Omron 3G3RX-A2015-V1, 3G3RX-A2022-V1, 3G3RX-A2037-V1, 3G3RX-A2055-V1, 3G3RX-A2075-V1 User Manual

...Page 1

High-function General-purpose Inverter

RX Series Type V1

User’s Manual

I578-E1-01

3G3RX--V1

Page 2

OMRON, 2012

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON

is constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

Page 3

1

Introduction

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Introduction

Thank you for purchasing the High-function General-purpose Inverter (Model: 3G3RX--V1).

This manual describes the installation and wiring methods of the 3G3RX-V1 Series Inverter, and

parameter setting methods which are required for the operation, as well as troubleshooting and

inspection methods.

This manual is intended for the following individuals.

Those who have electrical knowledge (certified electricians or individuals who have equivalent

knowledge) and also are qualified for one of the following:

• Introducing control equipment

• Designing control system

• Installing and connecting control systems

• Managing control systems and facilities

This manual contains information you need to know to correctly use the High-functi on General- purpose

Inverter (Model: 3G3RX--V1).

Before using the inverter, read this manual and gain a full understanding of the information provided

herein.

After you finished reading this manual, keep it in a convenient place so that it can be referenced at any

time.

Make sure this manual is delivered to the end user.

Intended Readers

Notice

Page 4

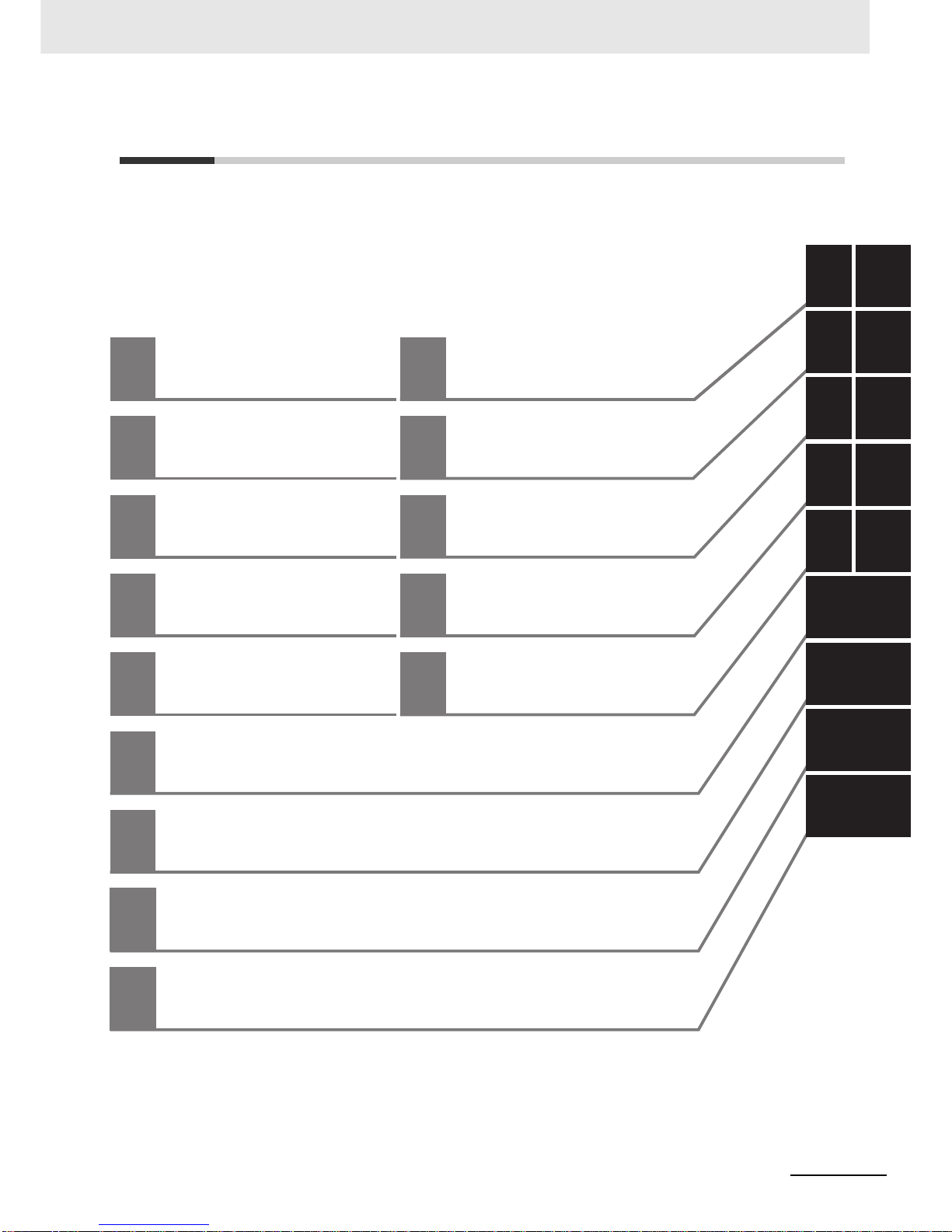

Manual Configuration

2

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Manual Configuration

This manual is compiled section by section for user’s convenience as follows.

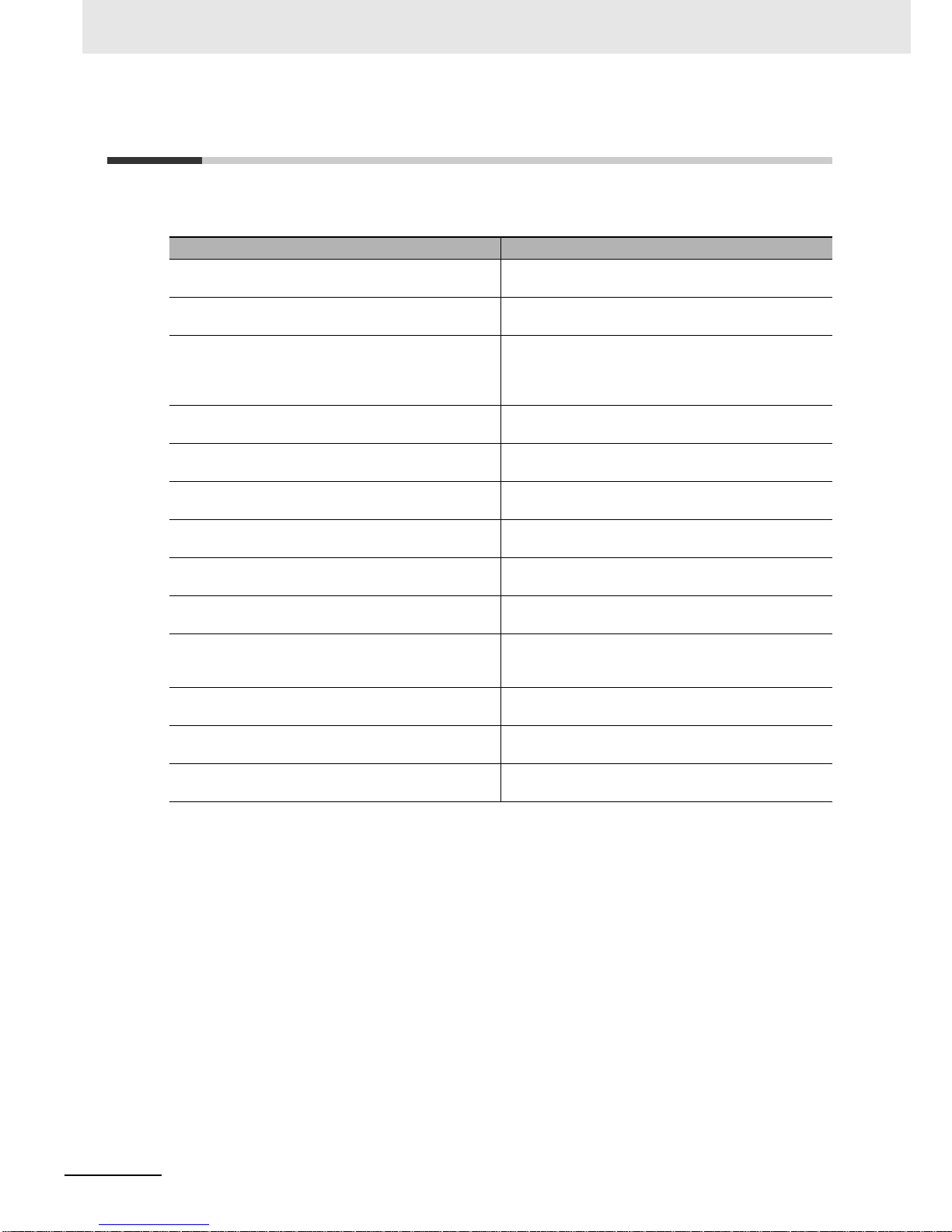

Section/Title Outline

Section 1 Overview

This section provides the features of this product,

specifications, external dimensions, and part names.

Section 2 Design

This section describes the installation and wiring

methods for this product.

Section 3 Operation and Test Run

This section describes the part names and key

operation of the Digital Operator, and the operation

method of this product as well as the test run

procedure.

Section 4 Parameter List

This section provides lists of parameters for setting

various functions of this product.

Section 5 Basic Settings

This section describes the basic functions, such as the

Run command.

Section 6 V ector Control

This section describes the applied functions, such as

vector control.

Section 7 Detailed Functions

This section describes the details of functions not

described in Section 5 or Section 6.

Section 8 Communications Func ti on s

This section describes the general-purpose serial

communications functions (RS-485 communication).

Section 9 Overview of DriveProgramming

This section describes the features of the

DriveProgramming.

Section 10 Troub le s h o oting

This section describes how to analyze the cause and

take countermeasures if the inverter fails, and provides

troubleshooting for possible troubles.

Section 11 Maintenance and Inspection

This section describes the maintenance and periodical

inspection items.

Section 12 Options

This section describes the specifications and external

dimension of peripheral equipment.

Appendices

This section provides information on the capacitor life

curve and the life alarm output.

