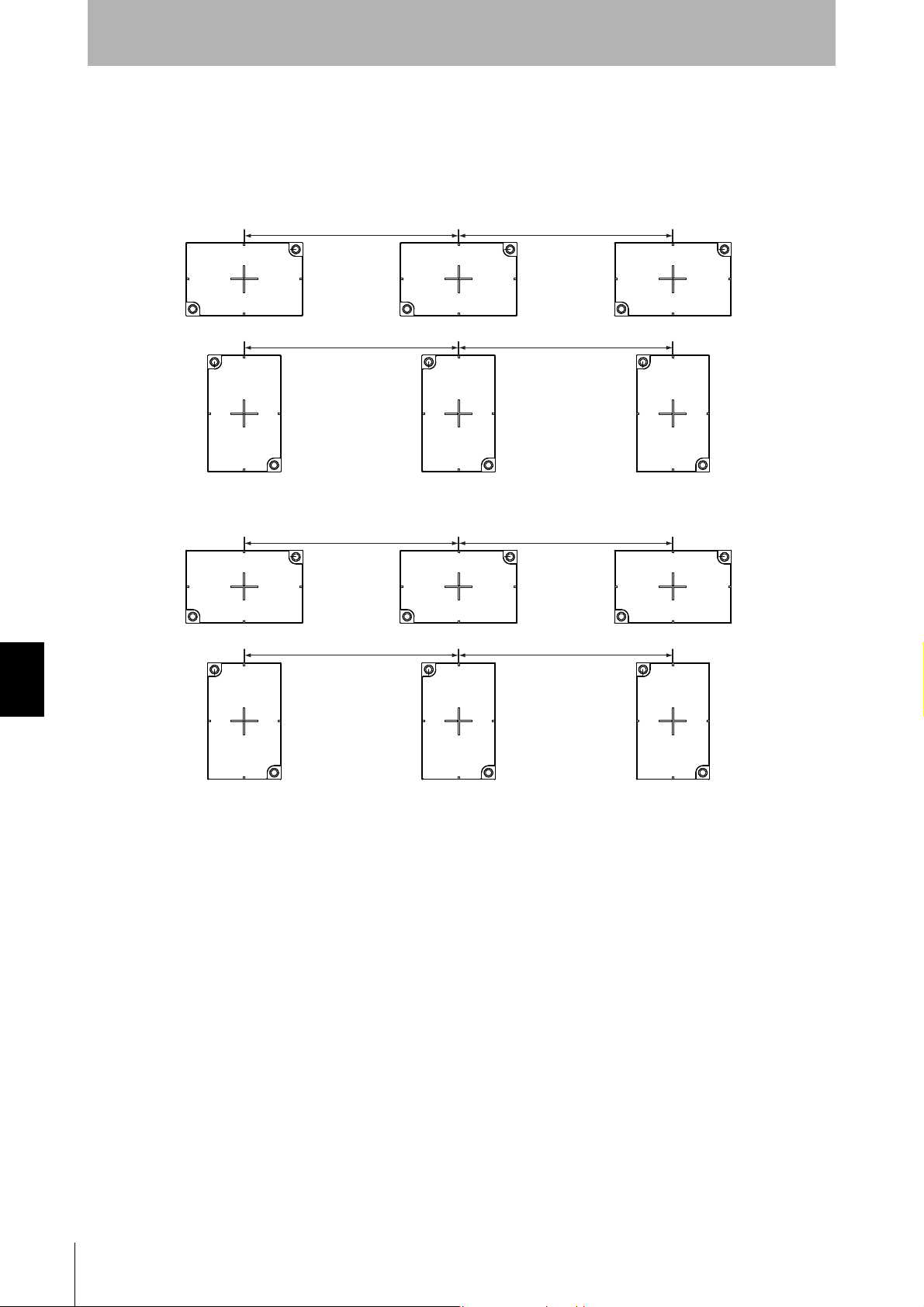

Mutual Interference with Tags (Reference)

To prevent malfunctioning due to mutual interference when using more than one Tag, leave sufficient

space between them as shown in the following diagram.

