Omron 6CYCIDV6400304 Users Manual

INTRODUCTION

ÇÕǹÇ?Ç ëÊ 1 èÕ ëÊ 2 èÕ ëÊ 3 èÕ ëÊ 4 èÕ

Introduction

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

Table of Contents/Precautions on Safety

SECTION 1 SECTION 2 SECTION 3 SECTION 4 SECTION 5 SECTION 6

Product Outline

Installation and Connections/Wiring

Preparing for Communications

Reading from/Writing to ID Tags

Troubleshooting

SECTION 6

Appendix

CIDRW System

V640-HAM11 Amplifier Unit

V640-HS61 CIDRW Head

V700-L22 CIDRW Controller

V700-L11 Link Unit

User's Manual

INTRODUCTION

INTRODUCTION

Warranty, Limitations of Liability, Application Considerations Disclaimers

Read and Understand this Manual

Warranty, Limitations of Liability, Application Considerations Disclaimers

Please read and understand this manual before storing, installing, programming, operating, maintaining, or disposing of

the products. Please consult your OMRON representative if you have any questions or comments.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one

year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY

BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is

asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED,

STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR

INAPPROPRIATE MODIFICATION OR REPAIR.

CIDRW System

2222

User’s Manual

INTRODUCTION

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

the product in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the

suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be

an exhaustive list of all possible uses of the p rodu cts, nor is it intended to im pl y th at the uses listed may be suit able for the

products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not

described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property.

INTRODUCTION

Warranty, Limitations of Liability, Application Considerations Disclaimers

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

CIDRW System

User’s Manual

3333

INTRODUCTION

INTRODUCTION

Warranty, Limitations of Liability, Application Considerations Disclaimers

PERFORMANCE DATA

Warranty, Limitations of Liability, Application Considerations Disclaimers

Performance data g ive n in this manual is provided as a guide for the use r in de term in ing suitability and d oes n ot c on sti tut e

a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual pe rformance i s subject to th e OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant

construction chang es are ma de . However, some spe cif ic atio ns of the product may be changed withou t any notice. When

in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your

request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased

product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are

shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical, or proofreading errors, or omissions.

CIDRW System

4444

User’s Manual

Applicable Standards

E4E6CYCIDV6400304

DonotremovetheferritecoreonthecableoftheCIDRWhead.

INTRODUCTION

INTRODUCTION

1. FCC Rules (Feder al Communications Comm ission)

This device complies with Part 15 Subpart C of the FCC Rules.

FCC ID: E4E6CYCID6400202

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device m us t a cc ep t a n y i nter fe re nc e r ec ei ved, including interfe renc e that may cause u nde si r ed ope r-

ation.

FCC NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limi ts are designed to provide reasonable prot ection against

harmful interference in a residential installation.

This equipment gen er ate s, us es and c an rad ia te r ad io fr equ enc y ene rgy and, if not installed and used

in accordance with the inst ructions, may cause harmful interfer ence to radio communications. However, there is no guarantee that interference wi ll not occu r in a particular in stallation. If this equipment

does cause harmfu l interference to r adio or television reception, which c an be determined b y turning

the equipment off and on, the user is en couraged to try to correct the interference by one or more of

the following measures:

Precautions for Safe Use

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC WARNING

Changes or modifica tions not expre ssly approved by th e party responsible for compliance cou ld void

the user's authority to operate the equipment.

Properly shielded and grounded cables and connectors must be used for connection to host

computer and/or peripherals in order to meet FCC emission limits.

CAUTION

This device must be professionally installed.

This CIDRW Head [Model: V640-HS61 (-X)] is dedicated to Amplifier Unit [Model: V640-HAM11 (-X)].

CIDRW System

User’s Manual

5

Applicable SEMI Standards

INTRODUCTION

INTRODUCTION

This CIDRW system complies with the following standards.

• SEMI E99 THE CARRIER ID READER/WRITER FUNCTIONAL STANDARD

• SEMI E5 EQUIPMENT COMMUNICATION STANDARD 2 MESSAGE CONTENT (SECS II)

• SEMI E4 EQUIPMENT COMMUNICATION STANDARD 1 MESSAGE TRANSFER (SECS I)

SEMI is the acronym for Semiconductor Equipment and Materials International.

SECS is the acronym for SEMI Equipment Communications Standard.

Precautions for Safe Use

CIDRW System

User’s Manual

7

INTRODUCTION

INTRODUCTION

Precautions for Safe Use

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

• Do not insert water or wires through gaps in the case. This could cause fire or electric shock.

• In the event of a malfunction, stop using the product immediately, turn off the power, and consult your

OMRON dealer.

• Dispose of this product as industrial waste.

CIDRW System

8

User’s Manual

INTRODUCTION

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable effects on

product performance.

Installation Site

Install the product at a location where:

• It is not exposed to direct sunlight.

• It is not exposed to corrosive gases, dust, metal chips, or salt.

• The working temperature is within the range stipulated in the specifications.

• There are no sudden variations in temperature (no condensation).

• The relative humidity is within the range stipulated in the specifications.

• No vibration o r shock excee ding the values st ipulated in t he specification s is transmitted di rectly to

the body of the product.

• It is not subject to splashing water, oil, or chemical substances.

INTRODUCTION

Precautions for Safe Use

Mounting

• This product com munic ates with ID Tags using the 134 kHz freque ncy band . No te that som e tran sceivers, motors, mo nitoring equipment, and power supplies (power supply ICs) generate electrical

waves (noise) that in terfere with communica tions with ID Tags. If you are using the product in the

vicinity of any of these devices, check the effect on communications in advance.

• In order to minimize the effects of noise, ground nearby metal bodies with a grounding resistance not

exceeding 100 ohms.

• When mounting Amplifier Units, tighten the screws with a torque no greater than 1.2 N·m.

• When mounting CIDRW Heads, tighten the screws with a torque no greater than 0.6 N·m.

• When multiple CIDRW Heads are mo unted next to each other, communications pe rformance could

be impaired by mutual interference. Note the information in this manual on mutual interference when

installing multiple heads.

Refer to page 115.

CIDRW System

User’s Manual

9

INTRODUCTION

INTRODUCTION

Power and Ground Cables

• Use the power supply voltage specified in this manual.

Precautions for Safe Use

• Ensure correct polarity when connecting to the +/- power supply terminals.

• The ground terminals must be connected to a ground with a grounding resistance not exceeding 100

ohms.

Wiring Work

• Always turn the power off before starting wiring work or connecting/disconnecting cables.

• Do not run high-voltage lines and power lines though the same conduit.

• To prevent damage by s tatic electricity, wear a wrist strap or eq uivalent, and take measures to prevent charging, before touching terminal components or parts inside connectors.

Screw Locking Adhesive

• Screw locking adhesive (screw lock) may cause deterioration and cracking of resin parts: do not use

it for screws in resin parts or anywhere where resin washers are used.

Cleaning

• Do not use organic solvents such as thinner or benzene.

10

CIDRW System

User’s Manual

Editor’s Note

INTRODUCTION

INTRODUCTION

Visual Aids

Indicates an explanation of a point that must be observed to ensure that the product is capable of its proper functions and performance. Read this information carefully and follow the cautions: if the product is used incorrectly, data or the equipment itself

could be destroyed.

Indicates summaries of points of particular importance relating to product performance, e.g. points to note during operation and

advice on how to use the product.

Indicates the number of a page where related information can be found.

Indicates information for reference when you encounter a problem.

Indicator Statuses

Precautions for Safe Use

The following symbol s are used to show the status of the indi cators on the CIDRW Controller and Amplifier

Units.

