Page 1

Cat. No. I570-E1-02

USER’S MANUAL

SYSDRIVE MX2

SERIES

Multi-function Compact Inverter

Page 2

Page 3

1

Introduction

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Introduction

Thank you for choosing the multi-function Inverter 3G3MX2. This User's Manual (hereinafter

called "this manual") describes the parameter setting methods required for installation/wiring

and operation of the 3G3MX2 model, as well as troubleshooting and inspection methods.

z This manual should be delivered to the actual end user of the product.

z After reading this manual, keep it handy for future reference.

z This manual describes the specifications and functions of the product as well as the relations

between them. You should assume that anything not described in this manual is not possible

with the product.

z Intended readers

This manual is intended for those with knowledge of the workings of electricity (qualified

electric engineers or the equivalent), and also in charge of:

Introducing the control equipment

Designing the control system

Installing and/or connecting the control equipment

Field management

Page 4

2

Read and Understand this Manual

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your

OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 5

3

Read and Understand this Manual

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 6

4

Read and Understand this Manual

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 7

5

Safety Precautions

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Safety Precautions

Indications and Meanings of Safety Information

In this user's manual, the following precautions and signal words are used to provide

information to ensure the safe use of the 3G3MX2 Inverter.

The information provided here is vital to safety. Strictly observe the precautions provided.

Meanings of Signal Words

Alert Symbols in this Document

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or in property damage.

WARNING

CAUTION

Turn off the power supply and implement wiring correctly. Not doing so may result in a serious injury

due to an electric shock.

Wiring work must be carried out only by qualified personnel. Not doing so may result in a serious

injury due to an electric shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to an electric shock or fire.

(200 V class: type-D grounding, 400 V class: type-C grounding)

Do not remove the terminal block cover during the power supply and 10 minutes after the power

shutoff.

Doing so may result in a serious injury due to an electric shock.

Do not operate the Digital Operator or switches with wet hands. Doing so may result in a serious

injury due to an electric shock.

Inspection of the Inverter must be conducted after the power supply has been turned off. Not doing

so may result in a serious injury due to an electric shock. The main power supply is not necessarily

shut off even if the emergency shutoff function is activated.

Do not change wiring, slide switches, or optional devices while power is being supplied.

Always turn off the power supply to the Inverter before changing wiring, changing the slide switches,

or attaching/removing options.

Do not touch the Inverter fins, braking resistors and the motor, which become too hot during the

power supply and for some time after the power shutoff. Doing so may result in a burn.

WARNING

Page 8

6

Safety Precautions

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Do not connect resistors to the terminals (+1, P/+2, N/−) directly.

Doing so might result in a small-scale fire, heat generation or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury. (A holding

brake is not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking

resistor, install a thermal relay that monitors the temperature of the resistor. Not doing so might result

in a moderate burn due to the heat generated in the braking resistor/regenerative braking unit.

Configure a sequence that enables the Inverter power to turn off when unusual overheating is

detected in the braking resistor/regenerative braking unit.

The Inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or

other property. Place covers on the openings or take other precautions to make sure that no metal

objects such as cutting bits or lead wire scraps go inside when installing and wiring.

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches the

Inverter capacity on the power supply side. Not doing so might result in damage to property due to

the short circuit of the load.

Do not dismantle, repair or modify this product.

Doing so may result in an injury.

CAUTION

Page 9

7

Precautions for Safe Use

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Precautions for Safe Use

Installation and Storage

Do not store or use the product in the following places.

Locations subject to direct sunlight.

Locations subject to ambient temperature exceeding the specifications.

Locations subject to relative humidity exceeding the specifications.

Locations subject to condensation due to severe temperature fluctuations.

Locations subject to corrosive or flammable gases.

Locations subject to exposure to combustibles.

Locations subject to dust (especially iron dust) or salts.

Locations subject to exposure to water, oil, or chemicals.

Locations subject to shock or vibration.

Transporting, Installation, and Wiring

Do not drop or apply strong impact on the product. Doing so may result in damaged parts or

malfunction.

Do not hold by the terminal block cover, but hold by the fins during transportation.

Do not connect an AC power supply voltage to the control input/output terminals. Doing so may

result in damage to the product.

Be sure to tighten the screws on the terminal block securely.

Wiring work must be done after installing the unit body.

Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

Take sufficient shielding measures when using the product in the following locations. Not doing

so may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

Main Circuit Power Supply

Confirm that the rated input voltage of the Inverter is the same as AC power supply voltage.

Operation and Adjustment

Be sure to confirm the permissible range of motors and machines before operation because the

Inverter speed can be changed easily from low to high.

Provide a separate holding brake if necessary.

Maintenance and Inspection

Be sure to confirm safety before conducting maintenance, inspection or parts replacement.

The life of the capacitor depends on ambient temperatures. Refer to the diagram of product life

specified in the manual. When the capacitor stops operating at the end of the product's life, the

Inverter must be replaced.

Page 10

8

Precautions for Correct Use

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Precautions for Correct Use

Installation

Mount the product vertically on a wall with the product's longer sides upright.

The material of the wall has to be nonflammable such as a metal plate.

Restart after Trip

Do not come close to the machine when using the Restart During Momentary Power Interruption

function because the machine may abruptly start when stopped by an alarm.

Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine

may abruptly start.

Operation Stop Command

Provide a separate emergency stop switch because the STOP key on the Digital Operator is valid

only when function settings are performed.

When checking a signal during the power supply and the voltage is erroneously applied to the

control input terminals, the motor may start abruptly. Be sure to confirm safety before checking a

signal.

Maintenance and Parts Replacement

The Inverter consists of many parts, and these parts must operate properly in order to make full

use of the designed functions of the Inverter. Among the electronic components, there are some

that require maintenance depending on their usage conditions. In order to keep the Inverter

operating normally over a long period of time, it is necessary to perform periodic inspections and

replace parts according to their service life.

Product Disposal

Comply with the local ordinance and regulations when disposing of the product.

Page 11

9

Precautions for Correct Use

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

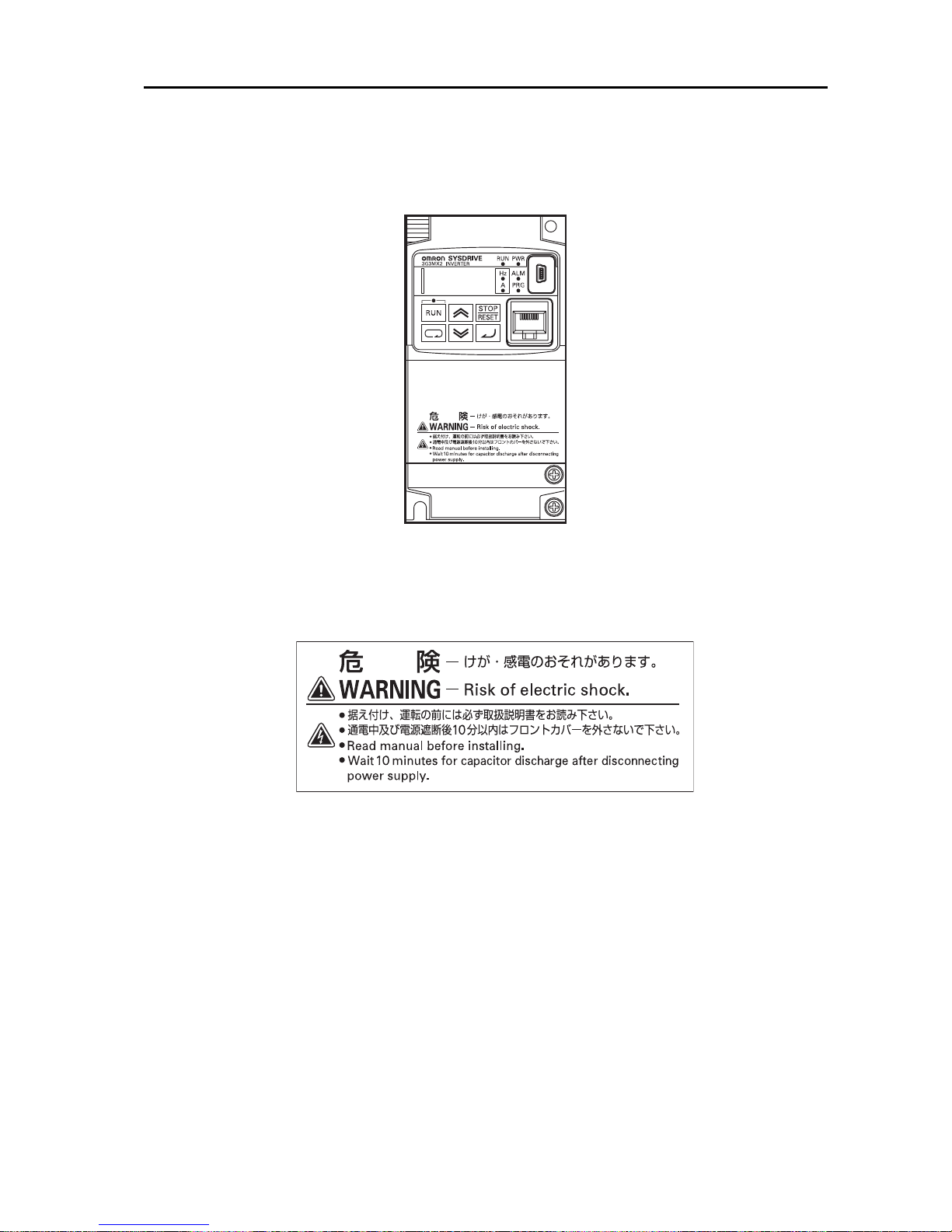

Warning Labels

Warning labels are located on the Inverter as shown in the following illustration.

Be sure to follow the instructions.

Warning Description

Page 12

10

Checking Before Unpacking

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Checking Before Unpacking

Checking the Product

On delivery, be sure to check that the delivered product is the Inverter 3G3MX2 model that you

ordered.

Should you find any problems with the product, immediately contact your nearest local sales

representative or OMRON sales office.

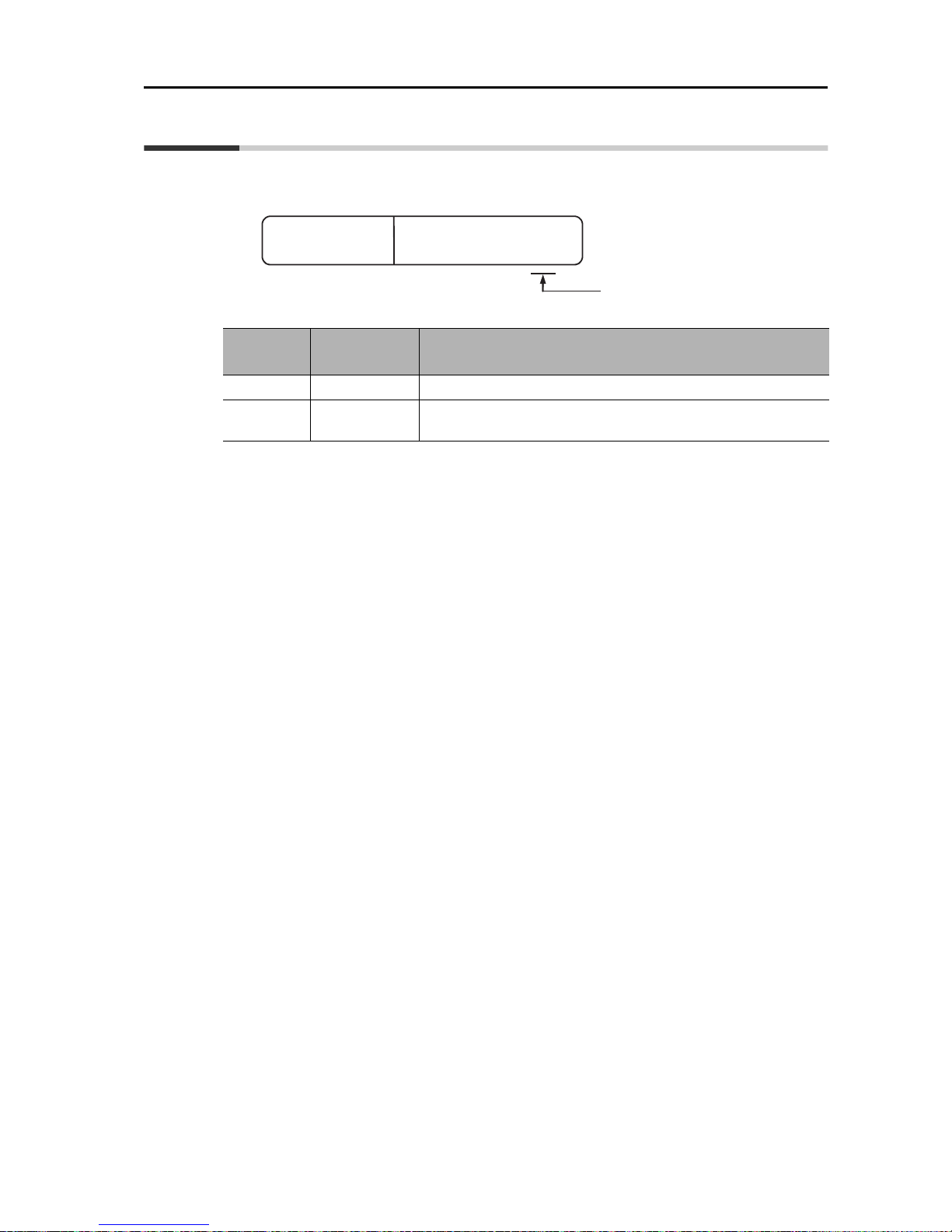

Checking the Nameplate

Checking the Model

Checking the Accessories

Note that Instruction manual is the only accessory included with the 3G3MX2 model.

