Page 1

USER’S MANUAL

SYSDRIVE 3G3MV

Multi-function Compact Inverter

Cat. No. I527-E2-02

Page 2

Thankyoufor choosing this SYSDRIVE3G3MV-seriesproduct.Properuse

and handling of the product will ensure proper product performance, will

lengthen product life, and may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product

with care.

NOTICE

1. This manual describes the functions of the product and relations with other

products. Youshould assume that anything not described in this manual is

not possible.

2. Although care has been given in documenting the product, please contact

yourOMRON representative if you haveany suggestions on improving this

manual.

3. The product contains potentially dangerous parts under the cover. Do not

attempt to open the cover under any circumstances. Doing so may result in

injuryordeathandmaydamage the product. Never attempt to repair or disassemble the product.

4. We recommend that you add the following precautions to any instruction

manualsyouprepareforthesystemintowhichthe productisbeinginstalled.

S Precautions on the dangers of high-voltage equipment.

S Precautionsontouchingtheterminalsoftheproduct evenafterpowerhas

been turned off. (These terminals are live even with the power turned off.)

5. Specifications and functions may be changed without notice in order to

improve product performance.

Items to Check Before Unpacking

Checkthefollowing items before removingtheproductfrom the package:

S Hasthecorrectproductbeendelivered(i.e., thecorrectmodelnumberand

specifications)?

S Has the product been damaged in shipping?

S Are any screws or bolts loose?

Page 3

Checking Before Unpacking

H Checking the Product

Ondelivery,always check that the delivered productisthe SYSDRIVE 3G3MV Inverter

that you ordered.

Should you find any problems with the product, immediately contact your nearest local

sales representative.

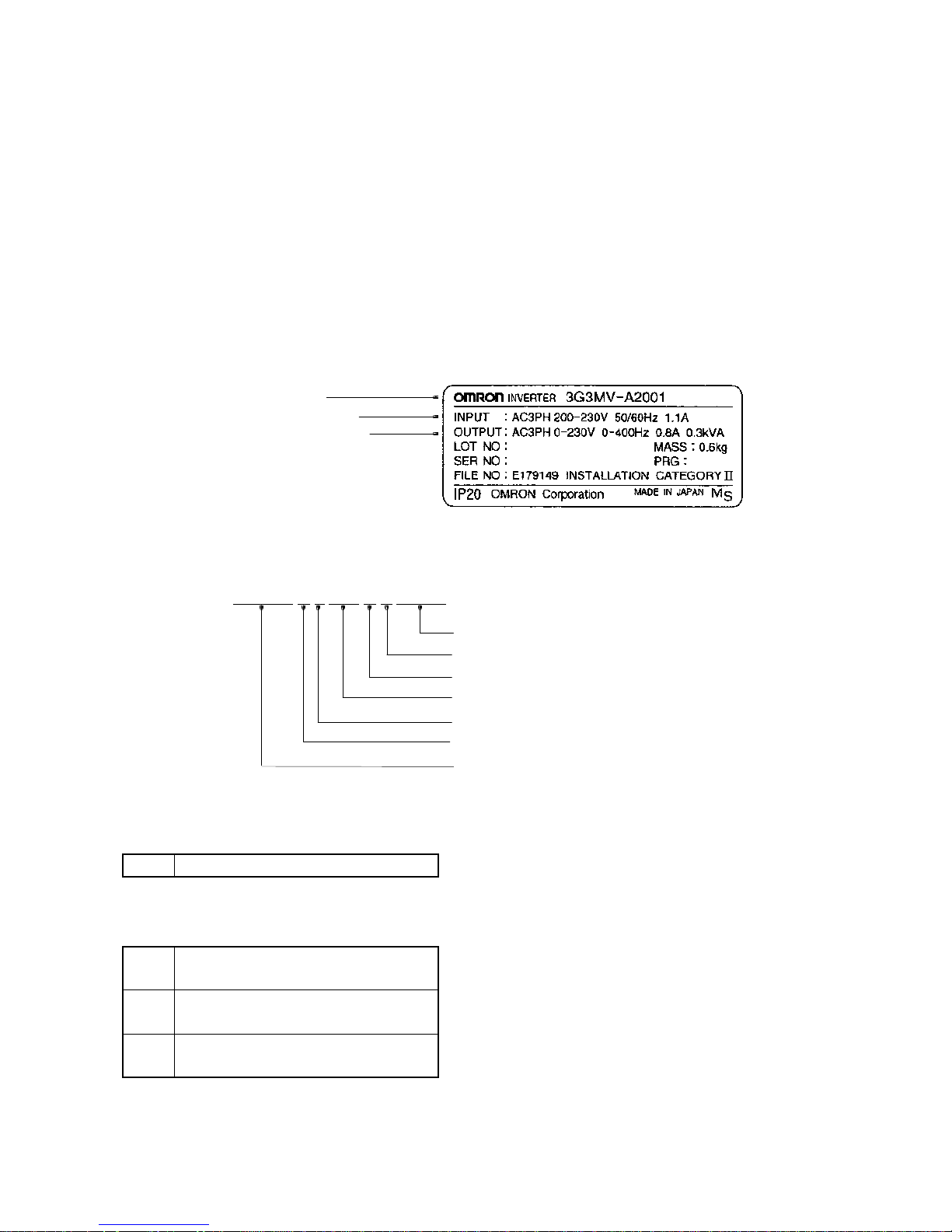

D Checking the Nameplate

Inverter model

Input specifications

Output specifications

D Checking the Model

3G3MV-A 4 007 N Z 00001

Special software option

No Heatsink

No potentiometer

Maximum applicable motor capacity

Voltage class

Installation type

Series name: 3G3MV Series

Installation Type

A Closed wall mounting

Voltage Class

2 Three-phase 200-VAC input

(200-V class)

B Single-phase 200-VAC input

(200-V class)

4 Three-phase 400-VAC input

(400-V class)

Page 4

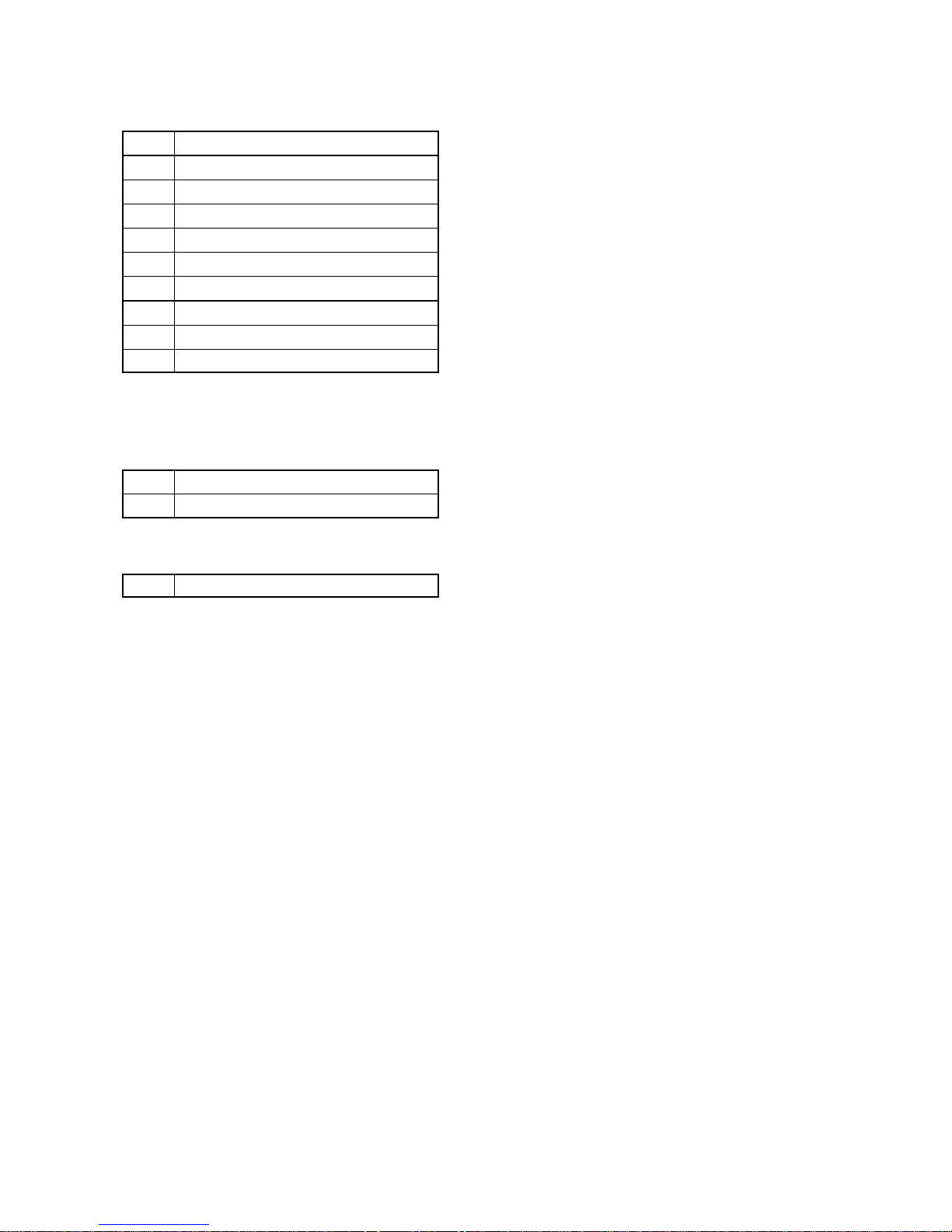

Maximum Applicable Motor Capacity

001 0.1 (0.1) kW

002 0.2 (0.25/0.37) kW

004 0.4 (0.55) kW

007 0.75 (1.1) kW

015 1.5 (1.5) kW

022 2.2 (2.2) kW

030 3.0 (3.0) kW

040 4.0 (4.0) kW

055 5.5 (5.5) kW

075 7.5 (7.5) kW

Note The figures in parentheses indicate capacities for motors used outside Japan.

Front Cover options

B Blank cover

N No potentiometer

Heatsink option

Z No Heatsink

D Checking for Damage

Checkthe overall appearance and checkfor damage or scratchesresulting from transportation.

Page 5

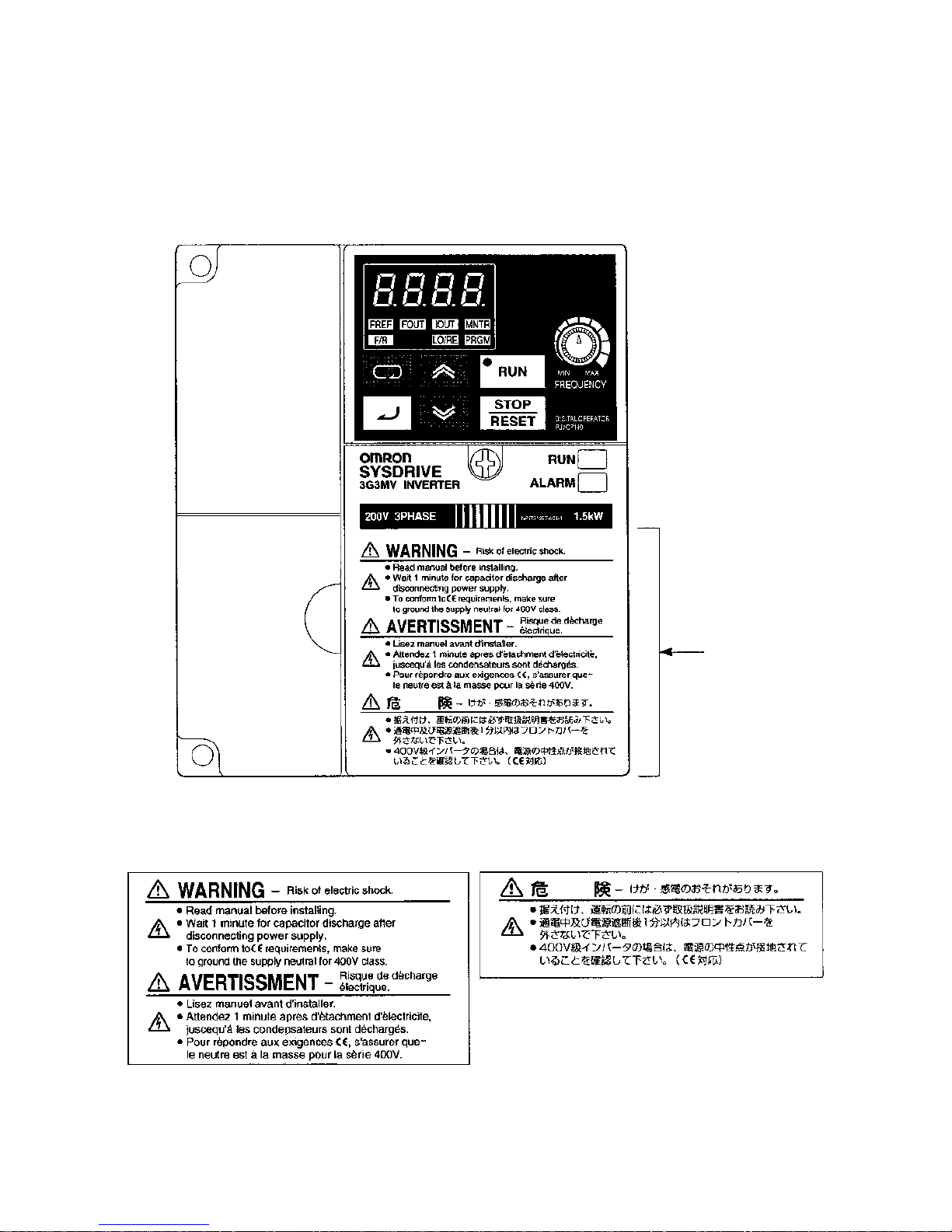

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

H Warning Labels

Warning label

H Contents of Warning

Page 6

!

