Page 1

Omnia.Multicast

Audio Processor/Codec Provisioner

Installation and Operation Manual

Version 2.1a / April 2006

v3.04.04 Release Software and Higher

A Telos Company

Omnia ● 2101 Superior Avenue Cleveland, Ohio 44114 USA

TEL: +1 216.241.7225 ● FAX: +1 216.241.4103 ● Email:

Omnia Europe ● Johannistraβe 6 D-85354 Freising Germany

TEL: +49 8161 42467 ● FAX +49 8161 42402 ● Email: europe@omniaaudio.com www.omniaaudio.com

info@omniaaudio.com www.omniaaudio.com

Page 2

GREETINGS!

Welcome to our latest offering, Omnia.Multicast. The heritage of this processor is based upon the growth

of codec based transmission systems. The emergence of Multicast as part of the HD Radio

with the bevy of additional coded services has created a demand for a processor of this type.

Omnia.Multicast defines a new category of processor, one that provides dynamics control and provisions

the signal for use with a codec.

Just about every medium now employs some form of coded audio. Therefore it’s vitally important to

provision the codec properly to ensure that the best audio quality possible traverses through the system. In

many ways, this is not much different than conventional transmission processing, as those devices are

designed specifically for their specific mediums. The same applies here, except Omnia.Multicast explores a

new realm of signal conditioning as it utilizes Sensus Technology. This innovative new tech, developed by

Omnia engineers, takes audio processing to another level, as our crew found another way to raise the

bar…yet again!

Omnia.Multicast is a fully digital system for all forms of digital radio, internet webcasters, podcasters,

cellcasters and whatever other form of encoded audio “casters” are out there. It is optimized for the unique

demands of encoded audio. A simple design, no not really. Simple to use…YES!

Omnia.Multicast’s flexibility is built-into the design. Instead of keeping the processing algorithms on a set

of EPROMs or proprietary potted modules, the system’s DSP (Digital Signal Processing) resources are

entirely configured through software contained on a plug-in PC Card (PCMCIA-type). Even fundamental

rearrangements of the system architecture can be easily accomplished in the field by plugging in a new PC

card or, by using the free downloadable Windows-based remote control application, through local serial

RS-232 connection or remotely through the optional plug-in modem card or optional Ethernet network

interface.

Omnia.Multicast, continuing the promise of digital…delivered.

Here’s to another step in a new frontier,

R

system, along

Frank Foti

Page 3

SAFETY INSTRUCTIONS

1. Read All Instructions. All safety and

operating instructions must be read before operating

the product.

2. Retain All Instructions. All safety and

operating instructions must be retained for future

reference.

3. Heed All Warnings. All warnings on the

product and those listed in the operating instructions

must be adhered to.

4. Follow All Instructions. All operating and

product usage instructions must be followed.

5. Heat. This product must be situated away

from any heat sources such as radiators, heat registers,

stoves, or other products (including power amplifiers)

that produce heat.

6. Ventilation. Slots and openings in the

product are provided for ventilation. They ensure

reliable operation of the product, keeping it from

overheating. These openings must not be blocked nor

covered during operation. This product should not be

placed into a rack unless proper ventilation is provided

through following the manufacturer’s recommended

installation procedures.

7. Water and Moisture. Do not use this

product near water—for example; near a bath tub,

wash bowl, kitchen sink or laundry tub; in a wet

basement; or near a swimming pool or the like.

8. Attachments. Do not use any attachments

not recommended by the product manufacturer as they

may cause hazards.

9. Power Sources. This product must be

operated from the type of power source indicated on

the marking label and in the installation instructions. If

you are not sure of the type of power supplied to your

facility, consult your local power company.

10. Grounding and Polarization. This product is

equipped with a polarized AC plug with integral safety

ground pin. Do not defeat the safety ground in any

manner.

11. Power Cord Protection. Power supply cords

must be routed so that they are not likely to be walked

on nor pinched by items placed upon or against them.

Pay particular attention to the cords at AC wall plugs

and convenience receptacles, and at the point where

the cord plugs into the product.

12. Lightning. For added protection for this

product during a lightning storm, or when it is left

unattended and unused for long periods of time,

unplug it from the AC wall outlet. This will prevent

damage to the product due to lightning and power line

surges.

13. Overloading. Do not overload AC wall

outlets, extension cords, or integral convenience

outlets as this can result in a fire or electric shock

hazard.

14. Object and Liquid Entry. Never push

objects of any kind into this product through openings

as they may touch dangerous voltage points or shortout parts that could result in a fire or electric shock.

Never spill liquid of any kind on the product.

15. Accessories. Do not place this product on

an unstable cart, stand, tripod, bracket, or table. The

product may fall, causing serious damage to a child or

adult, and serious damage to the product. Any

mounting of the product needs to follow

manufacturer’s installation instructions.

16. A Product and Cart Combination should be

moved with care. Quick stops, excessive force, and

uneven surfaces may cause the product and the cart

combination to overturn.

17. Servicing. Refer all servicing to qualified

servicing personnel.

18. Damage Requiring Service. Unplug this

product from the wall AC outlet and refer servicing to

qualified service personnel under the following

conditions:

a. When the AC cord or plug is damaged.

b. If liquid has been spilled or objects have

fallen into the product.

c. If the product has been exposed to rain or

water.

d. If the product does not operate normally

(following operating instructions).

e. If the product has been dropped or damaged

in any way.

f. When the product exhibits a distinct change

in performance. This indicates a need for

service.

19. Replacement Parts. When replacement parts

are required, be sure the service technician has used

replacement parts specified by the manufacturer or

that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric

shock, or other hazards.

20. Safety Check. Upon completion of any

repairs to this product, ask the service technician to

perform safety checks to determine that the product is

in proper operating condition.

21. Cleaning. Do not use liquid cleaners or

aerosol cleaners. Use only a damp cloth for cleaning.

Page 4

HAZARD / WARNING LABELS

The Exclamation Point

symbol, within an

equilateral triangle, alerts

the user to the presence

of important operating

and maintenance

(servicing) instructions in

product literature and

instruction manuals. manuals.

The Lightning Flash With

Arrowhead symbol, within an

equilateral triangle, alerts the

user to the presence of

uninsulated dangerous voltage

within the product's enclosure

that may be of sufficient

magnitude to constitute a risk

of electric shock.

4

Page 5

WARNING -- This equipment generates, uses, and can radiate radio frequency energy. If not installed

and used in accordance with the instructions in this manual it may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A computing device

(pursuant to subpart J of Part 15 FCC Rules), designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference, at which case, the user, at his own expense, will be required to take

whatever measures may be required to correct the interference.

See the following page for additional information.

CANADA WARNING – This digital apparatus does not exceed the Class A limits for radio noise

emissions set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectri ques depassant les limits applicables aux

brouillage radioelectrique edicte par le ministere des Communications de Can ada.

CE CONFORMANCE – This device complies with the requirements of the EEC Council Directives:

93/68/EEC (CE Marking); 73/23/EEC (Safety – low voltage directive); 89/336/EEC (electromagnetic

compatibility). Conformity is declared to those standards: EN50081-1, EN50082-1.

LITHIUM BATTERY CAUTION -- Danger of explosion if the internal battery is replaced

incorrectly. Replace only with same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer's instructions.

USE OF SHIELDED CABLING -- To conform to the CE requirements for High Frequency

radiation, shielded cables must be used for all audio and data connections. For analog and

digital connections, the cable shield MUST be connected to the XLR-type connector shell,

which is at chassis ground potential!

5

Page 6

Manual Update Notification

Due to the dynamic nature of audio processing products, this manual and all future manuals, will

be considered as 'preliminary documentation'.

Audio Processing is an art form that we take very seriously. As part of our dedication to this

science, we will continue to update both the product and its documentation based on continued

research, field experience and valued customer input.

We strongly encourage our customers to visit our Omnia website for product enhancement

announcements, software updates, manual updates, and customer care bulletins.

The following URL listing has been included for your update convenience:

Manual Updates

http://www.omniaaudio.com/support/manuals.htm

Installation Tips

Tech Bulletins and Papers

Tech Support – Software Upgrades

http://www.omniaaudio.com/tech/tips.htm

http://www.omniaaudio.com/tech/

http://www.omniaaudio.com/support/updates.htm

Thank you for selecting the incredible Omnia.Multicast Audio Processor. Your continued

patronage and support are appreciated.

Sincerely,

Team Omnia

6

Page 7

SPECIFICATIONS

Note: All measurements made with the supplied “No Process” preset, which is available in the Preset Submenu.

System

Signal to Noise: The measured noise floor will depend upon the settings of the Input and

Output Gain controls. The Omnia’s noise floor is primarily governed by

the dynamic range of the 24-bit Crystal Semiconductor CS5360 A/D Converter,

which has a specified Dynamic Range of 105 dB. The dynamic range of

the Omnia.Multicast digital signal processing chain is 144 dB. Typical SNR using

the “No Process” preset is greater than –80dB referenced to 100%

modulation.

Distortion: No greater than 0.01% THD 20 Hz -- 20 kHz bandwidth.

Analog I/O

Analog Audio Input: Configuration: Left/Right Discrete Stereo. Electronically balanced, floating and

symmetrical.

Input impedance: 10k ohms resistive, electronically balanced.

Maximum Input Level: +24 dBu.

Nominal Input Level: +4 dBu when the Input Level Control is set to 0.0 dB.

A/D Conversion: Crystal Semiconductor CS5360/5361, 24 bit 128x over-sampled delta sigma

converter with linear-phase anti-aliasing filter. Pre-ADC anti-alias filter,

with high-pass filter at <10 Hz.

