Omega Products FSW-410 Installation Manual

FSW-410 Series

1.0 Install the FSW-410 by inserting the 1/2” MNPT threaded sensor tip into

a tapped pipe or T fitting. Use Pipe Tape or Plumbers Putty on NPT

threads to aid in sealing. Tighten firmly, but do not over tighten as this

could damage the NPT threads and prevent proper sealing.

2.0 With provided connection cable disconnected, complete unit wiring by

connecting the Brown wire to +24VDC supply and the Blue wire to

common. The Black wire is now connected to the + side of your load.

The - side or common side of the load is now connected to the ground.

.

NOTE: Be sure that the common (ground) of the FSW-410 and the

LOAD are the same. The white wire (if present) is not used.

3.0 Upon initial power-up the unit will provide a temporary output as the unit is

adjusting to the zero flow rate of the media. After approximately 10-15

seconds the output will turn off. Once the unit output has turned off, the

unit is ready for operation. Once the threshold of the unit set point

(approx. .3-.4 meters/second) is reached the output will turn on.

4.0 As the FSW-410 unit also monitors the media temperature, the unit will

provide a loss of signal if the temperature of the media goes above the

threshold of the unit temperature set point (typically 50 or 70 Deg. C.),

even with proper media flow.

NOTE:

Use caution while installing the FSW-410 so as not to damage the tip of the sensor. The

electronics are embedded just behind the tip of the FSW-410 and denting or bottoming

out of the tip could cause damage.

Maintenance is not required, as the FSW-410 has no moving parts. However, should the

sensor become coated after a period of time in operation due to water or media conditions,

simply wipe the probe tip with a soft cloth and alcohol.

Thermal Flow Switches

M-4623/0208

FSW-410 SERIES INSTALLATION & INSTRUCTION SHEET

x

x

M-4623/0208

FSW-410 Series

Thermal Flow Switches

TECHNICAL INFORMATION

FSW-410 SERIES

The safe sensing solution for industrial cooling systems.

The FSW-410 utilizes the calorimetric principle and the All-in-One

monitoring of flow and temperature of the coolant.

The FSW-410 is especially designed, for all types of cooling systems,

as a reliable alternative to failure prone mechanical flow switches.

