Version 1.1

1 February, 2001

USERS MANUAL

Customer Service

We support you...

By phone/fax in the USA.

Customer service is available from 9:30 AM to 6:00 PM USA Eastern Time, Monday

through Friday at +1 (216) 241-7225. Fax: +1 (216) 241-4103.

By phone/Fax in Europe.

Service is available from Cutting Edge Europe in Germany at +49 81 61 42 467.

Fax: +49 81 61 42 402.

By E-Mail.

The address is: support@nogrunge.com.

Via World Wide Web.

The Cutting Edge Web site has a variety of information which may be useful for

product selection. The URL is: http://www.nogrunge.com.

Feedback

We welcome feedback on any aspect of the ToolVox

many good ideas from users have made their way into software revisions or new

products. Please contact us with your comments.

™

or this manual. In the past,

Cutting Edge

2101 Superior Avenue

Cleveland, OH 44114

USA

+1 (216) 241-3343

Fax: +1 (216) 241-4103

Updates

™

The operation of the ToolVox

is determined almost by software. A continuous

program of improvement is underway. Contact us to determine if a newer release is

available.

Trademarks

Cutting Edge, the Cutting Edge logo, Omnia and ToolVox are trademarks of TLS

Corporation. All other trademarks are property of their respective holders.

CUSTOMER SERVICE I

Copyright

Copyright © 1994-99 by TLS Corporation. Published by Cutting Edge, who reserves

the right to make improvements or changes in the products described in this manual,

which may affect the product specifications, or to revise the manual without notice.

All rights reserved.

Notice

All versions, claims of compatibility, trademarks, etc. of hardware and software

products not made by Cutting Edge mentioned in this manual or accompanying

material are informational only. Cutting Edge makes no endorsement of any

particular product for any purpose, nor claims any responsibility for operation or

accuracy.

Warranty

This product is covered by a one year limited warranty, the full text of which is

included in the Appendix of this manual.

Service

You must contact Cutting Edge before returning any equipment for factory service.

Cutting Edge will issue a Return Authorization number which must be written on

the exterior of your shipping container. Please do not return cables or accessories

unless specifically requested by Cutting Edge technical support. Be sure to

adequately insure your shipment for its replacement value. Packages without proper

authorization may be refused. USA customers: please contact Cutting Edge technical

support at +1 (216) 241-3343. All other customers should contact their local dealer to

make arrangements for service.

CUSTOMER SERVICE II

e

e

e

ee

Notices and Cautions

Notices and Cautions

Notices and CautionsNotices and Cautions

CAUTION:

THE INSTALLATION AND SERVICING INSTRUCTIONS IN THIS MANUAL ARE

FOR USE BY QUALIFIED PERSONNEL ONLY. TO AVOID ELECTRIC SHOCK, DO

NOT PERFORM ANY SERVICING OTHER THAN THAT CONTAINED IN THE

OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO. REFER

ALL SERVICING TO QUALIFIED PERSONNEL.

WARNING:

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT EXPOSE THIS

PRODUCT TO RAIN OR MOISTURE. DO NOT SHOWER WITH THE UNIT.

THIS SYMBOL, WHEREVER IT APPEARS, ALERTS YOU TO THE PRESENCE OF

UNINSULATED, DANGEROUS VOLTAGE INSIDE THE CLOSURE - VOLTAGE

WHICH MAY BE SUFFICIENT TO CONSTITUTE A RISK OF SHOCK.

e

e

ee

w

w

ww

h

THIS SYMBOL, WHEREVER IT APPEARS, ALERTS YOU TO IMPORTANT

OPERATING INSTRUCTIONS.

THIS SYMBOL REFERS TO A HOT TIP. HOT TIPS ARE USEFUL BITS OF

INFORMATION THAT WILL HELP YOU GET THE MOST OUT OF YOUR

TOOLVOX.

CUSTOMER SERVICE III

TO PREVENT RISKS OF

ELECTRIC SHOCK,

DISCONNECT POWER

CORD BEFORE SERVICING

USA CLASS A COMPUTING DEVICE INFORMATION TO USER.

WARNING:

If it is not installed and used as directed by this manual, it may cause interference to

radio communication. This equipment complies with the limits for a Class A computing

device, as specified by FCC Rules, Part 15, Subpart J, which are designed to provide

reasonable protection against such interference when this type of equipment is operated

in a commercial environment. Operation of this equipment in a residential area is likely to

cause interference. If it does, the user will be required to eliminate the interference at the

user’s expense.

other devices are connected to this device without the use of shielded interconnect

cables. FCC rules require the use of only shielded cables.

This equipment generates, uses, and can radiate radio-frequency energy.

NOTE:

Objectionable interference to TV or radio reception can occur if

CANADA WARNING: “

This digital apparatus does not exceed the Class A limits for

radio noise emissions set out in the Radio Interference Regulations of the Canadian

Department of Communications.” “Le present appareil numerique n’emet pas de bruits

radioelectriques depassant les limites applicables aux appareils numeriques (de les

Class A) prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.”

CUSTOMER SERVICE IV

Table of Contents

1 INTRODUCTION – WHAT IS THE TOOLVOX?...................................................1

2 INSTALLATION......................................................................................................3

3 QUICK SETUP GUIDE ...........................................................................................5

3.1 Powering Up...................................................................................................................................................... 5

3.2 Attaching Audio Cables .................................................................................................................................. 5

3.3 A Quick Look at the Front Panel................................................................................................................... 5

3.4 The Headphone Output .................................................................................................................................. 6

3.5 Installing the Remote Application Software ................................................................................................ 6

3.6 Connecting Your Computer to the ToolVox................................................................................................ 7

3.7 Creating a Connection to the ToolVox.......................................................................................................... 8

3.7.1 Serial connection ....................................................................................................................................... 9

3.7.2 Network connection .................................................................................................................................. 9

3.8 Adjusting the Audio Levels........................................................................................................................... 11

3.9 Let’s Begin Processing Some Audio ............................................................................................................ 11

3.10 Time to Become a Pro with ToolVox........................................................................................................... 12

4 THE FRONT PANEL ............................................................................................13

4.1 The LCD Screen and Edit Knob.................................................................................................................. 13

4.2 The Network LED.......................................................................................................................................... 14

4.3 The Phantom LED......................................................................................................................................... 14

4.4 LED Level Meter and Input / Output LEDs.............................................................................................. 14

4.5 Noise Gate LED.............................................................................................................................................. 14

4.6 De-esser LED .................................................................................................................................................. 15

4.7 Processing LED Bar graph........................................................................................................................... 15

4.8 Headphone Output and Control.................................................................................................................. 15

4.9 Setup Menu ..................................................................................................................................................... 16

TABLE OF CONTENTS V

5 THE REMOTE APPLICATION.............................................................................19

5.1 The File Menu................................................................................................................................................. 19

5.1.1 Open Preset.............................................................................................................................................. 19

5.1.2 Save Preset............................................................................................................................................... 20

5.1.3 Save Preset As ......................................................................................................................................... 20

5.1.4 Print Preset............................................................................................................................................... 20

5.1.5 Exit ........................................................................................................................................................... 20

5.2 The Options Menu ......................................................................................................................................... 21

5.2.1 Connect .................................................................................................................................................... 21

5.2.2 Disconnect................................................................................................................................................ 21

5.2.3 Edit Connection....................................................................................................................................... 22

5.2.4 Command Line........................................................................................................................................ 23

5.2.5 Preferences............................................................................................................................................... 24

5.3 The System Menu........................................................................................................................................... 25

5.3.1 Expert Edit Mode .................................................................................................................................... 25

5.3.2 Save System and I/O ............................................................................................................................... 25

5.3.3 I/O Configuration ....................................................................................................................................26

5.4 The Preset Menu ............................................................................................................................................ 28

5.4.1 Select........................................................................................................................................................ 28

5.4.2 Save Preset............................................................................................................................................... 28

5.4.3 Save Preset As ......................................................................................................................................... 29

5.5 The Help Menu............................................................................................................................................... 29

