Page 1

U

ser’s

Guide

Shoponline

at

omega.com

e-mail:

info@omega.com

For

latest

product

manuals:

omegamanual.info

FMG600 Series

Electroma

g

netic Flow Meters

Page 2

OMEGA

net

®

Onli

ne Service

I

nternet e-ma

il

omega.com info@omega.com

Ser

vicing

NorthAmerica:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO

9001

Certified

Stamford, CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

L

aval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail:

info@omega.ca

For

immediate

technicalorapplication

assistance:

U.S.A. and Canada: Sales Service:

1-800-826-6342/1-800-TC-OMEGA

®

Customer

Service:

1-800-622-2378/1-800-622-BEST

®

Engineering

Service:

1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Ser

vicing

Eur

ope:

Czech Republic: Frystatska 184, 733 01 Karvin

á

, Czech Republic

TEL:+420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL:

+49

(0)7056 9398-0

FAX:

+49

(0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail:

info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO

9002

Certified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL:

+44

(0)161 777 6611

FAX:

+44

(0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Itisthe

policy ofOMEGA

Engineering,

Inc.to

comply

with

all

worldwide

safety

and EMC/EMI

regulations

that

apply.

OMEGAisconstantly

pursuing

certificationofits

products

to the

European

New

Approach

Directives.

OMEGA

will

add

theCEmark to

every appropriate device

upon

certification.

The

information contained in

this

documentisbelievedtobe

correct,

but

OMEGA

acceptsnoliability for

any

errors

it

contains,

and

reserves

the

righttoalter

specifications

without

notice.

W

ARNING:

These

products

are

not

designed

for

use

in,

and

should

notbeused

for,

human

applications.

Page 3

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 1 of 44

Content

1. APPLICATION ............................................................................................................................................. 2

2. MEASUREMENT PRINCIPLE ..................................................................................................................... 2

3. TECHNICAL DESCRIPTION ....................................................................................................................... 3

3.1. GENERAL .................................................................................................................................................................. 3

3.2. METER DESIGN ........................................................................................................................................................... 3

3.2.1. Remote version ............................................................................................................................................... 3

3.2.2. Compact version .............................................................................................................................................. 4

4. TECHNICAL PARAMETERS ....................................................................................................................... 5

4.1. FLOW SENSOR ............................................................................................................................................................ 5

4.1.1. Selection of correct sensor size ....................................................................................................................... 5

4.1.2. Operational pressure of measured liquid .......................................................................................................... 6

4.1.3. Selection of electrode material ......................................................................................................................... 6

4.1.4. Sensor tube lining............................................................................................................................................. 6

4.1.5. Compact or remote meter version? .................................................................................................................. 6

4.1.6. Dimensions of flanged sensor .......................................................................................................................... 7

4.1.7. Dimensions Tri Clover sensor .......................................................................................................................... 8

4.1.8. Flow sensor specifications ............................................................................................................................... 9

4.2. ELECTRONIC UNIT BOX ................................................................................................................................................ 9

4.2.1. Electronic unit specifications .......................................................................................................................... 10

5. METER APPLICATION RULES..............................................................................................................................................11

5.1. SENSOR PLACEMENT IN PIPING ................................................................................................................................... 11

5.2. SENSOR GROUNDING ................................................................................................................................................ 14

5.2.1. Flanged version .............................................................................................................................................. 14

5.2.2 Tri Clover ......................................................................................................................................................... 15

6. FLOW METER INSTALLATION AND OPERATIONAL START ............................................................... 16

6.1. SENSOR INSTALLATION .............................................................................................................................................. 16

6.2. ELECTRIC CONNECTIONS OF INDUCTION FLOW METER ................................................................................................... 17

6.2.1. Connection to power source .......................................................................................................................... 17

6.2.2. Output signal connections ............................................................................................................................. 18

6.3. CONNECTION BETWEEN SENSOR AND ELECTRONIC UNIT (REMOTE VERSION) ...................... 18

6.4. CONNECTION BETWEEN SENSOR AND ELECTRONIC UNIT (REMOTE METER VERSION, PROTECTION CLASS IP 68) .................. 19

6.5. OPERATIONAL START ................................................................................................................................................ 19

6.5.1 Operational start .............................................................................................................................................. 19

6.5.2. Operational data ............................................................................................................................................. 20

6.5.3.1. Display formats of aggregate values .......................................................................................................... 22

6.5.3.2. Data reset ................................................................................................................................................... 22

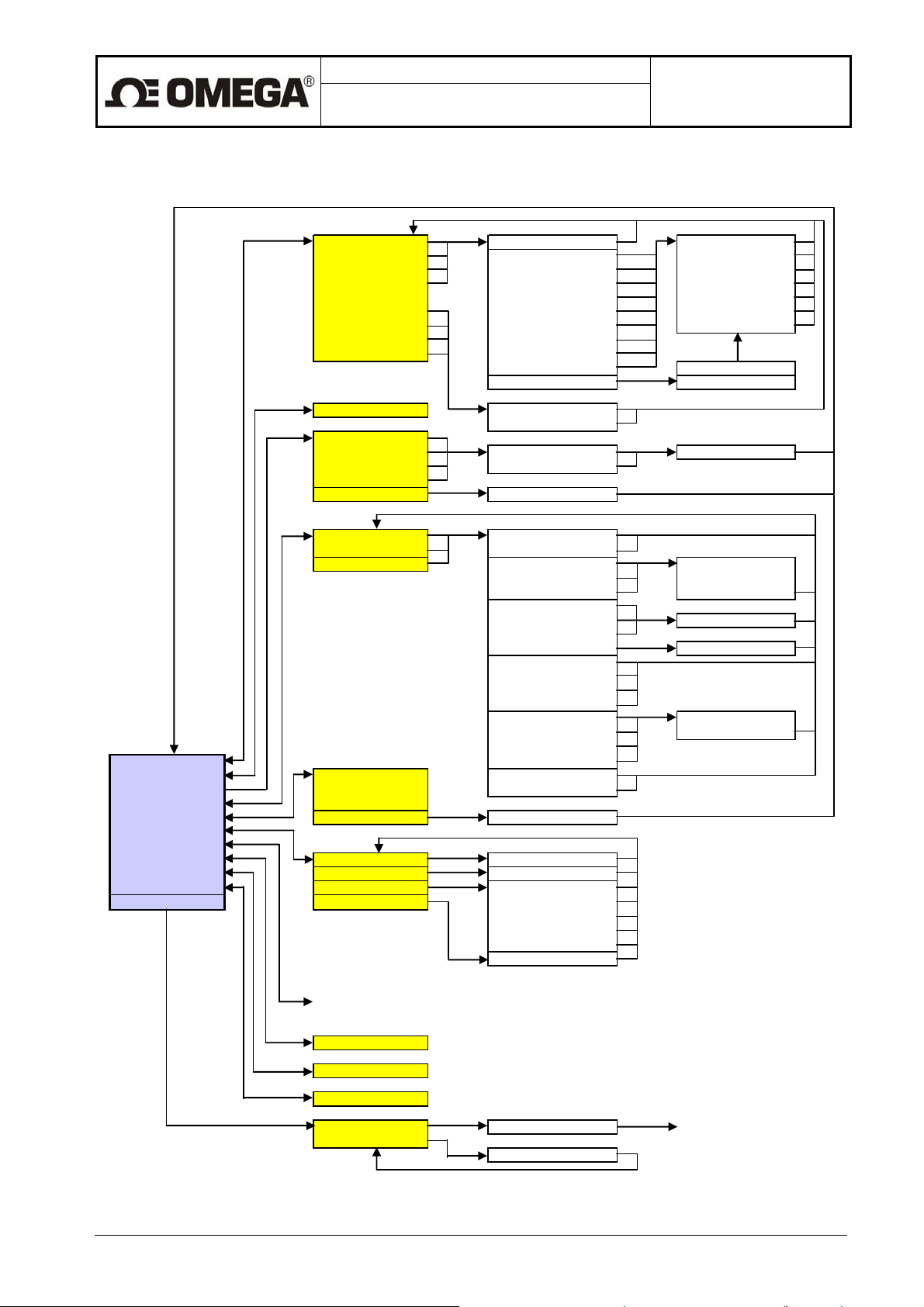

7. PROGRAMMING........................................................................................................................................ 23

7.1. PROGRAMMING OF THE BASIC MENU ITEMS .................................................................................................................. 24

7.1.1. Displayed data ............................................................................................................................................... 24

7.1.2. Samples ........................................................................................................................................................ 25

7.1.3. Analog output ................................................................................................................................................ 26

7.1.4. Output function .............................................................................................................................................. 29

7.1.5. Electrode cleaning .......................................................................................................................................... 34

7.1.6. Serial line ...................................................................................................................................................... 35

7.1.7. Production data ............................................................................................................................................. 37

7.1.8. Dose setting .................................................................................................................................................. 39

7.1.9. Zero setting ................................................................................................................................................... 40

7.1.10. 100 percent ................................................................................................................................................. 40

7.1.11. Exit .............................................................................................................................................................. 40

7.2. THE PARAMETER SETTING MENU ................................................................................................................................ 42

7.3. THE PRODUCTION DATA MENU ................................................................................................................................... 43

8. STANDARD TESTS ................................................................................................................................... 44

9. CALIBRATION AND VERIFICATION TESTS ........................................................................................... 44

Page 4

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 2 of 44

1. APPLICATION

Flow meters FMG600 SERIES are primarily used for measuring instantaneous flow rate and volume of water

or similar liquids passed through the meter. Flow meters shall only be used in standard non-explosive

environments.

Any installation of flow meter must be in conformity with technical conditions mentioned in this manual.

Measurements can be done in both flow directions, with high measurement accuracy over a wide range of

flow rates 0.33 to 32.8 ft/s (0.1 to 10 m/s). The minimum required conductivity of the measured medium is 20

µS/cm.

The measurement evaluation electronic unit includes a two-line alphanumeric display to show the measured

values where various operational parameters of the meter can be selected by means of an associated

keyboard. Available are two passive binary outputs (frequency, pulse and limit values), one active current

output and an output to connect a digital communication line. All meter functions and output parameters can

be reset during the meter operation.

Should the need arise; the user may combine any sensor of the FMG600 series with any electronic units

without re-calibration of the meter on a test stand. The only thing that needs be done is to enter into the

electronic unit memory the calibration constants and excitation frequency of the selected sensor; these data

are given on the rating plate of the sensor. The value of threshold flow rate shall be set between 0.5 and 1%

of the specified maximum flow rate.

2. MEASUREMENT PRINCIPLE

The function of an induction flow meter is based on Faraday’s induction law. The meter sensor consists

of a non-magnetic and non-conductive tube with two embedded measuring electrodes to pick up the induced

voltage. To create an alternating magnetic field, two coils are fitted onto the tube in parallel with the plane

defined by the active parts of the measuring electrodes. Now if a conductive liquid flows across magnetic

field B, voltage U will appear on the measuring electrodes proportional to the flow velocity v and the

conductor length l.

U = B x l x v

U induced voltage

B magnetic flux density

l distance between the measuring electrodes

v liquid flow velocity

Page 5

As the magnetic flux density and distance between the electrodes are constant, the induced voltage is

proportional to the liquid flow velocity in the tube. The value of the volume flow rate can then be readily

determined as a product of the flow velocity and square section of the tube, Q = v x S.

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 3 of 44

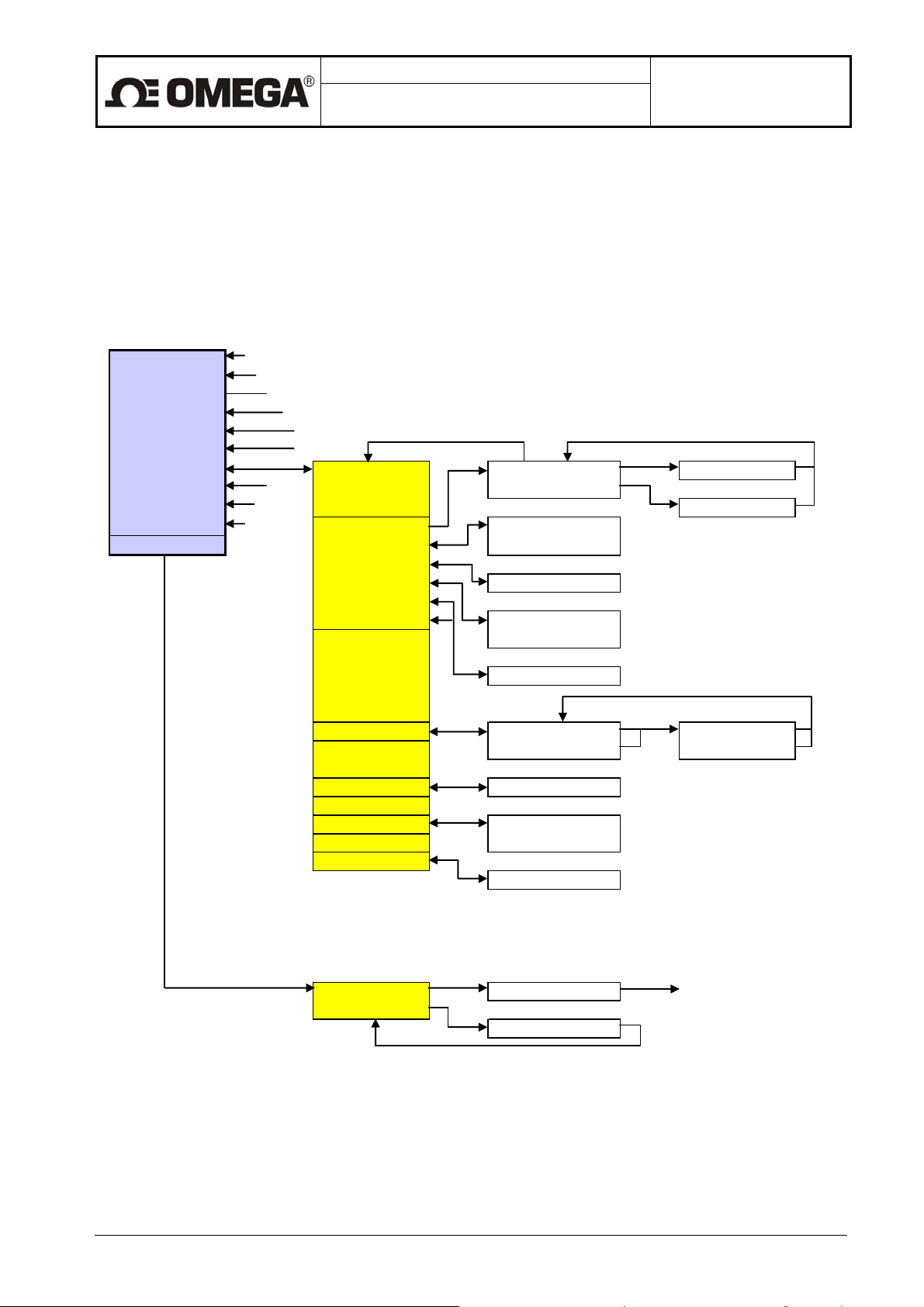

3. TECHNICAL DESCRIPTION

3.1. General

The induction flow meter consists of a sensor through which the measured liquid flows and an electronic unit

where the low-level signal from the sensor is modified to a standardized form suitable for further processing

in various industrial electronic devices. The output signal is proportional to the volume flow rate of the

measured liquid. The only factor limiting the application of induction flow meters is the requirement that the

measured liquid shall be conductive and non-magnetic. The induction flow meter can be designed either as

a compact device or with the sensor separated from the associated electronic unit. In the former case, the

electronic unit is fitted directly onto the meter sensor, in the latter case it is connected to the sensor by

special cable.