Mounting screws and other necessary parts must be provided by the user.

Inverter model

Input specifications

Output specifications

3G3MX2-A2055

Maximum applicable motor capacity (CT rating)

004

007

015

022

0.4 kW

0.75 kW

1.5 kW

2.2 kW

5.5 kW

7.5 kW

11 kW

15 kW

Voltage class

B

2

4

1-phase 200 V AC (200 V class)

3-phase 200 V AC (200 V class)

3-phase 400 V AC (400 V class)

Enclosure rating

A

Panel-mounting (IP10 min.) or closed

wall-mounting models

0.1 kW

0.2 kW

001

3.0 kW

3.7 kW

4.0 kW

030

037

040

002

055

075

110

150

Page 13

11

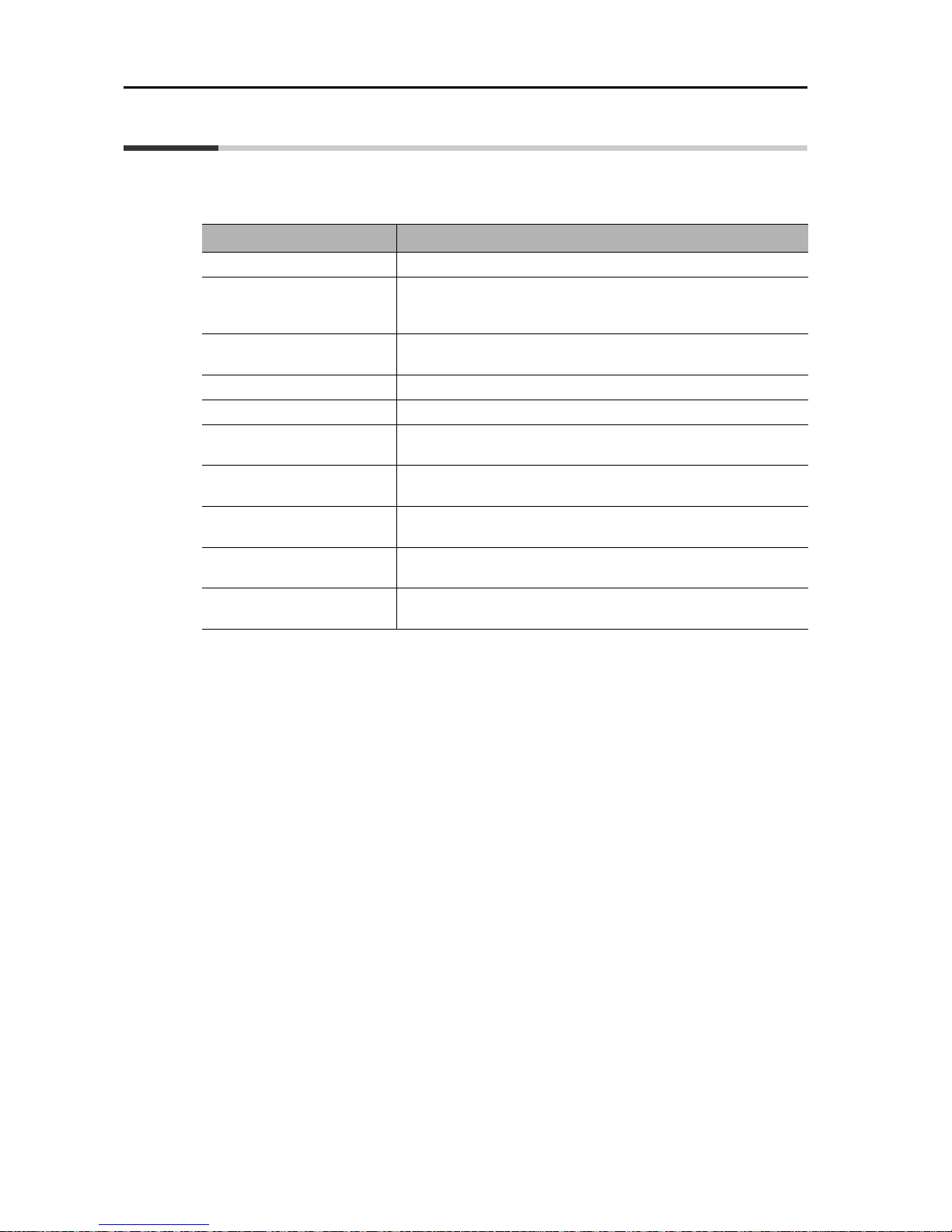

Revision History

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

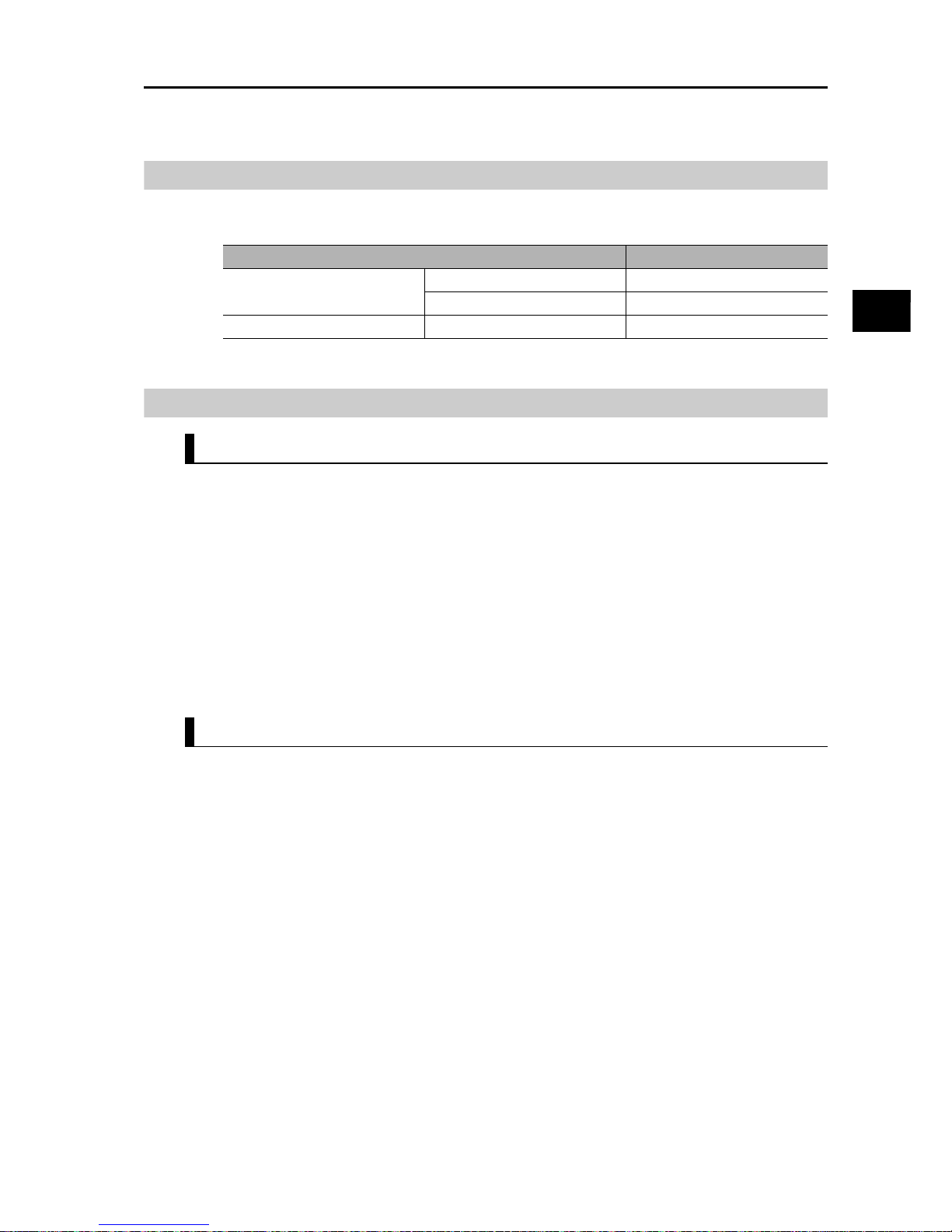

Revision History

A manual revision code appears as a suffix to the catalog number located at the lower left of

the front and back covers.

Cat.No. I570-E1-02

Revision code

Revision

code

Revision

date

Changes and revision pages

01 September 2009 First printing

02 March 2010

Revised information on the simple position control function and

revised/corrected manual contents.

Page 14

12

About This Manual

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

About This Manual

This User's Manual is compiled chapter by chapter for user's convenience as follows.

Understanding the following configuration ensures more effective use of the product.

Overview

Chapter 1 Overview Describes features and names of parts.

Chapter 2 Design

Provides external dimensions, installation dimensions, peripheral

device design/selection instructions, and other information necessary

for design.

Chapter 3 Operation

Describes names of parts, the Inverter's operations, including how to

use the keys on the Digital Operator, and the monitor function.

Chapter 4 Parameter List List of parameters set via Digital Operator.

Chapter 5 Functions Describes the functions of the Inverter.

Chapter 6

Communication

Function

Describes the Modbus-RTU communication.

Chapter 7

Maintenance

Operations

Describes the causes and their countermeasures if the Inverter fails,

including the solutions to possible troubles (troubleshooting).

Chapter 8

Inspection and

Maintenance

Describes items for periodical inspection and/or maintenance for the

Inverter.

Chapter 9 Specifications

Provides Inverter specifications, as well as the specifications and

dimensions of peripheral devices.

Appendix

Describes the derating chart, capacitor life curve, compliance with

international standards and index.

