Page 1

MICRO-MACHINED

SILICON TRANSDUCERS

WET/WET DIFFERENTIAL PRESSURE MODELS

mV/V, 0 to 5 or 0 to 10 Vdc, or 4 to 20 mA Outputs

Uni-Directional Ranges

0-10 inH2O to 0-1000 psid

PX409 Series

Standard

U Precision Micro-Machined Silicon Core

U 5-Point NIST Traceable Calibration

U High Stability, Low Drift

U Welded Stainless Steel Construction

U 316L SS Wetted Parts

U Premium Temperature Performance

U Broad Compensated Temperature Range

U Durable, 1 Million Cycle Life

U Ruggedized with Secondary

Containment

U Customized Specifications Available

Fast Delivery!

Stock to 2 Weeks

On Most Models

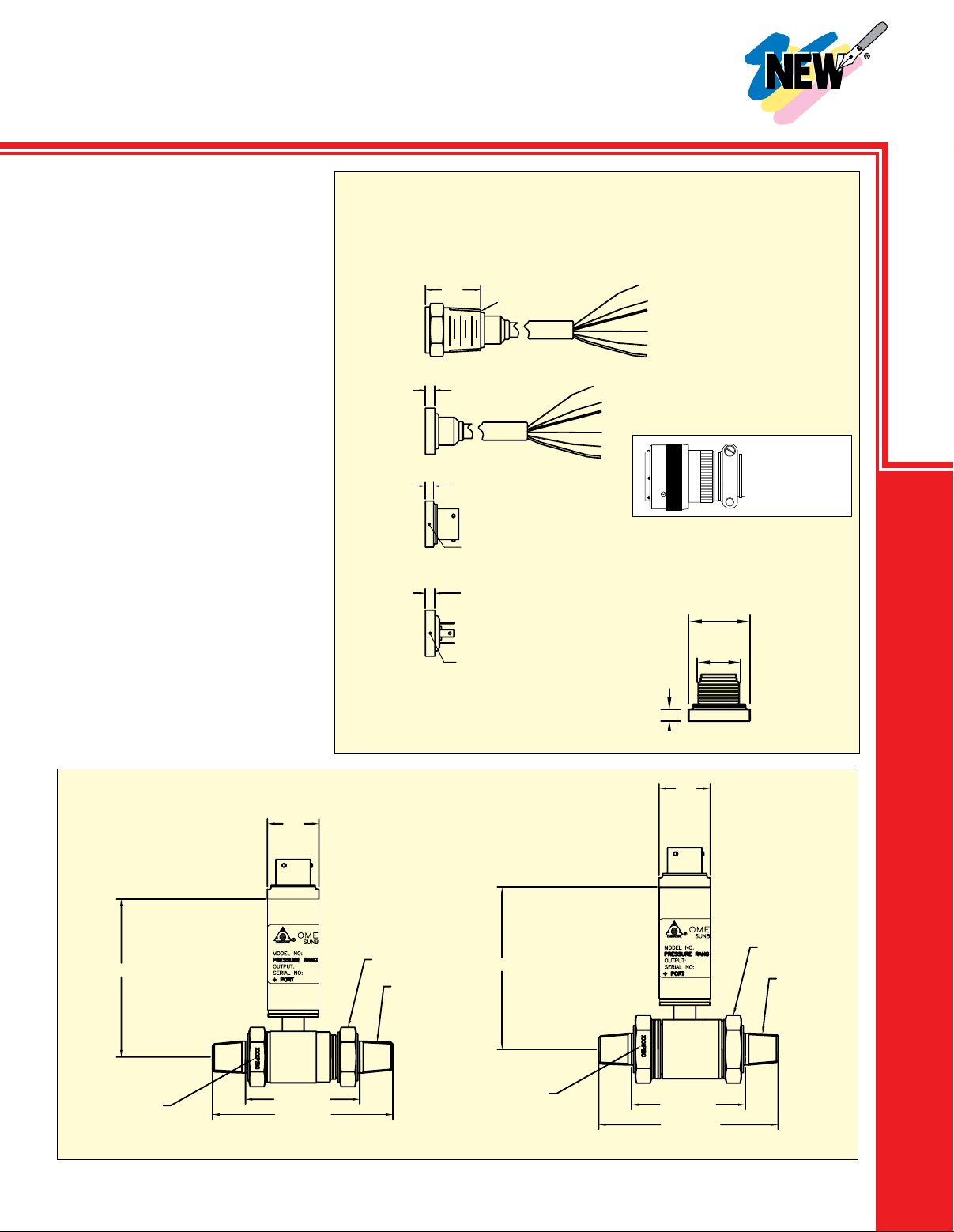

Cable

style.

