Omron 3G3MX2-V1 Series, 3G3MX2-A2004-V1, 3G3MX2-A2001-V1, 3G3MX2-A2002-V1, 3G3MX2-A2007-V1 User Manual

...Page 1

Multi-function Compact Inverter

MX2 Series Type V1

User’s Manual

I585-E1-01

3G3MX2-A-V1

Page 2

OMRON, 2013

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON

is constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

Page 3

1

Introduction

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Introduction

Thank you for purchasing the Multi-function Compact Inverter (Model: 3G3MX2--V1).

This manual describes the installation and wiring methods of the 3G3MX2-V1 Series Inverter, and

parameter setting methods which are required for the operation, as well as troubleshooting and inspection methods.

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing the control equipment

• Personnel in charge of designing the control systems

• Personnel in charge of installing and maintaining the control equipment

• Personnel in charge of managing the control systems and facilities

This manual contains information you need to know to correctly use the Multi-function Compact Inverter

(Model: 3G3MX2--V1).

Before using the inverter, read this manual and gain a full understanding of the information provided

herein.

After you finished reading this manual, keep it in a convenient place so that it can be referenced at any

time.

Make sure this manual is delivered to the end user.

Intended Readers

Notice

Page 4

Manual Configuration

2

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Manual Configuration

This manual is compiled section by section for user’s convenience as follows.

Section Overview

Section 1 Overview This section provides an overview of the 3G3MX2-V1

Series features, standard specifications, and external

dimensions by inverter capacity. It also shows the differences of this inverter from the conventional inverter for

those who use the previous model.

Section 2 Design This section describes the installation environment and wir-

ing methods.

Section 3 Operation and Test Run This section describes the part names and key operation of

the Digital Operator, and the operation method of this product as well as the test run procedure.

Section 4 Parameter List This section provides the parameter lists that show monitor

functions and available parameters for this inverter.

Section 5 Basic Settings This section describes the basic functions such as the Run

command.

Section 6 Vector Control and Applied Functions This section describes the vector control and applied func-

tions characteristic of this inverter.

Section 7 Other Functions This section describes the details of functions not described

in Section 5 or Section 6.

Section 8 Communications Functions This section describes the general-purpose serial commu-

nications functions (Modbus communication).

Section 9 Overview of DriveProgramming This section provides the features of the DriveProgram-

ming.

Section 10 Troubleshooting This section describes how to analyze the cause and take

countermeasures if the inverter fails, and provides troubleshooting for possible troubles.

Section 11 Maintenance and Inspection This section describes the maintenance and periodical

inspection items.

Section 12 Options This section describes the specifications and external

dimension of optional equipment.

Appendices This section provides information on derating, capacitor life

curve, compliance with the UL/cUL Standards, and inverter

selection.

Page 5

3

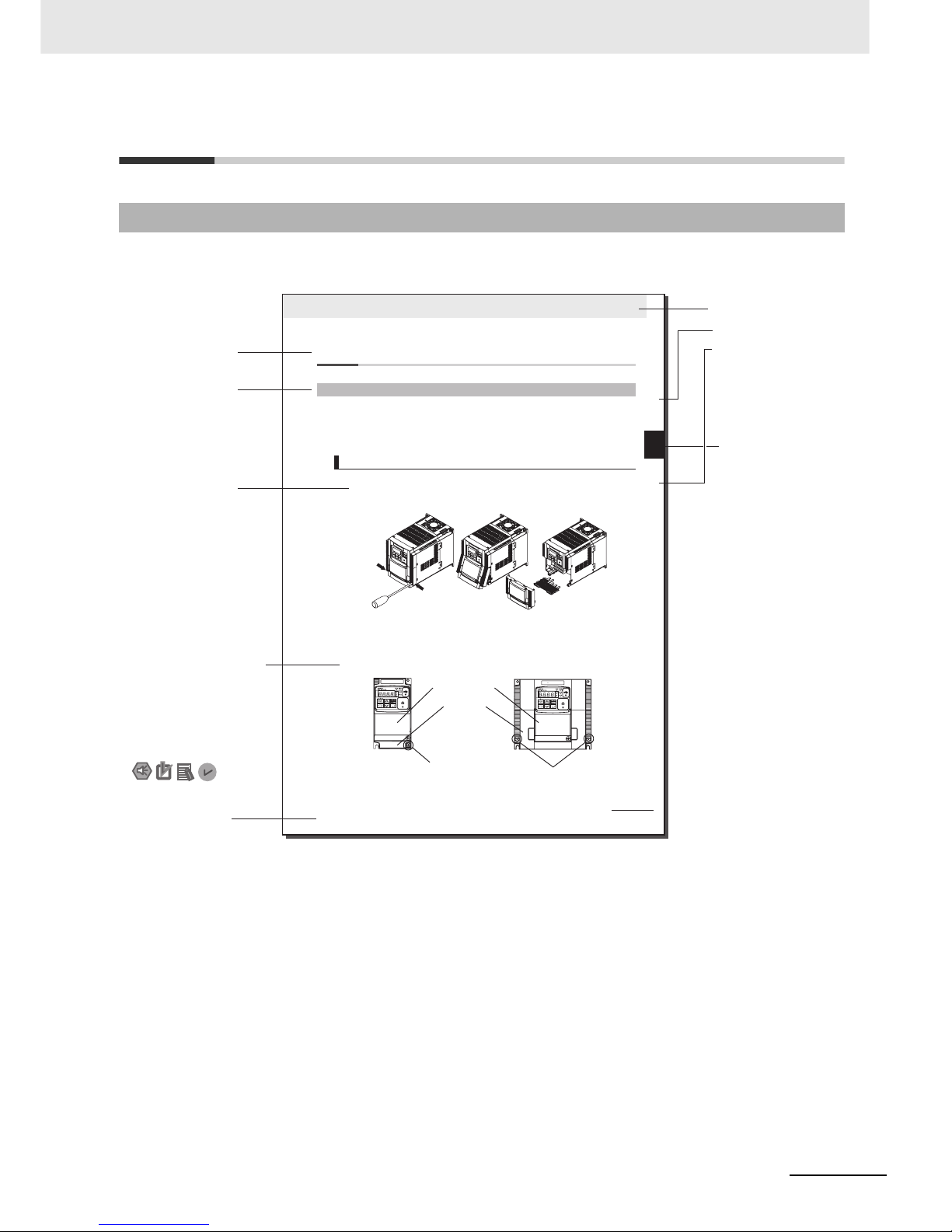

Manual Structure

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Manual Structure

The following page structure and symbol icons are used in this manual.

Note The above page is only a sample for illustrative purposes. It is not the actual content of the manual.

Page Structure and Symbol Icons

2 - 7

2 Design

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

2-2 Removal of Each Part

2

2-2-1 Removing Covers

2-2 Removal of Each Part

Before wiring each terminal block, you need to remove the terminal block cover and the backing plate.

This section describes how to remove these covers.

To install a communications unit or option unit, you must remove the option unit cover beforehand.

For how to install an option unit, refer to the user’s manual for each option unit.

1 Loosen the terminal block cover fixation screw(s).

2 Remove the terminal block cover from the bottom, while pressing its lower sides in the

directions of the arrows.

You can find one terminal block cover fixation screw at the lower right of the cover for Inverters

with a capacity of 3.0 kW or lower, or two terminal block cover fixation screws on both sides of

the cover for Inverters with a capacity of 3.7 kW or higher.

Also note that the option unit cover is screwed to the terminal block cover, but not fixed to the

Inverter body. Therefore, you can remove the terminal block cover without removing the option

unit cover.

2-2-1 Removing Covers

Removing Terminal Block Cover

Press in the arrow

directions to remove

the terminal block

cover from the bottom.

Option unit cover

Terminal block

cover

Terminal block cover

fixation screw

(1 for 3.0 kW or lower)

Terminal block cover

fixation screw

(2 for 3.7 kW or higher)

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

Operation Steps

Manual Name

Note, Supplementary

Information, Reference

Target

Level 3 heading

Section Number

of Level 1 heading

Shows which

paragraph the content

of the current page

belongs to.

Describes the operation

steps.

A note, supplementary

information, reference

target, etc. are provided

with difference icons.

Shows which

section the content

of the current

page belongs to.