Connectors: Two EMI-suppressed XLR female. Pin 1 chassis ground, and Pin 2 is “hot”.

Analog Audio Output: Configuration: Left/Right Discrete Stereo. Electronically balanced,

Source Impedance: 20 ohms, electronically balanced and floating.

Load Impedance: 600 ohms or greater, balanced or unbalanced.

Output Level (100% peak modulation): Adjustable from -2 dBu to +22

dBu peak, into 600 ohms or greater load, software-adjustable.

D/A Conversion: Crystal Semiconductor CS4390/4391 24 bit, 128x over-sampled.

Connectors: Two, EMI-suppressed XLR-male. Pin 1 chassis ground, Pin 2 “Hot”.

Digital I/O

Digital Audio Input: Configuration: Stereo per AES/EBU standard, CS8420 Digital Audio

Transceiver with 24 bit resolution, software selection of stereo, mono

from left, mono from right or mono from sum. Automatically accepts

and locks to input sample rates between 32kHz and 50kHz.

Connector: XLR-female, EMI-suppressed. Pin 1 chassis ground, pins 2 and 3

transformer isolated, balanced, and floating – AES3 standard 110 ohm

impedance.

7

Page 8

Digital Audio Output: Stereo per AES3 standard.

Output sample rate automatically synchronizes to external reference input with

fallback to 48kHz.

Connector: XLR-male, EMI-suppressed. Pin 1 chassis ground, pins 2

and 3 transformer isolated, balanced, and floating. Standard AES3

specified 110 ohm source impedance.

Digital Output Level: -22.0 to 0.0 dBFS software adjustable.

Remote Control

Remote Control

Methods: Configuration: Modem, Direct Serial, or 10/100BaseTX Ethernet.

Modem: Optional PCMCIA modem with pop-out X-jack connector or any

Hayes command set compatible external modem.

Direct Serial: Standard RS-232, no hardware handshaking employed.

Baud rates of 9,600, 19,200, and 57,600 supported.

TCP/IP Ethernet: Optional interface emulates a telnet session on port 23.

Connectors: RS-232 port, EMI-suppressed DB-25 female connector.

Industry standard EMI suppressed RJ-45 connector for Ethernet.

Remote Interface: Configuration: Eight (8) inputs, RS-232 level-compatible.

Software sensing of both 'go-high' and 'go-low' transitions.

Inputs are protected to +/- 15 VDC.

Connector: EMI suppressed DE-9 male.

Control: User-programmable using built-in Trigger Script feature in

Omnia.Multicast Remote Control software. Virtually any parameter of

Omnia may be programmed to change through this interface feature.

General

Power Requirements: Voltage: 100-250 VAC, 50/60/440 Hz., < 55VA

Connector: EMI suppressed IEC male. Detachable 3-wire power cords supplied

for US and European use.

Internal Power Supply: Overvoltage and short circuit protected. Meets EN55022, EN55011

Level B Conducted Emissions. EN61000-4-2, -3, -4, -5, -6 level 3

immunity compliant. Full international safety approval. CE marked.

Environmental: Operating Temperature: 32 to 122 degrees F / 0 degrees to 50 degrees C

for all operating voltage ranges.

Humidity: 0-95% RH, non-condensing.

Dimensions: 19” wide x 3.5” high x 16.25” deep (48.3cm wide x 8.9 cm high x

41.3 cm deep) including connectors. Unit requires two EIA rack

spaces for proper mounting.

Shipping Weight: 26 lbs. / 11.8 kg

Telos/Omnia Research and Development is constantly working to improve the quality of our products.

Actual specifications are subject to change or improvement without notice.

8

Page 9

Table of Contents

HAZARD / WARNING LABELS 4

Manual Update Notification 6

SPECIFICATIONS 7

Quick-Start Setup Guide 10

Chapter 1: Installation 13

Pre-Installation Tasks.............................13

Installation & Connections ....................15

Powering Up ..........................................18

Chapter 2: The User Interface 19

Using the Jog Wheel ..............................19

Main Menu Orientation..........................20

User Interface Tutorial...........................20

User Interface Concepts.........................22

Bargraph Display Metering Screens ......23

Menu Descriptions.................................24

Chapter 3: Processing Overview 29

Omnia.Multicast and Audio Processing 29

Chapter 4: Omnia.Multicast 31

Omnia.Multicast Connections................31

Processing Worksheet 34

Chapter 5: Editing Presets 34

Preset Editing Overview ........................34

The Processing Display..........................35

Parameter Editing...................................36

Saving, Renaming and Deleting Presets 39

Getting The Sound You Want................40

Chapter 6: Remote Control 44

Software Installation ..............................44

Setting Up and Configuring Omnia

Remote Control

Using the Remote Control .....................51

Using a Terminal Program and Direct

Connection

Trigger Interface and Script Editor........53

Chapter 7: Troubleshooting 60

Omnia Messages ....................................61

Diagnostic and Error Messages 64

Electrical and mechanical safety note! ..63

Narrowing down problems ....................64

Obtaining Service...................................65

WARRANTY 66

.............................................52

......................................45

9

Page 10

.

.Multicast

x3

Sensus Technology: Audio Processing

Overview

Digital audio processing, thus far, has been a numeric replication of tried-n-true analog methods. Sure, progress

was achieved as DSP made it possible to accomplish better algorithms that were either too difficult or expensive

in analog. Still, digital audio processors have not yet migrated from the same conceptual dimension that

dynamics processing has known…until now!

Sensus technology takes dynamics processing into a new realm. Instead of two-dimensional static architecture

and functionality, Sensus adds a third domain where it modifies processing algorithms, architecture, and

functions based upon conditions that are understood by the system. Simply stated, Sensus has the ability to

sense what must be done to a signal, and then “rearrange the furniture” to accomplish its goal. There are

numerous derivatives to this innovative tech, and it can be scaled to many different applications. Following is a

discussion of how this method is applied to a processor used in a coded audio environment.

Codec Provisioning

The codec is now a way of life in the world of audio and broadcasting. Digital broadcasting (HDTV, HD-

R

, DAB, DRM), podcasting, webcasting, cellcasting, and downloadable music files all employ some form

Radio

of codec. This presents a huge challenge to an audio processor. Traditional dynamics processors are designed to

fulfill the requirements of a medium where the functions are static, such as precision peak control and

bandwidth limiting for broadcasting, or the normalization needed for recording and mastering. Each of these

functions is a known static entity. They are singular, one-dimensional functions where the target is known and

the audio processor is designed to accommodate this.

The audio codec, on the other hand, is a moving target. No two codecs are alike, or sound the same. They vary

in sonic quality based upon bitrate…AND…more importantly they vary within the same architecture based

upon audio content! Here is where conventional audio processors fall short when used in a coding environment

and the Sensus tech comes into play.

Until now, dynamics processing has been able to address some of the hurdles and artifacts generated by audio

coding. The codec has the ability to adapt and modify its algorithm internally, in order to provide maximum

throughput, and this alters the sonic artifacts created by the coding process. Unless an audio processor can do

the same, it will hit and miss regarding how well it provisions the audio to avoid artifacts. Sometimes coded

audio sounds acceptable, and sometimes it doesn’t. Conventional processors play games with HF limiters and

static low pass filtering to minimize coding anomalies. In order to condition audio in hopes of artifact

avoidance, the processing will over-compensate audio bandwidth and dynamics. The result is dull, lifeless

sounding audio that still contains audible gremlins.

10

Page 11

Omnia.Multicast

The advent of HD RadioR has introduced the capability to broadcast multiple content streams within the 96kbps

digital channel. To facilitate multicast requires the use of lower bitrate audio coding. The broadcaster can

choose the bitrate for each content channel, as well as the number of desired channels, with a maximum limit of

seven. Therefore it is possible that extremely low bitrate audio channels will exist, and those will require

dynamics processing capable of consistent sound quality that yields low, or no sonic artifacts.

Omnia.Multicast is a processor designed for coded audio, especially low bitrate signals. An innovative codec

provisioning algorithm, using Sensus Technology, yields consistent audio quality that contains little, if any,

coding artifacts. Yet, audio quality does not suffer the dull or muffled quality due to extreme bandwidth

reduction that would normally be employed to mask codec “nasties.”

The Sensus algorithm detects troublesome content for a codec, modifies the processor’s architecture, and then

makes the appropriate changes. These could be dynamics control, bandwidth adjustment, a combination of both,

or the elimination of an unnecessary function. The result is consistent quality through the coded transmission

system, even at low bitrates; i.e. 18kbps – 21kbps. Voice by example, especially without any other

accompaniment, is very difficult to code at low bitrates without the quality and intelligibility suffering.

Omnia.Multicast generates clean, smooth, intelligible, and clear audio that is consistent sounding no matter

what the content is.

11

Page 12

Omnia.Multicast Quick-Start Setup Guide

g

We know that you're probably in a hurry to get on the air with your new Omnia.Multicast. If you have technical

expertise and previous knowledge of audio processor fundamentals, using the following Eight-Point Quick-Start

procedure will get you up and running as quickly as possible. Please refer to the remainder of the Operating

Guide for additional information.