5.5.1 About........................................................................................................................................................ 29

5.5.2 Version…................................................................................................................................................. 29

5.6 The Processing Diagram ............................................................................................................................... 29

5.7 The Metering Screen ..................................................................................................................................... 30

5.7.1 Input Level............................................................................................................................................... 30

5.7.2 Output Level............................................................................................................................................ 30

5.7.3 AGC ......................................................................................................................................................... 31

5.7.4 Expander .................................................................................................................................................. 31

5.7.5 Compressor.............................................................................................................................................. 31

5.7.6 De-Esser................................................................................................................................................... 31

5.8 Advanced network parameters.................................................................................................................... 32

5.9 Security ............................................................................................................................................................ 33

6 THE AUDIO PROCESSING CHAIN IN DETAIL .................................................35

6.1 A Look at Audio Levels in the ToolVox...................................................................................................... 35

6.2 The Analog Limiter and Analog Level Control......................................................................................... 36

6.3 The Highpass Filter........................................................................................................................................ 38

6.4 The Phase Rotator.......................................................................................................................................... 38

TABLE OF CONTENTS VI

6.5 The Automatic Gain Control........................................................................................................................ 41

6.5.1 Manual or Automatic .............................................................................................................................. 41

6.5.2 Reference .................................................................................................................................................41

6.5.3 Attack and Release .................................................................................................................................. 42

6.5.4 The Freeze Gate....................................................................................................................................... 43

6.6 The Three Equalizers .................................................................................................................................... 44

6.6.1 Frequency................................................................................................................................................. 44

6.6.2 Gain.......................................................................................................................................................... 44

6.6.3 Q Factor ................................................................................................................................................... 45

6.6.4 Highpass................................................................................................................................................... 46

6.6.5 Lowpass ................................................................................................................................................... 47

6.6.6 Bandpass .................................................................................................................................................. 48

6.6.7 High Shelving.......................................................................................................................................... 49

6.6.8 Low Shelving........................................................................................................................................... 50

6.6.9 Peak.......................................................................................................................................................... 51

6.7 The Compressor ............................................................................................................................................. 52

6.7.1 Threshold .................................................................................................................................................52

6.7.2 Attack ....................................................................................................................................................... 52

6.7.3 Release ..................................................................................................................................................... 53

6.7.4 Ratio ......................................................................................................................................................... 53

6.7.5 Boost ........................................................................................................................................................53

6.8 The Expander .................................................................................................................................................55

6.8.1 Threshold .................................................................................................................................................55

6.8.2 Attack ....................................................................................................................................................... 55

6.8.3 Release ..................................................................................................................................................... 55

6.8.4 Ratio ......................................................................................................................................................... 55

6.9 The De-Esser................................................................................................................................................... 56

6.9.1 Threshold .................................................................................................................................................57

6.9.2 Max Reduction ........................................................................................................................................ 57

6.10 TrueVerb

6.11 Output Stage ................................................................................................................................................... 65

6.11.1 Panorama .................................................................................................................................................65

6.11.2 Gain Control ............................................................................................................................................ 65

®

by Waves..................................................................................................................................... 58

7 SPECIFICATIONS................................................................................................67

8 WARRANTY AND APPLICATION CAUTION ....................................................69

9 APPENDICES.......................................................................................................69

TABLE OF CONTENTS VII

TABLE OF CONTENTS VIII

TOOLVOX USERS MANUAL

1 Introduction – What is the ToolVox?

The Omnia ToolVox is a high-performance, all-digital voice processor designed to

work in concert with on-air broadcast or webcast processing to deliver a smooth yet

powerful voice presence. It integrates everything needed for voice into a single

system—including state-of-the art DSP reverb. The algorithms used in ToolVox

were born out of the extensive dynamics control developed for the Omnia broadcast

processor. ToolVox fully exploits the power of DSP to perform frequency domain

analysis while implementing the latest discoveries in speech psychoacoustics. An

example is its de-esser, which uses an advanced FFT method to predict and reduce

the sibilant energy that often causes excessive clipping in on-air processors. The

result is a voice sound that’s smooth, never grating and always powerful.

ToolVox includes:

• A studio reference-grade mic preamp with up to 70 dB of programmable gain and

built-in phantom power;

• 24-bit A/D and D/A converters for maximum digital fidelity;

• Slow gain-riding AGC with smart-freeze gate, compressor and noise gate sections,

designed with ratios and time-constants that work in concert with those found in onair and webcast processors;

• A phase rotator for reducing the amount of asymmetry in voice,

• Fully adjustable HP, LP and shelving filters plus parametric EQ; and

®

• TrueVerb, a powerful psychoacoustic room simulation program from Waves

.

Each ToolVox can store 100 presets that can be easily edited, moved or deleted as

®

required by the system administrator using the included Windows

Remote Control

application.

Presets can be manually selected from the front panel in a jock-friendly fashion:

Rotate a knob until the desired preset name is displayed, then press a button to load

the preset. Presets can also be remotely and automatically selected since ToolVox is a

network-ready processor. To prevent unauthorized tampering, ToolVox includes

built-in security features.

ToolVox includes both processed stereo analog and AES/EBU digital outputs as well

as an unprocessed output specifically designed for feeding telephone hybrids. An

AES/EBU Sync Input is included for those facilities using a master sample or house

clock.

A front panel volume control and stereo headphone jack are included for convenient

monitoring of the mic processing.

To help you get started, several factory presets are provided in each ToolVox–from

these starting points, we’re certain you’ll want to make your own.

Omnia, the promise of digital. . . delivered.

CHAPTER 1 1

INTRODUCTION

2 Installation

Analog Limiter Setting (Internal Switch)

Before rack mounting your ToolVox, determine if there is a need to defeat the builtin analog limiter that protects the A/D converter against short transient signal peaks.

We recommend that the limiter be left in the signal path. If your application requires

that the limiter be taken out of the signal path, you must take off the top cover on the

unit and set switch SW2 to position C2.

Rack Mounting

The Omnia ToolVox requires 1RU (1.75" (44.45 mm)) of rack space. If possible, try

to leave one empty space above the ToolVox to provide extra ventilation. If rack

space is available, add another empty space below the ToolVox.

ToolVox is normally placed in the studio or on-air control room where it can be

accessed by board-operators or on-air talent to select presets as required. There is no

danger of accidental preset “corruption,” since all preset programming is performed

through software running on a computer. The only controls on the unit are for

selecting and loading processing presets.