When V680-HS63, V680-HS52 are Used

Section 7 Reference Data

When V680-HS65 is Used

158

RFID System

User's Manual

Page 11

Section 7

Antenna

Nuts

ID Tag

Steel

Toothed washer

Non-metallic

material

θ

Antenna

Nuts

ID Tag

Steel

Toothed washer

θ

Steel

Antenna

ID Tag

θ

Non-metallic

material

Antenna

ID Tag

Steel

θ

Antenna

ID Tag

θ

Non-metallic

material

Steel

Chemical Resistance

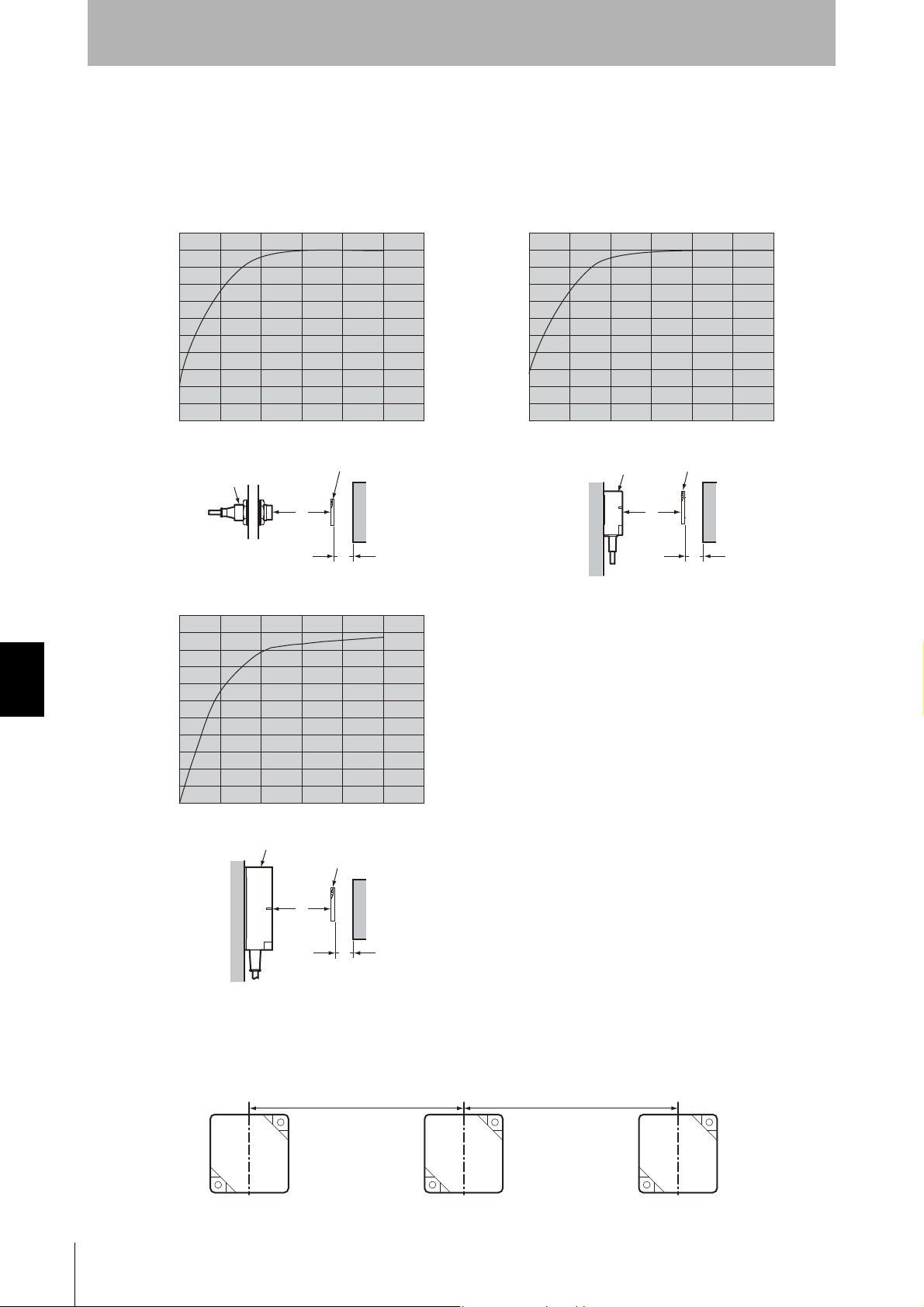

Infuence of Angle (Refernce)

Install Antennas and Tags as close to parallel to each other as possible. Communications are possible

even when an Antenna and a Tag are mounted at an angle, but the communications distance will be

shortened. The relation between the angle and the communications distance is shown below.

Percentage Drop in Communications Distance According to Angle of V680-D1KP52MT

Tag angle (θ°)

0 10 20 30 40

V680-HS51 and V680-D1KP52MT

0% -1% -5% -10% -15%

V680-HS51 and V680-D1KP52MT

(Metal: Steel)

V680-HS52 and V680-D1KP52MT

V680-HS52 and V680-D1KP52MT

(Metal: Steel)

V680-HS63 and V680-D1KP52MT

-: The measurement is no possible because the Tag comes in contact with the Antenna.

0% 0% 0% -4% -28%

0% 0% 0% -2% -6%

0% -6% -13% -25% -

0% -2% -5% -9% -14%

• V680-HS51 & V680-D1KP52MT • V680-HS51 & V680-D1KP52MT

(Metal: Steel)

• V680-HS52 & V680-D1KP52MT

• V680-HS52 & V680-D1KP52MT

(Metal: Steel)

Section 7 Reference Data

●形V680-HS63 & 形V680-D1KP52MT

RFID System

User's Manual

159

Page 12

Section 7

Antenna

ID Tag

θ

Antenna

ID Tag

Non-metallic material

θ

Metal

Antenna

ID Tag

θ

Chemical Resistance

Percentage Drop in Communications Distance According to Angle of V680-D1KP66T

Tag angle (θ°)