The sensor design shall take into consideration the type of the measured liquid and its operational

parameters. To facilitate fitting into the liquid piping, the sensor can be provided with end flanges, threaded,

or it maybe of a flangeless design. The supply voltage, types of output signal and communication interface

can be selected according to the customer requirements.

The basic configuration of induction flow meter includes two insulated passive binary outputs (each with

an opt coupler including a transistor output), insulated RS485 communications, dry relay, 4-20 mA output

and the USB communication interface. This USB interface is not insulated as it is used for factory calibration

purposes only. Optional accessories to this basic configuration are INPUT1 and OUTPUT3 for batching (all

with galvanic separation) –B, empty pipe detection -EPT.

Upon fastening the connecting wires into the respective terminals, make sure to tighten the bolts holding the

lid of the electronic unit and seal the cable glands. Fit blinds into the unused gland openings.

3.2. Meter design

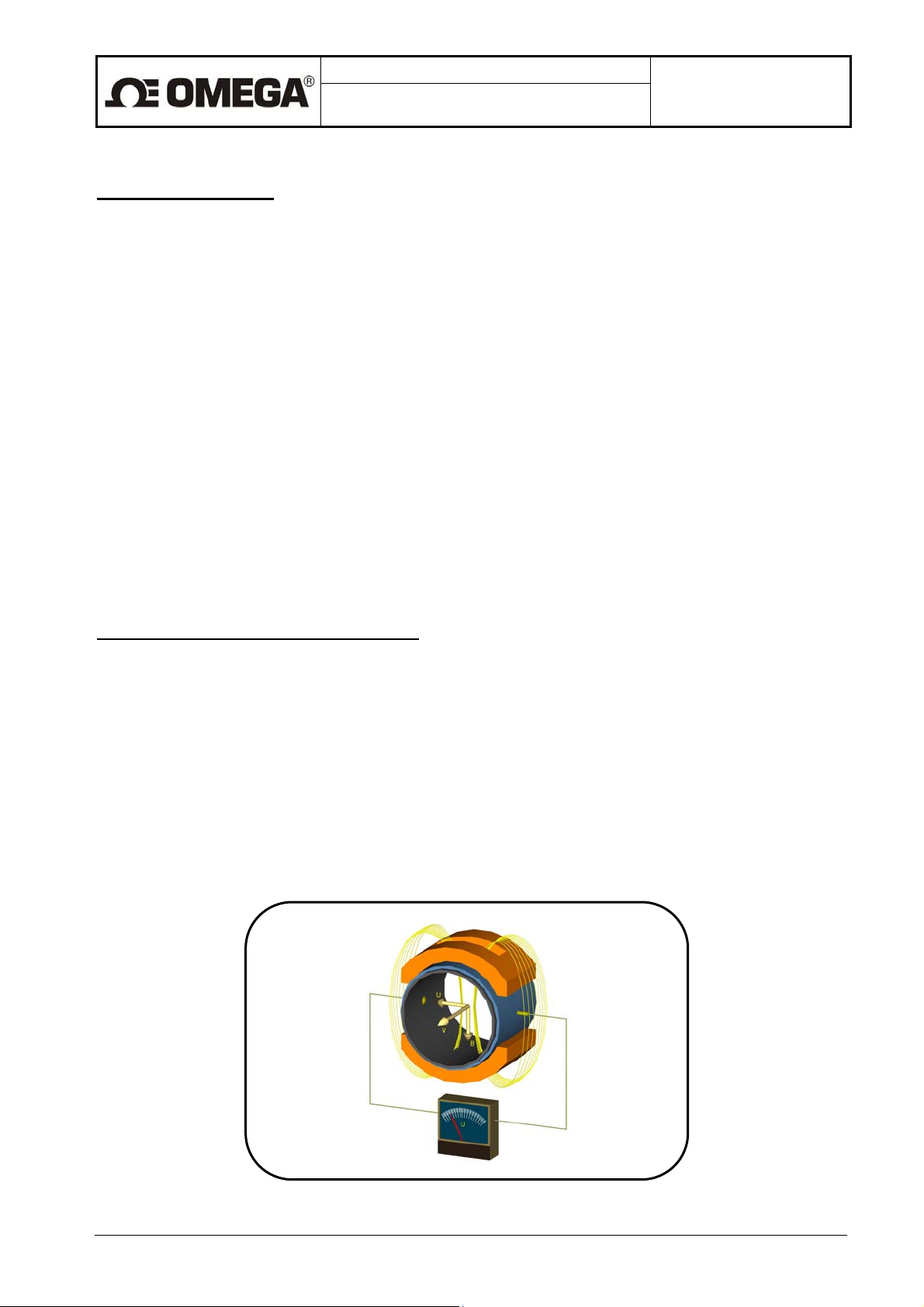

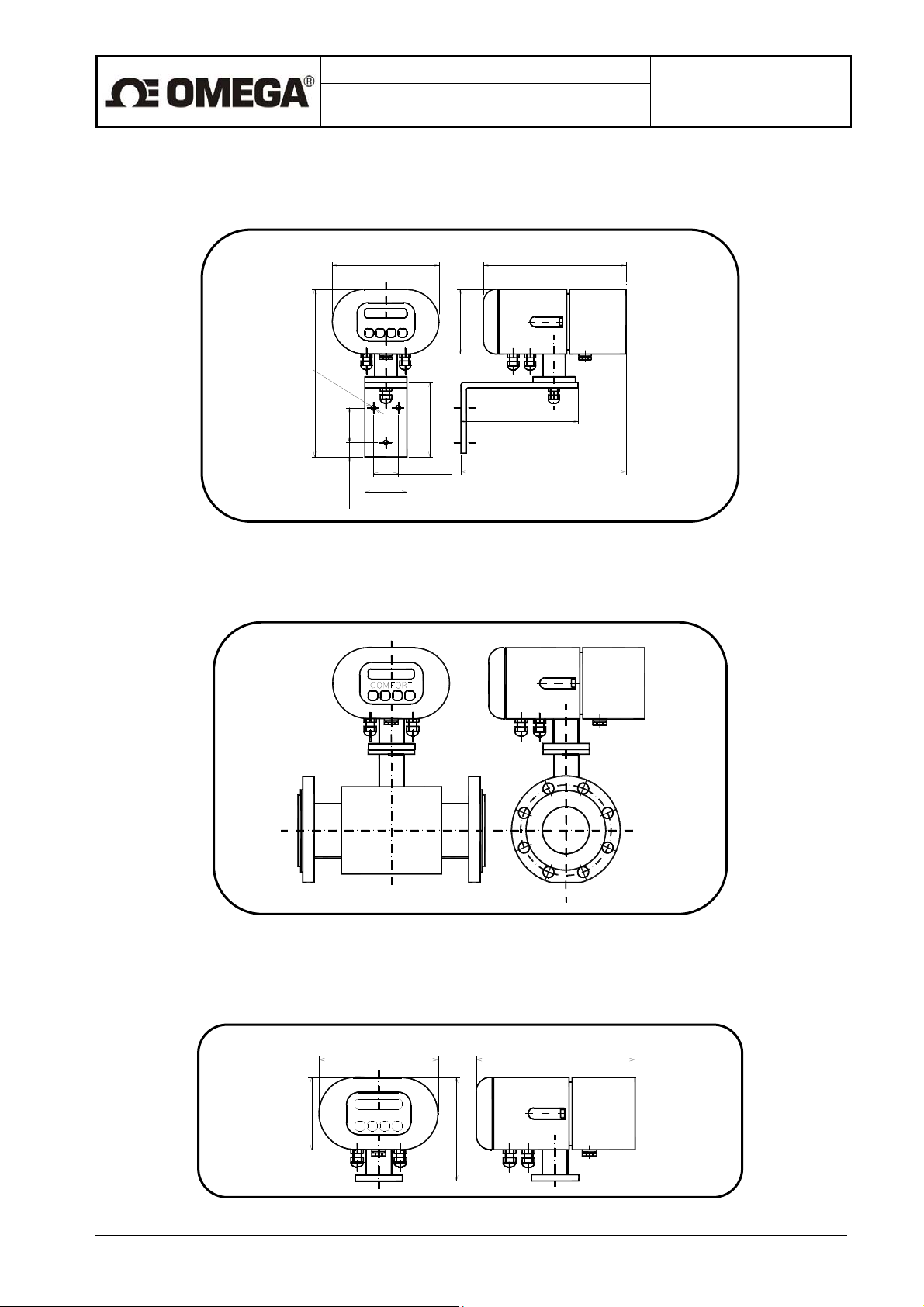

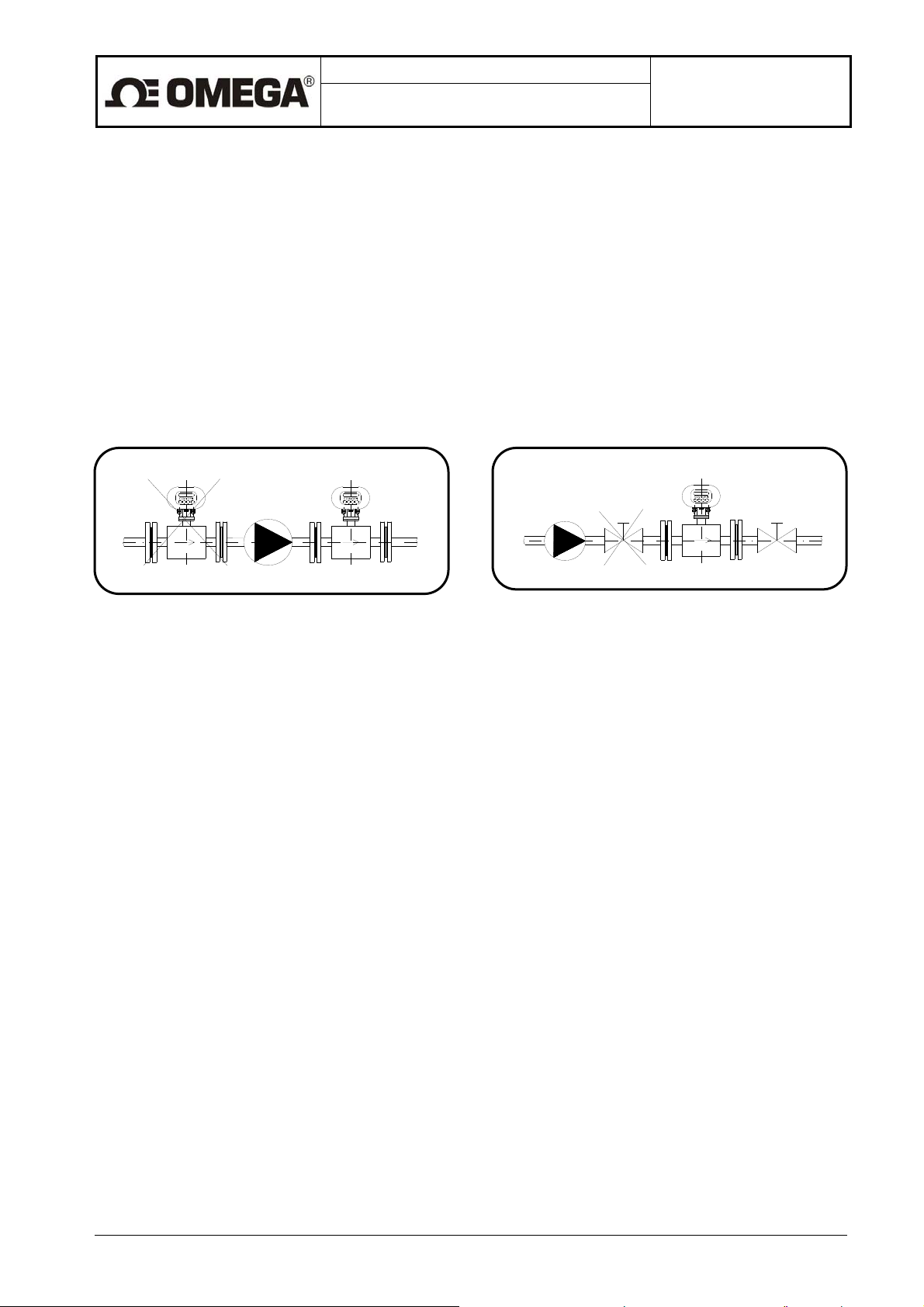

3.2.1. Remote version

Flanged sensor connected by a cable with the associated separate electronic unit.

