Page 1

2

MANCHESTER, UK

T

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

ISO 9001

CERTIFIED

CORPORATE QUALITY

STAMFORD, C

ISO900

CERTIFIED

CORPORATE QUALITY

FMG-550 SERIES

OMEGAMAG

Page 2

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certifi ed Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé arm

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certifi ed Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-48

e-mail: sales@omega.co.uk

.

dy 1868, 733 01 Karvin. 8

®

®

®

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certifi cation of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certifi cation.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifi cations without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

FMG-550 Series OMEGAMAG

0

SAFETY INSTRUCTIONS

1. Depressurize and vent systems without Hot-tap valve prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or face shield during installation/service.

5. Do not disassemble or alter product construction.

6. Disconnect power before attempting any service or wiring.

Specifi cations

Wetted Materials:

• 316L Stainless Steel body and electrodes

• PVDF Insulator

• O-rings: FPM standard, EPDM, Kalrez® optional

• Cable: 4-cond + shield, PVC jacket (Fixed cable models)

• Watertight rubber cable assembly w/NEMA 6P connector

(Submersible cable models)

Power Requirements

• 4 to 20 mA: 24 VDC nominal, 22.1 mA maximum

(21.6 VDC min. to 26.4 max.)

400 mV p-p maximum ripple voltage

• Frequency: 5 to 24 VDC nominal, 15 mA maximum

(5 VDC min. to 26.4 VDC max.)

• Reverse polarity and short circuit protected

Performance

• Pipe size range: 2 in. to 48 in.

• Minimum Flow Range 0.05 m/s (0.15 ft/s)

Maximum Flow range: 10 m/s (33 ft/s)

• Linearity: ±1% reading + 0.1% of max. range

• Repeatability ±0.5% of reading @ 25°C

• Accuracy: ±2% of measured value (in

reference conditions where the fl uid is water at ambient

temperature, the appropriate upstream and downstream

distances are observed, the sensor is inserted at the correct

depth and there is a fully developed fl ow profi le which is in

compliance with ISO 7145-1982 (BS 1042 section 2.2))

• Minimum Conductivity: 20 µS/cm

Output Specifi cations

Current output (4 to 20 mA)

• Programmable and reversible

• Loop Accuracy: 32 µA max. error

(@ 25°C @ 24 VDC)

• Temp. drift: ±1 µA per °C max.

• Power supply rejection: ±1 µA per V

• Isolation: Low voltage <48 VAC/DC

from electrodes and auxiliary power

• Maximum cable: 300 m (1000 ft.)

• Max. Loop Resistance: 300 Ω

• Error condition: 22.1 mA

Tests, Approvals & Standards

• CE

• EN 61326 Emissions and Immunity for Control Equipment

Immunity: EN 61000-6-1

Emissions: EN 55011 class B

Environmental

• NEMA 4 / IP65 (Fixed cable models only)

• NEMA 6P / IP68 (Submersible cable models only)

• Storage Temperature: -15°C to 70°C (5°F to 158°F)

(non-icing conditions)

• Operating Temperature (non-icing conditions)

Ambient: -15°C to 70°C (5°F to 158°F)

Media: -15°C to 85°C (5°F to 185°F)