Page 6

Manual Structure

4

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Special Information

Page 7

5

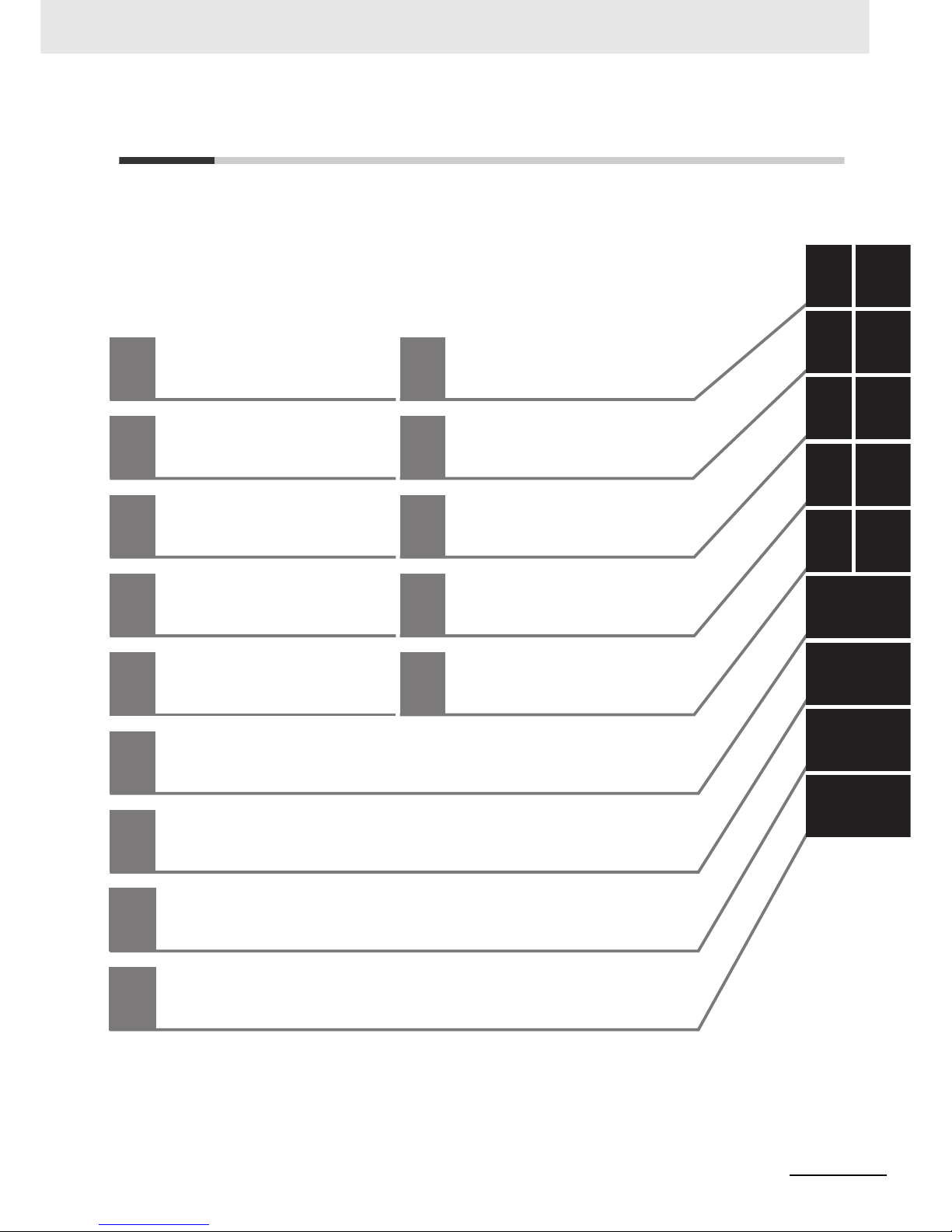

Sections in this Manual

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

1

10

2

11

3

12

4A

5

6

7

8

9

1

10

2

11

3

12

4A

5I

6

7

8

9

Overview Troubleshooting

Design

Maintenance and

Inspection

Operation and Test Run

Options

Parameter List Appendices

I

IndexBasic Settings

Vector Control and Applied Functions

Other Functions

Communications Functions

Overview of DriveProgramming

Sections in this Manual

Page 8

Terms and Conditions Agreement

6

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Terms and Conditions Agreement

Please read and understand this manual before purchasing the products. Please consult your OMRON

representative if you have any questions or comments.

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (a) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (b) repair the non-complying Product, or (c) repay or credit Buyer an amount equal to

the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products unless

Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any

Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination

with any electrical or electronic components, circuits, system assemblies or any other materials or

substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Read and understand this Manual

Warranty, Limitations of Liability

Warranties

Limitation on Liability; Etc

Page 9

7

Terms and Conditions Agreement

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Application Considerations

Suitability of Use

Programmable Products

Disclaimers

Performance Data

Change in Specifications

Errors and Omissions

Page 10

Safety Precautions

8

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Safety Precautions

To ensure that the Multi-function Compact Inverter (Model: 3G3MX2--V1) is used safely and correctly,

be sure to read this Safety Precautions section and the main text before using the product.

Learn all items you should know before use, regarding the equipment as well as required safety information and precautions.

Make an arrangement so that this manual also gets to the end user of this product.

After reading this manual, keep it in a convenient place so that it can be referenced at any time.

In this user’s manual, the following precautions and signal words are used to provide information to

ensure the safe use of the Multi-function Compact Inverter (Model: 3G3MX2--V1).

The information provided here is vital to safety. Strictly observe the precautions provided.

Indications and Meanings of Safety Information

Meanings of Signal Words

WARNING

Indicates an imminently hazardous situation which, if not avoided, is likely

to result in serious injury or may result in death. Additionally there may be

severe property damage.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury or in property damage.

Page 11

9

Safety Precautions

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

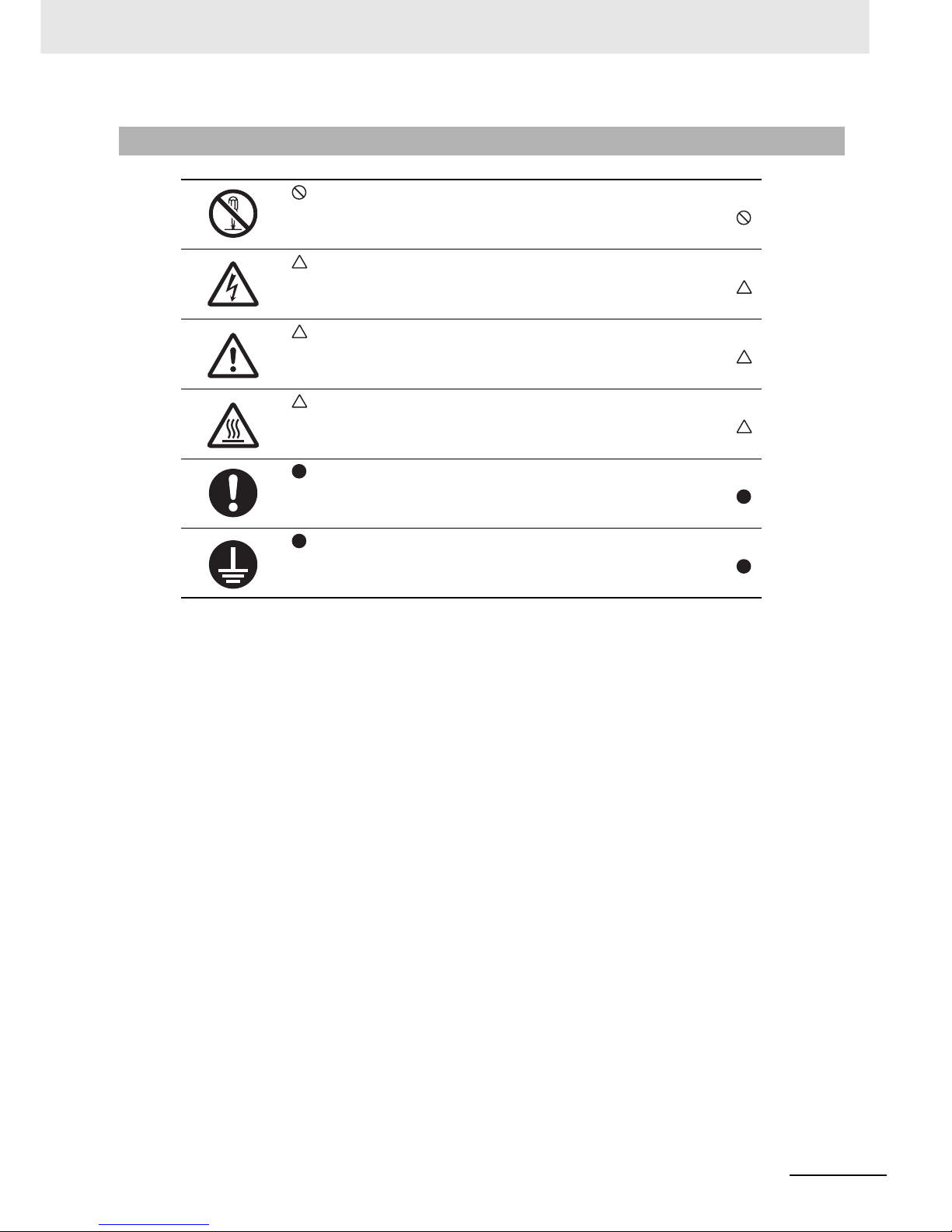

Explanation of Symbols

This symbol indicates a prohibited item (an item you must not do).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “disassembly prohibited.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “beware of electric shock.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “non-specific general danger.”

