Page 1

DATASHEET

3G3AX-MX2-EIO15-E

OMRON

OTHER SYMBOLS:

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

www.rgbelektronika.pl

www.rgbautomatyka.pl

Page 2

YOUR

PARTNER IN

MAINTENANCE

Repair this product with RGB ELEKTRONIKA

LINEAR

ENCODERS

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

OUR SERVICES

PLC

SYSTEMS

CNC

CONTROLS

ORDER A DIAGNOSIS

INDUSTRIAL

COMPUTERS

POWER

SUPPLIERS

∠

MOTORS

SERVO

DRIVERS

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

Buy this product at RGB AUTOMATYKA

OPERATOR

PANELS

BUY

∠

Page 3

CJ Series

(RS-485 Modbus Communication)

(3G3MX2 Series Type V1)

General-purpose Serial

Connection Guide

OMRON Corporation

Multi-function Compact Inverter

P641-E1-01

Page 4

About Intellectual Property Rights and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

Company names and product names in this document are t he trademarks or registered

trademarks of their respective companies.

Page 5

Table of Contents

1. Related Manuals ........................................................................................ 1

2. Terms and Definitions ............................................................................... 2

3. Precautions ................................................................................................ 3

4. Overview .................................................................................................... 4

5. Applicable Devices and Device Configuration ....................................... 5

5.1. Applicable Devices ............................................................................. 5

5.2. Device Configuration .......................................................................... 6

6. Serial Communications Settings ............................................................. 8

6.1. Parameters ........................................................................................ 8

6.2. Cable Wiring Diagram ........................................................................ 9

7. Serial Communications Connection Procedure ................................... 10

7.1. Work Flow ........................................................................................ 10

7.2. Setting up Inverter ............................................................................. 11

7.3. Setting up PLC ................................................................................. 17

7.4. Checking the Serial Communications .............................................. 31

8. Initialization Method ................................................................................ 35

8.1. Initializing PLC ................................................................................. 35

8.2. Initializing Inverter ............................................................................ 36

9. Program .................................................................................................... 37

9.1. Overview .......................................................................................... 37

9.2. Destination Device Command .......................................................... 42

9.3. Error Detection Processing .............................................................. 44

9.4. Memory Maps .................................................................................. 45

9.5. Ladder program ............................................................................... 48

9.6. Timing Chart ..................................................................................... 54

9.7. Error processing ............................................................................... 55

10. Revision History .................................................................................. 57

Page 6

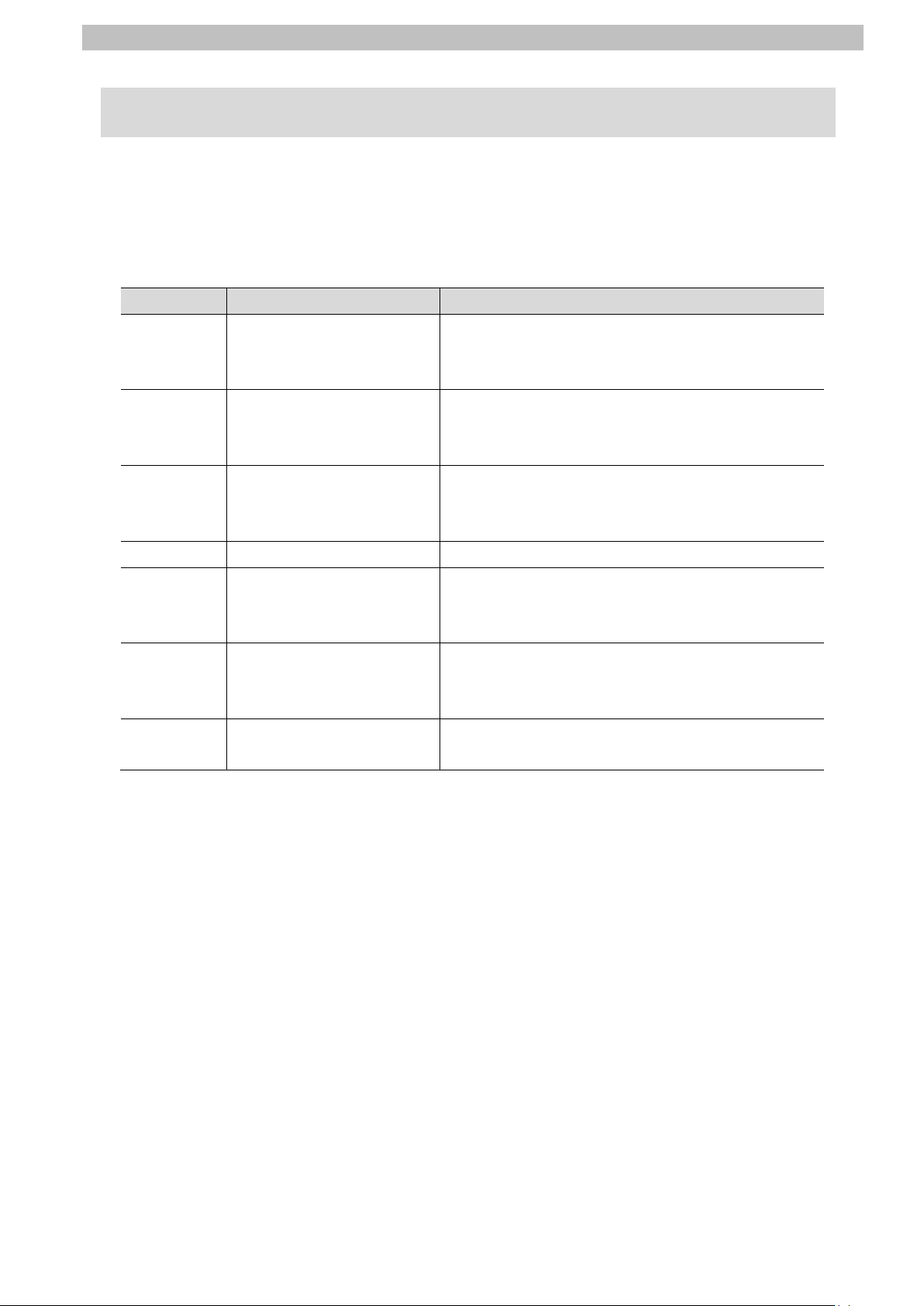

1.Related Manuals

1

1. Related Manuals

To ensure syst em safety, make sure to always read and heed the information provided in all

Safety Precautions and Precautions for Saf e Use of manuals for each device which is used in

the system.

The table below lists the manuals related to thi s document.

Cat. No. Model Manual name

W472 CJ2H-CPU6[]-EIP

CJ2H-CPU6[]

CJ2M-CPU[][]

W473 CJ2H-CPU6[]-EIP

CJ2H-CPU6[]

CJ2M-CPU[][]

W336 CJ1W-SCU[]1-V1

CJ1W-SCU[]2

W446 - CX-Programmer OPERATION MANUAL

W342 CJ2[]-CPU[][] CJ Series

W474 CJ2[]-CPU[][] CJ Series

I585 3G3MX2-A[][][][]-V1 Multi-function Compact Inverter

CJ Series

CJ2 CPU Unit Hardware USER’S MANUAL

CJ Series

CJ2 CPU Unit Software USER’S MANUAL

CJ Series

Serial Communications Units

OPERATION MANUAL

Communications Commands

REFERENCE MANUAL

Programmable Controllers

INSTRUCTIONS REFERENCE MANUAL

MX2 Series Type V1 User’s Manual

Page 7

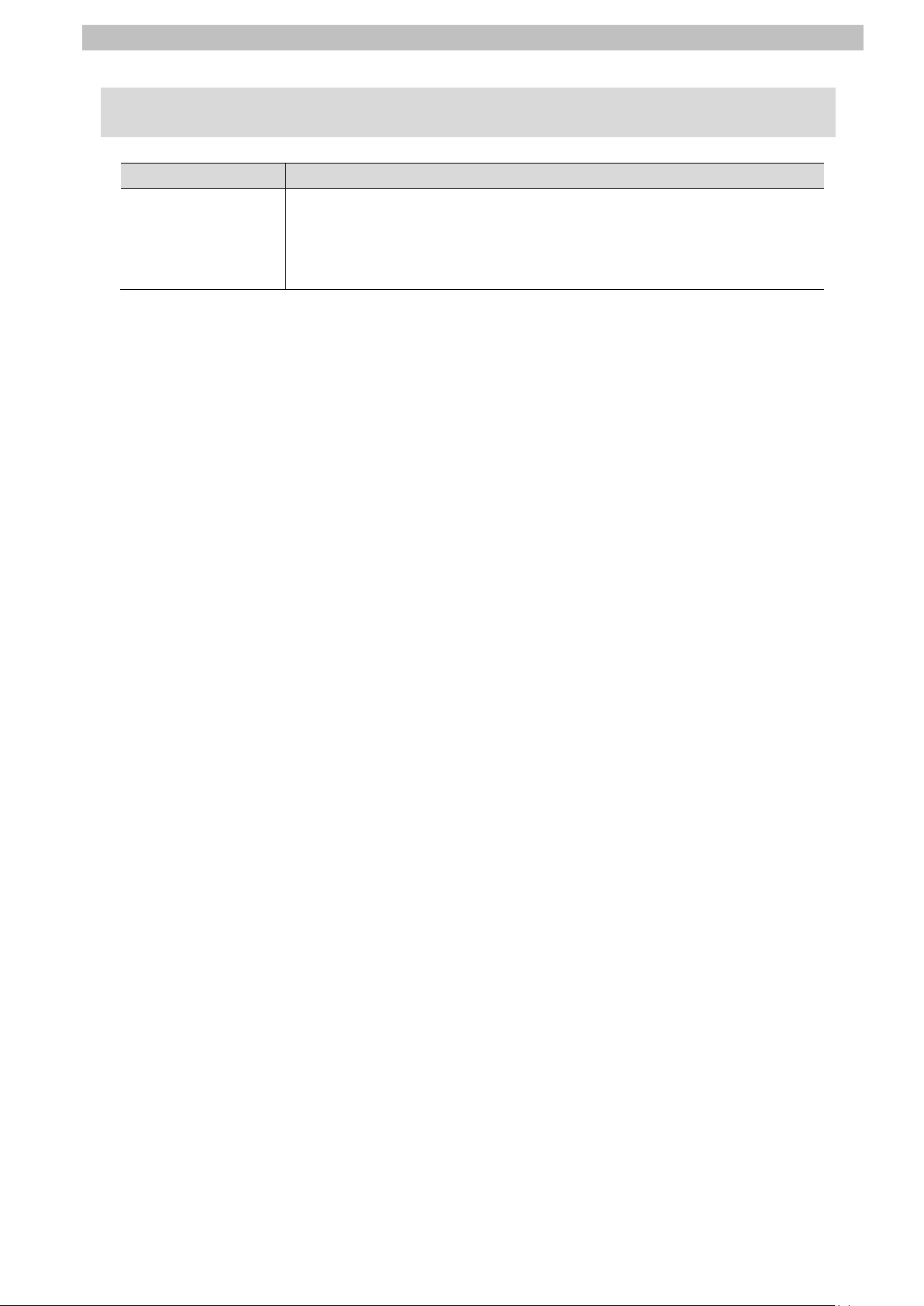

2

2. Terms and Definitions

Term Explanation and Definition

Serial Gateway

mode

This is a function of PLC that performs serial communic ations by

automatically converting a message (command data) to a specified

protocol (either CompoWay/F, Modbus-RTU, or Modbus-ASCII)

depending on a type of message.

2.Terms and Definitions

Page 8

3.Precautions

3

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Symbol

3. Precautions

(1) Understand the specifications of devices which are used in the system. Allow some

margin for ratings and performance. Provide saf ety measures, such as installing safety

circuit, in order to ensure safety and minimize ri sks of abnormal occurrence.