OFF

Flashing

ON

CIDRW System

User’s Manual

11

INTRODUCTION

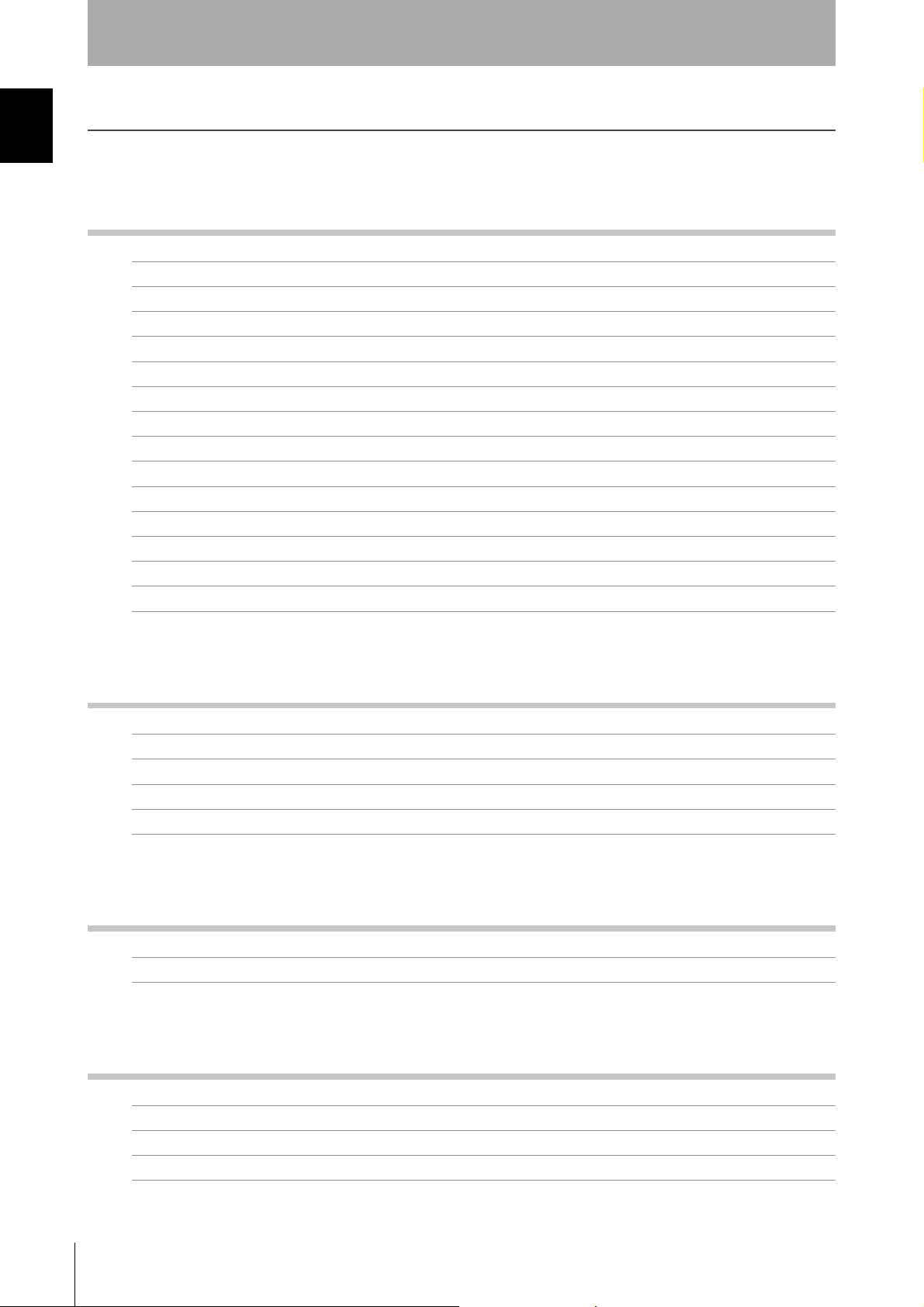

Table of Contens

INTRODUCTION

Table of Contents

Table of Contents

Introduction 3

Read and Understand this Manual 2

WARRANTY 2

LIMITATIONS OF LIABILITY 2

SUITABILITY FOR USE 3

PROGRAMMABLE PRODUCTS 3

PERFORMANCE DATA 4

CHANGE IN SPECIFICATIONS 4

DIMENSIONS AND WEIGHTS 4

ERRORS AND OMISSIONS 4

Applicable Standards 5

Applicable SEMI Standards 7

Precautions for Safe Use 8

Precautions for Correct Use 9

Editor’s Note 11

Table of Contents 12

SECTION 1 Product Outline 15

What is a C IDRW System? 16

Features 17

System Configuration 18

Component Names and Functi on s 19

Flowchart for Getting Started 23

SECTION 2 Installation and Connections/Wiring 25

Installation 26

Connections and Wiring 31

SECTION 3 Preparing for Communications 47

Set the Communications Conditions for the CIDRW Controller 48

Set the Communications Conditions for Amplifier Units 61

Set the Communications Conditions for Link Units 63

Communications Test 65

12

CIDRW System

User’s Manual

INTRODUCTION

Table of Contents

SECTION 4 Reading from/Writing to ID Tags 69

When SECS is Used 70

When SECS is Not Used 81

SECTION 5 Troubleshooting 91

When SECS is Used 92

When SECS is Not Used 98

SECTION 6 Appendix 103

Specifications and Dimensions 104

System Configuration Examples 108

Characteristic Data depending on Conditions of Use 110

Data Segment Area 122

Regular Inspection 123

SECS Protocol Specifications 124

ASCII Code Table 129

Protective Construction 130

Revision Histor y 134

INTRODUCTION

Table of Contents

CIDRW System

User’s Maual

13

INTRODUCTION

Table of Contens

INTRODUCTION

Table of Contents

MEMO

14

CIDRW System

User’s Manual

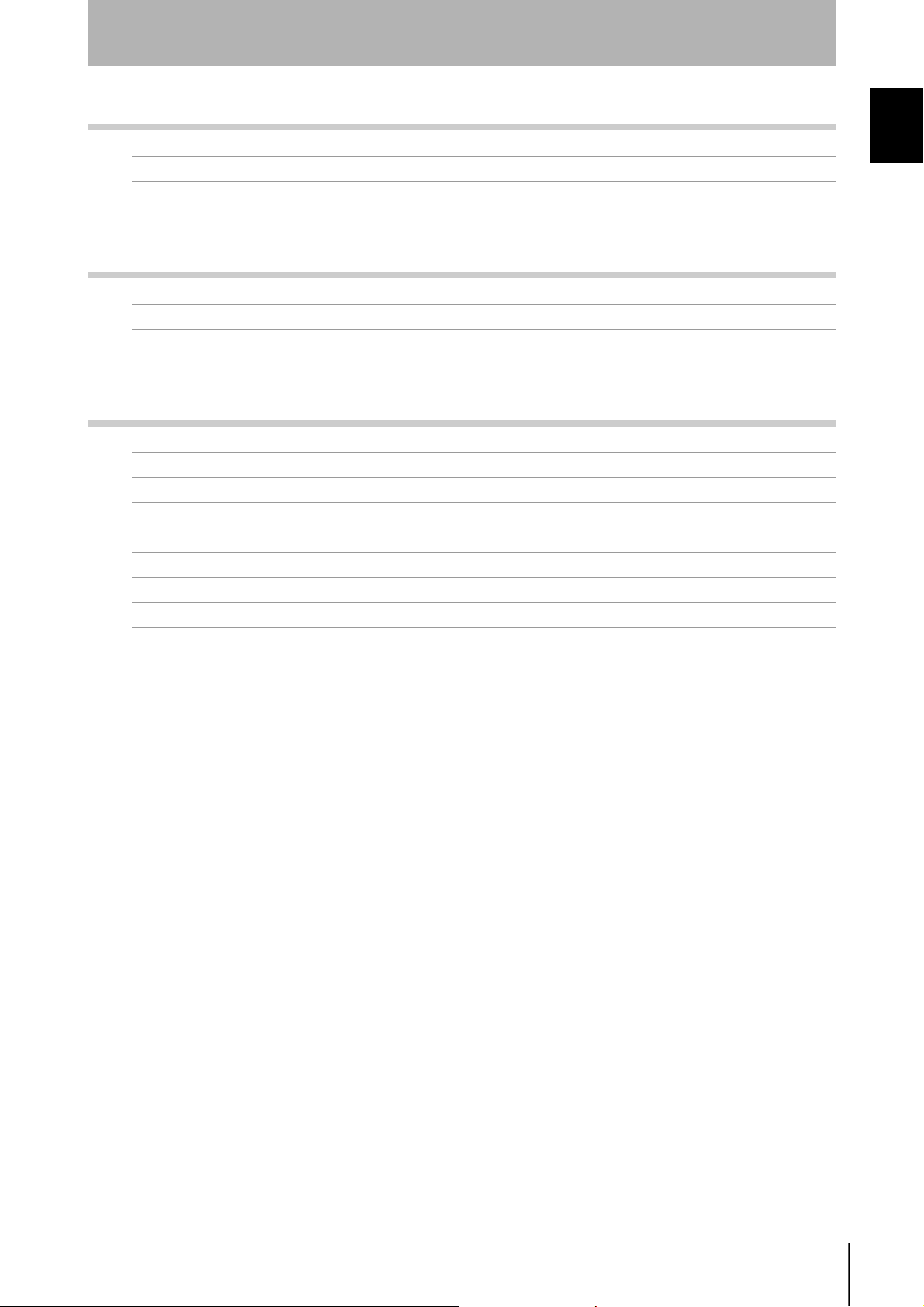

SECTION 1

Product Outline

What is a CIDRW System? 16

Features 17

System Configuration 18

SECTION 1

Product Outline

Component Names and Functions 19

Flowchart for Getting Started 23

CIDRW System

User’s Manual

15

SECTION 1

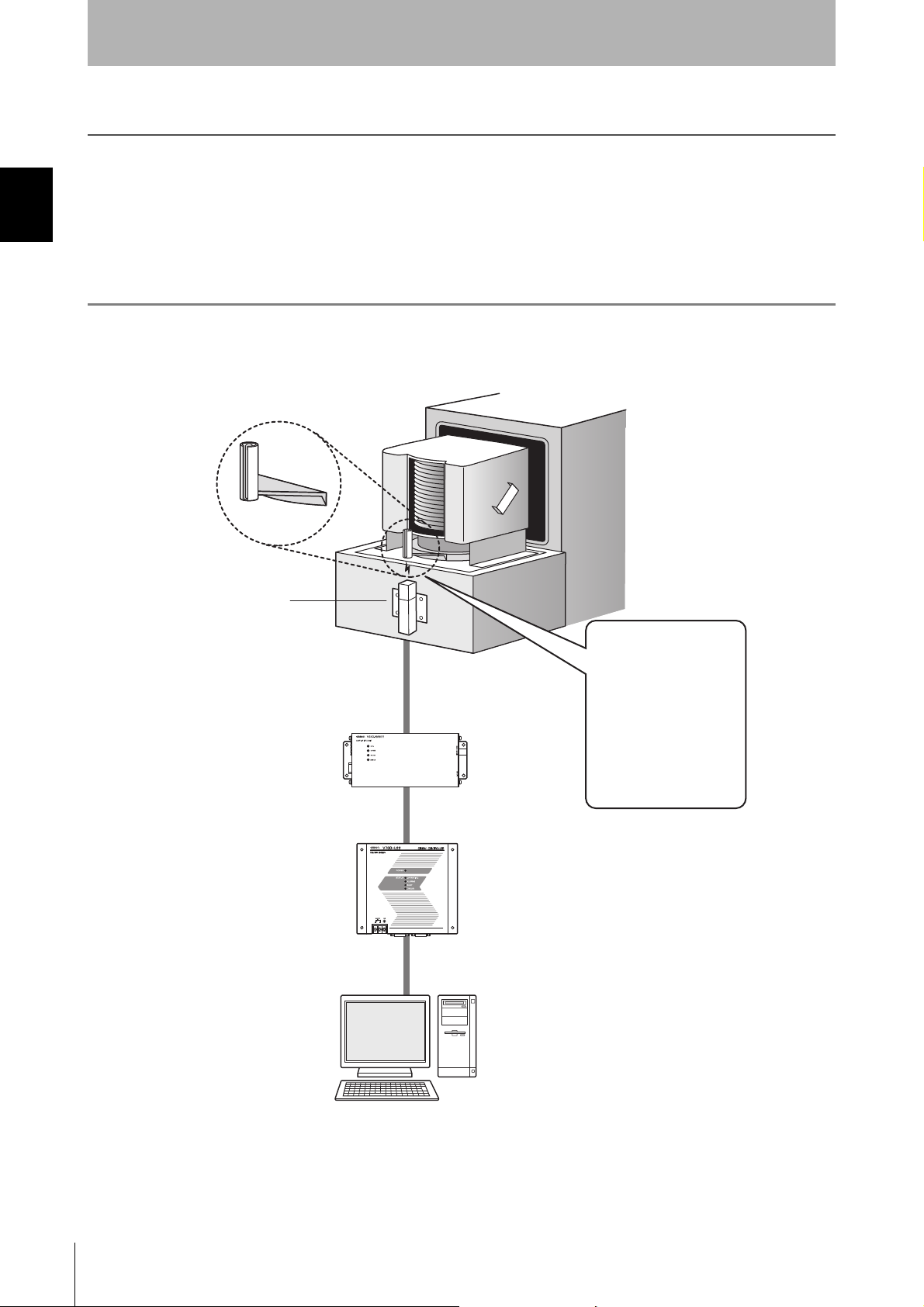