Page 5

3

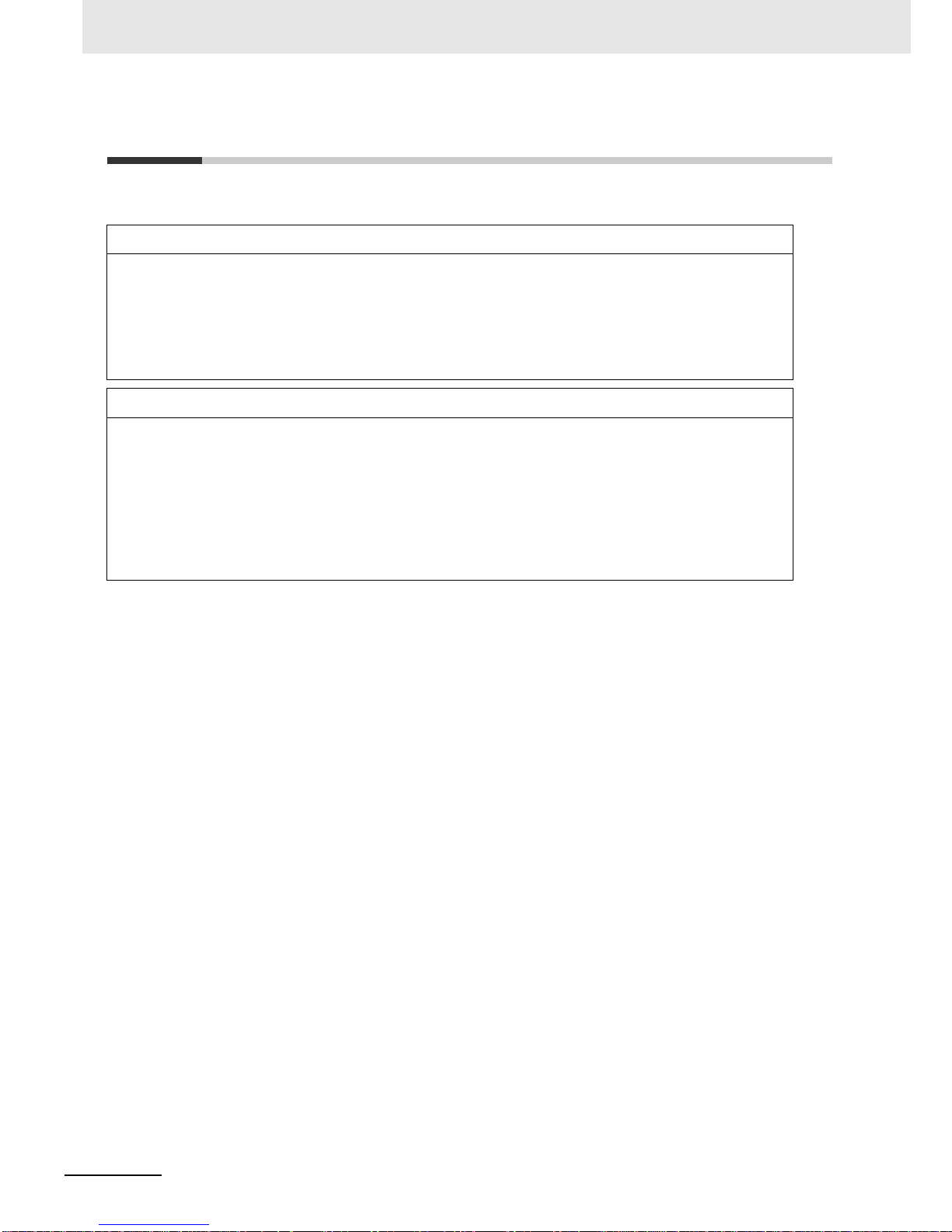

Manual Structure

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Manual Structure

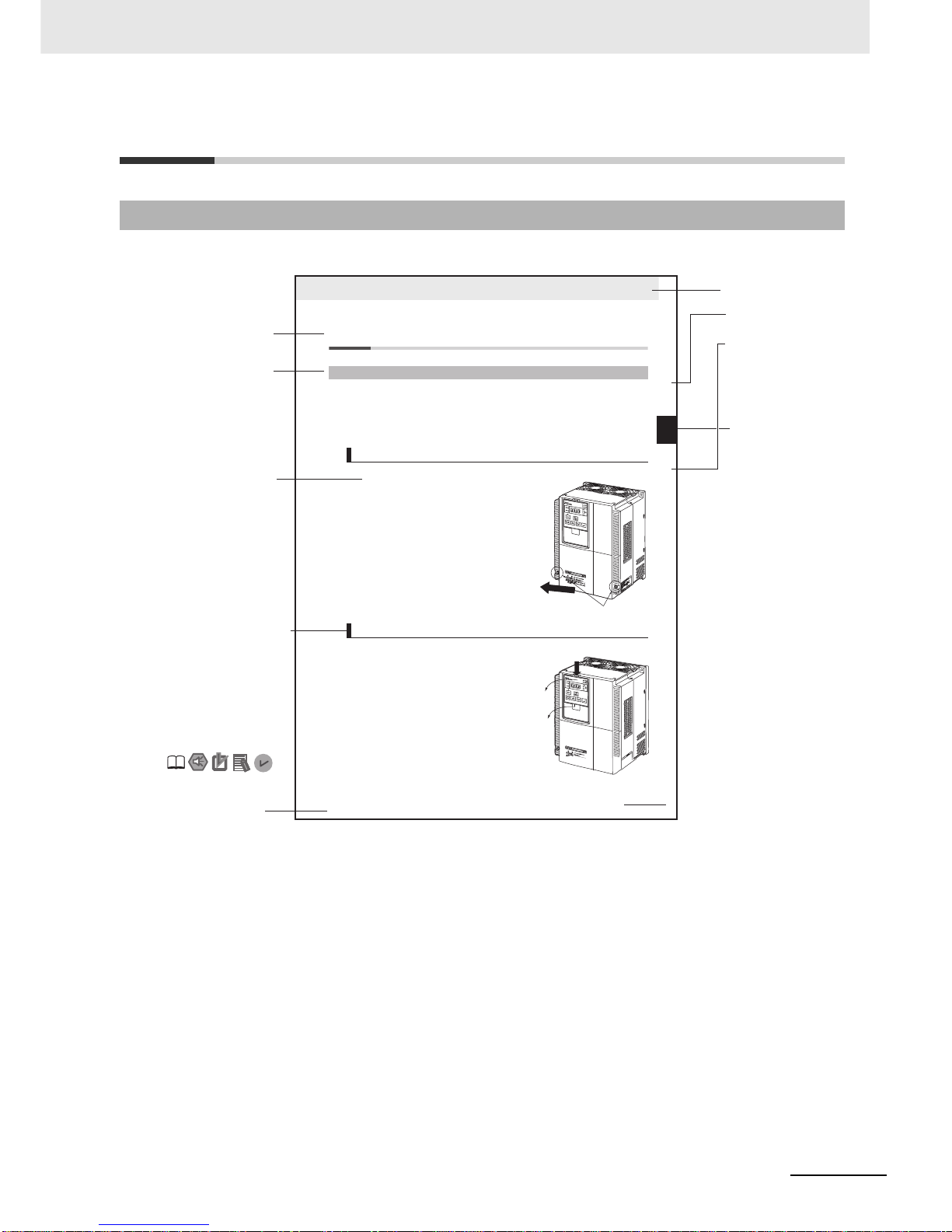

The following page structure and symbol icons are used in this manual.

Note The above page is only a sample for illustrative purposes. It is not the actual content of the manual.

Page Structure and Symbol Icons

2 - 9

2 Design

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

2-2 Removal of Each Part

2

2-2-1 Removing Covers

2-2 Removal of Each Part

Before wiring each terminal block, you need to remove the terminal block cover and the backing plate.

In addition, to install a PG Board or communications unit, you must remove the Digital Operator, spacer

cover, terminal block cover, and front cover beforehand.

This section describes how to remove these covers.

To r ein stall it, reverse the removal procedure.

1

Loosen the terminal block cover fixation screws.

There are two terminal block cover fixation screws,

one for each side of the cover.

Larger capacity Inverter models have three terminal

block cover fixation screws.

2

Remove the terminal block cover in the direction of

(a) while holding it from the bottom.

1

Remove the Digital Operator in the direction of (a) by

pushing the lip on the top.

2

In the same way, re move t he spacer cover in the

direction of (b).

2-2-1 Removing Covers

Removing Terminal Block Cover

Removing Digital Operator and Spacer Cover

(a)

Terminal block cover fixation screws

(a)

(b)

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

Operation Steps

Manual Name

Level 3 heading

Shows which

paragraph the

content of the current

page belongs to.

Describes the operation

steps.

Note, Supplementary

Information,

Reference Target

A note, supplementary

information, reference

target, etc. are

provided with

difference icons.

Shows which

section the content

of the current page

belongs to.

Section Number

of Level 1

heading

Page 6

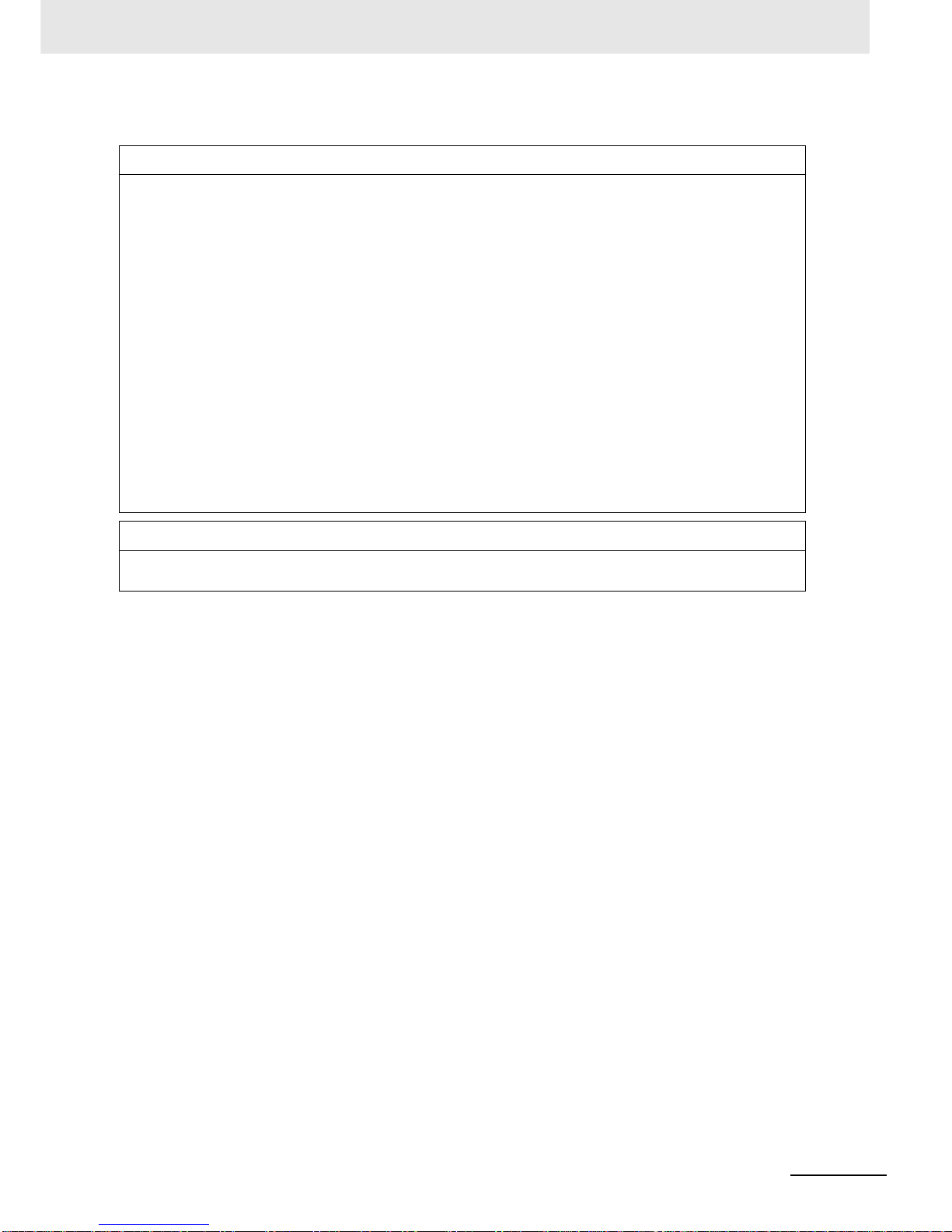

Manual Structure

4

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct UsePrecautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Special Information