0 10 20 30 40

V680-HS52 and V680-D1KP66T

0% -1% -2% -4% -7%

Section 7 Reference Data

V680-HS63 and V680-D1KP66T

V680-HS65 and V680-D1KP66T

0% -2% -3% -5% -9%

0% -1% -3% -6% -11%

• V680-HS52 & V680-D1KP66T • V680-HS63 & V680-D1KP66T

• V680-HS65 & V680-D1KP66T

160

RFID System

User's Manual

Page 13

Section 7

ID Tag

θ

Antenna

Antenna

ID Tag

Non-metallic material

θ

Antenna

ID Tag

θ

Metal

Chemical Resistance

Percentage Drop in Communications Distance According to Angle of V680-D1KP66MT

Tag angle (θ°)

0 10 20 30 40

V680-HS52 and V680-D1KP66MT

(Metal: Steel)

V680-HS63 and V680-D1KP66MT

(Metal: Steel)

V680-HS65 and V680-D1KP66MT

(Metal: Steel)

-: The measurement is no possible because the Tag comes in contact with the Antenna.

0% -1% -2% -5% -9%

0% -1% -4% -7% -13%

0% -1% -6% -15% -

• V680-HS52 & V680-D1KP66MT

(Metal: Steel)

• V680-HS65 & V680-D1KP66MT

(Metal: Steel)

• V680-HS63 & V680-D1KP66MT

(Metal: Steel)

Section 7 Reference Data

RFID System

User's Manual

161

Page 14

Section 7

ID Tag

θ

Antenna

Antenna

ID Tag

Non-metallic material

θ

Antenna

ID Tag

θ

Metal

Chemical Resistance

Percentage Drop in Communications Distance According to Angle of V680-D1KP66T-SP

Tag angle (θ°)

0 10 20 30 40

V680-HS52 and V680-D1KP66T-SP

0% -1% -2% -4% -7%

Section 7 Reference Data

V680-HS63 and V680-D1KP66T-SP

V680-HS65 and V680-D1KP66T-SP

0% -2% -3% -5% -9%

0% -1% -3% -6% -11%

• V680-HS52 & V680-D1KP66T-SP • V680-HS63 & V680-D1KP66T-SP

• V680-HS65 & V680-D1KP66T-SP

162

RFID System

User's Manual

Page 15

Chemical Resistance

ID Tag

θ

Antenna

Nuts

Steel

Toothed washer

Non-metallic

material

ID Tag

θ

Antenna

Nuts

Steel

Toothed washer

Non-metallic

material

ID Tag

θ

Antenna

Non-metallic

material

ID Tag

Antenna

Steel

θ

ID Tag

θ

Non-metallic

material

Antenna

Steel

Percentage Drop in Communications Distance According to Angle of V680-D2KF52M

Tag angle (θ°)

0 10 20 30 40

V680-HS51 and V680-D2KF52M

0% -2% -6% -12% -22%

Section 7

V680-HS51 and V680-D2KF52M

(Metal: Steel)

V680-HS52 and V680-D2KF52M

V680-HS52 and V680-D2KF52M

(Metal: Steel)

V680-HS63 and V680-D2KF52M

-: The measurement is no possible because the Tag comes in contact with the Antenna.

• V680-HS51 & V680-D2KF52M

• V680-HS52 & V680-D2KF52M

0% 0% 0% -7% -30%

0% 0% 0% -2% -5%

0% -2% -7% - -

0% 0% -1% -4% -9%

• V680-HS51 & V680-D2KF52M

• V680-HS52 & V680-D2KF52M

(Metal: Steel)

Section 7 Reference Data

(Metal: Steel)

• V680-HS63 & V680-D2KF52M

RFID System

User's Manual

163

Page 16

Section 7

ID Tag

θ

Antenna

Antenna

ID Tag

Non-metallic material

θ

ID Tag

θ

Metal

Antenna

Chemical Resistance

Percentage Drop in Communications Distance According to Angle of V680-D2KF67

Tag angle (θ°)

0 10 20 30 40

V680-HS52 and V680-D2KF67

0% -0% 0% -1% -2%

Section 7 Reference Data

V680-HS63 and V680-D2KF67

V680-HS65 and V680-D2KF67

0% -1% -2% -3% -6%

0% -1% -3% -7% -11%

• V680-HS52 & V680-D2KF67 • V680-HS63 & V680-D2KF67

• V680-HS65 & V680-D2KF67

164

RFID System

User's Manual

Page 17

Chemical Resistance

ID Tag

θ

Antenna

Antenna

ID Tag

Non-metallic material

θ

ID Tag

θ

Metal

Antenna

Percentage Drop in Communications Distance According to Angle of V680-D2KF67M

Tag angle (θ°)

0 10 20 30 40

V680-HS52 and V680-D2FKP67M

(Metal: Steel)

V680-HS63 and V680-D2FKP67M

(Metal: Steel)

V680-HS65 and V680-D2FKP67M

(Metal: Steel)

0% -1% -2% -4% -6%

0% -2% -5% -8% -14%

0% -2% -7% -16% -31%

Section 7

• V680-HS52 & V680-D2KF67M

• V680-HS65 & V680-D2KF67M

(Metal: Steel)