TOOLVOX USERS MANUAL

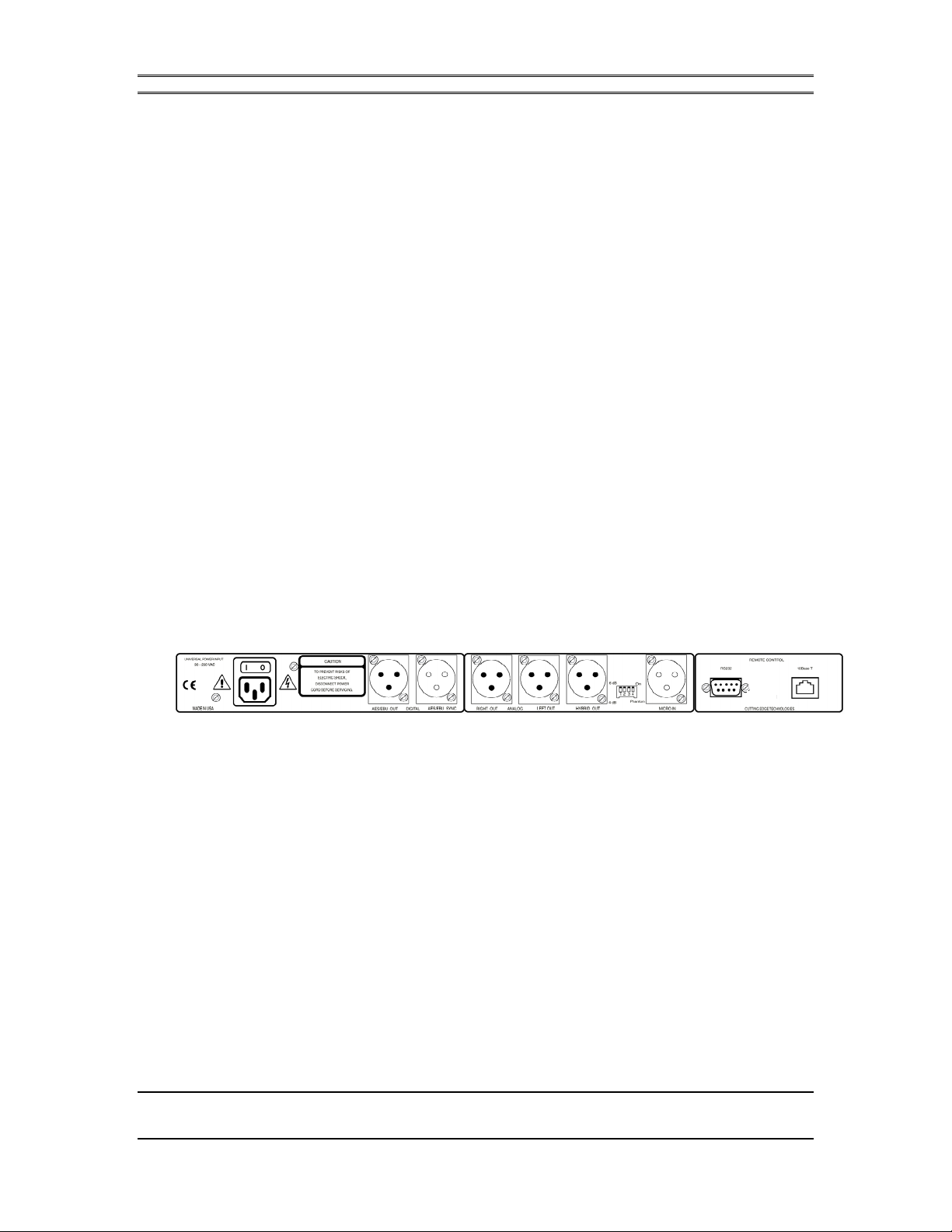

Rear Panel Connections & Controls

Power

The unit’s internal switching power supply can operate on 50 or 60 Hz power mains

supplying from 90 to 260 VAC. Plug the IEC power cord into the AC power entry

module on the rear of the unit. Turn on the power switch, also on the power entry

module.

DIP Switch (between MIC IN and HYBRID OUT)

The four position DIP switch is used to set installation parameters. At this time,

switches 1,2 and 3 are reserved for future options and are not used. Switch 4, when

set UP, turns on phantom power to the MIC IN connector. Circuitry in the ToolVox

actually confirms that 48 Volts is present before turning on the front panel

“Phantom” status LED.

RS232

CHAPTER 2 3

INSTALLATION

TOOLVOX USERS MANUAL

A 9-pin serial port connection for a local PC running the ToolVox Remote

application.

10Base-T

Ethernet network connector for connecting the ToolVox to a facility LAN. A single

computer, running the ToolVox applications, can control multiple ToolVox units

once each has been assigned a unique network address (TCP/IP). The Green LED

adjacent to the connector confirms a valid Ethernet connection, and the yellow LED

will flash during periods of network activity.

MIC IN (female XLR-type connector)

Any balanced dynamic or condenser microphone can be connected. If +48 Volt

phantom power is required, set DIP switch #4 (next to the MIC IN connector) to its

UP position. A front panel LED lights to indicate phantom power is switched on. If a

dynamic microphone is used set DIP switch #4 DOWN to turn off phantom power.

Level control is set using the ToolVox remote control application.

HYBRID OUT (male XLR-type connector)

A balanced +6 dBu mono output of the preamplified mic signal, designed for feeding

a telephone hybrid. This signal is extracted after the analog limiter. This analog feed

should connect directly to the SEND input of the telephone hybrid. Better hybrid

performance can be obtained by using unprocessed audio, so the HYBRID OUTPUT

is just a loopback of the analog input to the ToolVox.

ANALOG OUT (male XLR-type connector)

Stereo processed audio connections (LEFT OUT and RIGHT OUT) using standard

active balanced 50 Ohm outputs.

Connecting the ToolVox Output to Unbalanced Equipment

We urge you to always use balanced connections between equipment in a studio.

Connecting an unbalanced device in a very noisy environment might lead to noisy

audio signals. One possible way to improve signal quality in such a situation is to

ground one of the signal pins. ToolVox provides internal jumpers that allow pin 3 to

be grounded on the analog output connectors. [this should be repeated in the

installation section earlier before the customer puts the unit in the rack].

AES/EBU SYNC (female XLR-type connector)

Only used when a facility requires a house sample clock reference signal to

synchronize all digital devices. Connect using 110 ohm digital cable.

AES/EBU OUT (male XLR-type connector)

Stereo digital output of the processed microphone audio. Use 110 ohm digital cable

to route the output to a digital console or other AES/EBU-compatible device.

CHAPTER 2 4

INSTALLATION

3 Quick Setup Guide

3.1 Powering Up

As described in the previous section, apply AC via the IEC style connector on the

back of the unit. The power switch is located just above the power connector.

3.2 Attaching Audio Cables

The microphone should be connected to the Mic In female XLR connector. This

should be a balanced connection to reduce the effect of common-mode noise induced

in long cables. Adjust Dip-Switch 4 to the UP position when +48V Phantom Power

is required for your microphone.

For analog output, attach a female XLR cable to the Analog Out connector. The

analog output of the ToolVox is adjustable and has a 50 ohm source impedance. A

peak level of +15dBu is available.

TOOLVOX USERS MANUAL

For digital output, connect a female XLR cable to the AES/EBU OUT connector.

The Professional Mode AES/EBU format is used by the ToolVox. The output is

transformer isolated with 110 ohm source impedance (standard AES/EBU).

The HYBRID OUTPUT connector is provided for the broadcast facility which wants

to feed the output of the ToolVox into a call-in talk show system. This analog feed

should connect directly to the SEND input of the telephone hybrid. Better hybrid

performance can be obtained by using unprocessed audio, so the HYBRID OUTPUT

is just a loopback of the analog input to the ToolVox.

In many all-digital installations, an AES/EBU sync clock is used to synchronize all of

the equipment in a facility to a common sample rate. If your facility has such a

clock, the AES/EBU SYNC input connector should be used. This is also a standard

110 ohm AES/EBU connector.

3.3 A Quick Look at the Front Panel

CHAPTER 3 5

QUICK SETUP GUIDE

Once your audio connectors have been made, power up the unit and check the front

panel indicators. You should see a preset name and number indicated on the front

panel LCD. Assuming you have no audio input, the PROCESSING meter should

indicate a gain of 0dB, and no level should be present on the LEVEL meter. The

INPUT and OUTPUT LEDs indicate the audio source for the LEVEL meter.

You can change the current preset by rotating the large knob to the right of the LED

screen. Select a preset by pressing the ENTER button.

3.4 The Headphone Output

A ¼” stereo jack is provided on the front panel for monitoring the ToolVox. The

headphone volume is controlled by the knob on the far right of the front panel.

TOOLVOX USERS MANUAL

w

listening to the headphone output.

3.5 Installing the Remote Application Software

Included with the ToolVox is a CDROM containing the ToolVox Remote

Application and additional information about the ToolVox. All of the features of the

ToolVox are accessible through this program, so before operating the processor this

application must be installed on a computer.

The Remote Application must be run on a Microsoft Windows compatible PC. Insert

the disk in your CDROM drive. Open Windows Explorer. Select the drive letter of

your CDROM drive and copy the REMOTE.EXE file from the SOFTWARE

subdirectory on the CDROM to your hard drive (a good location would be a

c:\ProgramFiles\Cutting Edge\ToolVox directory).