Page 15

Page 16

14

Contents

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Introduction ...................................................................................... 1

Read and Understand this Manual .................................................. 2

Safety Precautions........................................................................... 5

Precautions for Safe Use................................................................. 7

Precautions for Correct Use ............................................................ 8

Checking Before Unpacking ............................................................ 10

Revision History............................................................................... 11

About This Manual........................................................................... 12

Chapter1 Overview

1-1 Functions......................................................................................................1-1

1-2 Appearance and Names of Parts ................................................................. 1-4

Chapter2 Design

2-1 Installation ....................................................................................................2-1

2-2 Wiring ...........................................................................................................2-6

Chapter3 Operation

3-1 Name of Parts of the Digital Operator .......................................................... 3-1

3-2 Operation Method......................................................................................... 3-7

3-3 Test Run.....................................................................................................3-10

3-4 Tripping ......................................................................................................3-12

Chapter4 Parameter List

4-1 Monitor Mode ...............................................................................................4-1

4-2 Function Mode..............................................................................................4-4

Chapter5 Functions

5-1 Monitor Mode ...............................................................................................5-1

5-2 Basic Functions ..........................................................................................5-13

5-3 Input/Output Terminals............................................................................... 5-29

5-4 Analog Signal ............................................................................................. 5-37

5-5 Settings Relating to Control Method........................................................... 5-46

5-6 Operation Functions ................................................................................... 5-56

5-7 Digital Operator/Operation Functions.........................................................5-84

5-8 Restart Functions .......................................................................................5-94

5-9 Functions Relating to Protections, Warnings

and Various Output Signals...................................................................... 5-110

5-10 Brake Settings .......................................................................................... 5-135

5-11 Sensorless Vector Control........................................................................ 5-144

5-12 Simple Position Control Function ............................................................. 5-158

5-13 Safety Function ........................................................................................5-170

5-14 Other Functions........................................................................................ 5-174

Page 17

15

Contents

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Chapter6 Communication Function

6-1 Communication Specifications..................................................................... 6-1

6-2 RS-485 Port Specifications and Connection................................................ 6-2

6-3 List of Modbus Communication (Modbus-RTU) Parameters ....................... 6-3

6-4 Modbus Communication (Modbus-RTU) Protocol ....................................... 6-4

6-5 Explanation of Each Parameter No.............................................................. 6-8

6-6 To Save the Change to the Holding Register (Enter Command)............... 6-19

6-7 Co-Inverter Communication ....................................................................... 6-22

6-8 List of Modbus Communication (Modbus-RTU) Data ................................ 6-27

Chapter7 Maintenance Operations

7-1 Error Display and Remedial Actions ............................................................ 7-1

7-2 Troubleshooting ..............................

........................................................... 7-10

Chapter8 Inspection and Maintenance

8-1 Inspection and Maintenance ........................................................................ 8-1

Chapter9 Specifications

9-1 Standard Specification List .......................................................................... 9-1

9-2 External Dimensions .................................................................................... 9-6

Appendices

Appendix-1 Derating Table ................................................................................. App-1

Appendix-2 Smoothing Capacitor Life Curve ......................................................App-7

Appendix-3 Life Alarm Output .............................................................................App-8

Appendix-4 Notes on Compliance with EC Directives and UL/cUL Standards ...App-9

INDEX

Page 18

Page 19

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

1

Overview

Describes the features, operating procedures, performance specifications and

other aspects of this Unit.

1-1 Functions............................................................................... 1-1

3G3MX2 Inverter Models ................................................................ 1-1

International Standards (EC Directives and UL/cUL Standards) .... 1-2

High-performance, Multi-function Compact Inverter Supporting

Wide-ranging Applications .............................................................. 1-2

1-2 Appearance and Names of Parts......................................... 1-4

Page 20

1-1

1-1 Functions

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

1-1 Functions

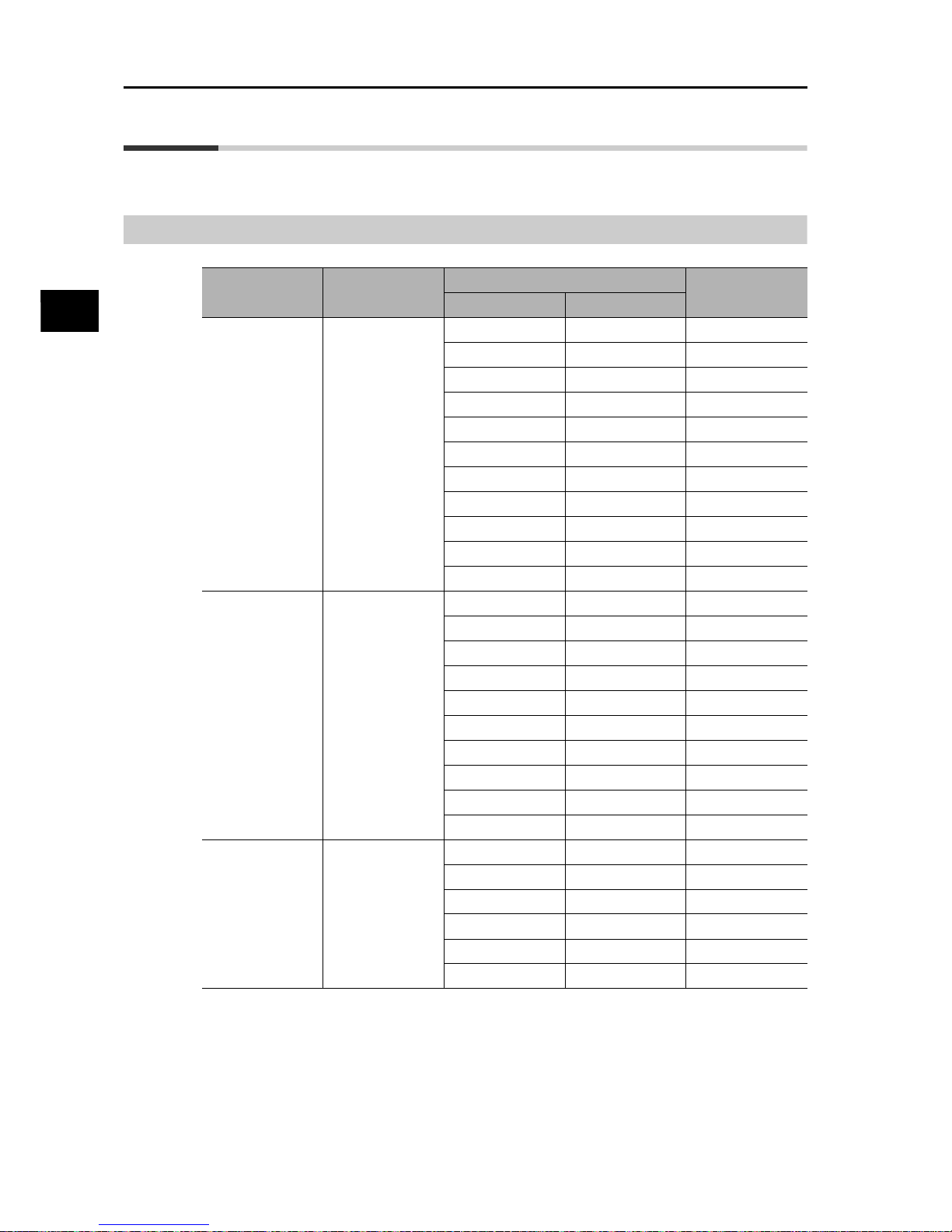

3G3MX2 Inverter Models

Rated voltage

Enclosure

ratings

Max. applicable motor capacity

Model

CT: Heavy load VT: Light load

3-phase 200 VAC IP20 0.1kW 0.2 kW 3G3MX2-A2001

0.2 kW 0.4 kW 3G3MX2-A2002

0.4 kW 0.75 kW 3G3MX2-A2004

0.75 kW 1.1 kW 3G3MX2-A2007

1.5 kW 2.2 kW 3G3MX2-A2015

2.2 kW 3.0 kW 3G3MX2-A2022

3.7 kW 5.5 kW 3G3MX2-A2037

5.5 kW 7.5 kW 3G3MX2-A2055

7.5 kW 11 kW 3G3MX2-A2075

11 kW 15 kW 3G3MX2-A2110

15 kW 18.5 kW 3G3MX2-A2150

3-phase 400 VAC IP20 0.4 kW 0.75 kW 3G3MX2-A4004

0.75 kW 1.5 kW 3G3MX2-A4007

1.5 kW 2.2 kW 3G3MX2-A4015

2.2 kW 3.0 kW 3G3MX2-A4022

3.0 kW 4.0 kW 3G3MX2-A4030

4.0 kW 5.5 kW 3G3MX2-A4040

5.5 kW 7.5 kW 3G3MX2-A4055

7.5 kW 11 kW 3G3MX2-A4075

11 kW 15 kW 3G3MX2-A4110

15 kW 18.5 kW 3G3MX2-A4150

1-phase 200 V AC IP20 0.1 kW 0.2 kW 3G3MX2-AB001

0.2 kW 0.4 kW 3G3MX2-AB002

0.4 kW 0.55 kW 3G3MX2-AB004

0.75 kW 1.1 kW 3G3MX2-AB007

1.5 kW 2.2 kW 3G3MX2-AB015

2.2 kW 3.0 kW 3G3MX2-AB022

Page 21

1-2

1-1 Functions

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

International Standards (EC Directives and UL/cUL Standards)

The 3G3MX2 Inverter meets the EC Directives and UL/cUL standard requirements for

worldwide use.

High-performance, Multi-function Compact Inverter Supporting Wide-ranging Applications

Powerful Torque Ideal for a Variety of Applications

High starting torque

With the sensorless vector control and auto-tuning functions, this Unit ensures high starting

torque of 200% at 0.5 Hz.

Note. The frame may have to be raised depending on the condition.

Overload limit/Overcurrent Suppression function

(1) The Inverter monitors the motor current during acceleration or constant speed operation in

order to lower output frequency automatically.

(2) This function suppresses significant change in current caused by rapid acceleration, etc.

Acceleration will be suppressed temporarily if the output current reaches approx. 180% of

the rated current during acceleration.

Various Applications

Safety Function

Conforming to stop category 0 under IEC60204-1 and the ISO13849-1: 2006 (PLd) standard

(certification pending)

Simple Position Control Function

(1) Comes standard with the pulse input functions.

(2) Supporting simple positioning to a maximum of 8 points by setting the position command,

speed reference and acceleration/deceleration time to parameters.

Comes Standard with RS-485 (Modbus-RTU)

(1) Comes standard with the Modbus-RTU communication function to communicate with, and

also read/write various parameters from/to, the host equipment.

Broadcasting from the host equipment is also supported.

(2) Transfer Speed: Supporting speeds up to 115.2 kbps

(3) Co-inverter communication is also supported.

Side-by-Side (Zero Clearance) Installation

Since the Inverter can be installed with its right or left face contacting a wall or other structure,

the installation space can be reduced.

Classification Applicable standard

EC Directives EMC directive EN61800-3: 2004

Low-voltage directive EN61800-5-1: 2003

UL/cUL Standards UL508C

Page 22

1-3

1-1 Functions

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

Note. The carrier frequency, etc. must be derated depending on the model.

Password Function

Comes with the password function to prevent reading or changing of parameters without

proper access privileges.