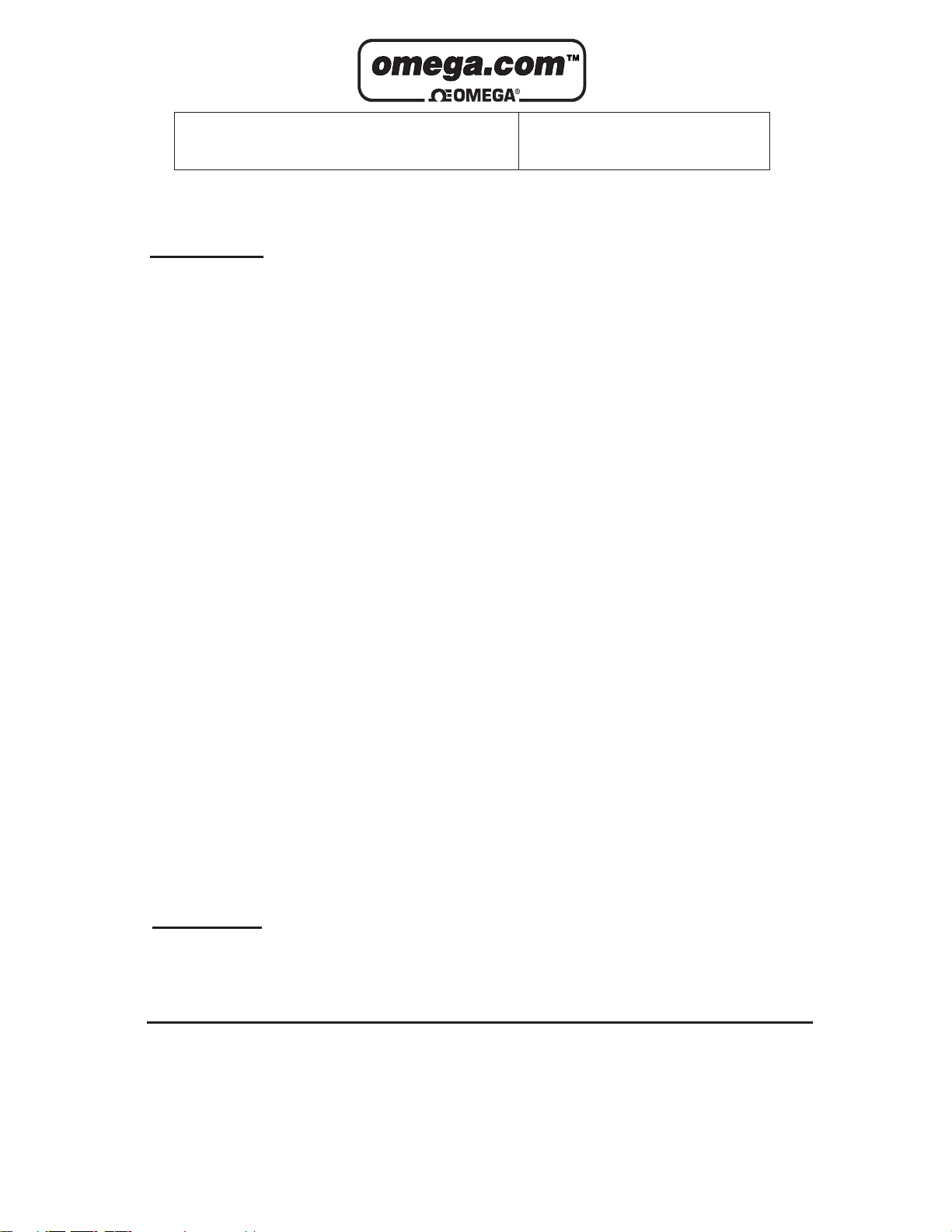

• Max. operating pressure:20.6 bar @ 25°C (300 psi @ 77°F)

bar psi

20.6

300

19.8

275

18.1

250

16.4

225

14.7

200

12.9

175

11. 2

150

9.5

125

7.8

6.0

4.3

2.6

0.9

100

°C

75

50

25

-10

5

°F

23

Safe to operate Hot-tap

Safe Media Pressure

and

Temperature Range

0

10

20-20 30 40 50 60 70 80 90

59 71

95 113 131

41

100

158 185 212

Frequency output:

• Max. Pull-up Voltage: 30 VDC

• Short Circuit Protected: ≤30 V @ 0Ω pull-up for one hour

• Reverse Polarity Protected to -40 V for 1 hour

• Overvoltage Protected to +40 V for 1 hour

• Minimum Current Sink: 50 mA

• Maximum cable: 300 m (1000 ft.)

1Omega 550 Series Magmeter

Page 4

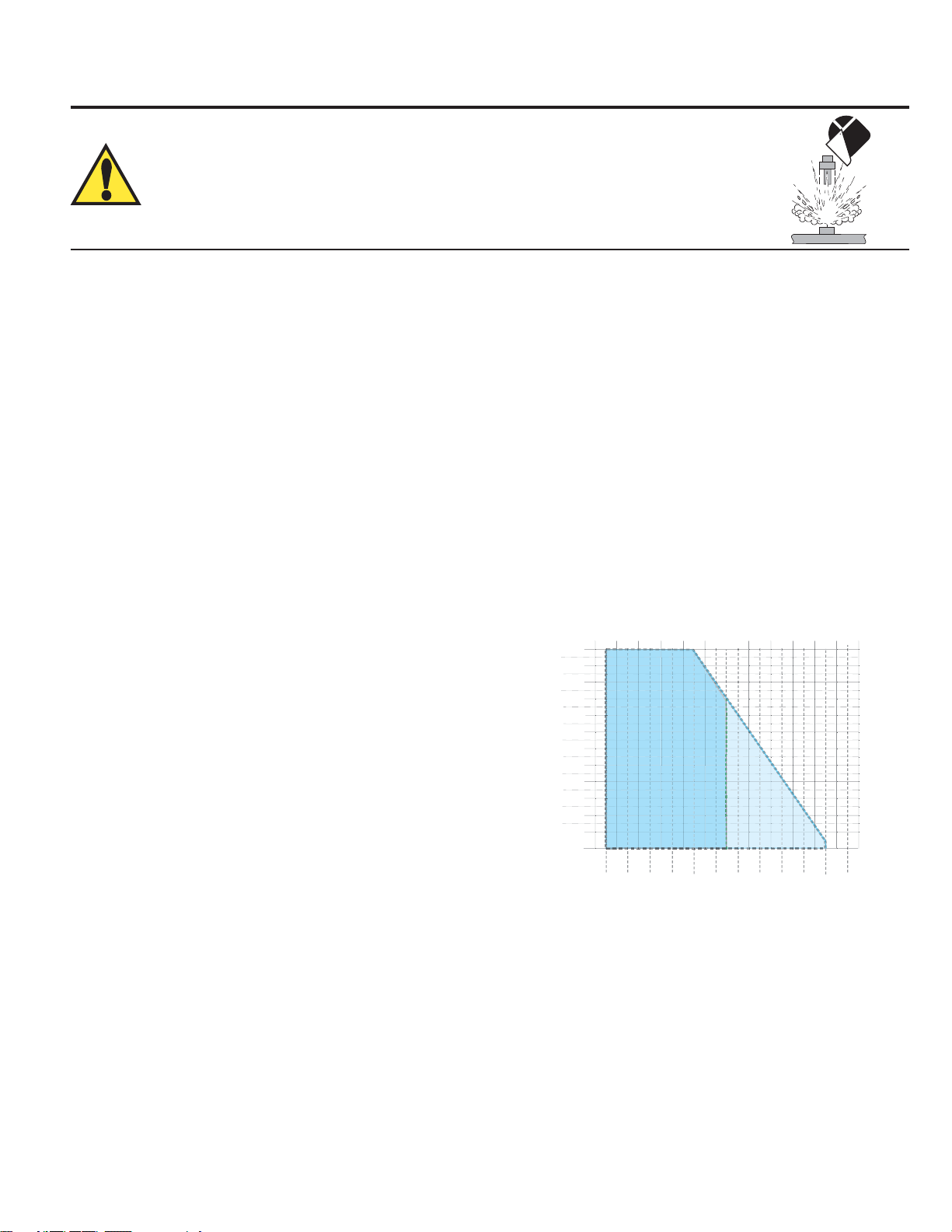

Selecting a Location

• The FMG-55x requires a fully developed turbulent fl ow profi le

for accurate measurement.

• If the piping system harbors air pockets or bubbles, locate

the sensor so the air pockets will not contact the electrodes.

• New magmeters should be allowed to soak in a full pipe for

24 hours before operation. This is especially important if the

conductivity of the process liquid is less than 100 μS.