!

!

!

!

!

!

!

!

!

!

W ARNING Be sure confirm that the RUN signal is turned OFF before turning ON the power

supply, resetting the alarm, or switching the LOCAL/REMOTE selector. Doing so

while the RUN signal is turned ON may result in injury.

Caution Be sure to confirm permissible ranges of motors and machines before operation

because the Inverter speed can be easily changed from low to high. Not doing so

may result in damage to the product.

Caution Providea separateholding brakewhen necessary.Not doingso may resultin injury.

Caution Donotperformasignalcheckduringoperation. Doingsomayresult ininjuryordam-

age to the product.

Caution Do not carelessly change settings. Doing so may result in injury or damage to the

product.

Maintenance and Inspection Precautions

W ARNING Do not touch the Inverter terminals while the power is being supplied.

W ARNING Maintenance or inspection must be performed only after turning OFF the power

supply, confirming that the CHARGE indicator (or status indicators) is turned OFF,

andafterwaiting for thetimespecified on the frontcover. Notdoing so may result in

electrical shock.

W ARNING Maintenance, inspection, or parts replacement must be performed by authorized

personnel. Not doing so may result in electrical shock or injury.

W ARNING Do not attempt to take the Unit apart or repair. Doing either of these may result in

electrical shock or injury.

Caution Carefully handle the Inverter because it uses semiconductor elements. Careless

handling may result in malfunction.

Caution Do not change wiring, disconnect connectors or Operator, or replace fans while

power is being supplied. Doing so may result in injury or malfunction.

Page 7

!

!

!

!

!

!

!

!

!

!

!

!

!

Caution Install external breakers and take other safety measures against short-circuiting in

external wiring. Not doing so may result in fire.

Caution Confirmthat therated inputvoltage ofthe Inverteris thesame asthe ACpower sup-

ply voltage. An incorrect power supply may result in fire, injury, or malfunction.

Caution IfyouuseaBrakingResistorora BrakingResistorUnit,connect themasspecifiedin

the manual. Not doing so may result in fire.

Caution Besuretowirecorrectly andsecurely.Not doingsomay resultininjuryordamage to

the product.

Caution Besure to firmlytighten thescrewson theterminal block. Notdoing so mayresult in

fire, injury, or damage to the product.

Caution DonotconnectanAC powertothe U,V,or Woutput.Doing somayresultindamage

to the product or malfunction.

Operation and Adjustment Precautions

W ARNING TurnONthe inputpower supplyonly aftermounting thefront cover,terminal covers,

bottom cover, Operator, and optional items. Not doing so may result in electrical

shock.

W ARNING Do not remove the front cover,terminal covers, bottom cover,Operator,oroptional

items whilethepower is being supplied. Notdoing so may result inelectricalshock.

W ARNING Do not operate the Operator or switches with wet hands. Doing so may result in

electrical shock.

W ARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

W ARNING Do not come close to the machine when using the error retry function because the

machinemayabruptlystartwhen stoppedbyan alarm.Doingso mayresult ininjury.

W ARNING Do not come close to the machine immediately after resetting momentary power

interruption toavoidan unexpected restart (if operation is settobe continued in the

processingselectionfunctionaftermomentarypowerinterruptionis reset).Doingso

may result in injury.

W ARNING Providea separate emergencystop switch becausethe STOPKeyon theOperator

isvalidonly when functionsettingsare performed. Notdoingso may result ininjury.

Page 8

!

!

!

!

!

!

!

!

!

!

!

!

Transportation Precautions

Caution Donotholdbyfrontcoveror panel,instead, holdbytheradiation fin(heatsink) while

transporting the product. Doing so may result in injury.

Caution Donotpull on thecables.Doing so mayresultin damage to theproduct or malfunc-

tion.

Caution Use the eye-bolts only for transporting the Inverter.Using them for transporting the

machinery may result in injury or malfunction.

Installation Precautions

Caution Be sure to install the product in the correct direction and provide specified clear-

ances between the Inverter and control panel or with other devices. Not doing so

may result in fire or malfunction.

Caution Donot allowforeign objectsto enterinside theproduct. Doingso mayresult infire or

malfunction.

Caution Do not apply any strong impact. Doing so may result in damage to the product or

malfunction.

Caution Provide an appropriate stopping device on the machine side to secure safety. (A

holdingbrakeis notastopping deviceforsecuringsafety.)Notdoing somayresultin

injury.

Caution Provideanexternalemergencystoppingdevice thatallowsaninstantaneousstopof

operation and power interruption. Not doing so may result in injury.

Wiring Precautions

W ARNING Wiring must be performed only after confirming that the power supply has been

turned OFF. Not doing so may result in electrical shock.

W ARNING Wiring must be performed by authorized personnel. Not doing so may result in

electrical shock or fire.

W ARNING Be suretoconfirm operation only after wiring the emergency stop circuit. Not doing

so may result in injury.

W ARNING Always connect the ground terminals to a ground of 100 W or less for the 200-VAC

class,or 10 W or lessforthe 400-VACclass. Not connectingto aproper ground may

result in electrical shock.

Page 9

!

!

!

!

!

!

!

!

!

General Precautions

Observe the following precautions when using the SYSDRIVE Inverters and peripheral

devices.

This manual may include illustrations of the product with protective covers removed in order

to describe the components of the product in detail. Make sure that these protective covers

are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

W ARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

W ARNING Operation, maintenance, or inspection must be performed after turning OFF the

powersupply,confirming that theCHARGE indicator (orstatus indicators) areOFF,

andafterwaiting for thetimespecified on the frontcover. Notdoing so may result in

electrical shock.

W ARNING Donot damage,pull on,apply stressto, placeheavy objectson, orpinch thecables.

Doing so may result in electrical shock.

W ARNING Do nottouchthe rotating parts of the motor underoperation.Doing so may result in

injury.

W ARNING Do not modify the product. Doing so may result in injury or damage to the product.

Caution Do not store, install, or operate the product in the following places. Doing so may

result in electrical shock, fire or damage to the product.

S Locations subject to direct sunlight.

S Locations subject to temperatures or humidity outside the range specified in the

specifications.

S Locationssubject tocondensation asthe resultof severechanges intemperature.

S Locations subject to corrosive or flammable gases.

S Locations subject to exposure to combustibles.

S Locations subject to dust (especially iron dust) or salts.

S Locations subject to exposure to water, oil, or chemicals.

S Locations subject to shock or vibration.

Caution Do not touch the Inverter radiator, regenerative resistor, or Servomotor while the

powerisbeingsuppliedorsoonafterthe poweristurnedOFF.Doingsomayresultin

a skin burn due to the hot surface.

Caution Do not conduct a dielectric strength test on any part of the Inverter. Doing so may

result in damage to the product or malfunction.

Caution Takeappropriateandsufficientcountermeasures wheninstallingsystems inthe fol-

lowing locations. Not doing so may result in equipment damage.

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

Page 10

!

!

!

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual.

Always heed the information provided with them. Failure to heed precautions can result in

injury to people or damage to property.

DANGER Indicatesan imminentlyhazardoussituation which,ifnotavoided, willresultin death

or serious injury.

W ARNING Indicatesapotentiallyhazardoussituationwhich,if notavoided,couldresultindeath

or serious injury.

Caution Indicatesa potentially hazardoussituation which,ifnot avoided,may result inminor

or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products,

often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

Ó

OMRON,200

1

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 11

Table of Contents

xi

Chapter 1. Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Function 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Nomenclature 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 NewFeatures 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Design 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Installation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Dimensions 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Installation Conditions 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Removing and Mounting the Covers 2-8. . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Terminal Block 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Standard Connections 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Wiring around the Main Circuit 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Wiring Control Circuit Terminals 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 Conforming to EC Directive 2-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3. Preparing for Operation and Monitoring 3-1. . . .

3-1 Nomenclature 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-1 Names of Parts and their Functions 3-2. . . . . . . . . . . . . . . . . . . . . . . . .

3-1-2 Outline of Operation 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Parameter Copy and Verify Function 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Parameter for Copying and Verifying Set Values 3-10. . . . . . . . . . . . . . .

3-2-2 Parameter Copying Procedure 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Parameter Read-prohibit Selection (Prohibiting Data Written to the

EEPROM of the Digital Operator) 3-18. . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-4 Parameter Copy or Verify Errors 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4. Test Run 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Procedure for Test Run 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Operation Example 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5. Basic Operation 5-1. . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Initial Settings 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 Setting the Parameter Write-prohibit Selection/Parameter Initialization

(n001) 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Setting the Control Mode (n002) 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Operation in Vector Control 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Operation in V/f Control 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-1 Setting the Rated Motor Current (n036) 5-7. . . . . . . . . . . . . . . . . . . . . .

5-3-2 Setting the V/f Patterns (n011 to n017) 5-7. . . . . . . . . . . . . . . . . . . . . .

5-4 Settingthe Local/Remote Mode 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Selectingthe Operation Command 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Table of Contents

xii

5-6 Settingthe Frequency Reference 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6-1 Selecting the Frequency Reference 5-12. . . . . . . . . . . . . . . . . . . . . . . . . .

5-6-2 Upper and Lower Frequency Reference Limits 5-13. . . . . . . . . . . . . . . .

5-6-3 Frequency Referencing by Analog Input 5-14. . . . . . . . . . . . . . . . . . . . .

5-6-4 Setting Frequency References through Key Sequences 5-19. . . . . . . . . .

5-6-5 Setting Frequency References by Pulse Train Input 5-25. . . . . . . . . . . . .

5-7 Settingthe Acceleration/Deceleration Time 5-27. . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Selectingthe Reverse Rotation-prohibit 5-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9 Selectingthe Stopping Mode 5-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10 Multi-function I/O 5-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10-1 Multi-function Input 5-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10-2 Multi-function digital Output 5-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-11 Multi-function Analog Output and Pulse Monitor Output 5-41. . . . . . . . . . . . . . .

5-11-1 Setting the Multi-function Analog Output (n065 through n067) 5-41. . .

5-11-2 Setting the Pulse Monitor Output (n065 and n150) 5-42. . . . . . . . . . . . .

Chapter 6. Advanced Operation 6-1. . . . . . . . . . . . . . . . . . . . .

6-1 Precise Vector Control Settings and Adjustments 6-2. . . . . . . . . . . . . . . . . . . . .

6-1-1 Precise Vector Control Settings 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-2 Adjusting Output Torque in Vector Control 6-3. . . . . . . . . . . . . . . . . . .

6-2 Energy-saving Control 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1 Energy-saving Control Operation 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2 Performing Energy-saving Settings 6-7. . . . . . . . . . . . . . . . . . . . . . . . .

6-3 PID Control 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-1 PID Control Applications 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-2 PID Control Operation 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3 Types of PID Control 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-4 Block Diagram of PID Control 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-5 Input Selection of PID Control Target Value and Detection Value 6-17.

6-3-6 PID Control Settings 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-7 PID Adjustments 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-8 PID Fine Tuning 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Settingthe Carrier Frequency 6-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 DC Injection Braking Function 6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 StallPrevention Function 6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Overtorque Detection Function 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8 Torque Compensation Function 6-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9 SlipCompensation Function 6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10 Other Functions 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10-1 Digital Operator Disconnection Error Detection 6-41. . . . . . . . . . . . . . .

6-10-2 Motor Protection Functions (n037 and n038) 6-41. . . . . . . . . . . . . . . . . .

6-10-3 Cooling Fan Operation Function (n039) 6-42. . . . . . . . . . . . . . . . . . . . .

6-10-4 Momentary Power Interruption Compensation (n081) 6-42. . . . . . . . . .

6-10-5 Fault Retry (n082) 6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10-6 Frequency Jump Function (n083 to n086) 6-44. . . . . . . . . . . . . . . . . . . .

Page 13

Table of Contents

xiii

6-10-7 Accumulated Operating Time (n087, n088) 6-45. . . . . . . . . . . . . . . . . . .

6-10-8 Frequency Detection Function 6-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10-9 UP/DOWN Command Frequency Memory (n100) 6-48. . . . . . . . . . . . .

6-10-10 Input Open-phase Detection (n166, n167) 6-50.. . . . . . . . . . . . . . . . . . .

6-10-11 Output Open-phase Detection (n168, n169) 6-51.. . . . . . . . . . . . . . . . . .

6-10-12 Fault Log (n178) 6-52.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7. Communications 7-1. . . . . . . . . . . . . . . . . . . . . . . .

7-1 Inverter Settings 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-1 Setting the Communications Conditions 7-2. . . . . . . . . . . . . . . . . . . . .

7-1-2 RUN Command Selection (n003) 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1-3 Frequency Reference Input Selection (n004) 7-6. . . . . . . . . . . . . . . . . .

7-1-4 Setting the Multi-function Inputs (n050 to n056) 7-7. . . . . . . . . . . . . . .

7-2 Message Communications Basic Formats 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 DSR Message and Response 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-1 Data Read (Function Code: 03 Hex) 7-12. . . . . . . . . . . . . . . . . . . . . . . .

7-3-2 Data Write/Broadcast Data Write (Function Code: 10 Hex) 7-15. . . . . .

7-3-3 Loop-back Test (Function Code: 08 Hex) 7-17. . . . . . . . . . . . . . . . . . . .

7-4 Enter Command 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 Settingthe Communications Data 7-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 Register Number Allocations in Detail 7-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6-1 I/O Function 7-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6-2 Monitor Functions 7-25.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 Communications Error Codes 7-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8 Self-diagnostic Test 7-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9 Communications with Programmable Controller 7-33. . . . . . . . . . . . . . . . . . . . . .