Compact electronic unit with no moving parts

No adjustment or calibration needed

Maintenance free

Fail safe normally open switch

Easy to Install

Technical Data

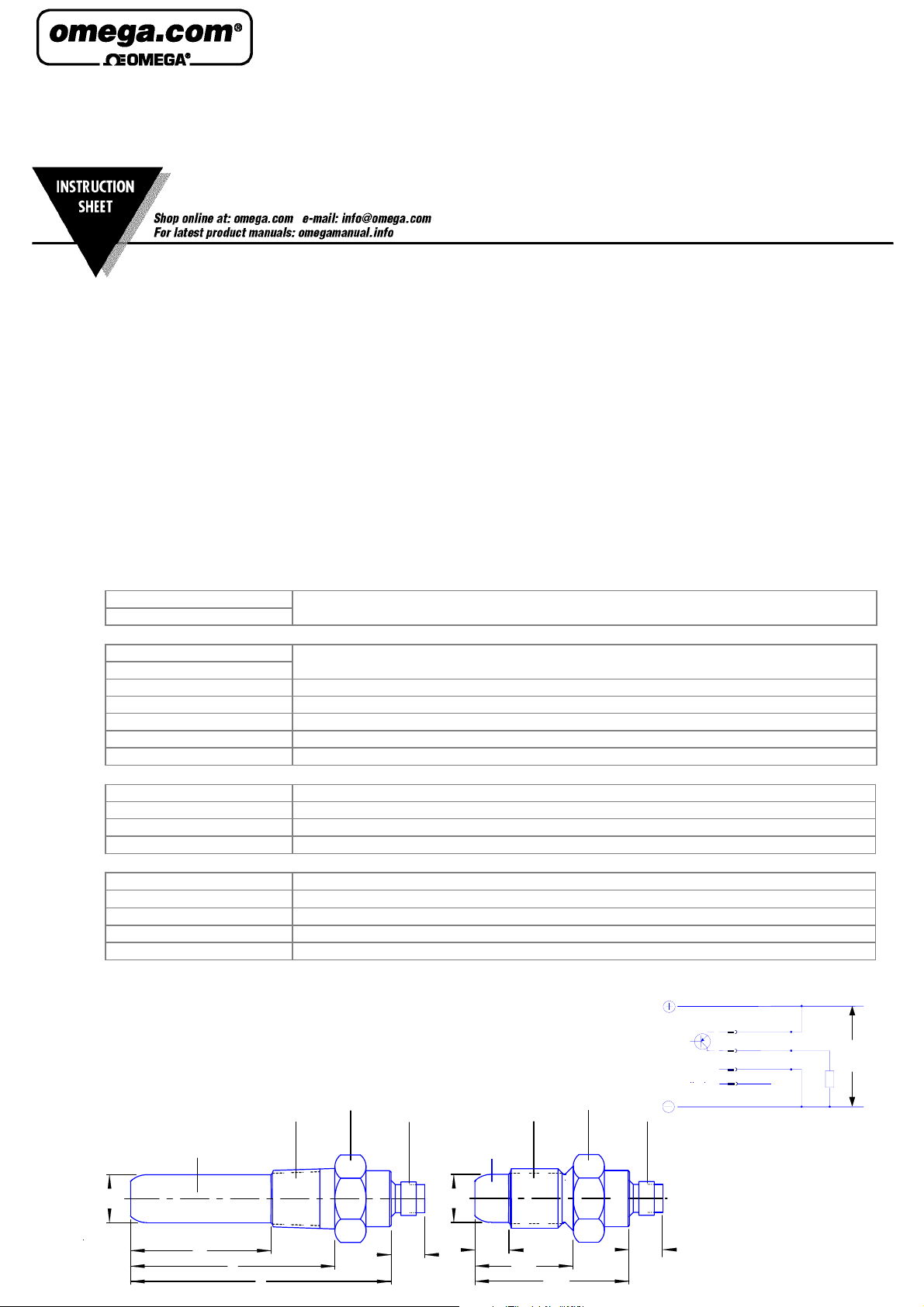

Type FSW-410

Medium Water based liquid

Sensor Data

Low Flow Set Point 0.3 m/s (.9 fps) (water related)

Hi Temp Set Point 50°C (122°F) or 70°C (158°F), other settings possible on OEM

Medium temperature -20°C (-4°F) to + 80°C (176°F)

Response time 5 – 10 seconds

Repeatability < 0.5 %

Hysteresis approx. 20% of setpoint value

Pressure 10 bar (150 PSI)

Mechanical Data

Protection class IP 67 (NEMA6)

Housing Material Stainless Steel 1.4301 (303)

Thread ½ “ –14

Connection M12 male socket, 4 pin + 2m connection cable with M12 connector

Electrical Data

Operating voltage 18 to 30 V DC, incl. residual ripple

Switching current

Power Consumption 4 W max.

Initial Operation after 15 seconds

Electrical Output PNP n.o. (switch closed with flow)

NPT

200 mA

(NPT)

Part Number Key: Example: FSW-414 Connection diagram

Temp Setpoint (°C), code: 50nc

Flow Set Point (m/s), code: .3no

Sensor Head Length, code: 50.5mm

Thread code: NPT

FSW-412,414,416

D 17

50.5

73

1/2 - 14 NPT

93

1/2”

27

Sechsk./ He

FSW-411,

M 12 Stecker

M 12 Connector

12

413,415

D 17

12.5

G 1/2 A

35

27

Sechsk./ He

55

M 12 Stecker

M 12 Connector

12

1 - brown

4 - black

3 - blue

2

V DC

Load

Loading...

Loading...