Page 1

T-73

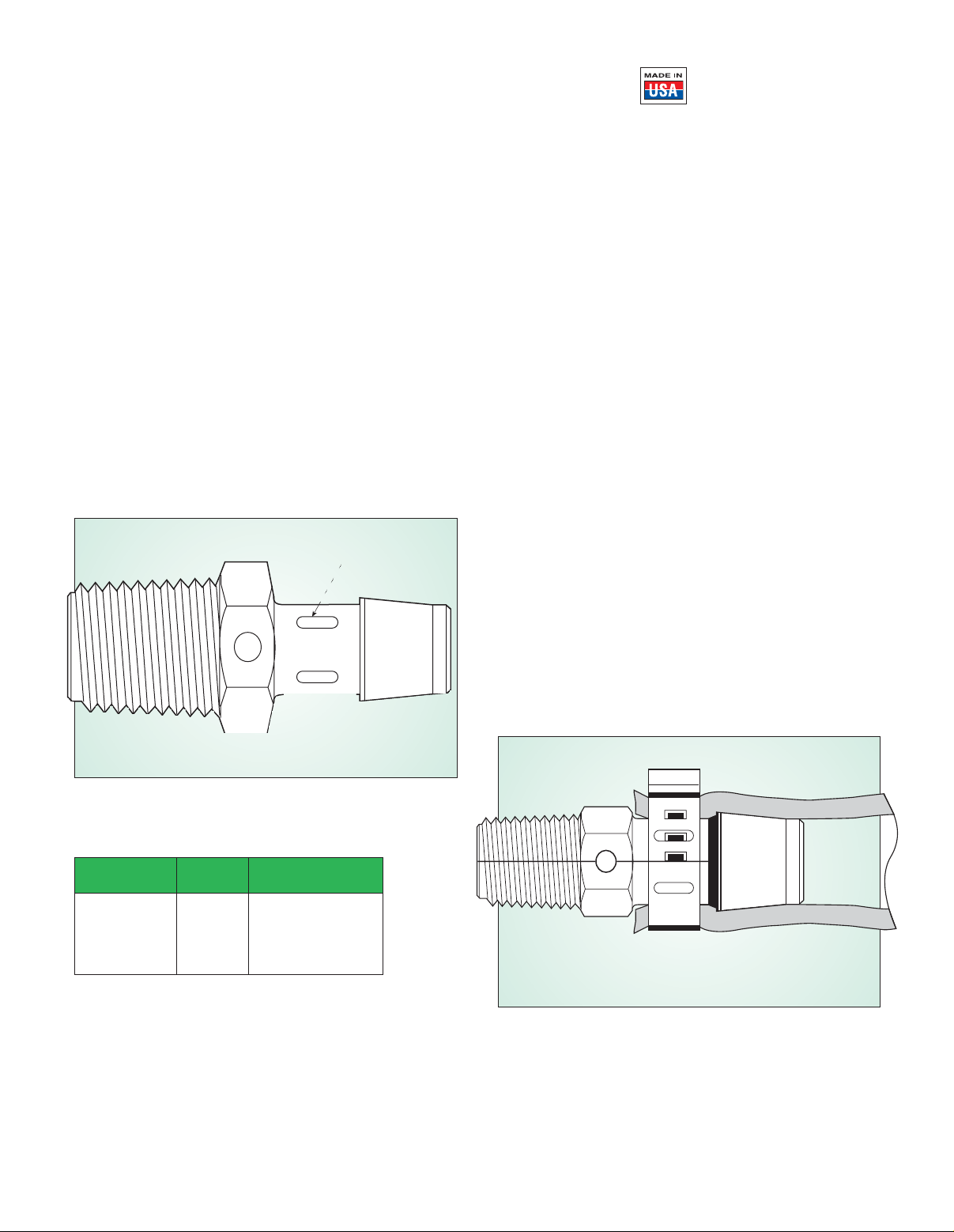

Never place a clamp over the large diameter of the barb.