(2) To ensure syst em safety, make sure to always read and heed the information provided in

all Safety Precautions and Precautions for Safe Use of manuals for each device which is

used in the system.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or the whole of this

document without the permission of OMRON Corporat ion.

(5) The information contained in this document is current as of November 2015. It is subject

to change without notice for improvement.

The following notations are used in this docum ent.

Indicates a potentially hazardous situation whi ch, if not avoided,

may result in minor or moderate injury or property damage.

Precautions on what to do and what not to do to ensure saf e usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase unders tanding or make operation easier.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicat es operations that you must do.

The specific operation is shown in the c ircle and explained in text.

This example shows a general precaution for something that must do.

Page 9

4

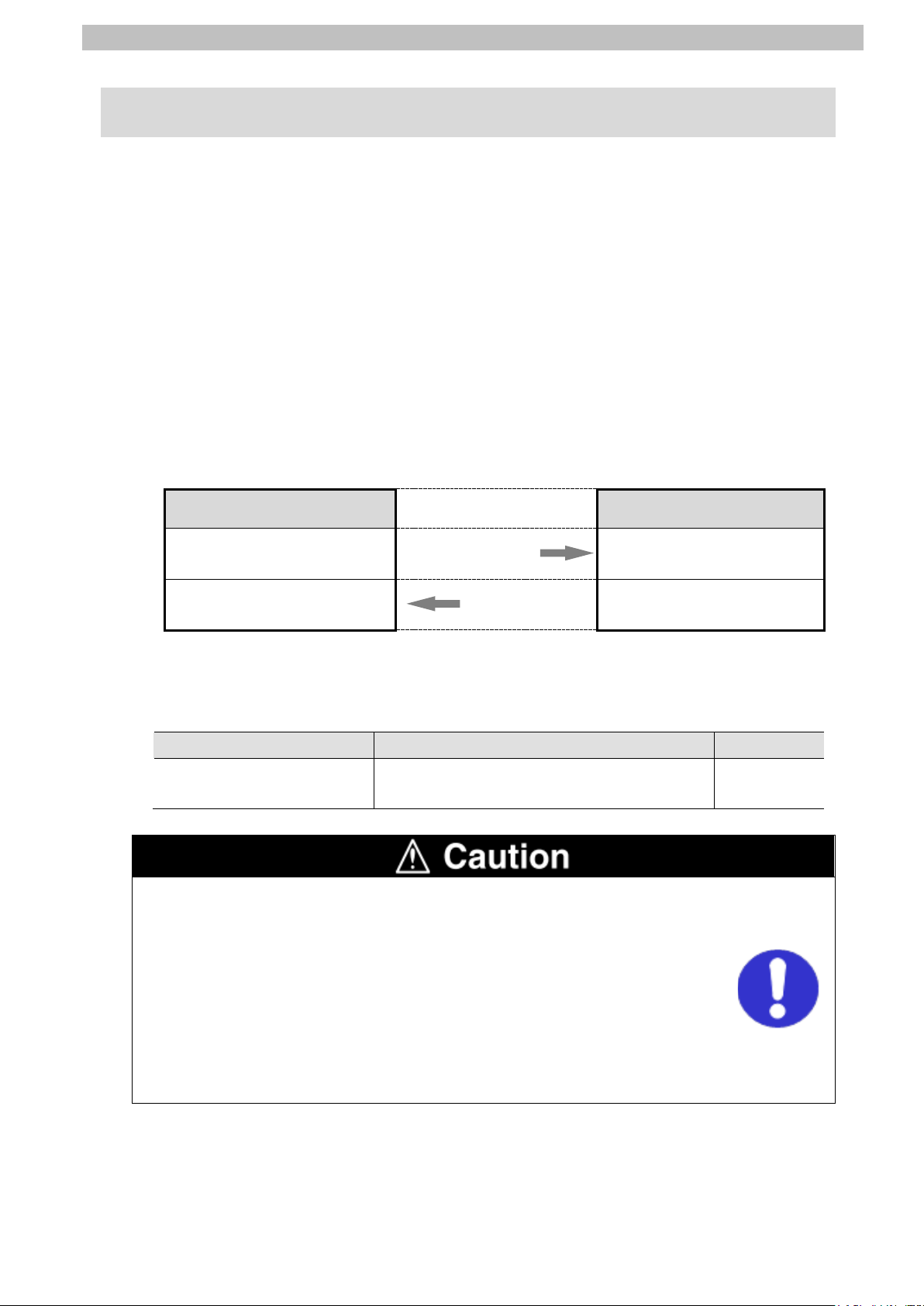

4. Overview

Serial communications

(RS-485)

Command data

Response data

This document describes the procedures f or connecting 3G3MX2 Series Type V1

Multi-function Compact Inverter (hereinafter referred to as Inverter) of OMRON Corporation

(hereinafter referred to as OMRON) to CJ-series Programmable Controller + Serial

Communications Unit (hereinafter referred t o as PLC) of OMRON using serial

communications as well as the procedures for checking their connections.

Refer to Section 6. Serial Communications Set tings and Section 7. Serial Communications

Connection Procedure to understand setting methods and key points to send or receive

messages using serial communications.

The ladder program in a prepared CX-Programm er project file is used to check the serial

connection by sending or receiving the messages of ''Total Power ON Time Monitor'' to/from

Inverter.

■Send/Receive messages of ''Total Power ON Time Monitor''

4.Overview

PLC

Sending the command data Executing the command

Receiving the response data

and storing in memory

Prepare a latest CX-Programmer project file bef orehand. To obtain a project file, contact your

OMRON representative.

Name File name Version

CX-Programmer project file

(extension: cxp)

This document aims to explain the wiring methods and communications settings

necessary to connect the corresponding devices and provide the setting

procedures. The program used in this document is designed to chec k if the

connection was properly established and i s not designed to be constantly used

at a site. Therefore, functionality and performances are not sufficiently t aken

into consideration.

When you construct an actual system, please use the wiring methods,

communications settings, and setting procedures described in this document as

a reference and design a new program according to your application needs.

OMRON_3G3MX2-V1_Mod485_EV100.cxp Ver.1.00

Returning the response data

Inverter

Page 10

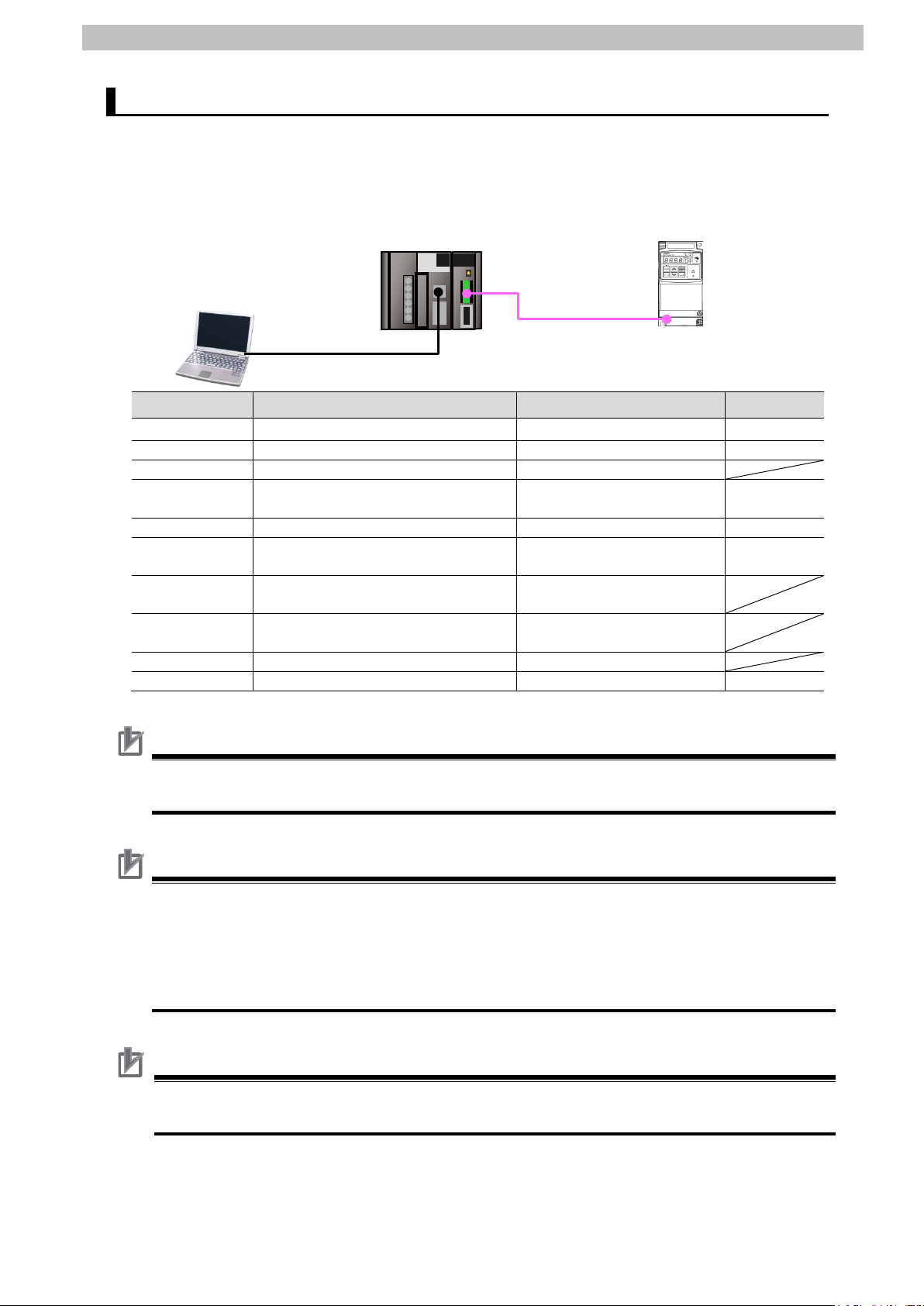

5.Applicable Devices and Device Configuration

5

OMRON

CJ2 CPU Unit

CJ2□-CPU[][]

OMRON

Serial Communications Unit

CJ1W-SCU[]1-V1

CJ1W-SCU[]2

OMRON

Inverter

your OMRON representative.

5. Applicable Devices and Device Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

3G3MX2-A[][][][]-V1

Precautions for Correct Use

As applicable devices above, the devices with the models and versions listed in 5.2. Device

Configuration are actually used in this document to describe the procedure for connecting

devices and checking the connection.

You cannot use devices with versions lower than the versions listed in 5.2.

To use the above devices with models not listed in 5.2. or versions higher than those listed in

5.2., check the differences in the specifications by referring to t he manuals before operating

the devices.

Additional Information

This document describes the procedure to es tablish the network connection. It does not

provide information on operation, installation, wiring method, device functionality or device

operation which is not related to the connection pr ocedure. Refer to the manuals or contact

Page 11

5.Applicable Devices and Device Configuration

6

OMRON

Serial Communications Unit

CJ1W-SCU42

Ver.2.0

OMRON

CPU Unit

CJ2M-CPU12

Ver.2.0

OMRON

Power Supply Unit

CJ1W-PA202

OMRON

CX-One

CXONE-AL[][]C-V4

/AL[][]D-V4

Ver.4.[][]

OMRON

CX-Programmer

(Included in CX-One)

Ver.9.54

OMRON

CX-Programmer project file

OMRON_3G3MX2-V1_M

od485_EV100.cxp

Ver.1.00

-

Personal computer

(OS: Windows 7)

- -

USB cable

(USB 2.0 type B connector)

-

-

Serial cable (RS-485)

- OMRON

Inverter

3G3MX2- A2002-V1

V2.0

Precautions for Correct Use

Precautions for Correct Use

Precautions for Correct Use

Serial cable

(RS-485)

CJ2M-CPU12+

CJ1W-SCU42

Personal computer

3G3MX2

V1

5.2. Device Configuration

The hardware components to reproduce the connect i on procedures of this document are as

follows:

(CX-One installed,

OS: Windows 7)

Manufacturer Name Model Version

USB cable

- A2002-

Prepare a latest project file beforehand.