Page 7

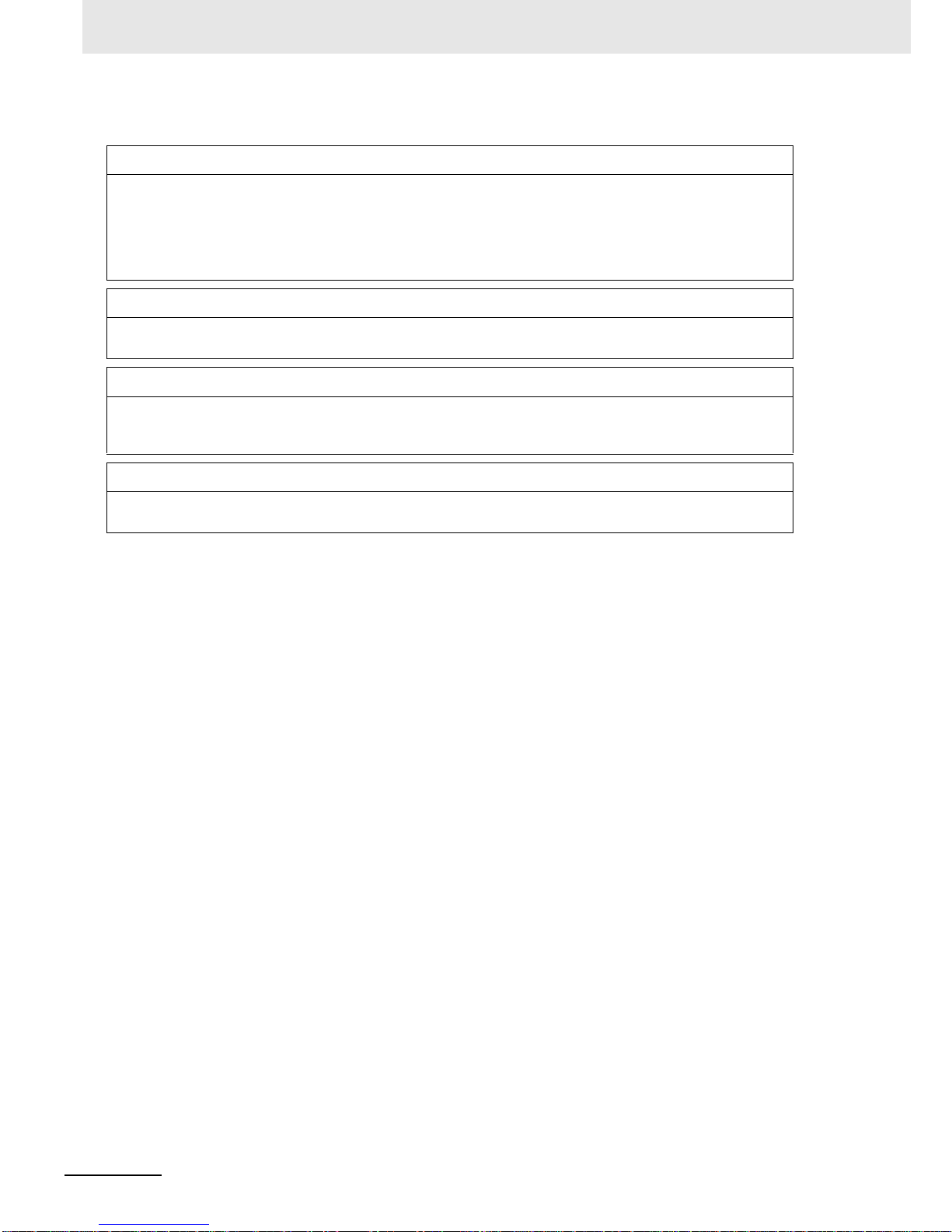

5

Sections in this Manual

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

1

10

2

11

3

12

4A

5

6

7

8

9

1

10

2

11

3

12

4A

5I

6

7

8

9

Overview Troubleshooting

Design

Maintenance and

Inspection

Operation and Test Run

Options

Parameter List Appendices

I

IndexBasic Settings

Vector Control

Detailed Functions

Communications Functions

Overview of DriveProgramming

Sections in this Manual

Page 8

Read and Understand this Manual

6

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Read and Understand this Manual

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of

one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PA RTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABL Y MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAM AGES , LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability

is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 9

7

Read and Understand this Manual

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer’s application or use of the products.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of

the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to

be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be

suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not

described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property. Please know and observe all

prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE WAS DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN

THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence

thereof.

Page 10

Read and Understand this Manual

8

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is

our practice to change model numbers when published ratings or features are changed, or when significant

construction changes are made. However, some specifications of the products may be changed without any notice.

When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on

your request. Please consult with your OMRON representative at any time to confirm actual specifications of

purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are

shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not

constitute a warranty . It ma y represent the result of OMRON’s test conditions, and the users must correlate it to actual

application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual was carefully checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical, or proofreading errors, or omissions.

Page 11

9

Safety Precautions

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Safety Precautions

To ensure that the High-function General-purpose Inverter (Model: 3G3RX--V1) is used safely and

correctly, be sure to read this Safety Precautions section and the main text before using the product.

Learn all items you should know before use, regarding the equipment as we ll as required safety

information and precautions.

Make an arrangement so that this manual also gets to the end user of this product.

After reading this manual, keep it in a convenient place so that it can be referenced at any time.

In this user’s manual, the following precautions and signal words are used to provide information to

ensure the safe use of the High-function General-pur p o se Inver t er (Mo de l: 3G 3RX--V1). The

information provided here is vital to safety. Strictly observe the precautions provided.

Indications and Meanings of Safety Information

Meanings of Signal Words

Indicates an imminently hazardous situation which, if not avoided, is likely to result in

serious injury or may result in death.

Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury or in property damage.

WARNING

Caution

Page 12

Safety Precautions

10

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

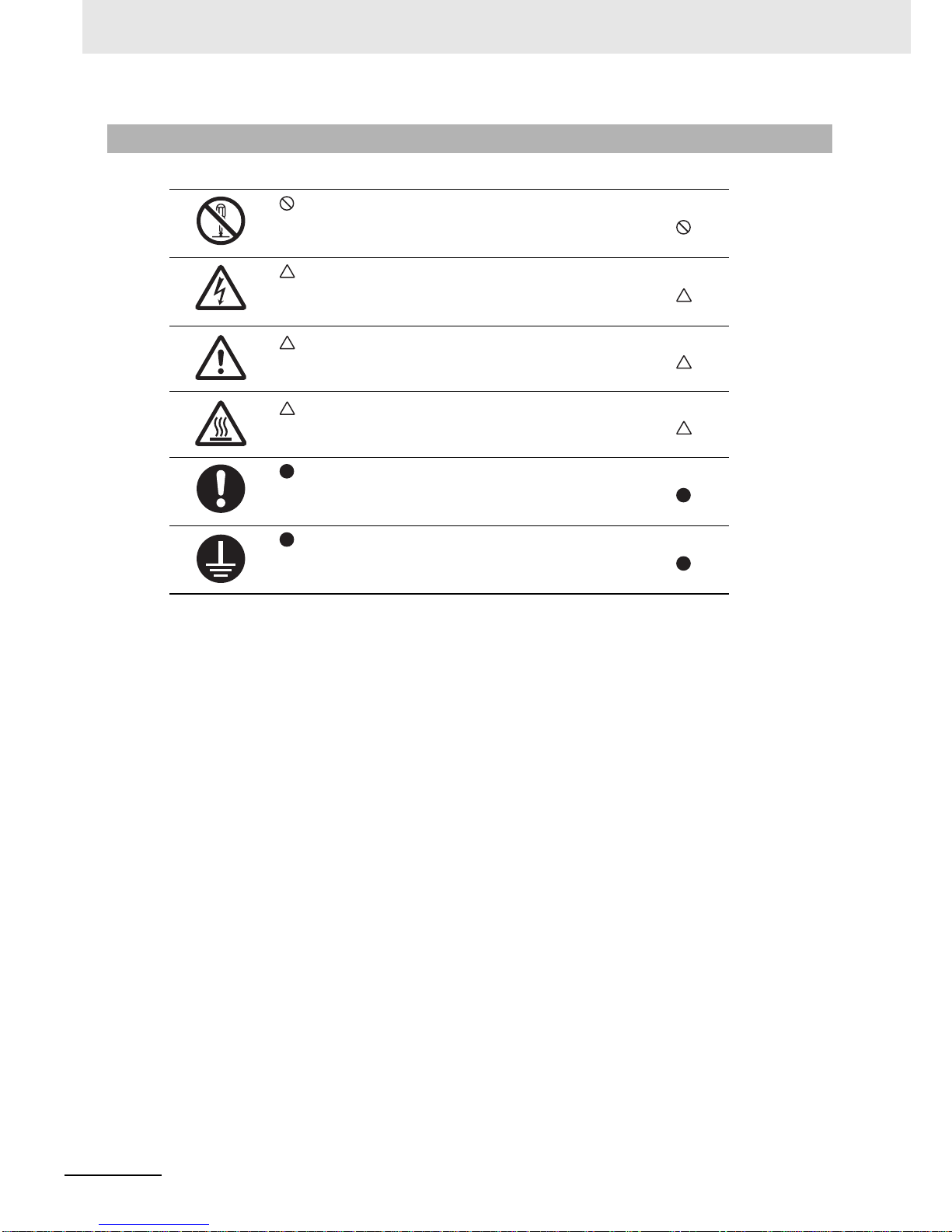

Explanation of Symbols

This symbol indicates a prohibited item (an item you must not do).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “disassembly prohibited.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “beware of electric shock.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “non-specific general danger.”

This symbol indicates caution (including warning).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “risk of hot surface.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “general compulsory items.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “grounding required.”