This symbol indicates caution (warnings included).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “risk of hot surface.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “general compulsory items.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “grounding required.”

Page 12

Safety Precautions

10

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

WARNING

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Do not change wiring and slide switches, put on or take off Operator and optional devices, replace

cooling fans while the input power is being supplied. Doing so may result in a serious injury due to

an electric shock.

Be sure to ground the unit.

Not doing so may result in a serious injury due to an electric shock or fire.

(200-V class: type-D grounding, 400-V class: type-C grounding)

Do not remove the terminal cover during the power supply and 10 minutes after the power shut off.

Doing so may result in a serious injury due to an electric shock.

Do not operate the Digital Operator or switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Inspection of the inverter must be conducted after the power supply has been turned off. Not doing

so may result in a serious injury due to an electric shock.

The main power supply is not necessarily shut off even if the emergency shut off function is activated.

Do not touch the inverter cooling fins, braking resistors, and the motor, which become too hot during the power supply and for some time after the power shut off. Doing so may result in a burn.

Page 13

11

Safety Precautions

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

CAUTION

Do not connect resistors to the terminals (+1, P/+2, N/–) directly. Doing so might result in a

small-scale fire, heat generation, or damage to the unit.

Install a stop motion device to ensure safety.

Not doing so might result in a minor injury.

* A holding brake is not a stop motion device designed to ensure safety.

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking

resistor, install a thermal relay that monitors the temperature of the resistor. Not doing so might

result in a moderate burn due to the heat generated in the braking resistor/regenerative braking

unit.

Configure a sequence that enables the inverter power to turn off when unusual over eating is

detected in the braking resistor/regenerative braking unit.

The inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or

other property. Place covers on the openings or take other precautions to make sure that no metal

objects such as cutting bits or lead wire scraps go inside when installing and wiring.

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches the

inverter capacity on the power supply side.

Not doing so might result in damage to property due to the short circuit of the load.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

Page 14

Precautions for Safe Use

12

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Precautions for Safe Use

Do not store or use the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to ambient temperature exceeding the specifications.

• Locations subject to relative humidity exceeding the specifications.

• Locations subject to condensation due to severe temperature fluctuations.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to direct shock or vibration.

• Do not drop or apply strong impact on the product. Doing so may result in damaged parts or malfunction.

• Do not hold by the front cover and terminal cover, but hold by the cooling fins during transportation.

• Confirm that the rated input voltage of the inverter is the same as AC power supply voltage.

• Do not connect an AC power supply voltage to the control input/output terminals. Doing so may result

in damage to the product.

• Be sure to tighten the screws on the terminal block securely. Wiring work must be done after installing the unit body.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output terminals.

• Take sufficient shielding measures when using the product in the following locations. Not doing so

may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

• If a parameter is set incorrectly when starting up, adjusting, maintaining, or replacing, an unexpected

operation may occur. Perform the operation after enough confirmation.

• When using the DriveProgramming, check that program is downloaded normally before starting operation.

• Be sure to confirm the permissible range of motors and machines before operation because the

inverter speed can be changed easily from low to high.

• Provide a separate holding brake if necessary.

• If the DriveProgramming stops during multi-function output, the output status is held. Take safety precautions such as stopping peripheral devices.

• Even when the inverter power is turned off, the counter-electromotive force occurs while the PM

motor rotates, which may result in electric shock.

Do not remove the terminal block cover of the inverter until the PM motor stops.

• Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine may

abruptly start.

Installation and Storage

Transportation, Installation, and Wiring

Operation and Adjustment

Page 15

13

Precautions for Safe Use

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

• Be sure to confirm safety before conducting maintenance, inspection or parts replacement.

• The capacitor service life is influenced by the ambient temperature. Refer to “Smoothing Capacitor

Life Curve” described in the manual. When a capacitor reaches the end of its service life and does

not work as the product, you need to replace the capacitor.

Maintenance and Inspection

Page 16

Precautions for Correct Use

14

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Precautions for Correct Use

Mount the product vertically on a wall with the product’s longer sides upright.

The material of the wall must be noninflammable such as a metal plate.

• Do not come close to the machine when using the restart selection function (b001, b008) because

the machine may abruptly start when stopped by an alarm.

Do not come close to the machine when selecting reset in Deceleration Stop Selection on Power Interruption (b050) because the machine may abruptly start after the power is turned on.

• Provide a separate emergency stop switch because the STOP Key on the Operator is valid only

when function settings are performed.

• When checking a signal during the power supply and the voltage is erroneously applied to the control

input terminals, the motor may start abruptly. Be sure to confirm safety before checking a signal.

• For the motor overload protection, be sure to set the rated current of your motor to the Electronic

Thermal Level (b012/b212) and PM Motor Rated Current (H105).

• Inverters contain components and will operate properly only when each component operates normally. Some of the electrical components require maintenance depending on application conditions.

Periodic inspection and replacement are necessary to ensure proper long-term operation of inverters. (Quoted from The Recommendation for Periodic Maintenance of a General-purpose Inverter

published by JEMA.)

• When a cooling fan reaches the end of its service life, replace it.

Comply with the local ordinance and regulations when disposing of the product.

Installation

Restart Selection Function

Deceleration Stop Function

Operation Stop Command

Motor Overload Protection

Maintenance and Parts Replacement

Product Disposal

Page 17

15

Precautions for Correct Use

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

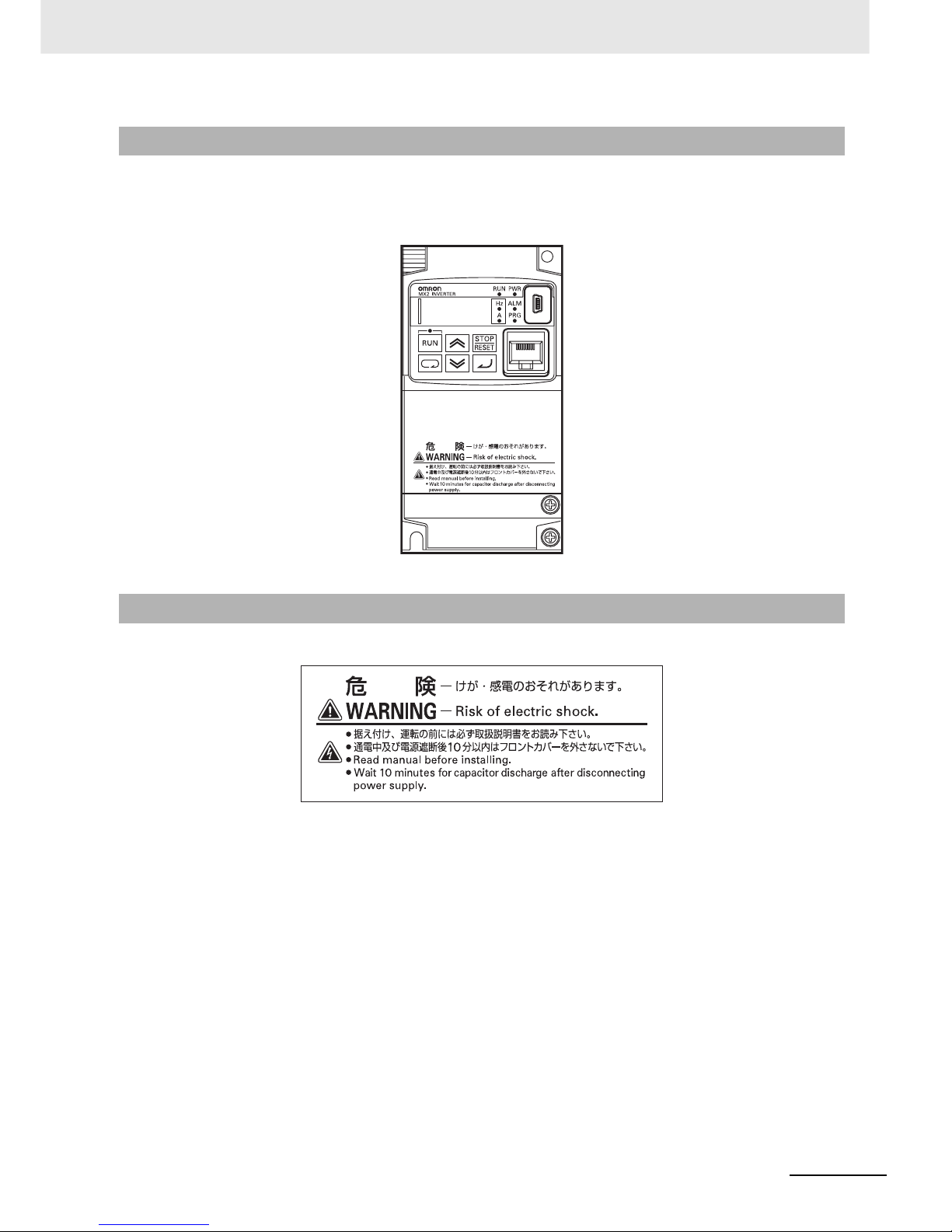

• This product bears a warning label at the following location to provide handling warnings.