Page 23

1-4

1-2 Appearance and Names of Parts

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

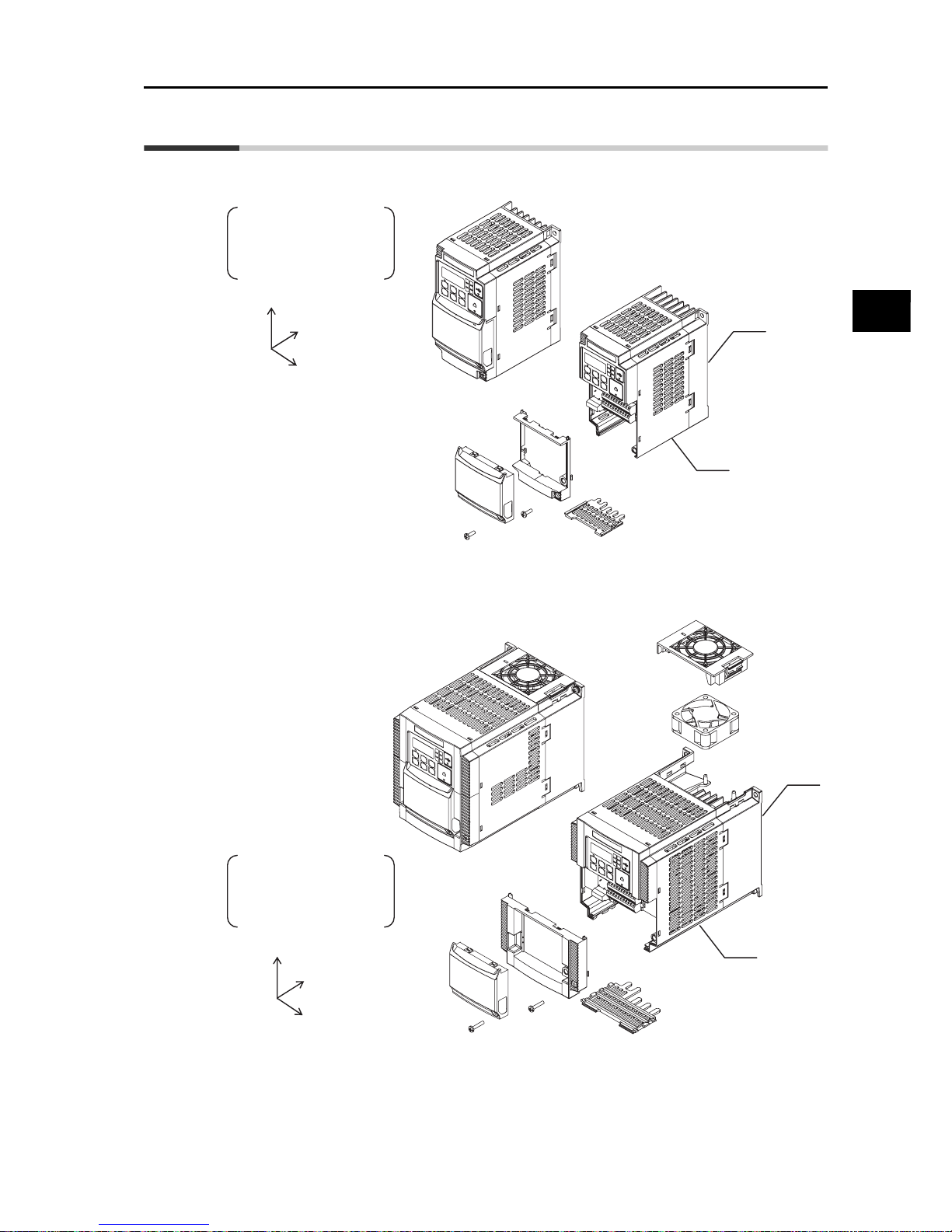

1-2 Appearance and Names of Parts

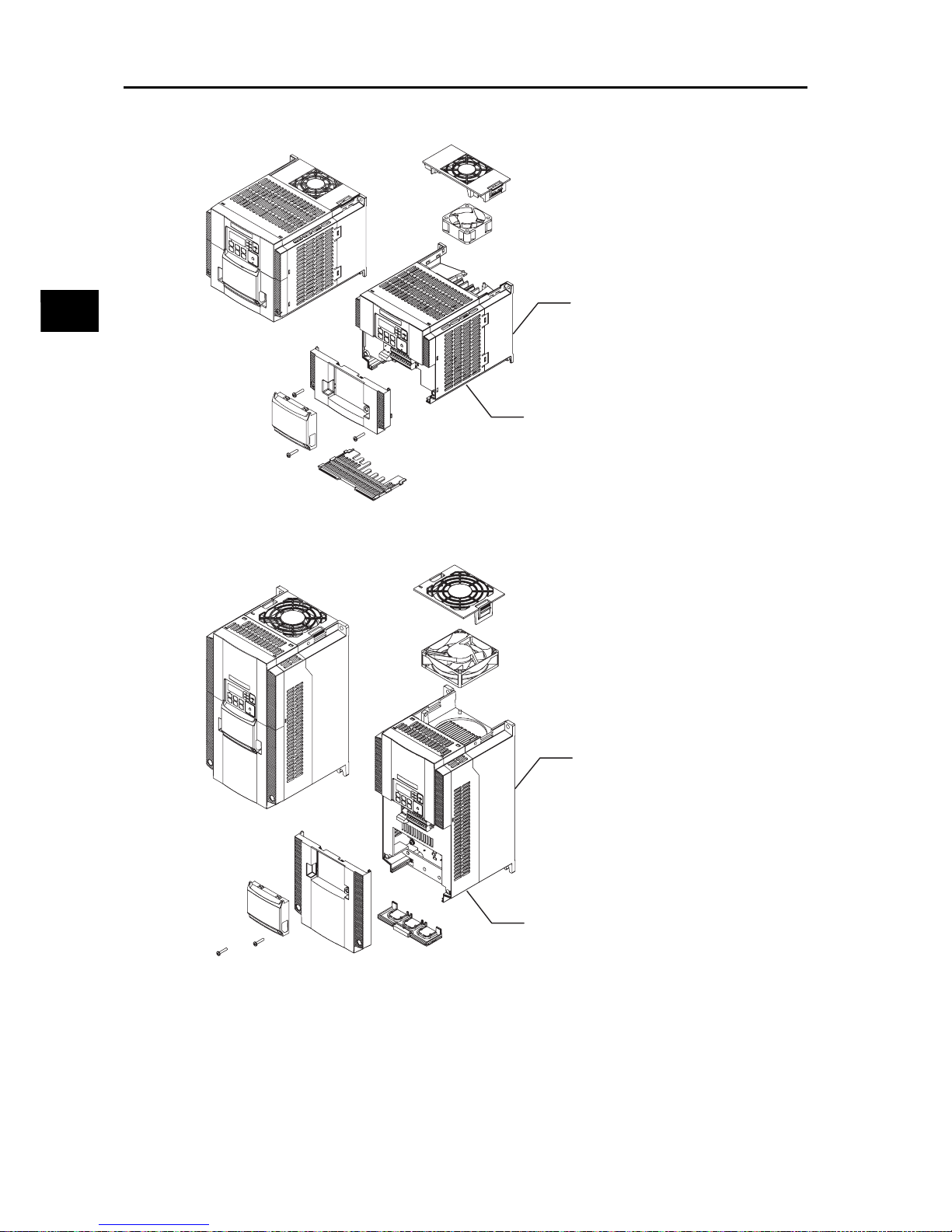

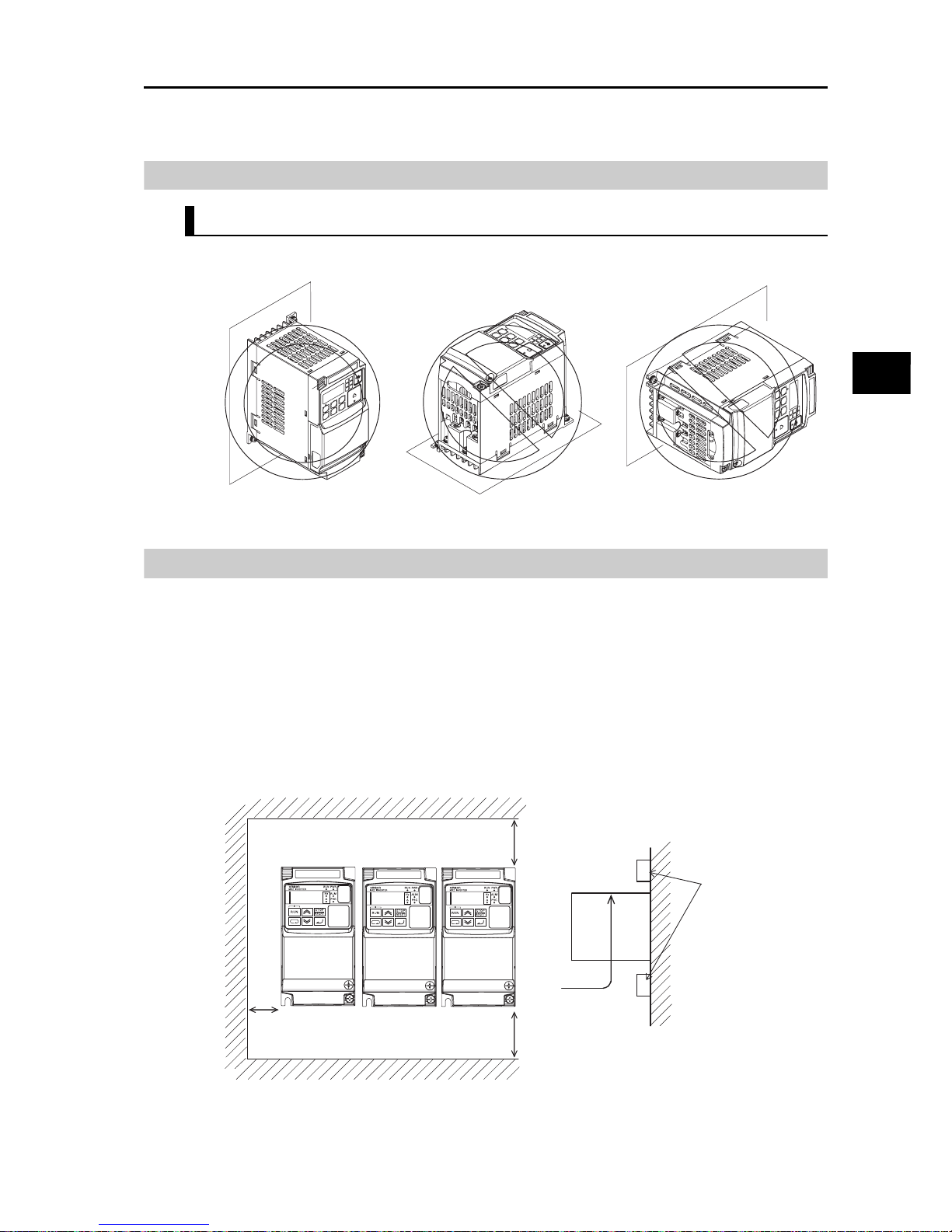

1-phase 200 V 0.1, 0.2, 0.4 kW

3-phase 200 V 0.1, 0.2, 0.4, 0.75 kW

1-phase 200 V 0.75, 1.5, 2.2 kW

3-phase 200 V 1.5, 2.2 kW

3-phase 400 V 0.4, 0.75, 1.5, 2.2, 3.0 kW

(1) Cooling fan cover (5) Terminal block cover

(2) Cooling fan (6) Optional board cover

(3) Cooling fin (7) Backing plate

(4) Main housing

Note: • 3-phase 200 V/0.75 kW models come with a cooling fan.

•

1-phase 200 V/0.75 kW models and 3-phase 400 V/0.4 kW/0.75 kW models do not come with a cooling fan.

Even if the W × H

dimension is the same, the

D dimension for the

cooling fin varies

depending on the capacity.

H

D

W

(5)

(6)

(7)

(4)

(3)

H

D

W

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Even if the W × H

dimension is the same, the

D dimension for the

cooling fin varies

depending on the capacity.