Page 13

11

Safety Precautions

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

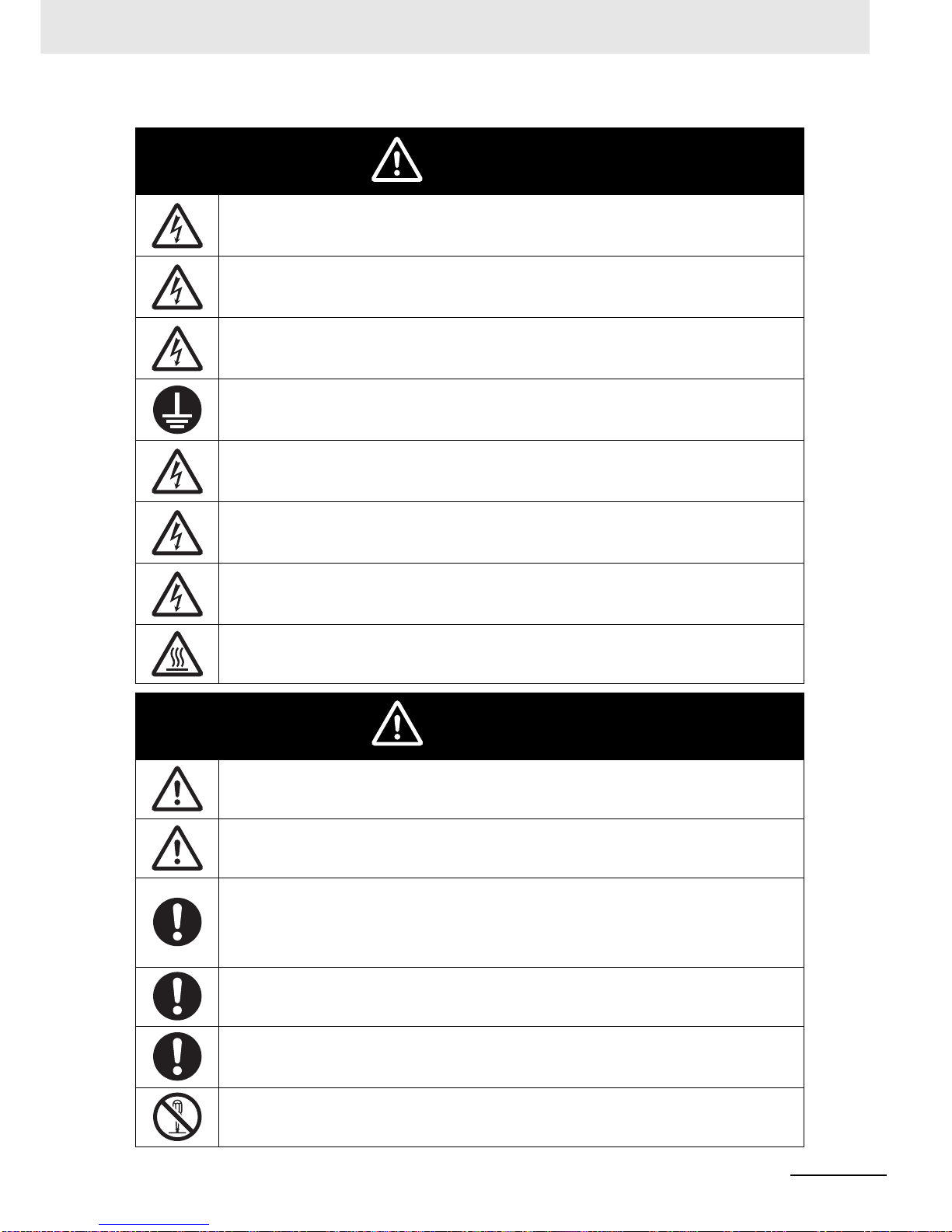

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Do not change wiring and slide switches (SW1), put on or take off Operator and optional devices,

replace cooling fans while the input power is being supplied. Doing so may result in a serious injury

due to an electric shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to an electric shock or

fire.

(200-V class: type-D grounding, 400-V class: type-C grounding)

Do not remove the terminal cover during the power supply and 10 minutes after the power shut off.

Doing so may result in a serious injury due to an electric shock.

Do not operate the Operator or switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Inspection of the inverter must be conducted after the power supply was turned off. Not doing so

may result in a serious injury due to an electric shock.

The main power supply is not nece ssarily shut off e ven if the emergency shut off function is activated.

Do not touch the inverter fins, braking resistors and the motor, which become too hot during the

power supply and for some time after the power shut off. Doing so may result in a burn.

Do not connect resistors to the terminals (+1, P/+2, N/–) directly. Doing so might result in a

small-scale fire, heat generation, or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury.

(A holding brake is not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking

resistor, install a thermal relay that monitors the temperature of the resistor. Not doing so might

result in a moderate burn due to the heat generated in the braking resistor/regenerative braking

unit. Configure a sequence that enables the inverter power to turn off when unusual over eating is

detected in the braking resistor/regenerative braking unit.

The inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or

other property. Place covers on the openings or take other precautions to make sure that no metal

objects such as cutting bits or lead wire scraps go inside when installing and wiring.

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches the

inverter capacity on the pow er su pp l y sid e.

Not doing so might result in damage to property due to the short circuit of the load.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

WARNING

Caution

Page 14

Precautions for Safe Use

12

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Precautions for Safe Use

Do not store or use the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to ambient temperature exceeding the specifications.

• Locations subject to relative humidit y exceeding the specifications.

• Locations subject to condensation due to severe temperature fluctuations.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

• Do not drop or apply strong impact on the product. Doing so may result in damaged parts or

malfunction.

• Do not hold by the front cover and terminal cover, but hold by the fins during transportation.

• Confirm that the rated input voltage of the inverter is the same as AC power supply voltage.

• Do not connect an AC power supply voltage to the control input/output terminals. Doing so may result

in damage to the product.

• Be sure to tighten the screws on the terminal block securely . Wiring work must be done after installing

the unit body.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

• Take sufficient shielding measures when using the product in the following locations. Not doing so

may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

• If a parameter is set incorrect ly when starting up , adjusting, maint aining, o r repla cing, a n unexpected

operation may occur. Perform the operation after enough confirmation.

• When using DriveProgramming, confirm that the program data is downloaded normally before

starting operation.

Installation and Storage

Transportation, Installation, and Wiring

Page 15

13

Precautions for Safe Use

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

• Be sure to confirm the permissible range of motors and machines before operation because the

inverter speed can be changed easily from low to high.

• Provide a separate holding brake if necessary.

• If the DriveProgramming stops during multi-function output, the output status is held. Take safety

precautions such as stopping peripheral device s.

• If the clock command is used in DrivePr ogra mming, an une x pected oper ation may occur due to weak

battery . Take measures such as detect ing a weak ba ttery by a chec k that the cloc k data returns to the

initial setting and stopping the inverter or programs. When the LCD Digital Operator is removed or

disconnected, DriveProgramming is in a waiting status by the clock command.

• Be sure to confirm safety before conduct ing maintenance, inspection or parts replacement.

• The capacitor service life is influenced by the ambi ent temperature. Refer to “Smoothing Capacitor

Life Curve” described in the manual. When a capacitor reaches the end of its service life and does

not work as the product, you need to replace the capacitor.

• When disposing of LCD digital operators and wasted batteries, follow the applicable ordinances of

your local government. When disposing of the battery, insulate it using tape.

• Do not short + and –, charge, disassemble, heat, put into the fire, or apply strong impact on the

battery . The bat tery may leak, e x plode , produce hea t or fire . Ne v er use the battery which was applied

strong impact due to such as fall on the floor, it may leak.

• UL standards establish that the batt ery shall be replaced by an expert engineer. The expert engineer

must be in charge of the replacement and a lso replace the battery according to the meth od described

in this manual.

• When the display of LCD Digital Operator can not be recognized due to the service life, replace the

LCD Digital Operator.

Operation and Adjustment

Maintenance and Inspection

The following display must be indicated when products using lithium pr imary batterie s (with

more than 6 ppb of perchlorate) are transport to or through the State of California, USA.

Perchlorate Material - special handling may apply.

See www. dtsc.ca.gov/hazardouswaste/perchlorate

The 3G3AX-OP05 has the lithium primary battery (with more than 6 ppb of perchlorate).

Label or mark the above display on the exterior of all outer shipping packages of your products when exporting your products which the 3G3AX-OP05 are installed to the State of California, USA.

Page 16

Precautions for Correct Use

14

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Precautions for Correct Use

Mount the product vertically on a wall with the product’s longer sides upright.

The material of the wall must be noninflammable such as a metal plate.

• Do not come close to the machine when using the Restart Selection function (b001, b008) because

the machine may abruptly start when stopped by an alarm.

• Be sure to confirm the RUN signal is turned off before resettin g the ala rm because the machine may

abruptly start.

Do not come close to the machine when selecting reset in the Deceleration Stop Function (b050)

because the machine may abruptly start after the power is turned on.

• Provide a separate emergency stop switch because the STOP Key on the Operator is valid only when

function settings are performed.

• When checking a signal during the pow er supply and the v oltage is err oneously applied to the contr ol

input terminals, the motor may start abruptly. Be sure to confirm safety before checking a signal.

• Inverters contain components and will operate properly only when each component operates

normally. Some of the electrical components require maintenance depending on application

conditions. Periodic inspection and replacement are necessary to ensure proper long-term operation

of Inverters. (Quoted from The Recommendation for Periodic Maintenance of a General-purpose

Inverter published by JEMA.)

• When a cooling fan reaches the end of its service life, replace it.

Comply with the local ordinance and regulations when disposing of the product.

Installation

Restart Selection Function

Deceleration Stop Function

Operation Stop Command

Maintenance and Parts Replacement

Product Disposal

Page 17

15

Precautions for Correct Use

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

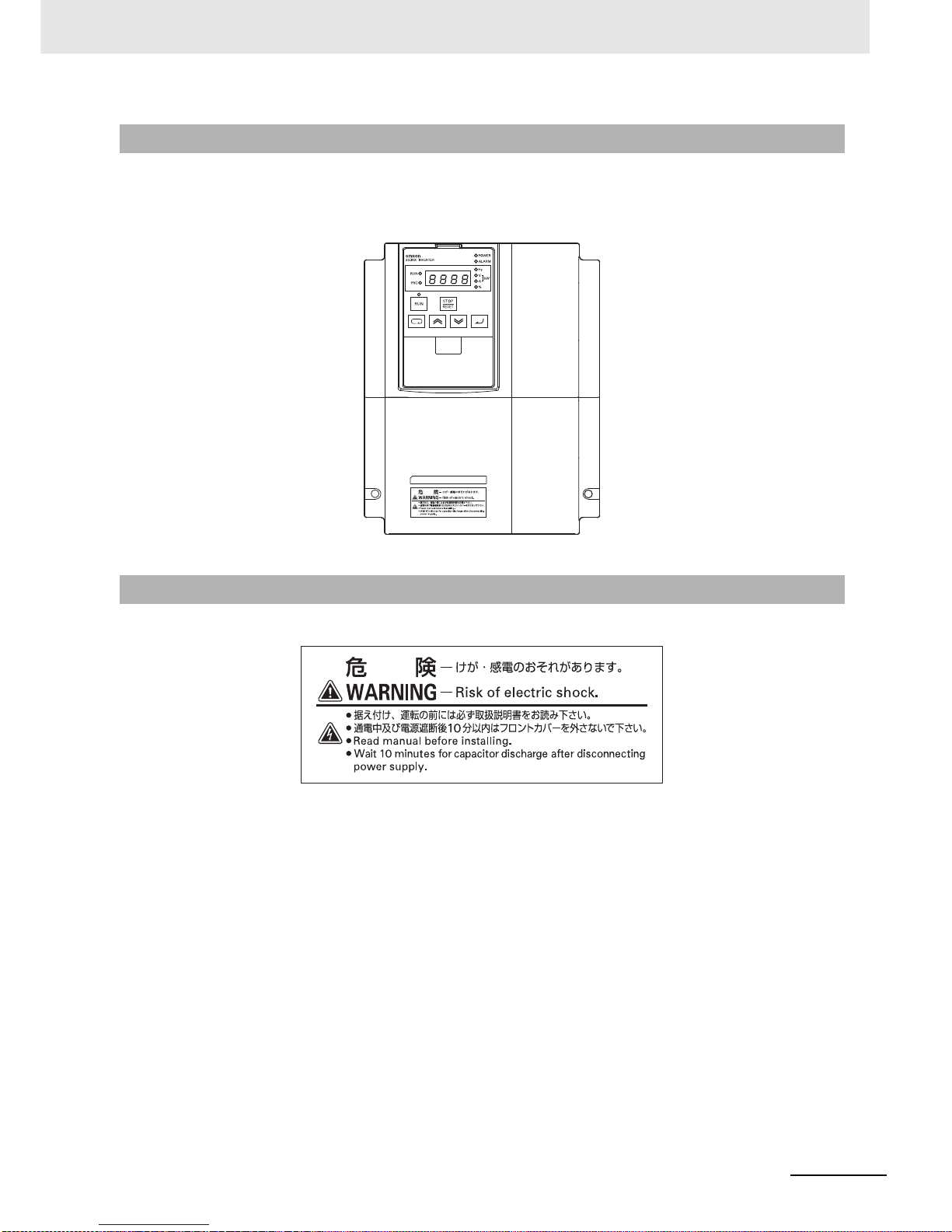

• This product bears a warning label at the follo wing location to provide handling warnings.