To obtain a project file, contact your OMRON representative.

Update CX-Programmer to the version specifi ed i n thi s clause or higher version.

If you use a version higher than the one specified in this clause, the procedures and related

screenshots described in Sect ion 7. and subsequent sections may not be applicable. In that

case, use the equivalent procedures described i n this document by referring to the

CX-Programmer OPERATION MANUAL (Cat. No. W446).

Turn ON the terminating resistance switch on Serial Communications Unit and connect a 100

to 125Ω(1/2W) terminating resistor to the end of Inverter on RS-422A/485 port.

Page 12

5.Applicable Devices and Device Configuration

7

Precautions for Correct Use

Additional Information

Additional Information

The maximum length of communications c able for Inverter is 500m.

Make sure to connect Serial Communications Uni t and Inverter with a 500m or less serial

cable (RS-485).

For information on the serial cable (RS-485), refer to 3-4 RS-232C and RS-422A/485 Wiring

of the CJ Series Serial Communications Unit s OPERATION M ANUA L (Cat. No. W336).

The system configuration in this document uses USB for the connection between Personal

computer and PLC. For information on how to install a USB driver, refer to A-5 Installing t he

USB Driver in Appendices of the CJ-series CJ2 CPU Unit Hardware USER'S MANUAL (Cat.

No. W472).

Page 13

6.Serial Communications Settings

8

Precautions for Correct Use

6. Serial Communications Settings

This section describes the specifications of parameters and wirings that are set in this

document.

6.1. Parameters

The parameters required for connecting PLC and Inverter using serial communications are

shown below.

Item

Unit number 0 Address number

(Slave address)

Communications (Connection )

port

Terminating resistor Yes (TERM: ON) No

2-wire or 4-wire 2-wire (WIRE: 2) 2-wire (Fixed)

Serial communications mode Serial Gateway Data length

(Transmission character)

Stop bit 1 bit 1 bit (Default)

Parity (Parity bit) No No (Default)

Transmission rate (Baud rate) 9,600 bps (Default) 9,600 bps (Default)

Communication selection - Modbus communication (Default )

PLC (Serial Communications Unit)

- 1 (Default)

(C072: Communication Station No.

Selection =1.)

Port 1 (RS-422/485)

8 bits 8 bits (Fixed)

-

(Terminating register selector switch OFF)

(C075: Communication Stop Bit Selection

= 01)

(C074: Communication Parity Selec tion =

00)

(C071: Communication Speed Select i on

= 05)

(C096: Communication Selection = 00)

Inverter

This document describes the setting procedures of CJ1W-SCU42 Serial Communications

Unit with unit number 0 and communications (connection) port 1. To connect devices under

different conditions, change the CIO area and the control wor d of CMND instruction used in

the program. Refer to Section 9. Program for details.

Page 14

6.Serial Communications Settings

9

Pin No.

Symbol

Signal name

Input/Output

(CJ1W-SCU42).

Terminating resistor

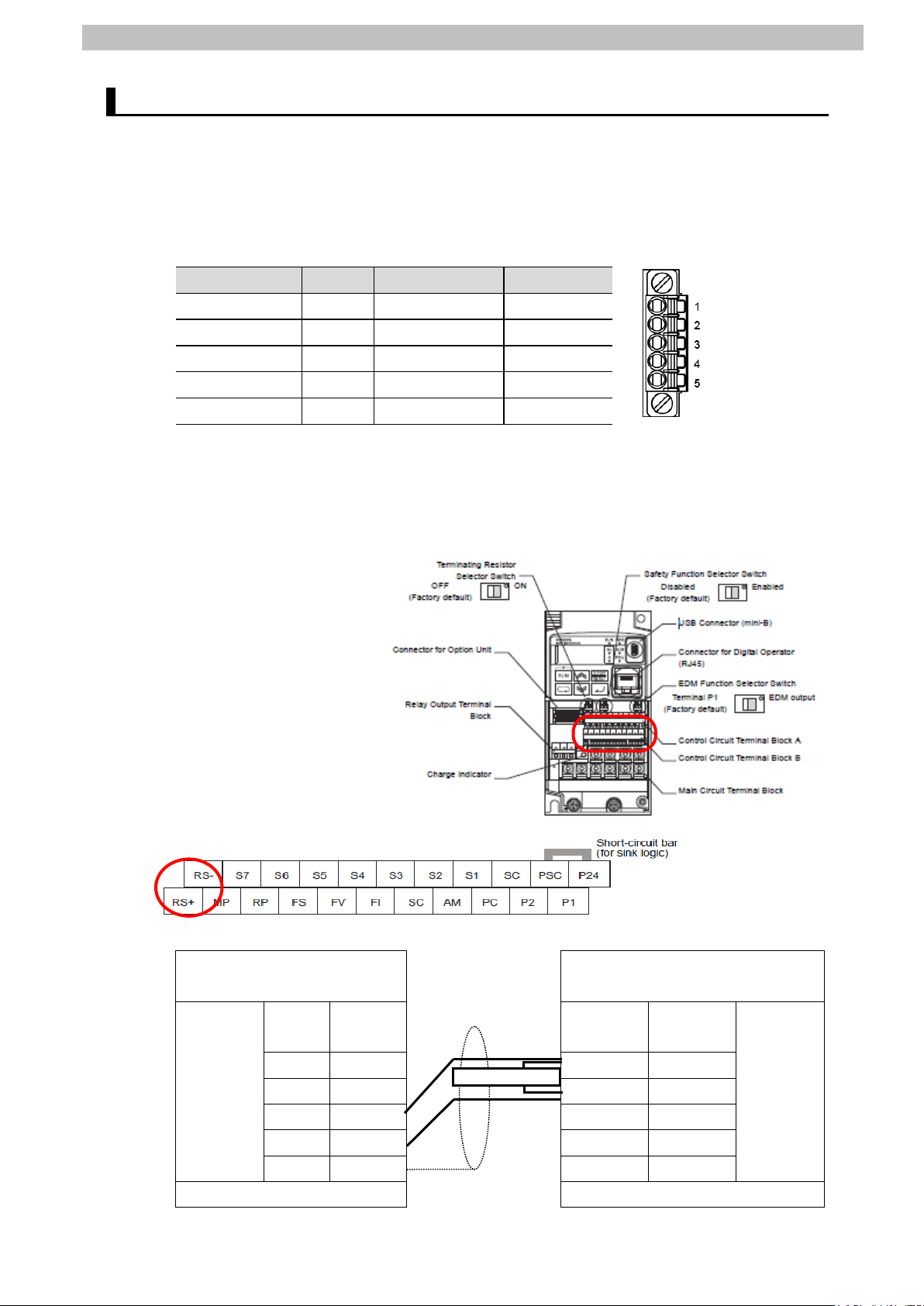

6.2. Cable Wiring Diagram

Refer to SECTION 3 Installation and Wiring of the CJ Series Serial Communications Units

OPERATION MANUAL (Cat. No. W336) for details on cable wirings.

Check connector configurations and signal li nes (pin assignments) before wiring.

■Connector configurations and signal lines (pin assignments)

CJ1W-SCU42 Serial Communications Unit applicable connector: Terminal block

1(See note 1.) RDA Receive data - Input

2(See Note 1.) RDB Receive data + Input

3(See Note 1.) SDA Send data - Output

4(See Note 1.) SDB Send data + Output

5(See Note 2.) FG Shield -

Note 1: For 2-wire connection, use either pins 1 and 2 or pi ns 3 and 4.

Note 2: Pin 5 (Shield) is connected to the GR terminal on Power Supply Unit though Serial

Communications Unit. The cable shield can thus be grounded by grounding the GR

terminal of Power Supply Unit.

Inverter (3G3MX2-A[][][][]-V1) applicable connector: Terminal block

Control Circuit Terminal

■Cable/Pin assignments

Serial Communications Unit

RS-422A/

485

interface

Terminal block Terminal block

Signal

name

RDA- 1 A1 RSRDB+ 2 B1 RS+

SDA- 3

SDB+ 4

FG 5

Pin No. Terminal

Inverter (3G3MX2-A[][][][]-V1)

Signal

block

name

RS-485

interface

Page 15

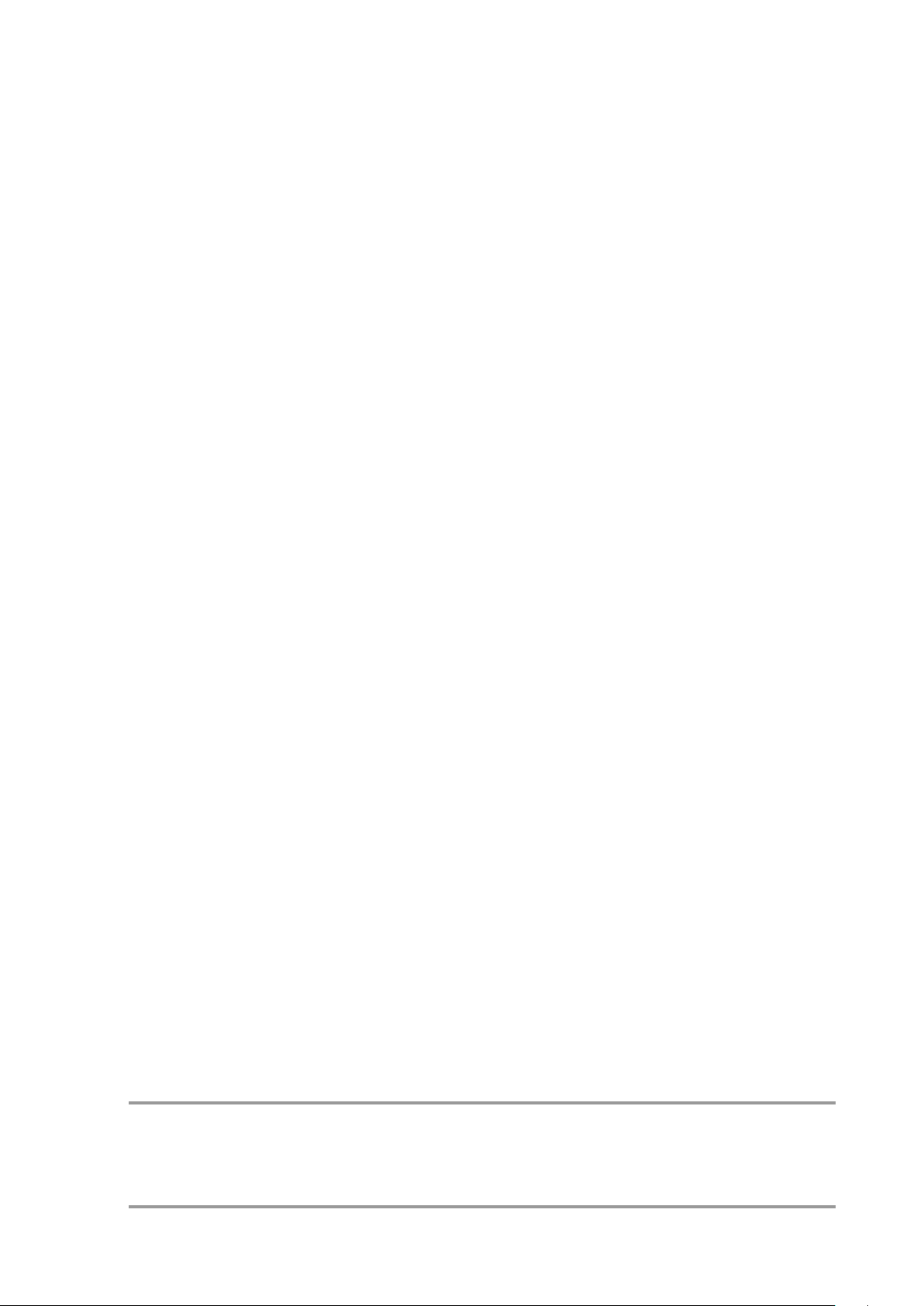

7.Serial Communications Connection Procedure

10

7.2. Setting up Inverter

Set up Inverter.