Product Outline

What is a CIDRW System?

SECTION 1

The CIDRW system writes data to, an d reads data from, the carrier IDs (ID Tags) mounted on the carriers

(FOUP) in semiconductor manufacturing processes without contacting these ID Tags. CIDRW is the

abbreviation of "Carrier ID Reader/Writer" and this abbreviation is used throughout this manual.

Reading and writing information such as models, process instructions, lots, and inspection results to and from

What is a CIDRW System?

ID Tags makes it possible to manage work instruction information from a host device.

Example: Management of information in semiconductor and wafer manufacturing processes

ID Tag

(holder is separate)

CIDRW Head

Amplifier Unit

CIDRW Controller

Host

Reading and writing

information

• Model information

• Process instruction

information

• Completion

information

• Lot information

• Inspection resu lts

Etc.

16

CIDRW System

User’s Manual

Features

SECTION 1

Product Outline

CIDRW Systems that Conform to SEMI Standards (SEMI E99, E5, E4)

CIDRW System Conforming to SEMI Standards

CIDRW Controller

Host

SECS I/II

RS-232C

List of Applicable Standards

• SEMI E99 THE CARRIER ID READER/WRITER FUNCTIONAL STANDARD

• SEMI E5 EQUIPMENT COMMUNICATION STANDARD 2 MESSAGE CONTENT (SECS II)

• SEMI E4 EQUIPMENT COMMUNICATION STANDARD 1 MESSAGE TRANSFER (SECS I)

SEMI is the acronym for Semiconductor Equipment and Materials International.

SECS is the acronym for SEMI Equipment Communications Standard.

V700-L22

RS-232C

Amplifier Unit

V640-HAM11

CIDRW Head

V640-HS61

ID Tag

RI-TRP-DR2B

(Made by Texas

Instruments)

SECTION 1

Features

CIDRW System

User’s Maual

17

SECTION 1

Product Outline

System Configuration

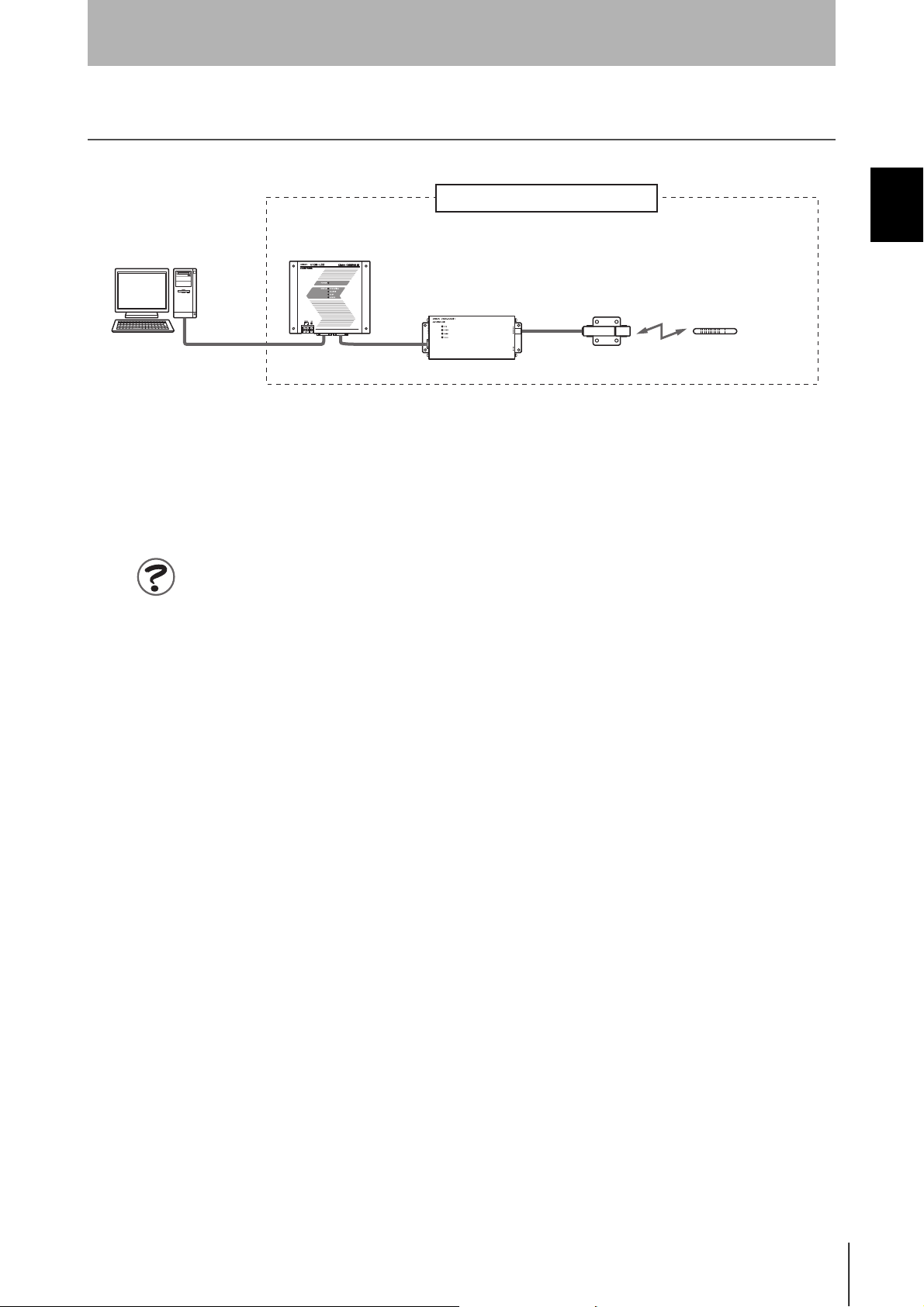

SECTION 1

System Configuration

When SECS is Used

Communication with the host device is possible using the SECS protocol.

CIDRW Controller

Host

RS-232C

SECS I/II

This is e.g. a host,

or equipment controller.

V700-L22

RS-232C

Multiple Amplifier Units

are controlled in

response to commands

(SECS) from the host

device.