• Be sure to follow the instructions.

The appearance differs depending on the capacity of the inv erter.

Warning Label

Warning Description

Page 18

Regulations and Standards

16

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Regulations and Standards

To export (or provide to nonresident aliens) any part of this product that falls under the category of

goods (or technologies) for which an export certificate or license is mandatory according to the Foreign

Exchange and Foreign Trade Control Law of Japan, an export certificate or license (or service

transaction approval) according to this law is required.

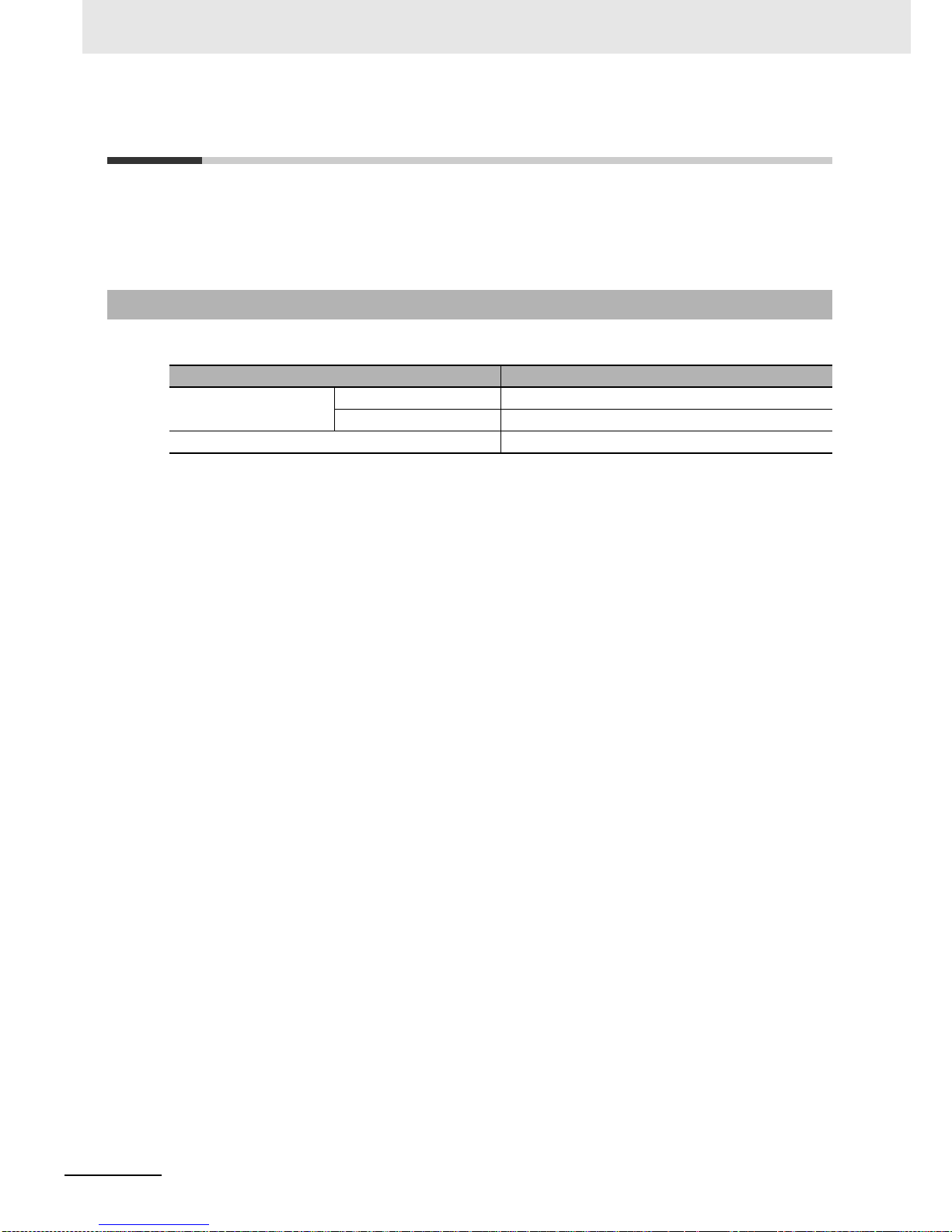

The 3G3RX-V1 Series complies as standard with both the EC Directives and UL/cUL Standards.

EC Directives and UL/cUL Standards

Standard Applicable Standard

EC Directives EMC Directive EN61800-3: 2004

Low Voltage Directive EN61800-5-1: 2003

UL/cUL Standards UL 508C

Page 19

17

Trademarks

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Trademarks

• Windows, Windows 98, Windows XP, Windows Vista, and Windows 7 are re gistered trademarks of

Microsoft Corporation in the USA and other countries.

• DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

• CompoNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

• Other company names and product nam es in this document are the trademarks or registered

trademarks of their respective companies.

Page 20

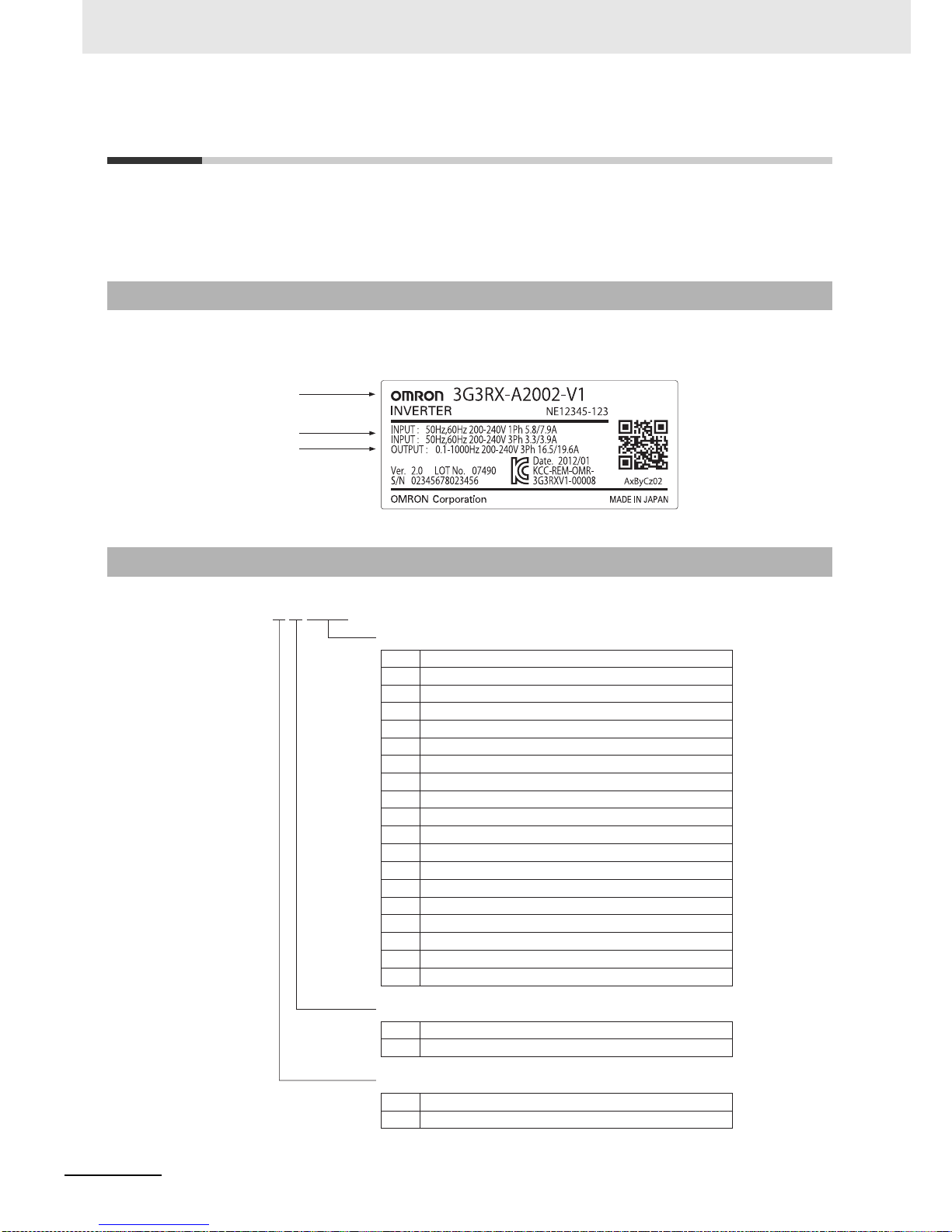

Items to Check after Unpacking

18

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Items to Check after Unpacking

After unpacking, check the following items.

• Is this the model you ordered?

• Was there any damage sustained during shipment?

The nameplate is affixed to the product.

Checking the Nameplate

Checking the Model

Inverter model

Input specifications

Output specifications

3G3RX-A2055-V1

Maximum applicable motor capacity

004

007

015

022

037

055

075

110

150

185

220

300

370

450

550

750

900

11K

13K

0.4 kW

0.75 kW

1.5 kW

2.2 kW

3.7 kW

5.5 kW

7.5 kW

11 k W

15 kW

18.5 kW

22 kW

30 kW

37 kW

45 kW

55 kW

75 kW

90 kW

110 kW

132 kW

Voltage class

243-phase 200 VAC (200-V class)

3-phase 400 VAC (400-V class)

Enclosure rating

A

Panel-mounting (IP20) or closed wall-mounting models

B Panel-mounting (IP00)

Page 21

19

Items to Check after Unpacking

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

This manual is the only accessory included in the High-function General-purpose Inverter (Model:

3G3RX--V1).

Mounting screws and other necessary parts must be provided by the user.