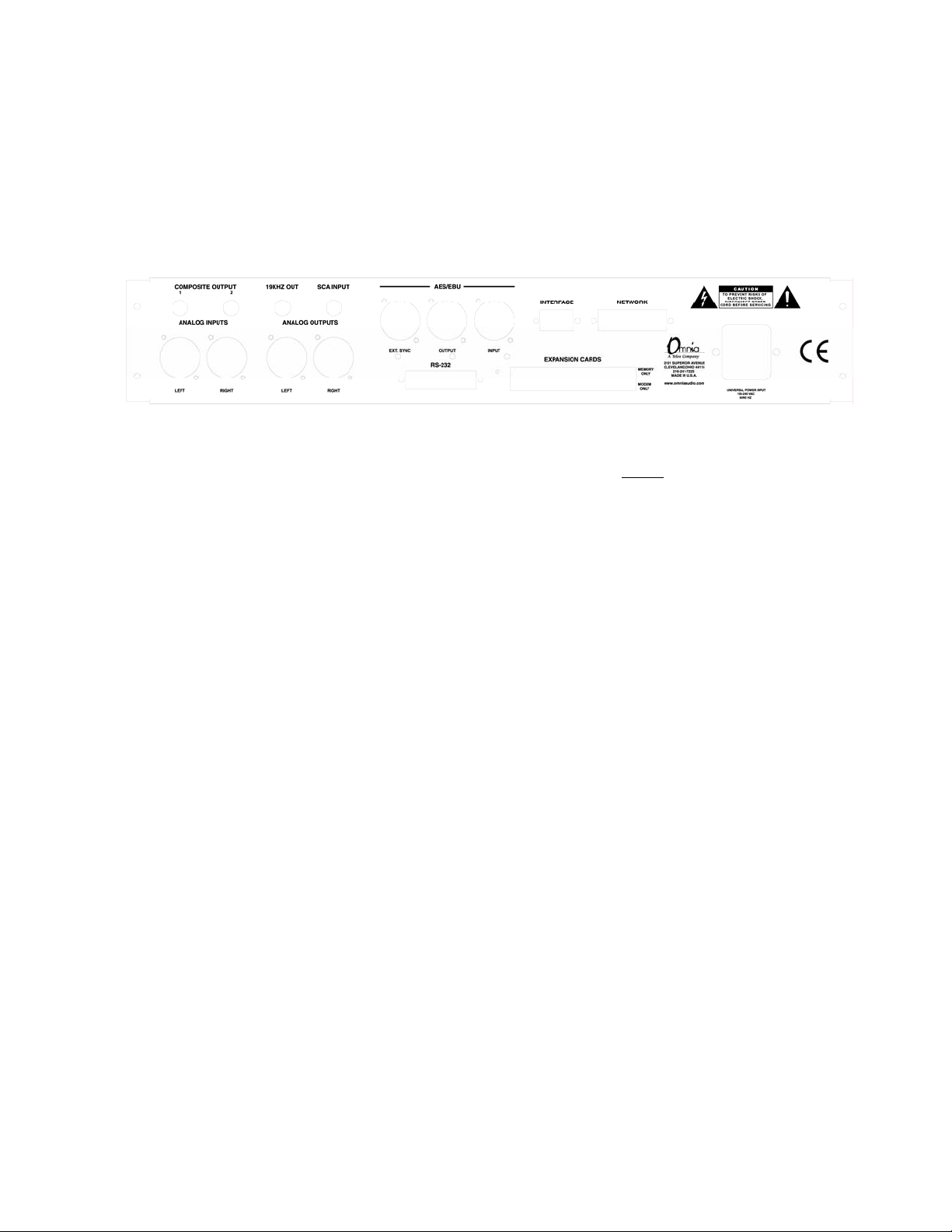

Refer to the following drawing for the location of the various connectors associated with the installation:

Omnia.Multicast Rear Panel View

1. Insert the supplied PCMCIA memory card into the top card slot on the rear panel with the large Omnia label

facing up and the version number sticker facing down. DO NOT FORCE!

until the black release button, to the right of the card, pops out about ½” [12.70 mm]. This indicates that the

card is properly inserted in the PCMCIA slot.

2. Install the Omnia.Multicast in the equipment rack using at least two rack screws. If only two screws are

used, they MUST be in the bottom holes of the rack ears!

3. Connect AC power to the unit, and turn on power using the rear-panel power switch.

4. Connect the audio inputs that are appropriate for your installation and provide normal program audio to the

Omnia.Multicast.

5. Navigate to the Input & Output menu by rotating the jog-wheel until Input & Output is highlighted and

then “click” (push in on the jog-wheel) to enter that menu. Navigate to Input Source, click, and select either

the Analog or AES/EBU input. Press the front panel push-button once to switch to the metering screen. If your

audio source is providing an audio feed you should see meter activity on the I/O and Process meters. Rotating

the jog-wheel switches between the I/O and Process bargraph screens. Turn it left for the I/O meters and right

for the Processing gain-reduction bargraphs.

6. Turn the Jog-Wheel to the left to display the I/O metering screen. Observe the input meters (L In and R In)

and adjust the controls in the Input Levels menu until the input meters are peaking up to about -15dB (or a little

higher) with normal program audio. Each press of the front panel push-button will switch between the selected

metering screen and the menu screen where the input level controls are.

7. Connect the audio outputs that are appropriate for your installation. For use in an HD Radio

“EXT SYNC” connector must be provided with an AES-11 (DARS/”AES black”) reference signal at a 44.1kHz

rate that is synchronous to the HD exciter 10MHz master clock. This may be obtained from the exciter directly,

or from an auxiliary GPS receiver.

NOTE: When a 44.1 kHz di

be present on the External Sync input jack or the output sample rate will be 48 kHz.

8. If you are using the Analog or Digital XLR audio outputs, navigate to the Input & Output Menu and adjust

the controls in the Output Levels menu to the correct peak level for the equipment that follows the

Omnia.Multicast.

You’re now ready to go!

ital output sample rate is needed, an external 44.1 kHz AES/EBU signal must

Gently press the card into the slot

R

system, the

12

Page 13

Chapter 1: Installation

Even though we believe the Omnia.Multicast is the easiest processor to install in its class, please take a few

minutes to read through this chapter before proceeding with the installation.

Pre-Installation Tasks

This section offers common procedures for installing Omnia.Multicast.

Omnia.Multicast Components

By now, you’ve unpacked the shipping carton to at least gain access to this manual. Be sure to inspect the

Omnia.Multicast and shipping carton for any shipping damage, which must be reported to your carrier for any

claims.

The Omnia.Multicast shipping box includes the following components:

• Omnia.Multicast processor (containing the DSP hardware)

• Omnia.Multicast PCMCIA card (holding the DSP software)

• Omnia.Multicast Operating Manual

• Warranty Registration Card (fill it out and fax it or return it)

• IEC Power Cord

PC Card and Optional Modem Installation

Before installing your Omnia.Multicast, or even plugging in the power cord, make sure the Omnia.Multicast PC

Memory Card and optional Modem Card (if ordered) are installed into the correct card slots on the back panel

and are fully seated. Installation or removal of cards must be done with the power off unless directed otherwise.

The PC Memory Card is inserted into the top card slot with the larger Omnia label facing up, and the version

sticker facing down. The optional Modem Card is inserted into the bottom card slot below the Omnia PC Card.

Both the PC Card and the Modem Card are keyed to prevent improper insertion. DO NOT FORCE!

press the cards into the slots until the black release button, to the right of the card, pops out about 1/2" [12.70

mm]. This indicates the card is properly seated in the PCMCIA slot.

Gently

13

Page 14

Important Note 1: The PC Card used in the Omnia.Multicast is not a generic PCMCIA cards that can be

bought in any local computer store. They are cards that are specified by Omnia specifically for this product. If

you need a backup card, please contact Omnia Customer Support to purchase an additional card. Inserting a

card of unknown origin risks damaging the Omnia or the cards, and doing so will void your warranty!

Important Note 2: If you wish to operate the Omnia.Multicast using a PCMCIA type modem, you must use the

optional modem card from Omnia. No other modem cards are approved for use at this time. We cannot assume

correct operation of any other modem card, nor can we provide support for it. Typically any external Hayes

compatible modem may be connected to the rear-panel serial port. See chapter 6 for more details on the Modem

and the Remote Control Software.

Note: The rear panel PCMCIA Memory Card must remain in the top slot unless you are prompted by the

system to remove it. Randomly removing the PC Card without system instruction may cause unpredictable

operation and PC Card data damage.

AC Environment

Since the Omnia.Multicast is microcomputer-based, it requires the same clean AC environment as any computer

system. Even though the unit has internal AC input transient suppression, we recommend that transient

suppressors/voltage regulation or an Uninterruptible Power Supply (UPS) be employed as well. This is

especially recommended when installing the processor at a transmitter site. (As is proper grounding) Heavy

transient demands on power lines, from normal switching to lightning strikes, have been known to wreak havoc

with data in computer systems. This is another reason we ask that you give your AC environment thorough

consideration before plugging in your unit. For more information on surge suppression and proper grounding

techniques, please see the tech-talk paper “The Ins and Outs of Surge Suppression” on the Telos website here:

http://www.telos-systems.com/techtalk/surge.htm

14

Page 15

Installation & Connections

Throughout this section reference is made to “software parameters.” These are part of the User Interface, which

is covered in Chapter 2.