• FMG-55x Magmeters equipped with the submersible cable

are rated NEMA 6P (IP68). These units can withstand

submersion to depths no greater than 2 m (6 ft.) for

prolonged periods.

• FMG-55x Magmeters with fi xed cables are rated NEMA 4 /

IP65. They are NOT suitable for submersion.

Select a location with suffi cient distance of straight pipe

immediately upstream of the sensor.

Dimensions

FMG-551, -552 models

206 mm

8.1 in.

FMG-553, -554 models

257 mm

10.1 in.

131 mm

5.14 in.

32 mm

1.25 in.

76 mm

3.0 in.

FMG-551, -552 models

238 mm

9.38 in.

FMG-553, -554 models

289 mm

11.38 in.

Inlet Outlet

Flange

10 x I.D. 5 x I.D.

2 x 90° Elbow

25 x I.D. 5 x I.D.

+GF+

+GF+

Reducer

15 x I.D. 5 x I.D.

2 x 90° Elbow

3 dimensions

40 x I.D. 5 x I.D.

+GF+

+GF+

90° Elbow

Valve/Pump

Locating the sensor in a trap or where the fl ow is upward helps to

protect the sensor from exposure to air bubbles when the system

is in operation.

NOTE: The system should be designed to keep the sensor wet at

all times.

O.K.O.K. O.K.

+

F

G

+

GF

+GF+

+

+

41 mm

1.6 in.

FMG-551, -552 models

187 mm/7.38 in.

FMG-553, -554 models

238 mm/9.38 in.

1.0 in.

+GF+

20 x I.D. 5 x I.D.

+GF+

50 x I.D. 5 x I.D.

1¼ in. NPT

threads

25.4 mm

These confi gurations are not recommended because it is diffi cult

to keep the pipe full.

+GF+

+

+

GF

+

G

Stroke length

F

+

In a gravity-fl ow system, the tank must be designed so the level

does not drop below the outlet.

This causes the pipe to draw air in from the tank.

If air bubbles pass across the Magmeter electrodes, the output

will become erratic.

-45°

Mounting the sensor upright is OK only where the pipe is full and

no air pockets are present at the top of the pipe.

Mount at a maximum of 45° when air bubbles are present.

Do not mount on the bottom of the pipe if sediments are present.

+45°

2 Omega 550 Series Magmeter

Page 5

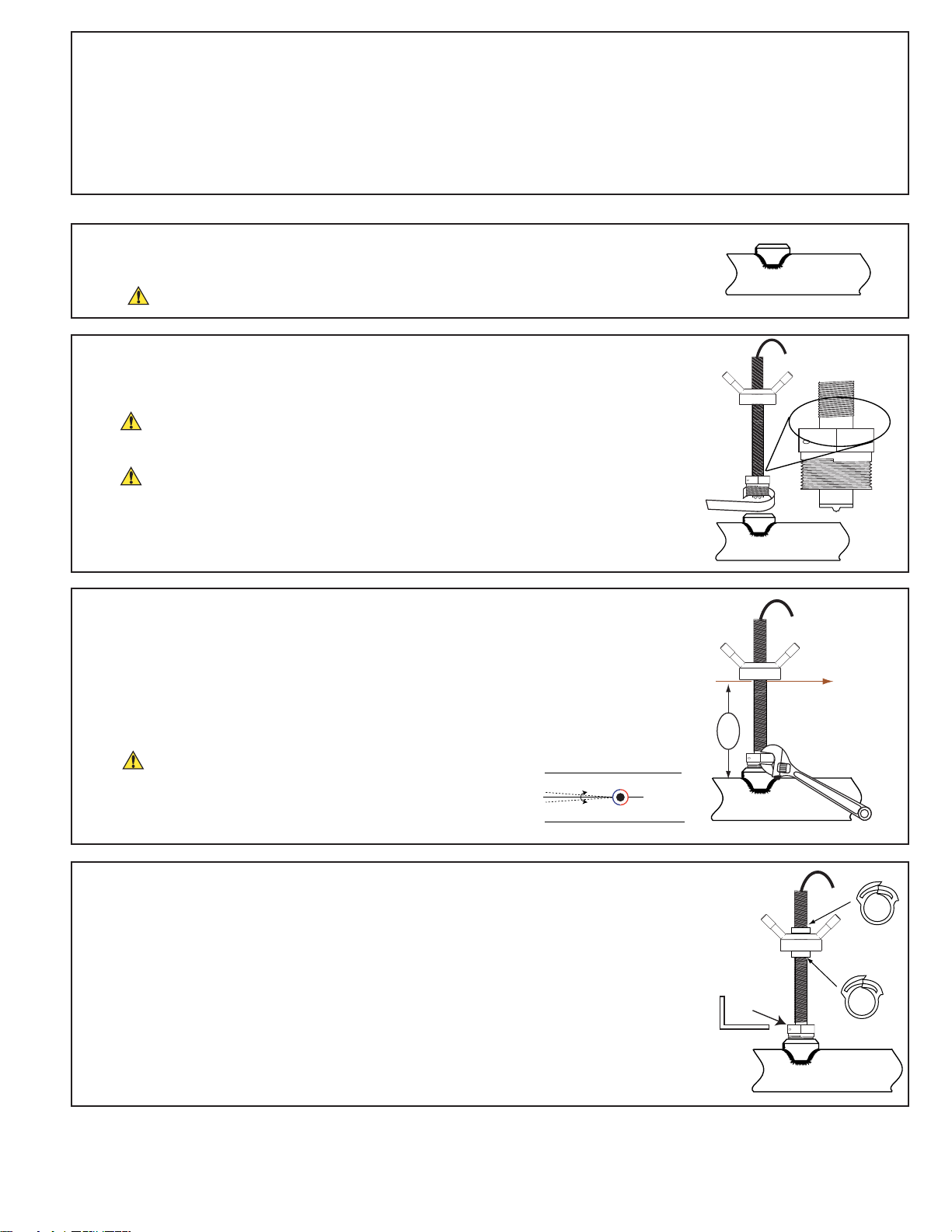

Standard Magmeter Installation

The following items are required to properly install the Magmeter:

• Supplied with FMG-551 and FMG-552 Magmeters:

• 12-inch Ruler

• Brass alignment rod

• H-dimension value for your pipe (See pages 9-10)

• Hex wrench

• 2 clamp rings

1. Prepare the pipe:

• Cut a 32 mm (1¼ in.) opening in the pipe.

