Omega Products FMG70 Installation Manual

Magnetic Inductive Flow Sensor

FMG70 Series

.

2

Table of contents page

1. Device description and intended use..................................................................................................3

2. Safety instructions...............................................................................................................................4

2.1. Qualified personnel ....................................................................................................................4

2.2. Special safety instructions .........................................................................................................4

3. Unpacking and inspecting the delivery ...............................................................................................5

4. Material specifications of components................................................................................................5

5. Suitable liquids (medium)....................................................................................................................5

6. Installation of the flow sensor..............................................................................................................5

6.1. Mechanical installation...............................................................................................................5

6.2. Electrical connection ..................................................................................................................7

7. Maintenance and repairs.....................................................................................................................8

8. Decommissioning and disposal ..........................................................................................................8

9. Technical data.....................................................................................................................................8

10. Dimensions, Pressure drop.................................................................................................................9

1. Device description and intended use

OMEGA flow sensors FMG70 Series are used for continuously measuring flow rates or for dosing electrically

conductive liquids. The operational safety of the supplied equipment is only guaranteed if it is operated

according to its intended use (measuring and dosing of liquids). The specified limit values (see the chapter

“Technical Data”) should never be exceeded.

It is your responsibility to select a technology which is suitable for your specific application, to install it correctly,

to carry out tests and to maintain all the components.

The magnetic inductive flow sensor features no moving parts and is, therefore, almost wear free and suitable for

a wide range of measuring applications. A flow-proportional frequency signal is provided as the output signal.