Start with the Headphone volume set to its lowest position before

CHAPTER 3 6

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

3.6 Connecting Your Computer to the ToolVox

The ToolVox must be connected to your computer by either of 2 methods:

•

Serial connection

Use the serial port on the back of your computer to link to the RS-232 port on the

ToolVox. Use the 9-pin serial cable included with the ToolVox, or use your own

serial cable. The RS-232 port on the ToolVox is a standard female DB9 connector

and can be attached to your computer’s DB9 or DB25 serial port using standard (nonnull modem) cables.

• TCP/IP Network Connection

Use a 10Base-T cable to connect the ToolVox to the local network. Also make sure

that the computer on which you will use the Remote Application software is

connected to the network.

h

If you use the serial port, make a note of which COM port to

which you have attached the serial cable, so you can configure

the Remote Application quickly and correctly.

CHAPTER 3 7

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

3.7 Creating a Connection to the ToolVox

Now you’re ready to begin experiencing the power of ToolVox. Start the ToolVox

Remote Application by either choosing it from the Start Menu – Programs selection

tool, or double-clicking the program icon from Explorer. The window below appears:

The first time you use the program, you will see a warning

window appearing with the following message: ”No connection

database, creating database.” Press OK.

h

You must create and configure a Connection using the application software. Go to

the Options Menu and choose Edit Connection. The dialog box shown below will

appear and will allow you to enter the connection parameters.

CHAPTER 3 8

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

3.7.1 Serial connection

First, give your connection a meaningful name. Then, enter the ToolVox password

that gives you the level of control you want. For example, use the password “corli”;

this gives the highest level of access to the ToolVox features. A complete list of

passwords and access levels is provided in the Remote Application chapter of this

manual. Now choose the COM radio button to select the RS-232 type of connection.

Select the COM port you used when attaching the serial cable to the unit, and press

OK.

3.7.2 Network connection

• Remote Application settings

First, give your connection a meaningful name. Then, enter the ToolVox password

that gives you the level of control you want. For example, use the password “corli”;

this gives the highest level of access to the ToolVox features. A complete list of

passwords and access levels is provided in the Remote Application chapter of this

manual. Now choose the TCP/IP radio button to select the Network connection.

Enter the IP Address of the ToolVox you want to connect to, on the right of the radio

button, and press OK.

CHAPTER 3 9

QUICK SETUP GUIDE

For more details concerning advanced network parameter settings (gateway

and subnet mask), see chapter 5.8.

w

w

ww

• ToolVox Settings

In order to use the ToolVox through the network, you need to assign it an unique IP

Address (To obtain an available address on the network you are connecting the

ToolVox to, see your network administrator).

Once you get this address, set up the ToolVox by holding the ENTER button for at

least 3 seconds. You will then see the Setup Menu appearing on the LCD screen.

Press ENTER again to select the IP Address item. The first number of the IP

address will be blinking. Use the large Edit Knob to scroll up (to the right) or down

(to the left) through the numbers from 0 to 255. Then, press the ENTER button to

confirm and switch to the next number. Repeat this last action for the three other

numbers.

TOOLVOX USERS MANUAL

Once the four numbers building the IP address are set, the ToolVox will

automatically reboot. Now, the ToolVox is ready for a network connection.

During the manipulations in the ToolVox Setup Menu, if no

parameters are changed in the 20 seconds following the

last change, the ToolVox will automatically close the menu

and come back to the presets view.

w

CHAPTER 3 10

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

Now that you have created a Connection, you can use it to communicate with the

ToolVox. Under the Options menu select Connect and choose any connection from

the list box. Press OK or double-click on the name to activate the connection. After

a few moments you should see the ToolVox Processing Diagram and the meter

information appear on the screen as shown below. If this doesn’t happen you may

have chosen the wrong COM port or the wrong IP address in your connection

creation. You can use Options – Edit Connection to change the settings of the

connections should you need to.

3.8 Adjusting the Audio Levels

To calibrate audio levels, you will need to provide an audio source to the unit: your

own voice will do just fine. Go the System menu and select I/O Configuration. In

the dialog box, change the Front Panel Level Meter selection to Input. Press OK.

Test the microphone input level by speaking in a normal voice and watching the

input level meter. If it is not peaking between -10dB and +10dB, you should adjust

the analog input level. Click once on the Input box in the Processing block diagram

and adjust the Analog Input Level until the audio level peaks in the range cited above

when you speak.

If the input is slightly out of range, don’t panic. The powerful

AGC functions in the ToolVox will optimize your levels.

h

Now monitor your output with the headphone jack on the front panel. Adjust the

headphone volume to a comfortable level.

3.9 Let’s Begin Processing Some Audio

The heart of the ToolVox is the ability to create custom presets tailored to the

individual(s) whose voices need to be processed. The ToolVox can store up to 100

CHAPTER 3 11

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

presets in the unit’s memory. The factory presets which come with the unit can be

replaced with your own at any time. Choose a preset by selecting Preset – Select

from the drop down menus. The Remote Application will upload all of the presets

from the unit’s memory (this will take a moment). Choose a preset to edit from the

list. Don’t worry about overwriting the factory preset now; you won’t be saving this

preset unless you absolutely want to.

To edit a preset, use the Processing Diagram in the upper half of the application

window. The Processing Diagram is a graphical interface to the ToolVox processing

parameters. Select a box in the diagram by clicking on it once. A dialog box will

appear and display the parameters associated with that processing function. Try

selecting different boxes and become familiar with the parameters and their effects.

Notice that the dialog boxes that appear can be moved around the screen just like any

other window. This is useful for viewing several processing parameters at once, as

well as keeping the meters in view when you adjust the sound.

Change the LEVEL meters so that they indicate the output level of the ToolVox

analog output by selecting System – I/O Configuration from the drop-down menu.

Using the Output processing box you can change the output level to match your

facility’s optimal audio level. Keep in mind that this will also change the volume in

your headphones.

3.10 Time to Become a Pro with ToolVox

Now that you are familiar with the ToolVox editing environment you can completely

customize your audio with the advanced features of ToolVox. The rest of this manual

covers every aspect of the Remote Application, Processing Parameters. Take the time

to read through all of the sections – you will want to know the ToolVox inside and

out to get the most out of this revolutionary new product!

CHAPTER 3 12

QUICK SETUP GUIDE

TOOLVOX USERS MANUAL

4 The Front Panel

Because the ToolVox system is designed to work primarily with the Remote

Application software, the front panel of the ToolVox is somewhat spare, displaying

only the essential information needed to indicate proper operation and to select

presets.

4.1 The LCD Screen and Edit Knob

The LCD indicates the currently selected preset. Use the large Edit Knob to scroll

through the presets stored in the unit. Press the Enter button to select a new preset.

The LCD screen and Edit Knob also allow access to a SETUP MENU (see chapter

4.9).

The ToolVox remembers the last preset selected. You can

“double-click” the Enter button to do an A/B comparison of the

current preset and the last preset selected.

h

CHAPTER 4 13

THE FRONT PANEL

4.2 The Network LED

When the ToolVox is properly connected to a TCP/IP network, this LED will

illuminate.

4.3 The Phantom LED

This LED indicates the status of the 48V phantom power on the microphone input.

Phantom power is selected using Dip Switch 4 on the back panel of the ToolVox.

ToolVox actually monitors the Phantom Power voltage, so this LED will also help

you troubleshoot any problems you might have (such as turning Phantom Power on,

and not getting any).

TOOLVOX USERS MANUAL

4.4 LED Level Meter and Input / Output LEDs

The LED bar graph on the left side of the front panel can be configured to display

one of the following audio levels: input, analog output, or digital output. A range of

–15dB to +15dB is indicated on the bar graph, with each LED representing an

additional 3dB of level. The range from +3dB to +15dB is indicated by red warning

LEDs. 0dB refers to the unit’s analog reference level of –15dBFS.

The Input and Output LEDs indicate which level is displayed. Use the Remote

Control application to change the level meter function (under the System – I/O

Configuration drop-down menu). The LED meters indicate the RMS average level,

as well as the true peak level of the audio.