Amplifier Unit

V640-HAM11

These are units that

control a CIDRW Head.

CIDRW Head

V640-HS61

These are antennae for

reading the carrier IDs

from the ID Tags and

writing the carrier IDs.

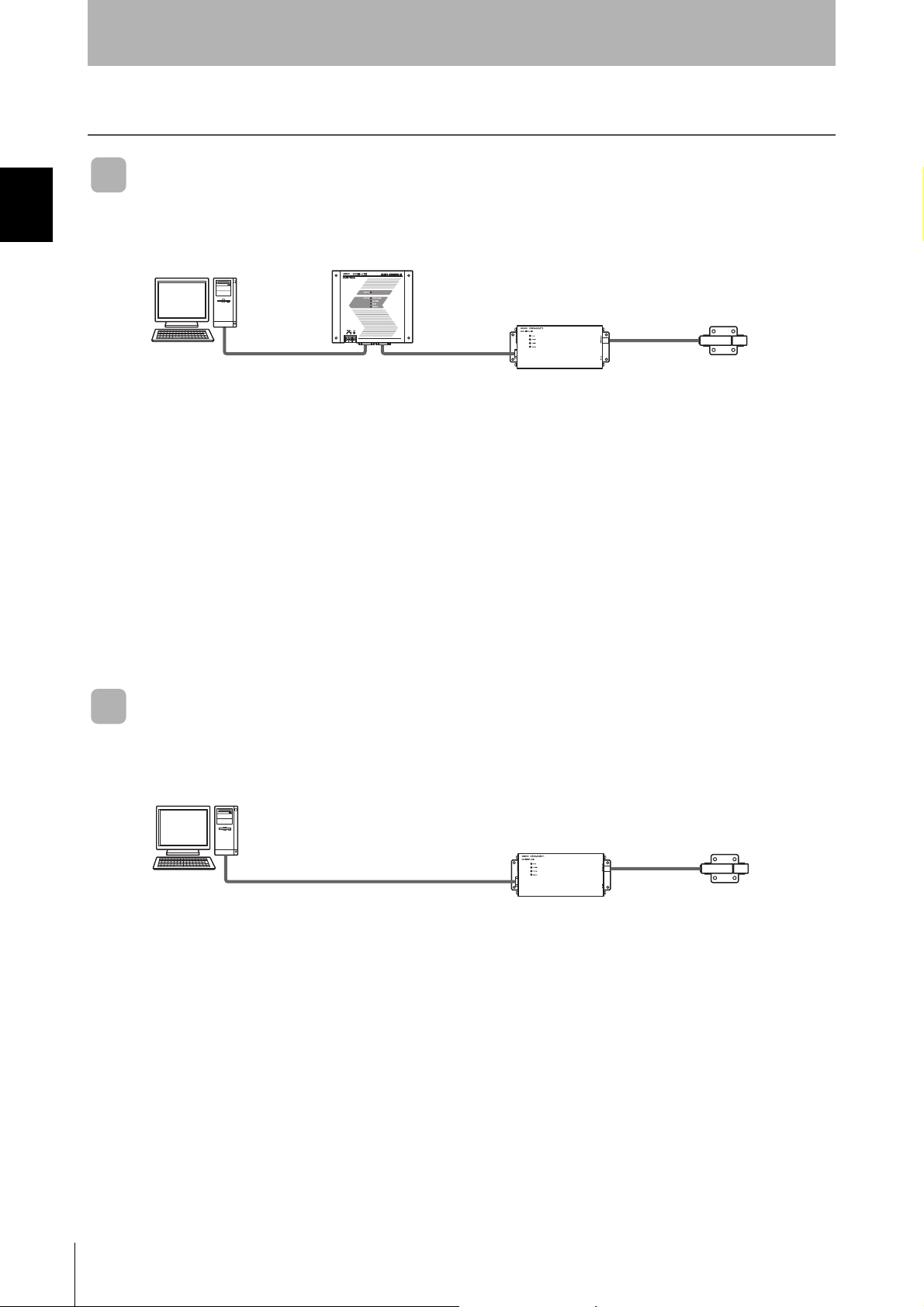

When SECS is Not Used

Communications with the host device follow the OMRON proprietary protocol.

The Amplifier Units are connected directly to the host device without using a CIDRW Controller.

Host

CIDRW Head

V640-HS61

These are antennae for

reading the carrier IDs

from the ID Tags and

writing the carrier IDs.

This is e.g. a host,

or equipment controller.

RS-232C

OMRON proprietary

Amplifier Unit

V640-HAM11

protocol

These are units that

control a CIDRW Head.

18

CIDRW System

User’s Manual

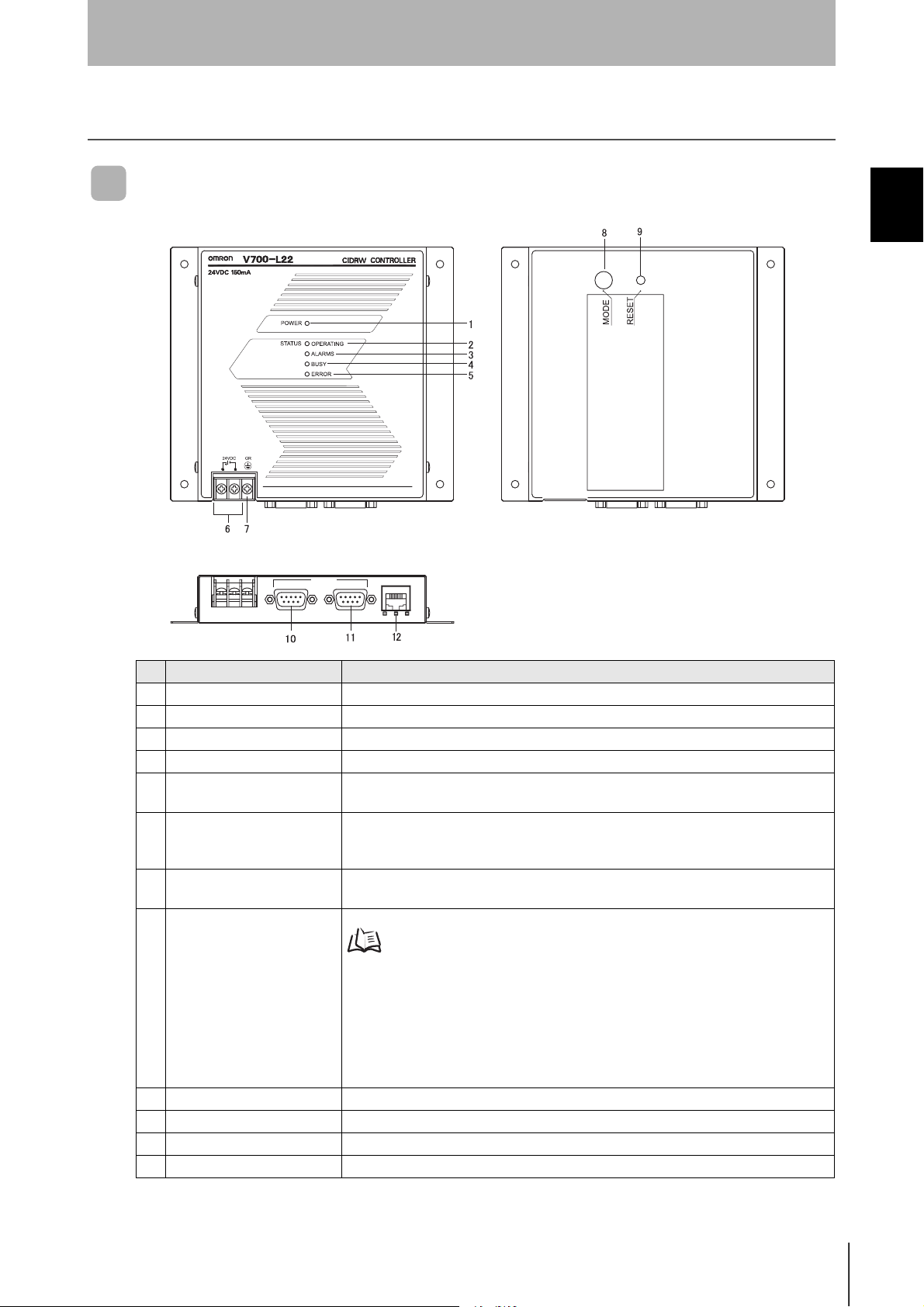

Component Names and Functions

CIDRW Controller V700-L22

SECTION 1

Product Outline

SECTION 1

Component Names and Functions

45%

5'%5 +&

No. Name Function

1 Power indicator (green) An LED that indicates whether the power is ON or OFF . Lit while the power is ON.

2 OPERATING indicator (green) Lit while the CIDRW system status model is operating.

3 ALARMS indicator (green) Lit when the status of "AlamStatus" of the CIDRW system is "Alarm (1)."

4 BUSY indicator (green) Lit when the status of "OparationalStatus" of the CIDRW system is "BUSY."

5 ERROR indicator (red) When a processing error is detected (when SSACK is other than "NO"), this indicator is

6 24 VDC power supply termi-

nals

(with cover)

7 Frame ground terminal

(with cover)

8 MODE switch Used to select the mode of operation.

/#+06'0#00%'

lit for 50 ms.