Page 6

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Dimensions of the box to accommodate separate electronic unit and the mounting bracket

7,9" (200)6" (152)

9,6" (245)

O

0

,

2

5

"

(

6

,

4

)

2" (50)

3,5" (90)

6,8" (173)

5,3" (135)

0,8" (20)

1,4" (35)

2,4" (60)

9,45" (243)

Page 4 of 44

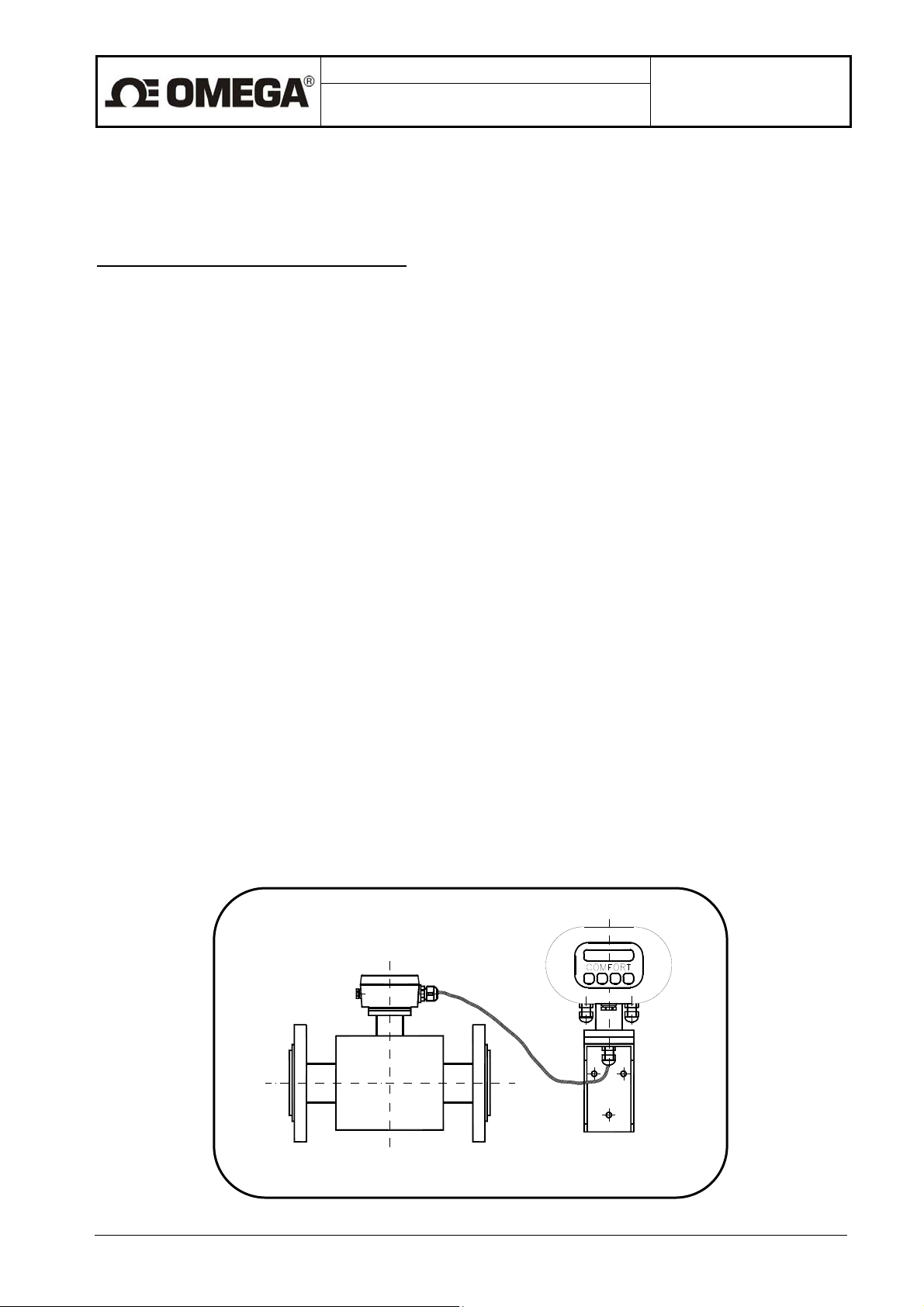

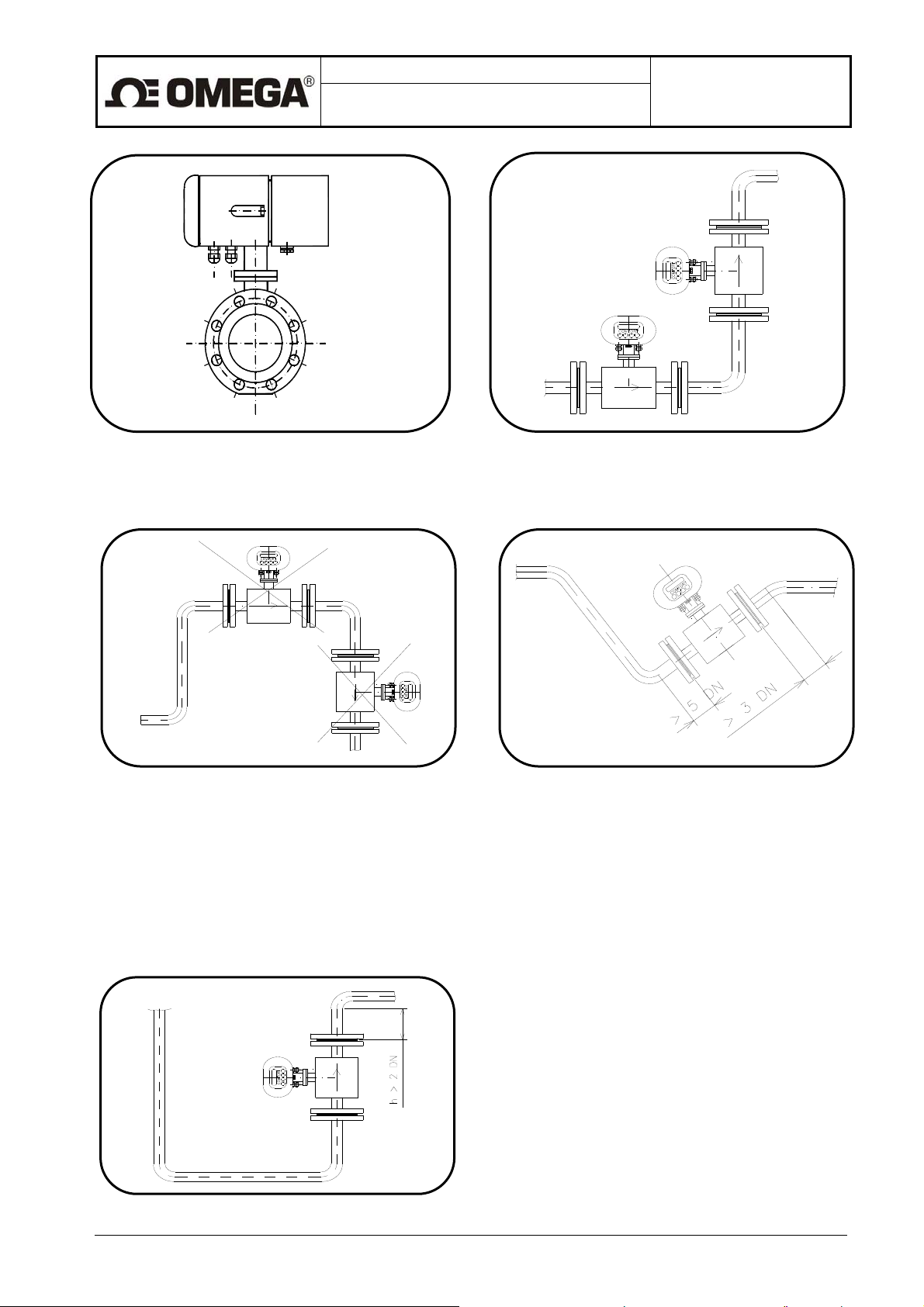

3.2.2. Compact version

Compact design solution for a flanged sensor with associated electronic unit

Dimensions of the box to accommodate a compact version of the flow meter

COMFORT

3,5" (90)

5,3" (135)

7,9" (200)6" (152)

Page 7

3

r

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 5 of 44

4. TECHNICAL PARAMETERS

4.1. Flow sensor

4.1.1. Selection of correct sensor size

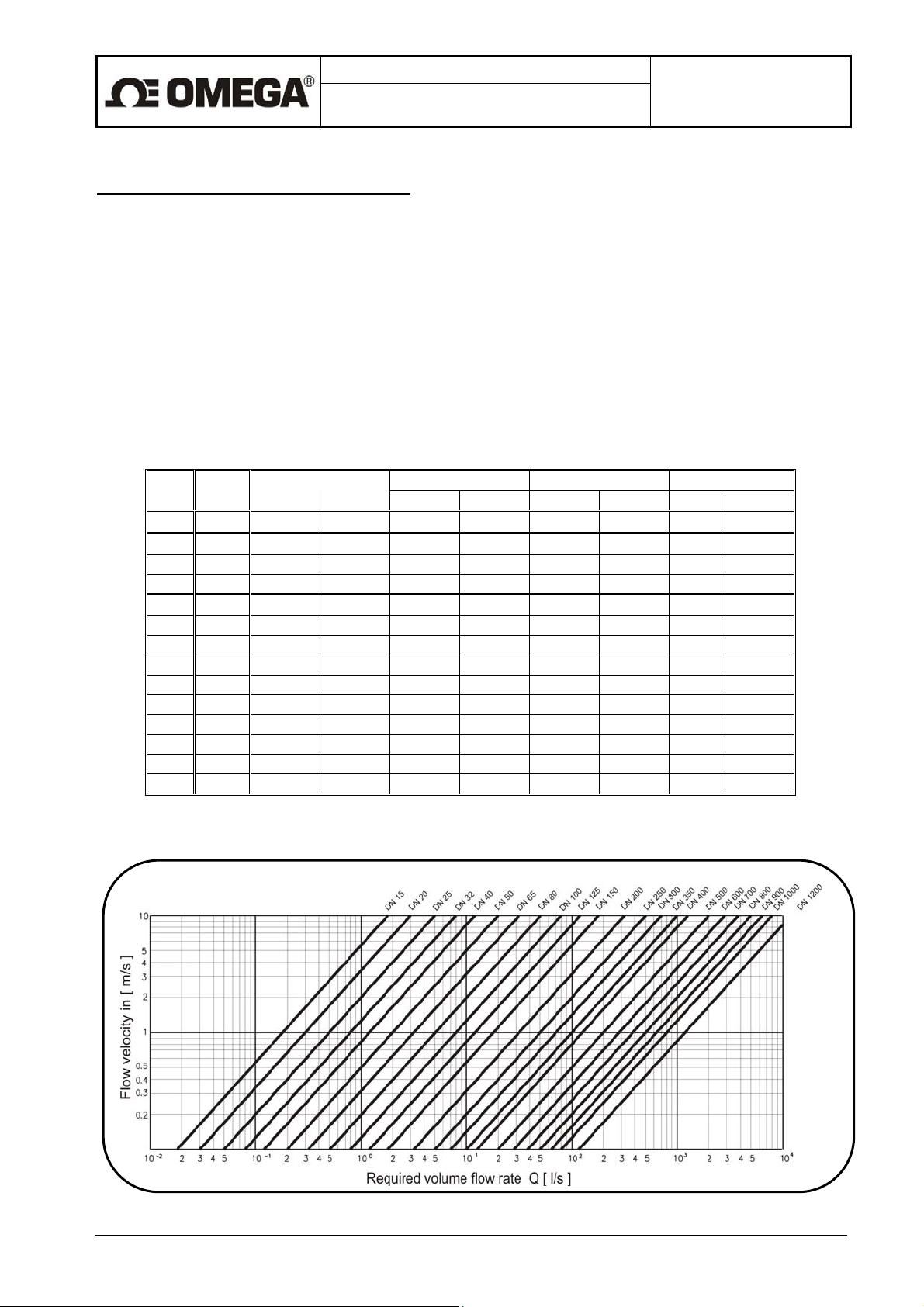

The following table shows minimum and maximum flow rates for various sensor sizes and flow velocities

ranging from 0.33 to 32.81 ft/s (0.1 to 10 m/s). The operational flow-velocity range is best to choose 1.64 to

16.40 ft/s (0.5 to 5 m/s), see the diagram below. For lower flow velocities, the measurement accuracy is

worse while at higher flow velocities the turbulences at contact edges may cause undesirable interference.

Minimum and maximum flow rates for various sensor sizes

DIN

Operational flow rates and flow velocities for various sensor sizes

ANSI GPM l / s GPH m

inches

DN

15

20

25 1 0.79 79 0.05 5 47.6 4755 0.18 18

32 1 ¼40

50 2 3.17 317 0.2 20 190 19020 0.72 72

65 2 ½

80 3 7.93 793 0.5 50 475.5 47552 1.8 180

100 4

125 5

150 6 28.62 2862 1.8055 180.55 1717 171711

200 8

250 10 79.25 7925 5 500 4755 475523 18 1800

300 12 111 11100 7 700 6657 665732 25.2 2520

Qmin Qmax Qmin Qmax Qmin Qmax Qmin Qmax

0.29 29 0.018 1.8 17.2 1712 0.065 6.5

0.528 52.8 0.0333

1.32 132 0.0833

1.98 198 0.125 12.5 118.9 11888 0.45 45

5.28 528 0.3333

12.33 1233 0.7777 77.77 739.6 73962

18.93 1893 1.1944 119.44 1136 113594

50.63 5063 3.194

3.33 31.7

8.33 79.3

33.33 317

319.4 3038

1

½

¾

½

3167 0.12 12

7925 0.30 30

31700 1.2 120

303764

/ hou

2.8 280

4.3 430

6.5 650

11.5 1150

Page 8

g

–

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 6 of 44

4.1.2. Operational pressure of measured liquid

The standard versions of flow sensors have the following pressure rating:

Sensor size Pressure ratin

DN 15

DN 300 1/2” and 12” PN 10 (1.0 MPa) 145 PSI

4.1.3. Selection of electrode material

Standard electrodes made of Hastelloy C4. However, in special applications it may be necessary to select a

different material. On request, Omega can supply electrodes made of tantalum -TGE.