4.5 Noise Gate LED

This LED follows the operation of the Expander.When the audio level is below the

Expander threshold, the Noise Gate LED will illuminate.

CHAPTER 4 14

THE FRONT PANEL

TOOLVOX USERS MANUAL

4.6 De-esser LED

When the De-esser is operating, this LED will indicate when there is excessive

sibilance being removed from the audio signal. The De-esser is controlled from the

Remote Application, in the Processing Diagram.

4.7 Processing LED Bar graph

The Processing LED bar graph shows a composite of the control signals applied by

the AGC, Compressor, Expander and De-esser sections. When any one of the

functions is controlling the audio, the Processing bar graph will indicate the amount

of gain increase (0 to +15dB) or decrease (0 to –15dB) applied to the audio level.

If only the AGC section is turned on, the bar graph will only

display a control signal if the AGC is set to Automatic. The

Manual setting disables the display of the AGC control voltage.

h

4.8 Headphone Output and Control

The ¼” Stereo Headphone Jack on the right side of the front panel allows monitoring

of the Analog Output of the ToolVox. Adjusting the Analog Output in the Output

block of the Remote Application Processing Diagram will change the level in the

headphone monitor. The headphone volume is controlled by the knob to the right of

the headphone jack.

CHAPTER 4 15

THE FRONT PANEL

TOOLVOX USERS MANUAL

4.9 Setup Menu

On the ToolVox, a SETUP MENU is implemented. This menu is composed of three options.

•

IP Address : used to set up the ToolVox dedicated IP address.

• Reboot function: used to reboot the ToolVox.

• Exit: exit from the Setup Menu.

To access this menu, hold the ENTER key for 3 seconds. The Setup Menu appears

on the LCD screen with the first option on the second line(IP Address).

To select or change the IP address, press the ENTER key. You will see the first

number of the IP address blinking. Use the large Edit Knob to scroll up (to the right)

or down (to the left) through the numbers from 0 to 255. Then, press the ENTER

button to confirm and switch to the next number. Repeat this last action for the three

other numbers. Once the four numbers building the IP address are set, the ToolVox

will automatically reboot.

To reboot the ToolVox, go to the Setup Menu, select the Reboot option by scrolling

to the right one time. Then, press ENTER. The ToolVox will reboot.

To exit from the Setup Menu, scroll right (or left) using the large Edit Knob until you

find the Exit option. Then, press ENTER. The ToolVox will end up at the Setup

Menu without rebooting.

During the manipulations in the ToolVox Setup Menu, if no

parameters are changed in the 20 seconds following the

last change, the ToolVox will automatically close the menu

and come back to the presets view.

w

CHAPTER 4 16

THE FRONT PANEL

w

TOOLVOX USERS MANUAL

During the reboot function, be aware that you will loose all

the I/O and preset settings that you changed, unless you

have saved them.

CHAPTER 4 17

THE FRONT PANEL

TOOLVOX USERS MANUAL

5 The Remote Application

The installation of the Remote Application software was covered in the Quick setup

section.

5.1 The File Menu

The File menu allows you to Load and Save presets from/to your hard drive or

floppy disk, Print preset settings, and Exit the Program. Preset files (files with

extension PRS) are used to store presets on your computer for archiving and copying

to other ToolVox units in your facility.

5.1.1 Open Preset

Use this command to load preset files from your computer into the Remote

Application. The stored preset will be immediately activated as the current preset in

the ToolVox connected to your computer.

h

Preset files can be downloaded from the Cutting Edge web site,

as well as e-mailed to different facilities and copied to other

computers.

CHAPTER 5 19

THE REMOTE APPLICATION

5.1.2 Save Preset

After you Open a preset into the Remote Application, you can make changes to the

preset and then save it back to your computer using the same name by selecting Save

Preset from the File menu.

w

TOOLVOX USERS MANUAL

Using Save Preset will overwrite the existing preset on your

computer.

5.1.3 Save Preset As

Use Save Preset As to save the currently modified preset to your computer using a new name. The dialog box will ask you to specify the directory in which to save the preset file, as well as the name of the file.

5.1.4 Print Preset

Print Preset is a used for generating a hard copy of the entire preset. This is a useful technique to save your work in tangible form. In addition, there is the possibility that new software revisions of the ToolVox will be incompatible with your current presets. Printing the preset is a useful way of keeping the preset parameters handy in case you need to enter the preset should you receive an incompatible software version.

5.1.5 Exit

A nice way to quit out of the Remote Application.

CHAPTER 5 20

THE REMOTE APPLICATION

5.2 The Options Menu

5.2.1 Connect

Connect brings up the list of Connections stored on your computer (assuming you have created at least one). A list of the available connections will appear, allowing you to choose one and connect to the ToolVox. After choosing a connection, the Processing Diagram and Meter Screen should appear. If not, use Edit Connection to check the particulars of this connection and make the necessary changes. Also check your cabling and make sure the ToolVox is powered up.

TOOLVOX USERS MANUAL

h

5.2.2 Disconnect

Disconnect will immediately terminate any connection you have running. If there are multiple ToolVox units that you are configuring (on a LAN, for example), use Disconnect to drop the current connection and then Connect to the next ToolVox to be configured.

You can open more than one instance of the Remote

Application to connect to more than one ToolVox at a time.

This is particularly useful in LAN applications, but if you have

multiple ToolVox units connected to separate COM ports on

your computer, this will work as well.