Clamps work best when tightened around the recess behind

the barb. For best results place the clamp behind the barb and

over the anti-rotation devices. The anti-rotation devices are

small oval shaped raised areas which inhibit hose rotation on

the barb. Rotation of the hose on the barb causes many of the

leaks that occur with other fittings.

PLASTIC FITTINGS FOR FLEXIBLE TUBING & HOSE

NYLON, POLYPROPYLENE

PVDF

Important Properties of PVDF Products

High Mechanical Strength

and Toughness

High Abrasion Resistance

Chemical and Solvent Resistance

Weathering Resistance

High Thermal Stability

High Dielectric Strength

UV Light and Radiation Resistance

Fungi Resistance

PVDF has been used as a pipe liner in chemical

processing plants since its introduction nearly

30 years ago. It has been used extensively in the

paper and paper pulp industries, where equipment

is constantly exposed to high concentrations of

Chlorine and Chlorine Dioxide. In these applications

the permeation resistance of PVDF components far

surpassed that of PTFE.

PVDF products are used extensively in silicon

microcircuit fabrication. Processes in this industry

commonly use deionized water, a fluid that is highly

corrosive to steel. The deionized water is often

sanitized through the injection of ozone and

exposure to UV light, both of which can seriously

degrade the integrity of materials less durable than

PVDF.

Outstanding Characteristics of PVDF Products

PROPER CLAMP PLACEMENT

Clamps must be used with all fittings which have Anti-Rotation Devices

PATENT PENDING

ANTI-ROTATION

DEVICE

F-FT-A

ANTI-ROTATION

DEVICE

PRICE CLAMPING RANGE

MODEL NO. (10/PK) (CLOSED-OPEN)

FT-CLAMP-1 $14 0.312-.875"

FT-CLAMP-2 14 0.500-1.00"

FT-CLAMP-3 14 0.625-1.25"

FT-CLAMP-4 14 0.625-1.500"

CLAMP

TUBING

PARTING LINE

BARB

FT-CLAMP

$

12

Basic Model

ALL MODELS AVAILABLE

FOR FAST DELIVERY!

Page 2

T

OMEGA’s threads are molded in precision-ground cavities

resulting in perfectly matched threads at the parting line.

While this method is the most costly, it produces the

cleanest, most accurate molded thread possible.

OMEGA’s single-barbed fittings are made so that the moldedin parting line stops at the base of the barb. The ridge and the

conical surface are free of the molded-in leak path. The

conical surface on the fitting is smooth and glass-like, for

excellent sealing.