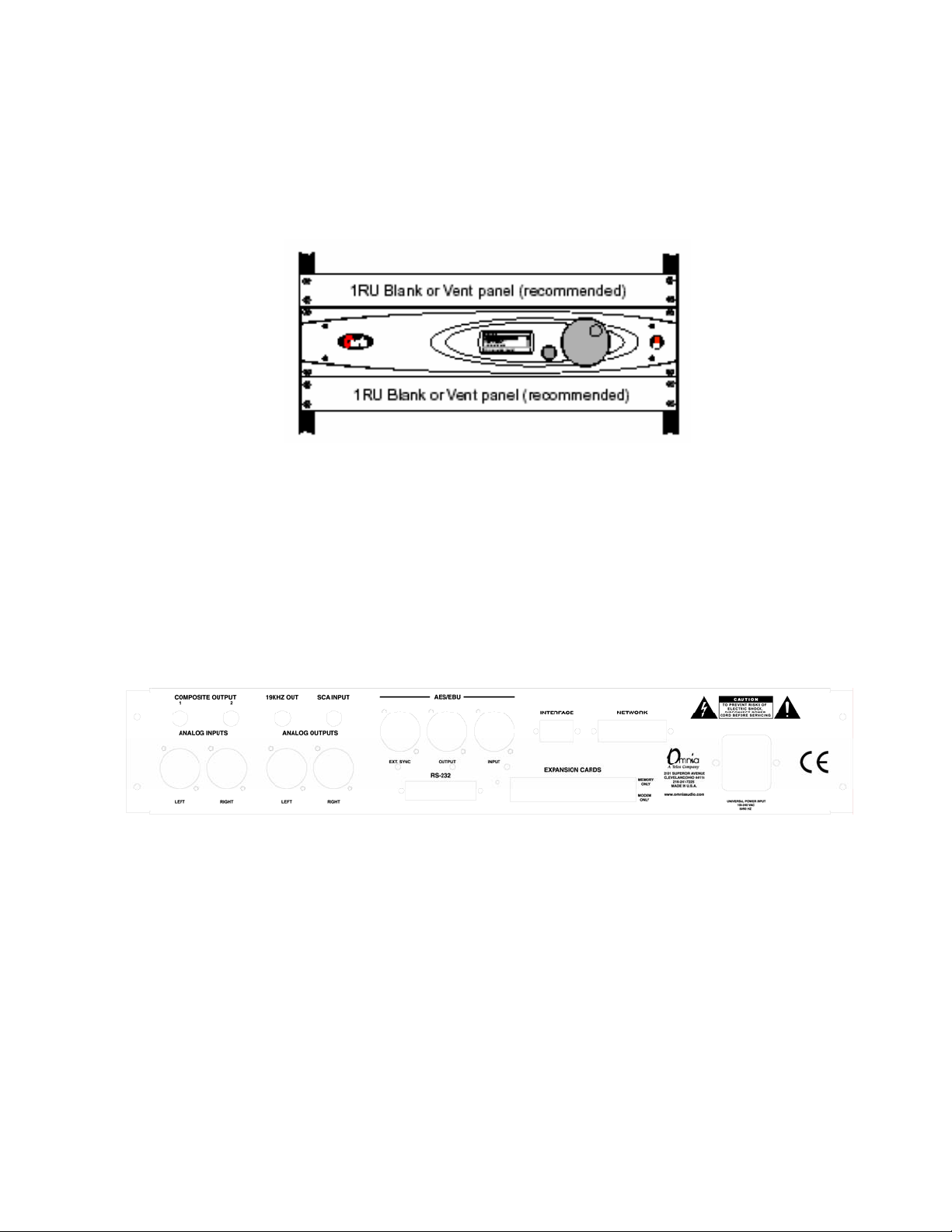

Omnia.Multicast Rack Mounting Requirements

Rack Mounting

The Omnia.Multicast requires 2RU (3.50" [89 mm]) of rack space. Rack mount the unit using four rack screws.

It is preferred to leave at least one rack unit of empty space above the Omnia.Multicast to enhance ventilation

and to prolong component life. Install a 1RU (1.75") vented or solid panel to fill this space. It is recommended

that another 1RU blank panel be installed below the unit for the same reason, if rack space is not at a premium.

Rear Panel Connections

Omnia.Multicast Back Panel Connections

AC Connection (IEC)

The Omnia.Multicast uses a universal power entry module with integral AC switch just above the IEC power

cord receptacle. It can operate on AC mains voltages from 100 to 240 VAC, 50/60 Hz since a self-adjusting

switching power supply is used. In the USA, plug the supplied AC power cord into the unit and then into an

isolated ground AC outlet. Outside of the USA you must obtain an appropriate local IEC power cord.

Audio Inputs (Female XLR)

Balanced XLR-type connectors are used to input both analog and AES-3 digital audio. Even though both analog

and digital cables can be connected, only one input can be set active. Input selection is done through the Input

Source software parameter in the Input & Output menu. The Analog input is the factory default selection.

The stereo analog inputs are designed for standard +4 dBu balanced signals. The digital AES-3 input accepts

any sampling rate between 32kHz and 50kHz. No user adjustment is necessary since a sample rate converter is

built into the unit. Individual channel gain and level setting for both analog and digital is done using the Input

& Output menu’s software parameter settings.

15

Page 16

A Note About Relative Phase: If the relative phase of your installation including the Omnia.Multicast differs

from your existing system, it could cause your announcers to feel they sound “weird” in their headphones. If

this happens, then the relative phase of the processor is 180 degrees from what your talent are used to. To

remedy this, you can reverse the polarity to both of the two analog inputs (is pin 2 or pin 3 hot!?), but it’s a lot

easier to accomplish this function by changing the Input Phase software parameter setting located under Input

Levels in the Input & Output menu.

Discrete Audio Outputs—Analog & Digital (Male XLR)

Individual Left and Right analog outputs are available on two male XLR jacks, as is a single stereo AES-3

output. The digital output is produced directly from the output of the final processing section. The sample rate

automatically synchronizes to any reference rate between 32kHz and 48kHz that is provided on the “EXT

SYNC” input in AES-11 (DARS / “AES black”) format. The sample rate will fall back to an internally

generated 48kHz if external sync is lost. In an HD Radio

R

system, this will make the loss of sync with the

exciter immediately and noticeably audible. The analog output is derived from a D/A converter driven from the

digital output.

Note: Both the analog and digital AES-3 outputs are always active and can be used simultaneously.

Digital Audio EXT Sync Input (Female XLR)

This input accepts an AES-11 (DARS / “AES black”) sample rate reference signal (if an AES-11 signal is not

available, ordinary AES-3 digital audio works as well, however careful layout of digital audio timing signals is

always recommended). The digital audio output will automatically lock to any valid sample rate between

32kHz and 48kHz when it is provided via this connector. If no valid signal is available, the output sample rate

will fall back to an internally generated 48kHz.

RS-232 Connection (DB-25F)

This connector serves two important purposes: It can be used for a local, bi-directional computer connection

with Omnia.Multicast Remote Control, or it can be used for troubleshooting and error code resolution. In the

former case, Omnia.Multicast Remote Control software is utilized. In the latter, any terminal emulation program

can be used. In either case, you must use a standard, straight-through serial cable (not a null modem cable)

between the RS-232 connector and the serial port connector on the computer. Typically, a DB25 male to DB-9

or DB-25 female cable will be used, with the DB-25 male end of the cable attached to the Omnia.Multicast.

The Remote Control application is available as a free download from the

covered in detail in Chapter 6.

www.omniaaudio.com website and is

16

Page 17

Interface Connection (DB-9M)

The 9-pin male Interface connector uses eight pins as “trigger” inputs with the ninth pin as the ground

reference. The trigger inputs can be used to dynamically alter the Omnia.Multicast’s operational attributes in

response to logic signal transitions. The Omnia.Multicast responds uniquely on each trigger input to both go-

high and go-low transitions. With eight inputs, and two possible triggers (logic go-high and go-low), sixteen

unique “trigger scripts” can be written (using the Omnia.Multicast Remote software) to control the

Omnia.Multicast in response to these trigger input logic transitions. The Trigger Script Interface Editor is

covered in detail in Chapter 6.

The Pinout of the Omnia.Multicast rear-panel DB-9 Interface connector is as follows:

PIN 1 activates Trigger Script 1 PIN 6 activates Trigger Script 2

PIN 2 activates Trigger Script 3 PIN 7 activates Trigger Script 4

PIN 3 activates Trigger Script 8 PIN 8 activates Trigger Script 7

PIN 4 activates Trigger Script 6 PIN 9 activates Trigger Script 5

PIN 5 is connected to ground

Ethernet Connection (Optional)

The Remote Control link for your Omnia.Multicast over 10BaseT and 100BaseT networks can be utilized if the

Ethernet Interface hardware option is installed. (Part # 2091-00013) Installation instructions are provided with

the hardware. The setup and operation of the Remote Control software application is covered in detail in

Chapter 6.

17

Page 18

Powering Up

Press the “I” side of the rear panel power switch to turn on the unit. The processor is designed to be turned on

and left on. Press the “O” side of the switch to turn off the unit for servicing.