Set the hardware switches on Inverter and connect

the cables.

Set the parameters for Inverter.

7.3. Setting up PLC

Set up PLC.

Set the hardware switches on Serial Communicati ons

Unit and connect the cables.

Start CX-Programmer, open the project file, and

Create the I/O table for PLC.

Set the parameters for Serial Communications Uni t.

7.3.5. Transferring the Project Data

Transfer the project data to PLC.

Communications

Start the send/receive processing and check that

Check that the correct data is written to the I/O

memory of PLC by using CX-Programmer.

7. Serial Communications Connection Procedure

This section describes the procedures for connecting PLC to Inverter using serial

communications.

In this document, the explanations of procedures for setting up PLC and Inverter are based on

the factory default settings. For the initializ ation, refer to Section 8. Initialization Method.

7.1. Work Flow

Take the following steps to connect PLC to Inverter using serial communications, and send

and receive messages.

↓

7.2.1. Hardware Settings

↓

7.2.2. Parameter Settings

↓

↓

7.3.1. Hardware Settings

↓

7.3.2. Opening the Project File and

Connecting Online with PLC

↓

7.3.3. Creating the I/O Table

↓

7.3.4. Parameter Settings

↓

connect online with PLC.

↓

7.4. Checking the Serial

↓

7.4.1. Checking the Receive Data

serial communications are normally performed.

Page 16

7.Serial Communications Connection Procedure

11

1

following procedure.

2

1: Loosen the mounting screw (x 1) from Option Unit Cover of the Inverter

3

Check that Terminating Resistor

4

Connect a Serial cable to

RS-485 terminal

Terminating resistor

Option Unit Cover

Mounting screw

Control Circuit

T erminal Block A

Control Circuit

Terminal Block B

SDB+

SDA-

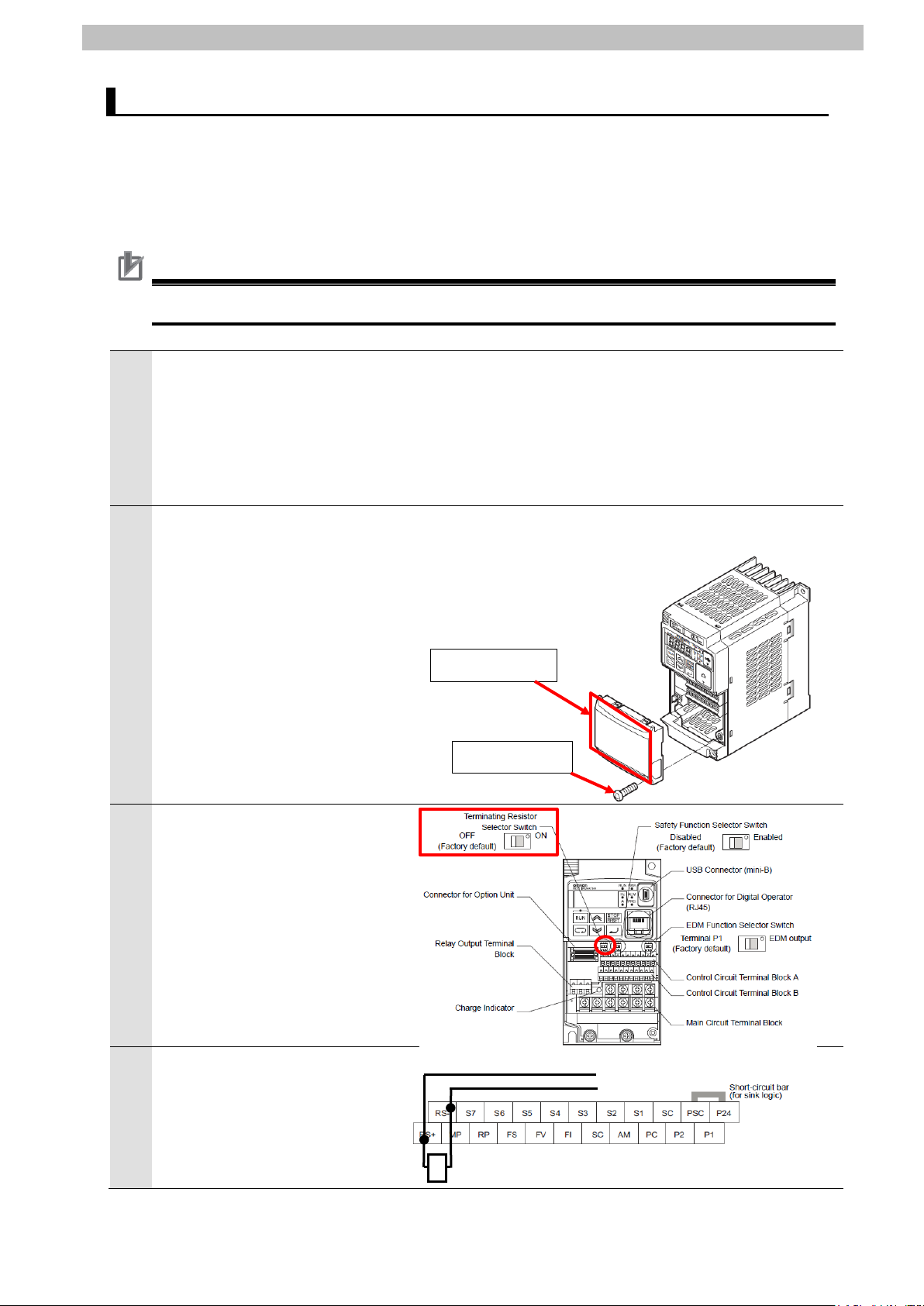

7.2. Setting up Inverter

Set up Inverter.

7.2.1. Hardware Settings

Set the hardware switches on Inverter and connect the c abl es.

Precautions for Correct Use

Make sure that the power supply is OFF when you perform the setting up.

Make sure that the power supply

to Inverter is OFF.

*If the power supply is turned

ON, settings may not be

applicable as described in the

Remove Option Unit Cover from

the Inverter front panel as

shown in the right figure.

front panel.

2: Remove Option Unit Cover.

Selector Switch inside of the

terminal block cover is OFF.

RS-485 terminal (RS-, RS+).

Connect Terminating resistor

(120Ω 1/2W) to RS-485 terminal

(RS-, RS+).

Serial cable

Page 17

12

Connect 3-Phase 200 VAC

No. I585).

6

Main power supply input

3-Phase 200 VAC

Power supply

5

power supply to Main power

supply input terminal on Inverter

with a Power supply cable.

*For details on wiring

specifications of the power

supply, refer to 2-3 Wiring of

the Inverter Multi-function

Compact Inverter MX2 Series

Type V1 User’s Manual (Cat.

7.Serial Communications Connection Procedure

terminal

cable

power supply

Mount Option Unit Cover on the

Inverter front panel.

Page 18

13

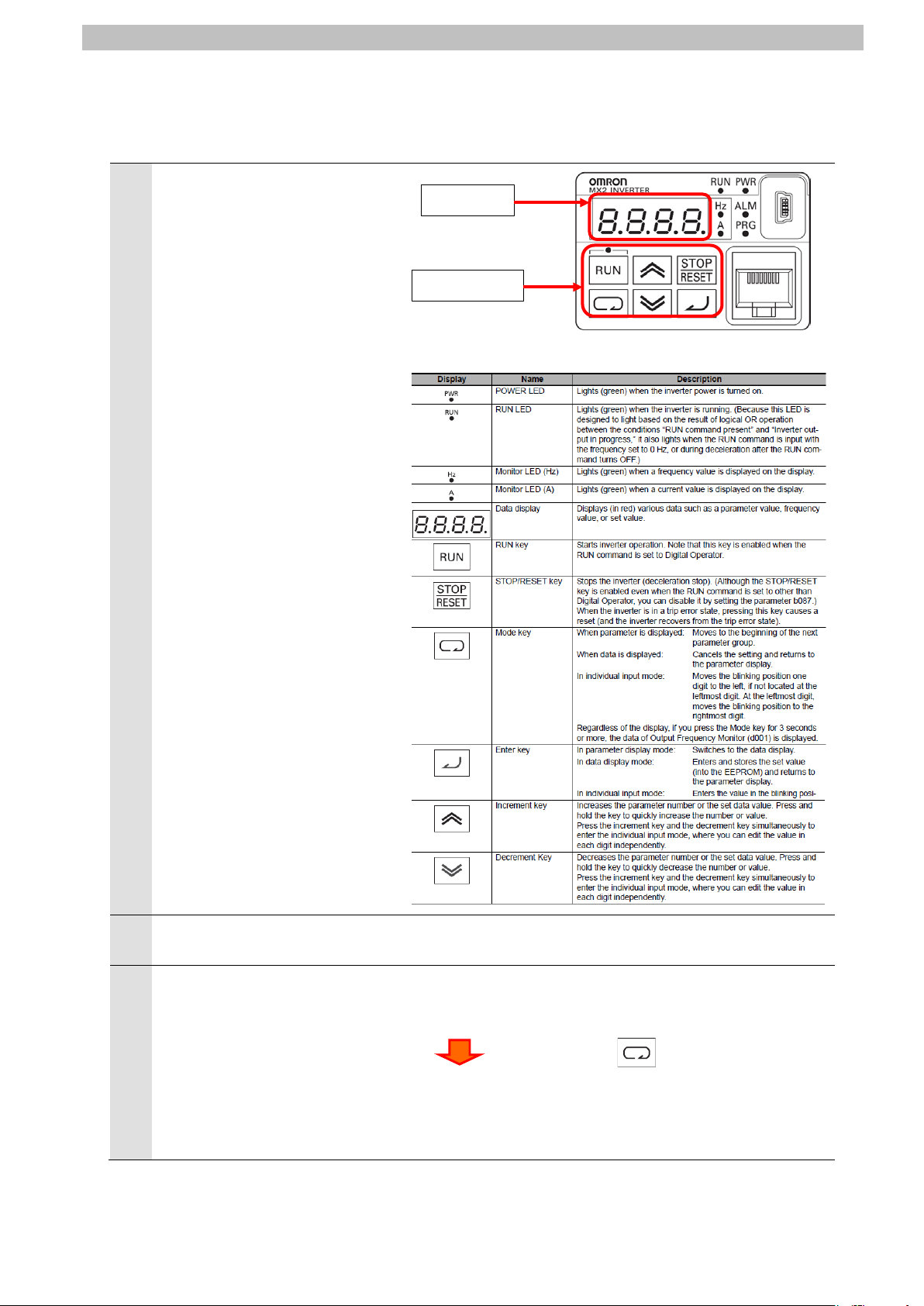

7.2.2. Parameter Settings

1

2

3

output frequency.

0.00

Data display

Operation keys

Data display.

Set the parameters for Inverter.

Check the positions of Data

display and Operation keys on

Digital Operator.

7.Serial Communications Connection Procedure

Digital Operator

Turn ON the power supply to

Inverter.