(Metal: Steel)

• V680-HS63 & V680-D2KF67M

(Metal: Steel)

Section 7 Reference Data

RFID System

User's Manual

165

Page 18

Section 7

ID Tag

θ

Metal

Antenna

ID Tag

θ

Metal

Antenna

ID Tag

θ

Metal

Antenna

ID Tag

θ

Metal

Antenna

Chemical Resistance

Percentage Drop in Communications Distance According to Angle of V680 -

Tag angle (θ°)

0 10 20 30 40

V680-HS63 and V680-D8KF68 or V680-D32KF68

(Horizontal-facing ID Tag)

V680-HS63 and V680-D8KF68 or V680-D32KF68

(Vertical-facing ID Tag)

V680-HS65 and V680-D8KF68 or V680-D32KF68

(Horizontal-facing ID Tag)

V680-HS65 and V680-D8KF68 or V680-D32KF68

(Vertical-facing ID Tag)

• V680-HS63 & V680-D8KF68 or V680-D32KF68

(Horizontal-facing ID Tag)

0% 0% 0% 0% 0%

0% -1% -2% -3% -5%

0% -1% -2% -4% -6%

0% -1% -3% -6% -10%

• V680-HS63 & V680-D8KF68 or V680-D32KF68

(Vertical-facing ID Tag)

D8KF68, V680-D32KF68

Section 7 Reference Data

• V680-HS65 & V680-D8KF68 or V680-D32KF68

(Horizontal-facing ID Tag)

• V680-HS65 & V680-D8KF68 or V680-D32KF68

(Horizontal-facing ID Tag)

166

RFID System

User's Manual

Page 19

ID Tag Memory

Address

Data

0000Hex

0001Hex

0002Hex

0003Hex

User area

03E6Hex

03E7Hex

:

:

1 byte

EEPROM is used as memory in the Tags.

The memory capacity available to the user is 1,000 bytes,

including 0000H to 0003H (the Write Protection Setting Area).

Address

Data

0000Hex

0001Hex

0002Hex

0003Hex

User area

07CEHex

07CFHex

:

:

1 byte

FRAM is used as memory in the Tags.

The memory capacity available to the user is 1,000 bytes,

including 0000H to 0003H (the Write Protection Setting Area)

Address

Data

0000Hex

0001Hex

0002Hex

0003Hex

User area

1FFEHe

1FFFHe

:

:

1 byte

FRAM is used as memory in the Tags.

The memory capacity available to the user is 8,192 bytes,

including 0000H to 0003H (the Write Protection Setting Area)

Address

Data

0000Hex

0001Hex

0002Hex

0003Hex

User area

7FFEHe

7FFFHe

:

:

1 byte

FRAM is used as memory in the Tags.

The memory capacity available to the user is 32,744 bytes,

including 0000H to 0003H (the Write Protection Setting Area)

V680-D1KP□□

V680-D2KF□□

Section 7

Chemical Resistance

V680-D8KF□□

V680-D32KF□□

Section 7 ID Tag Memory

メ モ リ へのア クセスは16ビ ッ ト単位(2バイ ト 単位)に行われま す。 た だ し、 1バイ ト ライ ト モー ド 指定の場合は、 8 ビ ッ ト 単位(1

バイ ト 単位)となります。

RFID System

User's Manual

167

Page 20

Section 7

Chemical Resistance

ID Tag Memory Capacities and Memory Types (V680 Series)

(As of December 2007)

Model

V680-D1KP52MT

V680-D1KP66T

V680-D1KP66MT

V680-D1KP66T-SP

V680-D2KF52M

V680-D2KF67

V680-D2KF67M

V680-D8KF68 8,192 bytes

V680-D32KF68 32,744 bytes

Memory capacity

(user memory)

1,000 bytes EEPROM

2,000 bytes

Memory type Life expectancy

Overwrite operations: 100,000 times for each address at

25°C

Data retention: 10 years (up to 85°C)

Number of accesses: 10 billion times

FRAM

Data retention: 10 years (up to 55°C)

Section 7 ID Tag Memory Capacities and Memory Types (V680 Series)

168

RFID System

User's Manual

Page 21

Section 7

Chemical Resistance

Chemical Resistance of the Antennas, and Tags

Chemical Resistance of the Antennas

Applicable Models

V680-HS51 V680-HS52-W/R V680-HS63-W/R V680-HS65-W/R

ABS resin is used for case material and epoxy resin for filling material. Refer to the following lists and do not

use chemicals that affect ABS and epoxy resin.

Chemicals That Cause Deformations, Cracks, Etc.

ABS resin Epoxy resin

Trichlene, acetone, xylene, toluene, gasoline, creosol,

methylene chloride, phenol, cyclohexane, aqua regia,

chromic acid, sulfuric acid (90% RT), methyl ethyl

ketone, aniline, nitrobenzine, monochlorobenzine,

pyridine, nitric acid (60% RT), formic acid (80% RT)

Aqua regia, chromic acid, sulfuric acid (90% RT),

nitric acid (60% RT), ammonia solution, acetone,

methylene chloride, phenol

Chemicals That May Cause Discoloration, Swelling, Etc.