7-9-1 Available Programmable Controller and Peripheral Device 7-33. . . . . .

7-9-2 Wiring the Communications Line 7-36. . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9-3 Outline of Protocol Macro Function 7-37. . . . . . . . . . . . . . . . . . . . . . . . .

7-9-4 Creating a Project File 7-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9-5 Ladder Program 7-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9-6 Communications Response Time 7-57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8. Maintenance Operations 8-1. . . . . . . . . . . . . . . . . .

8-1 Protective and Diagnostic Functions 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1-1 Fault Detection (Fatal Error) 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1-2 Warning Detection (Nonfatal Error) 8-11. . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Troubleshooting 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-1 Parameters Fail Set 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-2 Motor Fails to Operate 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-3 Motor Rotates in the Wrong Direction 8-21. . . . . . . . . . . . . . . . . . . . . . .

8-2-4 Motor Outputs No Torque or Acceleration is Slow 8-21. . . . . . . . . . . . .

8-2-5 Speed Accuracy of the Inverter Rotating at High Speed in Vector

Control is Low 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-6 Motor Deceleration Rate is Low 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 14

Table of Contents

xiv

8-2-7 Vertical-axis Load Drops when Brakes are Applied 8-22. . . . . . . . . . . . .

8-2-8 Motor Burns 8-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-9 Controller or AM Radio Receives Noise when Inverter is Started 8-24.

8-2-10 Ground Fault Interrupter is Actuated when Inverter is Started 8-24. . . .

8-2-11 Mechanical Vibration 8-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2-12 Stable PID Control is Not Possible or Control Fails 8-26. . . . . . . . . . . .

8-2-13 Inverter Vibrates in Energy-saving Control 8-26. . . . . . . . . . . . . . . . . . .

8-2-14 Motor Rotates after Output of Inverter is Turned OFF 8-27. . . . . . . . . .

8-2-15 Detects 0 V and Stalls when Motor Starts 8-27. . . . . . . . . . . . . . . . . . . .

8-2-16 Output Frequency Does Not Reach Frequency Reference 8-27. . . . . . . .

8-2-17 Inverter Does Not Run Because EF (Simultaneous Inputs of Forward and

Reverse Commands) is Detected, Or Motor Rotates Momentarily When

Control Device Power is Turned OFF 8-27. . . . . . . . . . . . . . . . . . . . . . .

8-3 Maintenance and Inspection 8-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9. Specifications 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1 Inverter Specifications 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 OptionSpecifications 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-1 EMC-compatible Noise Filter 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-2 DIN Track Mounting Bracket 9-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-3 DC Reactor 9-19.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-4 AC Reactor 9-20.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-5 Output Noise Filter 9-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2-6 CompoBus/D Communications Unit 9-24. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10. List of Parameters 10-1. . . . . . . . . . . . . . . . . . . . . .

Chapter 11. Using the Inverter for a Motor 11-1. . . . . . . . . . . .

Page 15

Chapter 1

Overview

1-1 Function

1-2 Nomenclature

1-3 New Features

1

Page 16

1-2

1-1 Function

The high-function compact SYSDRIVE 3G3MV-SeriesInverter is the first

compact Inverter to feature open-loop vector control.

The 3G3MV Inverter meets EC Directives and UL/cUL standard requirements for worldwide use.

Furthermore, the 3G3MV-SeriesInverter incorporates a variety of convenientcontrol,network,andI/Ofunctionsthatareversatile andeasy-to-use.

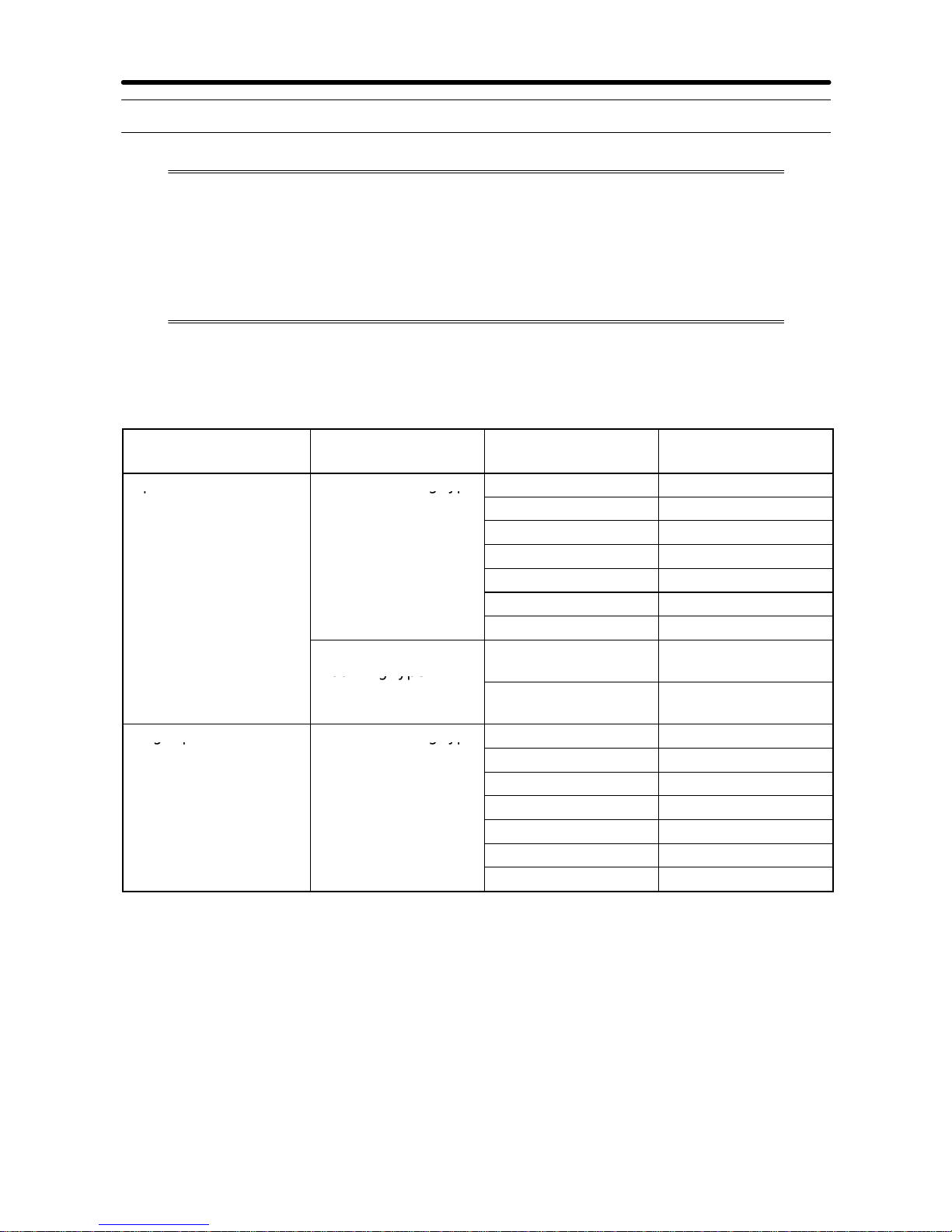

H SYSDRIVE 3G3MV Inverter Models

·The following 200-V-class (three- and single-phase 200-VAC types) and 400-V-class

(three-phase 400-VAC type) 3G3MV models are available.

Rated voltage Protective

structure

Maximum applied

motor capacity

Model

3-phase 200 VAC Panel mounting type

0.1 (0.1) kW 3G3MV-A2001

3-phase200VACPanelmountingtyp

e

(conform to IP20)

0.2 (0.25) kW 3G3MV-A2002

0.4 (0.55) kW 3G3MV-A2004

0.75 (1.1) kW 3G3MV-A2007

1.5 (1.5) kW 3G3MV-A2015

2.2 (2.2) kW 3G3MV-A2022

4.0 (4.0) kW 3G3MV-A2040

Closed wall

mounting type

5.5 (5.5) kW 3G3MV--A2055

mountingtyp

e

(conform to NEMA1

and IP20)

7.5 (7.5) kW 3G3MV--A2075

Single-phase 200 VAC Panel mounting type

0.1 (0.1) kW 3G3MV-AB001

Single-phase200VACPanelmountingtype

(conforming to IP20)

0.2 (0.25) kW 3G3MV-AB002

0.4 (0.55) kW 3G3MV-AB004

0.75 (1.1) kW 3G3MV-AB007

1.5 (1.5) kW 3G3MV-AB015

2.2 (2.2) kW 3G3MV-AB022

4.0 (4.0) kW 3G3MV-AB040

Overview Chapter 1

Page 17

1-3

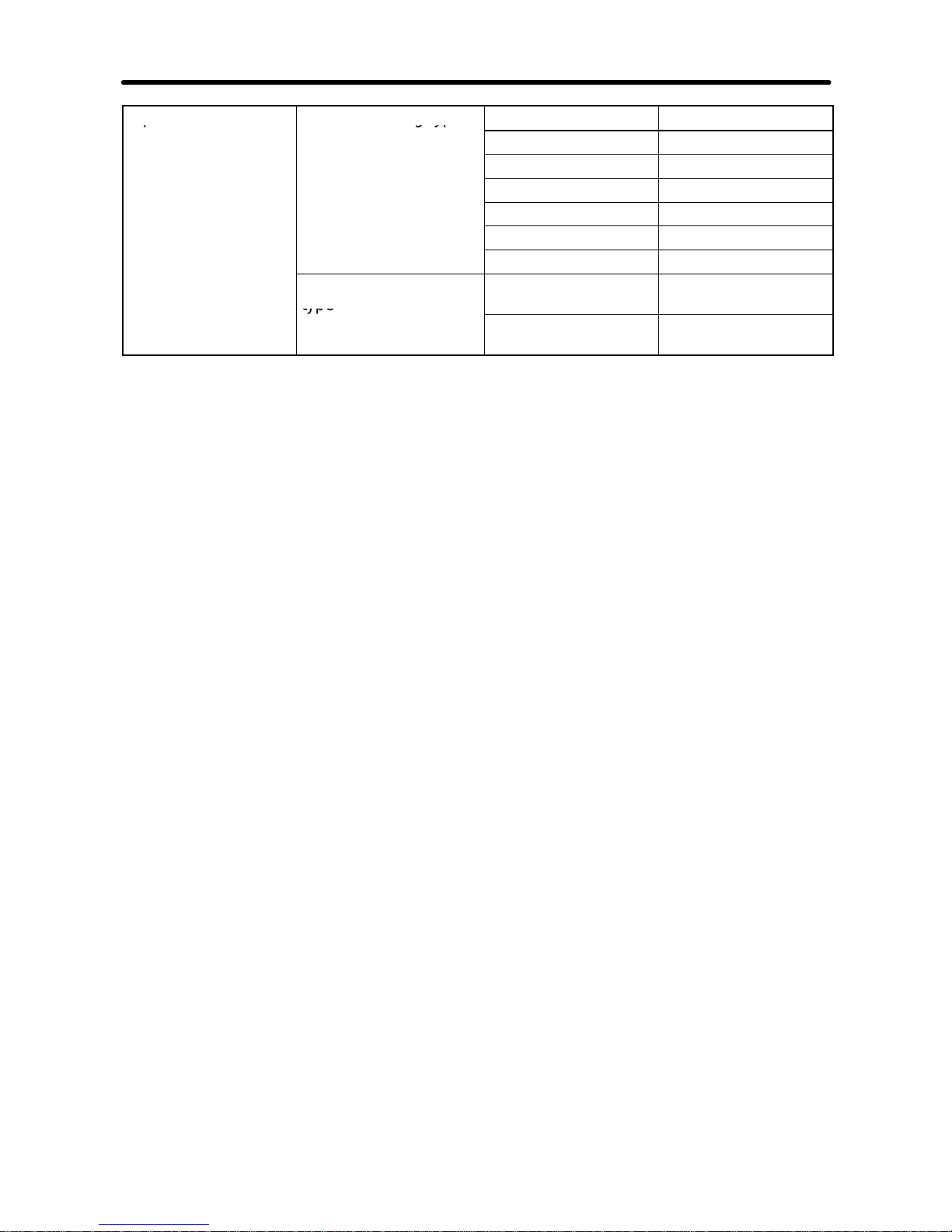

3-phase 400 VAC Panel mounting type

0.2 (0.37) kW 3G3MV-A4002

3-phase400VACPanelmountingtyp

e

(conform to IP20)

0.4 (0.55) kW 3G3MV-A4004

0.75 (1.1) kW 3G3MV-A4007

1.5 (1.5) kW 3G3MV-A4015

2.2 (2.2) kW 3G3MV-A4022

3.0 (3.0) kW 3G3MV-A4030

4.0 (4.0) kW 3G3MV-A4040

Closed wall mounting

typ

e

5.5 (5.5) kW 3G3MV--A4055

typ

e

(conform to NEMA1

and IP20)

7.5 (7.5) kW 3G3MV--A4075

Note The figures in parentheses indicate capacities for motors used outside Japan.

H Powerful Torque Ideal for a Variety of Applications

The 3G3MV is OMRON’sfirstcompact Inverter incorporating an open-loop vector controlfunction, which ensures a torque outputthatis 150% of the rated motortorque at an

output frequency of 1 Hz.

Ensures a more powerful revolution at low frequencies than any conventional inverter.

Furthermore, the 3G3MV Inverter suppresses the revolution fluctuation caused by the

load.

Incorporates a fully automatic torque boost function that drives the motor powerfully in

V/f control.

Incorporates a high-speed current limit function, thus suppressing overcurrent caused

by high torque and ensuring smooth operation of the motor.

H Convenient Easy-to-use Functions

·The FREQUENCY adjuster of the Digital Operator allows easy operation. The default

setting is for operation according to the FREQUENCY adjuster setting.