CHAPTER 5 21

THE REMOTE APPLICATION

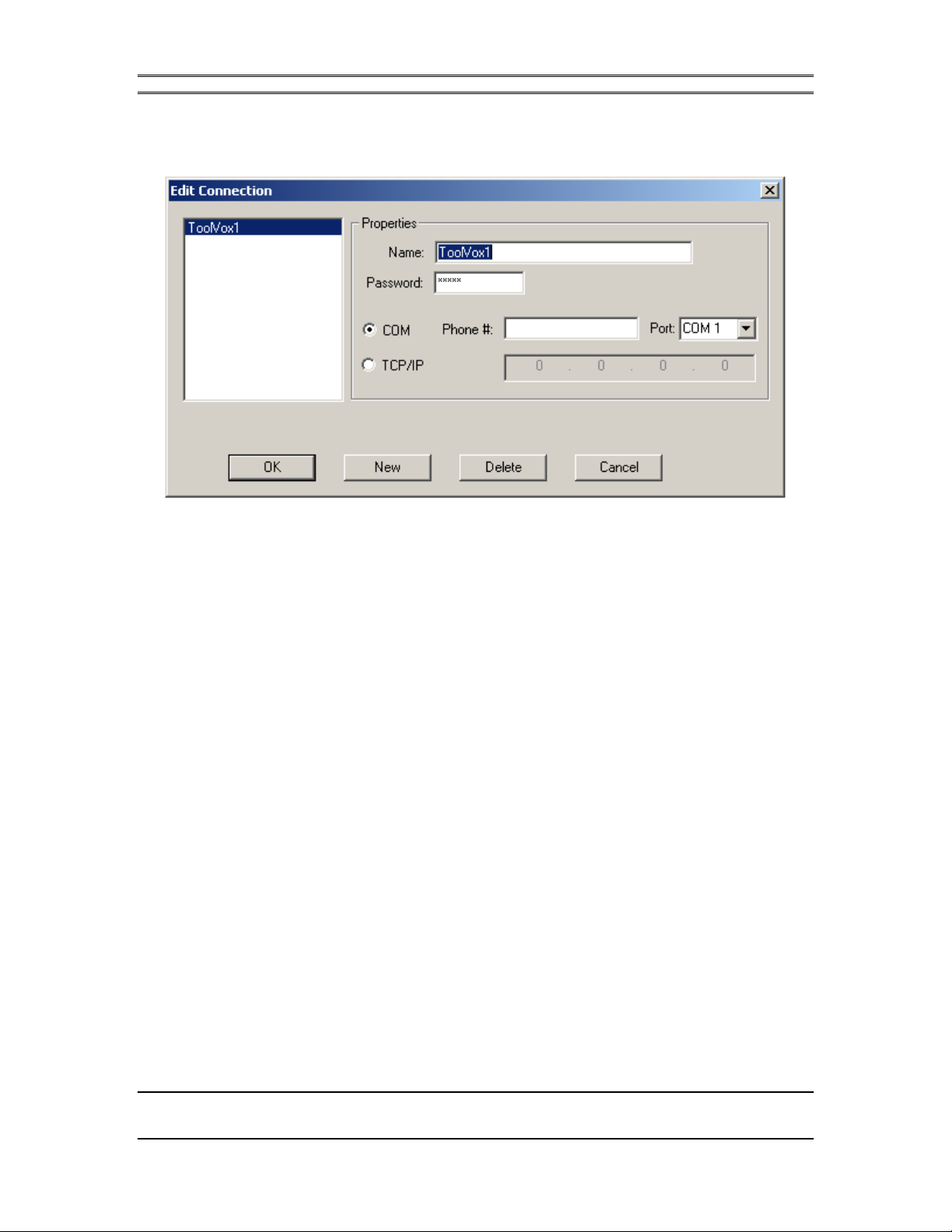

5.2.3 Edit Connection

Choosing Edit Connection brings up the following dialog box:

TOOLVOX USERS MANUAL

To make a new connection, select New. A default name will appear in the Name

box, and the other boxes will be set to their default settings. Change the name to

something meaningful (e.g. AirStudio). Enter the password (see Security in this

chapter) appropriate for this connection. Select either COM for a serial connection,

or TCP/IP for a LAN connection.

You are not required to enter the password when you create a

new Connection. The Remote Application will prompt you to

enter the password when you connect to the ToolVox. This is

useful for maintaining security on your computer.

h

For a COM connection, enter the phone number to dial (assuming you are using a

modem to configure the ToolVox), or simply choose the appropriate COM port for

this connection.

For a TCP/IP connection, enter the IP address for the ToolVox.

CHAPTER 5 22

THE REMOTE APPLICATION

To edit an existing connection, select that connection from the list box. The

parameters for that connection will be shown in the appropriate boxes. Make any

changes and then click OK to save them.

A new Connection should be created for each ToolVox in your facility which will be

connected to this computer.

5.2.4 Command Line

Command Line brings up the following window:

TOOLVOX USERS MANUAL

The command line is a very low level interface to the ToolVox operating system. If

you are having difficulty with the ToolVox, Cutting Edge Customer Service may

instruct you to open a Command Line interface to assisting in troubleshooting the

problem. There are a few other reasons to enter the Command Line which will be

covered later in the manual.

CHAPTER 5 23

THE REMOTE APPLICATION

5.2.5 Preferences

This screen allows you to customize the look and feel of the Remote Application

software.

TOOLVOX USERS MANUAL

Connect to Last Connected – When this box is checked, the Remote Application

will automatically connect to the last Connection used when you start up the

application. This is useful when you have your ToolVox on a LAN, or when you

leave it permanently connected to your computer’s serial port.

Decay Fade – When this box is checked, the level meters on the Remote Application

will visibly fade when the audio level is decaying.

Peak Indicator – The thin line on the Remote Application Level Meters that holds

the peak level can be turned on and off with this box.

Show as Solid Color – When checked, the 3-D appearance of the level meters will

be changed to a solid color.

CHAPTER 5 24

THE REMOTE APPLICATION

5.3 The System Menu

5.3.1 Expert Edit Mode

Currently not implemented.

5.3.2 Save System and I/O

TOOLVOX USERS MANUAL

This will immediately save the current I/O configuration (see I/O Configuration) to

the memory of the ToolVox. This prevents the ToolVox from reverting to the default

settings when you reboot the unit. This has no effect on presets or the audio

processing parameters.

CHAPTER 5 25

THE REMOTE APPLICATION

5.3.3 I/O Configuration

TOOLVOX USERS MANUAL

The I/O Parameters dialog box is divided into 2 parts: Appearance and Output.

Appearance parameters control the front panel of the ToolVox and what information

is displayed there. Output parameters control the source of the output audio as well as

AES/EBU Synchronization.

Front panel level meter has two choices: INPUT causes the LED bar graph to

display the level of the Input Audio (after the analog gain / limiting stage). OUTPUT

displays either the Digital Output level or the Analog Output level (selected by the

Output Meter selection).

Output METER allows you to display the DIGITAL or ANALOG output levels on

the level meters (both front panel and Remote Application).

Contrast selects among 3 choices for the LCD display contrast setting.

Backlight allows you to turn the LCD backlight on and off.

CHAPTER 5 26

THE REMOTE APPLICATION

TOOLVOX USERS MANUAL

Listen to selects the current audio processing parameters used to control the audio.

You can use this feature to do an A/B comparison of your current parameter settings

to those stored in the last selected preset within the ToolVox

When using the Listen to function, be aware that the Input Analog

Gain parameter is not considered a processing parameter. Thus, it

won’t change between the current state and the stored state.

w

Bypass all? Allows you to bypass the entire audio processing chain to listen to the

raw input audio. This is a good way to A/B the processed and unprocessed audio.

nd

2

channel source is a unique feature that gives you the ability to listen to the audio

removed by the de-esser in its analysis of the input audio. Selecting ANALYTIC

mode puts only the removed sibilance on the right channel output. This is a good

way to find out how much of the audio is being removed by the De-esser stage.

AES/EBU mode allows you force the AES/EBU output to synchronize to the

AES/EBU SYNC input source. The digital output will be sample-rate converted to

the recovered clock on the AES/EBU SYNC input.

Analog reference allows you to specify the output reference level for the analog

outputs. The gain (or cut) applied at this point will be based on the I/O reference

level of –15dBFS. This is explained in more detail in the Audio Processing section.

This setting is independent of the presets and should be set to optimize the output

level for your installation..

Digital reference allows you to specify the output reference level for the digital

output. The gain (or cut) applied at this point will be based on the I/O reference level

of –15dBFS. Again, this setting is independent of the presets.

CHAPTER 5 27

THE REMOTE APPLICATION

5.4 The Preset Menu

The Preset Menu gives you limited control over the presets stored in the connected

ToolVox. ToolVox has room for 100 presets in its internal memory. These presets

are all filled with factory presets when shipped. You can load any of the factory

presets, change them, and replace them using the Preset Menu. You can also load

your own presets and change them.

TOOLVOX USERS MANUAL

w

Note: The items in the Preset Menu affect presets stored in the ToolVox. This is in

contrast to the File Menu preset controls which modify presets on your computer.

5.4.1 Select

Select brings up a dialog box containing the list of all presets stored in the connected ToolVox. Clicking on one loads the selected preset.

5.4.2 Save Preset

Save Preset overwrites the current stored preset with the currently used set of processing parameters. The name of the preset will not be changed, but the stored preset will be lost (overwritten).

When you replace a preset inside the unit you will permanently

lose the old preset in that slot.

CHAPTER 5 28

THE REMOTE APPLICATION

5.4.3 Save Preset As

This choice allows you save the current preset under a new name. The old preset will

still be overwritten, as the same memory slot is used.

5.5 The Help Menu

5.5.1 About

The About screen displays pertinent information about the Remote Application, including the version number.

5.5.2 Version…

Version displays the software revisions of all software pieces in the connected

ToolVox.

TOOLVOX USERS MANUAL

5.6 The Processing Diagram

The Processing Diagram is the graphical user interface used to adjust the audio

processing parameters in the ToolVox. The Diagram is shown as a signal flow chain

to make it easy to visualize the effects and locations of the different processing

blocks.

CHAPTER 5 29

THE REMOTE APPLICATION

Clicking once on any block in the chain will bring up a dialog box containing the

processing parameters for that block. Each dialog box can than be dragged to any

location on the screen, and another processing block opened for editing. In this way,

you can modify several different processing blocks and listen to how they work in

concert.