Use the procedure on the right

to display the parameters in the

extended function mode C.

*If the output frequency is not

displayed in Data display, press

and hold the Mode Key for 3

seconds or more to display the

The output frequency is displayed in

Press the Mode Key 5 times.

C001 parameter is displayed.

c001

Page 19

14

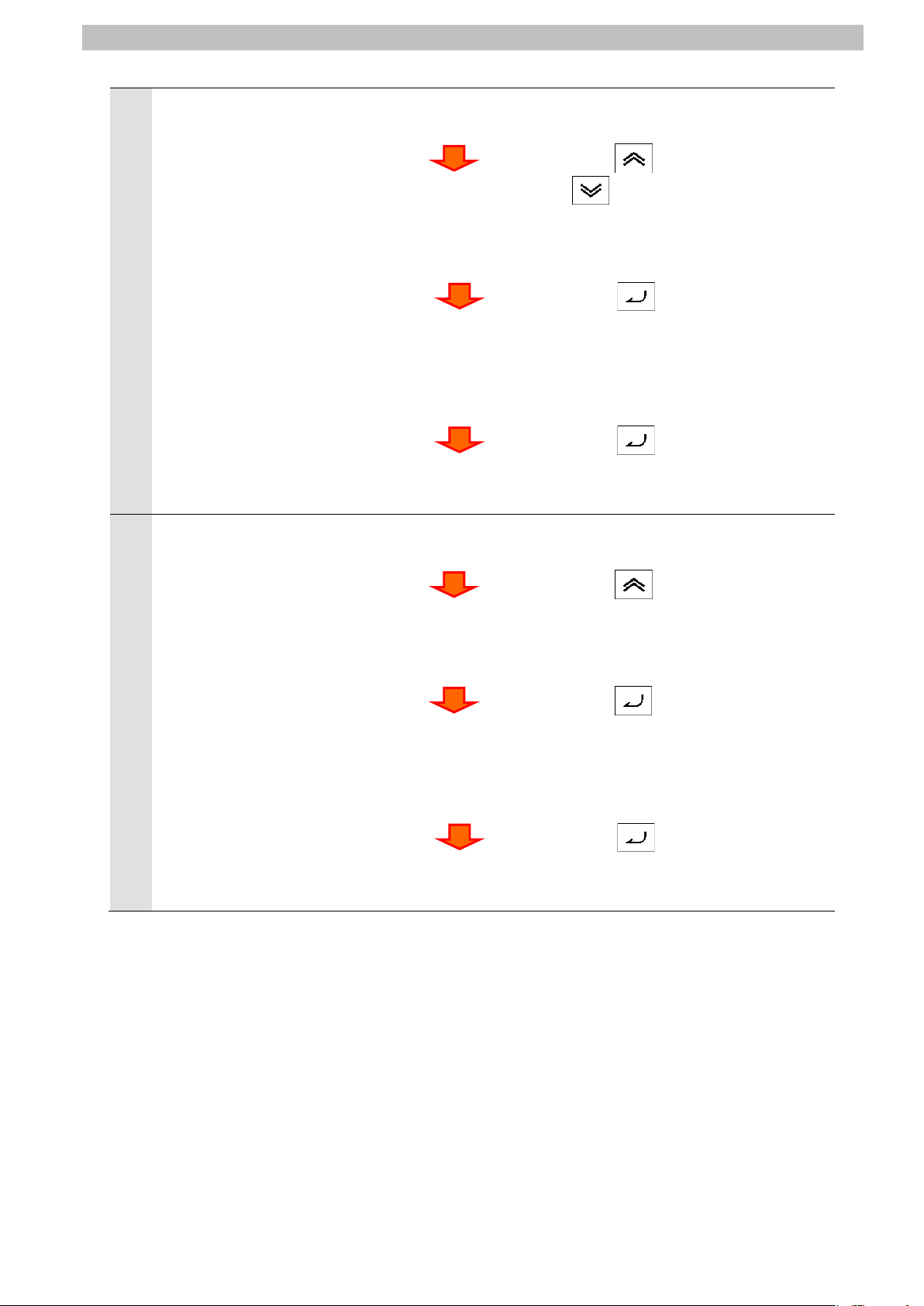

Use the procedure on the right

c001

c071

c071

c072

Check that the displayed value is the

Check that the displayed value is the

4

to set the parameters as follows:

C071 (Communication Speed

Selection): 05 (9600bps)

03: 2400bps 07: 38.4kbps

04: 4800bps 08: 57.6kbps

05: 9600bps 09: 76.8kbp

06: 19.2kbps 10: 115.2kbps

7.Serial Communications Connection Procedure

Press the Increment Key or

the Decrement Key to display

C071 parameter.

c071

05

Press the Enter Key.

C071 parameter is displayed.

Press the Enter Key.

default value ''05''.

*If the setting is different, change the

set value.

C071parameter is displayed again.

Use the procedure on the right

5

to set the parameters as follows:

C072 (Communication Station

No. Selection): 1.

Slave address: 1.

Setting range 1. to 247.

Press the Increment Key.

c072

Press the Enter Key.

1.

Press the Enter Key.

C072 parameter is displayed.

default value ''1.''.

*If the setting is different, change the

C072 parameter is displayed again.

set value.

Page 20

15

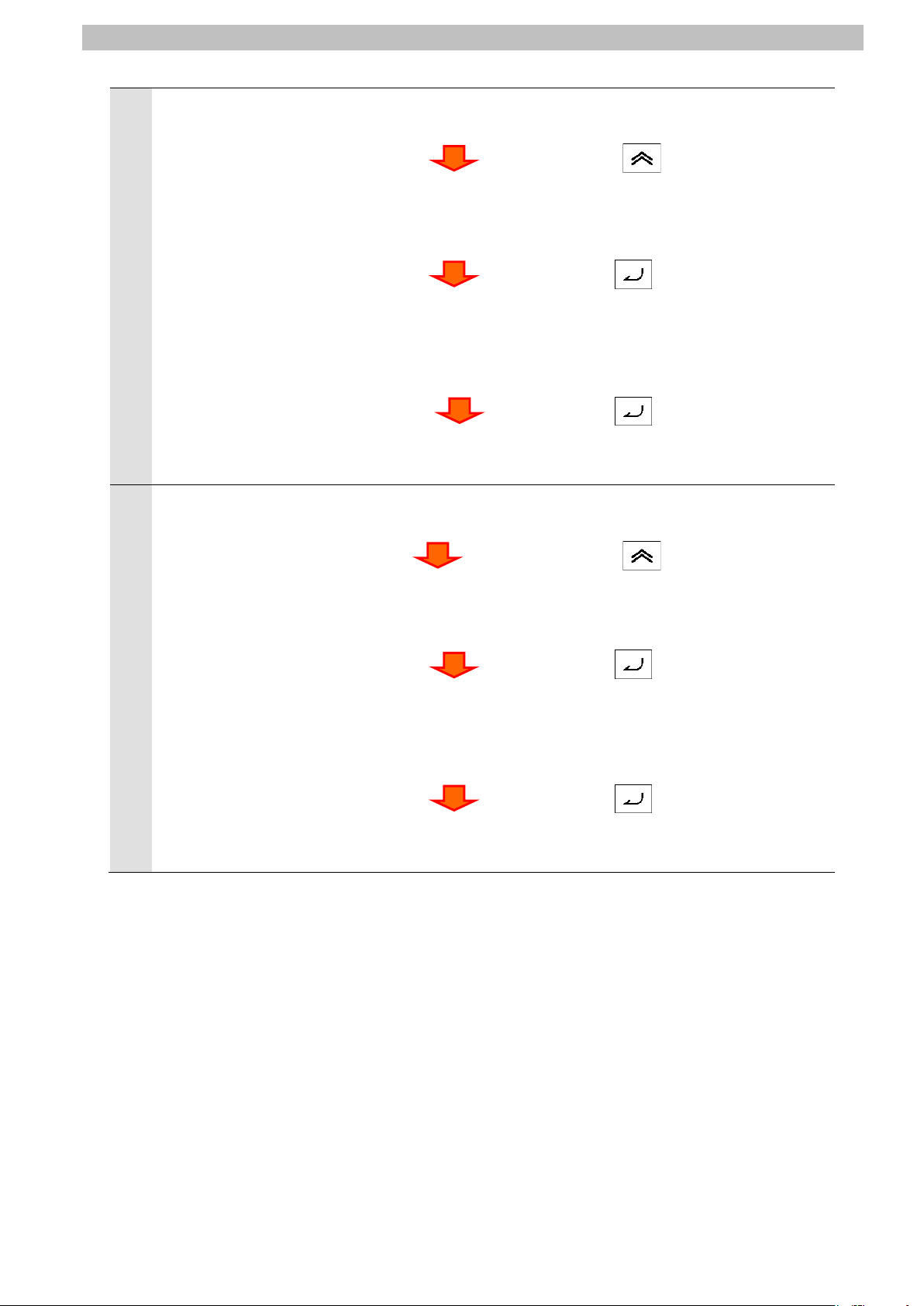

Use the procedure on the right

c072

c074

7

c074

c075

Check that the displayed value is the

set value.

Check that the displayed value is the

set value.

6

to set the parameters as follows:

C074 (Communication Parity

Selection): 00 (No parity)

00: No parity

01: Even parity

02: Odd parity

7.Serial Communications Connection Procedure

Press the Increment Key.

C074 parameter is displayed.

c074

Press the Enter Key.

default value ''00''.

00

Press the Enter Key.

*If the setting is different, change the

C074 parameter is displayed again.

Use the procedure on the right

to set the parameters as follows:

C075 (Communication Stop

Bit Selection): 01 (1 bit)

01: 1 bit

02: 2 bits

Press the Increment Key.

c075

Press the Enter Key.

01

Press the Enter Key.

C075 parameter is displayed.

default value ''01''.

*If the setting is different, change the

C075 parameter is displayed again.

Page 21

16

Use the procedure on the right

c075

c096

9

power supply again.

Check that the displayed value is the

set value.

8

to set the parameters as follows:

C096 (Communication

Selection): 00 (Modbus

communication)

00: Modbus communication

01: Co-inverter communication

02: Co-inverter communication

(management inverter)

7.Serial Communications Connection Procedure

Press the Increment Key or

the Decrement Key to display

C096 parameter.

C096 parameter is displayed.

c096

Press the Enter Key.

default value ''00''.

00

Press the Enter Key.

*If the setting is different, change the

Turn OFF the power supply to

Inverter.

*After connecting to PLC in the

procedure described on the

following page, turn ON the

C096 parameter is displayed again.

Page 22

7.Serial Communications Connection Procedure

17

1

following procedure.

the factory default setting.

TERM (Terminating resistance ON/OFF switch)

ON: Terminating resistance ON

WIRE (2-wire or 4-wire switch)

2:2-wire;4: 4-wire

7.3. Setting up PLC

Set up PLC.

7.3.1. Hardware Settings

Set the hardware switches on Serial Communicati ons Unit and connect the cables.

Precautions for Correct Use

Make sure that the power supply is OFF when you perform the setting up.

Make sure that the power supply

to PLC is OFF.

*If the power supply is turned

ON, settings may not be

applicable as described in the

Check the positions of hardware

2

switches on the front panel of

Serial Communications Unit by

referring to the right figure.

Set Unit number switch to 0.

3

*The unit number is set to 0 as

Set Terminating resistance

4

ON/OFF switch to ON

(Terminating res i stance ON).

Set 2-wire or 4-wire switch to 2

5

(2-wire).

OFF: Terminating resistance OFF

Page 23

18

Connect Serial Communications

PLC

Serial Communications Unit

End Cover

Serial cable

(RS-485)

Personal

USB cable

Power Supply Unit

CPU Unit

Inverter

6

Unit to PLC as shown on the

right.

