Page 1

High-Performance PCI-Based

Extended Warranty

Program

SM

Data Acquisition Boards

OMB-DAQBOARD-2000 Series

Starts at

$

689

⻬ 5 Models Available

⻬ 16-Bit, 200 kHz A/D

Converter

⻬ 8 Differential or

16 Single-Ended Analog

Inputs (Software

Selectable per Channel)

⻬ Expandable Up to

256 Analog Input Channels,

While Maintaining 200 kHz

(5 µs per Channel)

Scan Rate

⻬ Up to 4 Boards Can be

Installed into One PC

for Up to 1024 Analog

Input Channels

⻬ 100% Digital Calibration

⻬ 512-Location

Channel/Gain FIFO,

Capable of Scanning

All Channels, Including

256 Analog Expansion

Channels and Digital/

Counter Channels,

at 5 µs per Channel

⻬ DMA Bus Mastering for

Synchronous Analog I/O,

Digital I/O, and Counter

Inputs

OMEGACARESMextended warranty program is available for

models shown on this page. Ask your sales representative for

full details when placing an order. OMEGACARE

parts, labor and equivalent loaners.

⻬ Trigger Modes Include

Analog, Digital, and

Software, with <5 µs

Latency

⻬ Virtually Infinite

Pre-Trigger Buffer

⻬ Up to Four 16-Bit,

100 kHz Analog

Outputs with Infinite

Continuous Waveform

Output Capability

⻬ 40 Digital I/O Lines,

Can be Scanned

Synchronously or

Asynchronously

with Analog Inputs

⻬ Digital I/O is

Expandable Up to

272 Lines, Including

Optional Isolation and

Relay Closure

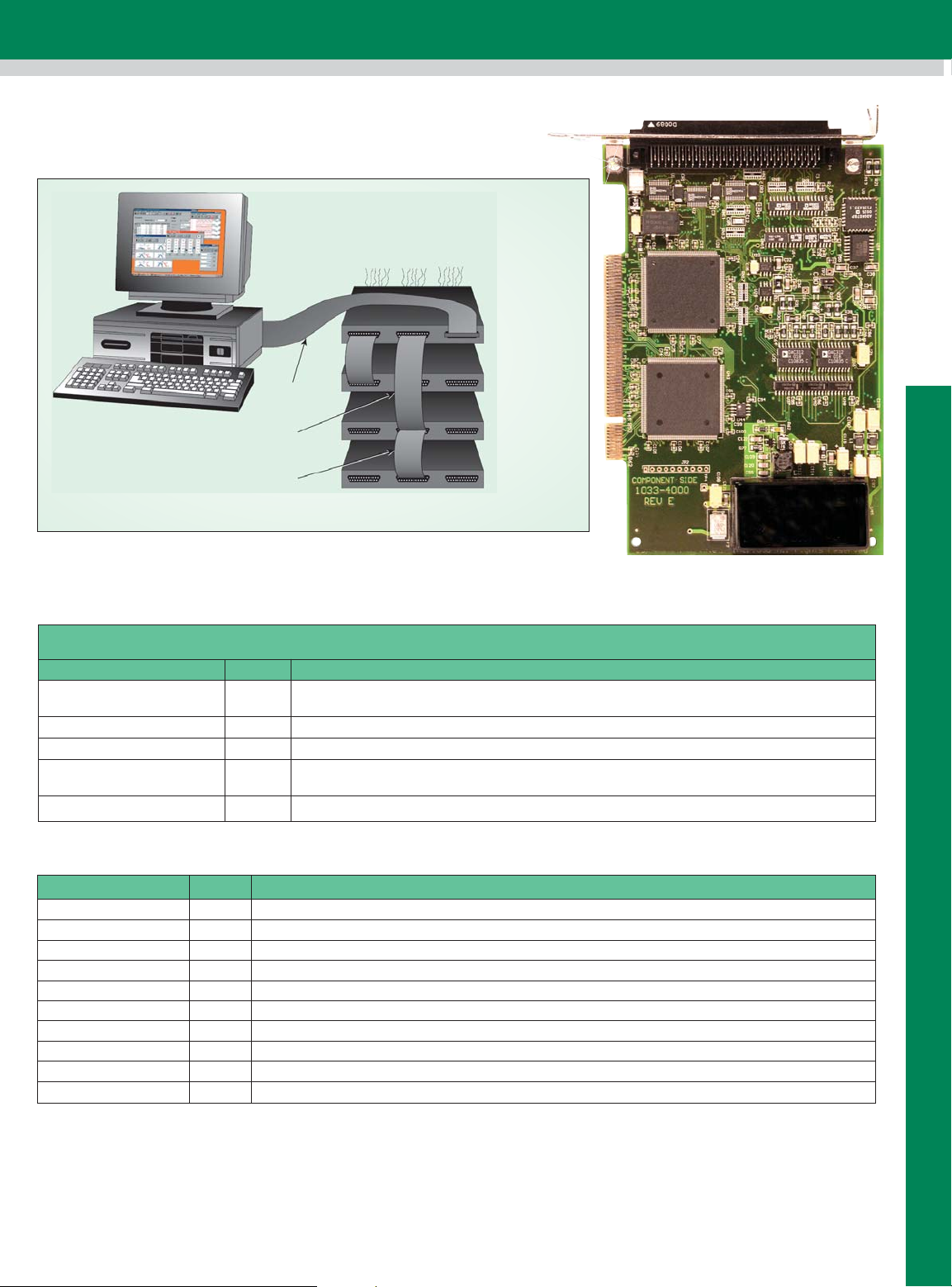

OMB-DAQBOARD-2000, $799,

shown smaller than actual size.

SM

covers

⻬ 4 Counter/Pulse Input

Channels Can be

Scanned Synchronously

or Asynchronously with

Analog Inputs

⻬ 2 Timer/Pulse

Output Channels

⻬ Signal Conditioning and

Expansion Options for

Thermocouples, Strain

Gages, Accelerometers,

Isolation, and RTDs—

Over 30 Options in All

⻬ Includes DaqView

Windows Software;