·The Digital Operator has a parameter copy function ensuring easy parameter control.

·Ease of maintenance is ensured. The cooling fan is easily replaceable. The life of the

coolingfancanbeprolongedbyturningONthe cooling fan only when the Inverter is in

operation.

·Incorporates a braking transistor. Therefore, the Inverter will provide powerful control

by just connecting a braking resistor.

·Incorporatesaninrush currentpreventivecircuitthatpreventscontactweldattheinput

power supply block.

Overview Chapter 1

Page 18

1-4

H International Standards (EC Directives and UL/cUL

Standards)

The 3G3MV Inverter meets the EC Directives and UL/cUL standard requirements for

worldwide use.

Classification Applicable standard

EC Directives

EMC directive EN50081-2 and EN50082-2

ECDirective

s

Low-voltage directive prEN50178

UL/cUL UL508C

H Compatible with CompoBus/D and RS-422/485

·Supports RS-422 andRS-485 communications conforming tothe MODBUS Communications Protocol, thus making itpossible to easily constructnetworks with the use of

the Protocol Macro or ASCII Unit mounted on an OMRON SYSMAC PC. The MODBUS Communications Protocol is a trademark of AEG Schneider Automation.

·Connects to the 3G3MV-PDRT1-SINVCompoBus/D Communications Unit. A remote

I/O function for CompoBus/D communications is available to the 3G3MV Inverter,

which ensures ease of communications just like standard I/O communications.

Furthermore, CompoBus/D communications conform to the DeviceNet communications protocol for open networks, thus allowing construction of multi-vendor networks

in which other companies’ devices can coexist.

Note Modbuscommunication and CompoBus/D communication cannot beperformed

simultaneously. It is necessary to select the type of communication required.

H Handles a Variety of I/O Signals

Handles a variety of I/O signals over a wide application range as described below.

·Analog voltage input: 0 to 10 V

·Analog current input: 4 to 20 or 0 to 20 mA

·Pulse train input: 0.1 to 33.0 kHz

·Multi-function analog output or pulse train output is selectable as monitor output

H Suppression of Harmonics

Connects to DC reactors, thus suppressing harmonics more effectively than conventional AC reactors.

Furtherimprovement inthesuppressionofharmonicsispossiblewith thecombineduse

of the DC and AC reactors.

Overview Chapter 1

Page 19

1-5

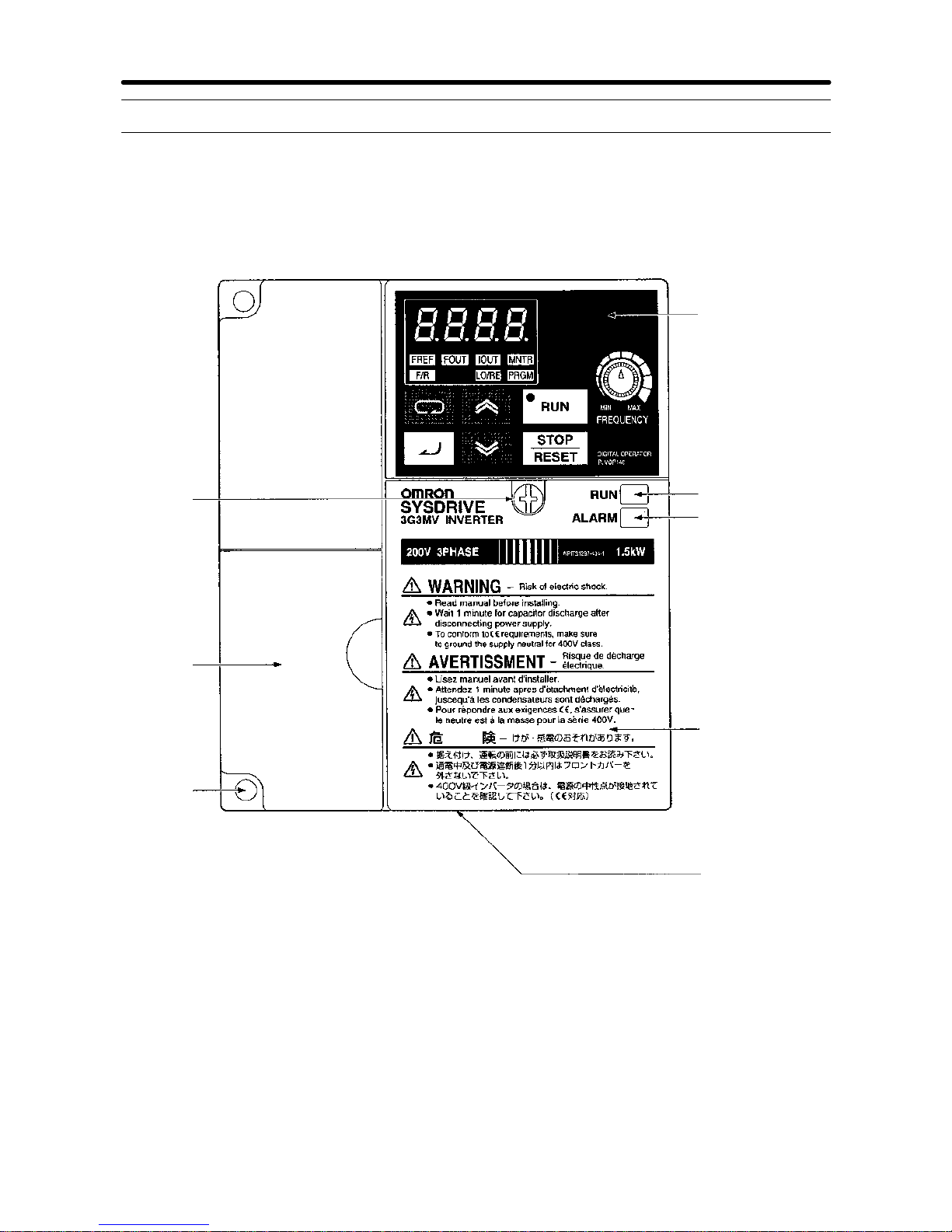

1-2 Nomenclature

H Panel

Front panel

mounting

screw

Digital Operator

ALARM display

RUN indicator

Front cover

Bottom cover

Terminal

cover

Four

mounting

holes

Note None of the following 200-V models have a terminal cover or mounting holes.

Instead,thefrontcover is used asaterminalcoverandtwo U-shaped cutouts are

provided in place of the mounting holes.

3G3MV-A2001 (0.1 kW), 3G3MV-A2002 (0.2 kW), 3G3MV-A2004(0.4 kW), and

3G3MV-A2007 (0.75 kW)

3G3MV-AB001 (0.1 kW), 3G3MV-AB002(0.2 kW),and 3G3MV-AB004(0.4 kW)

Overview Chapter 1

Page 20

1-6

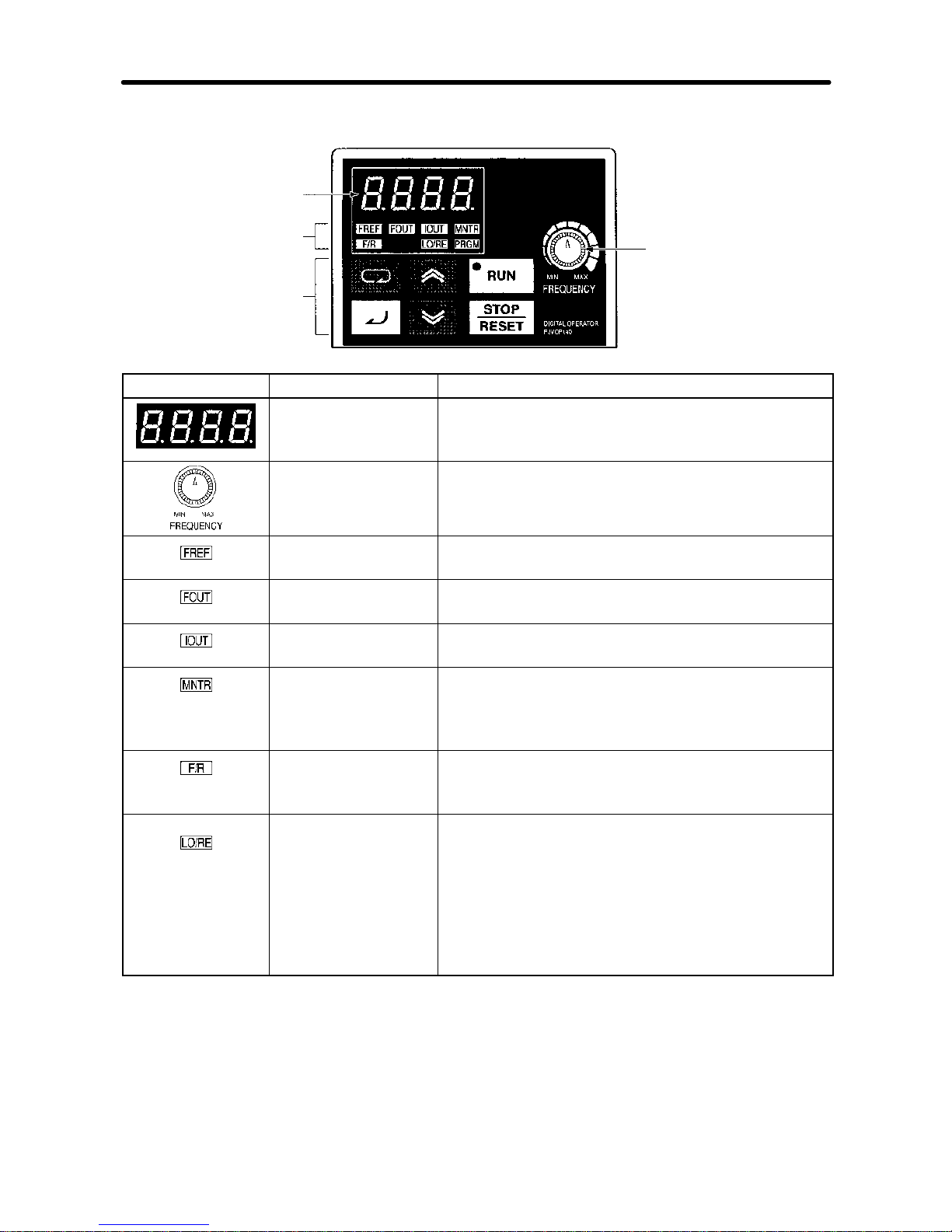

H Digital Operator

Data display

FREQUENCY

adjuster

Simplified-LED

indicators

Operation keys

Appearanc

e

Name Function

Data display Displays relevant data items, such as frequency

reference, output frequency, and parameter set

values.

FREQUENCY

adjuster

Sets the frequency reference within a range

between 0 Hz and the maximum output

frequency.

FREF indicator The frequency reference can be monitored or set

while this indicator is lit.

FOUT indicator The output frequency of the Inverter can be

monitored while this indicator is lit.

IOUT indicator The output current of the Inverter can be

monitored while this indicator is lit.

MNTR indicator The values set in U01 through U18 are

monitored while this indicator is lit. Depending on

the inverter capacity, the quantity of the Uxx will

be different.

F/R indicator The direction of rotation can be selected while

this indicator is lit when operating the Inverter

with the RUN Key.

LO/RE indicator The operation of the Inverter through the Digital

Operator or according to the set parameters is

selectable while this indicator is lit.

Note This status of this indicator can be only

monitored while the Inverter is in operation.

Any RUN command input is ignored while

this indicator is lit.

Overview Chapter 1

Page 21

1-7

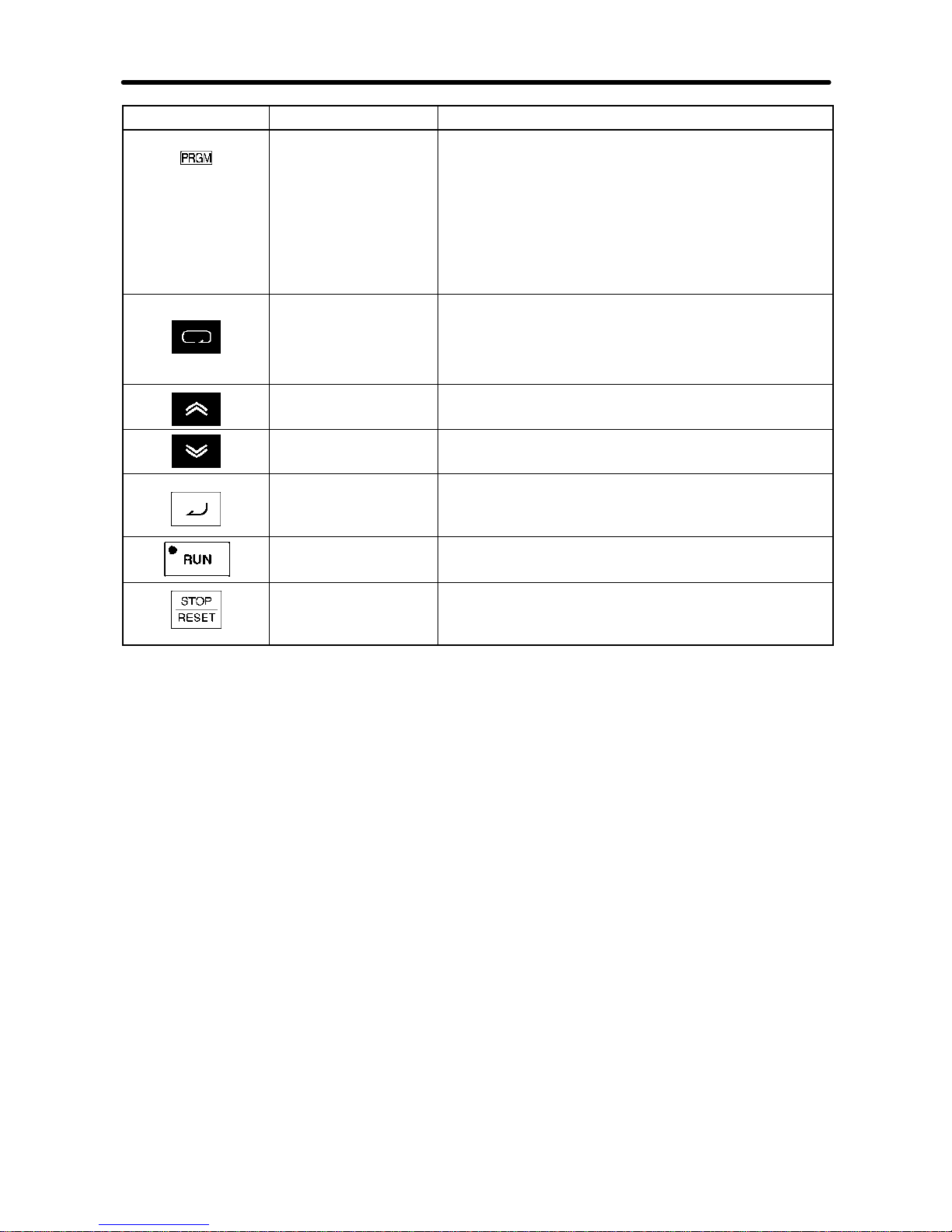

Appearance FunctionName

PRGM indicator The parameters in n001 through n179 can be set

or monitored while this indicator is lit.