Connect to the 24 VDC power supply.

The grounding wire is connected here. (Ground to 100 Ω or less)

Refer to page 48.

0 : Normal Operation mode. When mounting the Controller, set the switch to this posi-

tion.

3 : Setting mode, selected to set information such as the communication conditions.

When the switch on the bottom face of the Controller cannot be accessed, the operation mode can be changed from the host device while the switch is left at the "0" setting.

1 - 2, 4 - 7 :

9 RESET switch Restarts the CIDRW Controller.

10 SECS port Port for connecting the host device. Conforms to SECS I/II.

11 ID port An Amplifier Unit or Link Unit is connected here.

12 Maintenance port (with cover) Not used. Do not remove the cover.

Setting prohibited

CIDRW System

User’s Maual

19

SECTION 1

Product Outline

SECTION 1

Component Names and Functions

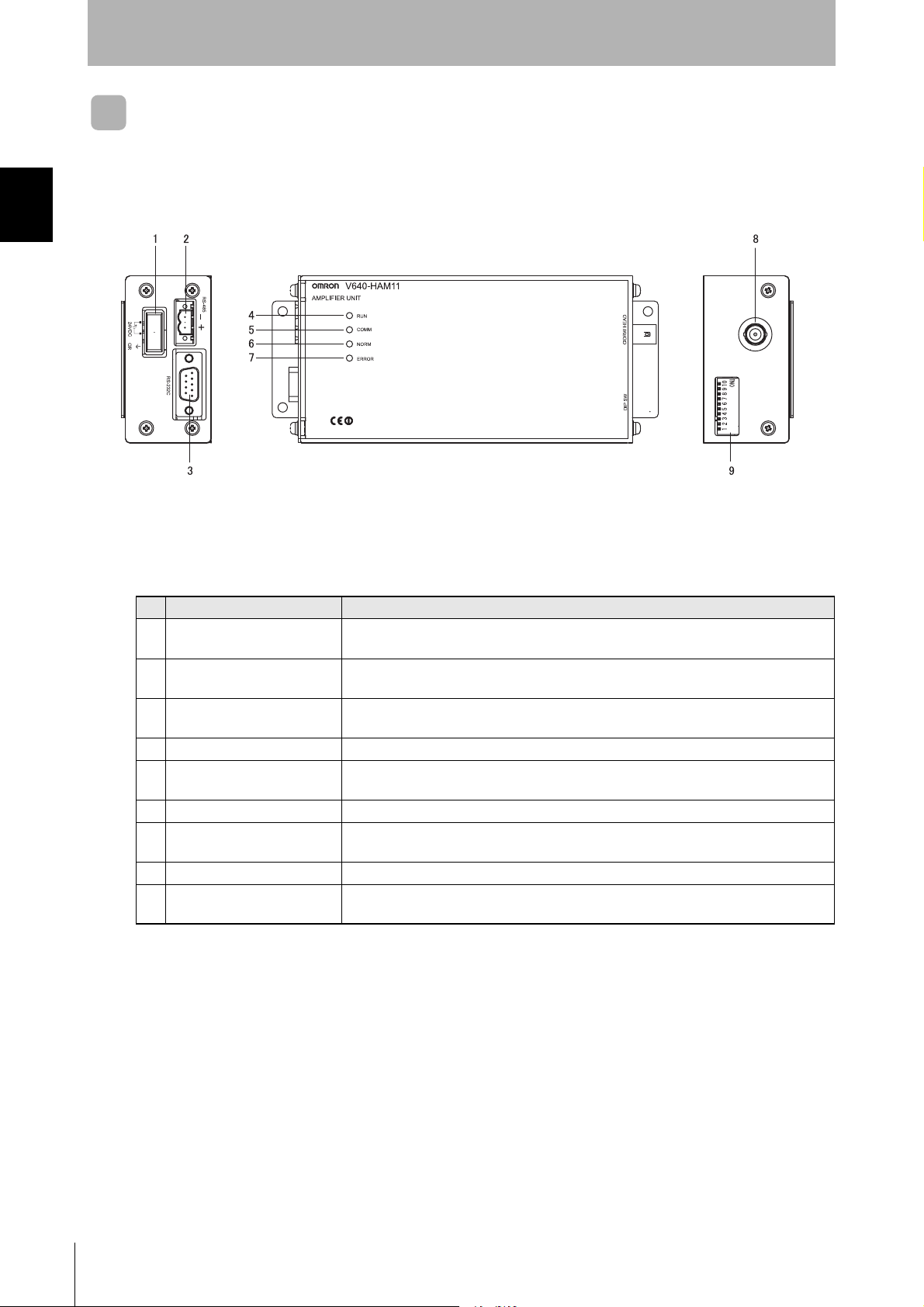

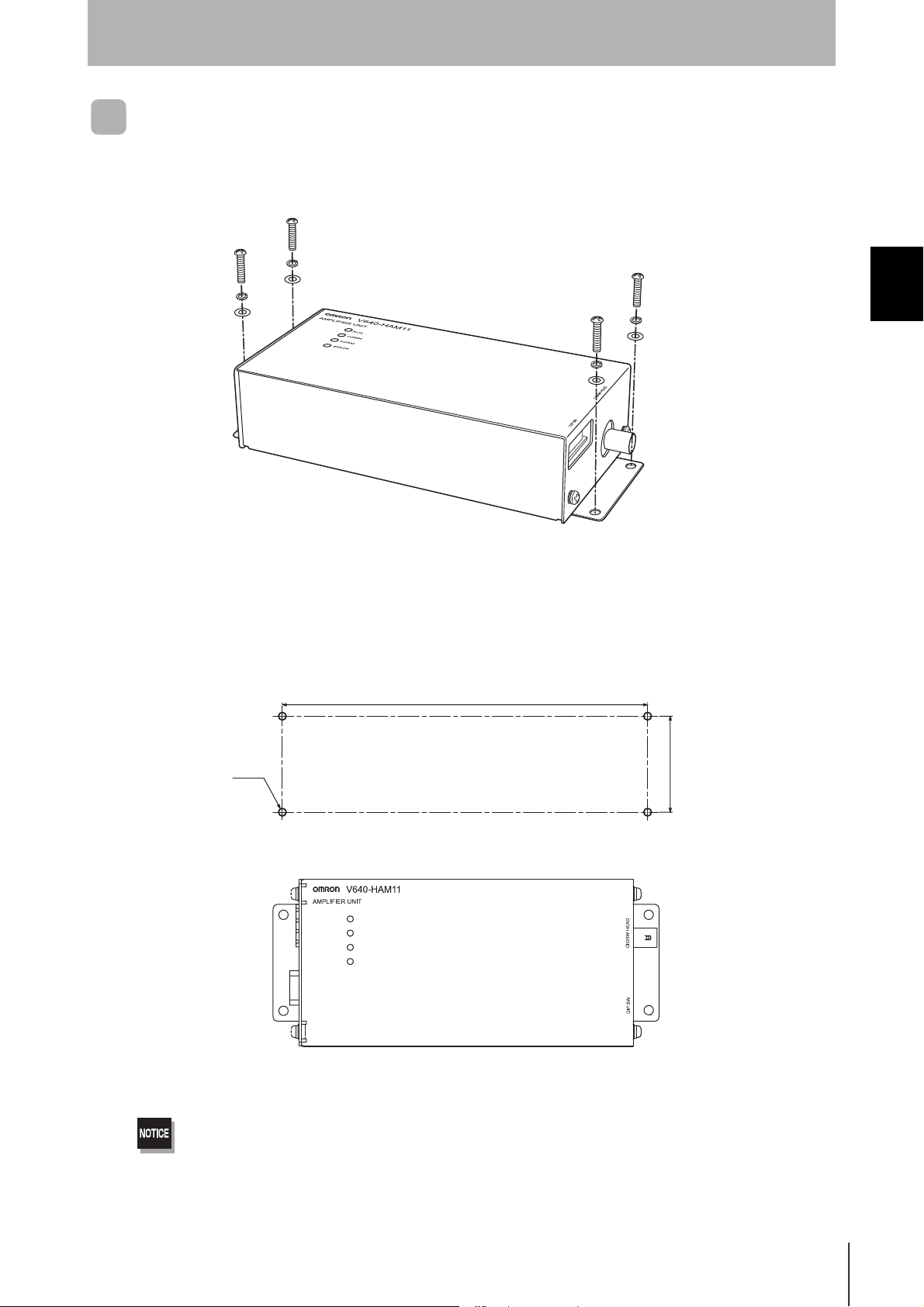

Amplifier Unit V640-HAM11

No. Name Function

1 Dedicated power supply con-

nector

2 RS-485 port When using multiple CIDRW Heads, connect this to the RS-485 port of another Amplifier

3 RS-232C port Connected to a CIDRW Controller or a host device.

4 RUN indicator (green) Turns ON when the Amplifier Unit is in normal operation.

5 COMM indicator (yellow) Turns ON during communications with the host device or during communications with an

6 NORM indicator (green) Turns ON when the communications finish with no error.

7 ERROR indicator (red) Turns ON when an error occurs during communication with the host device, or during

8 CIDRW Head connection port A CIDRW Head is connected here.

9 Setting DIP switches Used to set the node number, the communications conditions, and the RS-485 terminal

Connect to the 24 VDC power supply.