4.1.4. Sensor tube lining

Teflon

Teflon (PTFE) lining is a universal solution for highly corrosive liquids and temperatures ranging from -4 °F

to 302 °F (–20 to +150°C). Typical applications are in the chemical and food processing industries.

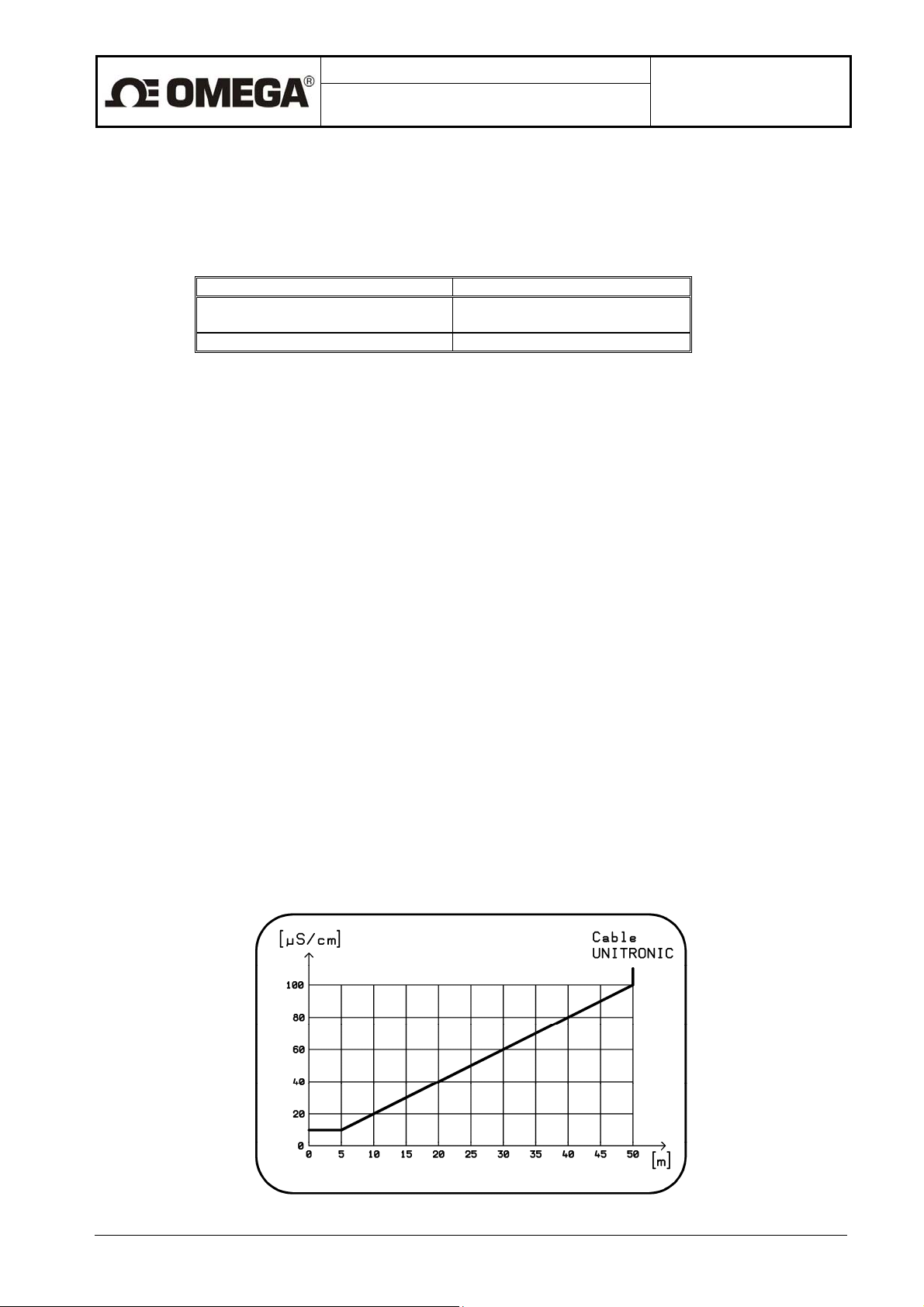

4.1.5. Compact or remote meter version?

Temperature of the liquid is lower than 122 °F (50°C): It is possible to use both, compact or remote

version. Using of the version is only question of the layout or customer wish.

Temperature of the liquid is higher than 122 °F (50°C): Must be used remote version!

To prevent electromagnetic interference via the connecting cable, the sensor and separate electronic unit

of the meter in the remote version should be located as close as possible to each other. The maximum cable

length depends on the conductivity of the measured liquid (see the following diagram). Standard cable length

is 19,7" (6 m). .

Page 9

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 7 of 44

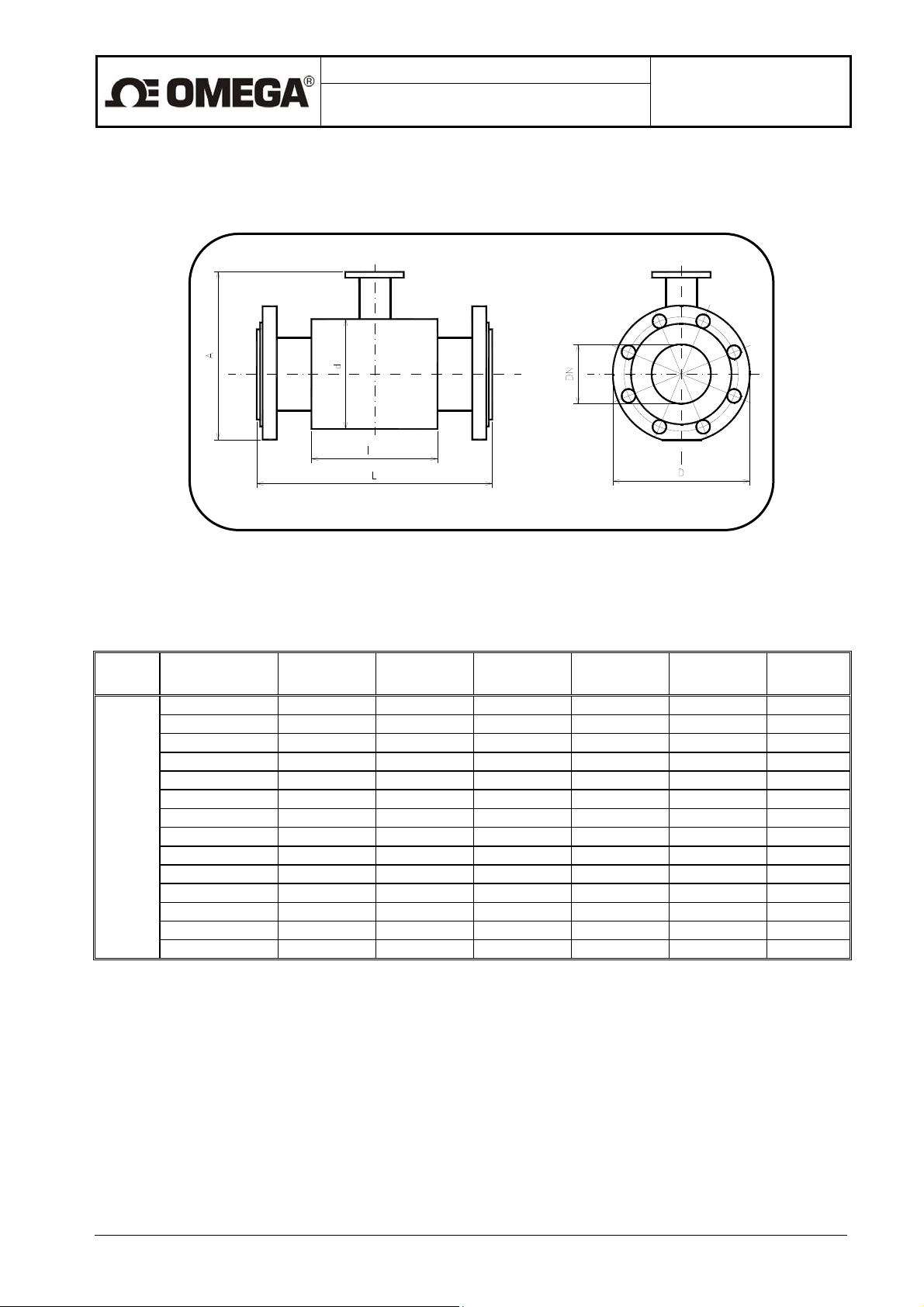

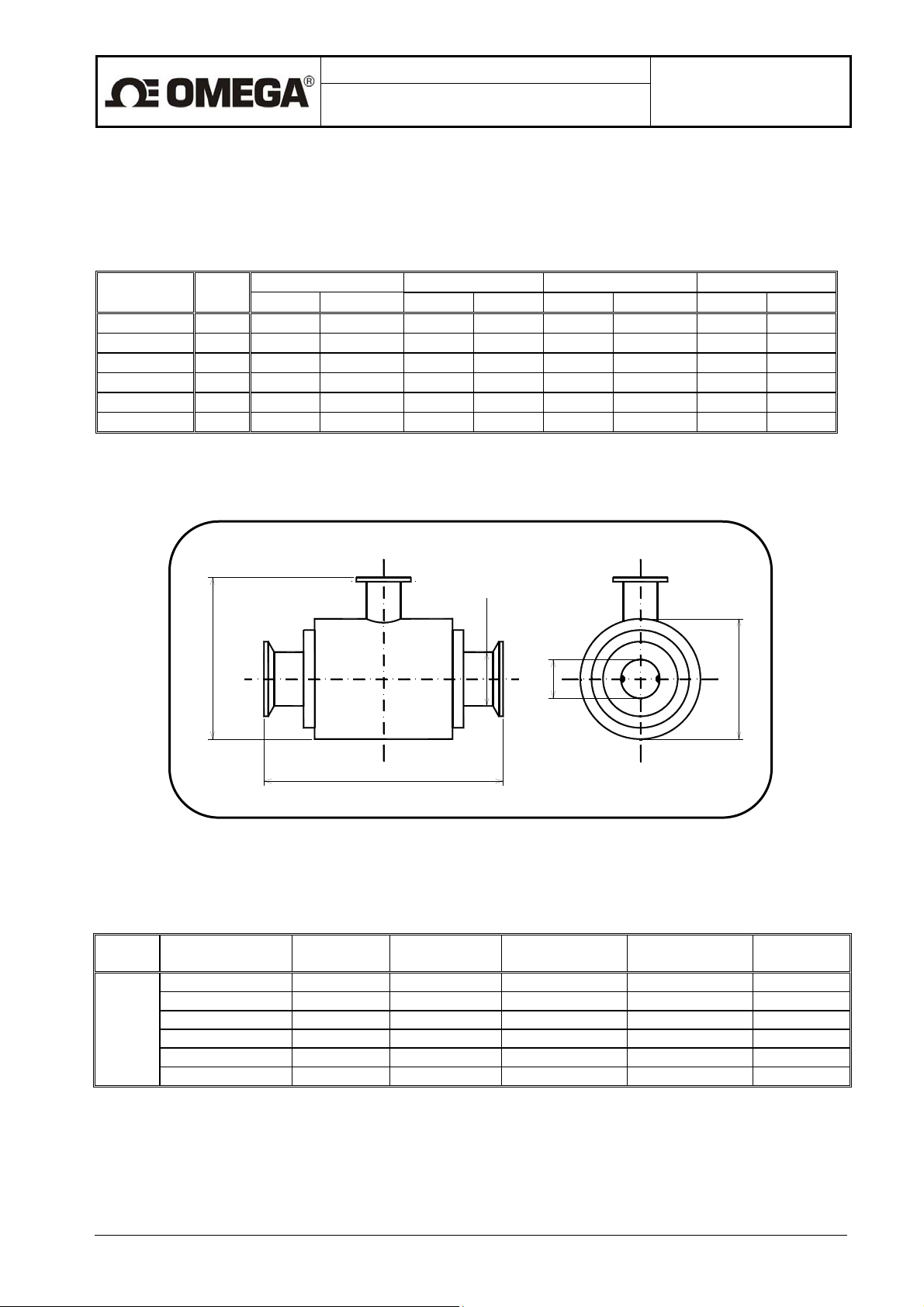

4.1.6. Dimensions of flanged sensor

Sensor dimensions for various rated diameters Line size (DN)

Flanges according standard ANSI B 16.5 150 lb/sq.in.

Nom. size DN

½" (15) 3.5 (89) 2.4 (62) 6.5 (164) 7.9 (200) 2.6 (66)

¾" (20) 3.9 (99) 2.4 (62) 6.7 (170) 7.9 (200) 2.6 (66)

1" (25) 4.3 (108) 2.8 (72) 7.1 (180) 7.9 (200) 3.8 (96)

1 ¼" (32) 4.6 (117) 3.2 (82) 7.8 (199) 7.9 (200) 3.8 (96)

1 ½" (40) 5.0 (127) 3.6 (92) 8.2 (209) 7.9 (200) 3.8 (96)

2" (50) 6.0 (152) 4.2 (107) 8.8 (223) 7.9 (200) 3.8 (96)

PN10 2 ½" (65) 7.0 (178) 5.0 (127) 9.6 (244) 7.9 (200) 3.8 (96)

3" (80) 7.5 (191) 5.6 (142) 10.2 (260) 7.9 (200) 3.8 (96)

4" (100) 9.0 (229) 6.4 (162) 11.0 (280) 9.8 (250) 3.8 (96)

5" (125) 10.0 (254) 7.6 (192) 12.2 (310) 9.8 (250) 5.0 (126)

6" (150) 11.0 (279) 8.6 (218) 13.4 (340) 11.8 (300) 5.0 (126)

8" (200) 13.5 (343) 10.8 (274) 15.7 (398) 13.8 (350) 8.3 (211)

10" (250) 16.0 (406) 14.6 (370) 18.9 (480) 17.7 (450) 8.3 (211)

12" (300) 19.0 (483) 16.5 (420) 21.1 (535) 19.7 (500) 12.6 (320)

* Dimension A (sensor height) is net of the electronic unit box (or terminal box in the remote meter

version).