• Be sure to follow the instructions.

The appearance differs depending on the capacity of the inverter.

Warning Label

Warning Description

Page 18

Regulations and Standards

16

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Regulations and Standards

To export (or provide to nonresident aliens) any part of this product that falls under the category of

goods (or technologies) for which an export certificate or license is mandatory according to the Foreign

Exchange and Foreign Trade Control Law of Japan, an export certificate or license (or service transaction approval) according to this law is required.

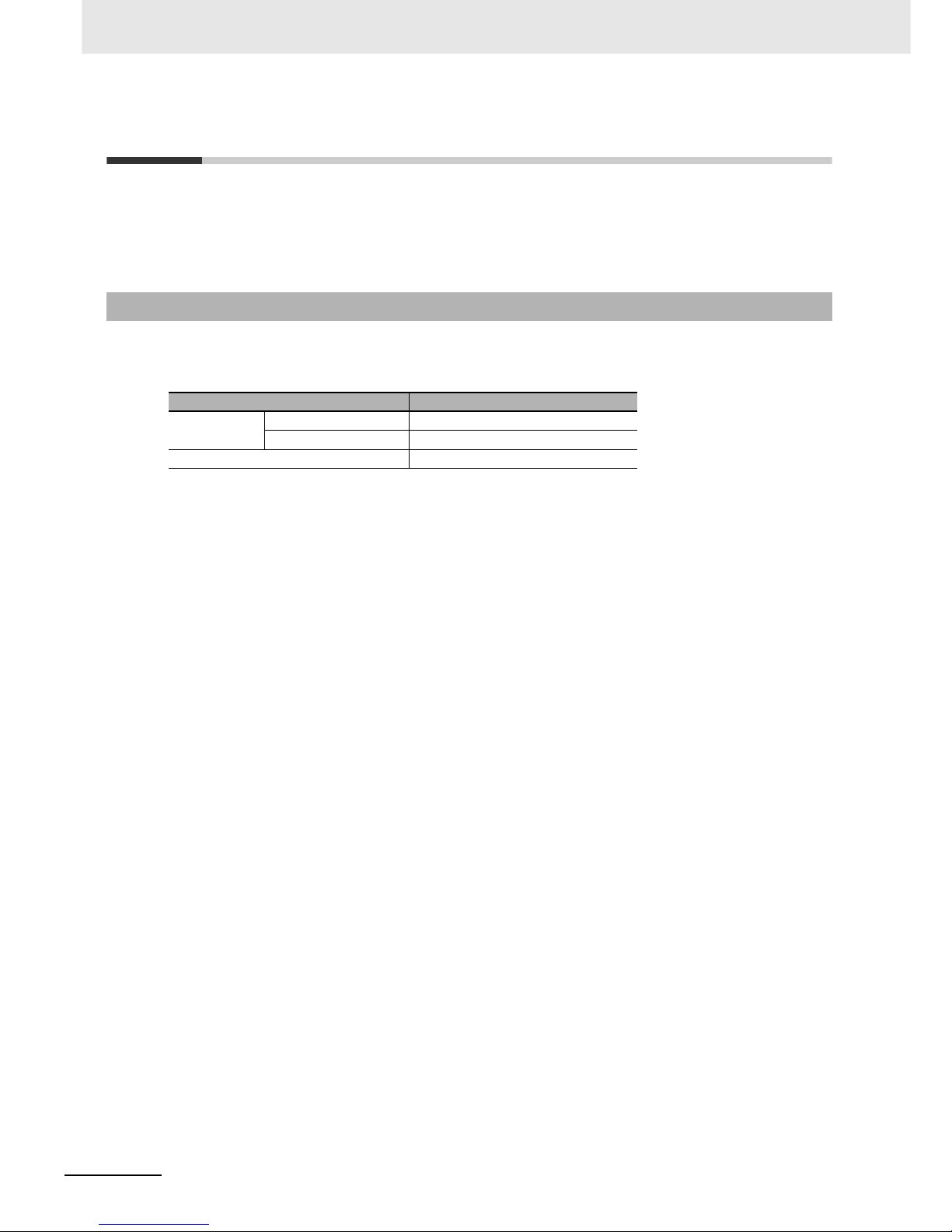

The 3G3MX2-V1 Series complies as standard with both the EC Directives and UL/cUL Standards.

EC Directives and UL/cUL Standards

Standard

Applicable standard

EC Directives EMC Directive EN61800-3: 2004

Low-voltage Directive EN61800-5-1: 2007

UL/cUL Standards UL 508C

Page 19

17

Trademarks

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Trademarks

• Windows, Windows 98, Windows XP, Windows Vista, and Windows 7 are registered trademarks of

Microsoft Corporation in the USA and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

• CompoNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

• Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

Page 20

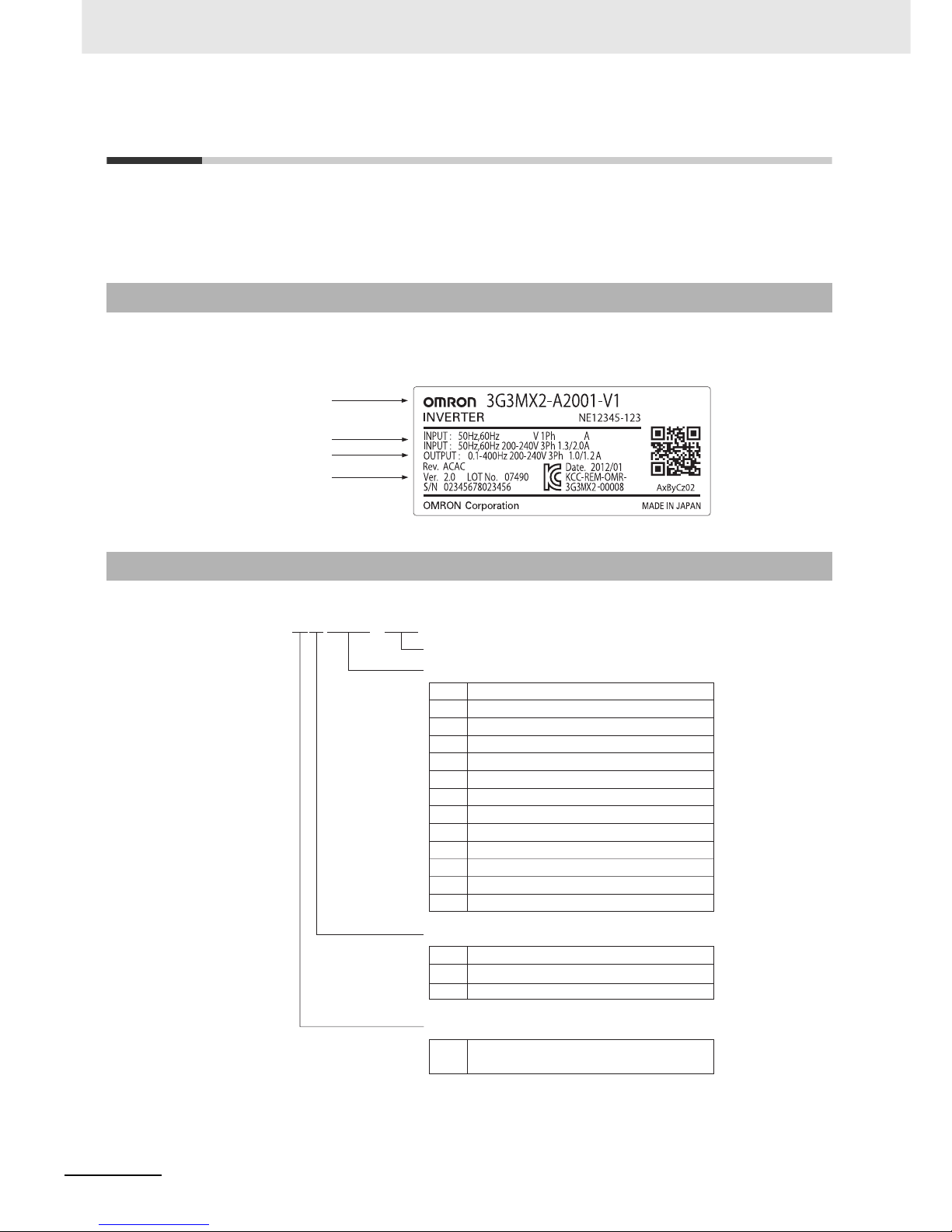

Items to Check after Unpacking

18

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Items to Check after Unpacking

After unpacking, check the following items.