• Install a 1¼ inch outlet onto the pipe.

This fi tting must withstand pressures up to 20 bar (300 psi).

2. Install the Magmeter into the pipe

• Apply sealing tape or paste to the male threads of the sensor

nut and thread it securely into the pipe fi tting.

The sensor is marked to identify the downstream

alignment. The arrow MUST point DOWNSTREAM.

Wear gloves to grip the sensor. Hold the sensor

securely while threading the sensor nut into the fi tting. Do not

allow the magmeter cable to become twisted while turning

the nut.

• Not supplied:

• Female pipe fi tting (weld-on or saddle)

with 1¼ in. NPT or ISO 7/1-Rc 1¼ threads

• 32 mm (1¼ in.) diameter drill

• Pipe thread sealant suitable for application

• Pipe wrench

FLOW →

FLOW →

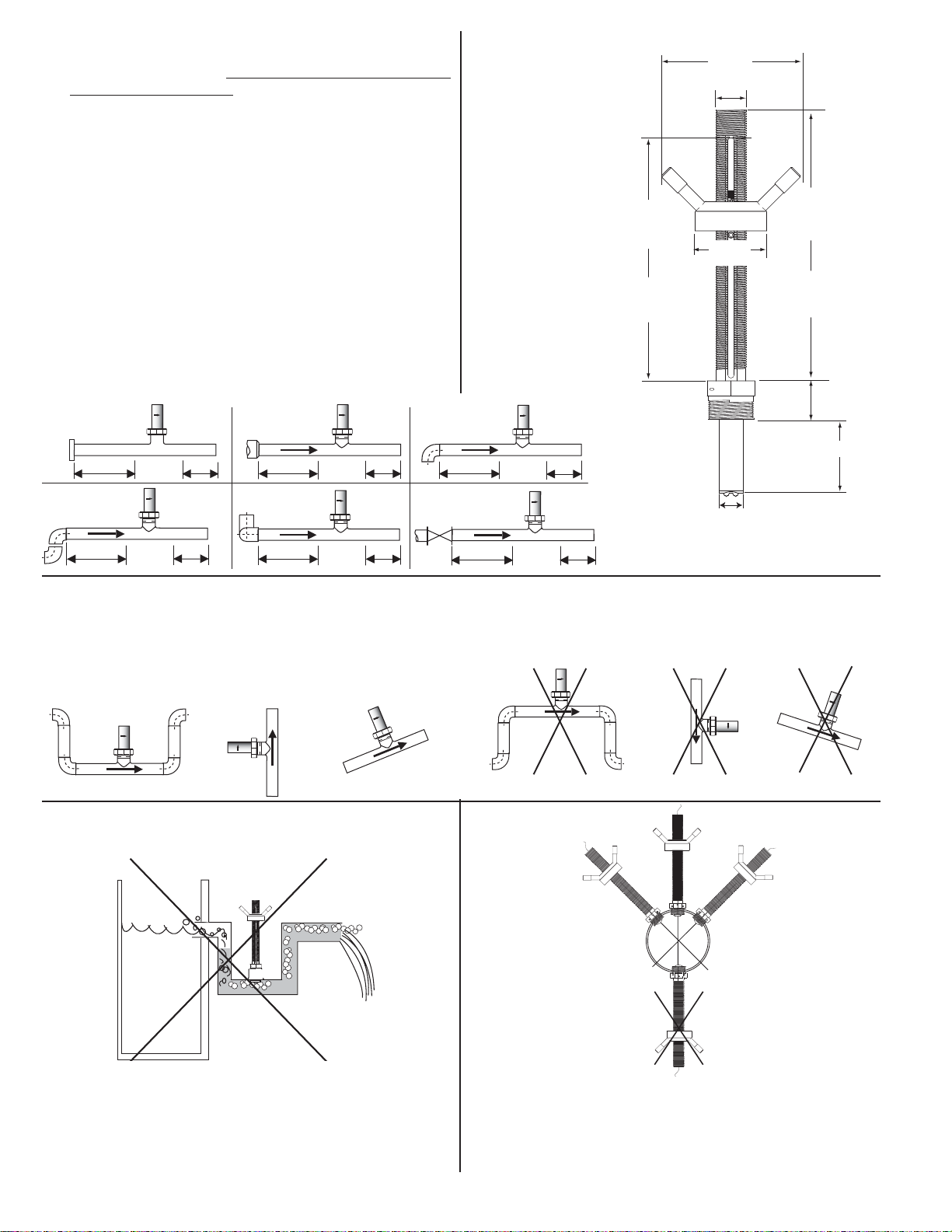

3. Adjust the magmeter position and insertion depth

• Find the H-dimension for your specifi c pipe size on pages 9-10.

• Insert the brass rod through the alignment opening at the top of

the sensor.

• Adjust the height of the magmeter so the distance (H) from the

OUTSIDE of the pipe to the bottom of the alignment rod is equal

to the H-dimension.

• Adjust the alignment rod so it is parallel to the pipe ±1°.

Misalignment will cause inaccurate measurement.

• A dry lubricant is applied to the threaded column at the factory.

If necessary, re-apply a suitable lubricant to the threaded column

to facilitate smooth operation.

Align Magmeter with pipe ±1°

4. Secure the Magmeter in position

• Secure the fi tting by tightening the set screw on the side of the sensor assembly.

A set screw wrench is provided in the magmeter package.

• Secure the height adjustment by installing the two pipe clamps.

• Spread the clamp apart to wrap it around the threaded stem.