PX409-015DWUV,

15 psid range,

10 mV/V output,

shown smaller

than actual size.

omega.com/pxconfig

IP65 environmental rating.

High 0.08%

Accuracy

Metric threads

available, see

Get all the great performance characteristics of the

Micro-Machined Silicon Transducers in these wet/

wet differential pressure models. These rugged

stainless steel transducers are ideal for tough industrial

automotive, or aerospace applications requiring a wet/

wet transducer. They can be used in test benches,

filter monitoring, hydraulic, flow, or water/wastewater

applications, as well as factory or pneumatic air, pitot

tubes, air speed and other industrial or aerospace

applications. The solid state silicon core and all stainless

steel wetted parts will provide long, reliable service life

with excellent long term stability.

COMMON SPECIFICATIONS

Accuracy: 0.08% BSL linearity, hysteresis and

repeatability combined

Minimum Resistance Between Transducer Body

and Any Wire: 100 MΩ

Operating Temperature:

mV/V and 5 to 10 Vdc Output: -45 to 121°C (-49 to 250°F)

mA Output: -45 to 115°C (-49 to 239°F)

Compensated Temperature Range:

10 inH

15 to 1000 psi: -29 to 85°C (-20 to 185°F)

Thermal Accuracy: Zero Span

% Shift over compensated temperature range

10 inH

2.5 to 1000 psi: ±0.50% ±0.50%

O to 5 psi: -17 to 85°C (1 to 185°F)

2

O to 1 psi: ±1.00% ±1.00%

2

Five Electrical

Termination Styles

IP67

environmental

rating.

PX409, 2 m (6') cable.

IP67

environmental

rating.

PX409C, conduit cable.

PX459, M12 connector.

IP65 environmental

rating.

PX419, mini DIN.

IP65

environmental

rating.

PX429, twist-lock.

B-243

Page 2

15 psid and below

Conduit backend PX409C

Integral cable backend PX409

Twist-lock backend PX429

mini DIN backend PX419

5 (0.2)

5 (0.2)

5 (0.2)

28

(1.1)

Vent with porous plug

(gage units only)

Conduit backend PX409C

Integral cable backend PX409

Twist-lock backend PX429

mini DIN backend PX419

5 (0.2)

5 (0.2)

5 (0.2)

28

(1.1)

½ NPT TH’D

Vent with porous plug

(gage units only)

Vent with porous plug

(gage units only)

MICRO-MACHINED

Ø 20.2

(0.8)

2

(0.2)

2 connector

bacend

SILICON TRANSDUCERS

WET/WET DIFFERENTIAL PRESSURE MODELS

Pressure Cycles: 1 million minimum

Long Term Stability (1-Year):

±0.1% FS typical

Bandwidth: DC to 1 kHz typical

Response Time: <1 ms

CE Complient: Meets EN1326-1: 2006

for industrial locations

Shock: 50 g, 11 mS half sine, vertical

and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute

cycle, Curve L, Mil-Spec 810 figure

514-2-2, vertical and horizontal axis

Wetted Parts: 316L stainless steel

Line/Static Pressure: 500 psi max

applied to both sides simultaneously

Proof Pressure (Differential):

10 inH

1 psi range = 6 times range

2.5 to 750 psi ranges = 4 times range

1000 psi range = 3 times range

Hi Side Containment Pressure

(Differential):

Ranges 15 to 1000 psi: to 3000 psi

Pressure Ports:

Electrical Terminations:

PX409: 2 m (6') cable

PX409C: 2 m (6') cable with

conduit thread

PX419: mini DIN

(mating connector included)

PX429: Twist-lock,

(mating connector sold separately)

PX459: M12 connector

PX429 Mating Connector:

PT06F10-6S

Weight: 200 g (7 oz) max

O range = 10 times range

2

Ranges 10 inH2O to 5 psi: to 1000 psi

1

⁄4 NPT male

1

⁄2 NPT

Dimensions: mm (inch)

ø = diameter

ø22.8

(0.9)

Dimensions: mm (inch)

Mating

Connector

PT06F10-6S

ø22.8

(0.9)

PRESSURE TRANSDUCERS

DIFFERENTIAL

B

68.5 (2.7)

Serial # and range

identify high port

50.8 (2.0)

78.7 (3.1)

30 psid and above

22.8 (0.875) hex

each end

¼ - 18 NPT

each end

Serial # and range

identify high port

B-244

71.1 (2.8)

50.8 (2.0)

78.7 (3.1)

25.4 (1.0) hex

each end

¼ - 18 NPT

each end

Page 3

WET/WET DIFFERENTIAL

PRESSURE MODELS

UNI-DIRECTIONAL RANGES WITH mV/V OUTPUTS

UNI-DIRECTIONAL mV/V

SPECIFICATIONS

Output: 10 mV/V ratiometric

Supply Voltage: 5 to 10 Vdc

Current Draw: 5 mA @ 10 Vdc

Input Impedance: 1000 to 5000 Ω

Output Impedance: 5000 Ω ±10% typical

Zero Balance:

Ranges ≤ 1psi: ±1% typ (2% max)

Ranges > 1psi: ±0.5% typ (1% max)

Span Setting:

Ranges ≤ 1psi: ±1% typ (2% max)

Ranges > 1psi: ±0.5% typ (1% max)

CABLE TERMINATION*

To Order Visit omega.com/px409-wwdif

for Pricing and Details

10 mV/V OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX409-001DWUV

0 to 2.5 psi 170 mbar PX409-2.5DWUV

0 to 5 psi 350 mbar PX409-005DWUV

0 to 15 psi 1 bar PX409-015DWUV

0 to 30 psi 2 bar PX409-030DWUV

0 to 50 psi 3.5 bar PX409-050DWUV

0 to 100 psi 7 bar PX409-100DWUV

0 to 150 psi 10 bar PX409-150DWUV

0 to 250 psi 17.5 bar PX409-250DWUV

0 to 500 psi 35 bar PX409-500DWUV

0 to 750 psi 50 bar PX409-750DWUV

0 to 1000 psi 70 bar PX409-1.0KDWUV

To order conduit fitting backend change model number

*

from “PX409” to “PX409C”, no additional cost.

MINI DIN TERMINATION

10 mV/V OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX419-001DWUV

0 to 2.5 psi 170 mbar PX419-2.5DWUV

0 to 5 psi 350 mbar PX419-005DWUV

0 to 15 psi 1 bar PX419-015DWUV

0 to 30 psi 2 bar PX419-030DWUV

0 to 50 psi 3.5 bar PX419-050DWUV

0 to 100 psi 7 bar PX419-100DWUV

0 to 150 psi 10 bar PX419-150DWUV

0 to 250 psi 17.5 bar PX419-250DWUV

0 to 500 psi 35 bar PX419-500DWUV

0 to 750 psi 50 bar PX419-750DWUV

0 to 1000 psi 70 bar PX419-1.0KDWUV

O 25 mbar PX409-10WDWUV

2

O 25 mbar PX419-10WDWUV

2

Fast Delivery!

Stock to 2 Weeks

On Most Models

Cable

style.

Metric threads

available, see

omega.com/pxconfig

PX409-030DWUV,

30 psid range, 10 mV/V

output, shown smaller

than actual size.

M12 or TWIST-LOCK

TERMINATION

10 mV/V OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX4[*]9-001DWUV

0 to 2.5 psi 170 mbar PX4[*]9-2.5DWUV

0 to 5 psi 350 mbar PX4[*]9-005DWUV

0 to 15 psi 1 bar PX4[*]9-015DWUV

0 to 30 psi 2 bar PX4[*]9-030DWUV

0 to 50 psi 3.5 bar PX4[*]9-050DWUV

0 to 100 psi 7 bar PX4[*]9-100DWUV

0 to 150 psi 10 bar PX4[*]9-150DWUV

0 to 250 psi 17.5 bar PX4[*]9-250DWUV

0 to 500 psi 35 bar PX4[*]9-500DWUV

0 to 750 psi 50 bar PX4[*]9-750DWUV

0 to 1000 psi 70 bar PX4[*]9-1.0KDWUV

Comes complete with 5-point NIST traceable calibration certificate.