Page 24

1-5

1-2 Appearance and Names of Parts

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

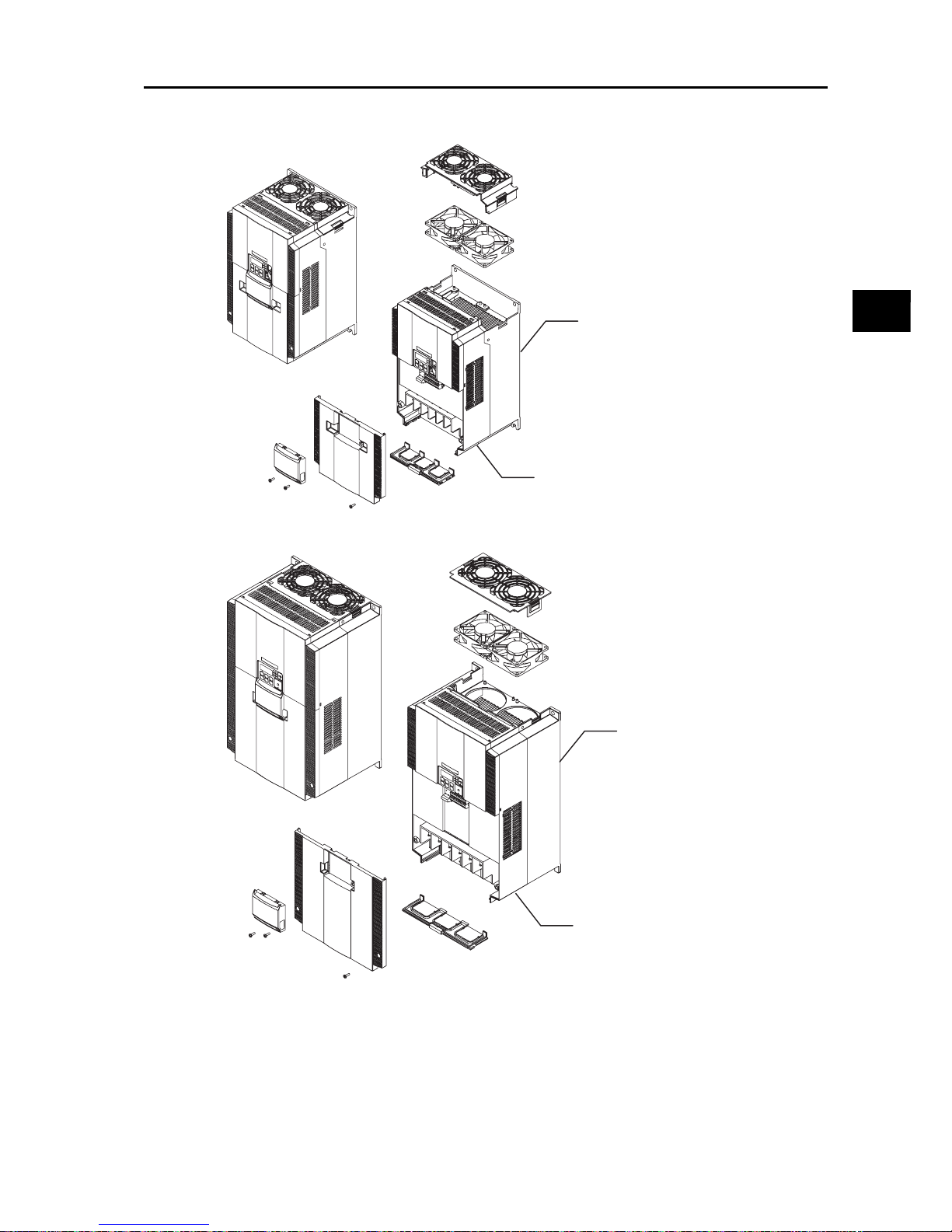

3-phase 200 V 3.7 kW

3-phase 400V 4.0 kW

3-phase 200 V 5.5, 7.5 kW

3-phase 400 V 5.5, 7.5 kW

(1) Cooling fan cover (5) Terminal block cover

(2) Cooling fan (6) Optional board cover

(3) Cooling fin (7) Backing plate

(4) Main housing

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Page 25

1-6

1-2 Appearance and Names of Parts

1

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

Overview

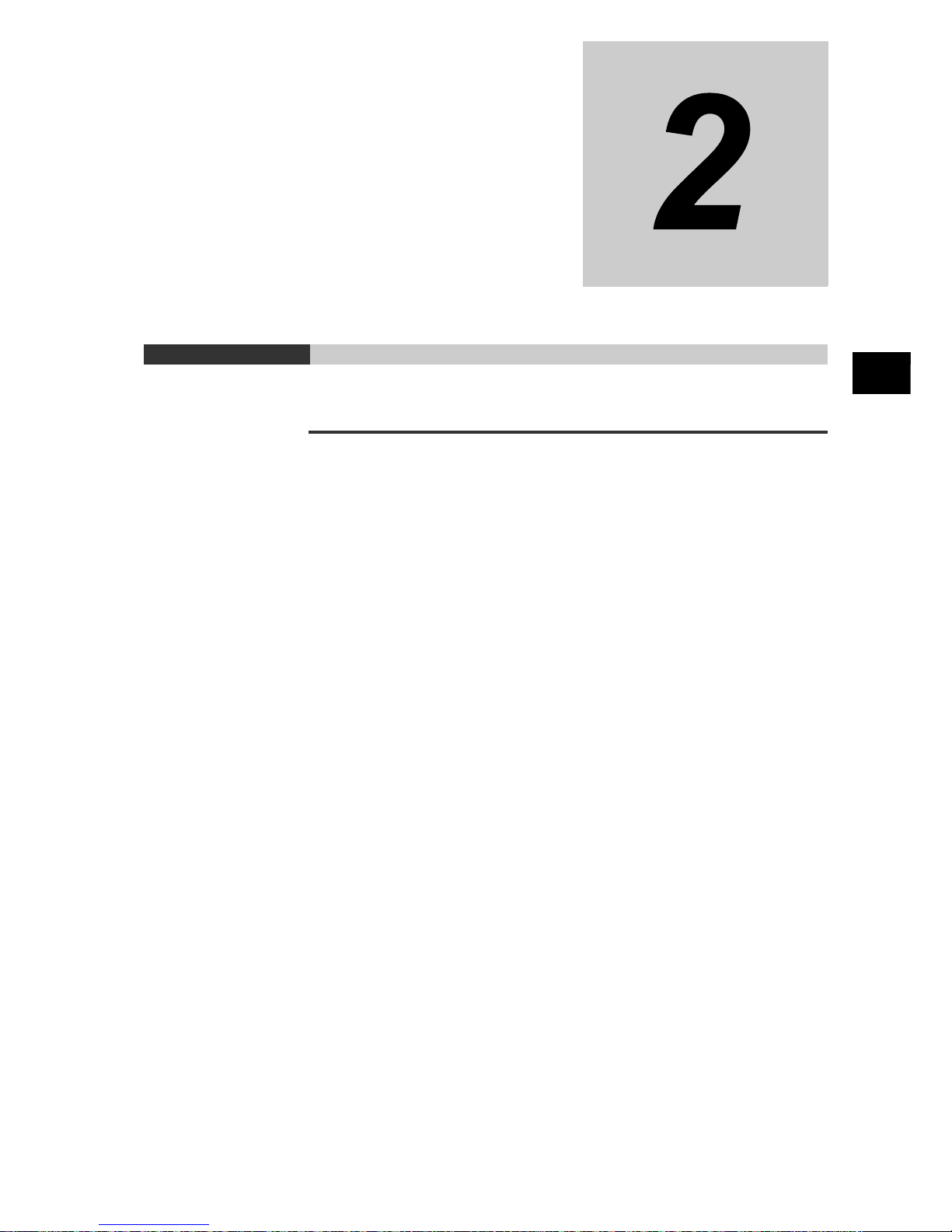

3-phase 200 V 11 kW

3-phase 400 V 11, 15 kW

3-phase 200 V 15 kW

(1) Cooling fan cover (5) Terminal block cover

(2) Cooling fan (6) Optional board cover

(3) Cooling fin (7) Backing plate

(4) Main housing

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Page 26

Page 27

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Describes the name and function of each part, installation method, wiring method,

etc.

2-1 Installation............................................................................. 2-1

Precautions for Safe Use ................................................................ 2-1

Precautions for Correct Use............................................................ 2-2

Installation Environment.................................................................. 2-2

Backing Plate .................................................................................. 2-3

Installation/Removal Method of the Terminal Block Cover ............. 2-4

Names of Parts Inside the Terminal Block Cover ........................... 2-5

2-2 Wiring..................................................................................... 2-6

Connection Diagram ....................................................................... 2-6

Wiring the Main Circuit Terminals ................................................. 2-10

Wiring Control Circuit Terminals ................................................... 2-18

Connection to Programmable Controller (PLC) ............................ 2-22

Page 28

2-1

2-1 Installation

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

2-1 Installation

Precautions for Safe Use

Installation and Storage

Do not store or use the product in the following places.

Locations subject to direct sunlight.

Locations subject to ambient temperature exceeding the specifications.

Locations subject to relative humidity exceeding the specifications.

Locations subject to condensation due to severe temperature fluctuations.

Locations subject to corrosive or flammable gases.

Locations subject to exposure to combustibles.

Locations subject to dust (especially iron dust) or salts.

Locations subject to exposure to water, oil, or chemicals.

Locations subject to shock or vibration.

Transportation, Installation, and Wiring

Do not drop or apply any strong impact to the Inverter to avoid damage to the parts and/or

the Inverter.

When transporting the Inverter, hold the fin, not the front cover or terminal block cover.

Do not connect an AC power supply to the control I/O terminals. Doing so may cause damage

to the Inverter.

Be sure to tighten the screws on the terminal block securely. Perform the wiring after

installing the Inverter.

Do not connect any load other than the 3-phase induction motor to the output terminals (U/

T1, V/T2, W/T3) of the Inverter.

Take appropriate and sufficient countermeasures when using the Inverter in the following

locations. Not doing so may result in damage to the Inverter.

Locations subject to static electricity or other forms of noise.

Locations subject to strong electromagnetic fields.

Locations close to power supplies.

Main Circuit Power Supply

Confirm that the rated input voltage of the Inverter matches the AC power supply voltage.

Page 29

2-2

2-1 Installation

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Precautions for Correct Use

Installation

Install the Inverter vertically on a wall.

Install the Inverter on a nonflammable wall surface material, like metal.

Installation Environment

Make sure the ambient temperature remains within the rated range (−10 to 50°C). Take note that if

the ambient temperature reaches or exceeds 40

°

C, the carrier frequency and output current must

be derated. If the Inverter is used in an environment exceeding the allowable operating temperature

range, the product life of the Inverter (specifically, the capacitor) will be shortened.

Measure and check the temperature approx. 5 cm from the bottom center of the Inverter body.

Provide sufficient space around the Inverter because it can become very hot (up to 150°C or so).

Keep the Inverter away from heating elements (such as a Braking Resistor, reactor, etc.).

Although side-by-side installation is possible. The ambient temperature of the installation site

must not exceed 40°C and the carrier frequency and output current must be derated if side-byside installation is used.

Do not install the Inverter in hot, humid sites or other sites subject to frequent bedewing.

Make sure that the humidity in the installation site is within the allowable operating range (20%

to 90% RH), as defined in the standard specifications.