• Place one clamp immediately above and one clamp immediately below the

magmeter adjustment hub.

• Squeeze the clamp together until it is fi rmly locked around the threads.

Pipe Top View

H

FLOW →

FLOW →

Set Screw

FLOW →

Hex Wrench

FLOW →

3Omega 550 Series Magmeter

Page 6

Hot-tap Magmeter Installation

The following items are required to properly install the Magmeter through a Hot-tap valve:

• Supplied with FMG-553 and FMG-554 Magmeters:

• 12-inch Ruler

• Brass alignment rod

• Allen wrench

• 2 clamps

• H-dimension value for your pipe (See pages 9-10)

• Not supplied:

• Female pipe fi tting (weld-on or saddle)

with 1¼ in. NPT or ISO 7/1-Rc 1¼ threads

• 32 mm (1¼ in.) pipe nipple

• 32 mm (1¼ in.) ball valve

• 32 mm (1¼ in.) drill bit

• Pipe thread sealant suitable for application

• Pipe wrench

1. Prepare the pipe:

• Install a 1¼ inch outlet onto the pipe.

This fi tting must withstand pressures up to 20 bar (300 psi).

• Thread the 1¼ in. pipe nipple into the outlet. Use a suitable paste or sealing tape to provide a

leakproof connection.

• Thread the 1¼ in. ball valve onto the pipe nipple.

Position the valve handle so it is parallel to the pipe. This will prevent the valve handle from

interfering with the adjustment and alignment of the magmeter.

• Cut a 32 mm (1¼ in.) opening in the pipe.

Hot- tap drilling requires special tools and skills.

This task should only be performed by qualifi ed personnel.

FLOW →

2. Install the Magmeter into the pipe

• Apply sealing tape or paste to the male threads of the sensor nut and

thread it securely into the pipe fi tting.

The sensor is marked to identify the downstream alignment. The

arrow MUST point DOWNSTREAM.

Wear gloves to grip the sensor. Hold the sensor securely while

threading the sensor nut into the fi tting. Do not allow the magmeter

cable to become twisted while turning the nut.

FLOW →

FLOW →

FLOW →

FLOW →

3. Adjust the magmeter position and insertion depth

• Find the H-dimension for your specifi c pipe size on pages 9-10.

• Insert the brass rod through the alignment opening at the top of the sensor.

• Adjust the height of the magmeter until the distance (H) from the OUTSIDE of the pipe to the

bottom of the alignment rod is equal to the H-dimension.

• Adjust the alignment rod so it is parallel to the pipe ±1°.

Misalignment will cause inaccurate measurement.

• A dry lubricant is applied to the threaded column at the factory.

If necessary, re-apply a suitable lubricant to the threaded column to facilitate smooth operation.

4. Secure the Magmeter in position

• Secure the fi tting by tightening the set screw on the side of the sensor assembly. A set screw

wrench is provided in the magmeter package.

• Secure the height adjustment by installing the two pipe clamps:

• Spread the clamp apart to wrap it around the threaded stem.

• Place one clamp immediately above and one clamp immediately below the magmeter

adjustment hub.

• Squeeze the clamp together until it is fi rmly locked around the threads.

Set Screw

et Screw

rench

H

FLOW →

FLOW →

4 Omega 550 Series Magmeter

Page 7

General Installation and Grounding Tips

→

DO NOT

OPEN

THIS VALVE

Sensor conditioning

The Magmeter output signal may be unstable immediately after installation. Allowing the sensor to soak in a full pipe (or in any

container of water) for 24 hours will stabilize the performance.

• Very low conductivity fl uids may require a longer conditioning period. (The Magmeter may not operate properly in fl uids where the

conductivity is less than 20 µS/cm.)

Grounding

The FMG-55x Magmeter is unaffected by moderate levels of

electrical noise, especially if installed in a properly grounded

metal piping system. However, in some applications it may

be necessary to ground portions of the system to eliminate

electrical interference. The grounding requirements will vary

with each installation.

One or more of the following steps may be applied if the

Magmeter is affected by electrical noise:

Connect a wire (14 AWG/2.08 mm

2

recommended) from

the ground terminal screw on the outside of the sensor nut

directly to a local Earth ground.

Install fl uid grounding devices immediately upstream and

downstream of the Magmeter.

Connect the fl uid grounds to the Earth ground terminal on

the FMG-55x.

Use fl anged grounding rings or metal electrodes on plastic

pipes, or metal clamps on metal pipes.

Fluid grounds must be in direct contact with the fl uid, and

as near to the Magmeter as possible.

Connect the SHIELD conductor to Earth ground at the

instrument.

Flow 6.25 GPM

Total 1234567.8>

2.

Blue

Black

Brown

White

Shield

3.

1.

4 in. to 50 in.

(10 cm to 1.3 m)

Grounding rings on plastic pipe

(Installed between flanges)

FLOW →

2.

4 in. to 50 in.

(10 cm to 1.3 m)

Bi-Directional Flow

The FMG-55x magmeter is designed to measure bi-directional fl ow.

• 4-20 mA output models: May be scaled to span any fl ow range:

For example: "4 to 20 mA = -100 GPM to +100 GPM"

• Frequency output models: Reverse fl ow is processed same as forward fl ow.

• The forward fl ow direction is indicated at the base of the sensor. The arrow must point

DOWNSTREAM.

Removal Instructions

REDUCE THE PROCESS TEMPERATURE TO LESS THAN 40°C (104°F)

• Remove the plastic clamp from the top of the assembly.

• Turn the sensor nut to the top of the threads to retract the sensor.

A light lubricant can be applied to the threads if required.

• Close the valve.

Install a LOCKOUT TAG on the closed valve to prevent accidents!

• Remove the magmeter from the top of the valve.

• Loosen the set screw from the sensor adapter fi tting.

• Use one pipe wrench to hold the valve in place while turning the sensor adapter with

a second wrench.

HOLD VALVE IN PLACE!

UNDER PRESSURE!

FLOW →

Turn magmeter adapter ONLY!