Note While the Inverter is in operation, the

parameterscanbeonly monitored and only

some parameters can be changed. Any

RUN command input is ignored while this

indicator is lit. Unless n001 is 5.

Mode Key Switches the simplified-LED (setting and

monitor) item indicators in sequence.

Parameter being set will be canceled if this key is

pressed before entering the setting.

Increment Key Increases multi-function monitor numbers,

parameter numbers, and parameter set values.

Decrement Key Decreases multi-function monitor numbers,

parameter numbers, and parameter set values.

Enter Key Enters multi-function monitor numbers,

parameter numbers, and internal data values

after they are set or changed.

RUN Key Starts the Inverter running when the 3G3MV is in

operation with the Digital Operator.

STOP/RESET Key Stops the Inverter unless parameter n007 is set

to disable the STOP Key. Functions as a Reset

Key when an inverter error occurs (see note).

Note Forsafety reasons,the resetwill notwork whilea RUNcommand (forwardor reverse)isineffect.

Wait until the RUN command is OFF before resetting the Inverter.

Overview Chapter 1

Page 22

1-8

1-3 New Features

New features have been added to 3G3MV-Series models with 5.5-kW and 7.5-kW capacities (i.e., the 3G3MV-A2055/A2075/ A4055/A4075). These features are outlined

below and explained in detail in Chapter 6.

H New Features for 3G3MV-A2055/A2075/ A4055/A4075 only

D Enclosure Rating: Closed Wall-mounting Conforming to IP20/NEMA1

The 5.5-kW and 7.5-kW Inverters have closed wall-mounting specifications that conform to

IP20/NEMA1, so they can operate in an ambient temperature range of --10 to 40°C.

Note Tooperate thisInverterwithin anambienttemperature range of --10to50°C, removethetop and

bottom covers to convert it to a panel-mounting model (IP00).

D Default Settings Changed for V/f Patterns (Parameters: n011 to n017)

For 5.5-kW and 7.5-kW Inverters, two of the default settings have been changed. The default settings

forthemiddle output frequencyvoltage(VC) (n015)andthe minimum outputfrequency voltage (VMIN

(n017) have both been changed to 10 V for 200-V-class models and to 20 V for 400-V-class models.

D Inverter Overheating Warning Input

(Parameters: n050 to n056; Fault Display: oH3)

AnInverter overheating warninginputhas beenaddedas a newfunction that canbe set formulti-function inputs1to 7 (n050 to n056). When thiswarningis input, an oH3 fault (nonfatal error, please check

page 8-11)willbe displayed. This input canbeused for functions such asthermal contact connections

for peripheral overheating detection.

D Frequency Reference Loss Detection (Parameter: n064)

Whenthefrequencyisreferencedusinganalogfrequency referenceinputs(0to 10V/4to20mA/0 to20

mA), this function detects sudden changes in analog inputs as errors (disconnection, short circuit,

breakdown,etc.)and outputs thefrequencyreference loss outputthatis set inmulti-functionoutputs 1

to3(n057ton059).After thechangeisdetected,operationcontinues at80%ofthefrequency reference

prior to the change.

D Accumulated Operating Time (Monitor: U-13; Parameters: n087, n088)

Thisfunction calculatesand storesin memorythe Inverter’saccumulated power-ONtime orRUN time.

Use it for checking and determining the maintenance schedule.

D Speed Search Adjustment (Parameters: n101, n102)

Afunctionhasbeenadded foradjustingthe speedsearch.(The speedsearchis afunctionfor detecting

and smoothly controlling the speed of a free running motor.) The speed search operating time and

search level can be adjusted.

D Input Open-phase Detection

(Parameters: n166, n167; Fault Display: PF)

Thisfunction detectsthe Inverter’sinput powersupply openphase. Openphases aredetected through

main circuit voltage fluctuations, so this function can alsobeusedfor detecting abnormal voltage fluctuations in the input power supply voltage.

Overview Chapter 1

Page 23

1-9

D Output Open-phase Detection

(Parameters: n168, n169; Fault Display: LF)

This function detects open phases between the Inverter output and the motor.

D Ground Fault Detection (Fault Display: GF)

This function detects ground faults between the Inverter output and the motor.

D Load Short-circuit Detection (Fault Display: SC)

Prior to an Inverter output, thisfunctiondetectswhether the output is short-circuited. If short-circuiting

occurs during an output, it detects an overcurrent (oC).

Overview Chapter 1

Page 24

Chapter 2

Design

2-1 Installation

2-2 Wiring

2

Page 25

2-2

2-1 Installation

2-1-1 Dimensions

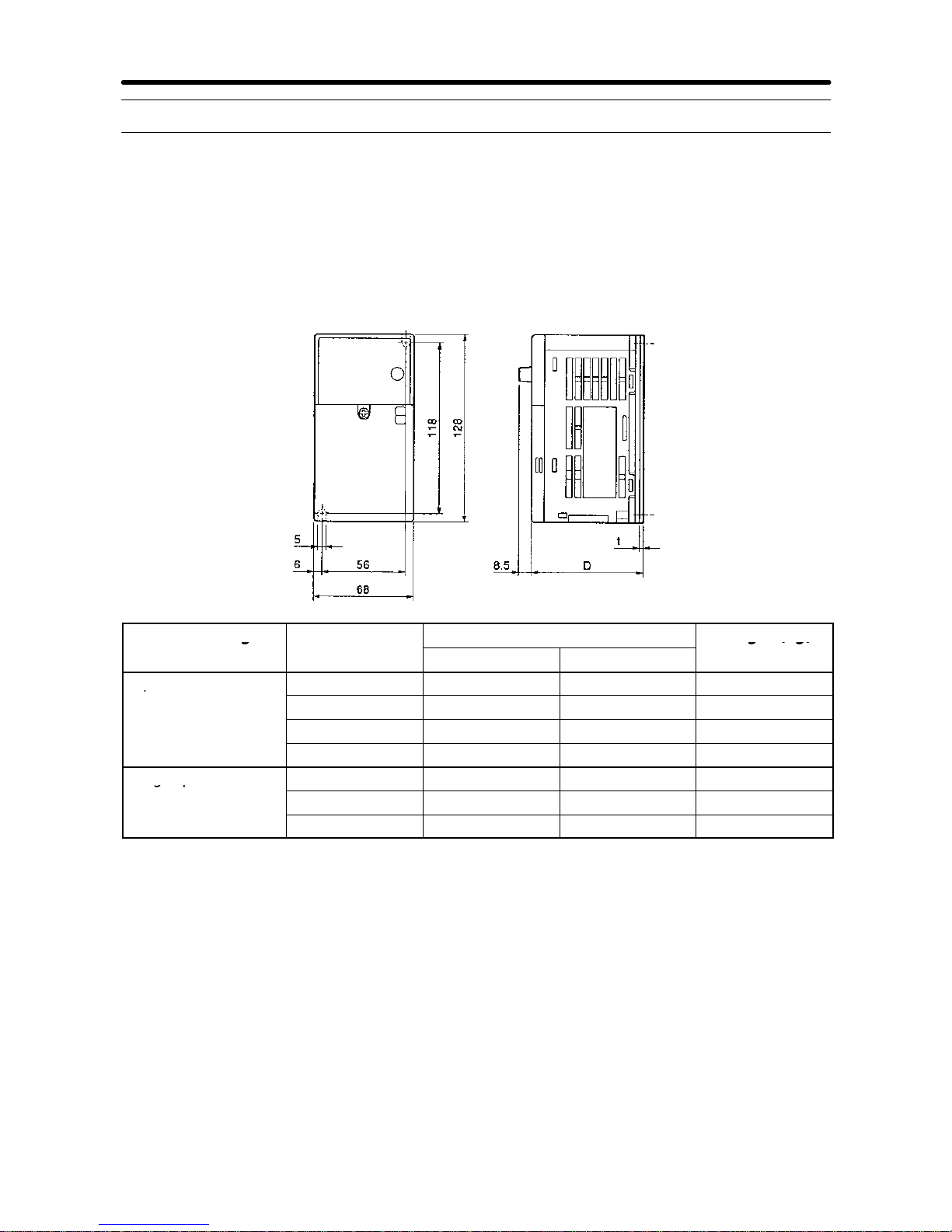

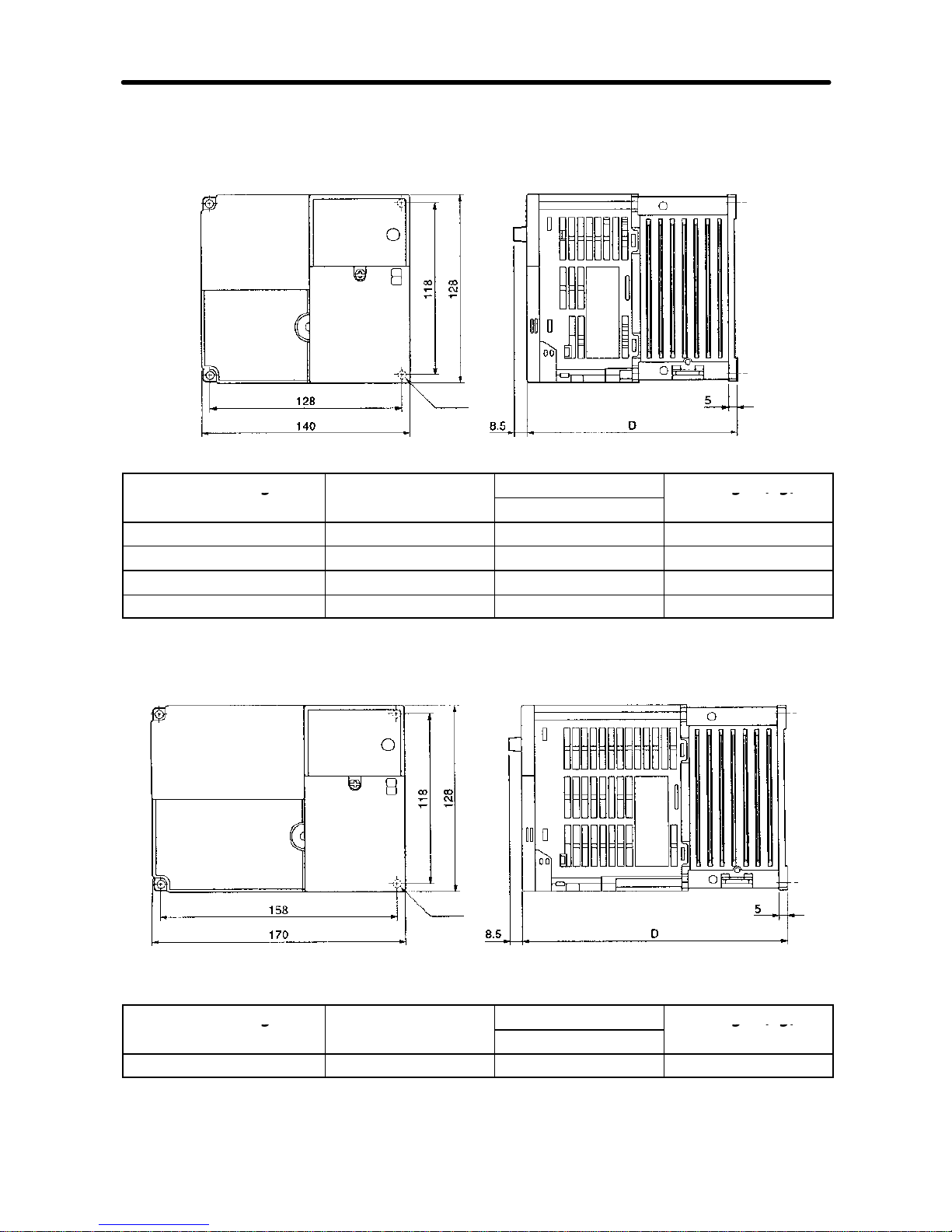

D 3G3MV-A2001 to 3G3MV-A2007 (0.1 to 0.75 kW) 3-phase 200-VAC Input

3G3MV-AB001 to 3G3MV-AB004 (0.1 to 0.4 kW) Single-phase 200-VAC

Input

Rated voltage Model 3G3MV-

Dimensions (mm)