ABS resin Epoxy resin

Hydrochloric acid, alcohol, Freon, sodium hydroxide,

hydrogen peroxide, benzine, sulfuric acid (10% RT),

nitric acid (10% RT), phosphoric acid (85% RT),

ammonia solution

Sulfuric acid (10% RT), nitric acid (10% RT), hydrochloric acid (30% RT), acetic acid (50% RT), oxalic acid,

calcium hydroxide, benzine, creosol, alcohol, cyclohexane, toluene, xylene, benzine, grease

Chemicals That Do Not Affect PPS Resin or Epoxy Resin

ABS resin Epoxy resin

Ammonia, kerosine, mineral oil, developer, Yushiroken

S50, Chemi-Cool Z, Velocity No. 3, Yushiroken EEE30Y, petroleum, grease, acetic acid, oxalic acid, calcium hydroxide, phosphoric acid (30% RT), hydrochloric acid (10% RT), potassium hydroxide

Note: The above results are from tests conducted a room temperature (23°C). Even if the chemicals

do not affect the ABS or epoxy resins at room temperature, they may affect the resins at higher or

lower temperatures. Check the chemicals carefully in advance.

Ammonia, hydrochloric acid (10% RT), potassium

hydroxide, petroleum, gasoline, Yushiroken S50,

Chemi-Cool Z, Velocity No. 3, Yushiroken EEE-30Y

Section 7 Chemical Resistance of the Antennas, and Tags

RFID System

User's Manual

173

Page 22

Section 7

Chemical Resistance

Chemical Resistance of Tags

Applicable Model

V680-D1KP52MT V680-D2KF52M

PPS resin is used for case material and epoxy resin for filling material. Refer to the following lists and do not

use chemicals that affect PPS and epoxy resin.

Tags cannot be used in applications with explosion-proof specifications.

Chemicals That Cause Deformations, Cracks, Etc.

PPS resin Epoxy resin

Aqua regia Aqua regia, chromic acid, sulfuric acid (90% RT),

nitric acid (60% RT), ammonia solution, acetone,

methylene chloride, phenol

Chemicals That May Cause Discoloration, Swelling, Etc.

PPS resin Epoxy resin

Nitric acid (60% RT) Sulfuric acid (10% RT), ni tric ac id (10% R T), hy drochl o-

ric acid (30% RT), acetic acid (50% RT), oxalic acid,

calcium hydroxide, benzine, creosol, alcohol, cyclohexane, toluene, xylene, benzine, grease

Section 7 Chemical Resistance of the Antennas, and Tags

Chemicals That Do Not Affect PPS Resin or Epoxy Resin

PPS resin Epoxy resin

Hydrochloric acid (37%RT), sulfuric acid (98%RT),

nitric acid (40%RT), Hydrogen fluoride solution

(40%RT), chromic acid (40%RT), hydrogen peroxide

(28%RT), sodium hydroxide solution (60%RT),

ammonia solution (28%RT), sodium chloride (10%RT),

sodium carbonate (20%RT), sodium hypochlorite,

phenol solution (5%RT), glacial acetic acid, acetic acid,

oleic acid, Methyl alcohol (95%RT), ethyl alcohol

(95%RT), Ethyl acetate, sebacic acid, diethylhexyl,

acetone, diethyl ether, n-heptane, 2-2-4 trimethylpentane, benzine, toluene, aniline, mineral oil, gasoline,

insulating oil, dichloroethylene, carbon tetrachloride

Note: The above results are from tests conducted a room temperature (23°C). Even if the chemicals

do not affect the PPS or epoxy resins at room temperature, they may affect the resins at higher

or lower temperatures. Check the chemicals carefully in advance.

Ammonia, hydrochloric acid (10% RT), potassium

hydroxide, petroleum, gasoline, Yushiroken S50,

Chemi-Cool Z, Velocity No. 3, Yushiroken EEE-30Y,

methyl ethyl ketone, sodium hydroxide (10%RT)

174

RFID System

User's Manual

Page 23

Applicable Models

V680-D1KP66T/66MT

Section 7

Chemical Resistance

Chemical

tempera-

ture

At room

Hydrochloric acid

Sulfuric acid

Nitric acid

Hydrogen fluoride solution

Chromic acid

Hydrogen peroxide solu-

tion

Sodium hydroxide solution

Ammonia solution

Sodium chloride

Sodium carbonate

A: Has no adverse effect, B: May cause discoloration, swelling, etc., C: Causes deformation, cracks, etc.

37% A A

10% A A

98% A B

50% A A

30% A A

3% A A

60% B C

40% A B

10% A A

40% A A

40% A A

28% A B

3% A A

60% A A

10% A A

1% A A

28% A B

10% A B

10% A A

20% A A

2% A A

At

90°C

Chemical

Sodium hypochlorite

Phenol solution

Glacial acetic acid

Acetic acid

Oleic acid

Methyl alcohol

Ethyl alcohol

Ethyl acetate

Sebacic acid diethylhexyl

Acetone

Diethyl ether

n-heptane

2-2-4 trimethylpentane

Benzene

Toluene

Aniline

Mineral oil

Gasoline

Insulating oil

Dichloroethylene

Carbon tetrachloride

5% A A

95% A A

95% A A

At room

tempera-

ture

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

At

90°C

Section 7 Chemical Resistance of the Antennas, and Tags

The above table shows the extent of changes in PPS resin exposed to each chemical at room temperature

and at 90

tables, always conduct tests under the actual conditions in which the Tags are to be used.

