Page 1

THERMAL DISPERSION FLOW SWITCHES

FSW-6000/7000 Series

Starts at

$

505

⻬ Simple to Install

and Low Cost

⻬ No Moving

Parts-Maintenance

Free Reliability

⻬ Optimal Temperature

Compensation—

Unaffected by

Temperature Gradient

⻬ Can Operate in

Temperatures up to

120°C (248°F) with

Sanitary Option

⻬ 300 Bar (4300 psi)

Maximum Working

Pressure

⻬ Chain of 8 LEDs-

Integrated Flow Rate/

Setpoint Indication

⻬ Can Be Used as a

Level Switch

The FSW-6000/7000 Series are

thermal flow switch monitors

designed to monitor flow status and

also used to detect level of liquids,

air and gas. A chain of 8 LEDs

gives the user a visual indication of

the flow rate. In addition, there is

FSW-6212, $505, shown smaller than actual size.

also a dichromatic LED, which

shows the switch point status of the

unit. The sensing element and

connection of the FSW-6000/7000

Series are made with 316 SS and

can be coated with ECTFE/ETFE

as an option. The standard

enclosure is glass-filled nylon and

is also available in an aluminum

enclosure for hazardous

environments. The FSW-6000/7000

Series can be made with a great

variety of process connections such

as threaded, flange, or sanitary.

The FSW-6000/7000 Series line of

thermal flow switch monitors is

based on the principle of thermal

dispersion. A typical configuration

uses two platinum Resistance

Temperature Detectors (RTDs) set

within the tip of the sensor. One RTD

is heated a few degrees above the

temperature of the medium and the

other RTD is used as a reference,

sensing the actual process

temperature. The second RTD also

monitors the temperature of the

medium, as any changes in

temperature must be compensated

for in the first RTD. As the process

medium flows over the tip of the

sensor it disperses some of the

heat from the first RTD. The

temperature change between the

two RTD's signals the probe’s

electronics and the switch changes

state once the setpoint has

reached.

The FSW-6000/7000 Series may

be installed in a pipe or tank using

the thread or connection provided.

Use only the hexagon when

tightening to achieve a seal, do not

use the body. The body should be

rotated after tightening to leave the

cable gland in suitable orientation.

The FSW-6000/7000 Series is not

affected by its fixing position so it

may be installed at any angle

around the pipe. However, it is

recommended that with horizontal

pipe runs the sensor should be

installed on the side, into the middle

of the pipe. In vertical pipes, the

FSW-6000/7000 Series should be

installed when there is flow in an

upward direction against gravity.

Care should be taken when

installing the sensor that the probe

extends clear of the pipe’s internal

wall and is fully immersed into the

flow. In pipes with smaller

diameters, some care should also

be taken so that the sensor is not

screwed too far into the line.

B-85

Page 2

SPECIFICATIONS

Accuracy: ±10% of setpoint

Repeatability: ±1% of setpoint

Power Supply:

FSW-6000: 85 to 240 Vac (50/60 Hz)

FSW-7000: 24 Vdc ±10%

Temperature Range:

Process: -20 to 80°C (-4 to176°F)

[sanitary option to 120°C (248°F) for CIP]

Operating: -20 to 60°C (-4 to140°F)

Max Pressure: 300 bar (4351 psi)

Protection Class: NEMA 4 (IP65)

Wetted Materials: 316 SS

Enclosure Material: Glass filled nylon

standard or aluminum die cast option

Process Connection:

1

⁄2 to 11⁄2 NPT, Tri-GripTM, or flange

(others available, consult Flow

Engineering Department)

Output: 250 Vac SPDT 5 A relay

Switch Point Adjustment: Potentiometer

Bargraph:

Green LED: Flow rate above setpoint

Yellow LED: Flow is at above setpoint

Red LED: Flow is below setpoint

Switch Point Status:

Red LED: No flow

Green LED: Flow

Response Time: 1 to 10 seconds

Max Start up Delay: 12 seconds

Switching Range:

3 cm/s to 3 m/s (0.09 to 9.84 ft/sec)

(liquid), 5 cm/sec to 15 m/sec

(0.16 to 49 ft/sec) (gas)

Dimensions:

Nylon Head: 88 Dia x 80 mm H

(3.5 x 2.5" H)

Aluminum Head: 88 Dia x 108 mm H

(3.5 x 4.25")

Insertion Length: 1

3

⁄8, 2 and 3" standard,

for other lengths consult Flow Engineering

Weight: Approx 680 g (1.5 lb)

AVAILABLE FOR FAST DELIVERY!