Weight (kg)

RatedvoltageModel3G3MV-

D t

Weight(kg

)

3-phase 200 VAC

A2001 76 3 Approx. 0.6

3-phase200VAC

A2002 76 3 Approx. 0.6

A2004 108 5 Approx. 0.9

A2007 128 5 Approx. 1.1

Single-phase

AB001 76 3 Approx. 0.6

Single-phas

e

200 VAC

AB002 76 3 Approx. 0.7

AB004 131 5 Approx. 1.0

Design Chapter 2

Page 26

2-3

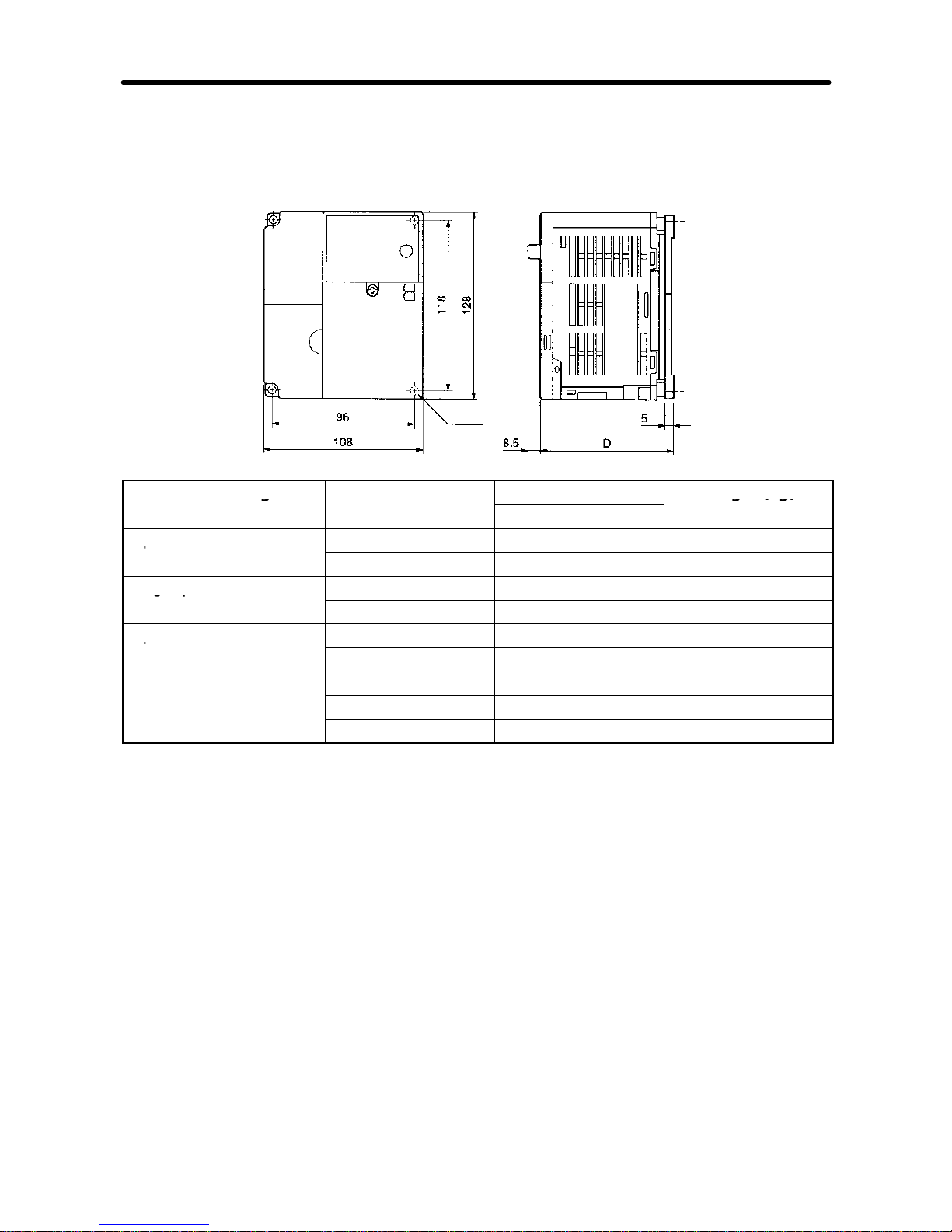

D 3G3MV-A2015 to 3G3MV-A2022 (1.5 to 2.2 kW) 3-phase 200-VAC Input

3G3MV-AB007 to 3G3MV-AB015 (0.75 to 1.5 kW) Single-phase 200-VAC

Input

3G3MV-A4002 to 3G3MV-A4022 (0.2 to 2.2 kW) 3-phase 400-VAC Input

Four, 5 dia.

Rated voltage Model 3G3MV-

Dimensions (mm)

Weight (kg)

RatedvoltageModel3G3MV-DWeight(kg

)

3-phase 200 VAC

A2015 131 Approx. 1.4

3-phase200VAC

A2022 140 Approx. 1.5

Single-phase 200 VAC

AB007 140 Approx. 1.5

Single-phase200VA

C

AB015 156 Approx. 1.5

3-phase 400 VAC

A4002 92 Approx. 1.0

3-phase400VAC

A4004 110 Approx. 1.1

A4007 140 Approx. 1.5

A4015 156 Approx. 1.5

A4022 156 Approx. 1.5

Design Chapter 2

Page 27

2-4

D 3G3MV-A2040 (4.0 kW) 3-phase 200-VAC Input

3G3MV-AB022 (2.2 kW) Single-phase 200-VAC Input

3G3MV--A4030 to 3G3MV-A4040 (3.0 to 4.0 kW) 3-phase 400-VAC Input

Four, 5 dia.

Rated voltage Model 3G3MV-

Dimensions (mm)

Weight (kg)

RatedvoltageModel3G3MV-DWeight(kg

)

3-phase 200 VAC A2040 143 Approx. 2.1

Single-phase 200 VAC AB022 163 Approx. 2.2

3-phase 400 VAC A4030 143 Approx. 2.1

3-phase 400 VAC A4040 143 Approx. 2.1

D 3G3MV-AB040 (4.0 kW) Single-phase 200-VAC Input

Rated voltage Model 3G3MV-

Dimensions (mm)

Weight (kg)

RatedvoltageModel3G3MV-DWeight(kg

)

Single-phase 200 VAC AB040 180 Approx. 2.9

Design Chapter 2

Page 28

2-5

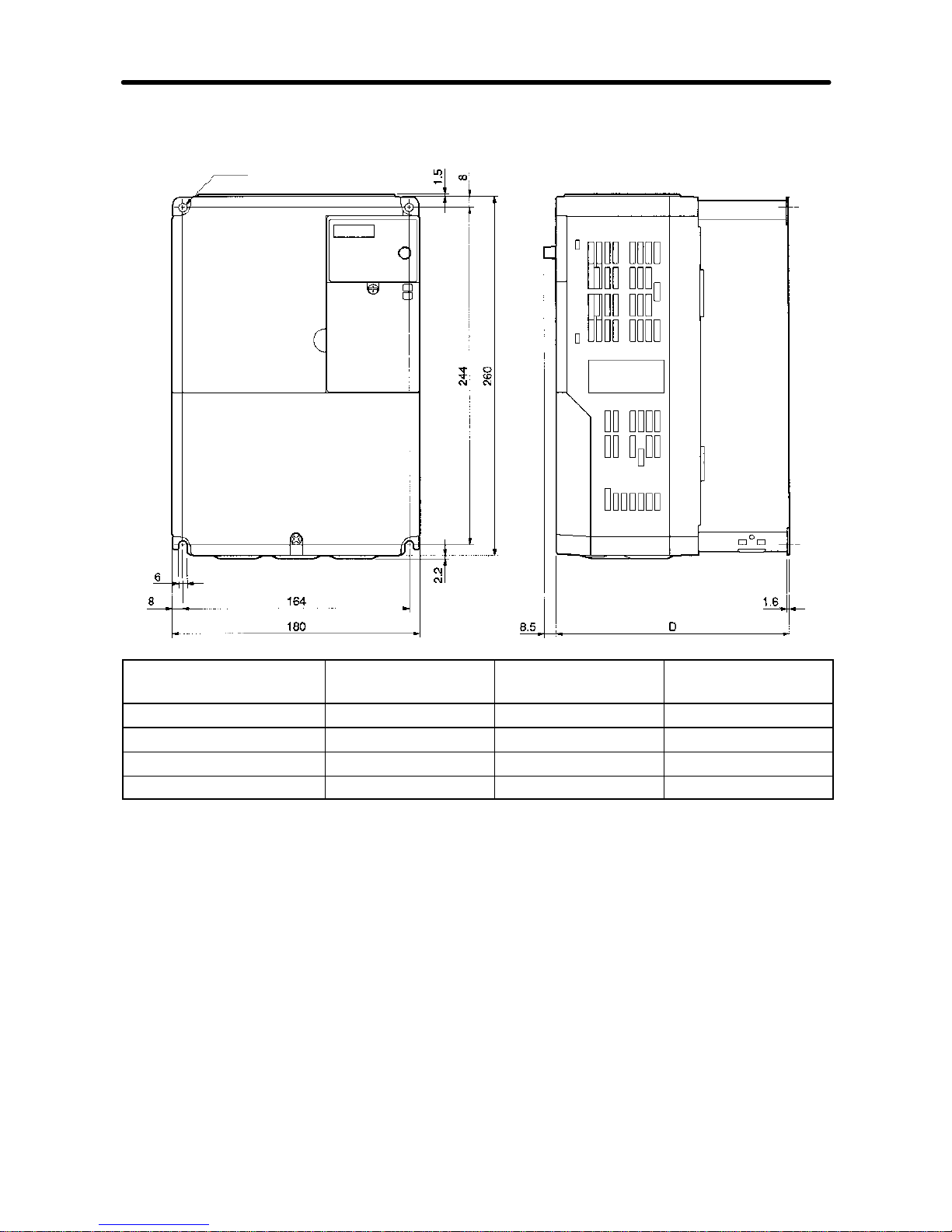

D 3G3MV-A2055 to 3G3MV--A2075 (5.5 to 7.5kW) 3-phase 200-VAC Input

3G3MV-A4055 to 3G3MV--A4075 (5.5 to 7.5kW) 3-phase 400-VAC Input

Two, 6 dia.

Rated voltage Model 3G3MV- Dimensions D

(mm)

Weight (kg)

3-phase 200 VAC A2055 170 Approx. 4.6

3-phase 200 VAC A2075 170 Approx. 4.8

3--phase 400 VAC A4055 170 Approx. 4.8

3--phase 400 VAC A4075 170 Approx. 4.8

Design Chapter 2

Page 29

!

!

!

!

!

2-6

2-1-2 Installation Conditions

W ARNING Providean appropriatestoppingdeviceonthemachineside tosecuresafety.

(A holding brake is not a stopping device for securing safety.) Not doing so

may result in injury.

W ARNING Providean externalemergencystoppingdevicethatallowsaninstantaneous

stop of operation and power interruption. Not doing so may result in injury.

Caution Be sure to install the product in the correct direction and provide specified

clearancesbetweentheInverter and control panel orwithotherdevices.Not

doing so may result in fire or malfunction. See explanation below.

Caution Donotallowforeignobjectstoenterinsidetheproduct.Doingsomayresultin

fire or malfunction.

Caution Donotapplyanystrongimpact.Doingsomayresultin damagetotheproduct

or malfunction.

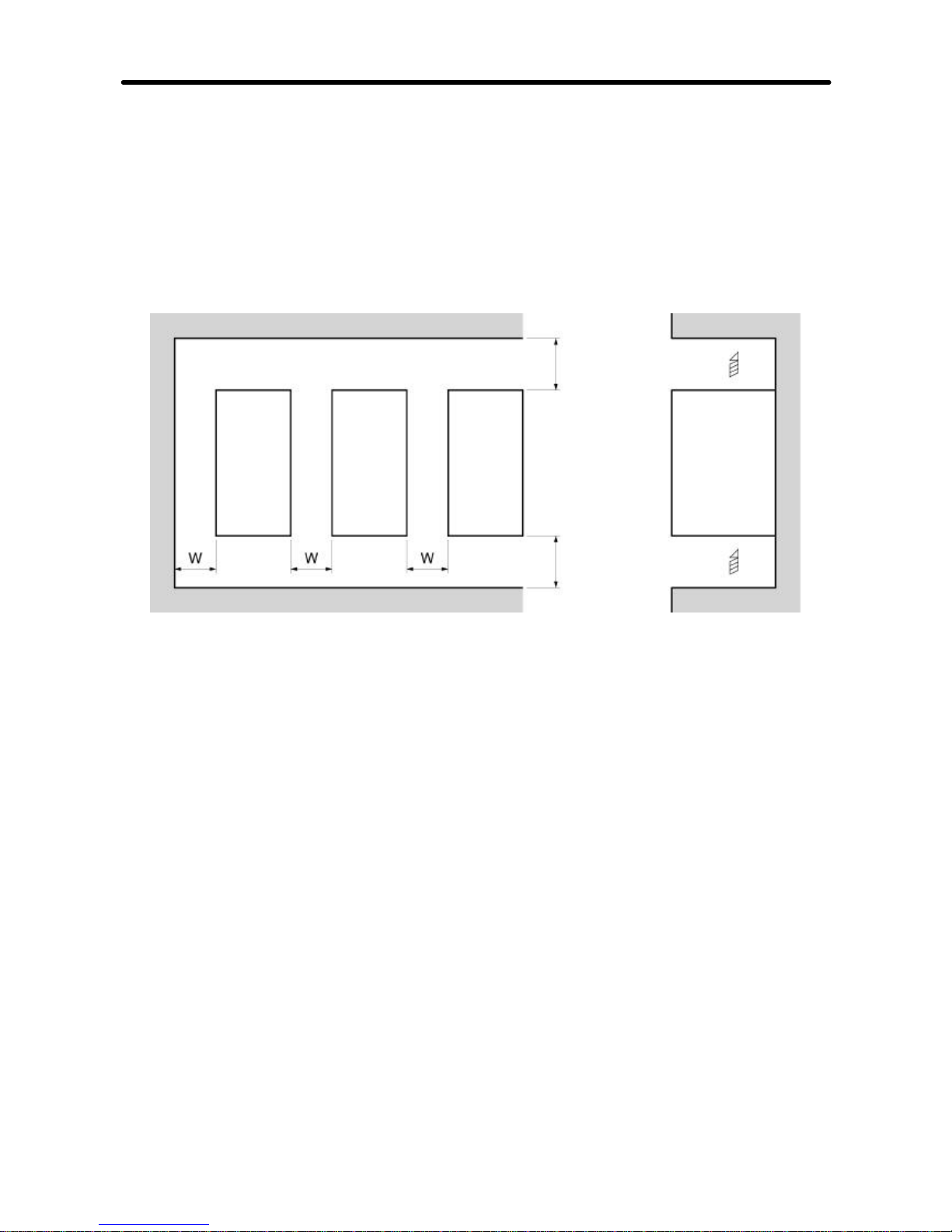

H Installation Direction and Dimensions

·Install the Inverter under the following conditions.