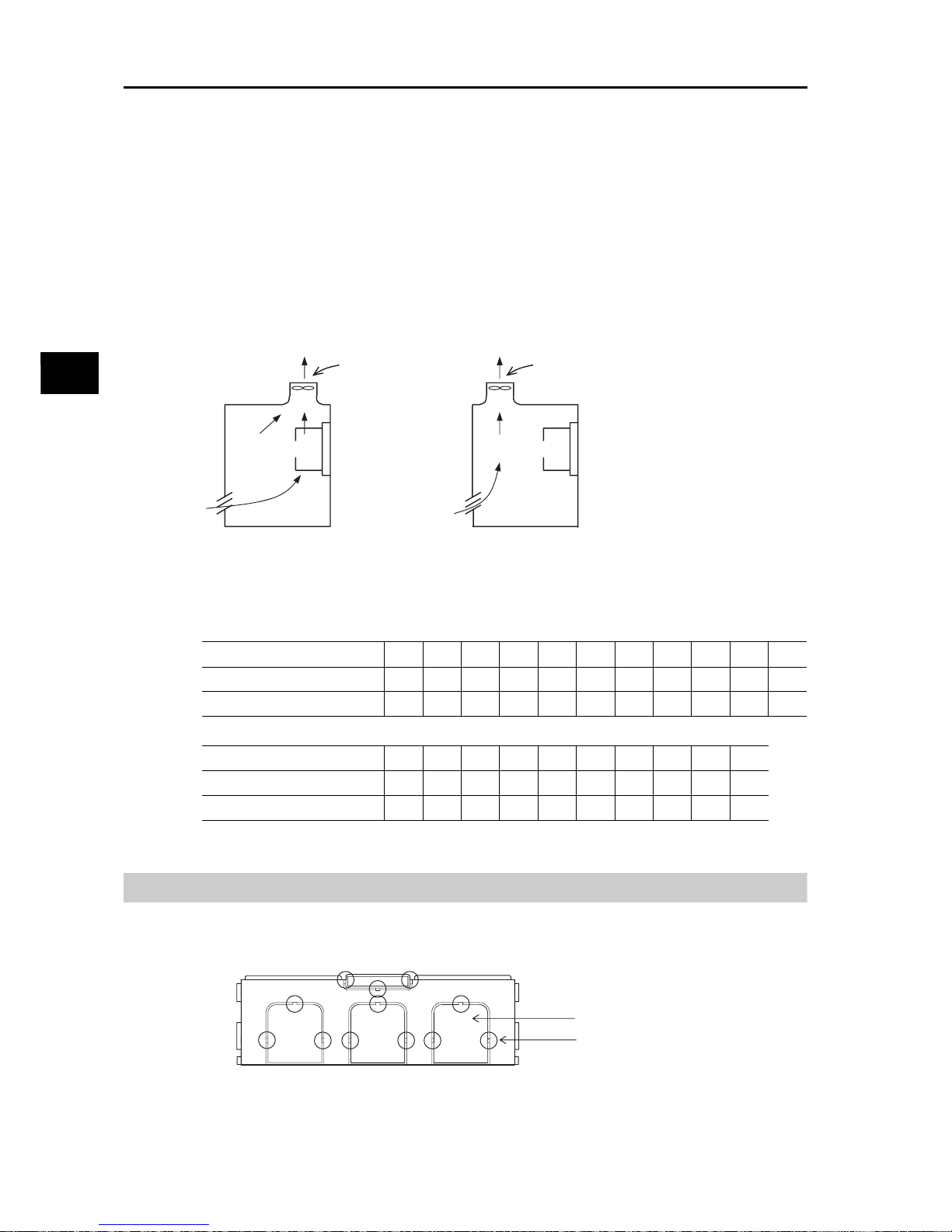

Air flow

100 mm or more

50 mm or more

Inverter

Wall

Provide sufficient

space so that the top

and bottom wiring

ducts, etc. will not

obstruct the flows of

cooling air.

100 mm or more

Page 30

2-3

2-1 Installation

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

In particular, make sure that the installation site is free from condensation. If condensed water

adheres to the Inverter's internal parts, the electronic components may short-circuit, causing

failure of the Inverter. In addition to avoiding condensation, avoid installing the Inverter under

direct sunlight.

Avoid an environment where the Inverter may be exposed to dust, gases (corrosive, explosive,

and/or flammable), grinding fluid mist, or salt. If a foreign object (e.g. dust) enters the Inverter,

it could result in failure of the Inverter. If using the Inverter in a dusty place, take appropriate

measures. (For example, place the Inverter in a closed panel.)

When several Inverters are installed in a panel and a ventilation fan is mounted in the panel,

be careful about the layout of the Inverters and the air intake apertures. Depending on the

layout, the Inverter's cooling effect may deteriorate, resulting in an increase in the ambient

temperature.

Heat Radiation from Inverter

1-phase/3-phase 200 V

3-phase 400 V

Backing Plate

With a model of 5.5 kW or higher capacity, cut off the connection points between the backing

plate and unnecessary portions with nippers or a wire cutter when running cables.

Inverter capacity (kW) 0.1 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15

Load with 100% loss (W) 12 22 30 48 79 104 154 229 313 458 625

Efficiency at rated output (%) 89.5 90 93 94 95 95.5 96 96 96 96 96

Inverter capacity (kW) 0.4 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15

Load with 100% loss (W) 35 56 96 116 125 167 229 296 411 528

Efficiency at rated output (%) 92 93 94 95 96 96 96 96.2 96.4 96.6

Ventilation fan

Ventilation fan

Inverter

Inverter

(Good example) (Bad example)

Unnecessary portions

Connection points

Page 31

2-4

2-1 Installation

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Installation/Removal Method of the Terminal Block Cover

1. Removal method

The terminal block cover is secured with one screw at the bottom right for 3.0 kW and smaller

models, or with two screws on both sides for 3.7 kW and larger models.

The optional board cover is affixed with screws onto the terminal block cover, but it is not

affixed onto the main unit. Accordingly, the terminal block cover can be removed without

removing the optional board cover.

2. Installation method

Follow the removal procedure in reverse. Set the top side of the terminal block cover onto the

main unit and push in the cover until you hear a "click" sound.

While pressing here in the direction

of the arrow, pull the terminal block

cover downward to remove.

Loosen the screw(s) (1 or 2

locations) securing the

terminal block cover.

While pressing the bottom of the

terminal block cover in the direction

of the arrow, pull the terminal block

cover downward to remove.

Optional board cover

Terminal block cover

Terminal block cover screw

(1 location for 3.0 kW and smaller models)

Terminal block cover screw

(2 locations for 3.7 kW and larger models)

8.8.8.8.

8.8.8.8.

Page 32

2-5

2-1 Installation

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Names of Parts Inside the Terminal Block Cover

Note. Refer to Chapter 3 "Operation" for the display and operating controls.

Name Description

Modbus-RTU

Termination resistor

selector switch

Use this Terminal Resistor selector switch for RS-485 terminals on the control circuit

terminal block. When this switch is turned ON, the internal 200

Ω

Resistor is connected.

Safety function

selector switch

Turn this switch ON when using the safety function. Turn OFF the power before

turning this switch ON/OFF.For details, refer to "Safety Function" on page 5-170.

EDM function

selector switch

Turn this switch ON when using the EDM output of the safety function. Turn OFF

the power before turning this switch ON/OFF. For details, refer to "Safety Function"

on page 5-170.

USB connector Use this mini-B USB connector to connect a PC.

Even when the Inverter is being operated by a PC, etc., via USB connection, it can

still be operated using the Digital Operator.

Connector for

Digital Operator

Use this connector to connect the Digital Operator.

Connector for

optional board

Use this connector to mount the optional board.

Communications Units and other options can be connected.

Control circuit

terminal blocks A

and B

These terminal blocks are used to connect various digital/analog input and output

signals for inverter control, etc.

Multi-function

contact terminal

block

Use this SPDT contact terminal block for relay outputs.

Main circuit

terminal block

Use this terminal block to connect an output to the motor and Braking Resistor, etc.

Also, use this terminal block to connect the inverter to the main power supply.

CHARGE

indicator (Charge

indicator LED)

This LED indicator is lit if the DC voltage of the main circuit (between terminals P/

+2 and N/−) remains approx. 45 V or above after the power has been cut off. Before

wiring, etc. confirm that the Charge LED indicator is turned OFF.

Modbus-RTU Termination resistor selector switch

Safety function selector switch

Connector for optional board

Multi-function contact terminal block

CHARGE indicator

Main circuit terminal block

OFF

(Factory default)

ON

USB connector (mini-B)

Connector for Digital Operator (RJ45)

EDM function selector switch

Control circuit terminal block A

Control circuit terminal block B

Disable

(Factory default)

Enable

P1 terminal

(Factory default)

EDM output

Page 33

2-6

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

2-2 Wiring

Connection Diagram

Single-phase

3-phase

power

supply

Shorting

bar

Shorting bar

Motor

ELB

MC

ON

R/L1 (L1)

*1

S/L2

T/L3 (N)

*1

24 VDC

MC

S7/EB

S5/TH

S4/GS2

S3/GS1

S2

S1

FS

FV

FI

RP

AM

MP

RS−

RS+

PC

P1/EDM

P2

MB

MA

N/−

SC

S6

P24

DC reactor

PSC

SC

SC

If any source-logic external

output devices or external

power supply is used, refer to

"Connection to

Programmable Controller

(PLC)" on page 2-22.

Multi-function

outputs (2 outputs)

Multi-function

relay output

Braking Resistor

*2

*1 Connect to terminals L1 and N on a single-phase, 200-V Inverter (3G3MX2-AB@@@).

*2 Optional.

Power: 1/4 W min.

Resistance: 2 kΩ min.

10 VDC power supply

(7 mA Max.)

Analog voltage input

0 to 10 V (10 bits)

Analog voltage

output 0 to 10 V

(10 bits)

Ground to 100 Ω or less for 200-V class

Ground to 100 Ω or less for 400-V class

Analog current input

4 to 20 mA (10 bits)

Pulse input

5 to 24 VDC

(32 kHz Max.)

Pulse output

0 to 10 VDC

(32 kHz Max.)

Serial communication port

(RS-485/Modbus-RTU)

RB

P/+2

+1

W/T3

V/T2

U/T1

M

3~

Remove the short bar

when connecting a

DC reactor.

RB

N/

−

Regenerative

Braking Unit

*2

P

RB

Braking Resistor

*2

When using a Regenerative Braking Unit

P

N

10 VDC

SC

SC

SC

SC

SC

Approx.

100 Ω

Terminal

Resistor

Terminal Resistor

selector switch

Approx.

10 kΩ

Thermistor

Optional board connector

Communications Option Unit

*2

OFF

MC

AX

MC

AX

Multi-function

inputs

(7 contact

inputs)

Page 34

2-7

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Main Circuit Terminals

Control Circuit Terminals

Terminal

symbol

Terminal name Description

R/L1 L1 Main power supply

input terminal

Connect the input AC power supply. Connect to terminals L1 and N

on a single-phase, 200-V Inverter (3G3MX2-AB@@@).

S/L2

T/L3 N

U/T1 Inverter output

terminal

Connect a 3-phase motor.

V/T2

W/T3

+1 DC reactor

connection terminal

Remove the shorting bar between terminals +1 and P/+2, and

connect the optional DC reactor.

P/+2

P/+2 Braking Resistor

connection terminal

Connect optional braking resistors. (If a braking torque is required)

RB

P/+2 Regenerative

braking unit

connection terminal

Connect optional regenerative braking units. (When braking torque

is required or the built-in braking circuit is not sufficient)

N/−

G Ground terminal This is a ground terminal. Connect this terminal to the ground.

Provide Class D grounding for 200 V class models, and class C

grounding for 400 V class models.

On 200 V class models of 3.7 kW or below and 400 V class models

of 4.0 kW or below, the ground terminal is located on the cooling fin.

Terminal

symbol

Terminal name Description Specifications

Analog

Power

supply

SC Input signal

common

This is a common terminal

used by the internal power

supply, digital input and

analog input/output

terminals.

FS Frequency

reference

power supply

10 VDC power supply for

the FV terminal.

Allowable max. current:

7 mA

Frequency

setting

input

FV

Frequency

reference input

terminal (analog

voltage input)

Use this terminal if the

frequency reference is

provided by 0 to 10 VDC

voltage input.

Input impedance

Approx. 10 kΩ

Allowable input voltage

range

−0.3 to +12 VDC

FI

Frequency

reference

terminal (analog

current input)

Use this terminal if the

frequency reference is

provided by 4 to 20 mA

current input.

Input impedance

100 Ω

Allowable input range

0 to 24 mA

Page 35

2-8

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Analog

Sensor

input

S5/TH External

thermistor input

(also used as

multi-function

input terminal)

Connect an external

thermistor between the

SCs, to trip the Inverter

when a temperature error

occurs. (The inverter will trip

when the input from

thermistor is approx. 3 kΩ or

higher.) Since this input is

also used as the multifunction input terminal,

setting of C005 is required.

For details, refer to

"Thermistor Trip Function"

on page 5-120.

PTC type

Output AM Multi-function

analog output

(voltage)

Specified signals can be

output using voltage signals

of 0 to 10 VDC.

AM

Digital

Power

supply

SC

Input signal

common

This is a common terminal

used by the internal power

supply, digital input and

analog input/output

terminals.

P24

Power supply

terminal for

input signal

24 VDC power supply for

contact input signal. This is

used as a common terminal

if the source logic is input.

Allowable max. current:

100 mA

PSC

Power supply

terminal for

input terminal

Sink logic input: Shorted

with P24

Source logic input: Shorted

with SC

To drive the contact input

using an external power

supply, remove the shorting

bar. For details, refer to

"Connection to

Programmable Controller

(PLC)" on page 2-22.

Input

Contact

S7/EB

S6

S5/TH

S4/GS2

S3/GS1

S2

S1

Multi-function

input terminal

Select 7 functions from

among 59, and allocate

them to terminals S1

through S7/EB. Both sink

and source logics are

supported. For details, refer

to "Connection to

Programmable Controller

(PLC)" on page 2-22.