Connect Inverter to Port 1 on

Serial Communications Unit with

a Serial cable (RS-485).

*For connections, refer to 6.2

Cable Wiring Diagram.

Connect Personal computer to

PLC with a USB cable.

7.Serial Communications Connection Procedure

computer

Page 24

7.Serial Communications Connection Procedure

19

1

PLC and Inverter.

2

start.

3

5

6

7.3.2. Opening the Project File and Connecting Online with PLC

Start CX-Programmer, open the project file, and connect online with PLC.

Install CX-Programmer and a USB driver on Personal c om puter beforehand.

Turn ON the power supplies to

Start CX-Programmer.

*If a confirmation dialog for an

access right is displayed at

start, execute a selection to

CX-Programmer starts.

Select Open from the File Menu.

4

The Open CX-Programmer

Project Dialog Box is displayed.

Select

OMRON_3G3MX2-V1_Mod485

_EV100.cxp and click Open.

*Obtain the project file from

OMRON.

After opening the project file,

select Programs in the project

workspace.

Page 25

20

Select Change Model from the

8

9

7

PLC Menu.

The Change PLC Dialog Box is

displayed.

From the pull-down list of Device

Type, select the device type of

PLC that you use.

Click Settings.

*CJ2M is selected in this

document.

7.Serial Communications Connection Procedure

The Device Type Settings

Dialog Box is displayed.

From the pull-down list of CPU

Type, select the CPU type that

you use.

Click OK.

*CPU12 is selected in this

document.

Page 26

7.Serial Communications Connection Procedure

21

11

Check that USB is set for

10

Network Type on the Change

PLC Dialog Box.

Click OK.

*If USB is not set for Network

Type, select USB from the

pull-down list.

*If you changed Device Type in

step 8 or CPU Type in step 9,

the dialog box on the right is

displayed. Check that there is

no problem and click Yes.

Make sure that the program

was normally converted. ("0

errors" must be shown.)

(Although duplicated output

warnings were detected in the

right dialog box, they are not

problems.)

Select Programs in the project

workspace.

Select Work Online from the

PLC Menu.

Page 27

22

A confirmation dialog box on the

during online connection.

Additional Information

Additional Information

12

right is displayed.

Check that there is no problem

and click Yes.

7.Serial Communications Connection Procedure

13

Check that CX-Programmer and

PLC are normally connected

online.

*The icon is press ed down

If PLC cannot be connected online, check the cable c onnection

After you check the cable connection, return to step 6, check the settings such as the

connection type in steps 7 to 9 and try again. For details, refer to Connecting Directly to a CJ2

CPU Unit Using a USB Cable of the CX-Programmer OPERATION MANUAL (Cat. No.

W446).

The dialog boxes explained in this document m ay not be displayed depending on the

environmental settings of CX-Programmer. For details on the environmental settings, refer to

Options and Preferences in CHAPTER 3 Projec t Reference in PART 1: CX-Programmer of

the CX-Programmer OPERATION MANUAL (Cat. No. W446).

This document explains the setting procedures when ''Confirm all operations affecting the

PLC'' is selected.

Page 28

23

7.3.3. Creating the I/O Table

1

Precautions for Correct Use

Create the I/O table for PLC.

If the operating mode of PLC is

Run Mode or Monitor Mode,

change it to Program Mode by

following the steps below.

(1)Select Operating Mode -

Program from the PLC Menu

of CX-Programmer.

(2)A confirmation dialog box on

the right is displayed. Check

that there is no problem and

click Yes.

*Refer to Additional Information

on the previous page for the

settings concerning the dialog

display.

(3)Check that Stop/Program

Mode is displayed on the right

of the PLC model in the

project workspace tree.

7.Serial Communications Connection Procedure

Select Edit - I/O Table and Unit

2

Setup from the PLC Menu of

CX-Programmer.

The PLC IO Table Window is

displayed.

The PLC will be reset after creating and transferring the I/O table in step 3 and subsequent

steps. Always confirm safety before creating and transferring the I/O table.

Page 29

24

Select Create from the Options

4

3

Menu in the PLC IO Table

Window.

A confirmation dialog box on the

right is displayed. Check that

there is no problem and click

Yes.

A confirmation dialog box on the

right is displayed. Check that

there is no problem and click

Yes.

7.Serial Communications Connection Procedure

The Transfer from PLC Dialog

Box is displayed.

Select IO Table and SIO Unit

Parameters and click Transfer.

When the transfer is completed,

the Transfer Results Dialog Box

is displayed.

Check that the transfer was

normally executed by referring

to the message in the dialog

box.

When the I/O table is created

normally, the dialog box displays

as follows:

Transfer Success: 1 Unit

Transfer Unsuccessful: 0 Unit

Click OK.

Page 30

7.Serial Communications Connection Procedure

25

1

2

3

7.3.4. Parameter Settings

Set the parameters for Serial Communications Uni t.

Double-click [0000] Main Rack

in the PLC IO Table Window to

expand the tree.

Right-click 00 [1500]

CJ1W-SCU42 and select Unit

Setup.

The View Parameters Dialog

Box is displayed.

Select Port1: Serial Gateway

Settings from the pull-down list

of Displayed Parameter.

Page 31

26

The setting items of Port1: Serial

5

6

4

Gateway Settings are listed as

shown in the right figure. (The

figure shows the default values.)

Select User settings from the

pull-down list of Set Value for

Port1: Port Settings.

7.Serial Communications Connection Procedure

Set the following parameters in

the same way as step 5.

・Serial communications mode

: Serial Gateway

・Data length: 8 bits

・Stop bits: 1 bit

・Parity: None

・Baud rate: Default(9600bps)

*Use the default settings for

other parameters.

Click Transfer[PC to Unit].

Page 32

27

A confirmation dialog box on the

8

9

7

right is displayed. Check that

there is no problem and click

Yes.

Check that the transfer is

completed as shown in the right

dialog box. Click Close.

7.Serial Communications Connection Procedure

A confirmation dialog box on the

right is displayed. Check the

contents and click Yes.

The Select Port Dialog Box is

displayed.

Select All ports and click OK.

The dialog box on the right is

displayed. Check the contents

and click OK.

Page 33

28

Click Compare on the View

12

13

10

Parameters Dialog Box.

7.Serial Communications Connection Procedure

Check that a message

11

"Compare successful" is

displayed in the dialog box on

the right. Click Close.

Click OK on the View

Parameters Dialog Box.

Select Exit from the File Menu

of the PLC IO Table Window to

close.

Page 34

29

1

2

3

7.Serial Communications Connection Procedure

7.3.5. Transferring the Project Data

Transfer the project data to PLC.

Select Programs in the project

workspace of CX-programmer.

Select Transfer - To PLC from

the PLC Menu.

Select Program(s), Comments,

and Program index.

Click OK.

*The I/O table and Special Unit

Setup are unnecessary to

transfer here, because they are

already set in 7.3.3. Creating

the I/O Table and 7.3.4.

Parameter Settings.

*The Comments and the

Program index Check Boxes

may not be displayed

depending on the device type.

In such a case, select

Program(s) only and transfer

the project data.

A confirmation dialog box on the

right is displayed. Check that

there is no problem and click

Yes.

Page 35

30

The dialog box on the right is

5

6

7

4

displayed (stating "Download

successful") when the transfer is

completed. Click OK.

Select Programs in the project

workspace. Select Transfer Compare with PLC from the

PLC Menu.

7.Serial Communications Connection Procedure

Select Program(s) and click OK.

Check that a message stating

"Compare successful" is

displayed. Click OK.

Page 36

7.Serial Communications Connection Procedure

31

Precautions for Correct Use

1

2

7.4. Checking the Serial Communications

Start the send/receive processing and check that serial communications are normally

performed.

If the PLC memory is changed by malfunction during monitoring power flow and

present value status in the Ladder Section Window or monitoring present values

in the Watch Window, the devices connected to output unit s may malfunction,

regardless of the operating mode of CPU Unit.

Confirm safety sufficiently before monitoring power fl ow and present value

status in the Ladder Section Window or in the Watch Window.

Check that a serial cable is connected before perform i ng the following procedure.

If it is not connected, turn OFF the power supply to each device, and then connect a serial

cable.

7.4.1. Checking the Receive Data

Check that the correct data is written to the I/O memory of PLC by using CX-Programmer.

Expand the Programs tree in the

project workspace of

CX-Programmer and

double-click Section1.

The Ladder Section Window

shows the Section1 ladder.

Ladder Section Window

Select Operating Mode Monitor from the PLC Menu.

Page 37

32

A confirmation dialog box on the

4

6

3

right is displayed. Check that

there is no problem and click

Yes.

Check that the operating mode

changes to Monitor Mode.

In the Ladder Section Window,

5

right-click Input_Start and select

Set - On.

7.Serial Communications Connection Procedure

Check that the Input_Start

contact is turned ON as shown in

the right figure.

*When the Input_Start contact is

turned ON, the send/receive

processing starts.

Page 38

33

Select Edit - Memory from the

8

9

11

7

PLC Menu.

Double-click CIO from the list in

the PLC Memory Window that is

displayed.

7.Serial Communications Connection Procedure

Enter 5500 in the Start Address

Field in the displayed CIO

Window.

Check that the start address

changes to CIO5500.

Select Monitor from the Online

10

Menu.

The Monitor Memory Areas

Dialog Box is displayed.

Select CIO and click Monitor.

Page 39

34

Check the received data in the

Function.

13

output frequency.

0.00

14

d001

d017

15

12

CIO Window shown on the right.

In the example on the right, the

stored data starting from

CIO5500 are in hexadecimal and

are described as follows:

・2804: Command code

・0000: End code

・01: Address number of Inverter

・03: Function code

・04: Number of bytes to read

・00, 00, 00, 62: Read data

*For details, refer to 9.2.2

Detailed Description of the

On Digital Operator, check the

values of Total Power ON Time

Monitor that are already read

out.

Press the Mode Key to display

the parameter of Monitor Mode

''d''.

*If the output frequency is not

displayed in Data display, press

and hold the Mode Key for 3

seconds or more to display the

7.Serial Communications Connection Procedure

Output frequency

Monitor Mode

d001

Parameter display

Press the Increment Key or the

Decrement Key to display d017.

Press the Enter Key to display

the total power ON time.

*For information on the display of

the total power ON time, refer to

7-1-16 Tot al Power ON Time

Monitor [d017] of the

Multi-function Compact Inverter

MX2 Series Type V1 User’s

Manual (Cat. No. I585).In the

example on the right, the total

power ON time shows 98, and it

accords with the read data

(00000062 in hexadecimal)

described in step 12.

( )

Total Power ON Time Monitor

Page 40

8.Initialization Method

35

8. Initialization Method

This document provides explanations of s etting procedures based on the factory default

settings.

Some settings may not be applicable as desc ri bed in t hi s document unless you use the

devices with the factory default settings.

8.1. Initializing PLC

To initialize the settings of PLC, it is necessary to initialize Serial Communications Unit and

CPU Unit. Change the operating mode of PLC to Program Mode before the initialization.

8.1.1. Serial Communications Unit

To initiali ze the settings of Serial Communications Unit, select Edit - I/O Table and Unit

Setup from the PLC Menu of CX-Programmer and perform the following steps.

(1) On the PLC IO Table Dialog Box, ri ght-click Serial Communications Unit and select Unit

Setup from the menu that is displayed.

(2) On the CJ1W-SCU42 [View Parameters] Dialog Box, click Set Defaults first, then click

Transfer[PC to Unit].