DaqX API Library, Drivers

for Visual Basic, C++, and

Delphi for Windows 95

and Higher; C++ for

Linux; DASYLab,

TestPoint, and LabVIEW

D1-1

Page 2

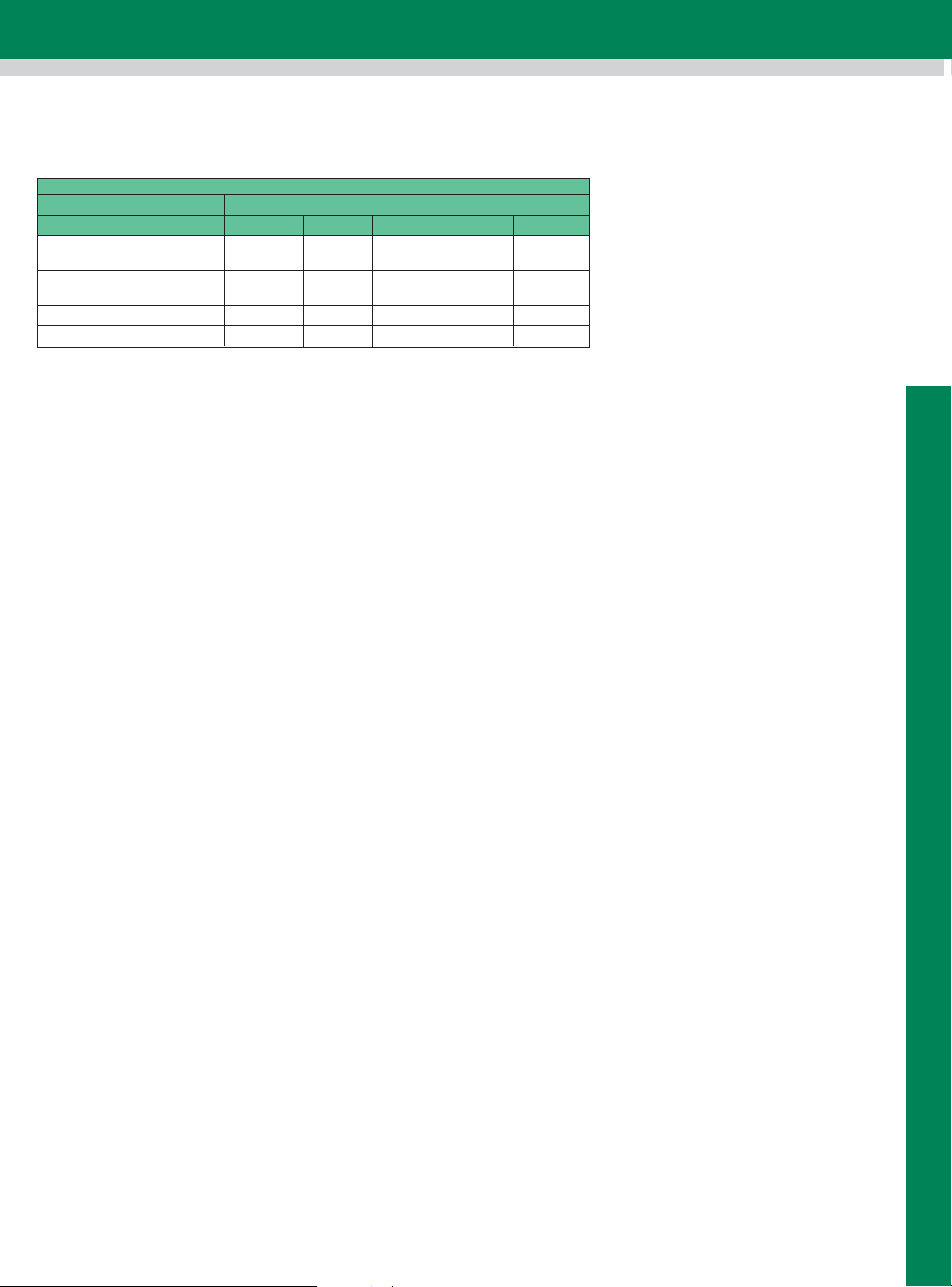

OMB-DAQBOARD-2000 Series Selection Chart

OMB-DAQBOARD Models I/O

Feature 2001 2000 2005 2004 2002

Analog Inputs (P1)

(16 bit/200 kHz)

Analog Outputs (P3)

16 bit/100 kHz)

Digital I/O (P2, P3) 40 40 40 40 40

Freq./pulse I/O (P3) 6 6 6 6 6-

The OMB-DAQBOARD-2000 Series

sets the price/performance

benchmark for high-speed,

multifunction plug-and-play data

acquisition for PCI bus computers.

The hardware design offers all the

features normally found on

significantly more expensive boards,

including 16-bit, 200 kHz A/D; 100%

digital calibration; bus mastering,

two or four 16-bit, 100 kHz A/D

converters; 40 digital I/O lines;

4 counters; and 2 timers.

The OMB-DAQBOARD-2000 Series

is supported by a growing family

of over 30 signal conditioning and

expansion options, offering signal

conditioning for thermocouples,

RTDs, accelerometers, isolation,

high voltage, strain gages, and

much more. Up to 528 channels

of analog and digital I/O can

be accessed with one

OMB-DAQBOARD-2000, while

maintaining the 5 µs per channel

update rate. Up to 4

OMB-DAQBOARD-2000s can

be installed into one PC.

The OMB-DAQBOARD-2000 has

more extensive software capabilities

than most other boards, with

comprehensive drivers for nearly

every programming environment

supported by Windows 95 and

higher. Included in this list are

Visual Basic, C++, Delphi,

TestPoint, LabVIEW, and

DASYLab, and C++ for Linux.

Also included is a suite of DaqView

software options for setup,

acquisition, display, and analysis

of acquired data—no programming

required.

16 16 16 - -

42-4 -

Synchronous I/O

for High-Speed Applications

The OMB-DAQBOARD-2000 Series

sets a new standard with its ability

to make analog measurements,

read digital inputs, and read counter

inputs, while synchronously

generating up to 4 analog outputs

and/or a 16-bit digital pattern output.

Most other boards require CPU

interaction to access I/O other than

analog input, making it impossible to

generate time-critical analog

waveforms or digital patterns. With

the OMB-DAQBOARD-2000 Series,

the true power of PCI-based PCs

can be unleashed.

The same synchronous features of

the OMB-DAQBOARD-2000 extend

to its family of OMB-DBK signal

conditioning and expansion options.

Up to 256 analog input channels

and 272 (P2 only) digital I/O

channels can also be accessed

synchronously to one another, with

precise and deterministic channelto-channel timing. Up to 4

OMB-DAQBOARD-2000s can be

installed in one PC, quadrupling the

channel capacity to over 1000

analog input channels, 1000 digital

I/O channels, and 16 high-speed

analog output channels.

Signal I/O

One 100-pin connector on the

OMB-DAQBOARD-2000 Series

provides access to all the

input and output signals. Unlike

other multifunction boards that

require multiple PC slots, the

OMB-DAQBOARD-2000 Series

accommodates all I/O using one

cable and has only one PCI slot.

The 100-pin OMB-DAQBOARD/2000

Series I/O connector, P4, is logically

divided into 3 subports: P1, P2, and

D1-2

P3. P1, the analog input port,

contains all of the analog input

channels, as well as the sequencer

control signals for accessing

external analog input options. All

analog expansion options attach to

the P1 port. P2, the general purpose

digital I/O port, can be used directly

to control and monitor 24 digital I/O

lines. P2 can also function as the

digital I/O expansion port, whereby

the 24 lines are exclusively used to

control external digital OMB-DBK

expansion options, for up to 256

lines of digital input or output. P3

contains an additional 16-bit digital

I/O port, as well as the counter

inputs, timer outputs, and analog

outputs. Several options are

available to provide easy user

access to all of the I/O signals on P4.

Analog Input (P1)

The OMB-DAQBOARD-2000 Series

has a 16-bit, 200 kHz A/D coupled

with 16 single-ended or 8 differential

analog inputs. Thirteen softwareprogrammable ranges provide

inputs from ±10 V to ±156 mV full

scale. Each channel can be

software configured for a different

range, as well as for single-ended or

differential and unipolar or bipolar

inputs. Beyond the 16 built-in

analog inputs, the user can expand

the OMB-DAQBOARD-2000 Series

up to 256 analog inputs using

external OMB-DBK signal

conditioning and expansion options.