Checking the Accessories

Page 22

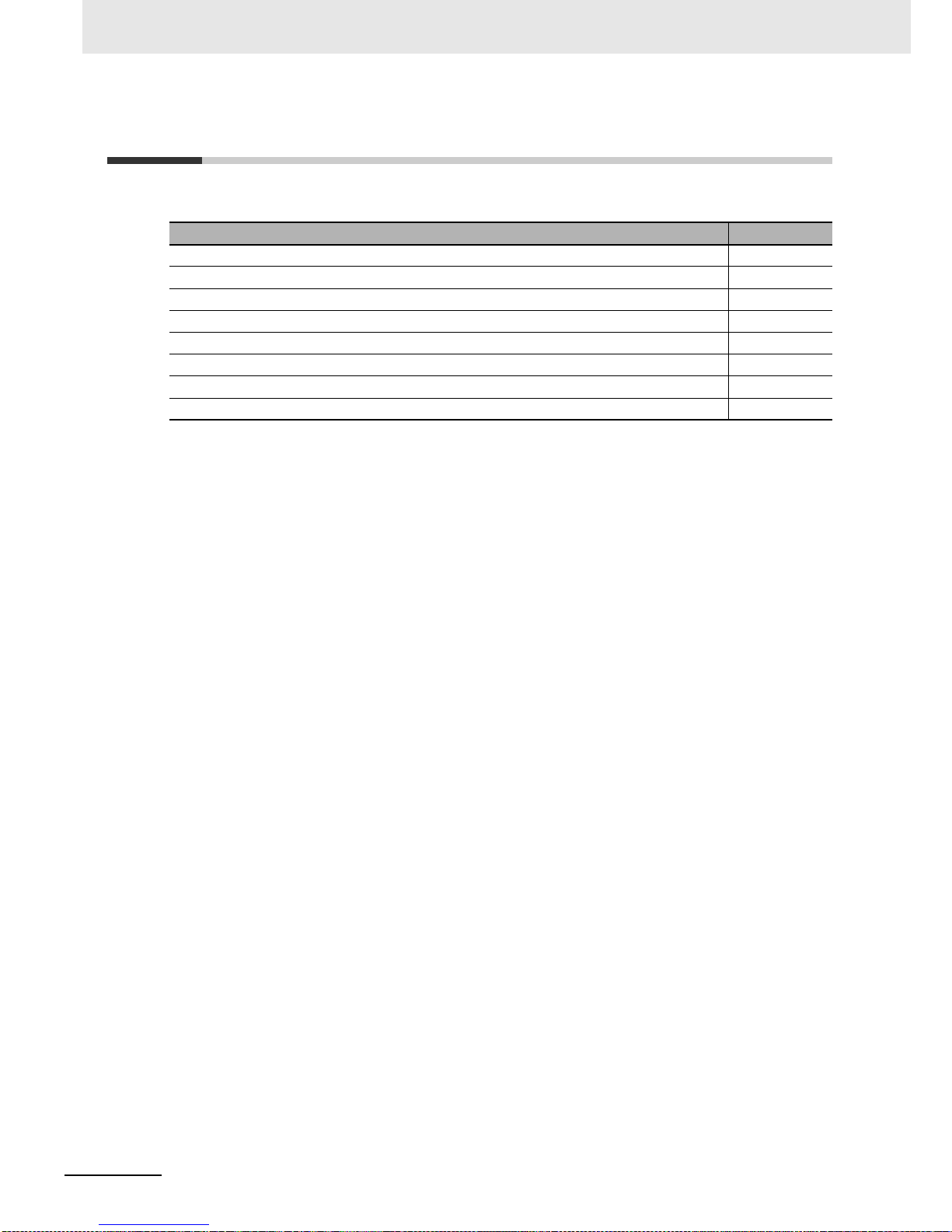

Related Manuals

20

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Related Manuals

Please see the manuals below for related product information.

Name Catalog No.

Regenerative Braking Unit 3G3AX-RBU User’s Manual I563

Encorder Feedback Board 3G3AX-PG User’s Manual I564

CX-Drive Operation Manual W453

LCD Digital Operator 3G3AX-OP05 User’s Manual I579

DriveProgramming User’s Manual I580

MX2/RX Series EtherCAT Communication Unit User's Manual I574

MX2/RX Series CompoNet Communications Unit User’s Manual I582

MX2/RX Series DeviceNet Communications Unit User’s Manual I581

Page 23

21

Revision History

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

Revision History

The manual revision co de is a number appended to the end of the catalog number found in the bottom

right-hand corner of the front and back covers.

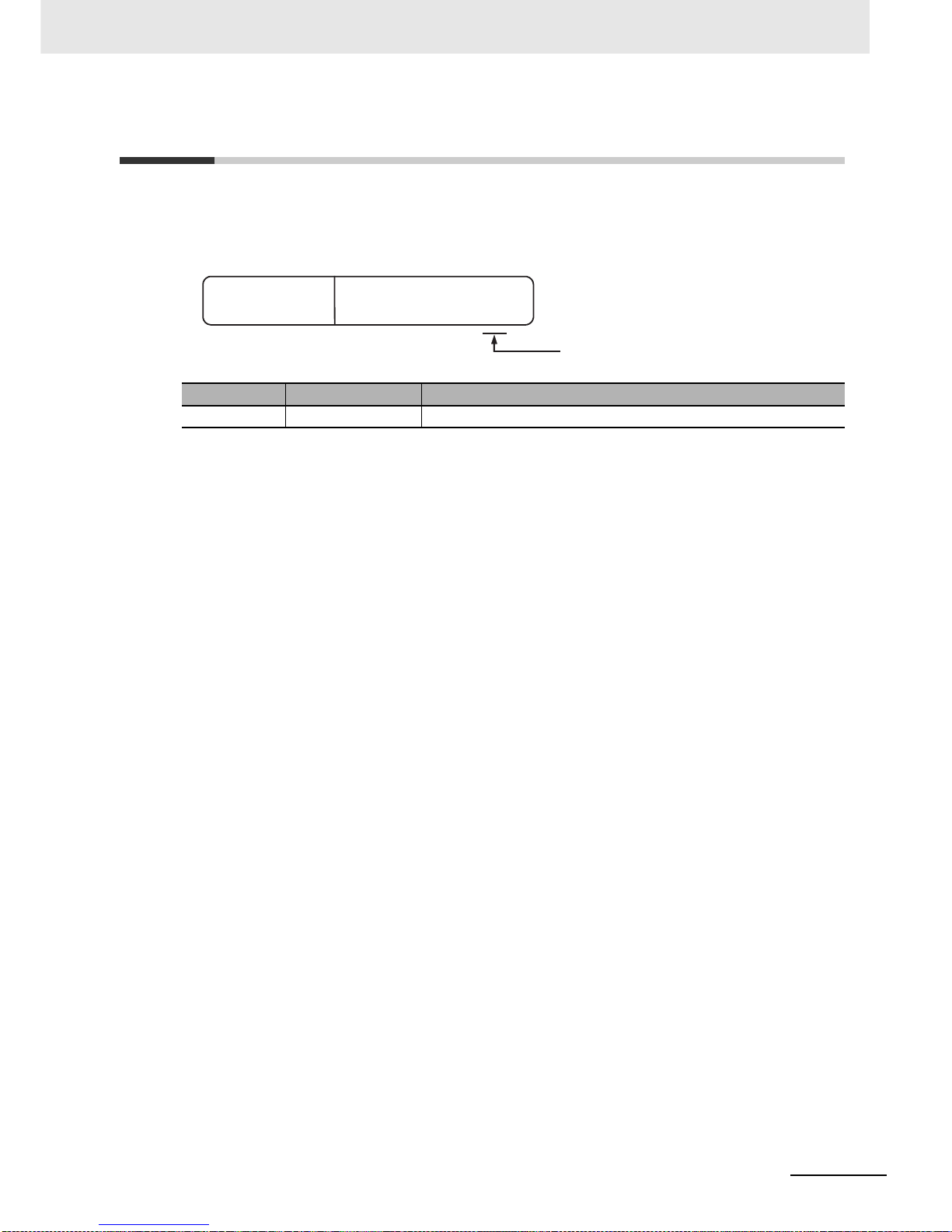

Example

Revision code Revision date Revised Content

01 November 2012 Original production

Cat.No. I578-E1-01

Revision code

Page 24

22

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Intended Readers........................................................................................................................................1

Notice...........................................................................................................................................................1

Manual Configuration ...............................................................................................2

Manual Structure. ......................................................................................................3

Page Structure and Symbol Icons...............................................................................................................3

Special Information.......................................... ................................. ...........................................................4

Sections in this Manual ............................................................................................5

Read and Understand this Manual ..........................................................................6

Safety Precautions....................................................................................................9

Indications and Meanings of Safety Information..........................................................................................9

Meanings of Signal Words...........................................................................................................................9

Explanation of Symbols.............................................................................................................................10

Precautions for Safe Use........................................................................................12

Installation and Storage.............................................................................................................................12

Transportation, Installation, and Wiring .....................................................................................................12

Operation and Adjustment............................................................................................... ... .......................13

Maintenance and Inspection......................................................................................................................13

Precautions for Correct Use...................................................................................14

Installation..................................................................................................................................................14

Restart Selection Function ........................................................................................................................14

Deceleration Stop Function .......................................................................................................................14

Operation Stop Command........................................................ ....................................... ..........................14

Maintenance and Parts Replacement........................................................................................................14

Product Disposal............................................................ ... ................................. ........................................14

Warning Label.......................................................... .................................. ................................................15

Warning Description................................................ ... .................................. .............................................15

Regulations and Standards....................................................................................16

EC Directives and UL/cUL Standards........................................................................................................16

Trademarks..............................................................................................................17

Items to Check after Unpacking.............................................................................18

Checking the Nameplate................................................................................ ... ........................................18

Checking the Model......................................... ................................. .................................. .......................18

Checking the Accessories .........................................................................................................................19

Related Manuals......................................................................................................20

Revision History......................................................................................................21

Section 1 Overview

1-1 Overview of Functions............................................................................................................ 1-2

1-1-1 Features of 3G3RX-V1 Series Inverter.......................................................................................1-2

1-1-2 Classes of 3G3RX-V1 Series Inverter ........................................................................................1-6

1-1-3 Compliance with International Standards (EC Directives and UL/cUL Standards).....................1-7

Page 25

23

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

1-2 Appearance and Part Names.................................................................................................. 1-8

1-3 Specifications .......................................................................................................................... 1-9

1-3-1 Standard Specifications.............................................................................................................. 1-9

1-3-2 External Dimensions................................................................................................................. 1-14

1-4 Restrictions............................................................................................................................ 1-23

1-5 Comparison with Previous Model.............................. ... .......................................... ... .... ... ... 1-24

Section 2 Design

Safety Information........................................................................................................................................3

2-1 Installation................................................................................................................................ 2-4

2-1-1 Inverter Installation .....................................................................................................................2-4

2-1-2 Installation Environment ............................................................................................................. 2-4

2-2 Removal of Each P art.............................................................................................................. 2-9

2-2-1 Removing Covers....................................................................................................................... 2-9

2-2-2 Terminal Blocks......................................................................................................................... 2-11