Typically, you would begin editing a preset by starting with the blocks at the far left

of the chain. Calibrate your input levels, for example, using the INPUT block. The

PHASE ROTATOR is next because it doesn’t have any effect on the audio level.

The AGC, EQ, and COMPRESSOR / EXPANDER are next in order to optimize the

audio level for the more analytical blocks – the DE-ESSER and REVERB. Finally,

the OUTPUT block would be adjusted to give the correct analog or digital levels for

your installation.

The next chapter covers each audio processing block in very fine detail, including

tips on how to get the particular effect you might be looking for.

5.7 The Metering Screen

The bottom half of the Remote Application window contains the Metering Screen.

The screen displays the audio levels and control signals within the ToolVox in realtime; this makes it easy for you to adjust each processing block and immediately see

the effect (if any) on the audio.

TOOLVOX USERS MANUAL

5.7.1 Input Level

The left-most meter displays the level of the audio input, after the analog limiter and

analog gain stage. Use this level indicator to ensure you are running your input at an

optimum level: that is, not so low that the noise floor will become a problem, and not

so high that you run out of headroom. A level indication of -10 to +10 dB is ideal at

this stage of the audio chain (the AGC and Compressor / Expander will fine tune the

level later). Note that the Input and Output levels on the remote do not indicate the

true Peak (like the LED meters), but rather show the peak of the RMS value (this was

done because of the sluggishness of the Windows interface).

5.7.2 Output Level

The output level meter shows either the digital or the analog output level (each can be

run at different gains). Choose the level to be displayed by using the System – I/O

Configuration drop-down menu. Each installation will have a different optimal

output level: use this meter to adjust yours.

CHAPTER 5 30

THE REMOTE APPLICATION

h

5.7.3 AGC

The AGC meter displays the amount of boost or cut (attenuation) applied to the

audio in order to maintain a constant level throughout the unit. The THRESH

symbol illuminates when the audio is below the freeze threshold. This means that

the freeze gate is active. In other words, the audio level is so quiet that the AGC will

not respond; this is useful to keep the AGC from trying to bring up the level of what

is perceived as noise. When the audio level comes back up above the freeze

threshold, the AGC will take over and begin controlling the audio level again.

TOOLVOX USERS MANUAL

Note that the output level is in stereo, while the input is mono.

This is because the TrueVerb processing generates a stereo

reverb signal.

5.7.4 Expander

The Expander meter displays the amount of attenuation applied to the audio signal during quiet passages. The THRESH symbol will illuminate when the audio is below the selected threshold and the expander is working to attenuate the noise (thereby expanding the dynamic range of the audio).

5.7.5 Compressor

The Compressor displays the amount of attenuation applied to the audio during louder passages (to compress the dynamic range of the audio signal). The THRESH symbol will illuminate when the audio level is above the selected compressor threshold and the compressor is operating to reduce the level.

5.7.6 De-Esser

The De-esser meter displays the amount of attenuation applied to the audio during periods of sibilance (when the De-Esser Threshold is exceeded). Notice that the attack and release times of the de-esser are much faster than the other control signals because the goal of the de-esser is to only remove sibilants and leave the rest of the audio unchanged.

CHAPTER 5 31

THE REMOTE APPLICATION

TOOLVOX USERS MANUAL

5.8 Advanced network parameters

In a network configuration the two following advanced parameters other than the IP

address need to be set up on the ToolVox:

• Gateway* (also called IP router): this parameter represents the IP address of

the router that allows the ToolVox to be accessed from outside of the local

network.

• Subnet mask*: this parameter depends on the Class type (A, B or C) of the

network, which the ToolVox is connected to.

*To obtain these parameters, see your network administrator.

To set up the Gateway and subnet mask parameters, you need to use the Command

line interface (see chapter 5.2.4) of the remote application by opening OPTIONS

menu and selecting Command Line.

Once the window is opened, use the Edit command window to perform the following

commands:

• setgateway <Gateway address>: (ex: setgateway 192.160.0.145). If the

address is correctly entered, you will see the following message appear in

the Messages window: IP Gateway set to [Gateway address].

• setmask <subnet mask>: (ex: setmask 255.255.255.0). If the number is

correctly entered, you will see the following message appear in the

Messages window: IP network mask set to [Subnet mask].

• netinfo: this command displays a summary of the network settings: IP

address, gateway and subnet mask.

• Setip <IP address>: (ex: setip 192.160.0.123). It is also possible to change

the dedicated IP address of the ToolVox from the remote application.

If you change the dedicated IP address of the ToolVox from

the remote application, be aware that you will loose the current

connection (even if you are connected through the serial port)

and that the ToolVox will reboot automatically.

During the reboot function, be aware that you will loose all the

I/O and preset settings that you changed, unless you have

w

saved them.

CHAPTER 5 32

THE REMOTE APPLICATION

5.9 Security

The ToolVox Remote Application allows you to maintain a degree of security with

regard to who can edit presets, and the degree to which each user can alter the

settings. Use the following list of passwords and security levels when giving access

to users:

Password Access

None None

“noac” Reserved for future use

“susa” User level: View settings, select presets

“corli” Administrator level: alter presets, save

TOOLVOX USERS MANUAL

presets

To change the passwords you must bring up the Command Line window (under the

Options menu). Type in the following command:

>> passwd <oldpassword> <new password> <new password>

The new password is entered twice for your protection.

CHAPTER 5 33

THE REMOTE APPLICATION

TOOLVOX USERS MANUAL

6 The Audio Processing Chain in Detail

The audio processing in the ToolVox is incredibly sophisticated. This chapter will

explain in a high level of detail each of the pieces of the ToolVox processing chain.

This will allow you to have greater control in your attempts to create the “perfect”

sound for your application.

6.1 A Look at Audio Levels in the ToolVox

From the first analog input stage to the final output stage, the ToolVox maintains

several different reference levels that must be understood to fully utilize the different

algorithms in the processing chain. It will also allow you to maintain the highest

audio quality (measured by signal-to-noise ratio and harmonic distortion). The

following diagram illustrates how the peak and reference levels shift through the

different stages of processing.

The analog input section expects a nominal level of 0dBu, with a peak level of

+22dBu. This can be attained by appropriately choosing the analog gain setting in

the Input processing block. The analog limiter in the microphone preamplifier will

limit the input audio to a peak level of +15dBu (the maximum input level of the A/D

converter). The limiter has a “soft knee” and will actually begin applying control

CHAPTER 6 35

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

when the audio level exceeds 0dBu. The amount of control will increase as the audio

level increases.

After the A/D converter, the +15dBu peak level will become 0dBFS (the maximum

audio level that can be represented in the digital domain). The 0dBu analog reference

level will be represented by –15dBFS (referred to as the I/O reference level).

Before the AGC block, the audio level is reduced by 10dB. The ToolVox has an

internal reference level of –25dBFS, which will hereafter be simply referred to as

0dB. All thresholds in the processing chain will be referenced to this level. For

example, setting the AGC Reference level to –5dB, will actually mean –30dBFS.

The reason for the– 25dBFS reference is to maintain adequate headroom for each of

the processing blocks. The noise floor in the DSP is less than –140dB, so this low

reference level will not affect the audio performance.

The AGC will attempt to keep the audio level at 0dB, assuming an AGC reference

level of 0dB.

The internal reference level is changed at the end of the processing chain to more

closely match the I/O reference of –15dBFS. The reference level in the ToolVox

processing chain is much lower than the A/D and D/A reference levels to provide

headroom for processing. The reference correction at the end of the chain will

depend on the Processing Parameters (Preset-based). The output level is adjustable

(for both the analog and digital outputs) to provide the right levels for your particular

installation. This Output Level Adjustment is tied to the ToolVox (independent of

presets).

Keep these levels in mind as you make adjustments to the audio chain; this way you

can avoid clipping the audio at the different stages in the processing.

6.2 The Analog Limiter and Analog Level Control

The ToolVox analog input section has 4 discrete gain settings that can be selected:

0dB, +20dB, +40dB, and +60dB. This allows ToolVox to work with a wide range of

CHAPTER 6 36

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

microphones, and even line levels. Choose a gain setting for your particular

microphone that produces, during normal speech, a level of approximately –10 to

+10dB as viewed on the level meters.