°C. If actual chemicals, concentrations, and temperatures are different from those shown in the

RFID System

User's Manual

175

Page 24

Section 7

Chemical Resistance

Applicable Models

V680-D1KP66T-SP

Chemical Resistance of Fluoroplastic PFA (Reference)

PFA: Tetrafluorethylene-Perfluoroalkylvinyletheir Copolymer

Fluoroplastic PFA does not react with most chemicals except molten alkali metal, hot pressurized

fluorine (F

was soaked in or exposed to commonly used organic and inorganic chemicals. In these tests, a

compression-molded test piece (1.3 mm thick) was soaked in the chemical at a specified temperat ure

for a week (168 houre) and taken out of the chemical, then the weight change, tensile strength, and

elongation of the test piece were immediately m easured. If the chan ge in the te nsile strength is 15 % or

less, the cange in the elongation is 10 % or less, and the increase in the weight is less than 0.5 %, the

results of the test can be considered normal.

If PFA is exposed to trichloroacetic acid, tri-n-butyl phosphate, perchloroethylene, carbon thtrachloride,

and other liquids (which easily make resin surfaces wet) at a high temperature, it tends to increase its

weight due to absorption and reduce its tensile strength. Even when PFA absorbs chemicals and solvents, its molecular structure will not change, If, however, PFA is subject to temperature or pressure

changes or mechanical damage when it has absorbed chemicals, the chemicals will repeatedly

expand and contract inside pfa, causing mechanical problems such as cracks and bulging. In fact, this

problem occurs with any kind of plastic.

2), and some halogen derivatives. The followin g t ables sh ow the result s of test s in which PFA

Section 7 Chemical Resistance of the Antennas, and Tags

Inorganic Chemicals

Test

Chemical name

concentrated hydrochloric acid 120 98 100 0.0

Concentrated sulfuric acid 120 95 98 0.0

Hydrofluoric acid (60%) 23 99 99 0.0

Fuming sulfuric acid 23 95 96 0.0

Aqua regia 120 99 100 0.0

Chromic acid (50%) 120 93 97 0.0

Consentrated nitric acid 120 95 98 0.0

Fuming nitric acid 23 99 99 0.0

Concentrated ammonia solution 66 98 100 0.0

Caustic soda (50%) 120 93 99 0.4

Hydrogen peroxide solution (30%) 23 93 95 0.0

Bromine 23 99 100 0.5

Chlorine 120 92 100 0.5

Ferrous chloride (25%) 100 93 98 0.0

Zinc chloride (25%) 100 96 100 2.7

Chlorosulfonic acid 151 91 100 2.7

Concentrated phosphoric acid 100 93 100 0.0

temperature

(°C)

Resulting characteristics

(%)

Tensile

strength

Elongation

Weight

increase

rate (%)

176

RFID System

User's Manual

Page 25

Organic Chemicals

Test

Chemical name

Glacial acetic acid 118 95 100 0.4

Acetic anhydride 139 91 99 0.3

Trichloroacetic acid 196 90 100 2.2

Isooctane 99 94 100 0.7

Naphtha 100 91 100 0.5

Mineral oil 180 87 95 0.0

Toluene 110 88 100 0.7

o-creosol 191 92 96 0.2

Nitrobenzene 210 90 100 0.3

Benzyl alcohol 205 93 99 0.3

Aniline 185 94 100 0.3

n-butylamine 78 86 97 0.4

Ethylenediamine 117 96 100 0.1

Tetrahydrofuran 66 88 100 0.1

Benzaldehyde 179 90 99 0.5

Cyclohexane 156 92 100 0.4

Methyl ethyl ketone 80 90 100 0.4

Acetophenone 202 90 100 0.6

Dimethylphtalate 200 98 100 0.3

n-butyl acetate 125 93 100 0.5

Tri-n-butyl phosphate 200 91 100 2.0

Methylene chloride 40 94 100 0.8

Perchloroethylene 121 86 100 2.0

Carbon tetrachloride 77 87 100 2.3

Dimethyl formamide 154 96 100 0.2

Dimethyl sulfoxide 189 95 100 0.1

Dioxane 101 92 100 0.6

Reference: Fluoroplastics Handbook, The Nikkan Kogyo Shimbun Ltd. (Takaomi Satogawa)

temperature

(°C)

Resulting characteristics

(%)

Tensile

strength

Elongation

Section 7

Chemical Resistance

Weight

increase

rate (%)

Section 7 Chemical Resistance of the Antennas, and Tags

RFID System

User's Manual

177

Page 26

Section 7

Chemical Resistance

Substances Extracted from Tag (Reference)

If chemicals penetrate into a Tag through PFA, ions may be extracted from the Tag.