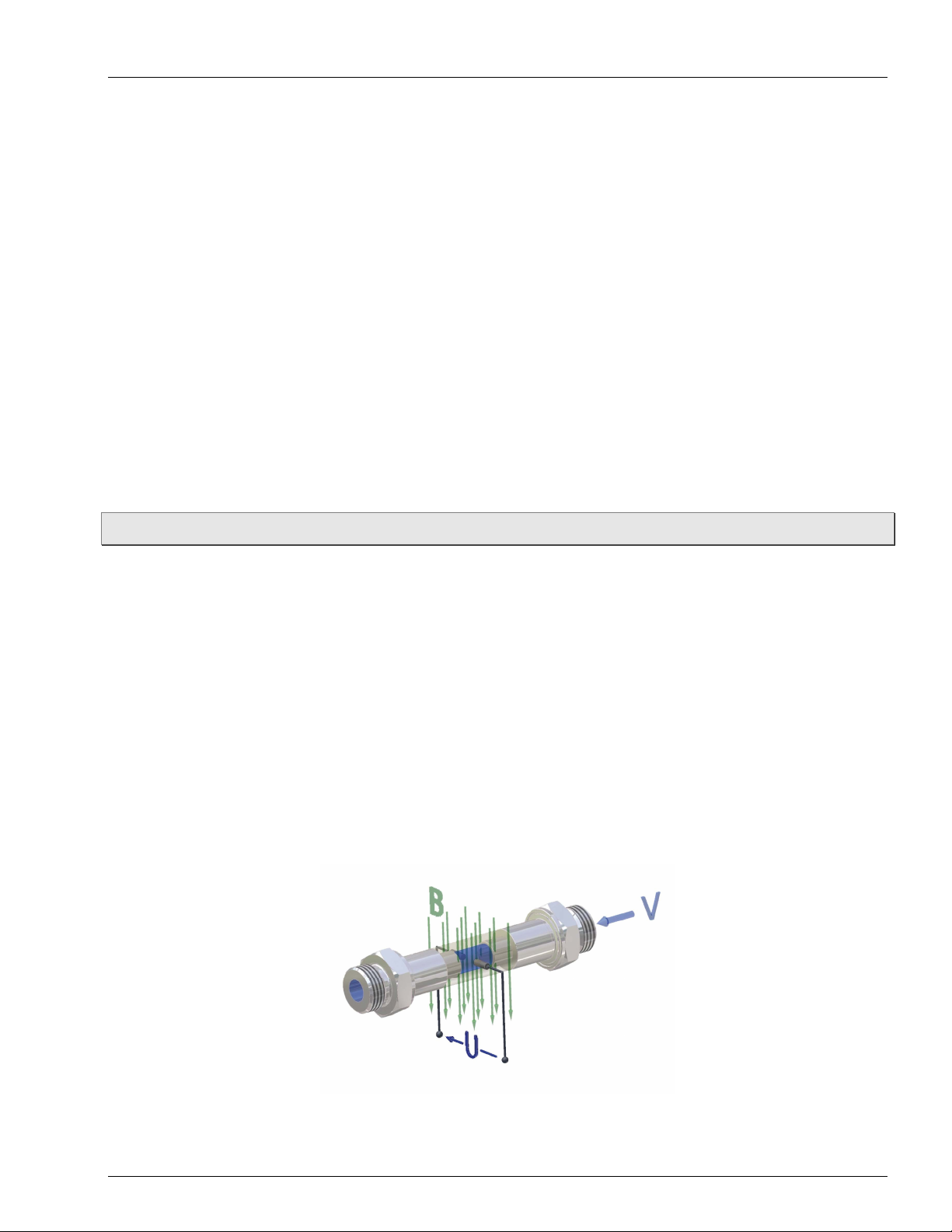

Functional principle

The magnetic inductive flow sensor functions according to the induction principle:

The measuring pipe is located in a magnetic field (B). If an electrically conductive medium (Q) flows through the

measuring pipe and, therefore, at right angles to the magnetic field, a voltage (U) which is proportional to the

mean flow velocity will be induced in the medium and subsequently picked up by the two electrodes.

Fig. 1: Functional principle

3

2. Safety instructions

Always read the operating instructions carefully prior to installing the new product. Always adhere to the

instructions contained herein, especially the safety instructions, otherwise there is a potential risk of personal

injury and damage to instruments and systems.

Even though OMEGA provides assistance through personal consultation or the respective literature, it is the

responsibility of the customers to determine the suitability of the product for the specific application.

The magnetic inductive flow sensors are state-of-the-art devices, concerning the accuracy, functioning and safe

operation of the device.

However, professional and safety conscious conduct of the operator is required to ensure safe operation.

2.1. Qualified personnel

The personnel entrusted with installing, operating and maintaining the FMG70 Series have to be suitably

qualified; the required knowledge can be gained via training courses or appropriate on-the-job instruction.

The personnel have to be familiar with the contents of these instructions, which have to be available to

them at all times.

The electrical connection should only be carried out by a fully qualified electrician.

All work has to be carried out in accordance with existing national regulations on accident prevention and

safety at work and with any internal regulations of the operator, even if they are not specified in these

instructions.

2.2. Special safety instructions

To avoid damages to the flow sensors and to the monitored system, only use OMEGA flow sensors to

measure liquid flows.

Prior to installation, ensure whether the material of the flow sensor is suitable for the medium which is to be

measured.

In order to achieve accurate measurements, only use liquids with a minimum conductivity of 50 S/cm.

Ensure that the max. specified operating pressure is not exceeded.

Never remove a flow sensor from a pipe system under pressure.

Ensure that the max. specified operating temperatures are not exceeded.

Select suitable measures to prevent the medium from freezing in the flow sensor.

Protect the flow sensor against external magnetic fields in the immediate vicinity, since these can impair

device functioning.

Caution: voltages!

Always de-energize the system before connecting the connector cable.

It is prohibited to remove or make type plates or any other information attached to the equipment

indecipherable, otherwise all warranties and the responsibility of the manufacturer no longer apply.

Caution: Ensure that the maximum electrical load specified on the type plate is never exceeded, otherwise

the electronic unit will be damaged.

Attention: Do not use FMG70 Series in processes in which a disturbance possibly causes a risk for health

and live of people.

The customer is to verify the applicability of the product on the basis of our technical details. By this

checking, hazards and risks are subrogated to the customer and our warranty expires.

If problems or questions arise, please contact your supplier or OMEGA directly:

4

Loading...

Loading...