Weights of the sensors are only approximate.

D

Inches (mm) d Inches (mm)

A*

Inches (mm)L Inches (mm) l Inches (mm)

Weight

lb (kg)

7 (3)

7 (3)

7 (3)

9 (4)

9 (4)

13 (6)

20 (9)

31 (14)

35 (16)

42 (17)

55 (26)

91 (41)

120 (54)

170 (77)

Page 10

3

r

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 8 of 44

4.1.7. Dimensions Tri Clover sensor

Tri-Clover

Size DN/OD

Inch (mm)

ID GPM l / s GPH m

mm

Qmin Qmax Qmin Qmax Qmin Qmax Qmin Qmax

½ (12.70) 9.40 0.1094 11.0001 0.0069 0.6940 6.564 660.006 0.0248 2.4984

¾ (19.05) 15.75

0.3091 30.8812 0.0195

1.9483 18.546

1852.872 0.0702 7.0139

1 (25.40) 22.1 0.6087 60.8018 0.0384 3.8360 36.522 3648.108 0.1382 13.8096

1 ½ (38.10) 34.8 1.5074 150.7603 0.0951 9.5115 90.444 9045.618 0.3424 34.2414

2 (50.80) 47.5 2.8087 280.8756 0.1772 17.7205 168.522 16852.536 0.6379 63.7938

2 ½ (63.50) 60.2

4.5110 451.1493 0.2846

28.4631 270.660

27068.958 1.0246 102.4672

OD Outer Diameter

ID Inner Diameter

A

DN/OD

ID

L

Sensor dimensions for various rated diameters Line size (DN)

Flanges according Tri Clover

OD Outer Diameter

ID Inner Diameter

Size DN/OD

Inches (mm)

inches (mm)D Inches (mm)

½" (12.70) 0,37 (9.40)

ID

A*

Inches (mm)

L

Inches (mm)

2.9 (74) 5.6 (143) 5.4 (137)

¾" (19.05) 0,62 (15.75) 2.9 (74) 5.6 (143) 5.4 (137)

PN10

1" (25.40) 0,87 (22.1)

1 ½" (38.10) 1,37 (34.8)

2" (50.80) 1,87 (47.5)

2.9 (74) 5.6 (143) 5.4 (137)

3.7 (94) 6.4 (163) 5.4 (137)

4.1 (104) 6.8 (173) 5.4 (137)

2 ½" (63.50) 2,37 (60.2) 5.1 (129) 7.8 (199) 7.6 (192)

* Dimension A (sensor height) is net of the electronic unit box (or terminal box in the distributed meter

version).

Weights of the sensors are only approximate.

/ hou

D

Weight

lb (kg)

3.5 (1.6)

3.5 (1.6)

3.7 (1.7)

4.8 (4.8)

()

()

Page 11

g

)

(

)

–

y

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 9 of 44

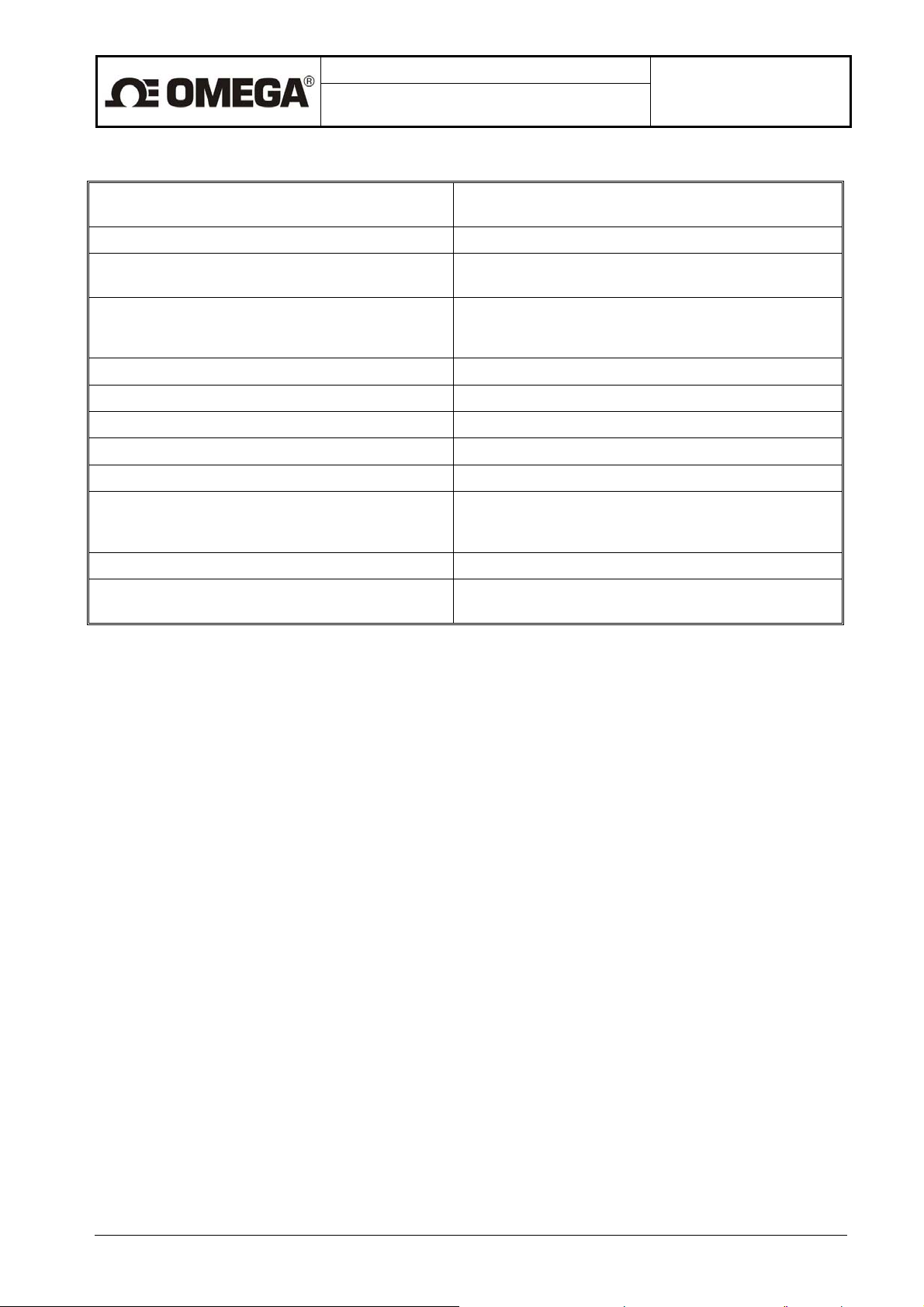

4.1.8. Flow sensor specifications

Sensor size Flanged sensors, ½ “ to 12 “ (DN 15 to DN 300)

Tri Clover, ½ " to 2 ½ "

Operational pressure PN 10 (1.0 MPa) for DN 15 to 300, Tri Clover

Mechanical connection Flanges acc. to 150# ANSI B

Tri Clover

grounding On flanges

Grounding rings

roundingelectrode

Limit flow velocities of measured liquid From 0.33 to 32.81 ft/s (0.1 m/s to 10 m/s)

Maximum temperature of measured liquid up to 302 ºF (150 ºC

Minimum conductivity of measured liquid 20 S/cm

Empty pipe alarm Optional from 2 “ (DN 50)-EPT

Lining Teflon

PTFE

Measuring electrodes Hastelloy C4 standard

Platinum/gold -GGE

Tantalum

TGE

Protection class IP 67

Storage temperature 14 to 158 ºF (-10 ºC to +70 ºC) at max. relative air

humidit

70%

4.2. Electronic unit box

The signal-processing electronic unit is accommodated in a cast aluminum box coated on the surface with

paint of hue RAL 1017. The box is held by four M5 bolts with hexagonal socket heads. Upon loosening the

bolts slightly the box can be rotated around horizontal axis through ±180°. At the rear of the box is a terminal

board under a lid held in position by six bolts with hexagonal socket heads. At the rear bottom part of the box

there are cable glands and a special valve preventing condensation of the air humidity inside the box. The

unused gland openings shall be blinded. The front panel of the box is fitted with a two-line backgroundilluminated display unit and a four-button membrane keyboard.

Prior to putting the meter in service, check the correct sealing of all active glands, blinding of the unused

ones and tightening of the bolts holding the terminal board lid.

Page 12

(

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 10 of 44

4.2.1. Electronic unit specifications

Power source 230 V~ (+10 % / -15 %) / 50 ÷ 60 Hz optional

115 V~ (+10 % / -15 %) / 50 ÷ 60 Hz optional

24 V~ (+10 % / -15 %) / 50 ÷ 60 Hz optional

24 V =

Power consumption 15 VA

Line fuse T250 mA, T2,0 A (with power supply 24 V)

Electric shock protection according to

Automated disconnection from power source in TN-S network

standard CSN 332000-4-41

Box material Aluminum casting

Weight 6.6 lb (3.0 kg)

Ambient temperature 23 to 131 ºF (-5 °C to 55 °C) (protected from direct sun light)

Storage temperature 14 to 158 ºF (-10 °C to 70 °C) at relative air humidity not

exceeding 70 %

Flow velocity range 0.33 to 32.8 ft/s ( 0.1 to 10 m/s)

Maximum flow error 0.2 % for 10 to 100 % Qmax

0.5 % for 5 to 100 % Qmax

Zero adjustment Standard

Output 1 - passive output, insulated

Output 2 - passive output, insulated

Relay output

Active current output, insulated

Binary multi-function optocoupler 30 V/50 mA

Binary multi-function optocoupler 30 V/50 mA

Binary multi-function relay 30V DC /0,3 A,

Analog 0 (4) to 20 mA, max. Load 1000 Ohm

Serial communication ports USB (not insulated) for factory calibration only

RS 485 (insulated)

Protection class IP 67

±10 %)Standard

Page 13

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 11 of 44

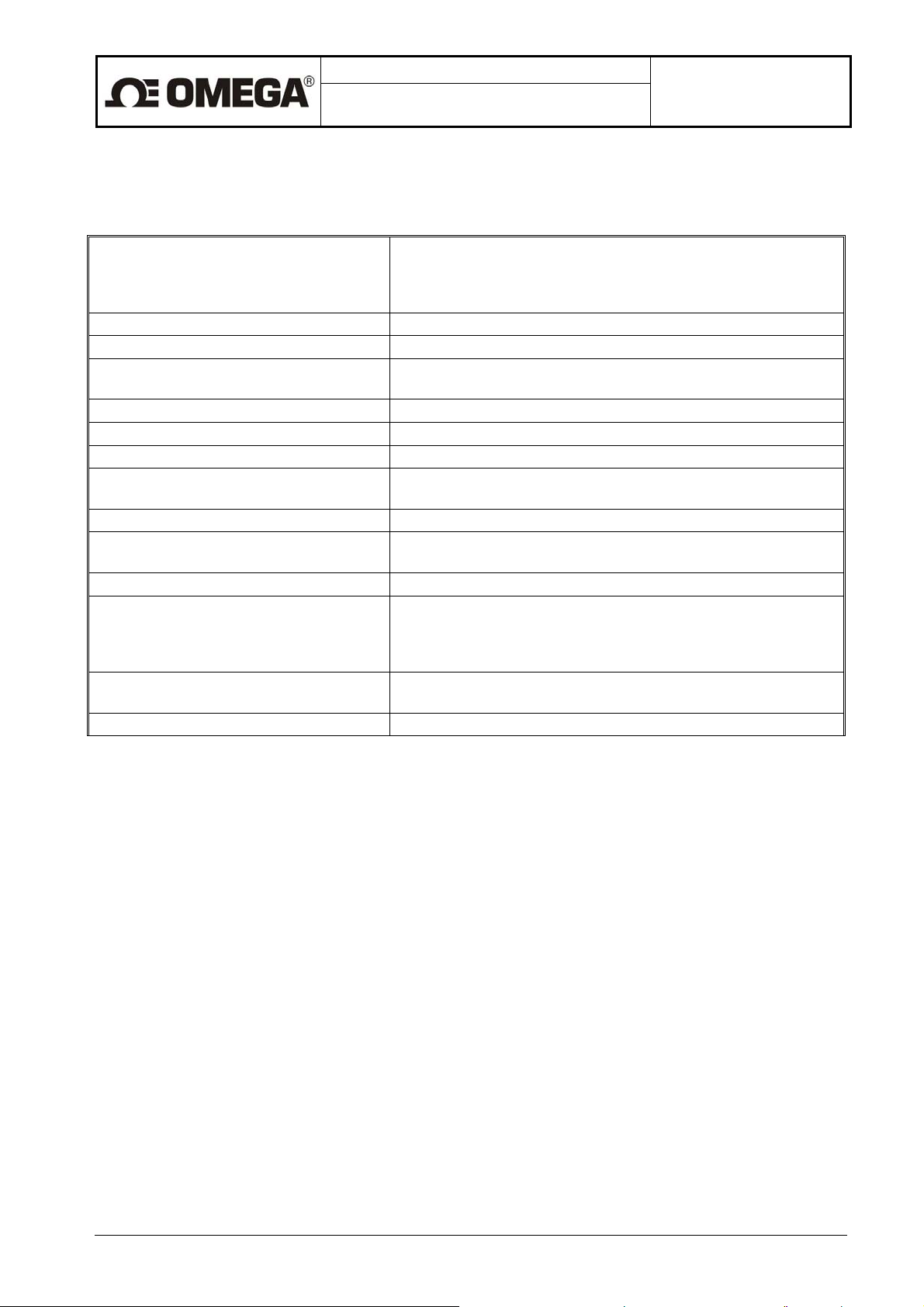

5. METER APPLICATION RULES

5.1. Sensor placement in piping

No chemical injection or batching unit (such as chlorine compound injector) should be located at the input

side of the sensor. The insufficient homogeneity of the flowing liquid may affect the flow-rate values indicated

by the meter.