Ambient operating temperature:

Panel-mounting models (conforming to IP20): --10 to 50°C (0.1- to 4.0-kW Inverters)

Closed wall-mounting models (conforming to NEMA1 and IP20):

--10 to 40°C (5.5- to 7.5-kW Inverters)

Humidity: 95% max. (with no condensation)

Note 1. By removing the top and bottom covers froma 5.5- to 7.5-kW Inverter,it can be used

as a panel-mounting model (conforming to IP00) within an ambient temperature

range of --10 to 50°C.

· Install the Inverter in a clean location free from oil mist and dust. Alternatively, install it in a

totally enclosed panel that is completely protected from floating dust.

· Wheninstalling or operating the Inverter ,always take special care so that metal powder,oil,

water , or other foreign matter does not get into the Inverter.

· Do not install the Inverter on inflammable material such as wood.

· Ifa5.5kWor7.5kW Inverter istobeinstalled insideofacontrolpanel,itmusthavethetopand

bottom covers removed and be used as a panel-mounting model (conforming to IP00).

Design Chapter 2

Page 30

2-7

H Direction

·Install the Inverter on a vertical surface so that the characters on the nameplate are

oriented upward.

H Dimensions

·When installing the Inverter, always provide the following clearances to allow normal

heat dissipation from the Inverter.

W = 30 mm min.

Inverter

100 mm min. Air

SideInverter Inverter

100 mm min. Air

H Ambient Temperature Control

·Toenhance operation reliability,theInvertershouldbe installed inanenvironmentfree

from extreme temperature changes.

·If the Inverter is installed in an enclosed environment such as a box, use a cooling fan

or air conditioner to maintain the internal air temperature below 50°C.

Thelifeofthebuilt-inelectrolyticcapacitorsoftheInverterisprolonged by maintaining

the internal air temperature as low as possible.

·The surface temperature of the Inverter may rise approximately 30°C higher than the

ambient temperature. Be sure tokeep away equipment andwires from the Inverter as

far as possible if the equipment and wires are easily influenced by heat.

H Protecting Inverter from Foreign Matter during Installation

·Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Uponcompletion ofinstallation,alwaysremovethecoverfromtheInverter.Otherwise,

ventilation will be affected, causing the Inverter to overheat.

Design Chapter 2

Page 31

2-8

2-1-3 Removing and Mounting the Covers

To mount the Inverter, it is necessary to remove the front cover, terminal

cover (unless the Inverter is a 200-V model), and the Digital Operator. To

wire the Inverter,it is necessary to remove the front cover, terminal cover

(unlesstheInverterisa200-Vmodel),andbottomcoverfromthe Inverter.

Follow the instructions below to remove the covers from the Inverter.

To mount the covers, take the opposite steps.

H Removing the Front Cover

·Loosen the front cover mounting screws with a screwdriver.

·Press the left and right sidesof the front coverin the arrow 1 directionsand lift the bot-

tom of the cover in the arrow 2 direction to remove the front cover as shown in the following illustration.

Design Chapter 2

Page 32

2-9

H Removing the Terminal Cover

D 0.2- to 3.7-kW Inverters

· Afterthe front cover is removed, press the left and right sides of the terminal cover in

thearrow1 directionsandliftthe terminal coverinthearrow 2 directionasshowninthe

following illustration.

D 5.5-/7.5-kW Inverters

· Loosen the terminal cover screws in the direction of arrows 1.

· Presstheleft andrightsidesoftheterminalcoverinthedirectionofarrows2andlift itin

the direction of arrow 3 as shown in the following illustration.

Note None of the following 200-V models have a terminal cover. Instead, the front

cover is used as a terminal cover.

3G3MV-A2001 (0.1 kW), 3G3MV-A2002 (0.2 kW), 3G3MV-A2004 (0.4 kW),

3G3MV-A2007 (0.75 kW), 3G3MV-AB001 (0.1 kW), 3G3MV-AB002 (0.2 kW),

and 3G3MV-AB004 (0.4 kW)

Design Chapter 2

Page 33

2-10

H Removing the Bottom Cover

·Afterremovingthefrontcoverandterminalcover,pressthebottomcoverinthearrow1

direction based on position A as a fulcrum.

A

A

H Removing the Digital Operator

·Afterremovingthefront cover,liftuptheupper andlowerright-handsides(positionsA)

of the Digital Operator in the arrow 1 direction as shown in the following illustration.

A

A

Design Chapter 2

Page 34

!

!

!

!

!

!

!

!

!

!

2-11

2-2 Wiring

W ARNING Wiring must be performed only after confirming that the power

supply has been turned OFF. Not doing so may result in electrical

shock.

W ARNING Wiring must be performed by authorized personnel. Not doing so

may result in electrical shock or fire.

W ARNING Be sure to confirm operation only after wiring the emergency stop

circuit. Not doing so may result in injury.

W ARNING Alwaysconnectthe groundterminalstoaground of100W orless for

the 200-VAC class, or 10 W or less for the 400-VAC class. Not

connecting to a proper ground may result in electrical shock.

Caution Install external breakers and take other safety measures against

short-circuiting in external wiring. Not doing so may result in fire.

Caution Confirmthatthe ratedinputvoltageofthe Inverteristhesameas the

AC power supply voltage. An incorrect power supply may result in

fire, injury, or malfunction.

Caution If you use a Braking Resistor or a Braking Resistor Unit, connect

them as specified in the manual. Not doing so may result in fire.

Caution Be sure to wire correctly and securely. Not doing so may result in

injury or damage to the product.

Caution Be sure to firmly tighten the screws on the terminal block. Not doing

so may result in fire, injury, or damage to the product.

Caution Do not connect an AC power to the U, V, or W output. Doing so may

result in damage to the product or malfunction.

Design Chapter 2

Page 35

2-12

2-2-1 Terminal Block

To wire the terminal block of the Inverter, remove the front cover, terminal

cover (unless the Inverter is a 200-V model), and bottom cover from the

Inverter.

There is a label under the front cover indicating the arrangement of main

circuitterminals.Be suretoremovethe labelafterwiringthe terminals.The

output terminal of the motor has a label as well. Remove the label before

wiring the motor terminal.

H Arrangement of Control Circuit Terminals

Control circuit terminals

H Arrangement of Main Circuit Terminals

D 3G3MV-A2001 through 3G3MV-A2007 (0.1 through 0.75 kW):

3-phase 200-VAC Input

3G3MV-AB001 through 3G3MV-AB004 (0.1 through 0.4 kW):

Single-phase 200-VAC Input

Power supply input Motor output

Braking resistor

Note For single-phase input, connect R/L1 and S/L2.

Design Chapter 2

Page 36

2-13

D 3G3MV-A2015 to 3G3MV-A2022 (1.5 to 2.2 kW): 3-phase 200-VAC Input

3G3MV-AB007 to 3G3MV-AB015 (0.75 to 1.5 kW):

Single-phase 200-VAC Input

3G3MV-A4002 to 3G3MV-A4022 (0.2 to 2.2 kW): 3-phase 400-VAC Input

Power supply input

Motor output

Braking

Resistor

Note For single-phase input, connect R/L1 and S/L2.

D 3G3MV-A2040 (4.0 kW) to --A2075 (4.0 to 7.5kW): 3-phase 200-VAC Input

3G3MV-AB022 to 3G3MV-AB040 (2.2 to 4.0 kW):

Single-phase 200-VAC Input

3G3MV--A4030 to 3G3MV-A4075 (3.0 to 7.5 kW): 3-phase 400-VAC Input

Power supply input

Motor output

Braking

Resistor

Note For single-phase input, connect R/L1 and S/L2.

Design Chapter 2

Page 37

2-14

H Main Circuit Terminals

Symbol Name Description

R/L1

Power supply input

3G3MV-A2j: 3-phase 200 to 230 VAC

S/L2

terminals3G3MV-ABj:Single-phase200to240VAC(seenot

e

1

)

T/L3

1

)

3G3MV-A4j: 3-phase 380 to 460 VAC

U/T1

Motor output

terminals

3-phase power supply output for driving motors. (see

note2

)

V/T2

terminalsnote2)

3G3MV-A2j and 3G3MV-ABj: 3-phase 200 to

W/T3

230VA

C

3G3MV-A4j: 3-phase 380 to 460 VAC

B1

Braking Resistor

Terminals for attaching an external Braking Resistor or

B2

connectionterminalsaBrakingResistorUnit.(Connecttodetectovervoltage

during braking.)

+1

Connection terminals

+1 and +2:

Connect the DC reactor for suppressing harmonics to

terminals +1 and +2.

+2

DCreactor

connection terminals

When driving the Inverter with DC power, input the DC

power to terminals +1 and --.

--

+1and--

:

DC power supply

input terminals

(Terminal+1isapositiveterminal.

)

Ground terminal Be sure to ground the terminal under the following

conditions.

3G3MV-A2j: Ground at a resistance of 100 W or less.

3G3MV-ABj: Ground at a resistance of 100 W or less.

3G3MV-A4j: Ground at a resistance of 10 W or less.

To conform to EC Directives, connect to the neutral

point of the power supply.

Note Be sure to connect the ground terminal directly

to the motor frame ground.

Note 1. Connect single-phase input to both the R/L1 terminal and the S/L2 terminal.

Note 2. The maximum voltage at theoutput side corresponds to the power supplyvolt-

age for Inverter input.

Design Chapter 2

Page 38

2-15

H Control Circuit Terminals

Symbol Name Specification

Input

S1 Multi-function input 1

(Forward/Stop)

Photocoupler

8 mA at 24 V DC (See notes 2 and 3.)

S2 Multi-function input 2

(Reverse/Stop)

8mAat24VDC(Seenotes2and3.

)

S3 Multi-function input 3

(External fault: Normally open)

S4 Multi-function input 4

(Fault reset)

S5 Multi-function input 5

(Multi-step speed reference 1)

S6 Multi-function input 6

(Multi-step speed reference 2)

S7

Multi-function input 7

(Inching frequency

command)

SC Sequence input com-

mon

FS Frequency reference

power supply output

20 mA at 12 V DC

FR Frequency reference

input

0 to 10 V DC (Input impedance: 20 kW)

FC Frequency reference

common

RP Pulse train input Response frequency: 0 to 33 kHz (30% to 70% ED)*

H: 3.5 to 13.2 V

L: 0.8 V max.

(Input impedance: 2.24 kW)

CN2

1 Multi-function analog

voltage input

Voltage input (between terminals 1 and 3):

0 to 10 V DC (Input impedance: 20 kW)

2 Multi-function analog

current input

0to10VDC(Inputimpedance:20kW)

Current input (between terminals 2 and 3):

4 to 20 mA (Input impedance: 250 W). This connector

3 Multi-function analog

input common

4to20mA(Inputimpedance:25

0W).Thisconnector

is located in the Unit Operator of the Inverter.

* ED = Operating Duty Cycle.

Design Chapter 2

Page 39

2-16

Symbol Name Specification

Output

MA Multi-function contact

output (Normally open:

During operation)

Relay output

1 A max. at 30 V DC

1 A max. at 250 V AC

MB Multi-function contact

output (Normally

closed:

During operation)

1Amax.at250VA

C

MC Multi-function contact

output common

P1 Multi-function photo-

coupler output 1

(Fault)

Open collector output 50 mA max.

at 48 V DC

P2 Multi-function photo-

coupler output 2

(Fault)

PC Multi-function photo-

coupler output common

AM Multi-function analog

output

· Analog output: 2 mA max. at 0 to 10 V DC

· Pulse train output (max. output voltage: 12 V DC)

(See note 4.)

When Used as Voltage Output

Load impedance

1.5 kW min.

10 kW min.

Output voltage (insulationtype)

+5 V

+10 V

Load

impedance

External

AC Multi-function analog

output common

When External Power Supply is Used

Note Do not use a 5-V DC or 24-V DC external power

supply.Doingsocancauseinternalcircuitdamage or malfunctioning.

Input current (mA)

from external power

supply

16 mA max.

External power supply (V)

12 V DC (±5%)

Externa

l

power

supply

12 V DC

Load

impedance

Input current

16 mA

max.