Voltage between each

input and PSC

ON voltage: 18 V min.

OFF voltage: 3 V max.

Allowable max. voltage: 27

VDC

Load current: 5 mA (at 24

V)

S4/GS2

S3/GS1

Safety input Enabled when the safety

function selector switch is

turned ON. For details, refer

to "Safety Function" on

page 5-170.

Terminal

symbol

Terminal name Description Specifications

Page 36

2-9

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Digital

Input

Pulse

RP

Pulse input-A A pulse input for frequency

setting. (Take note that the

internal circuit is different

from input terminals S7/

EB.)

Input pulse 32 kHz max.

Voltage between input and

SC

ON voltage: 4 V min.

OFF voltage: 1 V max.

Allowable max. voltage: 27

VDC

S7/EB

Pulse input-B A pulse input for frequency

setting. (Take note that the

internal circuit is different

from input terminal RP.)

Input pulse 1.8 kHz max.

ON voltage: 18 V min.

OFF voltage: 3 V max.

Allowable max. voltage: 27

VDC

Load current: 5 mA (at 24

V)

Output

Open collector

P1/EDM

P2

Multi-function

output terminal

Select 2 functions from

among 43, and allocate

them to terminals P1

through P2. Both sink and

source logics are

supported. For details, refer

to "Connection to

Programmable Controller

(PLC)" on page 2-22.

Open collector output

Between each terminal and

PC

Allowable max. voltage: 27

V

Allowable max. current: 50

mA

Voltage drop when ON: 4 V

max.

P1/EDM

Safety monitor Enabled when the EDM

function selector switch is

ON. For details, refer to

"Safety Function" on page

5-170.

Relay

MAMBRelay output

terminal

Select the desired functions

from among 43 functions,

and allocate them to these

terminals.

SPDT contact.

The factory default of Relay

Output (MA, MB) Contact

Selection (C036) is NC

contact between MA-MC,

and NO contact between

MB-MC.

Max. contact capacity

MA-MC:

250 VAC, 2 A (resistance)

0.2 A (induction)

MB-MC:

250 VAC, 1 A (resistance)

0.2 A (induction)

Contact min. capacity

100 VAC, 10mA

5 VDC, 100mA

MC

Relay output

common

Pulse

MP

Pulse output Pulses are output. Output pulse: 32 kHz max.

Output voltage: 10 VDC

Allowable max. current: 2

mA

Serial communication

RS+

RS−

Modbus port

(RS-485)

RS-485 port

RS+ RS-485 differential (+)

signal

RS- RS-485 differential (−)

signal

Max. speed: 115.2 kbps

Built-in Terminal Resistor:

200 Ω

Slide switch selection

Terminal

symbol

Terminal name Description Specifications

Page 37

2-10

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Wiring the Main Circuit Terminals

Before wiring, make sure that the CHARGE indicator is OFF.

Once the power supply is turned on, the capacitor in the Inverter is charged with high voltage for

a while even after the power supply is turned off and regardless of whether the Inverter is running

or not.

If you are going to change cable connections after the power supply is turned off, wait for at least

10 minutes. Before wiring, check for a residual voltage between terminals "P/+2" and "N/−" with

a circuit tester to ensure safety.

Main power supply input terminals (R/L1, S/L2, T/L3)

Use an earth leakage breaker for circuit (wiring) protection between the power supply and the

main power supply terminals (R/L1, S/L2, T/L3).

An earth leakage breaker may malfunction at high frequency. Use an earth leakage breaker

with a large high-frequency sensitive current rating.

As a guide for leakage current, if a CV wire is used and routed through a metal pipe, the

leakage current is 30 mA/km. Due to the higher specific inductive capacity of the H-IV wire, the

leakage current increases about eight times. Use a wire with a sensitivity current one-level

higher. The leakage current mentioned here is the effective value of the fundamental wave,

and high-frequency currents are excluded.

When the Inverter protective function is activated, your system may fail or an accident may

occur. Connect a magnetic contactor to turn off the Inverter power supply.

Do not start or stop the Inverter by switching ON/OFF the magnetic contactor provided in the

Inverter power supply input (primary) circuit and output (secondary) circuit. To start or stop the

Inverter via an external signal, use the operation command terminals (FW, RV) on the control

circuit terminal block.

Do not use this Inverter with an input phase loss connection. Doing so may damage the

Inverter.

The Inverter operates with 1-phase input during input phase loss, causing a trip (due to

undervoltage, overcurrent, etc.) or damage to the Inverter. Even if an input phase is open, the

internal capacitor is charged with voltage, and electric shock or injury may occur.

When changing the cable connections, refer to "Precautions for Use."

Inverter-motor distance Sensitivity current of earth leakage breaker

100 m max.

30 mA

300 m max.

100 mA

800 m max.

200 mA

Page 38

2-11

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

In the following cases, the internal converter module may be damaged:

Imbalance ratio of power supply voltage is 3% or more.

Power supply capacity is ten times or more than the Inverter capacity, and 500 kVA or more.

Rapid change in power supply voltage

Example) When several inverters are connected with a short bus.

When the phase advance capacitor is turned on/off.

Do not turn on the power and then turn it off again more than once every 3 minutes. Doing so

may damage the Inverter.

Inverter output terminal (U/T1, V/T2, W/T3)

For connection of the output terminal, use the compatible cable or a cable with a larger

diameter. Otherwise, the output voltage between the Inverter and the motor may drop.

Particularly during low-frequency output, a voltage drop occurs with the cable, resulting in

motor torque reduction.

Do not mount a phase advance capacitor or surge absorber, because these devices may

cause the Inverter to trip or cause damage to the capacitor or surge absorber.

If the cable length exceeds 20 m (particularly, with 400 V class), a surge voltage may be

generated at the motor terminal depending on stray capacitance or inductance of the cable,

causing the motor to burn out.

To suppress surge voltage, we offer a special filter (3G3AX-NFxxx). For details, contact our

authorized dealer.

To connect several motors, provide a thermal relay for each.

The RC value of each thermal relay should be 1.1 times larger than the motor rated current.

The relay may trip earlier depending on the cable length. In this case, connect an AC reactor

to the Inverter output.

DC Reactor Connection Terminal (+1, P/+2)

This terminal is used to connect the optional DC reactor.

By factory default, a shorting bar has been connected between terminals +1 and P/+2. Before

connecting the DC reactor, remove this shorting bar.

The length of the DC reactor connection cable should be 5 m or shorter.

If the DC reactor is not being used, do not remove the shorting bar.

If you remove the shorting bar without connecting the DC reactor, no power is supplied to the

Inverter main circuit, disabling operation.

Page 39

2-12

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

External Braking Resistor Connection Terminal (P/+2, RB)/Regenerative Braking Unit Connection Terminal (P/+2, N/−)

All models in the 3G3MX2 Series have a built-in regenerative braking circuit.

To improve braking capacity, mount the optional braking resistor to this terminal.

Do not mount a resistor whose resistance is lower than the specified value. Doing so may

damage the regenerative braking circuit.

The cable length should be 5 m or shorter. Twist the two wires.

Do not connect any device other than the optional Regenerative Braking Unit or Braking

Resistor to this terminal.

Ground Terminal

To prevent electric shock, be sure to ground the Inverter and the motor.

The 200 V class should be connected to the ground terminal under Class D grounding

conditions (conventional Class 3 grounding conditions: 100 Ω or less ground resistance), The

400 V class should be connected to the ground terminal under Class C grounding conditions

(conventional special Class 3 grounding conditions: 10 Ω or less ground resistance).

For the ground cable, use the compatible cable or a cable with a larger diameter. Make the

cable length as short as possible.

When several Inverters are connected, the ground cable must not be connected across several

Inverters, and must not be looped. Otherwise, the Inverter and surrounding control machines

may malfunction.

Inverter

Inverter

Inverter

Inverter

Inverter

Inverter

Your ground bolt

Page 40

2-13

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Arrangement of Main Circuit Terminal Block

Open the terminal block cover and wire the main circuit terminal blocks.

Applicable model Terminal arrangement

3G3MX2-A2001 to

A2007

3G3MX2-AB001 to

AB004

3G3MX2-A2015,

A2022

3G3MX2-A4004 to

A4030

3G3MX2-AB007,

AB015, AB022

Ground terminal

(M4) × 2

W/T3V/T2U/T1 T/L3S/L2R/L1

N/-

P/+2

+1

RB

From power supply

To motors

W/T3V/T2U/T1

NL1

N/-

P/+2

+1

RB

(Connect to L1 and N for 1-phase)

Ground terminal

(M4) × 2

From power supply

To motors

W/T3V/T2U/T1 T/L3S/L2R/L1

N/-

P/+2

+1

RB

Ground terminal (M4) × 2

From power supply

To motors

W/T3V/T2U/T1

NL1

N/-

P/+2

+1

RB

(Connect to L1 and N for 1-phase)

Ground terminal (M4) × 2

From power supply

To motors

Page 41

2-14

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

3G3MX2-A2037

3G3MX2-A4040

3G3MX2-A2055,

A2075

3G3MX2-A4055,

A4075

3G3MX2-A2110

3G3MX2- A4110 to

A4150

3G3MX2-A2150

Applicable model Terminal arrangement

P/+2

+1

Ground terminal (M4) × 2

W/T3V/T2U/T1 T/L3S/L2R/L1

N/−

RB

From power supply

To motors

GGRB

N/−

P/+2

+1

W/T3 V/T2U/T1T/L3S/L2R/L1

From power supply

To motors

GGRB

N/−

P/+2

+1

W/T3 V/T2U/T1T/L3S/L2R/L1

From power supply

To motors

GGRB

N/−

P/+2

+1

W/T3 V/T2U/T1T/L3S/L2R/L1

From power supply

To motors

Page 42

2-15

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Recommended Cable Size, Wiring Device and Crimp Terminal

Voltage

class

Motor

output

(CT)

kW

Inverter model

Wiring Applicable device

Power

cable

mm

Terminal-

block screw

size (terminal

block width)

mm

Tightening

torque

Earth

Leakage

Breaker

(ELB)

Magnetic

contactor

(MC)

Fuse size

(class J)

Rated

600 V AIC

200kA

3-phase

200 V

0.1 3G3MX2-A2001

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(5A)

H10C 10A

0.2 3G3MX2-A2002

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(5A)

H10C 10A

0.4 3G3MX2-A2004

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(10A)

H10C 10A

0.75 3G3MX2-A2007

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(10A)

H10C 15A

1.5 3G3MX2-A2015

AWG14

(2.0)

M4

(10)

1.4

EX30

(20A)

H20 15A

2.2 3G3MX2-A2022

AWG12

(3.5)

M4

(10)

1.4

EX30

(20A)

H20 20A

3.7 3G3MX2-A2037

AWG10

(5.5)

M4

(10)

1.4

EX50

(50A)

H25 30A

5.5 3G3MX2-A2055

AWG6

(14)

M5

(13)

3.0

EX60

(60A)

H35 30A

7.5 3G3MX2-A2075

AWG6

(14)

M5

(13)

3.0

EX100

(75A)

H50 40A

11 3G3MX2-A2110

AWG4

(22)

M6

(17.5)

3.9 to 5.1

EX100

(100A)

H65C 60A

15 3G3MX2-A2150

AWG2

(38)

M8

(23)

5.9 to 8.8

EX100

(100A)

H65C 80A

3-phase

400 V

0.4 3G3MX2-A4004

AWG16

(1.25)

M4

(10)

1.4

EX50

(5A)

H10C 10A

0.75 3G3MX2-A4007

AWG16

(1.25)

M4

(10)

1.4

EX50

(10A)

H10C 10A

1.5 3G3MX2-A4015

AWG16

(1.25)

M4

(10)

1.4

EX50

(10A)

H10C 10A

2.2 3G3MX2-A4022

AWG14

(2.0)

M4

(10)

1.4

EX50

(15A)

H20 10A

3.0 3G3MX2-A4030

AWG14

(2.0)

M4

(10)

1.4

EX50

(15A)

H20 15A

4.0 3G3MX2-A4040

AWG12

(3.5)

M4

(10)

1.4

EX50

(20A)

H20 15A

5.5 3G3MX2-A4055

AWG10

(5.5)

M5

(13)

3.0

EX50

(30A)

H25 15A

7.5 3G3MX2-A4075

AWG10

(5.5)

M5

(13)

3.0

EX50

(50A)

H35 20A

11 3G3MX2-A4110

AWG6

(14)

M6

(17.5)

3.9 to 5.1

EX60B

(60A)

H35 30A

15 3G3MX2-A4150

AWG6

(14)

M6

(17.5)

3.9 to 5.1

EX100B

(75A)

H65C 40A

Page 43

2-16

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Note 1: Applicable devices assume use of a standard 3-phase, 4-pole motor.