[*] Enter “5” for PX459 M12 connector or “2” for PX429 twist lock

connector (mating PX429 connector sold separately).

Ordering Examples: PX409-100DWUV, 0 to 100 psi uni-directional

wet/wet differential pressure range, 10 mV/V output, 0.08%

accuracy,

PX419-015DWUV, 0 to 15 psi uni-directional wet/wet differential

pressure range, 10 mV/V output, 0.08% accuracy,

mini DIN connector.

PX429-10WDWUV, 0 to 10 inH2O uni-directional wet/wet differential

pressure range, 10 mV/V output, 0.08% accuracy,

twist-lock connector plus PT06F10-6S, mating connector.

O 25 mbar PX4[*]9-10WDWUV

2

1

⁄4 NPT fittings, 2 m (6') cable.

1

⁄4 NPT fittings,

1

⁄4 NPT fittings,

CONNECTIONS—mV/V OUTPUT

PX429 TWIST-LOCK PX419/PX459 PX409 CABLE

Pin A +EXC Pin 1 +EXC Red +EXC

Pin B -EXC Pin 2 -EXC Black -EXC

Pin C +SIG Pin 3 +SIG White +SIG

Pin D -SIG Pin 4 -SIG Green -SIG

Pin E No Connection

Pin F No Connection

B-245

Page 4

WET/WET DIFFERENTIAL

PRESSURE MODELS

UNI-DIRECTIONAL RANGES WITH 0 to 5 Vdc OUTPUTS

UNI-DIRECTIONAL VOLTAGE

OUTPUT SPECIFICATIONS

Output Voltage/Supply Voltage: 0 to 5 Vdc/

10 to 30 Vdc; 0 to 10 Vdc/15 to 30 Vdc

(change “5V” to “10V” in model number)

Current Draw: 10 mA max

Maximum Current Output: 2 mA (= 2500 Ω min

load resistance)

Output Impedance: 100 Ω

Zero Balance:

Ranges > 1psi: ±0.5% typ (1% max)

Ranges ≤ 1psi: ±1% typ (2% max)

Span Setting:

Ranges > 1psi: ±0.5% typ (1% max)

Ranges ≤ 1psi: ±1% typ (2% max)

CABLE TERMINATION*

To Order Visit omega.com/px409-wwdif

for Pricing and Details

0 to 5 Vdc OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX409-001DWU5V

0 to 2.5 psi 170 mbar PX409-2.5DWU5V

0 to 5 psi 350 mbar PX409-005DWU5V

0 to 15 psi 1 bar PX409-015DWU5V

0 to 30 psi 2 bar PX409-030DWU5V

0 to 50 psi 3.5 bar PX409-050DWU5V

0 to 100 psi 7 bar PX409-100DWU5V

0 to 150 psi 10 bar PX409-150DWU5V

0 to 250 psi 17.5 bar PX409-250DWU5V

0 to 500 psi 35 bar PX409-500DWU5V

0 to 750 psi 50 bar PX409-750DWU5V

0 to 1000 psi 70 bar PX409-1.0KDWU5V

To order conduit fitting backend change model number

*

from “PX409” to “PX409C”, no additional cost.