As with the on-board channels,

expansion channels are scanned

at the same 5 µs/channel rate

(200 kHz), and most are software

programmable for range. There is

no speed penalty for scanning

expansion channels versus built-in

channels. The OMB-DBK expansion

options offer a wide variety of signal

measurements, including

thermocouples, RTDs, strain gages,

accelerometers, high voltage,

isolation, current, and much more.

D1

ANALOG INPUT AND

MULTIFUNCTION CARDS

Page 3

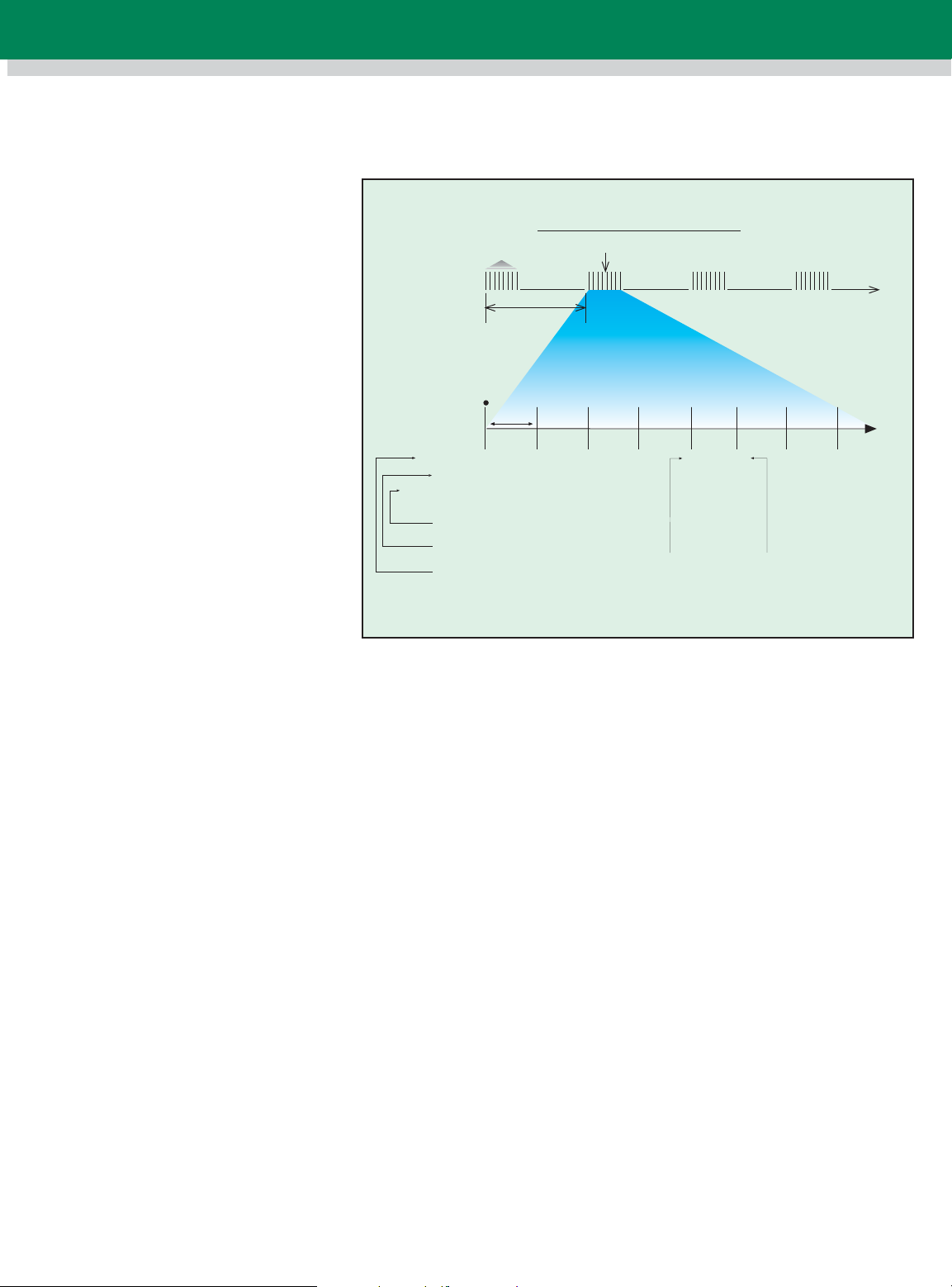

Scanning

The OMB-DAQBOARD-2000 Series

has an on-board scan sequencer

that permits the user to select any

combination of up to 512 channel/

range combinations. The sequencer

scans all channels contained in the

sequence at the fastest rate of

5 µs/channel, thereby minimizing the

time-skew from channel-to-channel.

The user can also set the time

between scan groups, from 0 to 6 hours.

In addition to scanning analog

inputs, the sequencer can scan

digital inputs and counter inputs.

Channel-Scanning

Flexibility

The OMB-DAQBOARD-2000 Series

offers a 512-location scan

sequencer that allows the user to

select each channel and associated

input amplifier gain at random. The

sequencer circuitry circumvents a

major limitation encountered with

many plug-in data acquisition

boards—a drastic reduction in the

scan rate for external expansion

channels. All OMB-DAQBOARD-2000

Series channels, including

the 528 potential expansion

channels, are scanned at 200 kHz

(5 µs/channel). In addition, the digital

and frequency inputs can be scanned

by using the same scan sequence

employed for analog inputs, enabling

the time correlation of acquired

digital data to acquired analog data.

The OMB-DAQBOARD-2000 Series

permits each scan group, which can

contain up to 512 channel/gain

combinations, to be repeated

immediately or at a programmable

interval of up to 6 hours. Within

each scan group, consecutive

channels are measured at a fixed

5 µs/channel rate.

Bus Mastering DMA

The OMB-DAQBOARD-2000 Series

supports bus mastering DMA, which

allows analog and digital/counter input

data, as well as analog and digital

output data, to flow between the PC

and the OMB-DAQBOARD-2000

Series without consuming valuable

CPU time.

The driver supplied with the

OMB-DAQBOARD-2000, as well as

all other third-party software support

such as TestPoint, LabVIEW, and

DAQBOARD Scanning Example

Channel

Unipolar or

bipolar

* DaqBoard-200 and 216 only

#2

x1

Gain

Uni Uni Bi Uni Bi Bi

Unipolar or bipolar operation can be

programmed for each channel dynamically*

Gain can be programmed for

each channel dynamically

Channels can be

sampled randomly

Scan group

Programmable,

immediately or at

intervals of

up to 10 hours

10 µ s

#4 #7 #2 D #18 #19 #16

x8 x8 x2 x100 x10

All channels within a scan group are

measured at a fixed 10 µs/channel

16 digital input lines

can also be sampled along

with the analog inputs

DASYLab, automatically use bus

mastering DMA to efficiently

conduct I/O from the PC to the

OMB-DAQBOARD-2000.

Triggering

Triggering can be the most critical

aspect of a data acquisition application.

The OMB-DAQBOARD-2000 Series

supports a full complement of

trigger modes to accommodate any

measurement situation.