Note 2: Select an applicable circuit breaker by also considering the cutoff capacity. (Use an inverter type.)

Use one circuit breaker for one inverter according to the applications shown in the above table.

Note 3: If the wiring distance exceeds 20 m, the power cable size must be increased.

Note 4: A H-IV wire (75°C) is recommended.

Note 5: Use an earth leakage breaker (ELB) to ensure safety.

Note 6: To meet the UL standards, always insert a UL-standard fuse of class J type on the power supply

side.

Note 7: Use a ground wire with a larger diameter than that of the power cable shown above.

Note 8: Tighten the terminal-block screws with the specified torque. If the screws are not tightened

securely, short-circuiting or fire may occur. Excessive tightening may cause damage to the

terminal block or the Inverter.

Note 9: Choose the sensitivity current of the earth leakage breaker (ELB) depending on the total distance

between the Inverter and the power supply, and the Inverter and the motor. Also, use an earth

leakage breaker of time-delay type. Use of a high-speed type may result in malfunction.

Note 10: If a CV wire is used and routed through a metal pipe, the leakage current becomes 30 mA/km.

Note 11: Due to the higher specific inductive capacity of the IV wire, the leakage current increases about

eight times. Accordingly, use a wire with a sensitivity current of eight times the applicable level

shown in the table below. Also, use a CV wire if the total wiring length exceeds 100 m.

1-phase

200 V

0.1 3G3MX2-AB001

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(5A)

H10C 10A

0.2 3G3MX2-AB002

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(5A)

H10C 10A

0.4 3G3MX2-AB004

AWG16

(1.25)

M3.5

(7.6)

1.0

EX30

(10A)

H10C 10A

0.75 3G3MX2-AB007

AWG12

(3.5)

M4

(10)

1.4

EX30

(15A)

H10C 15A

1.5 3G3MX2-AB015

AWG10

(5.5)

M4

(10)

1.4

EX30

(20A)

H20 20A

2.2 3G3MX2-AB022

AWG10

(5.5)

M4

(10)

1.4

EX30

(20A)

H20 30A

Voltage

class

Motor

output

(CT)

kW

Inverter model

Wiring Applicable device

Power

cable

mm

Terminal-

block screw

size (terminal

block width)

mm

Tightening

torque

Earth

Leakage

Breaker

(ELB)

Magnetic

contactor

(MC)

Fuse size

(class J)

Rated

600 V AIC

200kA

Total wiring length Sensitivity current (mA)

100 m max. 50

300 m max. 100

Page 44

2-17

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Main Circuit Connection Diagram

Name Function

(1) (2) (3) Refer to "Recommended Cable Size, Wiring

Device and Crimp Terminal" on page 2-15.

(4) AC reactor Apply this reactor as a harmonic suppression

measure, or when the imbalance ratio of

power supply voltage is 3% or more, power

supply capacity is 500 kVA or more, or power

supply voltage changes suddenly. It also

helps improve the power factor.

(5) Input noise filter This noise filter reduces the conducted noise

generated by the Inverter and traveling

through the wires. Connect it to the primary

(input) side of the Inverter.

(6) Radio noise filter When the Inverter is used, noise may

generate in a nearby radio, etc. through the

power wiring, etc. Use this noise filter to

reduce such noise (= reduce radiated noise).

(7) DC reactor This reactor suppresses the harmonics

generated by the Inverter.

(8) Braking Resistor

(9) Regenerative braking

unit

Use this Unit to increase the braking torque of

the Inverter to permit frequent ON/OFF

switchings, or decelerate a load whose

inertial moment is large.

(10) Output noise filter This noise filter is installed between the

Inverter and motor to reduce the radiated

noise emitted from the wires. Use it to reduce

radio interference in radios and TVs, or

prevent malfunctioning of measuring

equipment, sensors, etc.

(11) Radio noise filter Apply this noise filter to reduce the noise

generating on the output side of the Inverter

(both the input side and output side).

Power supply

(1)

(2)

ELB

(3)

Magnetic contactor

(4)

(5)

(6)

(7)

(8)

(9)

(8)

Inverter

RS

T

+1

P/+2

RB

N/

−

UVW

(10)

(11)

M

Page 45

2-18

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Wiring Control Circuit Terminals

Wiring and Arranging a Control Circuit Terminal Block

Terminals SC and PC are common terminals for input/output signals. They are isolated each

other. Do not short-circuit or ground these common terminals.

Do not ground these common terminals via external equipment and check the external

equipment ground conditions.

Connect diodes when wiring input/output signals for multiple inverters, because sneak circuit

paths are created.

For wiring of each control circuit terminal, use a twisted-pair shielded cable and connect the

shielded cable to each common terminal.

The control circuit terminal connection cable should be 20 m or shorter. Separate the control

circuit terminal connection cables from the main circuit cable (power cable) and the relay

control circuit cable. If the two cables must be crossed with each other, make sure they bisect

at right angles. Otherwise, the Inverters may malfunction.

For connection of the thermistor input terminal, connect the twisted wires to terminal SC

individually, and separate them from other SC common cables. Since a weak current flows

through the thermistor, the thermistor connection cable must be separated from the main

circuit cable (power cable).The thermistor connection cable should be 20 m or shorter.

When providing contacts for control circuit terminals (multi-function input terminals, etc.), use

a relay that will not cause contact failure even when the current or voltage is weak, such as a

relay with cross-bar twin contacts.

To use a relay for a multi-function output terminal, connect a surge-absorbing diode in parallel

with the coil.

Do not short-circuit the analog power supply terminals (FS-SC) and/or the interface power

supply terminals (P24 and SC). Doing so could result in failure of the Inverter.

The control circuit terminal block has two rows of terminals at top and bottom. Since wiring the

top terminals first makes it difficult to wire the bottom terminals, wire the bottom terminals first.

After the wiring, gently pull the wires to confirm that they are securely connected.

Page 46

2-19

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Wiring Example (Sink Logic)

When connecting a relay to the multi-function output terminal, install a surge-absorbing diode

in parallel with the relay. The output circuit can break down due to surge voltage when the relay

is switched on/off.

Switching Method for Input Control Logics

Multi-function input terminals are set to sink logic at the factory.

To switch the input control logic to source logic, remove the shorting bar between terminals

P24 and PSC on the control circuit terminal block, and connect it between terminals PSC and

SC.

RS+ MP RP FS FV FI SC AM PC P2

P1/EDM

RY

RS− S7/EB S6 S5/TH S4/GS2 S3/GS1 S2 S1 SC PSC P24

RY

Shorting bar

(sink logic)

Variable Resistor

Frequency reference

(1 to 2 kΩ)

Frequency reading

Signal during

RUN

Frequency arrival

signal

(27 VDC 50 mA max.)

PSC P24SCS1S2

Shorting bar

(1) Sink logic

PSC P24SCS1S2

Shorting bar

(2) Source logic

PSC P24S1 SC

S3

/GS1

S2

S5

/THS4/GS2

S6RS−

S7

/EB

P2

P1

/EDM

AM PCFI SCFS FVRPRS+ MP

MB MA MC

Relay output

Communication

RS-485

Logic input

Logic common and

power supply

Shorting

bar

Pulse

output

Pulse

input

Analog input and

power supply

Communication

RS-485

Analog

output

Logic output

Page 47

2-20

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Wire Sizes for Control Circuit Terminal Block and Relay Output Terminal Block

Recommended Terminal

To improve the ease of wiring and reliability of connection, use of ferrules of the following

specifications is recommended for signal wires:

* Manufacturer: Phoenix Contact

Crimp tool CRIPMFOX UD 6-4 or CRIMPFOX ZA 3

Relay output

terminal block

Control circuit terminal block

8 mm

Stripping length for

single/stranded wires:

Approx. 8 mm

Applicable wire

Single wire mm

2

(AWG)

Stranded wire mm

2

(AWG)

Ferrules mm2 (AWG)

Control Circuit Terminal

Block

0.2 to 1.5

(AWG 24 to 16)

0.2 to 1.0

(AWG 24 to 17)

0.25 to 0.75

(AWG 24 to 18)

Relay output terminal

block

0.2 to 1.5

(AWG 24 to 16)

0.2 to 1.0

(AWG 24 to 17)

0.25 to 0.75

(AWG 24 to 18)

Wire size

mm2 (AWG)

Ferrules

type*

L [mm] φd [mm] φD [mm]

0.25 (24) AI 0.25-8YE 12.5 0.8 2.0

0.34 (22) AI 0.34-8TQ 12.5 0.8 2.0

0.5 (20) AI 0.5-8WH 14 1.1 2.5

0.75 (18) AI 0.75-8GY 14 1.3 2.8

8

L

φ

d

φ

D

Page 48

2-21

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Wiring Method

1. Use a slotted screwdriver (width: 2.5 mm or less) to push in the orange part of the

control circuit terminal block. (The wire insertion part opens.)

2. With the slotted screwdriver pushed in, insert the wire or ferrule in the wire insertion

part (round hole).

3. Pull out the slotted screwdriver, and the wire will be fixed.

Note: When pulling out a wire, do so by also pushing in the part denoted by with a slotted screwdriver.

Use a slotted screwdriver

to push in the part.

Insert the wire. Pull out the slotted

screwdriver, and

the wire will be fixed.

2.5 mm

Page 49

2-22

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Connection to Programmable Controller (PLC)

Connection of Multi-function Input Terminal and Programmable Controller

When the Inverter's internal interface power

supply is used

When an external power supply is used

(Remove shorting bar on the control terminal block.)

Sink logicSource logicNo-voltage switch

P24

PSC

SC

S1

S7

24 VDC

Inverter

Shorting

bar

COM

S

Output module

P24

PSC

SC

S1

S7

24 VDC

Inverter

COM

S

Output module

24VDC

P24

PSC

SC

S1

S7

24 VDC

Inverter

Shorting

bar

COM

S

Output module

P24

PSC

SC

S1

S7

24 VDC

Inverter

COM

S

Output module

24 VDC

P24

PSC

SC

S1

S7

24 VDC

P24

PSC

SC

S1

S7

Shorting

bar

Shorting

bar

Inverter Inverter

24 VDC

P24

PSC

SC

S1

S7

24 VDC

P24

PSC

SC

S1

S7

24 VDC

24 VDC

Inverter

Inverter

Page 50

2-23

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Connection of Multi-function Output Terminal and Programmable Controller

Sink logic Source logic

P1/EDM

P2

PC

COM

24 VDC

Inverter

Input module

P1/EDM

P2

PC

COM

24 VDC

Inverter

Input module

Page 51

2-24

2-2 Wiring

SYSDRIVE MX2 Series USER'S MANUAL (3G3MX2-A@@@@)

2

Design

Note on Use of Multiple Inverters

If multiple Inverters are using a common input (switch, etc.) and the Inverters are turned on at

different timings, a sneak current path will be generated as shown below and the input may be

recognized as ON when it is actually OFF. In this case, be sure to insert a diode (rating: 50 V/

0.1 A) in the location shown below or use external power supply circuits to prevent the sneak

current path.

1. For Sink Logic

Add diodes.

P24

PSC

SC

S1

Shorting line

P24

PSC

SC

S1

Power ON

Power OFF

Shorting

line

Input ON

P24

PSC

SC

S1

P24

PSC

SC

S1