Results of Ion-exchange Chromatography

A built-in Tag was soaked in hot water (100°C for 16 houres), and extracted ions were analyzed. The

results are shown below.

Extracted Ions (Concentration)

Cl: 0.5 ppm, Na

Results of ICP Emission Spectral Analysis

The V680-D1KP66T-SP Tag was soaked in condentrated hydrochloric acid (which can easily penetrate

through PFA) at 80°C fo 300 hours, then extracted substances were analyzed.

Extracted Substances (Concentration)

Si: 700 ng/ml, S: 1,000 ng/ml, Ca: 30 ng/ml

+

: 10 ppm, NH4+: 11 ppm, K+: 1.0 ppm

Section 7 Chemical Resistance of the Antennas, and Tags

The chemical resistance and extracted substances presented here should be used for reference only. The

rates of change in Tag characteristics and the amounts of substances extracted will vary with temperatures

and chemical concentrations. Before using T ags under actual production environment, always conduct tests to

check for any problems

178

RFID System

User's Manual

Page 27

Section 7

Chemical Resistance

Applicable Models

V680-D2KF67/67M

Chemicals that affect Tags are shown below.

ABS resin is used for case material and epoxy resin for filling material. Refer to the following lists and do not

use chemicals that affect ABS and epoxy resin.

Tags cannot be used in applications with explosion-proof specifications.

Chemicals That Cause Deformations, Cracks, Etc.

ABS resin Epoxy resin

Trichlene, acetone, xylene, toluene, gasoline, creosol,

methylene chloride, phenol, cyclohexane, aqua regia,

chromic acid, sulfuric acid (90% RT), methyl ethyl

ketone, aniline, nitrobenzine, monochlorobenzine,

pyridine, nitric acid (60% RT), formic acid (80% RT)

Chemicals That May Cause Discoloration, Swelling, Etc.

ABS resin Epoxy resin

Hydrochloric acid, alcohol, Freon, sodium hydroxide,

hydrogen peroxide, benzine, sulfuric acid (10% RT),

nitric acid (10% RT), phosphoric acid (85% RT),

ammonia solution

Aqua regia, chromic acid, sulfuric acid (90% RT),

nitric acid (60% RT), ammonia solution, acetone,

methylene chloride, phenol

Sulfuric acid (10% RT), nitric acid (10% RT), hydrochloric acid (30% RT), acetic acid (50% RT), oxalic acid,

calcium hydroxide, benzine, creosol, alcohol, cyclohexane, toluene, xylene, benzine, grease

Chemicals That Do Not Affect PPS Resin or Epoxy Resin

ABS resin Epoxy resin

Ammonia, kerosine, mineral oil, developer, Yushiroken

S50, Chemi-Cool Z, Velocity No. 3, Yushiroken EEE30Y, petroleum, grease, acetic acid, oxalic acid, calcium hydroxide, phosphoric acid (30% RT), hydrochloric acid (10% RT), potassium hydroxide

Note: The above results are from tests conducted a room temperature (23°C). Even if the chemicals

do not affect the ABS or epoxy resins at room temperature, they may affect the resins at higher

or lower temperatures. Check the chemicals carefully in advance.

Ammonia, hydrochloric acid (10% RT), potassium

hydroxide, petroleum, gasoline, Yushiroken S50,

Chemi-Cool Z, Velocity No. 3, Yushiroken EEE-30Y

Section 7 Chemical Resistance of the Antennas, and Tags

RFID System

User's Manual

179

Page 28

Section 7

Chemical Resistance

Applicable Model

V680-D8KF68/D32KF68

Chemicals that affect Tags are shown below.

Polybutylene terephthalate (PBT) resin is used for case material and epoxy resin for filling material. Refer to

the following lists and do not use chemicals that affect PBT and epoxy resins.

Tags cannot be used in applications with explosion-proof specifications.

Chemicals That Cause Deformations, Cracks, Etc.

PBT resin Epoxy resin

Acetone, trichloroethylene, ethylene dichloride, sodium

hydroxide, and other alkaline substances

Chemicals That May Cause Discoloration, Swelling, Etc.

PBT resin Epoxy resin

Hydrochloric acid (10% RT), acetic acid (5% RT), benzene

Aqua regia, chromic acid, sulfuric acid (90% RT), nitric

acid (60% RT), liquid ammonia, acetone, methylene

chloride, phenol

Sulfuric acid (10% RT), nitric acid (10% RT), concentrated hydrochloric acid, acetic acid (50% RT), nitric

acid, calcium hydroxide, benzene, cresol, alcohol,

microhexanon, toluene, xylene, benzene, grease

Section 7 Chemical Resistance of the Antennas, and Tags

Chemicals That Do Not Affect PPS Resin or Epoxy Resin

PBT resin Epoxy resin

Nitric acid (30% RT), concentrated hydrochloric acid,

acetic acid, ethyl acetate (100% RT), potassium permaganate (5% RH), ethyl acetate, carbon tetrachloride,

methanol, ethanol, gasoline

Note: The above results are from tests conducted at room temperature (23°C). Even if the chemicals

do not affect the PPS or epoxy resins at room temperature, they may affect the resins at higher or lower

temperatures. Check the chemicals carefully in advance.