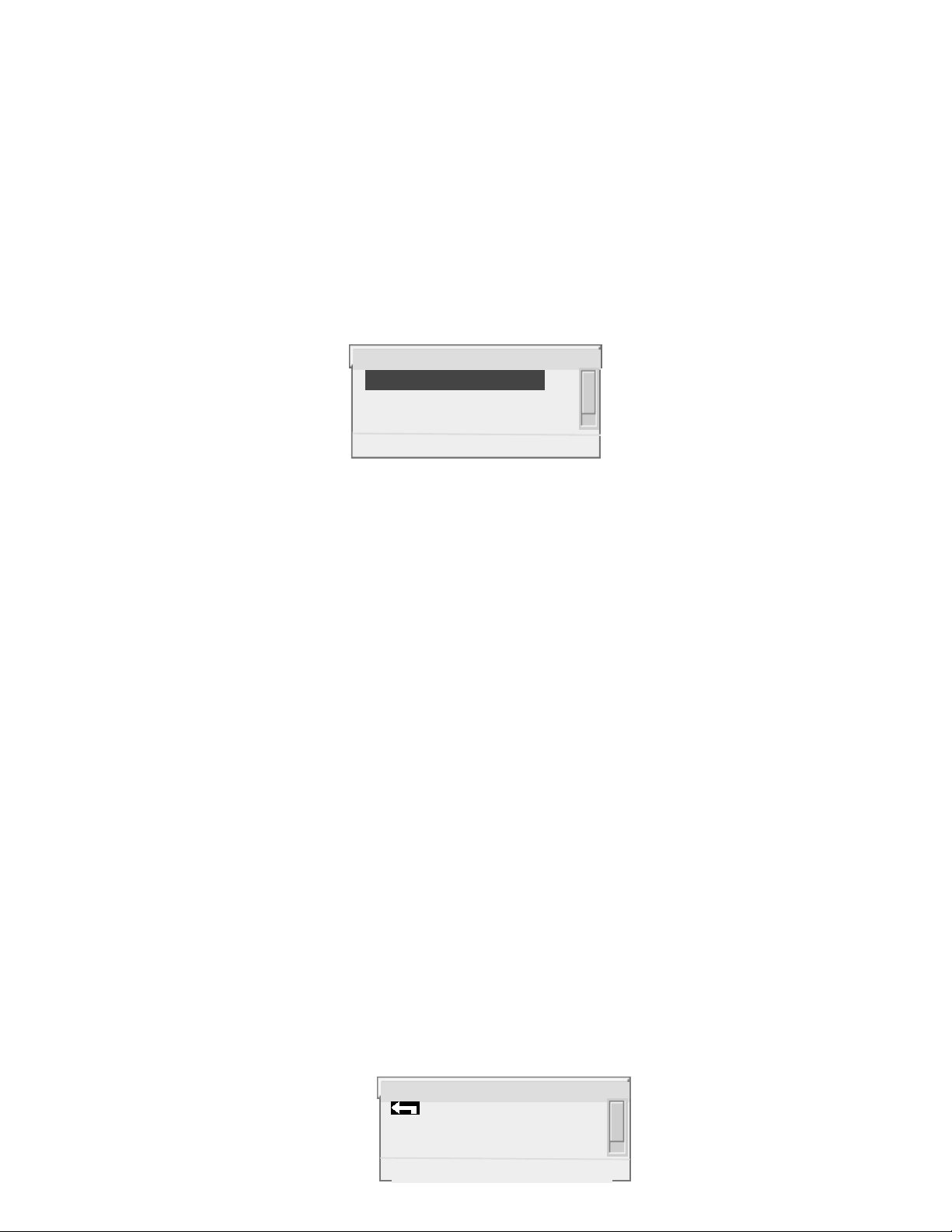

When the Omnia.Multicast is first turned on, there is a few seconds of delay as the system starts up. An

operating system start up screen is displayed. Under normal conditions it should appear as:

Load Algorithm...

After approximately ten seconds, audio will be present from the analog outputs. The AES/EBU output also

becomes usable at this time. However, full initialization of the software is not complete for several more

seconds. After a few seconds, the Main Menu display will appear:

OMNIA.Multicast

Audio Processing

Input/ Output

Display

Preset: 64kbAACSBR

At this point, the Omnia.Multicast is fully operational. The next chapter covers operation through the front-

panel user interface.

18

Page 19

Chapter 2: The User Interface

A

Now that your Omnia.Multicast is rack-mounted, connected to a program audio source, and turned on, you’re

ready to learn how to operate it! This chapter covers the Graphical User Interface, your window into the

Omnia.Multicast processor.

The user interface consists of a front panel-mounted jog-wheel with push-switch, a push-button and an LCD

screen. The LCD screen displays menus, parameter settings and bargraphs (Level Meters and Processing

activity). The push-button toggles between the two display modes: the menus/parameters mode and the

bargraph mode. The menus are used during initial setup and for adjusting the processing parameters. In normal

day-to-day operation, one of the bargraphs is typically displayed to dynamically indicate the real-time signal

processing.

udio Processing

Input/Output

Display

Using the Jog Wheel

The main user control for the Omnia.Multicast is the large, easy to use jog wheel with its integral push-switch.

We believe that you will quickly become comfortable with how it works, and appreciate its simplicity.

Rotating the Jog-Wheel moves a highlighting bar up or down through menus and parameter choices. Pressing

the jog-wheel (called “clicking”) selects the highlighted menu item or parameter choice. When editing the

parameter values, rotating the jog-wheel adjusts the parameter’s value up (by rotating CW) or down (CCW).

Once the desired value is reached, clicking the jog-wheel saves the value and returns the display to the previous

menu or sub-menu.

The behavior of the Omnia.Multicast's menu system is consistent across pages and is easy to learn. The

following procedure is used for all parameter selection and editing:

1. Use the jog-wheel to highlight a menu item or sub-menu item.

2. Click the jog-wheel to open up that item.

3. Once a parameter is displayed, highlight and click the name to open up the parameter value edit box.

4. Use the jog-wheel to adjust the value of the parameter.

5. Click to accept the value and return to the last sub-menu.

19

Page 20

When the front panel is in bargraph mode, the jog-wheel is used to select between various pages of bargraphs

that can be displayed. Push the push-button located to the left of the jog-wheel to change to bargraph mode.

Rotating the jog wheel counter-clockwise moves left one page and rotating clockwise moves right. The pages

do not wrap around from beginning to end or vice-versa. Rotating the wheel CCW will always eventually bring

up the I/O meter page and remain there.

Main Menu Orientation

When the processor is first turned on, several start-up screens are displayed. After ten to fifteen seconds the

Omnia.Multicast Main Menu is displayed with a sliding menu bar along the right side of the screen to indicate

your position within the menu hierarchy. A multipurpose help line is located at the bottom of the display.

Note: After a time-out, the help line will cycle through: the current preset name, and the day and date. The time

is displayed at the right side.

The menu system has been designed to be intuitive and simple to use, with a minimum of sub-menu layers.

Most operating parameters are found less than three sub-menus deep. This allows multiple processing changes

to be made “on-the-fly” with relative ease. The complete system is managed through the four menu choices on

the Main Menu. They are: Audio Processing, Input & Output, Display and Utility

The Audio Processing menu item is shown highlighted in the Main Menu Items illustration. The highlighting is

controlled by the jog-wheel. Rotate the jog-wheel CW to step the highlighting down through the menu items.

When the desired menu item is reached, press the jog-wheel once (“click”) to select that item. If the item has

sub-menus (like Audio Processing), then the sub-menu choices will be displayed. If the menu item is a

parameter selection, then the parameter choices or a bargraph value indicator is displayed. Rotating the jog-

wheel steps through the choices and raises (when rotated CW) or lowers (when rotated CCW) the parameter

value. Click the jog-wheel to select the parameter.

When a sub-menu is displayed, the top menu item will always be the return arrow. Highlight the return arrow

and then “click” to move back to the next higher menu.

OMNIA.Multicast

Audio Processing

Input/ Output

Display

Preset: 64kbAACSBR

User Interface Tutorial

The following two exercises are a useful introduction to the user interface. They also show you how to select an

input source and set input levels, which are among the first things that need to be done to set-up the processor.

Start from the top of the Main Menu (as displayed when the unit is first turned on).

The first exercise demonstrates how to make a parameter selection:

1. Rotate the jog-wheel to highlight Input & Output.

2. Select this menu item by “clicking” the jog-wheel (push once on the jog-wheel). The Input & Output

sub-menu is presented:

Input & Output

Input Levels

Output Levels

Go to additional options

20

Page 21

3. Rotate the jog-wheel CW to scroll down to highlight Input Source.

4. Click the jog-wheel to select Input Source. An expanded edit box appears with the word ANALOG

shown in large type (this is the default input selection).

5. Rotate the jog-wheel to alternate between the available parameter choices, in this case: ANALOG and

AES/EBU. Note that the choices do not “wrap around.” You must rotate the jog-wheel CCW to return

to a previous choice.

6. With ANALOG displayed, click the jog-wheel. The selection takes effect and the screen returns to the

sub-menu item (Input Source).

7. To exit the Input & Output menu and return to the Main Menu rotate the jog-wheel CCW until the

return arrow at the top of the menu is highlighted. Click on the return arrow to return to the Main

Menu.

The next exercise demonstrates how to adjust a parameter that uses a value:

1. From the Input & Output sub-menu, rotate the jog-wheel until Input Levels is highlighted.

2. Click the jog-wheel to select and display the Input Levels sub-menu. There are three menu items

displayed: Input Master, Right Trim and Input Phase.

3. The highlighted item is the Input Master parameter. Click to select.

4. An expanded edit box appears at the bottom of the display with a level bar displayed in the middle:

Edit Input Master setting

-4.0

+6.5

+0.6dB

(was -4.0)

5. Rotate the jog-wheel CW to increase the input gain in 0.1 dB steps. Rotate the jog-wheel CCW to

decrease the input gain. The current setting display updates as the jog-wheel is moved. Just below the

current setting is the previous setting display. “(was -4.0)” All parameters display the previous setting

below the current setting as soon as the jog-wheel is rotated. This allows the parameter to be easily

returned to its previous setting.

Note: The Input Master

control adjusts both the left and right channel levels simultaneously. If needed,

the relative level between the channels can be adjusted using the Right Trim control, which has a range of

–3 dB to +3 dB.

6. Adjust the input settings so that, with normal program audio, the L In and R In bargraphs in the I/O

metering screen (viewed by pressing the push-button and turning the jog-wheel to the left) show peak

indications hitting a bit higher than -15 dB (half to two-thirds of the way up).

21

Page 22

7. Once the desired gain is reached, click the jog-wheel to accept the value and to return to the sub-menu

item. The push-button will conveniently enable you to switch between the parameter adjustment and

the bargraph metering screens.