MINI-DIN TERMINATION

0 to 5 Vdc OUTPUT, 1⁄4 NPT MALE

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX419-001DWU5V

0 to 2.5 psi 170 mbar PX419-2.5DWU5V

0 to 5 psi 350 mbar PX419-005DWU5V

0 to 15 psi 1 bar PX419-015DWU5V

0 to 30 psi 2 bar PX419-030DWU5V

0 to 50 psi 3.5 bar PX419-050DWU5V

0 to 100 psi 7 bar PX419-100DWU5V

0 to 150 psi 10 bar PX419-150DWU5V

0 to 250 psi 17.5 bar PX419-250DWU5V

0 to 500 psi 35 bar PX419-500DWU5V

0 to 750 psi 50 bar PX419-750DWU5V

0 to 1000 psi 70 bar PX419-1.0KDWU5V

O 25 mbar PX409-10WDWU5V

2

FITTINGS

O 25 mbar PX419-10WDWU5V

2

M12 or TWIST-LOCK

TERMINATION

0 to 5 Vdc OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX4[*]9-001DWU5V

0 to 2.5 psi 170 mbar PX4[*]9-2.5DWU5V

0 to 5 psi 350 mbar PX4[*]9-005DWU5V

0 to 15 psi 1 bar PX4[*]9-015DWU5V

0 to 30 psi 2 bar PX4[*]9-030DWU5V

0 to 50 psi 3.5 bar PX4[*]9-050DWU5V

0 to 100 psi 7 bar PX4[*]9-100DWU5V

0 to 150 psi 10 bar PX4[*]9-150DWU5V

0 to 250 psi 17.5 bar PX4[*]9-250DWU5V

0 to 500 psi 35 bar PX4[*]9-500DWU5V

0 to 750 psi 50 bar PX4[*]9-750DWU5V

0 to 1000 psi 70 bar PX4[*]9-1.0KDWU5V

Comes complete with 5-point NIST traceable calibration certificate.

[*] Enter “5” for PX459 M12 connector or “2” for PX429 twist lock

connector (mating PX429 connector sold separately).

Note: To order 0 to 10 Vdc output, change “5V” to “10V” in model

number, no additional cost.

Ordering Examples: PX409-100DWU5V, 0 to 100 psi

uni-directional wet/wet differential pressure range, 0 to 5 Vdc output,

0.08% accuracy,

PX419-015DWU5V, 0 to 15 psi uni-directional wet/wet differential

pressure range, 0 to 5 Vdc output, 0.08% accuracy,

mini DIN connector.

PX429-10WDWU5V, 0 to 10 inH2O uni-directional wet/wet

differential pressure range, 0 to 5 Vdc output, 0.08% accuracy,

1

⁄4 NPT fittings, twist-lock connector plus PT06F10-6S,

mating connector.

CONNECTIONS—VOLTAGE OUTPUT

PX429 TWIST-LOCK PX419/PX459 PX409 CABLE

Pin A +EXC Pin 1 +EXC Red +EXC

Pin B -COM Pin 2 -COM Black -EXC

Pin C +SIG Pin 3 +SIG White +SIG

Pin D No Conn Pin 4 No Conn Green No Conn

Pin E No Connection

Pin F No Connection

PX419-100DWU5V,

100 psid range, 0 to 5 Vdc

output shown smaller than

actual size.

Metric threads available, see

omega.com/pxconfig

O 25 mbar PX4[*]9-10WDWU5V

2

1

⁄4 NPT fittings, 2 m (6') cable.

mini DIN

style.

Fast Delivery!

Stock to 2 Weeks

On Most Models

1

⁄4 NPT fittings,

PRESSURE TRANSDUCERS

DIFFERENTIAL

B

B-246

Page 5

WET/WET DIFFERENTIAL

PRESSURE MODELS

RANGES WITH 4 to 20 mA OUTPUTS

UNI-DIRECTIONAL

mA SPECIFICATIONS

Output: 4 to 20 mA

Supply Voltage: 9 to 30 Vdc;

[9 to 20 Vdc above 105°C (229°F)]

Max Loop Resistance: (Vs-9) x 50 Ω

Zero Balance:

Ranges > 1psi: ±0.5% typ (1% max)

Ranges ≤ 1psi: ±1% typ (2% max)

Span Setting:

Ranges > 1psi: ±0.5% typ (1% max)

Ranges ≤ 1psi: ±1% typ (2% max)

CABLE TERMINATION*

To Order Visit omega.com/px409-wwdif

for Pricing and Details

4 to 20 mA

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX409-001DWUI

0 to 2.5 psi 170 mbar PX409-2.5DWUI

0 to 5 psi 350 mbar PX409-005DWUI

0 to 15 psi 1 bar PX409-015DWUI

0 to 30 psi 2 bar PX409-030DWUI

0 to 50 psi 3.5 bar PX409-050DWUI

0 to 100 psi 7 bar PX409-100DWUI

0 to 150 psi 10 bar PX409-150DWUI

0 to 250 psi 17.5 bar PX409-250DWUI

0 to 500 psi 35 bar PX409-500DWUI

0 to 750 psi 50 bar PX409-750DWUI

0 to 1000 psi 70 bar PX409-1.0KDWUI

To order conduit fitting backend change model number

*

from “PX409” to “PX409C”, no additional cost.