Ammonia, hydrochloric acid (10% RT), calcium hydroxide, petroleum, gasoline, Yushiroken S50, Chemi-cool

Z, Velocity No. 3, Yushiroken EEE-30Y, methyl ethyl

ketone, sodium hydroxide

180

RFID System

User's Manual

Page 29

Section 7

200 mm

Chemical Resistance

Degree of Protection

Ingress protection degrees (IP-@@) are determined by the following tests. Be sure to check the sealing capa-

bility under the actual operating environment and conditions before actual use.

IP indicates the ingress protection symbol.

IEC (International Electrotechnical Commission) Standards

IEC 60529: 1989-11

(A) First Digit: Degree of Protection from Solid Materials

Degree Degree

0

No protection

Section 7 Degree of Protection

1

2

3

4

5

6

50 mm dia.

12.5 mm dia.

2.5 mm

1 mm

Protects against penetration of any solid object such as a hand that is 50 mm or more in diameter.

Protects against penetration of any solid object, such as a finger, that is 12.5 mm or more in diameter.

Protects against penetration of any solid object, such as a wire, that is 2.5 mm or more in diameter.

Protects against penetration of any solid object, such as a wire, that is 1 mm or more in diameter.

Protects against penetration of dust of a quantity that may cause malfunction or obstruct the safe

operation of the product.

Protects against penetration of all dust.

(B) Second Digit: Degree of Protection Against Water

Degree Protection Test method (with pure water)

0 No protection Not protected against water. No test

1 Protection against water

drops

Protects against vertical drops

of water towards the product.

Water is dropped vertically towards the product from

the test machine for 10 min.

182

RFID System

User's Manual

2 Protection against water

drop

Protects against drops of

water approaching at a maximum angle of 15°to the left,

right, back, and front from vertical towards the product.

Water is dropped for 2.5 min each (i.e., 10 min in total)

towards the product inclined 15° to the left, right, back,

and front from the test machine.

15˚

200 mm

Page 30

Chemical Resistance

Water rate is 0.07

liter/min per hole.

Degree Protection Test method (with pure water)

3 Protection against sprin-

kled water

Protects against sprinkled

water approaching at a maximum angle of 60° from vertical towards the product.

Water is sprinkled for 10 min at a maximum angle of

60° to the left and right from vertical from the test

machine.

Section 7

Water rate is 0.07

liter/min per hole.

4 Protection against water

spray

Protects against water spray

approaching at any angle

towards the product.

5 Protection against water jet

spray

Protects against water jet

spray approaching at any

angle towards the product.

6 Protection against high

pressure water jet spray

Protects against high-pressure water jet spray approaching at any angle towards the

product.

7 Protection underwater Resists the penetration of

water when the product is

placed underwater at specified pressure for a specified

time.

Water is sprayed at any angle towards the product for

10 min from the test machine.

Water is jet sprayed at any angle towards the product

for 1 min per square meter for at least 3 min in total

from the test machine.

2.5 to 3 m

Discharging nozzle: 6.3 dia.

12.5 liter/min

Water is jet sprayed at any angle towards the product

for 1 min per square meter for at least 3 min in total

from the test machine.

2.5 to 3 m

Discharging nozzle: 6.3 dia.

100 liter/min

The product is placed 1 m deep in water (if the product

is 850 mm max. in height) for 30 min.

1 m

Section 7 Degree of Protection

8

(See Note)

Protection underwater Can be used continuously

underwater.

The test method is determined by the manufacturer and

user.

Oil resistance (OMRON in-house standard)

Protection

Oil-resistant No adverse affect from oil drops or oil spray approaching from any direction.

Oil-proof Protects against penetration of oil drops or oil spray approaching from any direction.

Note: This OMRON in-house standard confirms resistance to cutting and other oils. It is equivalent to the

former JEM standard.

RFID System

User's Manual

183

Page 31

Revision History

Cat. No.: Z248-E1-04

Revision code

A manual revision code appears as a suffix to the catalog number at the bottom of the front and rear pages.

Revision code Date Revised contents

01 October 2006 Original production

02 May 2007 Added items for V680-D8KF68/-D32KF68 ID Tags.

03 July 2007

03A September 2007

04 December 2007

Added items for V680-A81, V680-HS65 Antenna, and the overseas regulations

and standards.

Added information on metal on back surface of the V680-HS65, corrected Tag

specifications, and made other minor corrections.

Added item for V680-HS51 Antenna, the overseas regulations and standards, ,

and made other minor corrections.

184

RFID System

User's Manual

Page 32

Authorized Distributor:

OMRON Corporation

Industrial Automation Company

Sensing Devices Division H.Q.

Industrial Sensors Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7022/Fax: (81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen,

Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

Pu Dong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Cat. No. Z279-E1-01

In the interest of product improvement, specifications are

subject to change without notice.

Printed in Japan

0308-0.3C (1006)

Loading...

Loading...