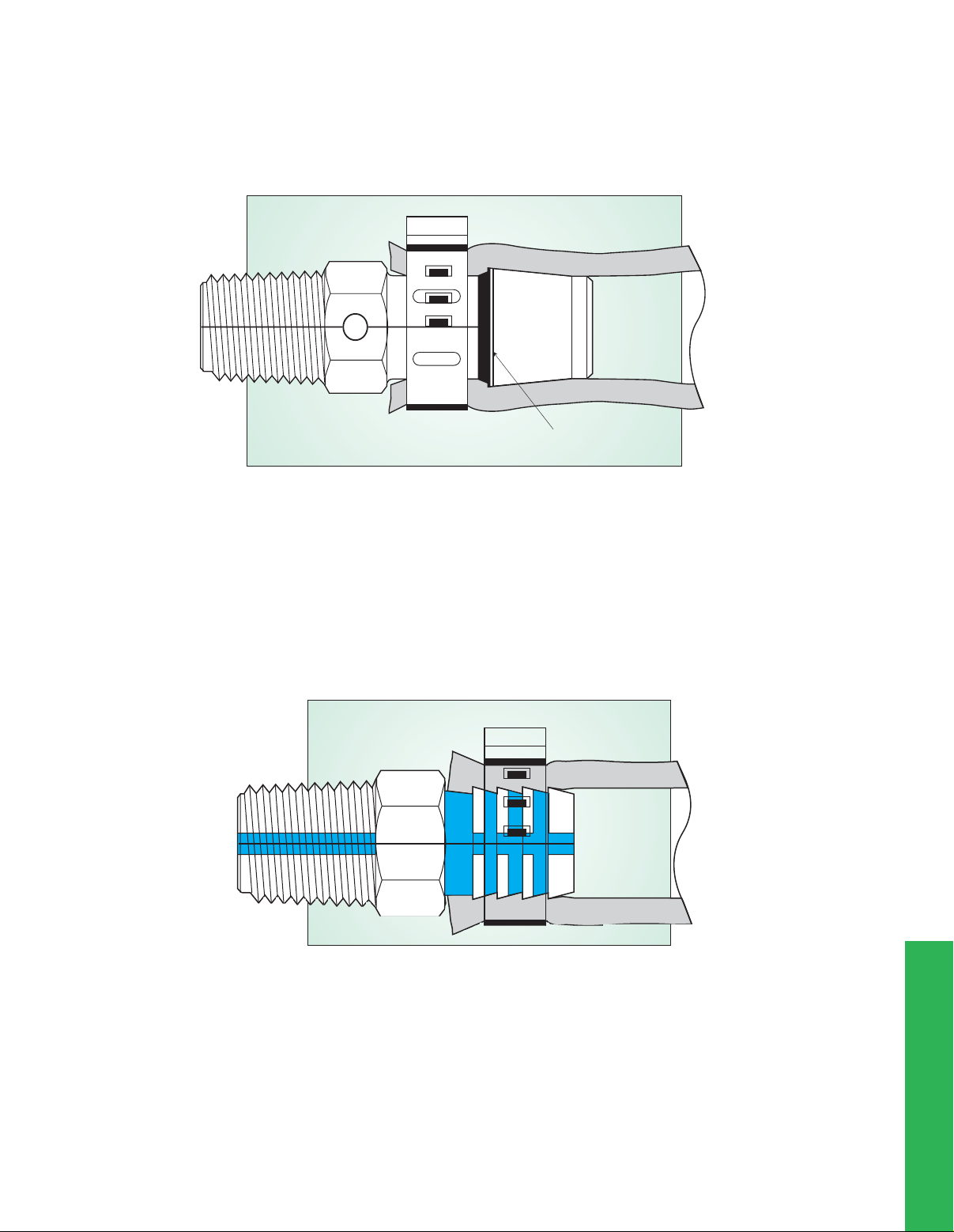

Why Multiple Barb Fittings Fail

Tooling mismatches often occur in poor-quality fittings causing

mismatched threads and barbs and resulting in leakage.

Tooling cannot be designed to avoid a parting line on multiple

barb fittings. This parting line creates a leak path which

becomes more pronounced as the tool wears.

TYPICAL CLAMPING POSITION

1. Clamping on top of barbs in attempt to force the tube down

behind the barbs can cause damage. It will round off the sharp

edges of the barb and cause it to bite less into the tube.

2. The clamping pressure causes the tube to flare out behind

the clamp. Barbs located behind the clamp will have little or

no effect.

Multiple barbs are typically in close succession. This prevents

the tubing from relaxing to its original size, which is essential

to the barb’s performance. If the tubing does not relax behind

the barb, the barb is rendered useless, as shown above.

(Note the bridging effect.)

ADDITIONAL NOTE: Brass fittings are machined and do not have the problem of molded-in parting lines.

However, brass fittings are usually designed with multiple barbs and have the other problem characteristics

shown above. In addition, machinable brass contains free lead. Brass parts cannot be used on any system if

internal heavy metals are undesirable or dangerous

.

Relaxed tubing behind the

barb is essential to the barb’s

ability to bite into the hose.

Clamping the relaxed hose behind the barb causes the

clamp to work like a drawstring, forcing the diameter of the

hose to become smaller than the flare of the fitting barb.

If the tubing swells from internal pressure (near burst), the

clamp will be pulled up tight to the back of the barb and the seal

will be maintained. When the clamps are placed over the

OMEGA

®

exclusive anti-rotation device the tubing cannot be

freed by a twisting motion.

CLAMP

FITTING

PARTING LINE

TUBING

FITTING

PARTING LINE

CLAMP

LEAK PATH

TUBING

Quality Tubing and Hose Fittings Features...

T-74

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...