Hardware Analog Triggering

Many data acquisition boards claim

analog triggering, but rely on the PC

to take readings and make a

decision, which leads to uncertain

and potentially long latencies. The

OMB-DAQBOARD-2000 Series

uses true analog triggering,

whereby the trigger level

programmed by the user sets an

analog DAC, which is then

compared in hardware to the analog

input level on the selected channel.

The result is analog trigger latency

that is guaranteed to be less than

5 µs, significantly shorter than that

of most data acquisition boards.

Any analog channel can be selected

as the trigger channel, including

built-in or expansion channels. The

D1-3

t

x1000

Uni

Expansion channels (up to

256) are sampled at the same

rate as on-board channels

user can program both the trigger

level and the edge (rising or

falling).

Digital and Pattern

Triggering (P1)

A separate digital trigger input line

is provided, allowing TTL-level

triggering, again with latencies

guaranteed to be less than 5 µs.

Both the logic levels (1 or 0) and

the edge (rising or falling) can be

programmed for the discrete

digital trigger input.

Software-Based Triggering

Software-based triggering differs

from the modes described above

because the readings—analog,

digital, or counter—are interrogated

by the PC to detect the trigger

event, not in the hardware as

described above. The advantage

of this mode is to permit triggering

based on more complex

situations, such as on a specific

temperature, which was derived

from the acquisition of at least

2 analog measurements, plus the

calculation of the measured

temperature using linearization

algorithms.

Page 4

The OMB-DAQBOARD-2000 Series

also supports digital pattern

triggering, whereby the user can

designate any of the digital input

ports as the trigger port. The

programmed digital pattern, including

the ability to mask or ignore specific

bits, is then compared to the actual

input until a match is detected, after

which the sequencer begins the

scan sequence. Triggering can also

be programmed to occur when one

of the counters reaches, exceeds,

or is within a programmed level.

Any of the built-in counter/totalizer

channels can be programmed as a

trigger source. Normally softwarebased triggering results in long

latencies from the time that a trigger

condition is detected until the actual

capturing of data commences. However,

the OMB-DAQBOARD-2000 Series

circumvents this undesirable

phenomenon by use of pre-trigger

data. Specifically, when

software-based triggering is

employed and the PC detects that a

trigger condition has occurred

(which may be thousands of

readings later than the actual

occurrence of the signal), the OMBDAQBOARD-2000 driver

automatically looks back to the

location in memory where the actual

trigger-causing measurement

occurred. The acquired data that

are presented to the user actually

begin at the point where the triggercausing measurement occurs. The

latency in this mode is equal to one

scan cycle.

Stop Trigger

Any of the software trigger modes

described above can also be used

to stop an acquisition. Thus an

acquisition can be programmed to

begin on one event, such as a

temperature level, and then can

stop on another event, such as a

digital pattern.

No pre-trigger, post-trigger stop

event.

acquires data upon receipt of the

trigger, and stops acquiring upon

receipt of the stop-trigger event.

This, the simplest of modes,

Fixed pre-trigger with post-trigger

stop event

specifies the number of pre-trigger

readings to be acquired, after

which acquisition continues until a

stop-trigger event occurs.

. In this mode, the user

No pre-trigger, infinite post-trigger.

No pre-trigger data are acquired in

this mode. Instead, data are

acquired beginning with the trigger

event, and are terminated when the

operator issues a command to halt

the acquisition.

Fixed pre-trigger with infinite posttrigger.

the amount of pre-trigger data to

acquire, after which the system

continues to acquire data until the

program issues a command to halt

acquisition.

The user specifies

Variable pre-trigger with

post-trigger stop event (driver

support only).

pre-trigger modes, this mode does

not have to satisfy the pre-trigger

number of readings before

recognizing the trigger event. Thus

the number of pre-trigger readings

acquired is variable and dependent

on the time of the trigger event

relative to the start. In this mode,

data continue to be acquired until

the stop-trigger event is detected.

Unlike the previous

Variable pre-trigger with infinite

post-trigger (driver support only).

This is similar to the mode

described above, except that the

acquisition

is terminated upon receipt of a

command from the program to halt

the acquisition.

appropriate calibration constant is

automatically applied to a

compensating DAC, thereby

calibrating the specific range. The

result is that readings generated by

the A/D are already calibrated, and

do not require additional processing.

This is significantly better than other

boards that merely adjust the

readings in software after they are

transferred to the PC. That method

has the disadvantage of reducing

the dynamic range of the A/D, and

can adversely affect the speed by

which the PC can obtain a calibrated

reading. The OMB-DAQBOARD-2000

Series also has a USERCAL mode,

whereby the user can adjust the

calibration of the board in his or her

system, without destroying the

factory calibration supplied with the

board. This is accomplished by

having 2 distinct calibration tables in

the OMB-DAQBOARD-2000 Series

on-board EPROM, one that contains

the factory calibration, and the other

that is available for user calibration.

Analog Output (P3)

OMB-DAQBOARD-2000, -2001,

and -2004 Only

Two or four 16-bit, 100 kHz

analog output channels are built into

the OMB DAQBOARD-2000 Series,

with an output from –10 V to 10 V.

These outputs are entirely separate

from the D/As which are used to

determine analog trigger level

(some data acquisition board

suppliers confusingly refer to trigger

D/As as if they are available to the

user). With bus mastering DMA,

each D/A output can continuously

output a waveform, which can be

read from PC RAM or a file on the

hard disk. In addition, a program

can asynchronously output a value

to either of the D/As for non-waveform

applications, presuming that the D/A

is not already being used in the

waveform output mode.

D1

ANALOG INPUT AND

MULTI-FUNCTION CARDS

Pre- and Post-Triggering

Modes

6 modes of pre- and post-triggering

are supported, providing a wide

variety of options to accommodate

any measurement requirement.

With pre-trigger, the user must

employ software-based triggering to

initiate an acquisition.

Calibration

Every range on the

OMB-DAQBOARD-2000 Series is

calibrated from the factory using a

digital calibration method. This

method works by storing a

correction factor for each range on

the OMB-DAQBOARD-2000 Series

at the time of calibration. Whenever

a particular range is selected, the

D1-4

Page 5

Additional low-speed D/A

channels can be added to the

OMB-DAQBOARD-2000 through the

use of the OMB-DBK2 analog

output option card. When used to

generate waveforms, the D/As

can be clocked in several different

modes. Each D/A can be separately

selected to be clocked from one of

the sources described below.

Asynchronous Internal Clock The

on-board programmable clock can

generate updates ranging from

1.5 Hz to 100 kHz, independent of

any acquisition rate.

Synchronous Internal Clock

The rate of analog output update

can be synchronized to the acquisition

rate derived from 100 kHz to once

every 5.96 hours.

Asynchronous External Clock

A user-supplied external input clock

can be used to pace the D/A,

entirely independent of analog inputs.

Synchronous External Clock

A user-supplied external input clock

can pace both the D/A and the

analog input.

Digital Pattern Generation

(P3)

The OMB-DAQBOARD-2000 Series

supports digital pattern generation

via bus mastering DMA on the

16-bit high-speed digital I/O port.

Like analog output, the digital

pattern can be read from PC RAM

or a file on the hard disk. Digital

pattern generation is clocked in the

same 4 modes as analog output

(when digital pattern generation is

used, one of the analog output

channels is limited to asynchronous

output mode).