Unit or to the multi-connection port of a Link Unit.

Uses the OMRON proprietary communications protocol.

ID Tag.

communication with an ID Tag.

resistance.

20

CIDRW System

User’s Manual

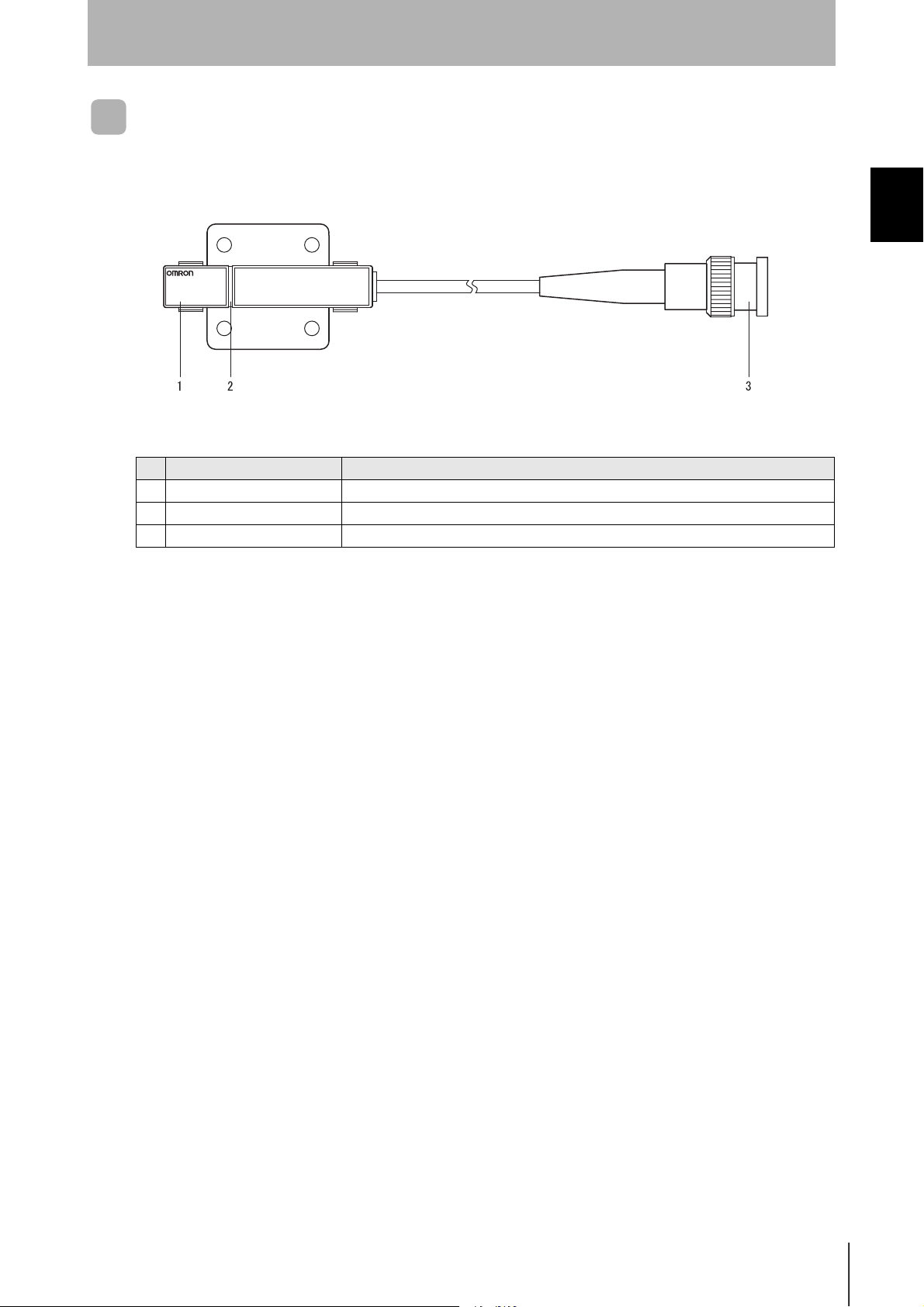

CIDRW Head V640-HS61

V640-HS61

CIDRW HEAD

No. Name Function

1 Antenna Used to communicate with ID Tags.

2 Antenna center This is the center of the communications area.

3 Connector Connect to an Amplifier Unit.

SECTION 1

Product Outline

SECTION 1

Component Names and Functions

CIDRW System

User’s Maual

21

SECTION 1

Product Outline

SECTION 1

Component Names and Functions

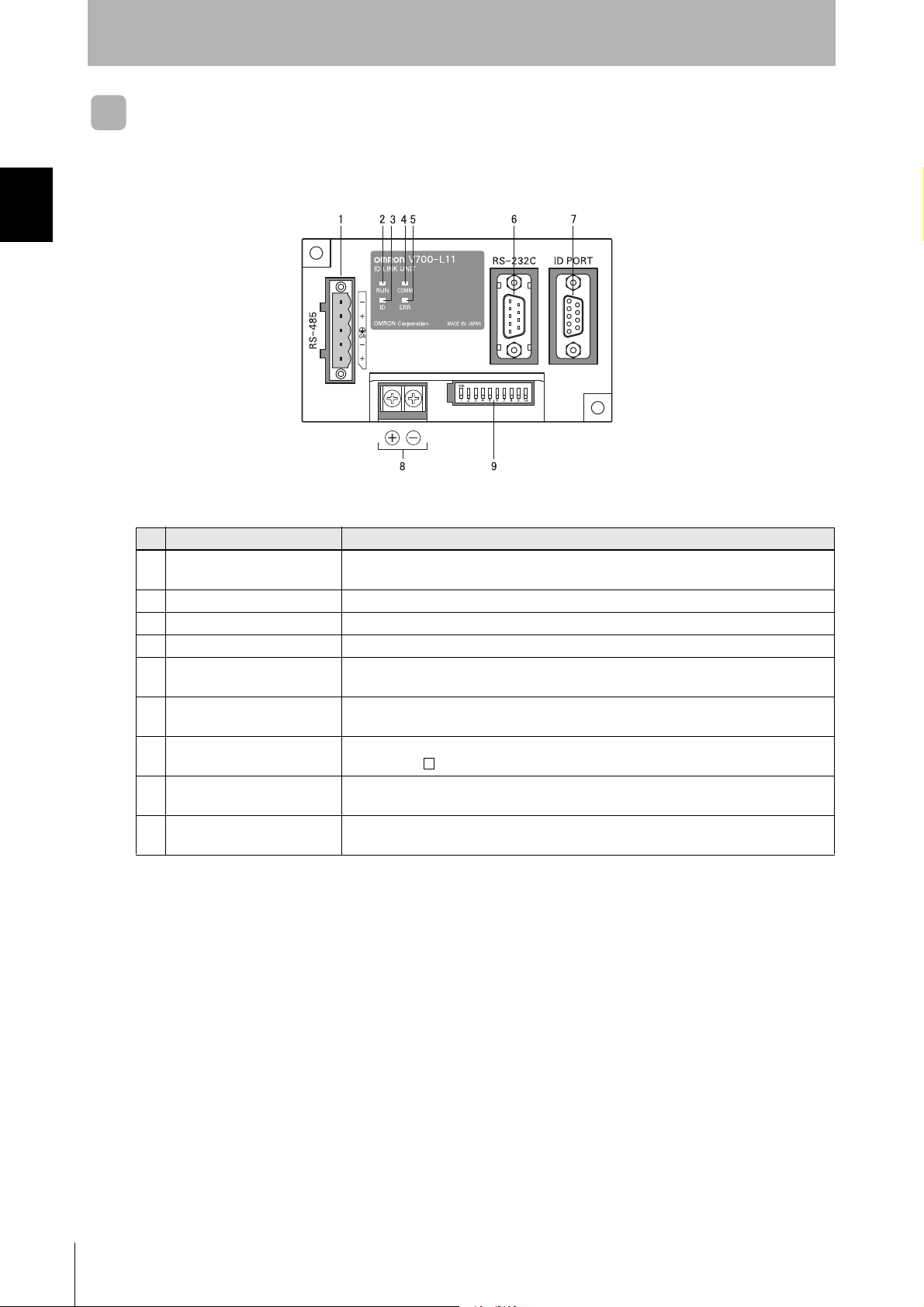

Link unit V700-L11

No. Name Function

1 Multi-connection port

(RS-485)

2 RUN indicator (green) Turns ON while the Link Unit is in normal operation.

3 ID indicator (green) Turns ON during data communications with a V700 series IDRW Head.

4 COMM indicator (green) Turns ON during data communications with the host device.

5 ERR indicator (red) Turns ON when an error occurs during data communications with the host device or

6 Host device connection port

(RS-232C)

7 ID connection port This is a dedicated port for connecting a V700 series IDRW Head. Connect either a

8 24 V power supply terminals

(inside the cover)

9 Setting DIP switches

(inside the cover)

This is the port that connects to the Amplifier Units when multiple CIDRW Heads are

connected to a CIDRW Controller. The GR (frame ground) terminal is also at this port.

head.