Page 41

8.Initialization Method

36

8.1.2. CPU Unit

To initiali ze the settings of CPU Unit, select Clear All Memory Areas from the PLC Menu of

CX-Programmer. Select Initialize on the Confirm All Memory Area Clear Dialog Box and click

OK.

8.2. Initializing Inverter

For information on how to initialize Inverter, refer to 5-1-2 Parameter Initialization of the

Multi-function Compact Inverter MX2 Series Type V1 User’s Manual (Cat. No. I585).

Page 42

9.Program

37

Additional Information

the disturbance such as electrical noise or the perf ormance variation of the device.

9. Program

This section describes the details on the program used in this document.

9.1. Overview

The following explains specifications and functions of the program that are used to check the

connection between OMRON Inverter (hereinafter referred to as Destination Device) and PLC

(Serial Communications Unit (hereinaft er referred to as SCU)).

This program performs the Modbus-RTU communication by CMND instruction (by using the

Serial Gateway function for SCU) to send and receive the command for Total Power ON Time

Monitor and detects a normal end or an error end.

A normal end of the send/receive processing means a normal end of the CMND instruction.

An error end means an error end of the CMND instruc tion and an error of Destination Device

(detected with the response data from Destinati on Devi ce).

Here, the "&" prefix is added to decimal data and the "#" prefix i s added to hexadecimal data

when it is necessary to distinguish between dec imal and hexadecimal data. (e.g., "&1000" for

decimal data and "#03E8" for hexadecimal data)

OMRON have confirmed that normal communic ations can be performed using this program

under 5.2. Device Configuration, however, we do not guarantee the normal operations under

Page 43

9.Program

38

PLC

CPU Unit

Serial Communications Unit

setting area

Serial Gateway

function

Command data

Response data

storage area

(2)Sends the command data

(Modbus-RTU communication)

(3)Executes the

(4)Receives the

CMND

(1) Executes the send

Communication is specified.)

9.1.1. Outline of Processing

The following figure shows the data flow from when PLC (SCU) issues command data to

Destination Device by using serial communi cations (Modbus-RTU communication) until when

it receives the response data from Destinati on Device.

(1)The ladder program executes the deliver command instruction (CMND instruction) for

which Modbus-RTU communication is specified.

(2)The command data of Total Power ON Time Monitor is sent to Inverter by Modbus-RTU

communication.

(3)The Inverter executes the command by receivi ng the command data from PLC and returns

the response data to PLC.

(4)The PLC receives the response data from Inverter and st ores in the specified address.

RS-485 Inverter

Ladder program

command instruction.

(CMND Instruction)

(The Modbus-RTU

CIO 5020 to 5023

Command Data

From CIO 5500

Response data

command and

returns the

response data.

response data and

stores it in the

specified memory.

Page 44

9.Program

39

Additional Information

28

Command

04

Command

code

Address

code

Data

+0CH

+1CH

**

**

**

**

**

Response

Command

code

Address

Function

code

End code

Data

28

04

+0CH

+1CH

+2CH

**

**

**

**

**

**

**

9.1.2. CMND Instructions and Send/Receive Messages

The following describes the network communic ations instruction (instruction word: CMND,

hereinafter referred to as CMND instruction) and outlines the basic operations of the

send/receive messages.

For details on the CMND instruction, refer to Network Instructions in SECTION 3 Instructions

of the CJ Series Programmable Controllers INST RUCT IONS REFERENCE MANUAL (Cat.

No. W474).

●CMND instruction operand data

S: First command word

・The first address is specified to set the send command.

・Data is sent from the first command word in the following format.

Function

*Command code #2804 is known as the FINS command for Modbus-RTU communication.

D: First response word

・The first address is specified to store the response.

・Data is received in the first response word in the following format.

Additional Information

For an address and a function code in the first command word, a defined device number by

Destination Device and a command code for a funct ion in executable status are set.

For details, refer to the manuals for Destination Devic e.

Page 45

9.Program

40

C: First control word

・The first address is specified to set the first control word.

・Data is set in the following format.

Item Description

Number of command data bytes The number of command data bytes is set. (#0002 to maximum data length)

Number of response data bytes The number of response data bytes is set . (#0000 to maximum data length)

Serial port number

(Physical port)

Destination network address One from the range of #00 to 7F is set. (#00: Own network)

Destination node address One from the range of #00 to the maximum node address is set.

Destination unit address The following (1) or (2) is set.

Response needed/not needed #0 or #8 is set. (#0: Response needed, #8: Response not need ed)

Logical port number One from the range of #0 to #7 is set.

Resend times One from the range of #0 to F (0 to 15 times) is set.

Response timeout One from the range of &1 to 65535 (#0001 to FFFF) (indicating 0.1 to

One from the range of #0 to #4 is set.

(#0: Not used, #1: Port 1, #2: Port 2, #3: Reserved, #4: Reserved)

*If you set the destination unit addres s to (2) Serial port's unit address as

described below, set #0: Not used.

(#00: Transmit within the local node)

(1)Unit address

CPU Unit : #00

CPU Bus Units : #10 + unit number

(e.g., for unit number (&5), Unit addr ess = #10 + #05 = #15)

Special I/O Unit : #20 + unit number

(e.g., for unit number (&10), Unit addr ess = #20 + #0A = #2A)

(2)Unit address of serial port

For SCU

Port 1: #80 + #04 x unit number

Port 2: #81 + #04 x unit number

(e.g., for Port 2 of unit number (&10),

Serial port's unit address = #81+#04×#0A(&10)= #81+#28=#A9)

6553.5 seconds) is set. (#0000: 2s ( default value))

Page 46

41

●Send/Receive messages

Additional Information

Overview of send/receive messages

S: Relation between the first command word (CMND ins truction operand) and the send

messages

9.Program

D: Relation between the receive messages and the first response word (CMND instruction

operand)

Silent interval: Waiting time to recognize the first frame using the Modbus-RTU

communication. During the reception standby, the first received data is deemed as the first

byte of frame after the waiting time of 3.5 characters with actual baud rate.

Additional Information

Error check: 16-bit data is expressed with two 8-bit data for the Modbus-RTU communication.

Error check result is calculated by the calculation formula called CRC (Cyclical Redundancy

Check).

Page 47

9.Program

42

Registers

Additional Information

9.2. Destination Device Command

The functions to read or write coils or registers are def ined as ''Modbus functions'' in the

Modbus-RTU communication. The Destination Device can be operated (comm and execution)

by using the Modbus functions to read or write coils or registers defined by Destination

Device.

9.2.1. Function Code List

In the Modbus functions, a function code is all ocated for each function. The following function

codes are available for Destination Device i n this document.

This program performs Total P ower ON Time Monitor by using the function '' Read from

Holding Register (function code: #03)''.

Code

(hex)

#01 Read Coil Status Reads the coil status (ON/OFF).

#03 Read from Holding

Register

#05 Write to Coil Writes the ON/OFF status to a single coil.

#06 Write to Holding

Register

#08 Loop-back Test Checks the communications between the mast er and the

#0F Write to Multiple Coils Rewrites the ON/OFF status to consecutive multiple

#10 Write to Multiple

Holding Registers

#17 Read/Write from/to

Multiple Holding

Function Description

Reads the contents of consecutive holding regist ers.

From the specified holding register, the specified number

of holding registers can be read.

Writes data to the specified holding register.

slave. Any value can be used for test data.

coils.

Writes data to consecutive multiple holding registers .

Reads data from and writes data to consecutive mul tiple

holding registers in a continuous manner.

For details on function codes, refer to 8-5 Explanati on of Each Function Code of the

Multi-function Compact Inverter MX2 Series Type V1 User’s Manual (Cat. No. I585).

Page 48

9.Program

43

Additional Information

No. I585).

CH

Contents

Data

Description

C

Number of command data bytes (4-digit hex)

#0008

8 bytes in S to S+3

C+1

Number of response data bytes (4-digit hex)

#000B

11 bytes from D to the upper byte of D+5

Upper

#0 (fixed)

#0 (fixed)

Serial port number (1-digit hex)

Not used.

Lower

Destination network address (2-digit hex)

Own network

Upper

Destination node address (2-digit hex)

Local node

Lower

Destination unit address (2-digit hex)

SCU number 0, Port 1

Upper

Response needed/not needed (1-digit hex)

Response needed

Logical port number (1-digit hex)

No.7 to use

#0 (fixed)

#0 (fixed)

Lower

Resend times (1-digit hex)

3 times

C+5

Response timeout (4-digit hex)

#0000

2s: Default value

CH

Contents

Data

Description

S

Command code (4-digit hex)

#2804

Modbus-RTU communication command

Upper

Slave address (2-digit hex)

#01: Destination Device address

Lower

Function code (2-digit hex)

#03: Read from Holding Register

S+2

Register address (4-digit hex) (= register number - 1).

#1016

Total Power ON Time Monitor

S+3

Number of read words (4-digit hex)

#0002

2 words

CH

Contents

Data

Description

D

Command code (4-digit hex)

#2804

Command code for S

D+1

End code (4-digit hex)

#

End code for FINS command

Upper

Slave address (2-digit hex)

#01: Slave address of S + 1

Lower

Function code (2-digit hex)

#03: Function code of S+1

Upper

Number of bytes to read (2-digit hex)

#04: Twice the number of read words S+3

Lower

Read data (first byte)

First byte of total power ON time

Upper

Read data (second byte)

Second byte of total power ON time

Lower

Read data (third byte)

Third byte of total power ON time

Upper

Read data (forth byte)

Forth byte of total power ON time

Lower

(Not used)

#00: (Not used)

9.2.2. Detailed Description of the Function

The following explains the details of Total Power ON Time Monitor (register number: #1017 to

#1018) performed by using ''Read from Holding Register (function code: #03)''.

For details on register addresses and register numbers, refer to 8-9 Modbus Communication

Data Lists of the Multi-function Compact Inverter MX 2 Series Type V1 User’s Manual (Cat.

●CMND instruction operand

・Setting contents of the first control word C (C: CIO 5010)

C+2

C+3

C+4

#0000

#0080

#0703

・Setting contents of the first command word S (S: CIO 5020)

S+1

#0103

・Storing contents of the first response word D (D: CI O 5500)

****

D+2

D+3

D+4

#0103

#04**

#****

D+5

●Send/Receive messages

・Send message Command data surrounded by bold lines above + CRC16 data (2 bytes)

・Receive message Response data surrounded by bold lines above + CRC16 data (2 bytes)

*CRC16: Error check code of send/receive data (When sending the data, the error check code

is automatically added in the send data by Modbus-RTU communication comm and.

After the error check code is automatically checked when rec ei ving the data, the

error check code is deleted from the receive data.)

#**00

Page 49

44

9.3. Error Detection Processing

01

03

10

16

00

02

Slave

address

Function

code

Number of read

words

01

83

Slave

address

Function

code + #80

Error

code

Additional Information

Serial cable

CJ2M-CPU12

CJ1W-SCU42

Destination Device

(1)

(2)

(3)

In this program, the error detection process i ng is performed by means of dividing the errors

into the following areas (1) to (3).

For details on error codes, refer to 9.7. Error Processing.

(1)Errors when executing the CMND instruc tion (CMND instruction error)

Errors such as the Unit error, the command format error, and the parameter error at the

execution of the CMND instruction are detect ed as CMND instruction errors. An error is

detected with Communications Port Error Flags (A 219.07) of related auxiliary area when

using the CMND instruction.

(2)Transmission errors when communicating with Destination Device (Communications error)

Errors occurred in communications with Destination Device, such as character corruption

and transmission errors caused by unmatched baud rate settings, are detected in CMND

instruction errors. Although the error is detected with (1), the allocated CIO area of SCU

''TransmissionErrorStatus (1508)'' is stored in the output area for the c om munication error

check.