Digital Inputs and Outputs

(P2, P3)

Forty TTL-level digital I/O lines are

included in the OMB-DAQBOARD-2000

Series. They are divided into three

8-bit ports (P2) and one 16-bit port (P3).

The P2 ports can be programmed in

8-bit groups as either input or

output. The 16-bit P3 port can be

programmed as all inputs or all

outputs. Ports programmed as

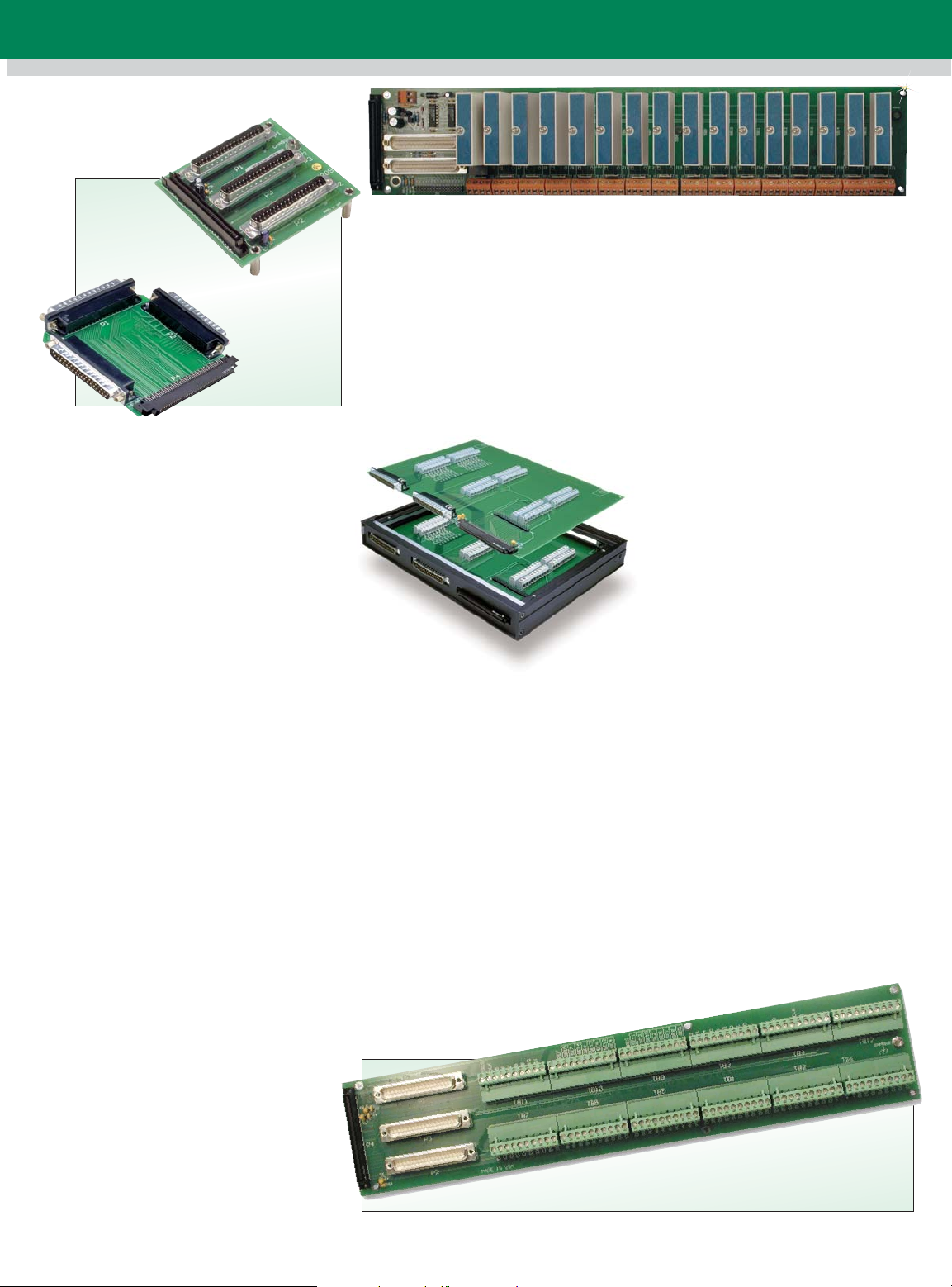

OMB-DBK200, $39,

shown smaller

actual size.

inputs can be part of the scan group

and scanned along with other

analog and digital input channels, or

can be asynchronously accessed

via the PC at any time, including

when a scanned acquisition is

occurring. In addition, the P2 ports

can be expanded up to 256 digital

I/O lines using external OMB-DBK

digital options. These options are

available as TTL-level I/O, relay

output, or optically isolated input

and output. Whenever expansion

digital I/O is attached to the

OMB-DAQBOARD-2000 Series,

the P2 I/O lines are no longer user

programmable, but are used to

communicate with the digital

expansion options.

Counter Inputs (P3)

Four 16-bit counters are built into

the OMB-DAQBOARD-2000, each

capable of counting up to 65,

536 TTL-level transitions. Each of

the 4 counters will accept frequency

inputs up to 10 MHz. The counters

can also be cascaded, allowing

over 4 billion counts to be accumulated.

As with all other inputs to the

OMB-DAQBOARD-2000 Series, the

counter inputs can be read

asynchronously under program

control, or synchronously as part of

an analog and digital scan group.

Timer Outputs (P3)

Two 16-bit timer outputs are built

into the OMB-DAQBOARD-2000,

each capable of generating

different square waves with a

programmable frequency range

from 16 Hz to 1 MHz.

Multiple OMB-DAQBOARD-2000s

Per PC

All of the features described for

the OMB-DAQBOARD-2000

can be replicated with up to

4 OMB-DAQBOARD-2000s

installed in the same PC.

Each OMB-DAQBOARD-2000 has

a serial number for identification,

and a user-selected name can be

assigned to each board for easy

program documentation. Thus, with

4 boards installed along with

OMB-DBK expansion options, over

1000 analog input channels and

over 1000 digital I/O channels could

be accessed from one PC. When

multiple boards are installed, all

boards can be operated synchronously.

The OMB-DAQBOARD-2000 Series

provides all I/O signals on one

100-pin connector. The following

adaptor options make it easy for the

user to attach signals and

expansion options to the

OMB-DAQBOARD-2000 Series.

OMB-DBK200

Adaptor Board

Suitable exclusively for analog-signal

expansion, the OMB-DBK200

adaptor board contains one 100-pin

connector that connects to the

OMB-DAQBOARD-2000 Series via

the OMB-CA-195 cable, and one

female DB37 connector that mates

directly with the P1 port of any of

the OMB-DBK analog signal

conditioning and expansion options.

This is the most convenient way to

add analog expansion options if

access to the OMB-DAQBOARD-2000

Series digital I/O or frequency

signals is not required. Access to

P1 analog signals is also possible

via included female-mating

solder-lug connectors or optional

OMB-CA-37-x or OMB-CA-37-xT

expansion cables.