• Is this the model you ordered?

• Was there any damage sustained during shipment?

The nameplate is affixed to the product.

Checking the Nameplate

Checking the Model

Inverter model

Input specifications

Output specifications

Unit version

3G3MX2-A2055-V1

Maximum applicable motor capacity (CT rating)

Type V1

004

007

015

022

0.4 kW

0.75 kW

1.5 kW

2.2 kW

5.5 kW

7.5 kW

11 kW

15 kW

Voltage class

B

2

4

Single phase 200 VAC (200-V class)

3-phase 200 VAC (200-V class)

3-phase 400 VAC (400-V class)

Enclosure rating

A

Panel-mounting (IP10 or higher) or

closed wall-mounting models

0.1 kW

0.2 kW

001

3.0 kW

3.7 kW

4.0 kW

030

037

040

002

055

075

110

150

Page 21

19

Items to Check after Unpacking

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

The instruction manual is the only accessory included in the Multi-function Compact Inverter (Model:

3G3MX2--V1).

Mounting screws and other necessary parts must be provided by the user.

Checking the Accessories

Page 22

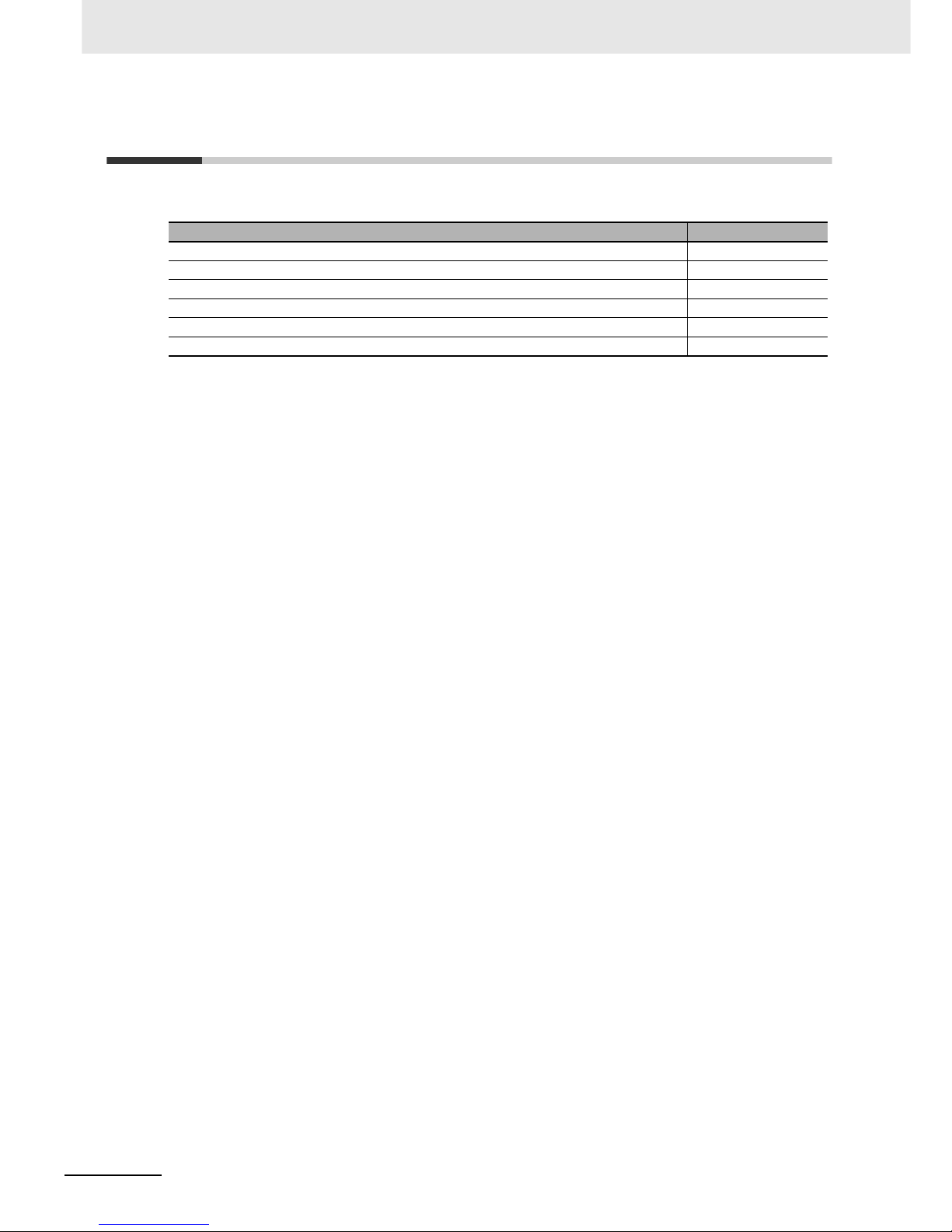

Related Manuals

20

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Related Manuals

Please see the manuals below for related product information.

Name Catalog No.

CX-Drive Operation Manual W453

DriveProgramming User’s Manual I580

Regenerative Braking Unit 3G3AX-RBU User’s Manual I563

MX2/RX Series EtherCAT Communication Unit User's Manual I574

MX2/RX Series CompoNet Communications Unit User’s Manual I582

MX2/RX Series DeviceNet Communications Unit User’s Manual I581

Page 23

21

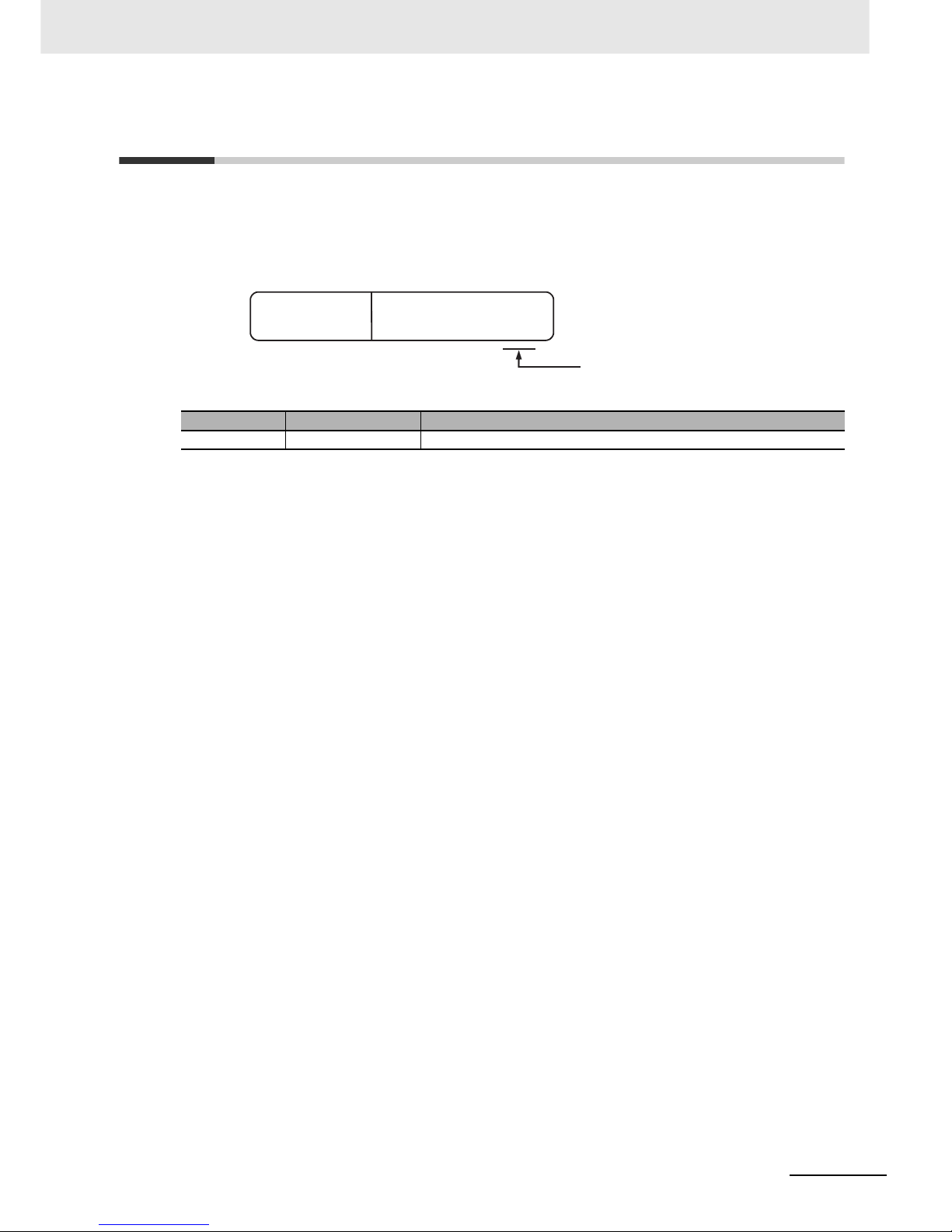

Revision History

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

Revision History

The manual revision code is a number appended to the end of the catalog number found in the bottom

right-hand corner of the front and back covers.