The meter performance will be the best if the liquid flow in the piping is well stabilized; therefore it is

necessary to observe specific rules for the sensor placement in piping. In the contact planes between the

sensor and the adjoining piping sections should be no edges as these would cause flow turbulence. Make

sure that straight piping sections are provided before and after the sensor; their required length is

proportional to the inner diameter of the piping concerned.

If more than one flow-disturbing element such as pipe bend or fitting is located near the sensor, the required

length of straight piping section on the sensor side concerned should be multiplied by the quantity

of such elements.

In the cases of bi-directional flow-rate measurement, the same conditions concerning flow stability shall be

met at the input and output sides of the sensor.

Required straight piping sections Pipe narrowing

.

In the case where the pipeline nominal size is bigger

than nominal size of flow meter, it is necessary to use

conical reduction with the maximum slope 15°. In the

case of bi-directional flow, conical reduction must be

installed on both sides, both with minimum straight

piping 5 DN. In the case of horizontal installation,

eccentric reduction must be use to prevent bubbling.

Pipe narrowing sections with angles not exceeding 8° can be taken for straight sections (see picture above)

Page 14

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 12 of 44

In the cases where the liquid is pumped, the flow sensor shall always be placed at the output side of the

pump to prevent underpressure in the piping which might damage the sensor. The required length of the

straight piping section between the pump and sensor is then at least 25 DN.

Pump in the piping Closing valve in the piping

For the same reason, the sensor shall be always placed before the closing valve in the piping.

The sensor can be fitted in the piping in either horizontal or vertical position. However, make sure that the

electrode axis is always horizontal and, if the sensor is mounted in a horizontal position, the flange section

for attachment of the electronic unit box faces upwards.

Page 15

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 13 of 44

Elektrode

axis

Electrode axis Sensor mounted in a vertical position

In the cases where the sensor is mounted in a vertical position, the flow direction shall always be upwards.

Risk of liquid aeration Permanent flooding of sensor

To ensure correct meter function at all times, the measured liquid shall completely fill up the sensor and no

air bubbles shall be permitted to accumulate or develop in the sensor tube. Therefore the sensor shall never

be placed in the upper pocket of the piping or in a vertical piping section where the flow direction is

downwards.

In piping systems where complete flooding of the piping cannot always be guaranteed, consider placing the

sensor in a bottom pocket where full flooding is sure.

If the sensor is located near a free discharge point, such point shall be by at least 2 DN higher than the top

part of the sensor.

Sensor placement near free discharge point

Page 16

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 14 of 44

Make sure that the adjoining piping is clamped/supported as close to the sensor as possible, to prevent

vibrations and damage to the sensor.

Undesirable sensor vibrations Sensor bypass

In applications where continuous liquid flow is essential, a bypass shall be provided to allow for sensor

servicing. A sensor bypass may be also reasonable solution in the cases where, to dismantle the flow sensor

from the piping, liquid from a very long piping section would have to be discharged.

5.2. Sensor earthing

The correct meter function requires that the sensor and adjoining piping sections be connected by lowimpedance earthing conductors to the earth potential and the protection conductor of the power source. The

overall arrangement shall be such that the potentials of the measured liquid at the sensor input and output

sides are close to the ground.

5.2.1. Flanged version

With a flanged sensor installed in conductive piping, the flanges shall be electrically connected and the

piping put to the earth.

Flange earthing connection Earthing rings

Should the adjoining piping sections be non-conductive, grounding rings or similar arrangement shall be

used to ensure that the electric potential of the measured liquid is put to the earth.

With a remote version, it is recommended to electrically connect flow sensor with electronics housing box

with conductors AWG10 or AWG12 to assure stabilization of the electric potentials.

Page 17

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 15 of 44

5.2.2 Tri Clover

Tri Clover Flange earthing connection Additional earthing

With a remote version, it is recommended to electrically connect flow sensor with electronics housing box

with conductors AWG10 or AWG12 to assure stabilization of the electric potentials.

Page 18

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 16 of 44

6. FLOW METER INSTALLATION AND OPERATIONAL START

The meter installation work shall be performed in strict observance of the procedures and rules described

in this manual.

To prevent undesirable interference, the power cables shall be laid at least 10“ (25 cm) away from all signal

cables. The signal cables include the cable connecting the sensor and the associated electronic unit (in the

case of a remote meter version), signal output cables and the cable of the RS 485 communication line. All

cables shall be laid outside the thermal insulation layer on the piping. Only shielded conductors shall be used

to connect the output signals and the RS 485 line where the shielding shall be connected to the ground

potential only on the side of the control system.

In applications where high levels of electromagnetic field interference at the measuring location can be

expected (e.g. in the vicinity of power frequency converters), the remote meter version should be avoided. In

these cases it is also recommended to include a filter in the power supply line to the electronic unit.

Filter specification: The filter suppresses spread of the undesirable high frequency disturbances from power

supply cable into the flow meter. It is possible to find standard product of any filter producer. Use filter with

desired protection, or install filter inside of the box with protection. Filter should be as near to the converter,

as possible. Keep all security standards.

Operating voltage: 115 V/60 Hz (250V/50Hz)

Nominal current: 0,5A and more

Losses: 10 kHz 10 to 20 dB

10MHz 40dB

6.1. Sensor installation

The measurement point chosen for the sensor installation should ensure that the internal part of the sensor

is fully flooded with the measured liquid at all times. Any, if partial, emptying or aeration of sensor

in operation shall be avoided. If the sensor is mounted in vertical position, the only permitted liquid flow

direction is upwards. No thermal insulation shall be used on the sensor body.

Sensor must never be under thermal insulation. If flow meter is installed in the pipeline with thermal

insulation, this insulation must be interrupted and sensor must be out of the insulation.

The internal diameters of the piping, connecting flanges and the sensor tube shall be identical. The flange

faces shall be perpendicular to the piping. The input and output piping sections including seals shall be

perfectly aligned, with no protruding edges. In the case of a non-conductive piping, use grounding rings

on both sides of the sensor.

The arrow on the sensor body shall indicate the liquid flow direction (positive flow direction).

Upon loosening the four bolts holding the electronic unit box in position on the sensor, the box can be rotated

through ±180°. The same system for the box rotation can be used if the box is mounted on a bracket

attached to a vertical support plate or wall.

Do not expose the electronics box to straight sunshine, for outdoor installation use cove or shield - it is

not in the normal scope of supply.

Page 19

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 17 of 44

6.2. Electric connections of induction flow meter

The terminals for connecting cables can be accessed upon removal of a cover at the rear part of the box

housing the electronic unit. The cover is held by six socket-head bolts. A schematic diagram of the

connections is shown on the rear side of the cover. Note: USB is for factory calibration only.

Examples of labels showing power supply (line voltage or 24VDC source) and meter signal interconnection

6.2.1. Connection to power source

Terminal 24V 115V 230V/AC/50 ÷ 60 Hz Terminal 24V/DC

PE PE grounding conductor PE PE grounding conductor

N N neutral conductor M M middle conductor

U L phase conductor C L+ +24 V

To connect the power source, use a standard cable of three conductors of square section, not exceeding

3 x AWG 16 (1,5 mm

temperature of at least 194 ºF (90 ºC). Only cables with outer diameters from 0.16" to 0.31“(4 to 8 mm) can

be used with grommet. Using of other diameters of cables cause breaking of protection IP67.

The earthing conductor shall be longer than the phase and neutral conductors. This is a safety requirement

as in the case of loosening the cable clamping in the gland, the earthing conductor shall be the last to be

disconnected from the terminal.

The power supply line shall be protected by an overcurrent circuit breaker. A seal should be applied on the

breaker to prevent unauthorised handling. The electronic unit has no independent power switch.. The

recommended rating of the overcurrent circuit breaker is 4 to 6 A.

2

). For ambient temperatures over 122 ºF (50 ºC), use a cable with rated operating

Page 20

t

t

y

t

A

A

A

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 18 of 44

6.2.2. Output signal connections

Terminal Polarity Function Comments

1 Switching contac

2 Central contact Output rela

3 Break contac

4 - pole Current output

5 + pole

6 Conductor B (-) RS 485

7 Conductor A (+)

8

9

10

11

node (+) Dosing (optional)

Cathode (-)

Optocoupler. collector (+) Dosing (optional)

Optocoupler emitter (-)

12 Optocoupler collector (+)

13 Optocoupler emitter (-)

14 Optocoupler collector (+)

15 Optocoupler collector (-)

Change-over contac

Binary input 1

Binary output 3

Binary output 2

Binary output 1

Optocoupler contacts.

0,3 A, 30 VDC

ctive output, loading Rz max. 1000 .

No external power source needed.

To be directly connected

to the communication line.

Passive input. 5 VDC, 10 mA.

Passive output, requires external power

source and loading resistor..

Passive output, requires external power

source and loading resistor.

Passive output, requires external power

source and loading resistor.

The output terminals can be connected to other electronic equipment using standard shielded signal cables.

For connecting between output terminal and other device can be used shielded data cable with diameter

0.12 to 0.26 “ (3 to 6,5 mm) and intersection AWG 20 to AWG 16 (0,5 to 1,5 mm

2

). For connection of output

signals and communication is necessary to use shielded cables. Shielding must be connected only on one

side of the control system.

After finishing connection, screw up all screws of covers and ensure that it is fixed well. Plug up all unused

grommets and check, that used grommets are tight.

6.3. Connection between sensor and electronic unit (remote version)

In a compact version of the meter, this connection is internal. With a remote meter version, the electronic unit

shall be connected to the associated sensor be means of a special cable supplied attached on the electronic

unit side. On the sensor side, connect the cable wires paying attention to the wire insulation colors and the

terminal identification labels.

Special cable UNITRONIC Cy PiDy 3x2x0.25 length up to 50m, temperature up to 70°C:

Brown BN

Blue BU B

White WH C

Green GN D

Yellow YE E

Yellow and green GNYE Shielding

Pink PK W2

Gray GY W1

Page 21

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 19 of 44

6.4. Connection between sensor and electronic unit (remote meter

version, protection class IP 68)

In the IP 68 version of the flow sensor, the terminal box is sealed by cast plastic and the connecting cable is

fixed on the sensor side. On the electronic unit side, the cable is provided with a screw-on connector with its

mating part mounted on the electronic unit bracket. To prevent unauthorised handling, this connector can be

sealed. The hole for the seal wire is provided in the bracket.

6.5. Operational start

6.5.1 Operational start

The induction flow meter of either compact or remote design shall first be fitted mechanically and then the

power supply and output terminals interconnected. Then switch on the power voltage. For a short while, the

meter display will read WELCOME TO OMEGA FMG600 SERIES. Then one of the items of the DISPLAYED

DATA menu will appear.

Page 22

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 20 of 44

6.5.2. Operational data

The meter includes a two-line alpha-numeric display of 2 x 16 characters with

a background illumination. The display illumination function works in a power-saving mode where the

illumination is automatically switched off 120 seconds following the last push-button action. On depressing

any push-button, the display background illumination is reactivated.

The keyboard includes four push-button provided with the following symbols:

1. Push-button

2. Push-button

3. Push-button

4. Push-button

The meter display makes possible reading of up to nine different types of data. To switch to the desired type

of data, use pushbuttons

To display temporary data, depress push-button

display mode.

1. Flow rate

Average flow rate determined from the specified number of samples.

Flowrate

120.678 m3/h

Display reading: Flow rate

2. Total volume +

The total volume of the measured fluid passed through the meter sensor in the direction of the arrow on the

sensor body since the measurement start, or the temporary volume, i.e. the volume of fluid passed since the

last resetting of the temporary volume + data.

Total volume +

1234.567 m3

Display reading: Total volume +

3. Total volume -

The total volume of the measured fluid passed in the direction against the arrow on the sensor body since

the measurement started, or the temporary volume since the last resetting of the temporary volume – data.

Total volume -

123.456 m3

Display reading: Total volume –

, the “roller” push-button, direction downwards

, movement upwards, in the direction of the arrow

, password entry push-button

, also referred to as the “enter” push-button

(direction downwards) and (direction upwards).

. Depress push-button again to return to the total data

Temp. volume +

765.432 m3

Temp. volume -

65.321 m3

Page 23

4. Total difference

The difference between fluid volumes passed in the positive (+) and negative (-) directions since the

measurement start, or temporary difference from the last resetting of the temporary difference data.

Total difference

1111.111 m3

Display reading: Total difference

5. Operational time

The length of the time period, in hours and minutes, counted from the first meter start, or the length of the

temporary time period measured since the last resetting of the temporary time data.

Operational time

12345:55 h:m

Display reading: Operational time

Upon switching off the induction flow meter, the data readings under items 3, 4, 5 and 6 are stored at the

EEPROM unit and restored upon each new meter start.

6. Percentage flow rate

Flow rate information in the form of a horizontal bar whose length corresponds to the flow rate value in per

cent of a selected 100% value (need not necessarily be the same as the maximum flow rate for the given

sensor). The figure on the right side offers the digital form of the same information. The minus sign before

the figure indicates negative flow data.

Percent.flowrate

_____ - 20%

Display reading: Per cent flow rate

7. Last error

Abbreviated text of the last error message.

Last error

7:sensor discon.

Display reading: Last error

In the case of a meter error, the display will immediately show a message including a short description of the

error concerned. Upon depressing push-button

abbreviated error message and error code are stored in the “previous errors” register. While an error is

indicated, the measurement functions continue undisturbed. In the cases of errors E6 and E7, zero flow rate

is indicated throughout the error condition duration.