2-2-3 Preparing Bac k ing Plate....................................................................................... ....................2-13

2-3 Wiring ..................................................................................................................................... 2-14

2-3-1 Standard Connection Diagram................................................................................................. 2-14

2-3-2 Arrangement and Function of Main Circuit Terminal Block....................................................... 2-15

2-3-3 Arrangement and Function of Control Circuit Terminal Block................................................... 2-16

2-3-4 Wiring for Main Circuit Terminals.............................................................................................. 2-20

2-3-5 Wiring for Control Circuit Terminals.......................................... ... .. ........................................... 2-43

2-3-6 Wiring for PG Board................................ ... .................................. ................................. ............ 2-49

2-3-7 Wiring for RS485 Communications Terminals .......................................................................... 2-53

2-3-8 Wiring for Digital Operator............................................. .. ... ... ....................................... ............ 2-55

2-3-9 Wiring for Emergency Shutoff Function....................................................... ... ..........................2-56

2-3-10 Conformance to EC Directives ................................................................................................. 2-58

2-3-11 Reference Manuals for Options................................................................................................2-60

Section 3 Operation and Test Run

Precautions for Safe Use..............................................................................................................................2

Precautions for Correct Use.........................................................................................................................3

3-1 Operation of Digital Operator.................................. ... ... .......................................... ... .... ... ... .. 3-4

3-1-1 Part Names and Descriptions.............................................................. ....................................... 3-4

3-1-2 Key Operation Method................................................................................................................3-6

3-2 Overview of LCD Digital Operator........................................................................................ 3-15

3-3 Connections and Functions of CX-Drive............................................................................. 3-16

3-3-1 CX-Drive Connection Method................................................................................................... 3-16

3-3-2 Outline of CX-Drive................................................................................................................... 3-20

3-4 Flow of Test Run.................................................................................................................... 3-24

3-5 Test Run Procedure............................................................................................................... 3-25

Section 4 Parameter List

4-1 Monitor Mode............... .......................................... ... ... ... .......................................... ... ............ 4-2

4-1-1 Group d....................................................................................................................................... 4-2

4-2 Basic Function Mode .............................................................................................................. 4-5

4-2-1 Group F: Basic Function Parameters.......................................................................................... 4-5

4-3 Extended Function Mode ......................................... ... ... .... ......................................... .... ... ..... 4-6

4-3-1 Group A: Standard Function Parameters...................................................................................4-7

4-3-2 Group b: Detailed Function Parameters................................................................................... 4-19

4-3-3 Group C: Multi-function Terminal Function Parameters............................................................4-28

Page 26

24

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

4-3-4 Group H: Motor Control Parameters.........................................................................................4-39

4-3-5 Group P: Option Parameters.....................................................................................................4-42

4-3-6 Group U: User Setting Display Parameters...............................................................................4-49

Section 5 Basic Settings

5-1 Parameter Display and Parameter Initialization.................................................................... 5-3

5-1-1 Display Selection........................................... ....................................... .......................................5-3

5-1-2 Parameter Initialization................................................................................................................5-6

5-2 V/f Control Settings.................................................................................................................5-8

5-2-1 Control Method (V/f Characteristics)...........................................................................................5-8

5-2-2 Heavy Load/Light Load Selection ......................................................................... ... ... ... ...........5-12

5-3 Motor Parameter Settings........... ... ... ... ... .... .......................................... ... ... ... .......................5-18

5-3-1 Motor Capacity/Pole Number Selection....................................................................................5-18

5-3-2 Electronic Thermal Function .....................................................................................................5-18

5-4 RUN Command Settings... ... ... .... .......................................... ... ... ... ....................................... 5-23

5-4-1 RUN Command Selection................................................... ... ... ... ....................................... ......5-23

5-5 Frequency Reference Settings.............................................................................................5-24

5-5-1 Frequency Reference Selection................................................................................................5-24

5-5-2 Frequency Limit.........................................................................................................................5-33

5-6 Acceleration/Deceleration Time Settings............................................................................ 5-35

5-6-1 Acceleration/Deceleration Time Settings..................................................................................5-35

5-6-2 Acceleration/Deceleration Pattern.............................................................................................5-37

5-6-3 Automatic Optimum Acceleration/Deceleration.........................................................................5-39

5-6-4 2-step Acceleration/Deceleration Function ................................................ ...............................5-41

5-7 Stop Method Settings............................................................................................................5-43

5-7-1 Stop Selection...........................................................................................................................5-43

5-7-2 Free-run Stop Selection............................................................................................................5-43

5-7-3 STOP Key Selection..................................................................................................................5-46

5-8 Reset Method Settings......................... ... .... ... ... .......................................... ... .... ... ................5-47

5-8-1 Reset.........................................................................................................................................5-47

5-8-2 Restart after Resetting..............................................................................................................5-48

5-9 Multi-function Input Settings................................................................................................5-51

5-9-1 Multi-function Input Selection....................................................................................................5-51

5-9-2 Multi-function Input Operation Selection............................................................................. ... ...5-52

5-9-3 Input Terminal Response Time.................................................................................................5-52

5-9-4 Reverse Command (RV)................................................................. ..........................................5-52

5-9-5 Multi-step Speed Operation Function........................................................................................5-53

5-9-6 Jogging (JG)..............................................................................................................................5-56

5-9-7 2-step Acceleration/Deceleration (2CH)................................................................................5-57

5-9-8 Reset (RS) ........................................................................................... ... ..................................5-57

5-9-9 3-wire Input Function (STA, STP, F/R) ......................................................................................5-58

5-10 Multi-function Output Settings............................................................................................. 5-59

5-10-1 Multi-function Output Selection.................................................................................................5-59

5-10-2 Multi-function Output Operation Selection................................................................................5-60

5-10-3 Multi-function Output ON/OFF Delay Time...............................................................................5-60

5-10-4 Signal during RUN (RUN)......................................................... ... .............................................5-61

5-10-5 Constant Speed Arrival Signal (FA1) ........................................................................................5-61

5-10-6 Alarm Signal (AL)......................................................................................................................5-62

5-10-7 0-Hz Detection Signal (ZS).......................................................................................................5-63

5-10-8 Operation Ready (IRDY) .................... ... .. ........................................ ..........................................5-63

5-10-9 Forward Run Signal (FWR).......................................................................................................5-64

5-10-10 Reverse Run Signal (RVR)........................................................................................................5-64

5-11 Torque Boost Function Settings .......................................................................................... 5-65

5-11-1 Torque Boost....................................................... ................................. .....................................5-65

5-12 Measures against Overvoltage................... .......................................... ... ... ... ....................... 5-68

5-12-1 Overvoltage Suppression Function during Deceleration...........................................................5-68

Page 27

25

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

5-12-2 Regenerativ e Br aking Function..................................................... ... ........................................ 5-70

Section 6 Vector Control

6-1 Overview of Vector Control..................................................................................................... 6-2

6-2 Sensorless Vector Control............. ... ... .... ... ... .......................................... ... .... ... ..................... 6-4

6-2-1 Sensorless Vector Control Parameter Settings........................................................................... 6-4

6-2-2 0-Hz Sensorless Vector Control Parameter Settings.................................................................. 6-4

6-2-3 Auto-tuning of Motor Parameters................................................................................................ 6-5

6-2-4 Motor Parameter Settings......................................................................................................... 6-11

6-2-5 Adjustment for Sensorless Vector Control................................................................................6-13

6-2-6 Adjustment for 0 Hz Sensorless Vector Control........................................................................ 6-14

6-3 Sensor Vector Control................. ... ... ... .... .......................................... ... ... ... .......................... 6-15

6-3-1 Sensor Vector Control Parameter Settings...............................................................................6-15

6-3-2 Overview of PG Board............................................. .................................. ...............................6-16

6-3-3 PG Board Function Settings..................................................................................................... 6-17

6-3-4 Auto-tuning of Motor Parameters.............................................................................................. 6-18

6-3-5 Motor Parameter Settings......................................................................................................... 6-24

6-3-6 Adjustment for Sensor Vector Control (Speed Control) ............................................................ 6-26

6-4 Speed Control....... ... .......................................... .... ... ... .......................................... ... ... .......... 6-27

6-4-1 Speed Control Gain Parameters...............................................................................................6-27

6-4-2 P/PI Switching Function............................................................................................................6-28

6-4-3 Control Gain Switching Function ..............................................................................................6-29

6-4-4 Torque Bias Function Settings......................................... ... ... ... ....................................... ......... 6-30

6-5 Torque Limit Function.............. ... ... ... ... .......................................... .... ... ... ... .......................... 6-31

6-5-1 Torque Limit Function Settings ................................................................................................. 6-31

6-5-2 Torque LADST OP Function Settings................................................................. ... .................... 6-33

6-6 Pulse Train Position Control Mode ...................................................................................... 6-34

6-6-1 Pulse Train Position Control Mode Settings.............................................................................. 6-34

6-6-2 Electronic Gear Function............................................... .. ........................................ .................6-36

6-6-3 Position Bias Function..............................................................................................................6-38

6-6-4 Speed Bias Function................................................................................................................. 6-39

6-7 Absolute Position/High-resolution Absolute Position Control Mode............................... 6-40

6-7-1 Absolute Position/High-resolution Absolute Position Control Mode Parameter Settings.......... 6-40

6-7-2 Operation Sequences...............................................................................................................6-43

6-7-3 Origin Search Function.................................................. .. ... ... ....................................... ............ 6-48

6-7-4 Teaching Function.....................................................................................................................6-50

6-7-5 Forward/Reverse Driving Stop and Position Limit Setting Functions........................................6-51

6-8 Orientation Function............................................................................................................. 6-53

6-8-1 Orientation Function Parameter Settings..................................................................................6-53

6-9 Torque Control...................... .... ... ... .......................................... ... ... .... ... ................................ 6-56

6-9-1 Torque Control Parameter Settings...........................................................................................6-56

Section 7 Detailed Functions

7-1 Monitor Mode (Group d).......................................................................................................... 7-2

7-2 Basic Functions (Group F)....................................................................................................7-14

7-3 Basic Functions (Group A)................................................................................................... 7-17

7-4 Detailed Functions (Group b)............................................................................................... 7-61

7-5 Multi-function Terminal Functions (Group C) ...................................................................7-108

7-6 Motor Parameters (Group H) .............................................................................................. 7-145

7-7 Option Functions (Group P)............................................................................................... 7-147

7-8 User Setting Display Functions (Group U)........................................................................ 7-149

Page 28

26

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

Section 8 Communications Functions

8-1 Communication Specifications ........... ... .......................................... .... ... ... ............................ 8-2

8-2 Modbus Method.......................................................................................................................8-6

8-3 Explanation of Each Function Code....................................................................................8-10

8-4 Saving a Change to Holding Register (Enter Command) .................................................. 8-20

8-5 Modbus Communication Register Number List ................................................................. 8-22

8-5-1 Coil Number List........................................................................................................................8-22

8-5-2 Monitor Function/Enter Command Register List.......................................................................8-27

8-5-3 Group F Register List................................................................ ... ... ..........................................8-37

8-5-4 Group A/b/C/H/P Register List................................................................................. ... ..............8-38