Revision code Revision date Revised Content

01 May 2013 Original production

Cat.No.

I585-E1-01

Example

Revision code

Page 24

CONTENTS

21

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

CONTENTS

Introduction ..............................................................................................................1

Manual Configuration ..............................................................................................2

Manual Structure ......................................................................................................3

Sections in this Manual ...........................................................................................5

Terms and Conditions Agreement..........................................................................6

Safety Precautions ...................................................................................................8

Precautions for Safe Use.......................................................................................12

Precautions for Correct Use.................................................................................. 14

Regulations and Standards...................................................................................16

Trademarks .............................................................................................................17

Items to Check after Unpacking............................................................................18

Related Manuals .....................................................................................................20

Revision History .....................................................................................................21

CONTENTS..............................................................................................................21

Section 1 Overview

1-1 Overview of Functions .......................................................................................................... 1-2

1-1-1 Features of 3G3MX2-V1 Series Inverter.....................................................................................1-2

1-1-2 Classes of 3G3MX2-V1 Series Inverter ......................................................................................1-6

1-1-3 Compliance with International Standards (EC Directives and UL/cUL Standards) .....................1-7

1-2 Appearance and Part Names ................................................................................................ 1-8

1-3 Specifications ...................................................................................................................... 1-12

1-3-1 Standard Specifications.............................................................................................................1-12

1-3-2 External Dimensions .................................................................................................................1-17

1-4 Restrictions .......................................................................................................................... 1-23

1-5 Comparison with Previous Model ...................................................................................... 1-25

Section 2 Design

2-1 Installation.............................................................................................................................. 2-4

2-1-1 Inverter Installation......................................................................................................................2-4

2-1-2 Installation Environment..............................................................................................................2-4

2-2 Removal of Each Part............................................................................................................ 2-7

2-2-1 Removing Covers........................................................................................................................2-7

2-2-2 Terminal Blocks...........................................................................................................................2-8

2-2-3 Preparing Backing Plate..............................................................................................................2-9

2-3 Wiring ................................................................................................................................... 2-10

Page 25

22

CONTENTS

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

2-3-1 Standard Connection Diagram.................................................................................................. 2-10

2-3-2 Arrangement and Function of Main Circuit Terminal Block........................................................2-11

2-3-3 Arrangement and Function of Control Circuit Terminal Block................................................... 2-12

2-3-4 Wiring for Main Circuit Terminals.............................................................................................. 2-15

2-3-5 Wiring for Control Circuit Terminals.......................................................................................... 2-33

2-3-6 Wiring for RS485 Communications Terminals .......................................................................... 2-40

2-3-7 Wiring for Digital Operator ........................................................................................................ 2-42

2-3-8 Safety Function (Under Application for Standards)................................................................... 2-43

2-3-9 Compliance with EC Directives................................................................................................. 2-44

Section 3 Operation and Test Run

3-1 Operation of Digital Operator ............................................................................................... 3-4

3-1-1 Part Names and Descriptions..................................................................................................... 3-4

3-1-2 Key Operation Method................................................................................................................ 3-6

3-2 Connections and Functions of CX-Drive........................................................................... 3-13

3-2-1 CX-Drive Connection Method................................................................................................... 3-13

3-2-2 Overview of CX-Drive Functions............................................................................................... 3-17

3-3 Flow of Test Run.................................................................................................................. 3-21

3-4 Operation Items for Test Run ............................................................................................. 3-22

Section 4 Parameter List

4-1 Monitor Mode ......................................................................................................................... 4-2

4-1-1 Group d....................................................................................................................................... 4-2

4-2 Function Mode ....................................................................................................................... 4-5

4-2-1 Group F: Basic Function Parameters .........................................................................................4-5

4-3 Extended Function Mode ...................................................................................................... 4-6

4-3-1 Group A: Standard Function Parameters.................................................................................... 4-7

4-3-2 Group b: Detailed Function Parameters ................................................................................... 4-14

4-3-3 Group C: Multi-function Terminal Function Parameters............................................................ 4-24

4-3-4 Group H: Motor Control Parameters......................................................................................... 4-32

4-3-5 Group P: Option/Applied Function Parameters ........................................................................ 4-35

4-3-6 Group U: User Parameters....................................................................................................... 4-41

Section 5 Basic Settings

5-1 Parameter Display and Parameter Initialization ................................................................. 5-3

5-1-1 Display Selection ........................................................................................................................ 5-3

5-1-2 Parameter Initialization ............................................................................................................... 5-6

5-2 V/f Control Settings ............................................................................................................... 5-9

5-2-1 Control Method (V/f Characteristics)........................................................................................... 5-9

5-2-2 Heavy Load/Light Load Selection............................................................................................. 5-12

5-3 Motor Parameter Settings ................................................................................................... 5-16

5-3-1 Motor Capacity/Pole Number Selection.................................................................................... 5-16

5-3-2 Electronic Thermal Function..................................................................................................... 5-16

5-3-3 Base Frequency and Maximum Frequency of Motor................................................................ 5-21

5-4 RUN Command Settings ..................................................................................................... 5-22

5-4-1 RUN Command Selection......................................................................................................... 5-22

5-5 Frequency Reference Settings ........................................................................................... 5-24

5-5-1 Frequency Reference Selection ............................................................................................... 5-24

5-5-2 Frequency Reference Correlation Chart................................................................................... 5-30

5-5-3 Frequency Limit ........................................................................................................................ 5-31

5-6 Acceleration/Deceleration Time Settings .......................................................................... 5-33

Page 26

CONTENTS

23

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

5-6-1 Acceleration/Deceleration Time Settings ..................................................................................5-33

5-6-2 Acceleration/Deceleration Pattern.............................................................................................5-34

5-6-3 2-step Acceleration/Deceleration Function ...............................................................................5-37

5-7 Stop Method Settings.......................................................................................................... 5-39

5-7-1 Stop Selection...........................................................................................................................5-39

5-7-2 Free-run Stop Selection ............................................................................................................5-39

5-7-3 STOP Key Selection .................................................................................................................5-42

5-8 Reset Method Settings ........................................................................................................5-43

5-8-1 Reset.........................................................................................................................................5-43

5-8-2 Restart after Resetting ..............................................................................................................5-45

5-9 Multi-function Input Settings .............................................................................................. 5-47

5-9-1 Multi-function Input Selection....................................................................................................5-47

5-9-2 Multi-function Input Operation Selection...................................................................................5-48

5-9-3 Input Terminal Response Time .................................................................................................5-48

5-9-4 Forward RUN Command (FW) and Reverse RUN Command (RV) .........................................5-48

5-9-5 Multi-step Speed Operation Function........................................................................................5-49

5-9-6 Jogging (JG)..............................................................................................................................5-52

5-9-7 2-step Acceleration/Deceleration (2CH)....................................................................................5-53

5-9-8 Reset (RS) ................................................................................................................................5-53

5-9-9 3-wire Input Function (STA, STP, F/R) ......................................................................................5-54

5-10 Multi-function Output Settings........................................................................................... 5-55

5-10-1 Multi-function Output Selection .................................................................................................5-55

5-10-2 Multi-function Output Operation Selection ................................................................................5-55

5-10-3 Multi-function Output ON/OFF Delay Time ...............................................................................5-56

5-10-4 Signal during RUN (RUN) .........................................................................................................5-56

5-10-5 Constant Speed Arrival Signal (FA1).........................................................................................5-57

5-10-6 Alarm Signal (AL)......................................................................................................................5-57

5-10-7 0-Hz Detection Signal (ZS) .......................................................................................................5-58

5-10-8 Operation Ready (IRDY)...........................................................................................................5-59

5-10-9 Forward Run Signal (FWR).......................................................................................................5-59

5-10-10 Reverse Run Signal (RVR) .......................................................................................................5-59

5-11 Torque Boost Function Settings ........................................................................................ 5-60

5-11-1 Torque Boost.............................................................................................................................5-60

5-12 Measures against Overvoltage........................................................................................... 5-63

5-12-1 Overvoltage Suppression Function during Deceleration...........................................................5-63

5-12-2 Regenerative Braking Function.................................................................................................5-65

Section 6 Vector Control and Applied Functions

6-1 Sensorless Vector Control....................................................................................................6-3

6-1-1 Sensorless Vector Control Parameter Settings...........................................................................6-3