In addition to gain programming in the analog section, there is also a limiter. This

limiter is designed to reduce peak levels on the microphone input in order to

maximize the headroom of the input audio. The limiter will apply a maximum of

7dB of gain reduction when the input audio exceeds the limiter threshold of +15dBu.

The limiter has a “soft knee,” so different amounts of gain reduction will be applied

depending on the audio level. This has the effect of allowing the input to be 7dB

hotter when applied to the A/D converter (in effect adding 7dB of headroom).

The limiter can be removed from the input circuit, although this is not recommended.

To disable the limiter, turn off the ToolVox remove the lid, and set switch SW2 to

position C2.

The following graph illustrates the input/output characteristics of the analog limiter in

the ToolVox.

CHAPTER 6 37

THE AUDIO PROCESSING CHAIN

6.3 The Highpass Filter

The Highpass Filter is designed to reduce rumble, wind noise, and other low

frequency sounds not normally associated with voice-band audio. Use the slide bar

to adjust the cutoff frequency of the filter from 20Hz to 100Hz, depending on the

frequency content of the audio you want eliminated. The filter can be disabled using

the On/Off box.

TOOLVOX USERS MANUAL

6.4 The Phase Rotator

The Phase Rotator can be turned on and off, and the amount of phase rotation (1

being the least, and 5 the most) can be adjusted in the Phase Rotator processing

block.

The Phase Rotator is an all-pass filter (meaning no attenuation of the signal at any

frequency) with a specific phase response designed to eliminate the asymmetry

commonly found in speech. Typical speech waveforms are such that the signal

amplitude is often greater on one side of the amplitude axis than the other. When an

asymmetric signal is clipped, the results are far more unpleasant to the ear than

symmetric clipping. Since clipping is often used in broadcast audio processing, a

phase rotator is a useful tool in a microphone processor.

CHAPTER 6 38

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

The following figures demonstrate the effect of a phase rotator on an asymmetric

audio waveform. The left-hand figures are (in descending order):

1) An asymmetric waveform consisting of the sum of two sine waves of

different amplitude, phase and frequency.

2) One of the sine waves

3) The other sine wave (higher frequency with a phase shift)

In the right column, the resulting signals are shown after the original audio is passed

through the phase rotator. The dotted lines in the top picture indicate a possible clip

threshold; you can see the difference in the symmetry of the clipped audio. The

bottom sine wave has been phase shifted with respect to the upper waveform. The

reason for this is shown below.

CHAPTER 6 39

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

The 3 graphs show the magnitude response, phase response, and group delay of a

phase rotator. The top graph shows that no gain or attenuation of the audio occurs at

any frequency. The third diagram is the most important indicator of the efficacy of a

a phase rotator. The group delay of a filter shows the amount of time delay applied

to different frequency components in a signal. A phase linear filter would show a

constant group delay, meaning no frequency component would be delayed with

respect to another. The phase rotator group delay curve shows that there is a

significant difference in group delay at low frequencies, but a constant delay at

higher frequencies. It is the changing group delay in the lower bands that remove the

asymmetry in audio by time-shifting the audio in those bands.

The 5 level settings affect the frequency at which the group delay curve begins to

level out. The higher the level setting, the higher the frequency where the curve

begins to flatten. In effect, the higher level settings will apply phase rotations to a

larger portion of the audio spectrum. The chosen setting will depend heavily on the

speaker and microphone selection. Generally speaking, the more asymmetric the

audio signal, the higher you should set the phase rotator level.

CHAPTER 6 40

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

6.5 The Automatic Gain Control

The purpose of the Automatic Gain Control in the ToolVox is to maintain a

constant audio level inside the processing chain (refer to the section on Audio Levels

in the ToolVox for details). The AGC can apply gain or attenuation to the audio

depending on the level going into the block, and the threshold (reference level) you

choose.

6.5.1 Manual or Automatic

The first field in the dialog box allows you to set the gain control to Automatic or

Manual. The Manual setting forces a constant gain (or cut) to be applied to the

audio, regardless of the input level. Use the Manual Gain Setting slider at the bottom

of the dialog box to set the amount of gain you want. Using Manual effectively

bypasses all of the settings in the dialog box. Typically, you would use the

Automatic setting, as the amount of gain applied is a function of the input audio and

will more accurately control the audio level in the ToolVox.

6.5.2 Reference

This slider allows you to adjust the target level for the AGC. This is the audio level

that the AGC will attempt to maintain, regardless of the input level. The levels

shown on the slider are relative to the –25dBFS nominal level in the ToolVox. For

example, a reference level setting of -5dB on the slider will cause the AGC to

maintain an audio level of –30dBFS in the processor (-25dBFS + -5dB).

The higher settings will result in louder audio at the expense of headroom; lower

settings maximize headroom (allowing you to boost the audio more in the equalizer)

while bringing the audio level closer to the noise floor.

CHAPTER 6 41

THE AUDIO PROCESSING CHAIN

6.5.3 Attack and Release

The Attack and Release sliders allow you to control how quickly the AGC control

signal will respond to changes in audio level. Move the slider to the left for fast

response (up to 500mS), and to the right for the slowest (20 seconds). These times

refer to the time constant of the filter applied to the control signal. The following

example demonstrates this.

Here, an audio waveform is applied to the AGC. In this example, the numbers are

chosen simply to illustrate the effect of AGC and are not related to the actual

ToolVox levels and time constants. The audio begins with a peak amplitude of 0.5,

but suddenly increases to an amplitude of 1.0, and then drops to an amplitude of 0.25.

The AGC reference level is set to 0.5, the Attack time to 1mS, and the Release time

to 0.5mS. As you can see, when the audio level is exactly at the reference level, there

is no control applied to the audio (control signal = 0dB). But, when the audio level

increases above the threshold of 0.5, the control signal immediately begins to try and

reduce the audio level – finally reaching a stable point of –6dB (one half). The

Attack time controls how quickly the AGC will reduce the gain. When the audio

level drops below the 0.5 reference, the AGC applies a positive control signal to the

audio and brings the level back up – reaching a stable point of +6db. The Release

time controls how quickly the AGC will increase the gain.

TOOLVOX USERS MANUAL

CHAPTER 6 42

THE AUDIO PROCESSING CHAIN

TOOLVOX USERS MANUAL

AGC Control (Attack = 1.0mS, Release = 0.5mS)

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

Signal Amplitude

-0.6

-0.8

-1

Original Audio

Control Signal (dB)

0.006 0.012

Time (S)

8

6

4

2

0

-2

Control Signal (dB)

-4

-6

-8

Fast Attack and Release times can be useful for creating a very uniform output level,

but may cause an unpleasant “sea-sickness” effect on the listener, as the level is

constantly riding up and down. The slower time constants will reduce the audible

artifacts of the AGC, but will obviously do less to keep the level uniformly constant.

6.5.4 The Freeze Gate

One of the inherent problems with a typical AGC is that when the audio level drops

very low (during pauses or periods of silence), the AGC will increase the gain to its

maximum. When the audio resumes, the huge boost will cause the audio to be

incredibly loud, and often clipped. For this reason, the ToolVox includes a Freeze

Gate as part of the AGC section. The Freeze Gate, during periods of low level, will

cause the AGC to hold the control signal level until the input audio exceeds the gate

threshold. This gate threshold is set by the Freeze Gate slider (from –28dB to

+10dB).

A high freeze threshold is good for speakers who maintain a constant level, but for

dynamic speakers, a high threshold will not adequately boost the level during quiet

speech periods. A low threshold is much better in that case, because it will not

CHAPTER 6 43

THE AUDIO PROCESSING CHAIN

disturb the normal speech, but will still prevent the AGC from boosting the noise

floor, and then distorting the normal audio.

6.6 The Three Equalizers

TOOLVOX USERS MANUAL

There are three filters that can be activated to equalize the audio. Each filter has a