D1-5

Page 6

System Configuration Examples

OMB-DBK82 OMB-DBK16 OMB-DBK15

14-channel high-accuracy

thermocouple

expansion card

OMB-DBK60

enclosure with

OMB-DBK82,

OMB-DBK16

and OMB-DBK15

analog expansion

cards installed;

optional rackmount bracket

OMB-DBK602, $124, OMB-DBK604,

$113, OMB-DBK605, $103,

termination panels installed

2-channel strain

gage card

16-channel universal

current/voltage input

card

CA-195

P4

CA-195

P4 P1

OMBDAQBOARD2001

The OMB-DBK200, $39, adaptor mates directly with

analog OMB-DBK signal conditioning options

CA-195

OMBDAQBOARD2001

OMB-DBK201

Adaptor

P4

P4 P1

CA-195

OMB-DBK200

Adaptor

P3

P2

OMB-DBK81

T/C/mV card with

screw-terminal

connect

Frequency I/O

CA-113

Analog I/O

Digital I/O

P1

D1

ANALOG INPUT AND

MULTI-FUNCTION CARDS

Industrial rack-mount PC with

OMB-DAQBOARD-2001 board installed

CA-37-1 (8)

Desktop PC with

OMB-DAQBOARD-2001,

$1149 (computer not

included)

CA-195

P4

OMB-DBK202

Adaptor

P2

P3

OMBDAQBOARD

-2001

The OMB-DBK202, $199, or OMB-DBK206, $249,

(P1, P2, P3) adaptor with screw-terminal connectors

OMB-DBK207, $245,

(up to 16) signal

conditioning and

expansion boards

for 5B-compatible

I/O modules; analog

and digital

expansion; mounted

using Rack3

OMB-DBK206, $249,

screw-terminal

adpator board

OMB-DBK208, $219

(up to 8) signal

conditioning and

expansion boards for

OPTO-22 compatible

solid-state-relay (SSR)

modules; analog and

digital expansion;

mounted using Rack3

NEMA enclosure with OMB-DBK207 (16),

OMB-DBK206 (1), and OMB-DBK208 (8)

D1-6

Page 7

OMB-DBK209,

$59, shown

smaller than

actual size.

OMB-DBK209,

$59, shown

smaller than

actual size.

OMB-DBK201 and OMBDBK209 Adaptor Boards

For both analog and digital

expansion, the OMB-DBK201

adaptor board mates with the

OMB-DAQBOARD-2000 Series

via a 1 m (3') OMB-CA-195 cable.

The OMB-DBK209 provides 3 male

DB37 connectors, divided into P1

analog input, P2 digital

I/O, and P3 analog output and

counter/timer I/O. Each port

on the OMB-DBK201 connects to

OMB-DBK expansion options via

an optional OMB-CA-37-x or

OMB-CA-37-xT expansion cable.

Alternatively, users can solder wires

to the included DB37 female-mating

solder-lug connectors, or custom

make their own cables that are

terminated with a female DB37. An

optional 1.8 m (6') cable is available

that contains a mating female DB37

connector at one end, and is

unterminated at the other end

(OMB-CA-113). The OMB-DBK209

is identical in function to the OMBDBK201 but is snap-track (DIN-rail),

and rack-mountable with optional

mounting kits.

OMB-DBK202

and OMB-DBK203 ScrewTerminal Adaptor Board

The OMB-DBK202 screw-terminal

board provides convenient

screw-terminal access to all signals

from the OMB-DAQBOARD-2000

Series. Divided into 3 ports (P1, P2,

and P3), the OMB-DBK202 also

provides another way to access

signals. There are male DB37

connectors on P1 and P2, and an

adaptor cable (OMB-CA-60) can

be used to connect to the P3

header for connection to DBK signal

conditioning and expansion options.

OMB-DBK207, $249, shown smaller than actual size

Mounting holes in the OMB-DBK202

permit it to be easily screw-mounted

into a user-provided enclosure. The

OMB-DBK203 is identical to the

OMB-DBK202, except that it is

housed in a shielded metal enclosure,

which easily mounts to other

OMB-DBK signal conditioning and

expansion modules. Optional

fastener panels are available for

attaching other OMB-DBK modules.

OMB-DBK202, $199, and OMB-DBK203,

$299, shown smaller than actual size.

OMB-DBK206 ScrewTerminal Adaptor Board

Similar in function to the

OMB-DBK202, but designed for

mounting in 19-inch enclosures,

the OMB-DBK206 features three

vertically mounted straight male

DB37 connectors for analog and

digital channel expansion (P1

analog I/O, P2 digital I/O, and P3

digital and counter-timer, plus

analog output). Two rows of

removable screw terminals provide

convenient access to all

OMB-DAQBOARD-2000 Series

I/O-signals (10-22 AWG wire). It

mates with the OMB-DAQBOARD-2000

Series via a 1 m (3')

OMB-CA-195 cable, and each port

(P1, P2, and P3) connects to DBK

signal conditioning and expansion

options via optional OMB-CA-37-x

cable(s). The standard OMB-DBK206

can be panel mounted, but it also is

DIN-rail mountable and rack-mountable

with optional mounting kits.

OMB-DBK207

and OMB-DBK207/CJC

Multiplexing Isolated

Analog Input Board

The OMB-DBK207 provides sockets

for 16 channels of isolated analog

input when populated with industrystandard 5B-style or compatible

signal conditioning modules. Each

channel features screw terminals

and sockets for current conversion

resistors (supplied with 5B current

input modules). The OMB-DBK207/CJC

features added cold-junction

compensation per channel for

thermocouple-based measurements.

Multiplexing is built-in, allowing up

to 16 OMB-DBK207 boards to be

directly connected to one

OMB-DAQBOARD-2000 Series

board for a total signal capacity

of 256 isolated analog inputs.

The 100-pin P4 connector on the

OMB-DBK207 attaches directly

to the OMB-DAQBOARD-2000

(via OMB-CA-195 cable). Two DB37

connectors permit daisy chaining to

other OMB-DBK207 boards, and to

any of the other OMB-DBK analog

signal conditioning boards and

modules. The OMB-DBK207/CJC

and the OMB-DBK207 can be rack

or snap-track mounted with optional

mounting kits.

OMB-DBK206, $249,

shown smaller than

actual size.

D1-7

Page 8

OMB-DBK208

Multiplexing—Isolated

Digital I/O Board

The OMB-DBK208 provides

sockets for 16 channels of isolated

digital I/O when populated with

industry-standard Opto-22 style or

compatible solid-state-relay modules.

Each socket also features screw

terminals and an LED to indicate

logic status. The 16 digital I/O can

be jumper configured as either

inputs or outputs in 8-channel groups.

Multiplexing is built-in,

allowing up to 16 OMB-DBK208

boards to be

OMB-DAQBOARD-2000

board, for a total signal capacity of

256 isolated digital I/O channels.

On-board logic ensures that outputs

are disabled during power-up and

by a CPU reset. Also included is the

ability to choose whether outputs

are “off” or in the “last known state”

when loss of external power occurs.

The 100-pin P4 connector on the

OMB-DBK208 attaches directly to

a OMB-DAQBOARD/2000 Series

board (via OMB-CA-195 cable),

while 2 DB37 connectors permit

daisy chaining to other OMB-DBK208

boards and to any of the other

OMB-DBK digital boards and modules.

connected to one

Series

OMB-DBK208, $219,

shown smaller than

actual size.