CLOSE VALVE

BEFORE REMOVING MAGMETER!

DANGER!

DO NOT

OPEN

THIS VALVE

y

a

:

This lock/tag m

only be removed by

e __________

Nam

Dept. ____________

ted date for

Expec

completion: ____

FLOW→

_

_____

5Omega 550 Series Magmeter

Page 8

Wiring the FMG-551 and FMG 553 with Frequency output

Wiring: Frequency output

• The FMG-551 and FMG-553 output an open collector

frequency signal that can be connected to most powered fl ow

meters. (Recommended for use with the Omega FP series

fl ow transmitters and the FPM series of fl ow monitors.

• DC power is provided to the Magmeter by these fl ow

instruments. No additional power is required.

• If connecting the Magmeter to a fl ow instrument from another

manufacturer, 5 to 24 VDC power must be provided to

the FMG-55x, and a 10 KΩ pull up resistor must also be

connected between the +V (Black) and the Freq. Out (Red)

wires.

FP-90 Series Flow Transmitter

9

8

7

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

White

Brown

Black

Blue

Shield

Connect AUX power on the FP-90 to provide

power for the FMG-55x output signal.

Freq. IN

Freq. IN

Std. Sensor

Third party Instrument

Sensor Ground

Frequency Out

5-24 VDC

10 KΩ

Install a pull-up resistor when connecting

the FMG-55x Magmeter to other

manufacturer's flowmeters.

Iso. Gnd

Sen. Pwr.

Open Collector

Sensor

Blue

Brown

Black

White

Shield

FPM-5500

Terminals

Blue

White

Brown

Black

Shield

Wiring the FMG-552 and FMG-554 with 4-20 mA Loop Output

The FMG-552 and FMG-554 Magmeters are traditional 2-wire passive 4-20 mA loop transmitters.

• External loop power (24 VDC ±10%) is required.

The maximum loop resistance the Magmeter can

accomodate is 300 Ω.

The cable length from the Magmeter to the loop monitor

cannot exceed 300 m (1000 ft.)

• All FMG-55x Magmeters are shipped from the factory

with the 4-20 mA output scaled for 0 to 5 m/s (0 to 16.4

ft/s). If this operating range is suitable, no adjustments are

necessary. The calibration charts in this manual list the

20 mA setpoint for each pipe size. Use this information

to program the 4-20 mA range of the loop device (PLC,

Datalogger, recorder, etc.)

FMG-55x Magmeter

White

Blue

Loop - (Ground)

X

Brown X

Black

Loop + (24 VDC)

4-20 mA Loop

+

-

monitor

(Maximum 300 Ω)

24 VDC ± 10%

+

6 Omega 550 Series Magmeter

Page 9

Calibration Data: K-factors and Full Scale Current Values

The data in this table is based on dimensions of metal pipe per ANSI 36.10 and ANSI 36.19.

Stainless steel and carbon steel pipe schedules are the same according to ANSI standards.

Pipe Size (Inch)

Schedule

40 2.375 0.15 2.07

2

80 2.375 0.22 1.94

2 ½

3½

10

12

14

16

18

20

22

24

40 2.875 0.20 2.47

80 2.875 0.28 2.32

40 3.500 0.22 3.07

3

80 3.500 0.30 2.90

40 4.000 0.23 3.55

80 4.000 0.32 3.36

40 4.500 0.24 4.03

4

80 4.500 0.34 3.83

40 5.563 0.26 5.05

5

80 5.563 0.38 4.81

40 6.625 0.28 6.07

6

80 6.625 0.43 5.76

40 8.625 0.32 7.98

8

80 8.625 0.50 7.63

40 10.75 0.37 10.0

80 10.75 0.59 9.56

STD 12.75 0.38 12.0

XHY 12.75 0.50 11.8

30 14.00 0.38 13.3

XHY 14.00 0.50 13.0

30 16.00 0.38 15.3

40/

XHY

STD 18.00 0.38 17.3

XHY 18.00 0.50 17.0

20/

STD

30/

XHY

20/

STD

30/

XHY

20/

STD

XHY 24.00 0.50 23.0 6 3/32 154.4 8 3/32 205.23 0.373 1.412 80414 21246

OD (Inches)

WALL (Inches)

16.00 0.50 15.0

20.00 0.38 19.3

20.00 0.50 19.0

22.00 0.38 21.3

22.00 0.50 21.0

24.00 0.38 23.3

ID (Inches)