All of the Omnia.Multicast’s software parameters are set in similar fashion through scrolling through menus and

sub-menus to select which parameter to edit. The parameter choices or values are then selected by rotating the

jog-wheel until the desired setting is displayed. Clicking the jog-wheel selects the parameter value and returns

to the menu or sub-menu item.

Note: Changing the parameter value affects the audio output in real time so that the changes can be auditioned

immediately.

User Interface Concepts

This section introduces you to several important concepts needed to understand and use the Omnia.Multicast.

Presets

The processor comes with presets designed for codec transmissions or netcasting applications. A preset contains

the saved values for every parameter listed under the Audio Processing menu. When a preset is loaded, these

values configure the Omnia.Multicast’s processing.

The factory presets can be used as-is by loading them using Select Preset, or they can be used as a starting point

to tailor the processing for a specific requirement. Any of the presets parameters can be edited (using Edit

Parameters) to obtain the desired sound. The edited preset can then be saved to the PC Card as a User Preset

(using Save to Card as) and selected just like the factory presets. Editing presets is covered in detail in Chapter

5, Editing Presets

Presets can be backed up to your computer using the free Remote Control software available for download at

www.omniaaudio.com. Full information about Remote Control is covered in Chapter 6.

System Parameters

System Parameters are any parameters that are not part of a processing preset. These include all settings in the

Input & Output menus as well as other system settings such as Trigger Scripts. Such parameters are typically

set once and left alone, and having them change when a new preset is selected would be undesirable. These are

stored in a battery-backed NVRAM chip on the motherboard. If an event should occur that clears the NVRAM

(such as a power outage combined with a dead battery etc.), the unit restarts using the last saved set of System

Parameters stored on the PC card. This means all Input & Output settings are restored from the PC card, as well

as other system settings such as Trigger Scripts. Also, the preset that was running when the system was saved to

the card is stored there as the default preset.

Important Note: You should save the System Parameters to the PC card after changing any System

Parameter or if you change your default processing preset.

If your current System Parameters were never backed up by saving them to the PC Card, the parameters

restored would be the factory defaults and the default preset would be the first factory preset in the preset list.

To save the System Parameters, navigate to the Utility Menu and click on System Attributes and then Save to

Card.

Also in the System Attributes menu are the options to Load Defaults (loads the factory defaults) and Load from

Card (loads previously saved parameters or those from another PC card).

22

Page 23

Security

The Omnia.Multicast includes two security levels that permit “lockout” of the unit to prevent unauthorized

personnel from making adjustments. Normal mode allows read-only access to the Omnia.Multicast and its

menu structures. An Engineer mode allows full access to all controls. Additionally, the unit can be locked

altogether, preventing any access whatsoever. Default passwords supplied with the unit are “vito” (all lower

case) for Normal mode and “tomtom” (all lower case) for Engineer mode.

Trigger Scripts

The Omnia.Multicast Remote Control software (available as a free download from www.omniaaudio.com)

contains a special script editor that allows the programming of System Parameter changes that can be

“triggered” by logic state changes on the rear-panel DB-9 “Interface” connector.

Using Trigger Scripts, you can make the Omnia.Multicast do things with contact closures that would normally

need to be done either by manual intervention at the front panel, or via Omnia.Multicast remote control. There

are 8 Trigger Inputs available, and they respond to dry contact closures on the rear-panel “Interface” connector.

Full information about Trigger Scripts is covered in Chapter 6, Remote Control.

Bargraph Display Metering Screens

The bargraph screens are displayed by pressing the front panel push-button (located between the LCD and the

jog-wheel). This toggles between the two display modes: the menus/parameter mode and the bargraph meter

mode. Multiple screens are available in bargraph mode, and are selected by turning the jog wheel. The first

screen can be reach by turning the wheel counter-clockwise until the screen no longer changes. Each screen is

titled in the lower right-hand corner as a navigation aid. The first I/O screen shows the input and output levels.

The second is a combined “Process” bargraph screen that shows the wideband AGC bargraph and three limiter

bargraphs.

I/O Levels Display

Both input and output levels are displayed in real time. The output bargraphs indicate the output levels of the

digital and analog XLR outputs. The bargraphs indicate peak levels below 0 dBFS, which is the absolute

maximum level of the internal digital signal processing. In normal operation with normal program audio, signal

level peaks should regularly indicate just above -15 dBFS and never hit 0 dBFS.

Process Display

The process bargraphs indicate the amount of processing (gain-reduction) of the AGC and Limiter bands in the

Omnia.Multicast. Maximum indicated gain-reduction is 25 dB, which occurs at the bottom of the screen. The

23

Page 24

bargraphs also have a GATED indication as determined by the Gate Thresh or Hold Thresh setting for that

band.

Note: It is normal for the wideband AGC to “recover” to a platform of 10 dB of gain reduction if it is gated

over a long period of time. Refer to Chapter 5, Editing Presets for more information on interpreting and using

the Processing bargraph display.

Menu Descriptions

This section gives an overview of the menus, sub-menus and parameters. The next chapter (Chapter 3,

Processing Overview) presents an overview of the Omnia.Multicast processing. Chapter 5, Editing Presets,

gives more information on editing parameters including procedures for editing the factory presets to create your

own custom presets.

Main Menu

This menu has four items: Audio Processing, Input & Output, Display and Utility.

Audio Processing

It is from the Audio Processing sub-menu items—Select Preset and Edit Parameters, that the unit’s processing

power is unleashed. Omnia.Multicast is equipped with numerous presets that can be selected to instantly

configure the processing. The presets are selected using Select Preset. Selecting Edit Parameters opens up the

parameter-editing sub-menu, which allows any processing parameter to be “fine-tuned” to tailor your

processing. Save to Card as allows the edited preset to be saved to the PC Card as a new User Preset.

Input & Output

This sub-menu provides the Input Levels and Output Levels adjustments for the discrete left and right inputs

and outputs, selection of Input Source (Analog or AES-3), and Mono Mode options. These are generally “set

once” selections or parameters, adjusted during installation and then generally left alone.

Display

This sub-menu has the adjustments for the LCD screen (Contrast and Backlight).

Utility

Numerous maintenance and utility functions are nested within this sub-menu. You can find the currently

running system software versions in the About sub-menu. The housekeeping of Preset and System Attributes

data, along with PC Card Maintenance is provided here. Enabling Security features to prevent tampering by

unauthorized personnel are also provided under this sub-menu. Finally, the Date, Time and the RS-232 serial

Ctrl Port Baud rate can be set here.

Audio Processing

This sub-menu is used to make changes that affect the on-air sound. It has five items: Select Preset, Edit

Parameters, Undo Edit, Save to Card, Save to Card as.

Select Preset

This opens up a selection box to select a factory preset or a user preset that was previously saved to the PC

Card. The name of the preset that is currently running is displayed. Use the jog-wheel to scroll through the list

to find a preset to load. Once the desired preset name is displayed, click the jog-wheel to immediately load that

preset into the unit’s memory. This also returns you to the Select Preset menu item.

Note that once you move the jog-wheel to display another preset name, a message below the preset name

indicates the previous selection, i.e., “(was 32kbWMA)” will be shown if that was the currently running preset.

24

Page 25

This serves as a reminder, so you can reselect that preset in case you change your mind about changing presets,

since there is no way to “cancel” selecting a new preset to load.

A thermometer bar along the left side of the window indicates where you are in the list of presets. All User

Presets are added onto the end of the list, so they will be found when the bar is toward the bottom of the

thermometer.

Editing Parameters

Here you have detailed control of all processing parameters. Such parameters as attack/release times, gate

thresholds, multiband EQ settings and limiting drive are available through a graphical block diagram based

interface. The first blocks name, “AGC Wideband” flashes, indicating that it’s the current parameter. To edit

the AGC Wideband parameters, click the jog-wheel. A list of the parameters relevant to that part of the

processing algorithm is shown (in this case; Phase Rotator, Wideband AGC, etc.). To edit another block’s

parameters, rotate the jog-wheel until the desired block name is flashing and then click the jog-wheel. Detailed

editing is covered in more detail in Chapter 5, Editing Presets.

Undo Edit

Restores the preset state from before the last edit operation.

Save to Card

Saves the current parameters to the PC Card, overwriting any previous settings saved under the current Preset

name. This function cannot be used with factory presets, since they cannot be changed. If you have made

changes to a factory preset and wish to save them, use Save to Card as to save the changes under a new name.

Save to Card As

Opens up a Preset Naming dialog box to allow the Preset name to be changed before saving the preset to the PC

Card. Preset names can be up to 12 characters in length. Click the jog-wheel to select a highlighted character to

be changed. Then rotate the jog-wheel to step through all the possible characters. Once the desired character is

displayed, click the jog-wheel to select that character. The highlighting moves to the next character. To insert a

new character between others, select the character after the insertion point, then change it to the “ins” symbol.

To delete an existing character select it, then change it to the “del” character. When the last character is

reached, rotate the jog-wheel to highlight “Save”. Click to save the preset. Highlight “Cancel” to cancel the

operation.

Input & Output

This sub-menu has five main items: Input Levels, Output Levels, Input Source, Mono Mode, and LPF

Frequency.

Input Levels

Three parameters are located under this sub-menu item: Input Master, Right Trim, and Input Phase.