Accuracy**

One Year, 0 to 35°C (% Reading + % Range)

Voltage Range* Absolute

0 to 10 V 0.015 + 0.005

0 to 5 V 0.015 + 0.005

0 to 2.5 V 0.015 + 0.005

0 to 1.25 V 0.015 + 0.008

0 to 0.625 V 0.015 + 0.008

0 to 0.3125 V 0.015 + 0.008

-10 to 10 V 0.015 + 0.005

-5 to 5 V 0.015 + 0.005

-2.5 to 2.5 V 0.015 + 0.005

-1.25 to 1.25 V 0.015 + 0.005

-0.625 to 0.625 V 0.015 + 0.008

-0.3125 to 0.3125 V 0.015 + 0.008

-0.156 to 0.156 V 0.02 + 0.008

* Specifications assume differential-input single-channel scan, 200 kHz scan rate, unfiltered.

** Accuracy specification is exclusive of noise.

D1

ANALOG INPUT AND

MULTI-FUNCTION CARDS

DAQVIEW Software

The DAQVIEW software allows the

user to verify signal connections,

acquire and save data to disk, and

graphically view real-time data within

moments of installing a system.

Easily set up all hardware,

acquisition, and display parameters

without programming, via a simple,

spreadsheet-style screen. The

software is a full-featured

and display application

all the functionality needed for many

data logging applications.

acquisition

that provides

Specifications

GENERAL (ALL BOARDS)

Power Consumption

(per Board): 3.5 W (up to 10 W

with external accessories)

Power Available for External

Signal Conditioning and

Expansion Options: 5 V @ 1 A

(all boards); ±15 V @ 75 mA each

(except for 2002)

Operating Temperature:

0 to 60°C (32 to 140°F)

Vibration: MIL STD 810E

Signal I/O Connector: 100-pin

high-density edge-type carries all

analog and digital I/O signals

Dimensions:

165 W x 15 D x 108 mm H

(6.5 x 0.6 x 4.2")

ANALOG INPUTS

(2000, 2001 and 2005) Channels:

16 single-ended or 8 differential,

programmable on a per-channel

basis as single-ended or differential

and unipolar or bipolar

D1-8

Expansion: Up to 256 channels per

board (4 boards per PC), without

degradation in maximum

channel-to-channel scan rate

(5 µs/channel)

Bandwidth: 500 kHz

Settling Time: 5 µs to 1 LSB

for full scale step

Maximum Input Voltage: ±11 V

relative to analog common

Overvoltage Protection: ±35 V

Ranges: Software or sequencer

selectable on a per-channel basis

A/D SPECIFICATIONS

(2000, 2001 and 2005)

Type: Successive approximation

Resolution: 16-bit

Conversion Time: 5 µs

Maximum Sample Rate: 200 kHz

Non-Linearity (Integral): ±1 LSB

Non-Linearity (Differential):

No missing codes

Page 9

INPUT SEQUENCER

(2000, 2001, 2002, 2004 and 2005)

Analog, digital and counter inputs

can be scanned synchronously,

based on either an internal

programmable timer or an external

clock source. Analog and digital

outputs can be synchronized to

either of these clocks.

Scan Clock Sources: 2

1. Internal, programmable from 5 µs

to 5.96 hours in 5 µs steps

2. External, TTL-level input up to

200 kHz max

Programmable Parameters

per Scan: Channel (random order),

gain, unipolar/bipolar

Depth: 512 location

On-Board Channel-to-Channel

Scan Rate: 5 or 10 µs per channel,

programmable

Expansion Channel Scan Rate:

5 or 10 µs per channel,

programmable

EXTERNAL ACQUISITION SCAN

CLOCK INPUT

(2000, 2001 and 2005)

Maximum Rate:

200 kHz

Clock Signal Range: 0 to 5 V

Minimum Pulse Width:

50 ns high, 50 ns low

Triggering

Trigger Sources: 6, individually

selectable for starting and stopping

an acquisition. Stop acquisition can

occur on a different trigger source

than start acquisition, and can be

triggered via modes 2, 4, 5 or 6.

Pre-trigger is supported with fixed or

variable pre-trigger periods.

1. Single-channel analog hardware

trigger latency: 5 µs max

(2000, 2001 and 2005)

2. Single-channel analog software

trigger latency: one scan period max

(2000, 2001 and 2005)

3. Single-channel digital trigger

latency: 5 µs max

(2000, 2001, 2002, 2004 and 2005)

4. Digital pattern triggering

latency: one scan period max

(2000, 2001, 2002, 2004 and 2005)

5. Counter/totalizer triggering

(2000, 2001, 2002, 2004 and 2005)

latency: one scan period, max

(all boards)

6. Software triggering (all boards)

trigger can be initiated under

program control.