H Dim mm

FMG-551

FMG-552

/32 inch mm /32 inch mm

8 16/32

8 15/32

8 14/32

8 12/32

8 12/32

8 10/32

8 10/32

8 8/32

8 8/32

8 6/32

8 4/32

7 28/32

7 24/32

7 20/32

7 16/32

7 11/32

7 10/32

7 7/32

7 6/32

7 3/32

6 28/32

6 25/32

6 22/32

6 18/32

6 16/32

6 12/32

6 9/32

6 6/32

8

8

7

216.4

215.1

214.1

212.6

212.3

210.6

210.8

208.9

209.3

207.3

206.2

203.8

203.0

200.0

197.1

193.5

190.8

186.2

185.6

183.0

182.4

179.8

177.3

174.8

172.2

169.7

167.1

164.6

162.1

159.5

157.0

H Dim mm

10 16/32

10 15/32

10 14/32

10 12/32

10 12/32

10 9/32

10 10/32

10 8/32

10 8/32

10 5/32

10 4/32

10

10

9 28/32

9 24/32

9 20/32

9 16/32

9 11/32

9 10/32

9 6/32

9 6/32

9 3/32

9

8 28/32

8 25/32

8 22/32

8 19/32

8 16/32

8 12/32

8 9/32

8 6/32

FMG-553

FMG-554

267.0 46.19 174.83 649.5 171.6

265.9 52.49 198.68 571.5 151.0

264.9 32.37 122.54 926.7 244.8

263.4 36.57 138.42 820.3 216.7

263.1 20.97 79.36 1431 378.0

261.4 23.47 88.82 1278 337.8

261.6 15.68 59.34 1914 505.6

259.7 17.44 66.01 1720 454.5

260.1 12.18 46.09 2464 651.0

258.1 13.48 51.03 2225 587.9

257.0 7.748 29.33 3872 1023

254.6 8.519 32.25 3521 930.4

253.8 5.365 20.31 5591 1477

250.8 5.946 22.51 5045 1333

247.9 3.098 11.73 9683 2558

244.3 3.394 12.85 8838 2335

241.6 1.966 7.440 15262 4032

237.00 2.158 8.170 13899 3672

236.4 1.371 5.187 21890 5783

233.8 1.429 5.410 20987 5545

233.2 1.124 4.255 26688 7051

230.6 1.168 4.420 25690 6787

228.1 0.849 3.212 35352 9340

225.6 0.877 3.320 34202 9036

223.0 0.663 2.510 45233 11950

220.5 0.683 2.585 43931 11610

217.9 0.533 2.016 56330 14880

215.39 0.547 2.069 54876 14500

212.85 0.437 1.654 68643 18136

210.31 0.448 1.694 67037 17711

207.77 0.365 1.382 82172 21710

K-Factor

Pulse/liter

K-Factor

Pulse/Gal

Factory set

20 mA (liter/min)

Factory set

20 mA (GPM)

7 Omega 550 Series Magmeter

Page 10

Pipe Size (Inch)

Schedule

OD (Inches)

WALL (Inches)

ID (Inches)

H Dim mm

FMG-551

FMG-552

H Dim mm

FMG-553

FMG-554

K-Factor

Pulse/liter

K-Factor

Pulse/Gal

Factory set

20 mA (liter/min)

Factory set

/32 inch mm /32 inch mm

26 STD 26 0.38 25.25 6 151.89 8 202.69 0.310 1.172 96917 25606

20/XHY 26 0.50 25.00 5 28/32 149.35 7 28/32 200.15 0.316 1.195 95008 25101

28 STD 28 0.38 27.25 5 25/32 146.81 7 25/32 197.61 0.266 1.006 112879 29823

20/XHY 28 0.50 27.00 5 22/32 144.27 7 22/32 195.07 0.271 1.025 110817 29278

30 STD 30 0.38 29.25 5 19/32 141.73 7 19/32 192.53 0.231 0.873 130056 34361

20/XHY 30 0.50 29.00 5 16/32 139.19 7 16/32 189.99 0.235 0.888 127842 33776

32 STD 32 0.38 31.25 5 12/32 136.65 7 12/32 187.45 0.202 0.765 148449 39220

20/XHY 32 0.50 31.00 5 9/32 134.11 7 9/32 184.91 0.205 0.777 146084 38595

34 STD 34 0.38 33.25 5 6/32 131.57 7 6/32 182.37 0.179 0.676 168059 44401

20/XHY 34 0.50 33.00 5 3/32 129.03 7 3/32 179.83 0.181 0.686 165541 43736

36 STD 36 0.38 35.25 5 126.49 7 177.29 0.159 0.601 188885 49903

20/XHY 36 0.50 35.00 4 28/32 123.95 6 28/32 174.75 0.161 0.610 186215 49198

38 STD 38 0.38 37.25 4 25/32 121.41 6 25/32 172.21 0.142 0.538 210926 55727

XHY 38 0.50 37.00 4 22/32 118.87 6 22/32 169.67 0.144 0.546 208105 54981

40 STD 40 0.38 39.25 4 19/32 116.33 6 19/32 167.13 0.128 0.485 234184 61872

XHY 40 0.50 39.00 4 16/32 113.79 6 16/32 164.59 0.130 0.491 231210 61086

42 STD 42 0.38 41.25 4 12/32 111.25 6 12/32 162.05 0.116 0.439 258658 68338

XHY 42 0.50 41.00 4 9/32 108.71 6 9/32 159.51 0.117 0.444 255532 67512

48 STD 48 0.38 47.25 3 25/32 96.01 5 25/32 146.81 0.088 0.335 339377 89664

XHY 48 0.50 47.00 3 22/32 93.47 5 22/32 144.27 0.089 0.338 335795 88717

20 mA (GPM)

Installation instructions for other pipes

If your pipe is not listed in the tables, you can calculate the proper

H-dimension as illustrated here.

Contact the factory for a custom K-factor.

Height from the sensor tip to the alignment rod is:

FMG-551, -552: 225.5 mm ( 8.88 in. )

FMG-553, -554: 276.3 mm ( 10.88 in. )

Subtract:

- Wall Thickness: _____ mm ( ______ in.)

Subtract:

- 10% of pipe id: _____ mm ( ______ in.)

Result:

= H dimension: _____ mm ( ______ in.)

Note: 1 in. = 25.4 mm

Set Screw

Set Screw

Wrench

mm

270

260

250

240

230 220

210

200 190

Sensor Height:

180 170

FMG-551, -552: 225.5 mm ( 8.88 in. )

H DIMENSION

FMG-553, -554: 276.3 mm ( 10.88 in. )

160 150 140

Subtract:

- Wall Thickness: _____ mm ( ______ in.)

130

- 10% of pipe id: _____ mm ( ______ in.)

120

110

Result:

H

100

= H dimension: _____ mm ( ______ in.)

90

Note: 1 in. = 25.4 mm

80

70

60 50 40

Wall Thickness

10% of

inside diameter

8Omega 550 Series Magmeter

Page 11

Maintenance

There are no user-serviceable components in the FMG series Magmeter.

• If the fl uid contains deposits and solids that may coat the electrodes, a regular cleaning schedule is recommended.

• Do not use abrasive materials on the metal electrodes. Clean with soft cloth and mild detergent only.

• Use a cotton swab and mild detergent to remove deposits on the metal electrodes at the tip of the sensor.

• If the sensor nut will not turn smoothly, a light lubricant can be applied to the threads.

Environmental Recommendations:

• When used properly, this product presents no inherent danger to the environment.