MINI DIN TERMINATION

4 to 20 mA OUTPUT, 1⁄4 NPT MALE

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX419-001DWUI

0 to 2.5 psi 170 mbar PX419-2.5DWUI

0 to 5 psi 350 mbar PX419-005DWUI

0 to 15 psi 1 bar PX419-015DWUI

0 to 30 psi 2 bar PX419-030DWUI

0 to 50 psi 3.5 bar PX419-050DWUI

0 to 100 psi 7 bar PX419-100DWUI

0 to 150 psi 10 bar PX419-150DWUI

0 to 250 psi 17.5 bar PX419-250DWUI

0 to 500 psi 35 bar PX419-500DWUI

0 to 750 psi 50 bar PX419-750DWUI

0 to 1000 psi 70 bar PX419-1.0KDWUI

OUTPUT, 1⁄4 NPT MALE FITTINGS

O 25 mbar PX409-10WDWUI

2

O 25 mbar PX419-10WDWUI

2

Fast Delivery!

Stock to 2 Weeks

On Most Models

FITTINGS

UNI-DIRECTIONAL

Twist-lock

style.

PX429-005DWUI, 5 psid

range, 4 to 20 mA output,

shown smaller than

actual size.

Metric threads available, see

omega.com/pxconfig

M12 or TWIST-LOCK

TERMINATION

4 to 20 mA OUTPUT, 1⁄4 NPT MALE FITTINGS

RANGE METRIC MODEL NO.

0 to 10 inH

0 to 1 psi 70 mbar PX4[*]9-001DWUI

0 to 2.5 psi 170 mbar PX4[*]9-2.5DWUI

0 to 5 psi 350 mbar PX4[*]9-005DWUI

0 to 15 psi 1 bar PX4[*]9-015DWUI

0 to 30 psi 2 bar PX4[*]9-030DWUI

0 to 50 psi 3.5 bar PX4[*]9-050DWUI

0 to 100 psi 7 bar PX4[*]9-100DWUI

0 to 150 psi 10 bar PX4[*]9-150DWUI

0 to 250 psi 17.5 bar PX4[*]9-250DWUI

0 to 500 psi 35 bar PX4[*]9-500DWUI

0 to 750 psi 50 bar PX4[*]9-750DWUI

0 to 1000 psi 70 bar PX4[*]9-1.0KDWUI

Comes complete with 5-point NIST traceable calibration certificate.

[*] Enter “5” for PX459 M12 connector or “2” for PX429 twist lock

connector (mating PX429 connector sold separately).

Ordering Examples: PX409-100DWUI, 0 to 100 psi uni-directional

wet/wet differential pressure range, 4 to 20 mA output, 0.08%

accuracy,

PX419-015DWUI, 0 to 15 psi uni-directional wet/wet differential

pressure range, 4 to 20 mA output, 0.08% accuracy,

mini DIN connector.

PX429-10WDWUI, 0 to 10 inH2O uni-directional wet/wet differential

pressure range, 4 to 20 mA output, 0.08% accuracy,

twist-lock connector plus PT06F10-6S, mating connector.

CONNECTIONS—CURRENT OUTPUT

PX429 TWIST-LOCK PX419/PX459 PX409 CABLE

Pin A +SUP Pin 1 +SUP Red +SUP

Pin B -SUP Pin 2 -SUP Black -SUP

Pin C No Conn Pin 3 No Conn White No Conn

Pin D No Conn Pin 4 No Conn Green No Conn

Pin E No Connection

Pin F No Connection

O 25 mbar PX4[*]9-10WDWUI

2

1

⁄4 NPT fittings, 2 m (6') cable.

1

⁄4 NPT fittings,

1

⁄4 NPT fittings,

B-247

Loading...

Loading...