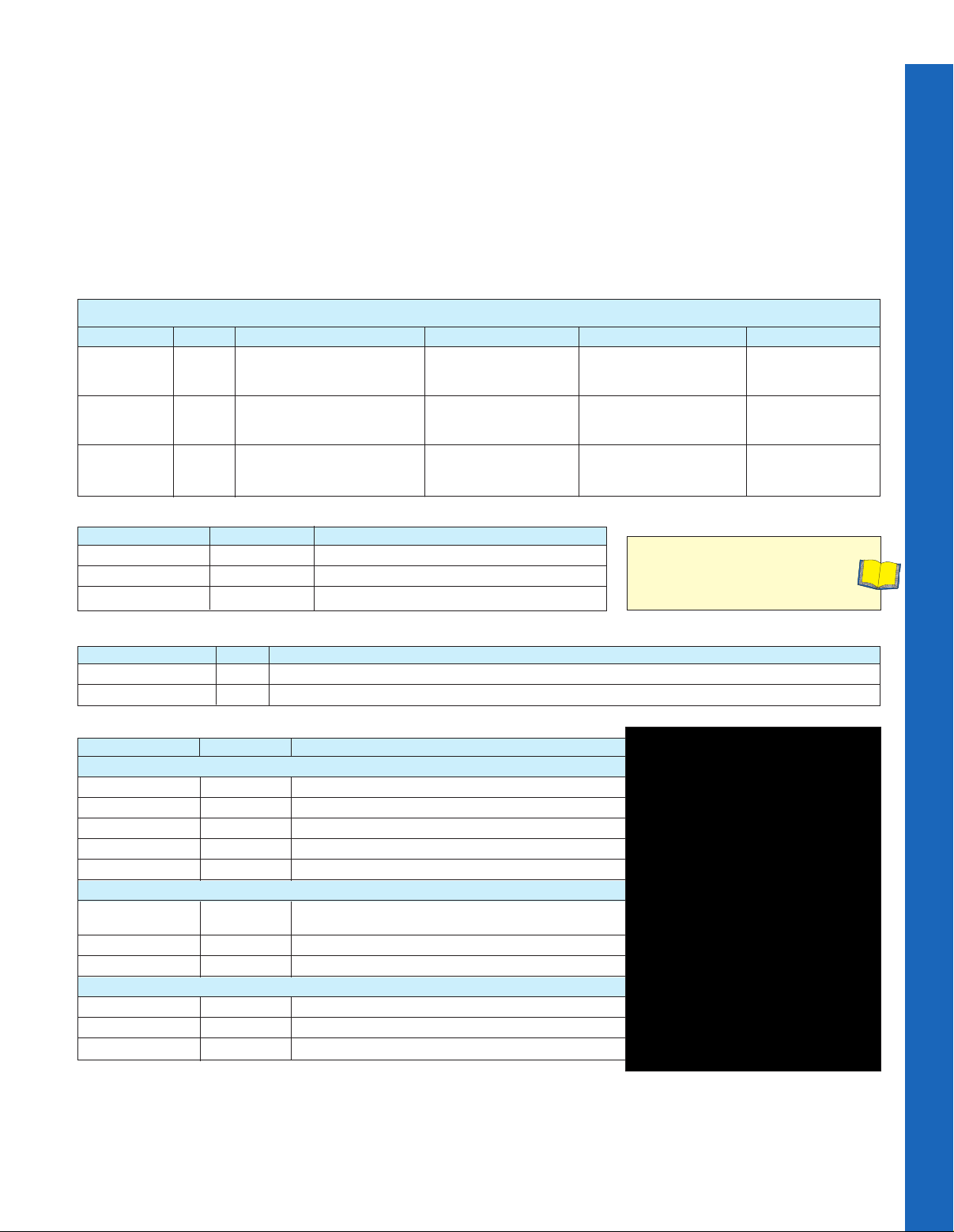

To Order (Specify Model Number)

Model No. Price Description Process Connection Enclosure Insertion Length

FSW-6212 $505

FSW-7112 505

FSW-7111 505

Thermal dispersion flow

switch, 85 to 240 Vac power

Thermal dispersion flow

switch, 24 Vdc power

Thermal dispersion flow

switch, 24 Vdc power

3

⁄

1

1

4

⁄

2

⁄

2

NPT

NPT

NPT

Glass filled nylon,

1

NPT conduit, cable

⁄

2

gland, and 2 m (6.5') cable

Glass filled nylon,

1

NPT conduit, cable

⁄

2

gland, and 2 m (6.5') cable

Glass filled nylon,

1

NPT conduit, cable

⁄

2

gland, and 2 m (6.5') cable

51 mm (2")

for 1 to 4" pipe

51 mm (2")

for 1 to 4" pipe

35 mm (13⁄8")

1

for

to 1" pipe

⁄2

B

Accessories

Model No. Price Description

70A-1 $20 Continuous tone alarm

TX4-100 35 4-conductor wire, 30.5 m (100') spool

U24Y175 169 24 Vdc power supply

Recommended Reference Book:

Valve Handbook,

FW-306, $135. Visit

omega.com/bobi for Additional Books

Build to Order Models

Model No. Price Description

FSW-6(*)(**)(***) $475

Flow switch, 85 to 240 Vac power; specify connection (*), enclosure (**) and insertion length (***)

FSW-7(*)(**)(***) 475 Flow switch, 24 Vdc power; specify connection (*), enclosure (**) and insertion length (***)

Options

Ordering Suffix Add’l Price Description

Process Connection (*)

1 N/C

2 N/C

3 N/C 1 NPT thread

5 $186 1.5" Tri-Grip

6 300 2" ANSI flange, 15016 316 SS

Enclosure (**)

1 $30 Glass filled nylon with

2 102 Aluminum die cast with

3 108 Aluminum die cast with cable gland

Insertion Length (***)

1 N/C 35 mm (1

2 N/C 50 mm (2")

3 N/C 75 mm (3")

Comes complete with operator’s manual.

To order ECTFE/ETFE element coating, add suffix “-ETFE” to model number and

$200 to price.

Ordering Examples: FSW-6212, flow switch, 85 to 240 Vac power,

51 mm (2") insertion length, and 70A-1, alarm, $505 + 20 = $525.

FSW-7113, flow switch, 24 Vdc power,

1

NPT thread

⁄

2

3

NPT thread

⁄

4

TM

1

NPT conduit,

⁄

cable gland, and 2 m (6.5') cable

3

")

⁄

8

1

NPT fitting, glass filled nylon, 75 mm (3") insertion length, $505.

⁄

2

2

1

NPT conduit

⁄

2

3

NPT fitting, glass filled nylon,

⁄

4

FSW-6000 flow switches are

available with 1.5" Tri-Grip

(Tri-Clamp®compatible)

connection for sanitary

TM

applications.

B-86

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...