This is a port for connecting to the CIDRW Controller via an RS-232C interface. A dust

cover is fitted on shipment from the factory. Remove this cover before using the port.

V700-HMD13 or V700-HMD11-1 IDRW Head.

Connect to the 24 VDC power supply.

Used to set the equipment number, the communications conditions, and the RS-485 terminal resistance.

22

CIDRW System

User’s Manual

Flowchart for Getting Started

SECTION 1

Product Outline

SECTION 1

Installation

Refer to page 26.

Connection and Wiring

Refer to page 31.

Set the Communications Conditions for the CIDRW Controller

Refer to page 48.

Set the Communications Conditions for Amplifier Units

Refer to page 61.

Flowchart for Getting Started

Preparation for Communicatio nsTrial Operation Installation and Connections

Set the Communications Conditions for Link Units

Refer to page 63.

Test for Communications with the Host Device

Refer to page 65.

ID Tag <-> CIDRW System Communications Test

Refer to page 66.

Check the Surrounding Environment

Refer to page 28.

CIDRW System

User’s Maual

23

SECTION 1

Product Outline

SECTION 1

Flowchart for Getting Started

Communications

When SECS is Used

Refer to page 70.

When SECS is Not Used

Refer to page 81.

When you Encounter a Problem...

When SECS is Used

Refer to page 92. List of Error Messages

Refer to page 92. Controller Indicators

Refer to page 93. Operation Check Flowchart

When SECS is Not Used

Refer to page 98. List of Error Messages

Refer to page 98. Amplifier Unit Indicators

Refer to page 99. Operation Check Flowchart

24

CIDRW System

User’s Manual

SECTION 2

Installation and Connections/Wiring

Installation 26

Connections and Wiring 31

SECTION 2

Installation and Connections/Wiring

CIDRW System

User’s Maual

25

SECTION 2

SECTION 2

Installation and Connections/Wiring

Installation

CIDRW Controller

There is a switch for selecting the operation mode (Normal Operation mode <-> Setting mode) on the bottom face of the

CIDRW Controller. Set the communications conditions in the Setting mode (switch position 3) before mounting the

CIDRW Controller.

Refer to page 48.

Installation

Set the Controller to the Normal Operation mode (switch position 0) when mounting it.

Mount the CIDRW Controller with the resin washers and four M4 screws provided as accessories.

26

• Tighten the M4 screws with a torque not exceeding 1.2 N·m.

• Do not apply organic solvents used with screw locking agents at the locations where the screws are inserted.

CIDRW System

User’s Manual

Mounting dimensions

r

(Unit: mm)

/

r

SECTION 2

Installation and Connections/Wiring

Amplifier Unit

Use spring washers and flat washers with the four M4 screws when mounting the Amplifier Unit.

SECTION 2

Installation

Mounting dimensions

/

(Unit: mm)

r

r

RUN

COMM

NORM

ERROR

Tighten the M4 screws with a torque not exceeding 1.2 N·m.

CIDRW System

User’s Manual

27

SECTION 2

Installation

SECTION 2

Installation and Connections/Wiring

CIDRW Head

The area for communications with ID Tags varies substantially according to the installation orientations

and the background con dition s (metals, no ise, etc .). Check the comm unicati ons ar ea before de cidin g

the installation position.

For details on actual com munications dis tances, see Characte ristic Data dependin g on Conditions of

Use in Appendix.

Refer to page 109.

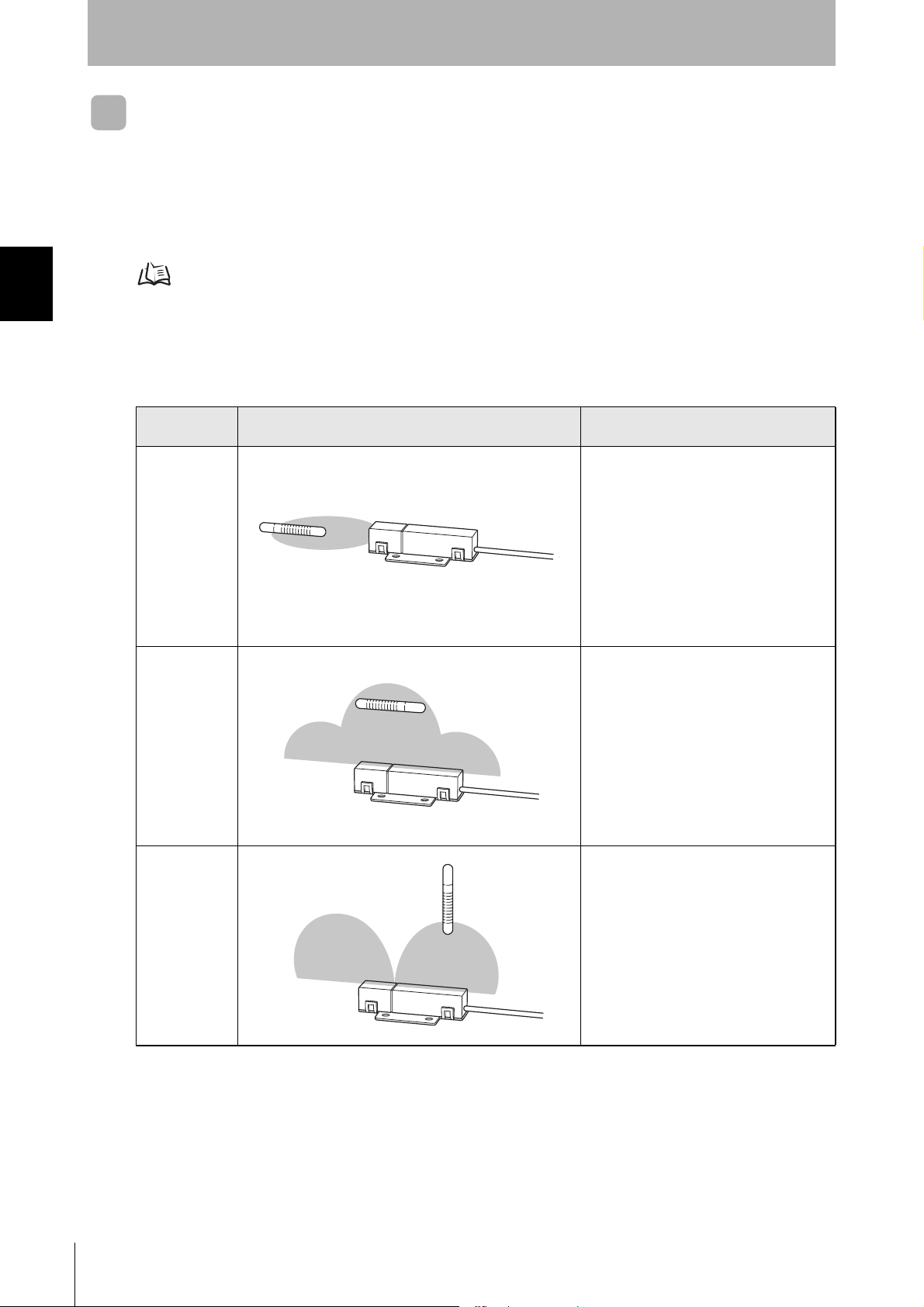

Positional Relationship between the CIDRW Head and the ID Tag

The communications area differs according to the positional relationship during communications.

Mounting

orientation

Coaxial The maximum communications area is

Parallel The maximum communications area is

Vertical When the center point of the antenna on the

Communications area (purely illustrative) Explanation

obtained when the centerlines of the CIDRW

Head and the ID Tag coincide.

obtained when the center point of the

antenna on the CIDRW Controller is aligned

with the centerline of the ID Tag.

CIDRW Head is aligned with the centerline of

the ID Tag, the communications area is substantially reduced.

28

Data Reading and Writing

The communicatio ns distances for reading and writ ing are not the same; the d istance is shorter for

writing. Therefore, when data is to be both r ead and writt en, take the distance for writing as the reference distance when installing the CIDRW Head and the ID Tag.

CIDRW System

User’s Manual

Installation and Connections/Wiring

Influence of Background Metal on ID Tag

Metals in the vicinity of the communications area will affect the range, making it smaller.

Refer to page 115.

SECTION 2

Influence of Noise

This CIDRW system uses a freque ncy of 134 kH z for communi cations wi th ID Tags. Equipment such

as switching power supplies, inverters, servomotors, or monitors in the surrounding area will adversely

affect communications, restricting the communications area.

The noise levels in the vicinity of the CIDRW Head can be determined with the environmental noise measurement command (applies only when SECS is not used). Refer to page 89.

For details on the relationship between noise and communications distance, see Appendix. Refer to page 121.