Input Master & Right Trim: These level controls are active when either Analog input or AES/EBU input is

selected since their adjustments take place in the digital domain. The factory default setting is 0.0, which

corresponds to a nominal average program audio input level of +4 dBu. To change input level, rotate the jogwheel to adjust the level in 0.1 dB steps. The Input Master affects both the left and right inputs simultaneously,

while the Right Trim only affects the right channel over a +/- 3 dB range. Use the level bargraphs to make this

adjustment so that signal peaks read a bit higher than -15 dB with normal program audio. 0 dB corresponds to 0

dBFS (decibels below Full Scale digital, i.e. the digital clip point) so be sure that peaks do not reach 0 dB

regularly or distortion will result.

25

Page 26

It is vital that proper levels are set as they affect the performance of the Sensus algorithm. This is important for

mono content, such as dry, live, voice. A level imbalance will reduce the efficiency of the system to reduce

coding artifacts.

Input Phase: If the relative phase relationship of the Omnia.Multicast is different from your existing system, it

could cause your announcers to think they sound “weird” when monitoring through the system using their

headphones. If this happens, the relative phase of the Omnia.Multicast is 180 degrees different from what your

announcers are used to. To remedy this, you can reverse the polarity with this menu selection. This is the same

as but much more convenient than swapping pins 2 & 3 on both L & R input XLR connectors!

Output Levels

Two parameters are located under this sub-menu item: Output Master and Right Trim.

Adjustment of the left/right audio levels is done in the same manner as setting the input levels. Since these

settings take place before the D/A converter, the settings affect both digital (AES/EBU) and analog XLR

outputs.

Note: Both the analog and digital AES/EBU outputs are active at the same time. Connections can be made

simultaneously to the analog and digital outputs.

Input Source

Selects whether the input is supplied by the Analog or AES/EBU digital input.

Mono Mode

This sub-menu has five items: Stereo, Mono L, Mono R, Mono L+R and Swap.

The Stereo selection indicates that the processor will process a 2-channel stereo signal. Please note that the two

channels cannot be separate un-related signals since the processing is stereo strapped.

Mono L: The signal at the left input is fed to both the left and right channels of the processing.

Mono R: The signal at the Right input is fed to both the left and right channels of the processing.

Mono L+R: A sum of the two input channels is fed to both left and right channels of the processing.

Swap is similar to Stereo but the L & R channels are reversed. (swapped)

Display

Two parameters are set under this sub-menu: Contrast and Backlight.

Contrast adjusts the brightness difference between the lightest and darkest segments in the front panel display.

Note that if this setting is mis-adjusted the display will “disappear.”

Backlight adjusts the LCD’s backlight to compensate for room brightness.

Utility

There are nine parameters or sub-menus reached through this menu item: About, Preset, System Attributes,

Card Maintenance, Security, Set Time, Set Date and Control Port Baud.

About

The first thing displayed when you click on About is the Omnia factory telephone number in Cleveland! To

display the currently running software versions, click OK. The Style and Release version will be displayed.

Click OK again and the Bios, display and Loadset versions are displayed. Clicking OK again brings up the

copyright screen and one more click returns you to the Utility menu.

26

Page 27

Preset

This sub-menu has two parameters: Delete and Rename. Select Delete to permanently delete a User Preset

from the PC Card. A selection box will be displayed allowing you to choose a preset for deletion. Once a

choice is made, a confirmation box is displayed. The preset will not be deleted until “OK” is selected from the

confirmation box. Select Rename to change the name of an existing User Preset. A selection box will be

displayed allowing you to choose a preset to be renamed. Once a choice is made, a naming box is displayed to

enter the new name for the preset. This works as described above in “Audio Processing”: “Save to Card as”.

System Attributes

There are three parameters under this sub-menu item: Load Defaults, Load From Card and Save to Card.

Load Defaults: Reloads all of the factory default system parameters into the system. System parameters are

anything that is not saved with the processing preset, such as input and output levels, and RS-232 baud rate.

User presets saved to the PC card are not affected but the default preset is reset to the first factory preset shown

in the list.

Load From Card: Loads previously saved system parameters from the PC Card.

Save to Card: Saves system parameters to the PC card. This makes a “copy” of the system configuration that

normally resides in the nonvolatile RAM within the Omnia.Multicast, storing it on the PC Card. This simplifies

getting back to a previous state after numerous system adjustments have been made, but you want to return.

Card Maintenance

Erase User Data: Choose this selection when you want to erase all user information on the PC Card, including

user presets, saved system settings, and trigger scripts. When this function is selected, the PC Card is restored to

the initial factory condition, and only the factory presets are available. Before this function is executed, a pop-

up screen will ask for confirmation. Follow the instructions presented on the screen to confirm erasure of the

card.

Security

This menu allows configuration of all Omnia security features, such as password access, screen locking, and

remote access control. There are six sub-menus: Lock Unit, Login, Lock Password, Engineer Password,

Enable Remote and Disable Remote.

Lock Unit: Immediately locks the front panel controls and display. A dialog box is presented for password

entry to unlock the unit. Either the normal mode or engineer mode password can be used to unlock the unit.

Login: Permits access at one of two security levels (Normal or Engineer), using the appropriate password:

Normal mode: vito (all lower case)

Engineer mode: tomtom (all lower case)

Lock Password: Allows changing the password for “Normal” access. This really should be called “Normal

Password”, but our software engineers wanted to include something to keep the users on their toes. This can be

performed either from “Normal” or “Engineer” security levels.

Engineer Password: Allows changing the password for “Engineer” access. Can be performed only from the

“Engineer” security level.

To change a password, use the standard click and turn of the jog-wheel to select the character position you wish

to change, and to select the character for that position.

27

Page 28

After choosing a new password, continue rotating the jog-wheel until OK is highlighted. Push on the jog-wheel.

The password is now saved. If you wish to cancel this operation, just scroll onto the Cancel box and press the

jog-wheel. The operation is canceled.

Caution: Do not attempt to assign the same password to both security levels! You will lock yourself out

permanently!

Enable Remote: Allows remote control access to individual system parameters previously inhibited by the

Disable Remote command (see below). In other words, you can selectively cancel individual parameters that

were disabled for remote access. A list of parameters that have been disabled (through the Disable Remote

menu) for remote users is displayed. When a parameter is selected, it becomes available to “Engineer”

password users to edit through the remote software. Selecting Exit (None on am and net styles) exits the

Enable Remote screen without changing the current settings.

Disable Remote: Allows the user to restrict access to a list of system parameters so that remote users won’t be

able to change the selected parameters. When the Disable Remote option is selected, a list of the system

parameters that are editable through the remote is displayed. When a parameter is selected, it is no longer

editable through the remote command interpreter. Selecting Exit exits the Disable Remote screen without

disabling any parameters. To restore a parameter so that remote users can edit it, use the Enable Remote option.

Set Time

Sets the current time for the unit. The time is set using the familiar “turn and push” action of the jog wheel.

Note: The time can be synchronized to “:00” seconds by pressing the jog wheel in synchronization with the

seconds indicator of an external clock. Note: An additional menu will prompt you to set the unit to Daylight

Saving or Standard time.

Set Date

Sets the current date. The date is set using the familiar “turn and push” action of the jog wheel.

Control Port Baud

This option sets the RS-232 serial communications port baud rate. The default rate is 19200 bps.

28

Page 29

Chapter 3: Processing Overview

This chapter presents an overview of the processor using the block diagram to provide a guide to the various

processing sections.

Note: More detailed technical information about the audio processing employed in Omnia.Multicast can be

found in the Technical Papers section on the Omnia web site (www.omniaaudio.com).

Omnia.Multicast and Audio Processing

There are ten possible processing blocks to be discussed. There is an input AGC function for initial level

control, bass and warmth EQ adjustment sections, a multiband crossover section, a multiband limiter, a mixer

circuit and a final limiter at the output. The following block diagram presents the order of these processing

architecture.

Wideband AGC: A very flexible wideband leveler section to provide transparent and smooth control of the

input program. This is achieved through two significant innovations: a dual referenced gate and an intelligent

“makeup” gain algorithm. The dual gate reference is a unique process that references the input dynamics to a

“rolling” reference level.

A user-adjustable Make-Up Gain feature uses an algorithm incorporating a hidden control signal that knows

when a sustained softer portion of program is occurring. It then “fills in” the softer section so that the average

level is increased. This allows the overall AGC function to operate with a slower time constant, yielding lower

intermodulation distortion without losing loudness in the softer passages.

As an example, with classical music, the orchestra might be playing along at a fairly robust level, then enter into

a quiet passage. A conventional AGC would hold the softer passage down until it was able to slowly recover,

keeping the soft passage much too quiet! With Omnia.Multicast’s makeup gain function, the hidden, faster time

constant will allow a quick recovery, but only during the softer passage. As soon as the orchestra starts to play

louder, the “makeup” time constant yields control to the primary AGC circuit, hence returning gain to the

previous platform level. This sophistication better preserves the dynamic integrity of the signal.

Typically the wideband AGC should be adjusted to give 10-12 dB of gain reduction on moderately loud

passages.

A built-in phase rotator ensures symmetrical processinging of positive and negative peaks. But, for a more

musically transparent sound (or if phase rotation is built-in to your mic processing) this feature can be defeated.

A third-order (18dB/Octave) high pass filter with five selectable cutoff frequencies from 60 Hz down to 20 Hz

allows removal of subsonic frequencies that may cause problems in processing and further along the

transmission path.

29

Page 30

Bass EQ: For those who demand thunderous bass, the Omnia.Multicast’s got it! Up to 12 dB of “thunder” can

be added to shake your listener’s walls! This is not some simple bass EQ, but rather a sophisticated concept that

takes into consideration the time alignment of the low frequencies as they pass through the entire system. This

allows loud, clean low end, with no sacrifice to the overall loudness of your signal. The Deep Bass and Phat

Bass parameters are found under the Bass menu. Deep Bass is a shelf boost at 90 Hz that utilizes a phase linear

12 dB/octave slope to produce the shelving EQ function. Phat Bass is a unique enhancement that adds filtered

harmonics to the bass frequencies. Low frequency texture is emphasized with this parameter. Older materials

sound fuller (or phatter) with the added illusion of loudness.