External power

supply ground

Com-

R+

Receiver side Conforming to RS-422/485

Com

-

mu-

R--

ReceiversideConformingtoRS-422/485nica

-

S+

Sender side

tion

s

S--

Sendersid

e

Design Chapter 2

Page 40

2-17

Note 1. Parametersettingscanbeused to select various functions for multi-function inputs 1

to 7, multi-function contact outputs, and multi-function photocoupler outputs. The

functions in parentheses are the default settings.

Note 2. NPN is the default setting for these terminals. Wire them by providing a common

ground. No external power supply is required.

Note 3. To provide an external power supply and wire the terminals through a common posi-

tive line, set SW1 to PNP and use a 24 V DC ±10% external power supply.

Note 4. When multi-function analog outputs are used for pulse train outputs, they can be di-

rectly connected to the pulse train inputs at other 3G3MV-seriesInverters for simple

synchronization or other applications.

H Selecting Input Method

·Switches SW1 and SW2,bothofwhichare located above the control circuit terminals,

are used for input method selection.

Remove the front cover and optional cover to use these switches.

Selectors

Control circuit

terminal block

Design Chapter 2

Page 41

2-18

D Selecting Sequence Input Method

·By using SW1, NPN or PNP input can be selected as shown below.

24 VDC

S1 to 7

S1 to 7

(Default setting)

SW1

SW1

(+/--10%)

D Selecting RS-422/485 T ermination Resistance

·Terminationresistance can be selectedby setting pin 1 of the SW2 toON. The default

setting for the pin is OFF.

Selects RS-422/485 termination resistance

Selects frequency reference input method

Design Chapter 2

Page 42

2-19

Communications method Pin 1 setting

RS-422 Set to ON

RS-485 Set to ON only if the Unit is the end Slave.

120-W termination resistance (1/2 W)

Pin 1

D Selecting Frequency Reference Input Method

·By using pin 2 of SW2, voltage input or current input can be selected as the input

method for frequency reference. The default setting is for voltage input.

Parametersettingsarerequiredtogetherwiththeselectionofthe frequency reference

input method.

Frequency reference input

method

Pin 2 setting Frequency reference

selection (parameter n004)

Voltage input (default

setting)

V (OFF) Set value 2

Current input I (ON) Set value 3 or 4

Note Do not set pin 2 to ON for current input while voltage input is ON, otherwise the

resistor in the input circuit may burn out.

Design Chapter 2

Page 43

2-20

2-2-2 Standard Connections

DC reactor

(optional)

Noise Filter

3-phase 200/400 VAC

Single-phase 200 VAC (see note)

Multi-function input 1

Sequence input common

Frequency reference power

supply 20 mA at +12 V

FREQUENCY

adjuster (2kW

1/4 W min.)

Frequency reference input

Frequency reference common

Multi-function contact output

NO

NC

Common

Multi-function analog

output/Pulse monitor

output

Multi-function analog output

common

Braking Resistor

(optional)

Multi-function input 2

Multi-function input 3

Multi-function input 4

Multi-function input 5

Multi-function input 6

Multi-function input 7

Pulse

generator

Pulse train input

RS-422

communications

(RS-485 selection)

Multi-function analog voltage input (0--10V)

Multi-function analog current input (4--20mA)

Analog input common

Connector

Digital Operator

Multi-function

photocoupler output 1

Multi-function

photocoupler output 2

Multi-function

photocoupler output

common

3G3MV--PCN--CN2 cable can be used for

multi--function analog input

(rear side)

Note Connect single-phase 200 VACto terminals R/L1 and S/L2 of the 3G3MV-ABj.

Design Chapter 2

Page 44

2-21

D Example of 3-wire Sequence Connections

Stop

switch

(NC)

RUN

switch

(NO)

Direction switch

RUN input (Operates with the RUN switch closed)

Stop input (Stops with the stop switch opened)

Sequence input common

Sequence input common

Note Set parameter 052 to forward/reverse rotation command 0 for 3-wire sequence

input.

2-2-3 Wiring around the Main Circuit

H Wire Size, Terminal Screw, Screw Tightening Torque, and

Molded-case Circuit Breaker Capacities

·For the main circuit and ground, always use 600-V polyvinyl chloride

(PVC) cables.

·If any cable is long and may cause voltage drops, increase the wire size according to

the cable length.

D 3-phase 200-VAC Model

Model

3G3MV-

Terminal symbol Termi-

nal

screw

Screw

tighten-

ing

torque

(NSm)

Wire

size

(mm2)

Recom-

mended

wire

size

(mm2)

Molded-

case

circuit

breaker

capac-

ity (A)

A2001

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

A2002

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

A2004

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

Design Chapter 2

Page 45

2-22

Model

3G3MV-

Molded-

case

circuit

breaker

capac-

ity (A)

Recom-

mended

wire

size

(mm2)

Wire

size

(mm2)

Screw

tighten-

ing

torque

(NSm)

Termi-

nal

screw

Terminal symbol

A2007

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 10

A2015

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5

2

20

3.5

A2022

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 3.5 20

A2040

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 5.5 30

A2055

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M5 2.5 5.5 to 8 8 50

A2075

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M5 2.5 5.5 to 8 8 60

D Single-phase 200-VAC Model

Model

3G3MV-

Terminal symbol Termi-

nal

screw

Terminal

torque

(NSm)

Wire

size

(mm2)

Recom-

mended

wire

size

(mm2)

Circuit

breaker

capac-

ity (A)

AB001

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

Design Chapter 2

Page 46

2-23

Model

3G3MV-

Circuit

breaker

capac-

ity (A)

Recom-

mended

wire

size

(mm2)

Wire

size

(mm2)

Terminal

torque

(NSm)

Termi-

nal

screw

Terminal symbol

AB002

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

AB004

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 10

AB007

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5

3.5

20

2

AB015

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5

5.5

20

3.5

AB022

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 5.5 40

AB040

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M5 2.3 to 2.4 5.5 to 8 8

50

M4 1.2 to 1.5 2 to 8 5.5

D 3-phase 400-VAC Model

Model

3G3MV-

Terminal symbol Termi-

nal

screw

Screw

tighten-

ing

torque

(NSm)

Wire

size

(mm2)

Recom-

mended

wire

size

(mm2)

Molded-

case

circuit

breaker

capac-

ity (A)

A4002

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 2 5

Design Chapter 2

Page 47

2-24

Model

3G3MV-

Molded-

case

circuit

breaker

capac-

ity (A)

Recom-

mended

wire

size

(mm2)

Wire

size

(mm2)

Screw

tighten-

ing

torque

(NSm)

Termi-

nal

screw

Terminal symbol

A4004

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 2 5

A4007

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 2 5

A4015

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 2 10

A4022

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5 2 10

A4030

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5

2

20

3.5

A4040

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.2 to 1.5 2 to 5.5

2

20

3.5

A4055

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M4 1.8 5.5 5.5 30

A4075

R/L1, S/L2, T/L3, B1, B2,

--, +1, +2, U/T1, V/T2,

W/T3

M5 1.8 5.5 to 8 5.5 30

Design Chapter 2

Page 48

2-25

H Wiring on the Input Side of the Main Circuit

D Installing a Molded-case Circuit Breaker

Alwaysconnect thepowerinputterminals(R/L1,S/L2,andT/L3) andpowersupplyviaa

molded case circuit breaker (MCCB) suitable to the Inverter.

·Install one wiring circuit breaker per Inverter.

·Choose an MCCB with a capacity of 1.5 to 2 times the Inverter’s rated current.

·For the MCCB’s time characteristics, be sure to consider the Inverter’s overload

protection (one minute at 150% of the rated output current).

·IftheMCCB istobeusedincommonamongmultiple Inverters,orotherdevices,setup

a sequence such thatthe power supply will be turned OFF by a fault output, asshown

in the following diagram.

3-phase/

Single-phase

200 VAC

3-phase

400 VAC

Power

supply

Inverter

Fault output

(NC)

(see

note)

Note Use a 400/200 V transformer for a 400-V model.

D Installing a Ground Fault Interrupter

Inverteroutputsuse high-speed switching, so high-frequency leakage current is generated.

Ingeneral, aleakagecurrent ofapproximately100 mAwilloccur foreachInverter(when

the power cable is 1 m) and approximately 5 mA for each additional meter of power

cable.

Therefore, at the power supply input area, use a special-purpose breaker forInverters,

which detects only the leakage current in the frequency range that is hazardous to

humans and excludes high-frequency leakage current.

Design Chapter 2

Page 49

2-26

·For the special-purpose breaker for Inverters, choose a ground fault interrupter with a

sensitivity amperage of at least 10 mA per Inverter.

·When using a generalleakagebreaker,choose a ground fault interrupter with asensitivity amperage of 200 mA or more per Inverter and with an operating time of 0.1 s or

more.

D Installing a Magnetic Contactor

If the power supplyof the main circuit is to be shut off because ofthe sequence, amagnetic contactor can be used instead of a molded-case circuit breaker.

When a magnetic contactor is installed on the primary side of the main circuit to stop a

load forcibly,however, the regenerative braking does not work and the load coasts to a

stop.

·A load can be started and stopped by opening and closing the magnetic contactor on

the primary side. Frequently opening and closing the magnetic contactor, however,

may cause the Inverter to break down.

·WhentheInverterisoperated withtheDigitalOperator,automaticoperation cannotbe

performed after recovery from a power interruption.

·WhenusingtheBrakingResistorUnit,besuretoarrangeasequence inwhichthethermal relay of the Unit turns the magnetic contactor OFF.

D Connecting Input Power Supply to the Terminal Block

Inputpowersupplycanbeconnectedto any terminal on the terminal block because the

phasesequence of input power supply isirrelevantto the phase sequence (R/L1,S/L2,

and T/L3).

D Installing an AC Reactor

If the Inverter is connected to a large-capacity power transformer (660 kW or more) or

the external phase advance capacitor of the customer is switched, an excessive peak

current may flow through the input power circuit, causing the converter unit to break

down.

To prevent this, install an optional AC reactor on the input side of the Inverter.

This also improves the power factor on the power supply side.

D Installing a Surge Absorber

Always use a surge absorber or diode for the inductive loads near the Inverter. These

inductive loads include magnetic contactors, electromagnetic relays, solenoid valves,

solenoid, and magnetic brakes.

Design Chapter 2

Page 50

2-27

D Installing a Noise Filter on the Power Supply Side

The Inverter’s outputs utilize high-speed switching, so noise may be transmitted from

the Inverter to the power line and adversely affect other devices in the vicinity. It is recommended that a Noise Filter be installed at the Power Supply to minimize this noise

transmission.Conversely, noise canalsobereducedfrom thepowerlinetothe Inverter.

Wiring Example

Power

supply

3G3MV-PFI

Noise

Filter

3G3MV

SYSDRIVE

Programmable

Controller

Other controllers

Note Use a special-purpose Noise Filter for the SYSDRIVE 3G3MV. A general pur-

pose noise filter will be less effective and may not reduce noise.

Please, use the noise filters as explained in Chapter 9-2.

H Wiring on the Output Side of the Main Circuit

D Connecting the Terminal Block to the Load

Connect output terminals U/T1, V/T2, and W/T3 to motor lead wires U, V, and W.

Check that the motor rotates forward with the forward command. Forward meansshaft

of the AC motor rotates in CCW (Counter Clock Wise), if you look from shaft to motor

end.Switch overanytwooftheoutputterminalsto eachotherandreconnectif themotor

rotates in reverse with the forward command.

D Never Connect a Power Supply to Output Terminals

Never connect a power supply to output terminals U/T1, V/T2, or W/T3.

Ifvoltageis appliedtotheoutput terminals,theinternal circuitofthe Inverterwillbedam-

aged.

D Never Short or Ground Output Terminals

Ifthe outputterminalsaretouchedwithbare handsorthe outputwirescome intocontact

withtheInvertercasing, an electric shockorgroundingwilloccur.Thisis extremely hazardous.

Also, be careful not to short the output wires.

Design Chapter 2

Page 51

2-28

D Do not Use a Phase Advancing Capacitor or Noise Filter

Never connect a phase advance capacitor or LC/RC Noise Filter to the output circuit.

Doing so will result in damage to the Inverter or cause other parts to burn.

D Do not Use an Electromagnetic Switch of Magnetic Contactor

Do not connect an electromagnetic switch of magnetic contactor to the output circuit.

If a load is connected to the Inverter during running, an inrush current will actuate the

overcurrent protective circuit in the Inverter.

D Installing a Thermal Relay

The Inverter has an electronic thermal protection function to protect the motor from

overheating. If, however, more than one motor is operated with one inverter or a multipolar motor is used, always install a thermal relay (THR) between the Inverter and the

motor and set n037 to 2 (no thermal protection).

In this case, program the sequence so that the magnetic contactor on the input side of

the main circuit is turned OFF by the contact of the thermal relay.

D Installing a Noise Filter on the Output Side

ConnectaNoiseFiltertotheoutputsideoftheInvertertoreduceradionoiseandinduction noise.

Power

supply

3G3MV

SYSDRIVE

3G3IV-PFO

Signal line

Induction noise Radio noise

Controller

AM radio

Note Please, check page 2-41 for more detailed explanation.

Induction Noise: Electromagneticinduction generates noise on the signal line, caus-

ing the controller to malfunction.

Radio Noise: Electromagnetic waves from the Inverter and cables cause the

broadcasting radio receiver to make noise.

Design Chapter 2

Page 52

2-29

D Countermeasures against Induction Noise

As described previously, a Noise Filter can be used to prevent induction noise from

being generated on the output side. Alternatively, cables can be routed through a

grounded metal pipe to prevent induction noise. Keeping the metal pipe at least 30 cm

away from the signal line considerably reduces induction noise.

Power supply

3G3MV

SYSDRIVE

Metal pipe

30 cm min.

Signal line

Controller

D Countermeasures against Radio Interference