The user may review earlier error codes and messages up to 255 previous error messages stored in the

error register. To access this function, depress push-button

E-XXX YYY/ZZZ are: XXX the error code, YYY error ordinal number, and ZZZ the total number of error

codes stored in the register. To page in the list use push-button

depress push-button

. Error register is reset with switching power on.

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Temp.difference

700.111 m3

Temporary time

543:21 h:m

Last error

E-007 015/015

, the meter will return to the data display mode, while the

(previous error display). In the data format

Page 21 of 44

. To return to the data display mode,

Page 24

The error messages are:

E0: No error.

E1: Error in CRC EEPROM. Incorrect data check sum in the EEPROM unit. This error may occur when the

processor, following a power failure, does not manage to store all data in the EEPROM unit.

E2: OUT1 (multi-functional output) is in the impulse mode of operation and the memory block storing the

unsent impulses overflows.

E3: OUT2 (multi-functional output) is in the impulse mode of operation and the memory block storing the

unsent impulses overflows.

E4: Multifunctional output RELAY is set for pulse output and there is memory of pulses overflow.

E5: WDOG: the processor reset due to the overflow condition in the timer controlling the length of the

programming loop.

E6: Not fully flooded piping.

E7: Open current loop in the impulse generation circuitry of the meter sensor.

E8: Error in +5 V power line.

E9: Error in +24 V power line.

E10: Error in -5 V power line.

E11: Actual flow rate exceeded the selected Imax value.

E12: Failure in frame receipt confirmation while communicating via the RS 232 serial line.

E13: Not processed

Error indication mode enabled: error information is displayed and entered into the error register. Some errors

result in setting the indicated flow rate at zero.

Error indication mode disabled: the error information is entered into the error register.

8. Dosing

Dosing is visible and functional provided this data display mode has been selected.

The selected fluid volume (dose) will wait for the active initiation signal to be brought to terminals 8-9. As

soon as such signal is received, a count towards zero will commence. Upon reaching zero, OUT3 will close.

The dosing action can be repeated by depressing push-button

set the required dose, follow the respective procedure in the programming menu.

Dosing mode

500.00 l

Display reading: Dosing mode

Design, Assembly and Service Manual

Induction flow meter FMG600 series

. To interrupt dosing, use push-button . To

Page 22 of 44

6.5.3.1. Display formats of aggregate values

If the displayed value occupies more than 11 digit places including the decimal point, the calculated value

will be displayed alternately with the selected measurement unit.

6.5.3.2. Data reset

The user is not permitted to reset the aggregate data values under items 3, 4, 5 or 6. Resetting is only

possible with running (“temporary”) values associated with items 3, 4 5 and 6 accessible via push-button

(another depression of push-button

temporary value is displayed, depress push-button

push-button

button

temporary value, depress any of push-buttons

value mode, depress push-button

temporary values will be unaffected.

to reset the temporary value. By depressing any of push-buttons and after that push-

, return to the total value display mode. If you stop the temporary mode and wish not to reset the

, will return the display to the total value display mode). When a

to discontinue the temporary value mode, and depress

, whereby the count continues. To return to the total

. This procedure will reset the edited temporary value only, the other

Page 25

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 23 of 44

7. PROGRAMMING

The induction flow meter can be programmed in two ways: using a computer connected to the serial meter

interface, or using its own keyboard. The following description concerns the keyboard (push-button)

programming procedures.

The keyboard includes four push-buttons provided with the following symbols:

1. Push-button

2. Push-button

3. Push-button

back in the menu;

4. Push-button

In any menu, the selected item is on the first line with the first character blinking.

Entry the programming mode, movement within a menu and data saving

To enter the programming mode, depress push-button

against unauthorized action by a password (a four-digit number) that needs be entered before accessing the

basic programming menu. Upon delivery, from the manufacturing plant, every new meter has a password of

0000.

Password

0000

Display reading: Password

With a new meter, enter password 0000 and confirm by push-button

your own password, enter the same and confirm by depressing push-button

programming mode, the password can be changed without any limitation.

Use the push-button

will return to the left side of the line. The cursor is a short horizontal line to be placed under the character we

wish to edit/change.

Use the push-button

direction downwards. Upon reaching the last character in the character series available, the first eligible

character will reappear.

Upon completing the editing action, confirm your choice by push-button

password, the display will read “Incorrect password Try again” while the program will return to the data

display mode.

Password OK

Press any key

Display reading: confirmation of correct password entry: Password OK. Press any key.

With the display reading “Password OK Press any key”, depress any push-button (preferably

basic programming menu.

, the “roller” push-button, direction downwards;

, movement to the right in the direction of the arrow, direction upwards;

, password entry push-button, movement upwards in the direction of the arrow, movement

, also referred to as the “enter” push-button (command confirmation).

and then . The programming mode is protected

. Provided you have already chosen

. Prior to leaving the

to move the cursor to the right. Upon reaching the extreme right position, the cursor

to change the selected character in the direction upwards, or push-button in the

. Should you enter an incorrect

) to enter the

Page 26

A

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 24 of 44

The two-line display will always show two of the following basic menu options:

Displayed data

Samples

nalog output

Output function

Electrode clean

Serial line

Production data

Dose setting

Zero setting

100 percent

Exit

Display reading: the basic menu

Use push-buttons

and to move upwards and downwards in the menu. As in any meter menu, the

selected item is on the first display line with the initial character blinking.

Depress push-button

depress push-button

to enter a subordinated menu, or to edit an item. When in a subordinated menu,

to return to the higher-level menu (the “Escape” function). When in the basic menu,

the Escape command will bring forth the possibility to terminate the programming mode via the selection

of the “Exit” item of the basic menu.

7.1. Programming of the basic menu items

7.1.1. Displayed data

The “Displayed data” menu allows the operator to choose which parameters are to be displayed. Using

push-buttons

cancelled.

Menu: Displayed data, depress

The two-line display unit will always show two of the items from the following menu. Use push-buttons

to page upwards and downwards through the menu items.

Menu: Displayed data, depress

Display line 1 will read “Do not display”, line 2 “l/s …. l“. Use push-buttons

menu items. If you choose “Do not display”, depress

display If you wish to display “Total volume +”, select the”Total Volume +” item on the menu; depress pushbutton

skip line 1,(Do not display) and select line 2, “l/s …. l“ (flow-rate unit … volume unit). Using pushbuttons

selection by depressing

(downwards) and

depressing

and , select parameters from the following list. The Flow Rate display cannot be

and

Flow rate

Total volume +

Total volume Total difference

Operational time

Percent. Flow rate

Last error

Dosing mode

/ Total volume depress

and to go up and down in the

to return to the “Displayed data” menu. If you wish to

(downwards) and (upwards), select the desired flow-rate and volume units and confirm the

. The display line 1 will then show “0” and line 2 “0.0“.Using push-buttons

(upwards), select the desired number of decimal positions, confirm the selection by

and return to the “Displayed data” menu.

Page 27

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 25 of 44

Comment:

The measurement unit selected for “Flow Rate” is automatically set for all other flow-rate quantities referred

to in the Programming menu.

The measurement unit selected for “Total Volume +” is automatically set for all other flow-volume quantities

in the Programming menu.

The measurement units for the “Total Volume –“ and “Total Difference” quantities can be selected as need

be, and their selection will not affect any other measured quantities to be set within the Programming menu.

Table of flow-rate and volume units Table of decimal positions

l/s …. l 0

l/min …. l 0.0

l/h …. l 0.00

m3/s …. m3 0.000

m3/min…. m3 0.0000

m3/h …. m3 0.00000

GPS …. G 0.000000

GPM …. G

GPH …. G

User-specified units

When defining a user-specific unit, it is necessary to enter a conversion constant (a multiple of the standard

flow-rate or volume units – “l/s” or “l”, then depress

define number of decimal positions, depress

and return to the “Displayed data” menu.

, define the unit name (six characters), depress ,

Example: the desired flow rate unit is US barell per second; the conversion constant is 0.006283811; unit

name bl/s; number of decimal positions 0.000.

The same procedures apply to parameter setting with Flow rate, Total volume +, Total volume – and Total

difference.

While setting the parameters of Operational time, Per cent flow rate, Last error and Dosing, the options to

select from are only “DISPLAY” and “NO DISPLAY”.

To leave the “Displayed data” mode and return to the basic programming menu, depress push-button

.

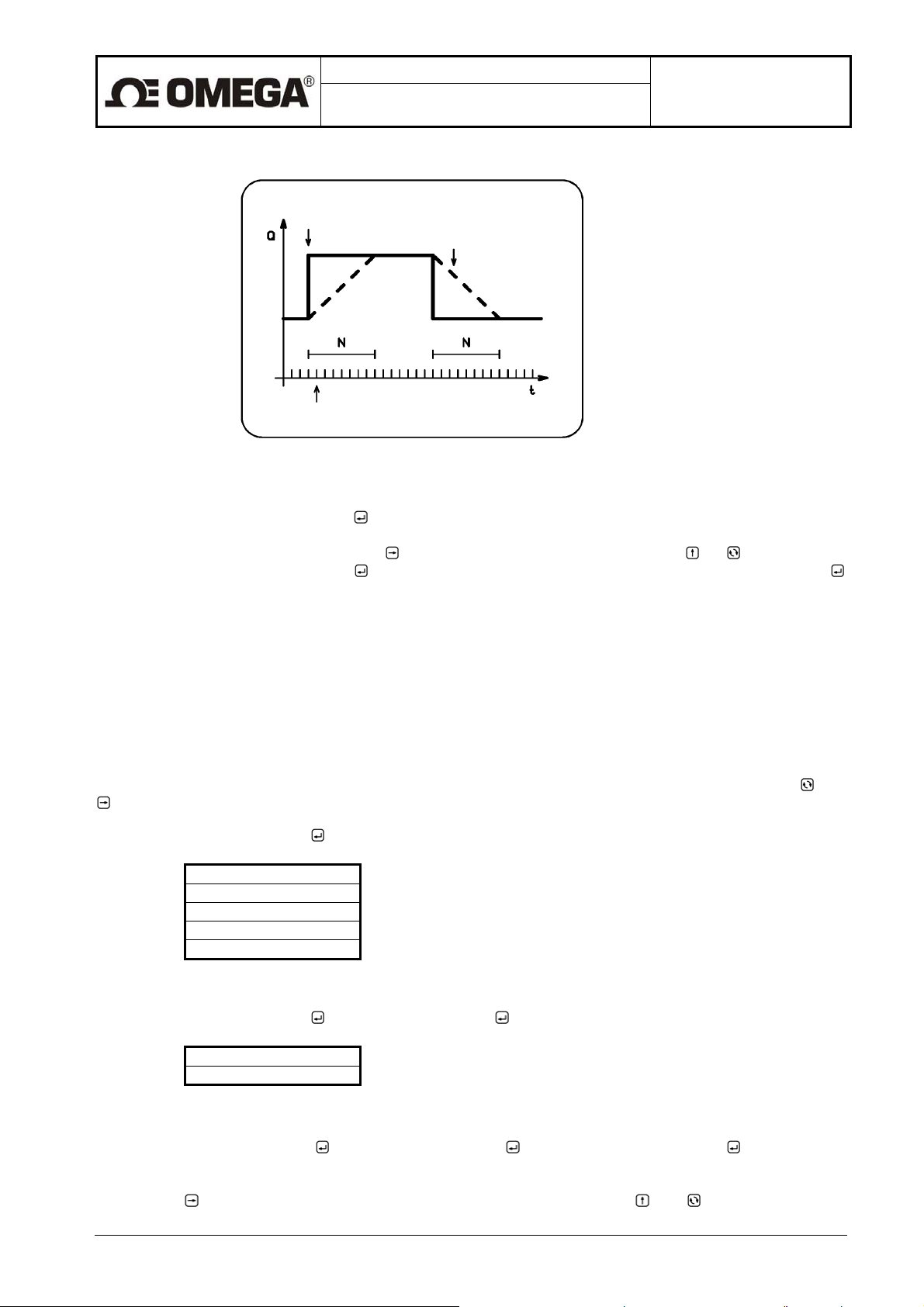

7.1.2. Samples

The number of samples N, on the basis of which the average flow rate value is determined, can be set within

the range of 1 to 255. While the measurement frequency is 6.25Hz (or 3.125, 1 or 0.5Hz), fast (step)

changes in the flow rate will be smoothened within the interval of 0.08 to 20.40s (0.16 to 40.80s, 0.5 to

127.5s or 1 to 255s). The averaging feature is useful in the cases where the flow through the meter sensor is

unstable, the fluid is turbulent or where there are air bubbles trapped in the fluid flow.

The averaging function helps suppress fast changes in the fluid flow rate. Average flow rate as measured

and displayed is the parameter used to calculate other meter outputs.

Page 28

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 26 of 44

Current flow rate

Average flow rate

Sampling

Suppression of step changes in flow rate

Menu: Number of samples, depress

The display will read “Number of samples xxx“. Replace xxx by a number from the range of 1 to 255 (usually

25). Move the cursor using push-button

Confirm the selection by push-button

, and increase/decrease number using or , respectively.

. The display will then read “Value entered Press any key”. Press

or any other push-button.. This action will take you to the basic menu.

7.1.3. Analog output

Setting options

Connected to terminals 4 and 5 is a programmable current output. It is an active current output, insulated

from other meter parts. The maximum output load is 1,000. Depending on the fluid-flow characteristics , the

output can be used in four different modes of operation (see the graphs below) and in two selectable

measurement ranges.

The two-line display unit will always show two of the items from the following menu. Use push-buttons and

to page downwards and upwards through the menu items.

Menu: Analog output, depress

0..+Q Output

0..-Q Output

|Q| Output

–Q..+Q Output

Fixed current

In all operational modes excepting the “Fixed current” mode the current output range can be user defined.

Menu: Analog output, depress / Output 0..+Q, depress

Output 0.. 20 mA

Output 4.. 20 mA

Selection of current output

Menu: Analog output, depress

Imax

The current output setting consists of defining flow rate Qmax corresponding to Imax. Move the cursor using

push-button

, and increase/decrease the Qmax value using push-buttons and . Select the desired

/ Output 0..+Q, depress / Output 0.. 20 mA, depress / Flow rate for

Page 29

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 27 of 44

Qmax and confirm the setting by depressing . The display will then read “Value entered Press any key”.