• Please follow local ordinance when disposing of this or any product with electronic components.

Troubleshooting

Symptom

• Frequency output or Current

output is erratic.

• Output is not 0 when fl ow is stopped.

• 4-20 mA output is incorrect.

Possible Cause Possible Solution

• Magmeter installed too close to

upstream obstruction.

• Magmeter electrodes are coated with

solids.

• Magmeter electrodes exposed to air

bubbles/pockets.

• Electrical noise is interfering with the

measurement.

• New sensor, metal surface not

properly conditioned.

• Electrodes not adequately conditioned.

• Pipe is empty, Magmeter is not in fl uid.

• Electrical noise is interfering with the

measurement.

• Defective Magmeter

• Magmeter 4-20 mA is not scaled

same as Loop device.

• Loop device is not scaled same as

Magmeter.

• Defective Magmeter

• Move the Magmeter upstream at least

10 pipe diameters from obstruction.

• Clean the electrodes with soft cloth.

Do not use abrasives.

• Eliminate air bubbles in the pipe.

• Remove the Magmeter and reinstall

with the fl ow direction arrow on the

sensor body pointed DOWNSTREAM.

• Modify grounding as required

to protect the Magmeter from

interference.

• Soak sensor overnight in fl uid.

• Soak sensor overnight in fl uid.

• Confi gure pipe so electrodes are

always in fl uid.

• Modify grounding as required

to protect the Magmeter from

interference.

• Return to factory for service.

• Respan the Magmeter to match the

Loop device.

• Respan Loop device to match

Magmeter.

• Return to factory for service.

• Frequency output is inoperative

• Loop output is inperative.

• Magmeter is wrong model.

• Wiring is not correct.

• Frequency input to other

manufacturer's fl ow instrument does

not have pull-up resistor.

• Frequency model is FMG-551 or -553.

• 4-20 mA model is FMG-552 or -554.

• Blue wire must be grounded for freq

out, open for S

3

L out.

• Check wiring, make corrections.

• Install 10kΩ resistor.

• Output is 22.1 mA.

• Conductivity is less than 20 µS/cm.

• Electrical noise

• Electronic component failure.

• Unsuitable application for Magmeter.

• Check grounding, eliminate noise

source

• Return to factory for service.

Troubleshooting with the RED and BLUE lights

The FMG-55x uses two colored LEDs to indicate the status of the measurement. They are located at the top of the magmeter, recessed

inside the threaded steel housing. Look down the tube to see them.

No Lights: The power is off or the sensor is not connected

Solid Blue: The power is on but there is no fl ow in the pipe.

Blinking Blue: Normal operation, blink rate is proportional to the fl ow rate.

Alternating Red-Blue: Empty pipe indication (electrodes are not wet.)

Blinking Red: System errors (electrical noise interference)

Solid Red: Instrument error (defective electronics component)

9 Omega 550 Series Magmeter

e

u

l

B

R

e

d

Page 12

Ordering Information

Part No. Description

FMG-551 7.3 in. Sensor protrusion depth, 1¼ in. NPT, Fixed Cable, Frequency Output

FMG-552 7.3 in. Sensor protrusion depth, 1¼ in. NPT, Fixed Cable, 4 to 20 mA Output

FMG-551-SUB 7.3 in. Sensor protrusion depth, 1¼ in. NPT, Connector, Frequency Output

FMG-552-SUB 7.3 in. Sensor protrusion depth, 1¼ in. NPT, Connector, 4 to 20 mA Output

FMG-553 9.3 in. Sensor protrusion depth, Hot-tap, 1¼ in. NPT, Fixed Cable, Frequency Output

FMG-554 9.3 in. Sensor protrusion depth, Hot-tap, 1¼ in. NPT, Fixed Cable, 4 to 20 mA Output

FMG-553-SUB 9.3 in. Sensor protrusion depth, Hot-tap, 1¼ in. NPT, Connector, frequency Output

FMG-554-SUB 9.3 in. Sensor protrusion depth, Hot-tap, 1¼ in. NPT, Connector, 4 to 20 mA Output

FMG-550-S-CABLE-19FT 4-conductor, 22 AWG, water-tight connector, 6m (19.5 ft.) for -SUB models

Page 13

Notes

11 Omega 550 Series Magmeter

Page 14

Notes

12 Omega 550 Series Magmeter

Page 15

SA

MAD E

IN

IN

USA

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period

to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT

OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in

our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold

OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a

manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specifi c problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of

OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specifi c problems

relative to the product.

Page 16

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

•

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

•

Wire: Thermocouple, RTD & Thermistor

•

Calibrators & Ice Point References

•

Recorders, Controllers & Process Monitors

•

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

•

Transducers & Strain Gages

•

Load Cells & Pressure Gages

•

Displacement Transducers

•

Instrumentation & Accessories

FLOW/LEVEL

•

Rotameters, Gas Mass Flowmeters & Flow Computers

•

Air Velocity Indicators

•

Turbine/Paddlewheel Systems

•

Totalizers & Batch Controllers

pH/CONDUCTIVITY

•

pH Electrodes, Testers & Accessories

•

Benchtop/Laboratory Meters

•

Controllers, Calibrators, Simulators & Pumps

•

Industrial pH & Conductivity Equipment

DATA ACQUISITION

•

Data Acquisition & Engineering Software

•

Communications-Based Acquisition Systems

•

Plug-in Cards for Apple, IBM & Compatibles

•

Datalogging Systems

•

Recorders, Printers & Plotters

HEATERS

•

Heating Cable

•

Cartridge & Strip Heaters

•

Immersion & Band Heaters

•

Flexible Heaters

•

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

•

Metering & Control Instrumentation

•

Refractometers

•

Pumps & Tubing

•

Air, Soil & Water Monitors

•

Industrial Water & Wastewater Treatment

•

pH, Conductivity & Dissolved Oxygen Instruments

6-2552.090-OM Rev. A 04/07 M-4416/0407

Loading...

Loading...