6-1-2 Offline Auto-tuning for Motor Parameters ...................................................................................6-4

6-1-3 Motor Parameter Settings ...........................................................................................................6-9

6-1-4 Adjustments for Sensorless Vector Control...............................................................................6-10

6-2 Torque Limit Function......................................................................................................... 6-12

6-2-1 Torque Limit Function Settings..................................................................................................6-12

6-2-2 Torque LADSTOP Function Settings.........................................................................................6-14

6-3 Overtorque/Undertorque Function .................................................................................... 6-15

6-3-1 Overtorque/Undertorque Function Settings ..............................................................................6-15

6-4 Torque Control..................................................................................................................... 6-16

6-4-1 Torque Control Settings.............................................................................................................6-16

6-4-2 Torque Bias Function Settings ..................................................................................................6-17

6-5 V/f Control with Speed Feedback....................................................................................... 6-18

6-5-1 Settings of V/f Control with Speed Feedback............................................................................6-18

6-5-2 Recommended Encoder and Its Wiring ....................................................................................6-19

6-5-3 Protective Detection under V/f Control with Speed Feedback ..................................................6-23

6-5-4 Adjustments for V/f Control with Speed Feedback....................................................................6-24

Page 27

24

CONTENTS

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

6-6 Brake Control Function.......................................................................................................6-25

6-6-1 Operation Sequence of Brake Control Function ....................................................................... 6-25

6-6-2 Brake Control Function Settings............................................................................................... 6-26

6-7 Simple Position Control ......................................................................................................6-28

6-7-1 Feedback Settings for Simple Position Control ........................................................................ 6-28

6-7-2 Recommended Encoder for Simple Position Control and Its Wiring ........................................ 6-29

6-7-3 Simple Position Control Operation and Settings....................................................................... 6-34

6-7-4 Origin Search Function, Current Position Preset, Position Data Storage at Power Shutoff ..... 6-40

6-7-5 Restarting Positioning............................................................................................................... 6-45

6-7-6 Multi-step Position Control Settings.......................................................................................... 6-45

6-7-7 Turntable Control...................................................................................................................... 6-47

6-7-8 Speed/Position Switching ......................................................................................................... 6-48

6-7-9 Interlock Function with Simple Position Control and Brake Control.......................................... 6-49

6-8 PM Motor Mode .................................................................................................................... 6-53

6-8-1 PM Motor and PM Motor Control..............................................................................................6-53

6-8-2 Functional Limitations in PM Motor Mode................................................................................. 6-55

6-8-3 Switching to PM Motor Mode.................................................................................................... 6-57

6-8-4 Offline Auto-tuning for PM Motor Parameters........................................................................... 6-57

6-8-5 PM Motor Parameter Settings .................................................................................................. 6-61

6-8-6 Adjustment of PM Motor Mode Settings ................................................................................... 6-63

Section 7 Other Functions

7-1 Monitor Mode ......................................................................................................................... 7-4

7-1-1 Output Frequency Monitor [d001] ............................................................................................... 7-4

7-1-2 Output Current Monitor [d002].................................................................................................... 7-4

7-1-3 RUN Direction Monitor [d003]..................................................................................................... 7-5

7-1-4 PID Feedback Value Monitor [d004]........................................................................................... 7-5

7-1-5 Multi-function Input Monitor [d005] ............................................................................................. 7-5

7-1-6 Multi-function Output Monitor [d006]........................................................................................... 7-6

7-1-7 Output Frequency Monitor (After Conversion) [d007]................................................................. 7-6

7-1-8 Real Frequency Monitor [d008] .................................................................................................. 7-7

7-1-9 Torque Reference Monitor [d009] ............................................................................................... 7-7

7-1-10 Torque Bias Monitor [d010]......................................................................................................... 7-8

7-1-11 Output Torque Monitor [d012]..................................................................................................... 7-8

7-1-12 Output Voltage Monitor [d013].................................................................................................... 7-8

7-1-13 Input Power Monitor [d014]......................................................................................................... 7-9

7-1-14 Integrated Power Monitor [d015] ................................................................................................ 7-9

7-1-15 Total RUN Time Monitor [d016]................................................................................................. 7-10

7-1-16 Total Power ON Time Monitor [d017]........................................................................................7-10

7-1-17 Fin Temperature Monitor [d018]................................................................................................ 7-10

7-1-18 Life Assessment Monitor [d022] ................................................................................................7-11

7-1-19 Program Counter (DriveProgramming) [d023]...........................................................................7-11

7-1-20 User Monitor 0 to 2 (DriveProgramming) [d025 to d027]

....

.......................................................7-11

7-1-21 Position Command Monitor [d029] ...........................................................................................7-12

7-1-22 Current Position Monitor [d030] ................................................................................................ 7-12

7-1-23 Dual User Monitor [d050].......................................................................................................... 7-13

7-1-24 Inverter Mode Monitor [d060].................................................................................................... 7-13

7-1-25 Frequency Reference Source Monitor [d062]........................................................................... 7-14

7-1-26 Run Command Source Monitor [d063]..................................................................................... 7-14

7-1-27 Fault Counter [d080]................................................................................................................. 7-14

7-1-28 Fault Monitor 1 to 6 [d081 to 086]............................................................................................. 7-15

7-1-29 Warning Monitor [d090] ............................................................................................................ 7-15

7-1-30 DC Voltage Monitor [d102]........................................................................................................ 7-15

7-1-31 Regenerative Braking Load Rate Monitor [d103]...................................................................... 7-16

7-1-32 Electronic Thermal Load Rate Monitor [d104] .......................................................................... 7-16

7-1-33 Analog Voltage Input FV Monitor [d130]................................................................................... 7-16

7-1-34 Analog Current Input FI Monitor [d131] ....................................................................................7-16

7-1-35 Pulse Train Input RP Monitor [d133]......................................................................................... 7-17

7-1-36 PID Deviation [d153]................................................................................................................. 7-17

7-1-37 PID Output Monitor [d155]........................................................................................................ 7-17

Page 28

CONTENTS

25

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

7-2 Multi-function Input/Output Functions .............................................................................. 7-18

7-2-1 Multi-function Input Selection....................................................................................................7-18

7-2-2 Multi-function Output Selection.................................................................................................7-20

7-3 Analog I/O Settings ............................................................................................................. 7-22

7-3-1 Analog Input (FV, FI).................................................................................................................7-22

7-3-2 Analog Input Filter.....................................................................................................................7-24

7-3-3 Analog Command Hold Function (AHD) ...................................................................................7-24

7-3-4 Analog Input Adjustment...........................................................................................................7-25

7-3-5 Analog Input Start/End Function Settings ................................................................................. 7-25

7-3-6 Terminal MP (Pulse/PWM Output)............................................................................................7-27

7-3-7 Terminal AM (Analog Output)....................................................................................................7-29

7-4 Inverter Control Settings ....................................................................................................7-31

7-4-1 Carrier Frequency .....................................................................................................................7-31

7-4-2 Automatic Carrier Reduction.....................................................................................................7-32

7-4-3 2nd Control Function (SET) ......................................................................................................7-33

7-5 Other Operation Functions ................................................................................................. 7-35

7-5-1 Starting Frequency....................................................................................................................7-35

7-5-2 Reduced Voltage Startup Selection...........................................................................................7-36

7-5-3 Frequency Jump Function.........................................................................................................7-36

7-5-4 Acceleration/Deceleration Stop Function..................................................................................7-37

7-5-5 RUN Direction Limit Selection...................................................................................................7-38

7-5-6 Permission of RUN Command..................................................................................................7-38

7-5-7 Frequency Calculation Function................................................................................................7-39

7-5-8 Frequency Addition Function ....................................................................................................7-39

7-5-9 Remote Operation Function (UP/DWN)....................................................................................7-40

7-5-10 Output Voltage Gain..................................................................................................................7-41

7-5-11 AVR (Automatic Voltage Regulator) Function ...........................................................................7-42

7-5-12 PID Function .............................................................................................................................7-44

7-5-13 Automatic Energy-saving Operation Function...........................................................................7-50

7-5-14 Commercial Switching (CS) ......................................................................................................7-50

7-5-15 Stabilization Parameter .............................................................................................................7-52

7-5-16 Pulse Train Frequency Input .....................................................................................................7-52

7-5-17 LAD Cancel Function ................................................................................................................7-53

7-6 Digital Operator and Operation Functions ........................................................................ 7-54

7-6-1 Soft Lock Function (SFT) ..........................................................................................................7-54

7-6-2 Forced Operator Function (OPE)..............................................................................................7-55

7-6-3 Forced Terminal Block Function (F-TM)....................................................................................7-55

7-6-4 Operation Selection at External Operator Disconnection..........................................................7-56

7-6-5 Initial Screen Selection (Initial Screen after Power-on).............................................................7-56