Warmth EQ: The Warm Bass parameter is found under the Warmth menu. Warm Bass is a shelf boost that

functions up to 150 Hz. Adjusting Warm Bass compensates for program material that is naturally lacking in

upper-bass punch. The parameter is adjustable over a 6 dB range.

Phase Linear, Time Aligned Crossover: Most multiband audio processors must make a compromise in the

crossover area: provide true phase linearity, or dynamic flat response. The problem with implementing only the

former is that, under dynamically controlled conditions, peaks or notches will occur at the crossover frequencies

once the bands are recombined. In an effort to minimize this problem in older designs, crossover frequencies

were phase-offset, so when they were recombined, these peaks and notches would be minimal—thus

maintaining some degree of flatness. Such a compromise results in the loss of phase linearity, which reduces

clarity. In Omnia.Multicast’s DSP implementation, the crossover network is carefully time-aligned so the

recombined spectrum remains flat, regardless of the amount of gain control being applied within any band. This

yields a phase linear response, so that no harmonic content is ever displaced in time. The result: a truer, more

natural sound without smearing.

Multiband Dynamic Peak Limiter: These are not just simple limiter sections using single time constants, but

rather a process that can make adjustments based upon the “peak weight” of the signal. The sophisticated

algorithm relies upon a peak-weighted calculation to determine the strength of a transient peak. It then

determines if very fast dynamic control is required. In this fashion, faster timing is used only when necessary,

and then only under certain conditions that are dictated by the density of the peak signal. If the peak is very

short in nature, then the limiter will ignore it and let it pass onto the next processing stage (the final limiter). A

built-in Hold feature allows the limiter to rest momentarily in order to reduce IM distortion.

Non-Aliasing, Intermodulation Controlled Look-Ahead Limiter: A unique algorithm that provides absolute

peak control to enable maximum system headroom. This contains an embedded intermodulation control method

that removes the artifacts commonly associated with look-ahead limiting, yet producing a clean, intelligible

signal. The Sensus function is also built into this block.

30

Page 31

Chapter 4: Omnia.Multicast

This chapter presents important installation and operation information for Omnia.Multicast. A block diagram is

shown below. A Parameters Worksheet is included at the end of this chapter. Use it as a master sheet for

photocopying so that the parameter settings for any custom presets can be recorded. Presets can also be saved to

your computer and printed using the Remote Control software.

Processor Location

Believe or not, this is an important consideration! Where you choose to locate the processor can have a

profound impact on the overall performance. It is recommended to locate the processor close to the encoder.

There should not be any other signal devices inserted between Omnia.Multicast and the encoder.

Omnia.Multicastnet Connections

The Omnia.Multicast is designed to provide audio processing for Multicasting, HD Radio, DAB and similar

applications. The unit provides full maximum 20 kHz bandwidth and audio processes which are optimized for a

variety of coding algorithms. Because of our extensive experience with MP3 and other codec technologies, the

Omnia.Multicast is designed to maximize the sound quality, even at low bit-rate settings.

When the unit is connected to a professional-grade real-time encoder, the AES/EBU outputs will generally be

used to eliminate conversion steps. Some encoders require the sample rate of input signals fed to them to be

synchronous to their internal rate (or another “master” rate). Examples of such equipment include HD Radio

exciters and importers, as well as many computer audio cards. When connecting the Omnia’s digital output in

such a circumstance, the External Sync connector provides a means to synchronous the Omnias output rate to

the required sample rate. Connect an AES/EBU signal running at the required sample rate to this input, and the

output will automatically synchronize to it (provided it is between 32kHz and 48kHz).

The analog outputs can also be used to connect to the encoding equipment. If the encoder is a PC card, care

should be exercised to prevent ground loops and other connection problems. In the case where the PC card

audio inputs are unbalanced (typically an RCA or mini-phone jack is used), connect the + signal output (pin 2

on the XLR connector) to the tip of the unbalanced plug. Connect the shield on the unbalanced plug to pin 1

(Ground) on the XLR connector. In this application you do not connect pin 3 of the XLR (the - output).

The inputs can be from either analog or digital (AES/EBU) sources, as required. The active input source is

software selectable (c.f. Input & Output menu).

The factory processing presets have been optimized for use with coded audio. They should be used as a starting

point to optimize the audio for your exact coding requirements. For more information on audio processing for

the Internet, refer to the white paper on Audio Processing for Digital Radio and the Internet found on the Omnia

web page:

http://www.omniaaudio.com/

Adjustments to the processing preset parameters are covered in Chapter 5, Editing Presets.

31

Page 32

Processing Presets

Numerous processing presets have been provided as starting points for customizing the sound of your

transmission. Note that we do not warrant in any way that these presets are the de facto standards for the codec

names used. Each was derived in an effort to create a generic starting point for each respective codec.

With all of that having been said, please rely on the presets to get yourself going. From there, we can provide

assistance, if you desire, or you can venture off to discover new frontiers of processed sound. It is our belief that

there is not any nirvana of processed sound, or special secret preset that we keep for our friends. Each situation

in each market is unique unto itself. Try to remember that when “crafting” that special sonic personality for

your installation. Omnia.Multicast gives you the power to create a sound totally different from, and better than,

your competitors. Enjoy that power!

We could publish list after list, but chances are that we will continue to develop new or modify existing presets.

So, a list that is guaranteed to be obsolete would be of little help. Besides, the name of each should be self-

explanatory. If you need more clarification, fell free to contact our technical support department.

Adjustments to the processing preset parameters are covered in Chapter 5, Editing Presets.

32

Page 33

Omnia.Multicast Parameter Worksheet

Preset Name__________________

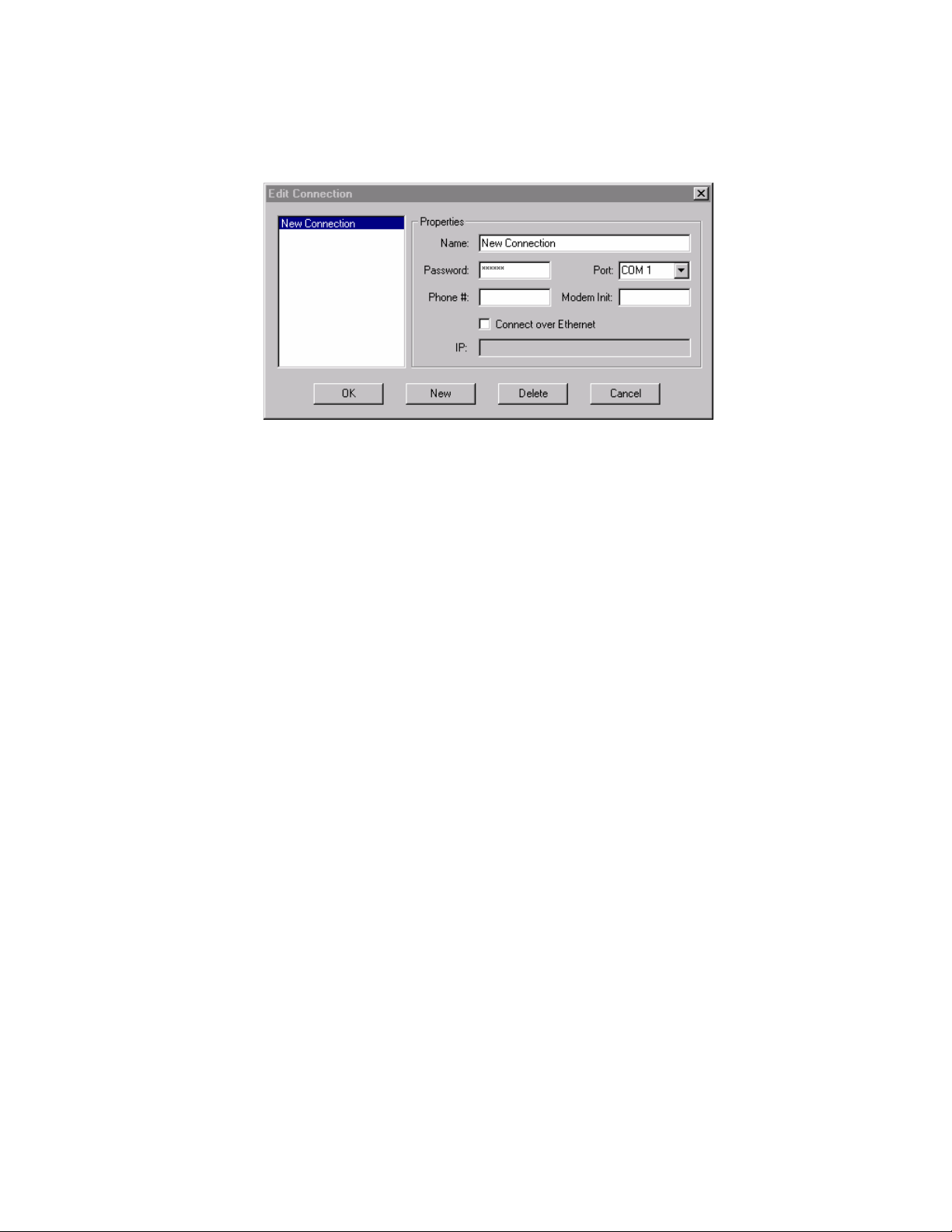

Engineer