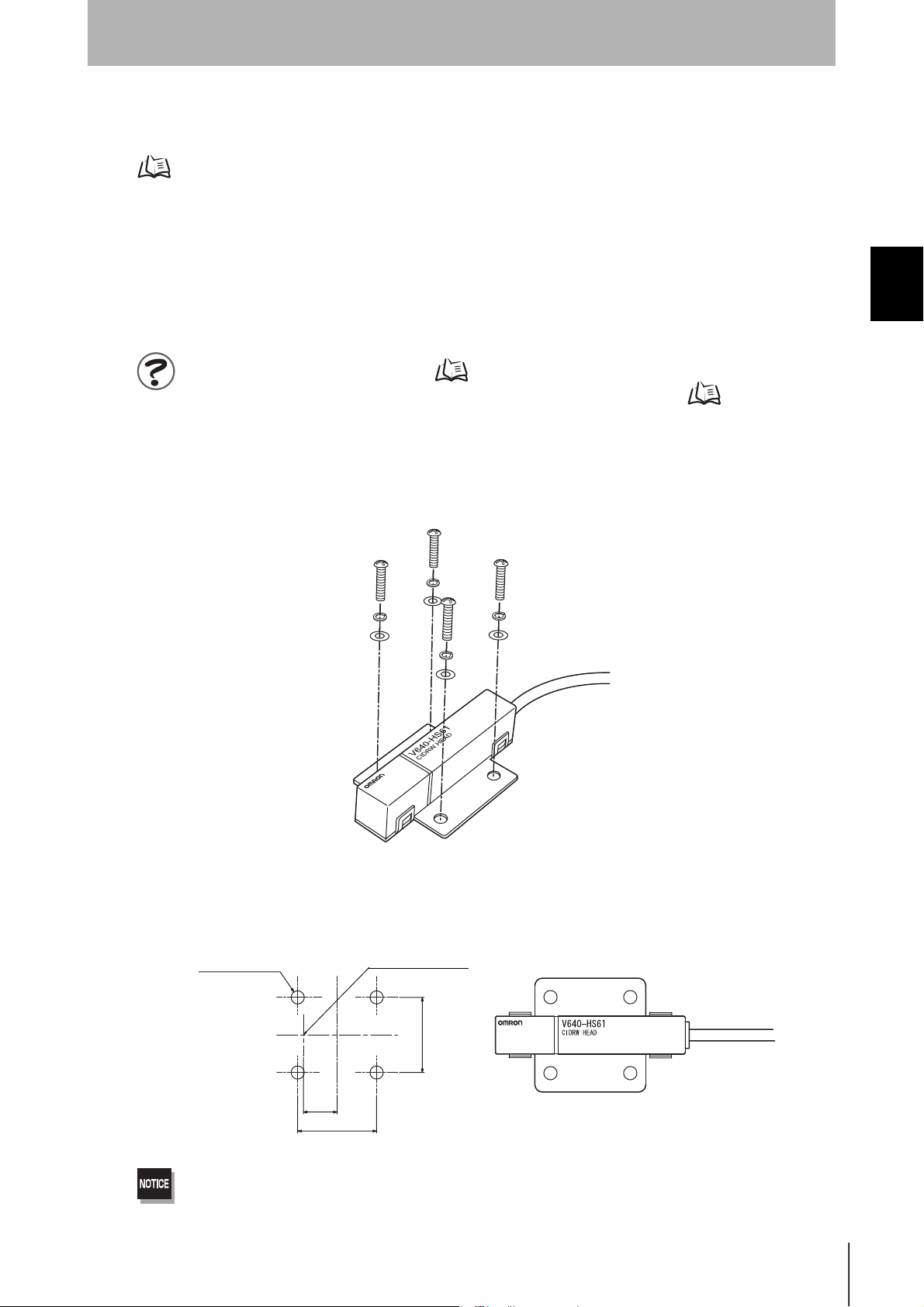

Mounting

Use spring washers and flat washers with the four M3 screws when mounting a CIDRW Head.

SECTION 2

Installation

Mounting dimensions

(Unit: mm)

/14Ǿ

r

Tighten the M3 screws with a torque not exceeding 0.6 N·m.

Be sure to install the Amplifier Unit in a panel or metal-shielded equipment.

Antenna center

r

CIDRW System

User’s Manual

29

SECTION 2

Installation

SECTION 2

Installation and Connections/Wiring

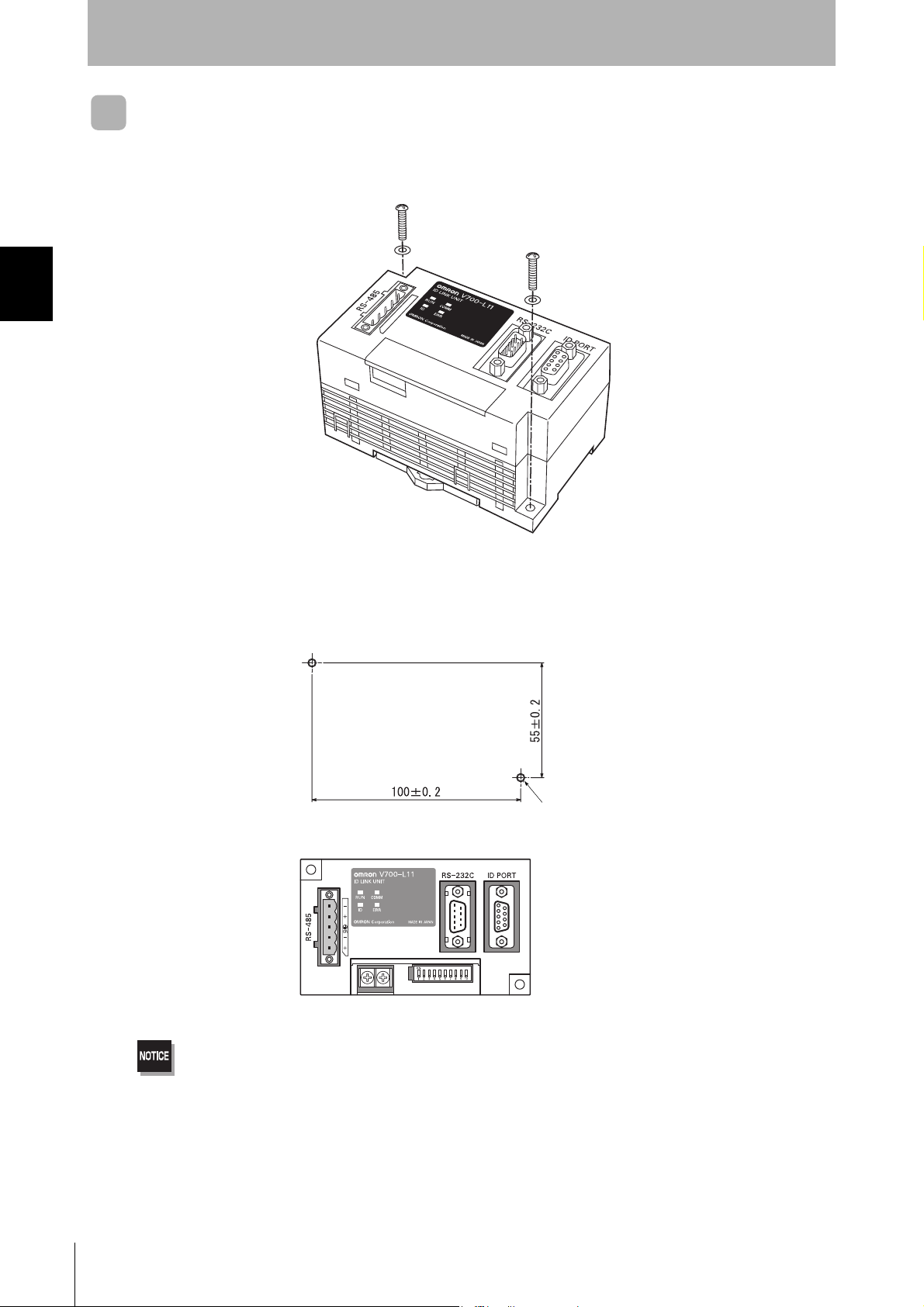

Link Unit

Mount Link Units with the two M4 screws and washers provided as accessories.

Mounting dimensions

(Unit: mm)

Two M4 or 4.2-dia. holes

• Tighten the M4 screws with a torque not exceeding 1.2 N·m.

• Do not apply organic solvents used with screw locking agents at the locations where the screws are inserted.

30

CIDRW System

User’s Manual

Connections and Wiring

CIDRW Controller

Power Supply and Grounding Wires

Connect the wires to the 24 VDC power supply terminals and frame ground terminal.

SECTION 2

Installation and Connections/Wiring

SECTION 2

Connections and Wiring

24 VDC

Ground to 100 Ω or less.

• Crimp terminals

The terminal screws on the terminal block are M3 size. Use appropriate crimp terminals for M3 screws

as shown below.

Crimp terminals

Shape Size

Forked

6 mm max.

Round

6 mm max.

• Power supply

Use a power supply unit that satisfies the following conditions.

Condition

Power supply voltage Output current

24 VDC +10%, -15% 500 mA DC min.

Recommended model

Manufacturer Model

OMRON S82K-01524

Be sure to replace the cover after wiring.

CIDRW System

User’s Manual

31

Loading...

Loading...