(3)Errors in Destination Device (Desti nation Device errors)

Destination Device errors include function code error, register address error, data error, and

execution failure in Destination Device. An error is detected with the response data which is

returned from Destination Device. If an error occurs in Destination Device, a function code

that is obtained by adding #80 in the transmitted f unction code is returned (in this program,

#83 is returned when #03 is sent). This program detects an error bas ed on the difference

between the send/receive function codes.

9.Program

Send message

Receive

message

(at error)

Register address

**

CRC16

CRC16

For information on the CIO area allocated to SCU, refer to 9.4.2 List of Fixed Allocations.

Page 50

45

9.4. Memory Maps

Precautions for Correct Use

The following is the memory maps of this program.

9.4.1. Lists of Addresses

The tables below list the addresses necessary to execute this program.

You can change the allocation below to any addresses.

Make sure there is no duplicated address when changing an address.

●Input memory

The below address is used to operate this progra m.

Address Data type Variable name Description

5000.00 BOOL Input_Start When this flag changes from OFF to ON, the

send/receive processing start s .

9.Program

●Output memory

The execution results of the program are stored in these addresses.

Address Data type Variable name Description

5000.02 BOOL Output_NormalEnd Turns ON when the send/receive

processing ends normally.

5000.03 BOOL Output_ErrorEnd Turns ON when one or more of the following

errors occur.

(1)CMND instruction error

(2)Communications error

(3)Destination Device error

5500 UINT FirstResponseWord The received data is stored.

5501 UINT ResponseWord_1 The received d ata is stored.

5502 UINT ResponseWord_2 The received d ata is stored.

5503 WORD ResponseWord_3 The received data is stored.

5504 WORD ResponseWord_4 The received data is stored.

5505 WORD ResponseWord_5 The received data is stored.

H400 WORD Output_CMND_ErrorCode An Error code is stored when a CMND

instruction error occurs.

H401 WORD Output_TransmissionErrorStatus Content of transmission error status ''CIO

1508'' is stored when a communication error

occurs.

H402 WORD Output_DestinationDeviceErrorCode An error code receiv ed from Destination

Device is stored when an error occ ur s in

Destination Device.

Page 51

46

●Internal memory

These addresses are used to operate this program only.

Address Data type Variable name Description

5000.01 BOOL Local_CMND_Executing CMND instruction execution status is indicated.

5000.04 BOOL Local_CMND_NormalEnd Turns ON when a CMND instruction ends

5000.05 BOOL Local_CMND_ErrorEnd Turns ON when a CMND instruction error

5000.06 BOOL Local_DestinationDeviceError Turns ON when a Destination Device error

5010 UINT Local_FirstControlWord Execution parameter of CMND i ns truction

5011 UINT Local_ControlWord_1 Execution parameter of CMND instruction

5012 UINT Local_ControlWord_2 Execution parameter of CMND instruction

5013 UINT Local_ControlWord_3 Execution parameter of CMND instruction

5014 UINT Local_ControlWord_4 Execution parameter of CMND instruction

5015 UINT Local_ControlWord_5 Execution parameter of CMND instruction

5020 UINT Local_FirstCommandWord Send data of CMND instruct ion

5021 UINT Local_CommandWord_1 Send data of CMND instruction

5022 UINT Local_CommandWord_2 Send data of CMND instruction

5023 UINT Local_CommandWord_3 Send data of CMND instruction

9.Program

Turns ON when a CMND instruction is being

executed, and turns OFF when a CMND

instruction is not executed.

normally.

(including a communications error) occurs.

occurs.

Page 52

9.Program

47

Additional Information

Additional Information

9.4.2. List of Fixed Allocations

The tables below list the addresses necessary t o execut e this program.

●Allocated CIO area

The following is the fixed addresses determined by the unit address (unit number) that is set

for SCU. Therefore, you must not change these allocations.

Unit number 0 is used in this program.

Address Data type Variable name

1508.15 BOOL TransmissionError_SCU_0_P1

1508 WORD TransmissionErrorStatus_SCU_0_P1

For details on the allocated CIO area of SCU, refer to 2-3-2. CIO Area in 2-3. I/O Memory

Allocations in SECTION 2 Initial Sett ings and I/O Memory Allocations of the CJ Series Serial

Communications Units OPERATION MANUAL (Cat. No. W336).

●Related auxiliary area

The addresses of the following related auxiliary area are determined by the communications

port (internal logical port) specified in the pro gram (CMND operand). Therefore, you must

not change these allocations.

This program uses communications port (internal l ogical port) No. 7.

Address Data type Variable name

A202.07 BOOL CommPortEnabledFlag_P7

A219.07 BOOL CommPortErrorFlag_P7

A210 WORD CommPortCompletionCode_P7

For information on related auxiliary area for t he CMND instruction, refer to Related Auxiliary

Area Words and Bits in Network Instructions (CMND) in SECTION 3. Instructions of the CJ

Series Programmable Controllers INSTRUCTIONS REFERENCE MANUAL (Cat. No.

W474).

Page 53

48

9.5. Ladder program

processing.

9.5.1. Functional Components of the Ladder Program

The functional components of this program are shown bel ow.

Major classification Minor cl assification Description

1.Initialization

processing

2.CMND instruction

execution

management

1.1. Response code clear

1.2. Control word setting for

CMND instruction

1.3. Send/Receive symbol

setting

2.1. CMND instruction

executing

2.2. CMND instruction

execution processing

2.3. Normal/Error detection

The area of use is cleared and the

initialization setting is performed as a

preparation for communications.

CMND instruction (Modbus-RTU

communication) is executed. A normal end

or an error end is detected based on the

related flags and receive data.

9.Program

3.Normal end state

management

4.Error end state

management

3.1. Normal end processing

3.2. Response code setting

4.1. Error end processing

4.2. Response code setting

The normal completion flag is turned ON.

The response code for a normal end is set.

The error end flag is turned ON.

The response code corresponding to an

error cause is set.

9.5.2. Detailed Description of Each Functional Component

The program configured in this document is shown below.

●1. Initialization processing

No. Outline Description

1.1. Res ponse code

clear

The Error code storage area is initialized.

Page 54

9.Program

49

No. Outline Description

1.2. Control word setting

for CMND instruction

1.3. Send/Receive

symbol setting

The control word of CMND instruction is set.

For details on the settings, refer to 9.2.2. Detail ed

Description of the Function.

The FINS command and the Destination Device function are

set to the send symbol, and the receive data storage area i s

initialized.

Page 55

50

●2. CMND instruction execution management

processing

instruction is not being executed.

Precautions for Safe Use

Precautions for Correct Use

9.Program

ss

No. Outline Description

2.1. CMND i nstruction

executing

2.2. CMND i nstruction

execution

Make sure to sufficiently check the overall program before spec ifying the area to store the

receive data of the CMND instruction. Otherwise, t he data may be written to an unintended

memory area.

This program uses communications port (internal l ogical port) No.7.

Do not use communications port No.7 for other purpose. If you have no choice but to use

communications port No. 7, check that Communications Port Enabled Flag (A202.07) is ON.

CMND instruction executing status is entered.

The executing state is reset at a normal end or an error end

of the program.

CMND instruction is executed under the following

conditions: Communications port No.7 can be used. CMND

Page 56

9.Program

51

No. Outline Description

2.3. Normal/Error

Detection

Processing

Detects a normal end or an error end of the result of

send/receive processing.

It is identified as a normal end when all the foll owi ng conditions

are satisfied.

・Normal end of CMND instruction (No CMND instruction error)

(Condition of ''No communication error'' is included in (1).)

・Receives normal messages from Destination Devi ce

(No Destination Device error)

If any of the above errors occurs under the conditi ons above,

the corresponding error flag will turn ON.

Page 57

52

●3. Normal end state management

9.Program

No. Outline Description

3.1. Normal end

processing

3.2. Res ponse code

setting

Turns ON the normal end flag if it is detected in 2.3.

Normal/Error detection processing that the send/receive

processing ends normally.

Sets response code "#0000" for a normal end in the

response code storage area.

Page 58

53

Additional Information

●4. Error end state management

9.Program

No. Outline Description

4.1. Error end processing Turns ON the error end flag if it is detected in 2.3.

4.2. Res ponse code

setting

Refer to 9.7 Error Processing in this document for details on the response codes.

Normal/Error detection processing that the send/receive

processing ends in an error.

Sets the response code corresponding to the error in the

response code storage area when an error occurs.

Page 59

54

9.6. Timing Chart

Pattern

Normal end

Error end (1)

instruction error

Error end (2)

error

Error end (3)

Device error

Command

Normal

Error

Normal

Normal

Destination

Device

Normal

Normal or error

Normal or error

Error

Response

Yes

No

No

Yes

The timing charts are shown below.

The definitions of the timing chart patterns are as f ol lows:

9.Program

CMND

Communications

Destination

Page 60

55

9.7. Error processing

Main response code

Sub-response code

Main

Sub

Main response code

Sub-response code

02

05

Destination node error

Response timeout

10

04

Command format error

Command format error

25

05

Unit error

CPU Bus Error

Additional Information

Bit

Description

15

1: Transmission error 0: No transmission error

8 to 14

(Not used)

7

1: FCS check error 0: F CS check normal

6

(Not used)

5

1: Timeout error 0: Normal

4

1: Overrun error 0: Normal

3

1: Framing error 0: Normal

2

1: Parity error 0: Normal

0, 1

(Not used)

The following tables list the errors that oc cur during executing this program.

9.7.1. CMND Instruction Error Code

H400 stores the end code of the network communications instruction.

[Format]

Bit 15 8 7 0

[Response codes (Excerpt)]

9.Program

For details, refer to 5-1-3 End Codes in 5-1 Command Lists in SECTION 5 FINS Commands

of the CJ Series Communications Commands REF ERENCE MANUAL (Cat. No. W342).

Additional Information

For details on the CMND instruction error and troub l eshooting, refer to 12-3 Troubleshooting

in SECTION 12 Troubleshooting and Maintenance of the CJ Series Serial Communications

Units OPERATION MANUAL (Cat. No. W336).

9.7.2. Transmission error status

H401 stores contents of the transmission error st atus ''1508''.

[Contents of each bit in the transmission error status]

Page 61

56

9.7.3. Destination Device Error Code

#01

An unsupported function is specified.

Additional Information

Upper byte of H402 stores the following error codes.

[Format]

Bit 15 8 7 0

9.Program

Error code

#Always #00

[Error code list]

Error code (hex) Description

#02 The specified address does not exist.

#03 The specified data is in an unacceptable format.

#21 Writing to a holding register is specified, but the data is out of the range

allowed for the inverter.

#22 The inverter does not allow this function because:

・Function attempts to change a register that cannot be changed

during RUN.

・Function attempts to issue the Enter command during RUN (UV

・Function attempts to write data to a register during trip (UV

・Function attempts to write data to a register on which the soft lock

function is enabled.

・Function attempts to change an I/O terminal that cannot be

changed.

・Function attempts to change the contact type of the term inal to

which the RS (Reset) is allocated.

・Function attempts to write data to a register when t he auto-tuning

function is enabled.

・Function attempts to write data to a password-locked register when

the password function is enabled.

etc.

*1. UV: Undervoltage

#23 Func tion attempts to write data to a read-only register (coil).

*1

).

*1

).

For details and troubleshooting on the Desti nation Device errors, refer to 8-4-4 Abnormal

Response in 8-4 Modbus Communication Protocol of the Multi-function Compact Inverter

MX2 Series Type V1 User’s Manual (Cat. No. I585).

Page 62

57

10. Revision History

code

Revision

01 November 16, 2015 First edition

Date of revision Revision r easo n an d r evision page

10.Revision History

Page 63

58

Page 64

2015

P641-E1-01

1115- (-)

Loading...

Loading...