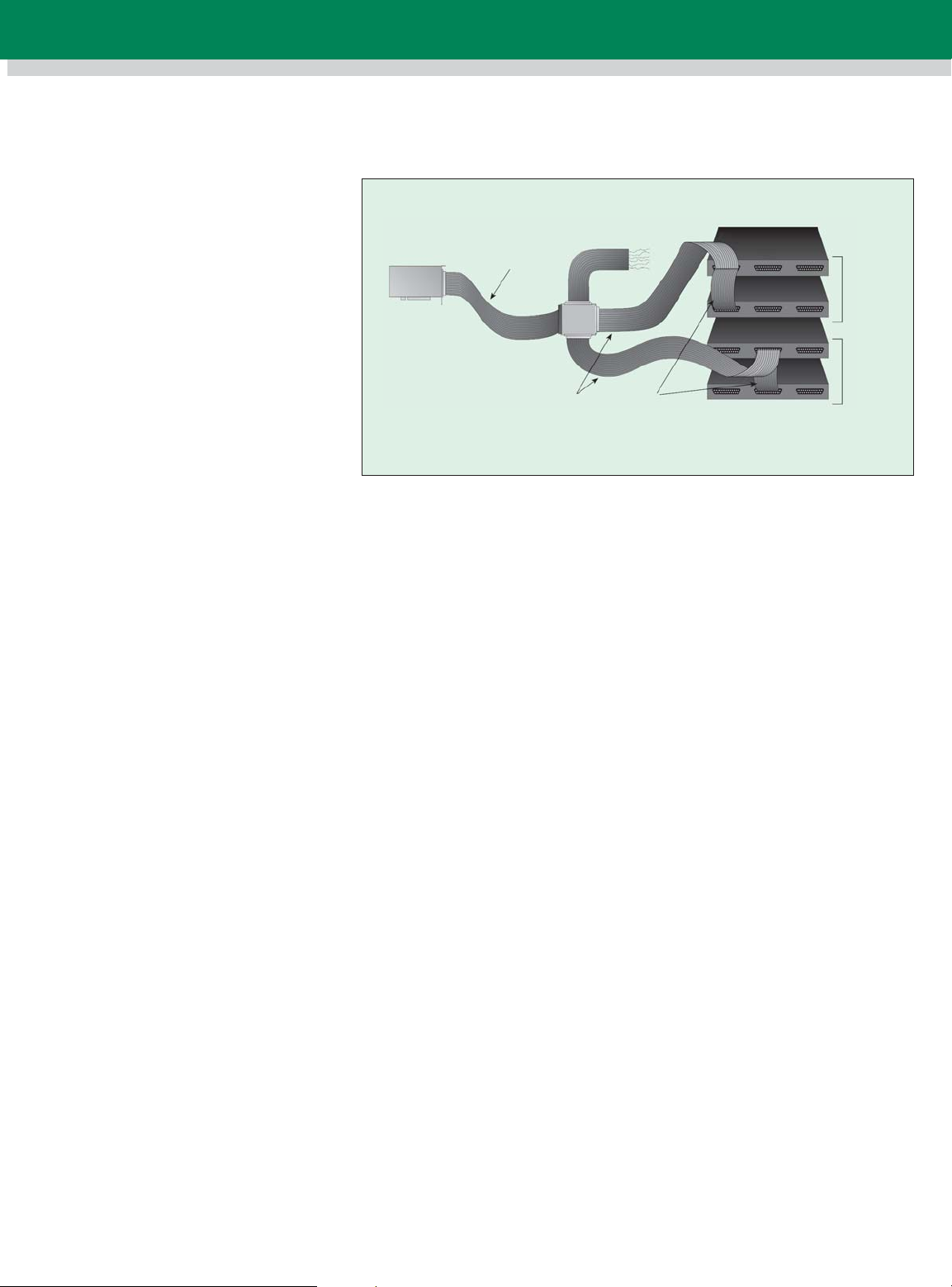

OMB-DAQBOARD-2001

OMB-CA-113

OMB-CA-195

P3

P4 P1

P2

OMB-CA-37-3T

The OMB-DBK201, $49 adaptor with analog and digital DBK signal

conditioning and expansion modules terminal connectors

ANALOG OUTPUTS

(2000, 2001 and 2004)

The 2 or 4 analog output channels

are updated synchronously relative

to scanned inputs, and clocked from

either an internal on-board clock or

an external clock source. Analog

outputs can be updated

asynchronously, independent of any

other scanning in the system. Bus

mastering DMA provides CPU and

system-independent data transfers,

ensuring accurate outputs

independent of other system

activities. Streaming from disk or

memory is supported, allowing

continuous, nearly infinite-length,

waveform outputs (limited only by

available PC system resources).

Channels: 2 (2000); 4 (2001

and 2004)

Resolution: 16-bit

Output Voltage Range: ±10 V

Clock Sources: 4, programmable

1. On-board D/A clock, independent

of scanning input clock

2. On-board scanning input clock

(2000, 2001 & 2004 only)

3. External D/A input clock,

independent of external scanning

input clock

4. External scanning input clock

(2000, 2001 and 2004 only)

DIGITAL I/O

(2000, 2001, 2002, 2004 and 2005)

Channels: 40, expandable up to

208 with OMB-DBK options

Input Scanning Modes:

2, programmable

1. Asynchronous, under program

control at any time

2. Synchronous with input scanning

Analog

DBK

Module

Digital

DBK

Module

OMB-CA-37-1T

Ports: 3 x 8-bit (82C55 emulation),

and 1 x 16-bit; each port is software

programmable as input or output

Input Characteristics:

100 ≈ series, 20 pF to common

I/O Levels: TTL

Sampling/Update Rate: 200 kHz

max

Output Characteristics:

Output 12 mA per pin, 200 mA total

continuous (per bank of 40 outputs)

Pattern Generation Output

(2000, 2001, 2002, 2004 and 2005)

The P3 16-bit digital I/O port can

be configured for 16-bit pattern

generation. The pattern can be

updated synchronously with an

acquisition.

7

COUNTER

(2000, 2001, 2002, 2004 and 2005)

Counter inputs can be scanned

synchronously along with analog

and digital scanned inputs, based

either on internal programmable

timer or an external clock source.

Counter can also be read

asynchronously.

Channels: 4 x 16-bit; cascadable as

2 x 32-bit

Frequency Measurement Rate:

10 MHz max

Trigger Level: TTL

FREQUENCY/PULSE

GENERATORS

(2000, 2001, 2002, 2004 and 2005)

Channels: 2 x 16-bit

Output: 1 MHz base rate divided by

1 to 65,535 (programmable)

D1-9

Page 10

OMB-DAQBOARD-2001, $1149,

shown smaller than actual size.

Desktop PC with

OMB-DAQBOARD-2001, $1149

(computer not included)

OMB-DBK203

Adaptor

Analog

OMB-CA-195

OMB-CA-255-4T

OMB-CA-255-2T

The OMB-DBK203, $299, adaptor with screw-terminal connectors

OMB-DBK84

Digital

OMB-DBK24

Digital

OMB-DBK23

ALL MODELS AVAILABLE FOR FAST DELIVERY!

D1

ANALOG INPUT AND

MULTI-FUNCTION CARDS

To Order

(Specify Model Number)

Model No. Price Description

OMB-DAQBOARD-2001 $1149 16-bit, 2000 kHz data acquisition board for the PCI-bus with 16 analog inputs, 40 digital

OMB-DAQBOARD-2000 799 Same as OMB-DAQBOARD-2001 but with only 2 analog outputs

OMB-DAQBOARD-2005 689 Same as OMB-DAQBOARD-2001 but with no analog outputs

OMB-DAQBOARD-2004 749 Same as OMB-DAQBOARD-2001 with analog output and digital I/O only

OMB-DAQBOARD-2002 349 Same as OMB-DAQBOARD-2001 with digital I/O only (no analog I/O)

I/O, 6 counter/timers, 2 frequency generators and 4 analog waveform outputs

(no analog inputs)

Accessories

Model No. Price Description

OMB-DBK200 $39 Adaptor board for analog I/O (P1 port)

OMB-DBK202 199 Screw terminal adaptor board, P1, P2, P3

OMB-DBK203 299 Screw terminal adaptor board, P1, P2, P3, with enclosure

OMB-DBK206 249 Screw terminal adaptor board

OMB-DBK207 249 Signal conditioning board

OMB-DBK207/CJC 399 Signal conditioning board with CJC

OMB-DBK208 219 Solid state relay board

OMB-DBK209 59 DIN rail-mount adaptor board for P1, P2, P3 ports

OMB-CA-195 79 100-conductor expansion 0.9 m (3') cable

OMB-CA-195-6 89 100-conductor expansion 1.8 m (6') cable

All OMB-DAQBOARD-2000s include a CD-ROM with all documentation, including operator’s manual, DaqView Windows Software, DAQX API

library for Windows 98/2000/ME/NT for C++, Visual Basic and Delphi, and drivers for LabVIEW, TestPoint and DASYLab.

Ordering Example: OMB-DAQBOARD-2001, data acquisition board, OMB-DBK200, adaptor board, OMB-DBK11A*, screw terminal panel,

OMB-CA-195, cable, and OMEGACARE 1-year extended warranty for OMB-DAQBOARD-2001

(adds 1 year to standard 1-year warranty), $1149 + 39 + 189 + 79 + 114 = $1570.

*Refer to section H (signal conditioners) of the OMEGA

for details on all the OMB-DBK expansion options that are available for use with the OMB-DAQBOARD-2000 Series.

®

Complete Data Acquisition and Computer Interface Handbook and Encyclopedia

®

D1-10

Page 11

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...