Press any key, preferable the

pusch-button. This action will take you back to the main programming

menu, item “Analog output”.

In the “Fixed current” mode, the output current can be set within the range of 0 to 20mA. This mode is used

for meter servicing purposes.

Menu: Analog output, depress

Move the cursor using push-button

/ Fixed current, depress / Fixed current 0.. 20 mA

, and increase/decrease the current value using push-buttons and

. Select the desired current value and confirm the setting by depressing . The display will then read

“Value entered Press any key”. Pres any key, preferably

. This action will take you back to the main menu,

item “Analog output”. At the same time, the defined current will start to flow through the output circuit.

The following graphs show the relationships between current I and flow rate Q for various operational

modes.

Output current for 0 ...+Q Output current for 0 ...-Q

Output current for |Q| Output current for –Q ...+Q

Page 30

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 28 of 44

Examples of analog output interconnections

Q+ Q-

Equipment with a current input Equipment with current inputs

Outputs 1 and 2 serving the purpose of

identifying fluid flow direction.

Multifunctional outputs programmed to identify the fluid flow direction and negate the flow direction, will

divide the analog output operated in the “Absolute Flow Rate Value” mode into two outputs, one for each

flow direction.

Page 31

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 29 of 44

Equipment with voltage input Current output connected as a voltage

source to feed the (passive) output 2

The output voltage for the associated equipment is defined as the voltage drop on resistor R. It holds:

U = I R.

For the voltage range of 0.. 10V, select R = 500 and the analog current output range 0.. 20mA. Resistor R

shall be placed as close to the input terminals of the co-operating (controlled) equipment as possible. The

maximum voltage (voltage drop on the resistor) is 10V. The input impedance of the controlled equipment

shall be at least 100 times higher than that of resistor R.

The interconnection of the current output as an auxiliary power source for the binary outputs is shown in the

above picture. This arrangement assumes that the current output is not used for the purposes of flow rate

indicator. Here the current output needs be set in the “Fixed current” mode of operation. The voltage drop on

resistor Ri is used as supply voltage for the binary output (via resistor Rz). The input impedance of the

associated equipment shall be at least 10 times higher than that of resistor Rz, while Rz shall be at least

10 times higher than Ri. It holds: Ri < Rz < input impedance of the associated equipment.

Technical specifications of analog output

The analog output is controlled by a 12-bit DA converter. The operational range 0 to 20mA is divided into

4,096 steps. One step (1LSB) therefore corresponds to about 0.005mA (0.025% of 20mA). This resolution

applies to all output ranges. The current range 4 ... 20mA is software-defined with the converter steps

reduced accordingly. The maximum voltage at the current output is 20V; the maximum resistance of the

current loop is 1,000.

7.1.4. Output function

The configuration of the induction flow meter includes two binary multifunctional outputs, electrically isolated

by means of optocouplers. The output transistors of the optocouplers are accessible via terminals 12-13 and

14-15. These are passive outputs that need external power source. Alternatively they can be powered by the

analog output in the fixed-current mode as described above. The binary outputs can be loaded and

repeatedly switch on and off currents 1 to 50mA.

Default settings: Output 1: frequency output, Output 2: pulse output.

Flow meter can be equipped with an output relay, designated in the menu as item "Relay functions".

Electrically isolated relay contacts are accessible via terminals 1-2-3. For impulse output, both the impulse

width and the minimum gap length are set at 0,5 s. To ensure correct functioning of the impulse function, it is

necessary to set the outputimpulse constant (the fluid volume per impulse) so that the memory block of

unsentimpulses would never overflow.

Page 32

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 30 of 44

Menu: Output function, depress

The display will offer the following selection:

OUT1 function

OUT2 function

RELAY function

The two-line display unit will always show two of the items from the following menu. Use push-buttons

and

to page downwards and upwards through the menu items.

Menu: Output function, depress

/ Output 1 function, depress

The two-line display unit will always show two of the items from the respective menu. Use push-buttons

to page downwards and upwards through the menu items.

and

The output functions available are shown in the following table:

Frequency can not be used for relay output

Permanently open

Perm. closed

|Q| pulses

Q+ pulses

Q- pulses

Q+ frequency

Q- frequency

|Q| frequency

Fixed frequency

Negative flow

Non-neg. flow

Error occurred

No error occurred

Q>Q lim.

Q<Q lim.

|Q|>Q lim.

|Q|<Q lim.

Cleaning

Not cleaning

Permanently closed (open)

These modes are only used for servicing purposes.

Menu: Output function, depress

depress

/ Output 1 (2) function, depress /Permanently closed (open),

This will return the display to the menu item “Output 1 Function” or “Output 2 Function”.

To return to the basic programming menu, depress push-button

.

Page 33

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 31 of 44

Pulse outputs

In any of the pulse modes, an pulse will be generated as soon as a defined (preset) fluid volume passes

through the meter sensor. The impulse mode requires specification of the following

three parameters: pulse width “t

“, minimum time gap between two successive impulses “t

U

“ and fluid

D

volume per impulse “V”.

This mode provides for integration of the flow rate

values in time. As soon as a preset fluid volume V

passes through the meter, an impulse of width t

generated. After each impulse, a gap of at least t

follows. If, after elapsing of the t

period, fluid volume

D

U

is

D

V has not yet passed through the sensor, the output

remains inactive. If the volume passed is equal to or

greater than V, another impulse plus gap are

immediately generated. Should the preset volume V

pass before the end of the previous impulse, the nongenerated impulse will be stored in a accumulator with

the capacity of 255 impulses. Should the impulse

accumulator overflow, an error message will be

generated. To ensure correct functioning of the meter

impulse function, it is necessary to set the impulse

output parameters so that the expected impulse

frequency shall correspond to the impulse width and

gap length selected.

Pulse generation principle

It holds: maximum pulse frequency = 1 / ( tU + tD)

The volume per impulse parameter can be set within the range of 0.001 to 1,000,000 liters. The pulse width

and gap length can be set at 10 to 2,550ms in steps of 10ms. The setting procedure consists

of selecting numbers from 1 to 255 on the meter display. Multiplied by 10, the figure shows the impulse width

or gap length in milliseconds.

From the above it follows that the maximum impulse frequency is 50 per sec.

Regarding the flow rate conditions (see below), impulses can be generated in three different modes. During

the tU periods, the output is closed.

Impulse frequency Impulse frequency Impulse frequency

Flow rate Flow rate Flow rate

Impulses for |Q| Impulses for Q+ Impulses for Q-

Page 34

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 32 of 44

Menu: Output function, depress / Output 1 (2) function, depress / Pulses for |Q|, depress .

The display will read “Pulse width [1] xxx“. Move the cursor using push-button

values at various “x” positions using push-buttons

when multiplied by 10, will give the pulse width in ms. Depress

Press any key”. Press any key, preferably

Move the cursor using push-button

. The display will then show the message “Gap length [1] xxx“.

, and increase/decrease the values using push-buttons or ,

or , respectively. Replace xxx by a figure which,

. The display will read “Value entered

, and increase/decrease the

respectively. Replace xxx by a figure which, when multiplied by 10, will give the gap length in ms. Depress

. The display will read “Value entered Press any key”. Press any key, preferably

show the message “Volume per pulse [1] xxxxxxx“. Move the cursor using push-button

increase/decrease the “x” values using push-buttons

or , respectively. Replace xxxxxxx by a figure

. The display will then

, and

equal to the desired fluid volume per pulse. This figure is elsewhere referred to as the impulse constant or

impulse number. Depress

preferably

. This will return the display to the menu items “Output 1 function” or Output 2 function”. To

return to the basic menu, depress push-button

. The display will read “Value entered Press any key”. Press any key,

.

Pulse number selection for FMG600 SERIES

Dimension Qmax Imp.number

Qmax

coefficient Imp.number

Inches (DN) l/s l/imp GPM gallon/imp.

½ “ 15 1.8 1

¾ “ 20 3.33 1

1“ 25 5 1

- 32 8.33 5

1½“ 40 12.5 5

2“ 50 20 5

- 65 33.33 10

3“ 80 50 10

4“ 100 77.77 50

- 125 119.44 50

6“ 150 180.55 50

8“ 200 319.4 100

10“ 250 500 100

12“ 300 700 500

28.53058

52.78157

79.25161

132.03318

198.12903

317.00644

528.29124

792.51611

1232.67956

1893.16249

2861.77568

5062.59292

7925.16112

11095.22557

3.785412 1

3.785412 1

3.785412 1

3.785412 1

3.785412 1

18.92706 5

18.92706 5

18.92706 5

18.92706 5

37.85412 10

37.85412 10

189.2706 50

189.2706 50

189.2706 50

1 gallonUS = 3.785412 l

pulse width = 100 ms

minimum gap length = 100 ms

f <= 5Hz

0.264172037 gall = 1 l

15.85032224 gall/min = 60 l/min

Impulse number selection for FMG600 SERIES for sensors Tri Clover

Dimension Qmax Imp.number

Qmax

coefficient Imp.number

Inches mm l/s l/imp GPM gallon/imp.

½ “ 12.70 0.6940 1

¾ “ 19.05 1.9483 1

1“ 25.40 3.8360 1

1½“ 38.10 9.5115 5

2“ 50.80 17.7205 5

2½“ 63.50 28.4631 10

11.0001

30.8812

60.8018

150.7603

280.8756

451.1493

3.7854 1

3.7854 1

3.7854 1

3.7854 1

18.9270 5

18.9270 5

Page 35

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 33 of 44

Frequency outputs

In the frequency modes, the output signals will be impulses of impulse-to-gap ratio 1:1. The frequency range

available is from 1Hz to 10kHz.

Comment:

The electronic unit of the meter includes only one frequency generator. It is therefore impossible

to select different frequencies for each output, or combine the fixed-frequency mode at one output with

frequency related to flow rate mode at the other output. On the other hand, the operator may select the

frequency related to flow rate mode in the positive direction at one output with that in the negative direction

at the other output, with the same frequency-to-flow-rate ratios.

Regarding the flow rate conditions, the frequency outputs can be operated in three different modes (see

below).

Frequency for Q+ Frequency for Q- Frequency for |Q|

Menu: Output function, depress

The display will read “Flow rate per 1kHz xxxx“. Move the cursor using push-button

increase/decrease the values at various “x” positions using push-buttons

by a figure representing the maximum flow rate. Depress

key”. Press any key, preferably

/ Output 1 (2) function, depress / Frequency for Q+, depress .

, and

or , respectively. Replace xxxx

. The display will read “Value entered Press any

. This will return the display to the menu items “Output 1 function” or

“Output 2 function”.

The fixed-frequency mode is used for servicing purposes only. The required frequency is set in Hz within the

range of 1 to 10,000 in steps of 1Hz.

Menu: Output function, depress

The display will read “Fixed frequency xxxxx“. Move the cursor using push-button

“x” values using push-buttons

frequency in Hz. Depress

/ Output 1 (2) function, depress / Fixed frequency, depress .

, increase/decrease the

or , respectively. Replace xxxxx by a figure equal to the desired

. The display will read “Value entered Press any key”. Pres any key, preferably

. This action will return the display to the menu items “Output 1 Function” or “Output 2 Function”.

To return to the basic menu, depress push-button

.

Negative (non-negative) flow direction

This mode is used to identify the flow direction. In the case of negative flow direction, the output is closed

(open).

Menu: Output function, depress

direction, depress

.

/ Output 1 (2) function, depress / Negative (Non-negative) flow

The display will return to the menu items “Output 1 Function” or “Output 2 Function”.

To return to the basic programming menu, depress push-button

.

Error (no error) condition

In the case of a meter error, the output will close (open) and stay so as long as the error condition exists.

Menu: Output function, depress

/ Output 1 (2) function, depress / Error (No error) condition, press

Page 36

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 34 of 44

The display will return to the menu items “Output 1 Function” or “Output 2 Function”.

To return to the basic menu, depress push-button

.

Exceeding (dropping below) the limit values of flow rate

In the cases of exceeding (dropping below) the preset flow-rate limit values, the output will close (open).

Upon return within the normal operating range, the output will open (close) again with a preset hysteresis.

Regarding the flow rate conditions, there are four different modes of operation:

Q > Q lim. Q < Q lim.

IQI > Q lim. IQI < Q lim.

Menu: Output function, depress

The display will read “Flow rate limit [1] xxxxxx“. Move the cursor using push-button

increase/decrease the values at various “x” positions using push-buttons

/ Output 1 (2) function, depress / Q > Q lim., depress

, and

or , respectively. Replace

xxxxxx by a figure equal to the flow rate which, when exceeded, should cause the output to close. Depress

. The display will read “Value entered Press any key”. Press any key, preferably . The display will then

show the message “Hysteresis [1] xxxx”. Move the cursor using push-button

“x” values using push-buttons

between the closing and opening output functions. Depress

any key”. Press any key, preferably

or , respectively. Replace xxxx by a figure representing hysteresis,

. The display will read “Value entered Press

. The display will return to the menu items “Output 1 function” or

, and increase/decrease the

“Output 2 function”.

To return to the basic menu, depress push-button

.

Electrode cleaning in progress (No cleaning)

While the electrode cleaning process is in progress, the output is closed (open).

Menu: Output function, depress

depress

/ Output 1 (2) function. depress / Cleaning in progress (No cleaning),

The display will return to the menu items “Output 1 Function” or “Output 2 Function”.

To return to the basic menu, depress push-button

.

7.1.5. Electrode cleaning

During the meter operation, non-conducting substances may accumulate in the form of a layer on the sensor

electrodes. This increases the contact resistance between the electrode and the measured fluid and results

in decreased measurement accuracy. The FMG600 SERIES flow meter offers a sensor electrode cleaning

function without sensor dismantling. The cleaning method is based on the electro-chemical phenomenon

Page 37

Design, Assembly and Service Manual

Induction flow meter FMG600 series

Page 35 of 44