7-6-6 Initial Screen Automatic Return Function..................................................................................7-56

7-6-7 Inverter Display on Operator Connection..................................................................................7-57

7-6-8 Display Fixed (DISP).................................................................................................................7-57

7-6-9 Password Function....................................................................................................................7-57

7-6-10 User Parameter Setting Function..............................................................................................7-60

7-6-11 User Parameter Automatic Setting Function.............................................................................7-60

7-7 Restart Functions ................................................................................................................ 7-61

7-7-1 Frequency Matching Restart and Frequency Pull-in Restart ....................................................7-61

7-7-2 Restart during Power Interruption, Undervoltage/Overvoltage, Overcurrent ............................7-63

7-7-3 Power Recovery Restart Prevention Function (USP) ...............................................................7-67

7-7-4 Deceleration Stop on Power Interruption Function ...................................................................7-68

7-8 Functions Related to Protection, Warning, and Various Output Signals....................... 7-72

7-8-1 Free-electronic Thermal Function .............................................................................................7-72

7-8-2 Motor Electronic Thermal Function ...........................................................................................7-73

7-8-3 Electronic Thermal Warning......................................................................................................7-75

7-8-4 Overload Limit/Overload Warning ............................................................................................. 7-76

7-8-5 Overcurrent Suppression Function ...........................................................................................7-79

7-8-6 External Trip (EXT) ...................................................................................................................7-79

7-8-7 Thermistor Trip Function...........................................................................................................7-80

7-8-8 Signal during RUN (RUN) .........................................................................................................7-80

7-8-9 Frequency Arrival Signal (FA2 to FA5)......................................................................................7-81

7-8-10 RUN Time/Power ON Time Over (RNT/ONT)...........................................................................7-82

Page 29

26

CONTENTS

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

7-8-11 Logic Operation Output Signal (LOG1 to LOG3) ...................................................................... 7-83

7-8-12 Capacitor Life Warning Signal (WAC).......................................................................................7-84

7-8-13 Cooling Fan Operation.............................................................................................................. 7-84

7-8-14 Cooling Fan Life Warning Signal (WAF)................................................................................... 7-85

7-8-15 Communication Disconnection Detection Signal (NDc)............................................................ 7-85

7-8-16 Starting Contact Signal (FR)..................................................................................................... 7-86

7-8-17 Cooling Fin Overheat Warning (OHF) ...................................................................................... 7-86

7-8-18 Low Current Signal (LOC) ........................................................................................................ 7-87

7-8-19 Fatal Fault Signal (MJA)........................................................................................................... 7-87

7-8-20 Window Comparator (WCFV/WCFI) (Disconnection Detection FVDc/FIDc) ............................ 7-88

7-8-21 Frequency Reference Selection Status Signal (FREF)............................................................. 7-89

7-8-22 RUN Command Status Signal (REF)........................................................................................ 7-89

7-8-23 2nd Control Selection Signal (SETM).......................................................................................7-90

7-9 DC Injection Braking Function ........................................................................................... 7-91

7-9-1 DC Injection Braking (DB)......................................................................................................... 7-91

7-10 Safety Function (Under Application for Standards)......................................................... 7-97

7-10-1 Overview of Safety Function..................................................................................................... 7-97

7-10-2 Safety Function Settings........................................................................................................... 7-97

7-10-3 Wiring Safety Function for Use ................................................................................................. 7-98

7-10-4 Wiring Example......................................................................................................................... 7-99

7-11 Option/Applied Functions (Group P) ............................................................................... 7-101

7-11-1 Operation Selection on Option Error....................................................................................... 7-101

7-11-2 Communications Option Function........................................................................................... 7-101

7-11-3 DriveProgramming Function Parameters ............................................................................... 7-102

Section 8 Communications Functions

8-1 Communications Specifications .......................................................................................... 8-3

8-2 RS485 Terminal Arrangement and Connection .................................................................. 8-4

8-3 Modbus Communication Parameters .................................................................................. 8-5

8-4 Modbus Communication Protocol ....................................................................................... 8-7

8-4-1 Message Configuration............................................................................................................... 8-7

8-4-2 Required Communications Time ................................................................................................ 8-9

8-4-3 Normal Response....................................................................................................................... 8-9

8-4-4 Abnormal Response ................................................................................................................... 8-9

8-4-5 No Response............................................................................................................................ 8-10

8-5 Explanation of Each Function Code .................................................................................. 8-11

8-5-1 Read Coil Status [01 hex]..........................................................................................................8-11

8-5-2 Read from Holding Register [03 hex]........................................................................................8-12

8-5-3 Write to Coil [05 hex] ................................................................................................................ 8-13

8-5-4 Write to Holding Register [06 hex]............................................................................................ 8-14

8-5-5 Loop-back Test [08 hex]............................................................................................................ 8-15

8-5-6 Write to Multiple Coils [0F hex]................................................................................................. 8-16

8-5-7 Write to Multiple Holding Registers [10 hex]............................................................................. 8-18

8-5-8 Read/Write from/to Multiple Holding Registers [17h]................................................................ 8-19

8-5-9 Exception Response................................................................................................................. 8-20

8-6 Saving a Change to Holding Register (Enter Command) ................................................ 8-21

8-6-1 How to Issue Enter Command.................................................................................................. 8-21

8-6-2 EEPROM Write Mode.............................................................................................................. 8-23

8-7 Modbus Mapping Function ................................................................................................. 8-24

8-7-1 Operation of Modbus Mapping Function................................................................................... 8-24

8-7-2 Modbus Mapping Function Settings ......................................................................................... 8-25

8-7-3 Compressed Single-word Registers ......................................................................................... 8-26

8-7-4 Troubleshooting for Modbus Mapping Function ....................................................................... 8-28

8-7-5 Endian Function........................................................................................................................ 8-29

8-8 Co-inverter Communication ............................................................................................... 8-31

8-8-1 Co-inverter Communication Parameters .................................................................................. 8-32

8-8-2 Co-inverter Communication Settings ........................................................................................ 8-35

Page 30

CONTENTS

27

Multi-function Compact Inverter 3G3MX2-V1 User’s Manual (I585-E1)

8-9 Modbus Communication Data Lists................................................................................... 8-37

8-9-1 Coil Number List........................................................................................................................8-37

8-9-2 Monitor Function/Enter Command Register List .......................................................................8-41

8-9-3 Group F Register List................................................................................................................8-50

8-9-4 Group A/b/C/H/P Register List ..................................................................................................8-51

8-9-5 2nd Control Register Number List.............................................................................................8-96

Section 9 Overview of DriveProgramming

9-1 Overview of DriveProgramming ........................................................................................... 9-2

Section 10 Troubleshooting

10-1 Alarm Display and Remedies ............................................................................................. 10-2

10-1-1 Alarm Display............................................................................................................................10-2

10-1-2 Alarm Code List.........................................................................................................................10-4

10-1-3 Option Unit Protective Function List........................................................................................10-10

10-1-4 Warning Display......................................................................................................................10-12

10-1-5 Other Indications on Digital Operator......................................................................................10-13

10-2 Troubleshooting ................................................................................................................ 10-14

Section 11 Maintenance and Inspection

11-1 Maintenance and Inspection .............................................................................................. 11-2

11-1-1 Daily Inspection......................................................................................................................... 11-3

11-1-2 Cleaning.................................................................................................................................... 11-3

11-1-3 Periodic Inspection.................................................................................................................... 11-3

11-1-4 Daily/Periodic Inspection Items................................................................................................. 11-4

11-1-5 Megger Test .............................................................................................................................. 11-7

11-1-6 Withstand Voltage Test.............................................................................................................. 11-7

11-1-7 Inverter/Converter Unit Test ...................................................................................................... 11-7

11-1-8 I/O Voltage/Current/Electric Power Measurement Method ....................................................... 11-9

Section 12 Options

12-1 Overview of Optional Equipment ....................................................................................... 12-3

12-1-1 Part Names and Descriptions ...................................................................................................12-3

12-2 Regenerative Braking Unit (Model: 3G3AX-RBU) ...................................................... 12-5

12-2-1 Specifications ............................................................................................................................12-5

12-2-2 External Dimensions ................................................................................................................. 12-7

12-2-3 Connection Examples ............................................................................................................. 12-11

12-3 Braking Resistor (Model: 3G3AX-RBA/RBB/RBC)............................................. 12-12

12-3-1 Specifications ..........................................................................................................................12-12

12-3-2 External Dimensions ...............................................................................................................12-13

12-3-3 Connection Examples .............................................................................................................12-15

12-4 Regenerative Braking Unit and Braking Resistor Combination Selection Table ........ 12-16

12-5 DC Reactor (Model: 3G3AX-DL) .......................................................................... 12-20

12-5-1 Specifications ..........................................................................................................................12-20

12-5-2 External Dimensions ...............................................................................................................12-22