8-5-5 2nd Control Register Number List.............................................................................................8-71

8-5-6 3rd Control Register Number List..............................................................................................8-75

8-6 ASCII Method ......................................................................................................................... 8-77

8-6-1 Communications Procedure......................................................................................................8-77

8-6-2 Communications Commands....................................................................................................8-78

Section 9 Overview of DriveProgramming

9-1 Overview of DriveProgramming.............................................................................................9-2

Section 10 Troubleshooting

10-1 Alarm Codes and Remedies ................................................................................................. 10-2

10-1-1 Alarm Display........................................................... .................................. ...............................10-2

10-1-2 Alarm Code List ........................................................................................................................10-3

10-1-3 Option Board Protective Function List.......................................................................................10-9

10-2 Warning Function ....... .... ... ... ... .......................................... .... ... ... ........................................10-12

10-3 Other Indications on Digital Operator................................................................................10-14

10-4 Troubleshooting................................................................................................................... 10-15

Section 11 Maintenance and Inspection

Precautions for Safe Use.............................................................................................................................2

Precautions for Correct Use ........................................................................................................................3

11-1 Inspection............................................................................................................................... 11-4

11-1-1 Daily Inspection.........................................................................................................................11-4

11-1-2 Periodic Inspection....................................................................................................................11-4

11-1-3 Inspection Items........................................................................................................................11-5

11-2 Cleaning ................................................................................................................................. 11-8

11-3 Test Methods.......................................................................................................................... 11-9

11-3-1 Megger Test ..............................................................................................................................11-9

11-3-2 Withstand Voltage Test..............................................................................................................11-9

11-3-3 Inverter/Converter Unit Test....................................................................... ... ..........................11-10

11-3-4 I/O Voltage/Current/Electric Power Measurement Method......................................................11-12

Section 12 Options

12-1 Overview of Optional Equipment ............................................................... ... .... ... ... ... ..........12-3

12-1-1 Part Names and Descriptions...................................................................................................12-3

12-2 Regenerative Braking Unit (Model: 3G3AX-RBU)......................................................... 12-5

Page 29

27

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

12-2-1 Specifications............................................................................................................................ 12-5

12-2-2 External Dimensions.................................................................................................................12-7

12-2-3 Connection Examples.............................................. ....................................... ........................12-11

12-3 Braking Resistor (Model: 3G3AX-RBA/RBB/RBC)............................................... 12-12

12-3-1 Specifications.......................................................................................................................... 12-12

12-3-2 External Dimensions...............................................................................................................12-13

12-3-3 Connection Example.................... ... ....................................... ... .............................................. 12-15

12-4 Regenerative Braking Unit and Braking Resistor Combination Selection Table .......... 12-16

12-5 DC Reactor (Model: 3G3AX-DL) ............................................................................ 12-23

12-5-1 Specifications.......................................................................................................................... 12-23

12-5-2 External Dimensions...............................................................................................................12-25

12-5-3 Connection Examples.............................................. ....................................... ........................12-28

12-6 AC Reactor (Model: 3G3AX-AL)............................................................................. 12-29

12-6-1 Specifications.......................................................................................................................... 12-29

12-6-2 External Dimensions...............................................................................................................12-31

12-6-3 Connection Examples.............................................. ....................................... ........................12-32

12-7 Input Noise Filter (Model: 3G3AX-NFI)........................................................................ 12-33

12-7-1 Specifications.......................................................................................................................... 12-33

12-7-2 External Dimensions...............................................................................................................12-35

12-7-3 Connection Examples.............................................. ....................................... ........................12-40

12-8 Output Noise Filter (Model: 3G3AX-NFO)................................................................... 12-41

12-8-1 Specifications.......................................................................................................................... 12-41

12-8-2 External Dimensions...............................................................................................................12-43

12-8-3 Connection Example.................... ... ....................................... ... .............................................. 12-44

12-9 Radio Noise Filter (Model: 3G3AX-ZCL).........................................................................12-45

12-9-1 Specifications.......................................................................................................................... 12-45

12-9-2 External Dimensions...............................................................................................................12-46

12-9-3 Connection Example.................... ... ....................................... ... .............................................. 12-47

12-10EMC Noise Filter (Model: 3G3AX-EFI)......................................................................... 12-48

12-10-1 Specifications..........................................................................................................................12-48

12-10-2 External Dimensions...............................................................................................................12-50

12-10-3 Connection Example........................................................... ... ....................................... .......... 12-52

12-11Digital Operator (Model: 3G3AX-OP01/

OP05

).................................................................... 12-53

12-11-1 Specifications..........................................................................................................................12-53

12-11-2 External Dimensions...............................................................................................................12-54

12-12Digital Operator Cable (Model: 3G3AX-OPCN).............................................................. 12-56

12-12-1 Specifications..........................................................................................................................12-56

12-12-2 External Dimensions...............................................................................................................12-56

12-13PG Board (Model: 3G3AX-PG01)........................................................................................ 12-57

12-13-1 Specifications..........................................................................................................................12-57

12-13-2 External Dimensions...............................................................................................................12-58

12-13-3 Connection Examples.................................................................................. ... ........................12-58

12-14EtherCAT Communications Unit (Model: 3G3AX-RX-ECT).............................................. 12-59

12-14-1 Specifications..........................................................................................................................12-59

12-14-2 External Dimensions...............................................................................................................12-60

12-15CompoNet Communications Unit (Model: 3G3AX-RX-CRT-E)......................................... 12-61

12-15-1 Specifications..........................................................................................................................12-61

12-15-2 External Dimensions...............................................................................................................12-62

12-16DeviceNet Communications Unit (Model: 3G3AX-RX-DRT-E) ......................................... 12-63

12-16-1 Specifications..........................................................................................................................12-63

12-16-2 External Dimensions...............................................................................................................12-64

Appendices

A-1 Smoothing Capacitor Life Curve............................................................................................A-2

Page 30

28

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

CONTENTS

A-2 Life Alarm Output ..................................................... ... ... .......................................... ... ... .........A-3

A-3 Packing Dimensions and Weight ..... ... ... .... .......................................... ... ... ... .... .....................A-4

A-4 Overview of Inverter Selection ... ... ... ... ... .......................................... .... ... ... ... .........................A-5

Index

Page 31

1 - 1

1

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

This section provides an overview of the 3G3RX-V1 Series features, standard

specifications, and external dimensions by inverter capacity. It also shows the

differences of this in verter from the con ventiona l inv erter for those who use t he prev ious

model.

1-1 Overview of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 Features of 3G3RX-V1 Series Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Classes of 3G3RX-V1 Series Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-1-3 Compliance with Intern ational Standards

(EC Directives and UL/cUL Standards) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-2 Appearance and Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-1 Standard Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-3-2 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1-4 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1-5 Comparison with Previous Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Overview

Page 32

1 Overview

1 - 2

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

1-1 Overview of Functions

The High-function General-purpose Inverter (Model: 3G3RX--V1) is a human- and

environmental-friendly inverter suitable for a variety of applications. It provides various features, such

as convenient functions intended for ease of use, network support, and diverse I/O.

In addition, the 3G3RX-V1 Series complies as standard with both the EC Directives and UL/cUL

Standards. You can use this product as a world standard inverter.

The 3G3RX-V1 Series Inverter has the following f eatures.

The 3G3RX-V1 Series provides high performance and high functionality, which are the requirements of

a general-purpose inverter.

It enhances the capability to support applications and addresses diverse needs with optimal

performance.

Addition of the dual rating function (heavy load and light load)

In addition to the conventional heavy load mode, the 3G3RX-V1 Series Inverter newly has the light

load mode to provide the dual ra ting function.

The light load mode is available for a fan, pump, or other device that operates at the rated motor

torque or less in a normal state. Setting the light load mode causes the rated current of the inverter

to increase, enabling the inverter to drive a motor that is one size larger in capacity.

However, pay attention to when selecting an inverter because the overload capacity decreases to

1 minute, 120% of the rated current.

Precautions for Correct UsePrecautions for Correct Use

Switching between the heavy load mode and the light loa d mode changes the se tting ranges and

default datas of the relate d parameters . Ref er to 5-2-2 He avy Load/Light Load Selection on page

5-12 for details.

Implementation of the programming function

The 3G3RX-V1 Series has the buit-in simple sequen ce function (DriveProg ramming), which enab les

a stand-alone inverter to perform simple sequence control.

You can create programs easily in flowchart or text language method by using the CX-Drive.

For details, refer to “DriveProgramming User’s Manual (I580)”.

1-1-1 Features of 3G3RX-V1 Series Inverter

Enhanced Application Support

Page 33

1 - 3

1 Overview

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

1-1 Overview of Functions

1

1-1-1 Features of 3G3RX-V1 Series Inverter

Implementation of the vector control functions

With sensorless vector control, the inverter realizes a high starting torque at 200% of the motor

rating in 0.3 Hz.

With 0-Hz sensorless vector control, the inverter can also output a high starting torque at 150% of

the motor rating in even lower frequencies.

The inverter has various vector control functions as listed below, in addition to V/f control.

• Sensorless vector control

• 0-Hz sensorless vector control

• Sensor vector control

Availability of position control by the feedback

The inverter can realize accurate po sition contr ol b y feeding back the load -side position inf ormation,

just like a servo system. It is effective to save costs for the whole sysytem because the position

control system with a motor over 15 kW is available, and also other position controllers are

unnecessary if the inverter’s internal position control function is used.

This inverter has the follo wing position control functions.

• Absolute position control mode and high-resolut ion absolute position control mode that can

control up to 8 points

• Pulse train position control mode that can control via pulse input from the host controller

• Orientation function that controls a rotating shaft to stop at a fixed position

PID control function

The inverter provides PID control that adjusts the feedback value to match the target value.

This is available to the process control such as temperature, pressure, flow rate without temperature

controller or external controller.

Power interruption restart function

If a momentary power interruption occurs during operation, th e inv erter automatically recognizes the

rotation speed of the motor at power recovery, without detecting undervoltage, to enab le a smooth

restart.

Stall prevention function

Induction motors may stall (or step out) if a large load is applied due to rapid acceleration or load

fluctuation.

This inverter has the overload limit function that prevents such a stall condition and ensures a

persistent operation.

Page 34

1 Overview

1 - 4

High-function General-purpose Inverter 3G3RX-V1 User’s Manual (I578-E1)

The 3G3RX-V1 Series Inverter contributes to the reduction of man-hours in all phases of

inverter-related work: from wiring, parameter setting, operation, throug h to maintenance.

Removable Digital Operator as standard equipment

This inverter has a removable Digital Operator as standard equipment.

By connecting the optional special cable, it is possible to operate th e Digital Operator at hand or

install it to the front face of the control panel. This is convenient during setup or maintenance

operation.

The operability of the keys and the method to initialize parameters were changed to the same as

those for the 3G3MX2 Series .

Addition of the initial screen automatic return function

The inverter newly has the “initial scree n automatic return function” which aut omatically swit ches the

screen to the initial screen if the Digital Operator is not operated for 10 minut es.

5-line LCD Digital Operator

This inverter supports the newly released LCD Digital Operat or 3G3AX-OP05 wit h the 5-line d isplay