Page 1

http://www.omega.com

e-mail: info@omega.com

FMG-400’s

Electromagnetic Flowmeters

(Flange type)

Page 2

OMEGAnetSM On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

.

USA: One Omega Drive, Box 4047

ISO 9001 Certified

Canada: 976 Bergar

Stamford, CT 06907Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail:

canada@omage.com

0047

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service:1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-TC-OMEGASM FAX: (95) 203-359-7807

En Espanol: (203) 359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice, Czech Republic

Tel: 420 (69) 6311627 FAX: 420 (69) 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: 25 Swannington Road, P.O. Box 7, Omega Drive,

ISO 9002 Certified Broughton Astley, Leicestershire, Irlam, Manchester,

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44 (1455) 283912 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

SM

SM

SM

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA

is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will

add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected

applications.

1

Page 3

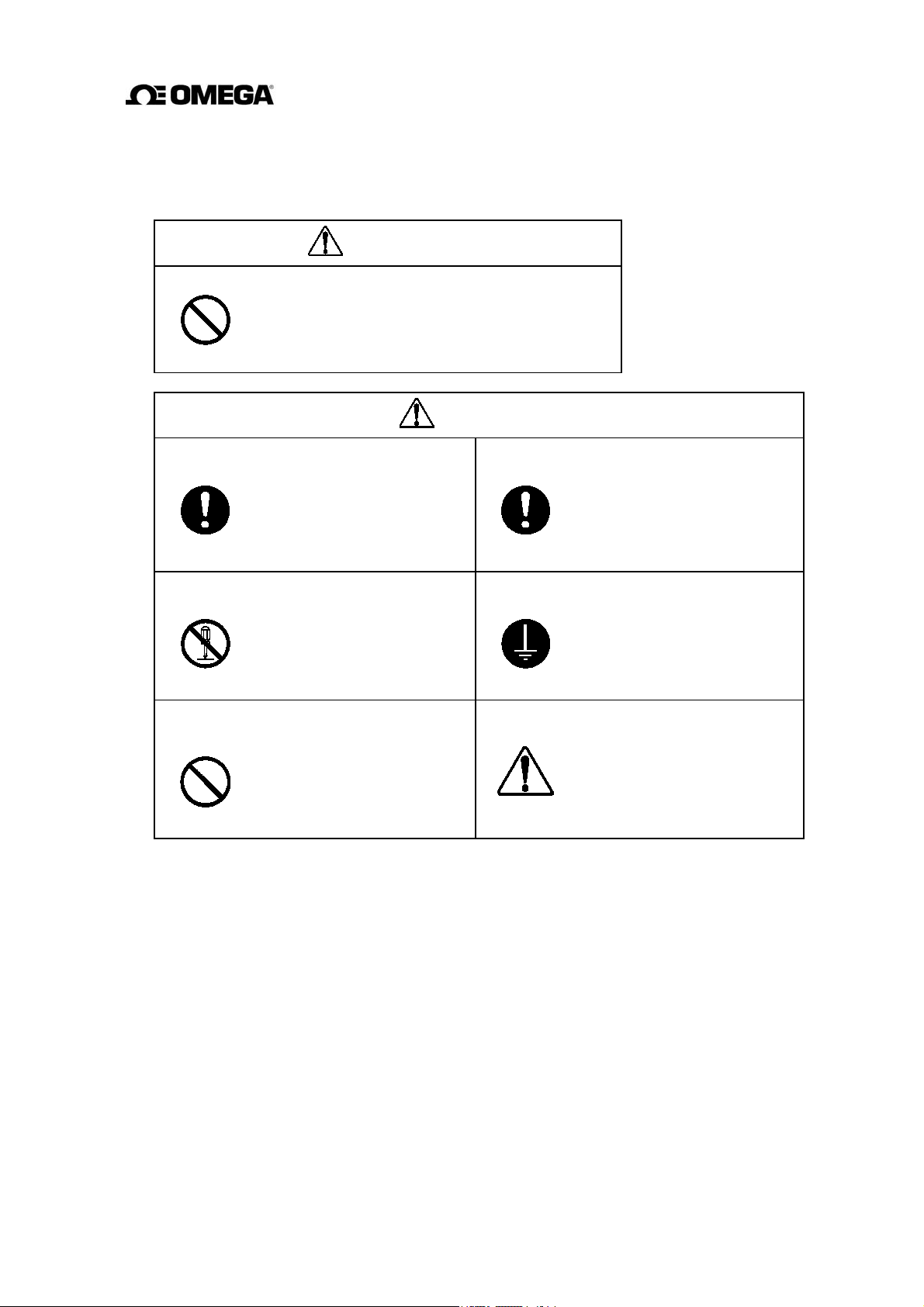

SAFETY PRECAUTIONS

Safety signs and labels affixed to the product and/or described in this manual give important

information for using the product safely. They help prevent damage to property and obviate

hazards for persons using the product.

Make yourself familiar with signal words and symbols used for safety signs and labels. Then read

the safety precautions that follow to prevent an accident involving personal injury, death or

damage to property.

Explanation of signal words

The signal word or words are used to designate a degree or level of hazard seriousness.

The signal words used for the product described in this manual are WARNING and CAUTION.

Indicates a potentially hazardous situation which,

WARNING

CAUTION

if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which,

if not avoided, may result in minor to moderate

injuries or in property damage.

Safety symbols

The following symbols are used in safety signs and labels affixed to a product and/or in the

manual for giving safety instructions.

Indicates an action that is prohibited. Simply DON’T do this action.

The

prohibited action is indicated by a picture or text inside or next to the

circle

Indicates an action that is mandatory. DO this action.

The

mandatory action is indicated by a picture or text inside or next to the

circle.

Indicates a potential hazard. The potentially hazardous situation is

indicated by a picture or text inside or next to the triangle.

2

Page 4

SAFETY PRECAUTIONS (continued)

Safety Precautions for Installation and Wiring

WARNING

Do not use the FMG400 Series in an explosive atmosphere.

Using this product in an explosive atmosphere can cause

explosion.

DON’T

CAUTION

Turn off main power before working on

pipes.

Working on pipes while

power is applied can cause

electric shock.

DO

Install a switch and fuse to isolate the

FMG400 Series from main power.

Power supply from main

power can cause electric

DO

Turn off main power before conducting

wiring work.

shock or circuit

breakdown.

Wiring while power is

applied can cause electric

shock.

DO

Do not conduct wiring work with bare

hands.

Remaining electric

charge even if power is

DON’T

Do not work on piping and wiring with

wet hands.

turned off can still cause

electric shock.

Wet hands may result in

electric shock.

DON’T

Use an appropriate device to carry and

install the FMG400 Series.

If this product falls to the

ground, injury, or malfunction of

DO

Do not modify or disassemble the

FMG400 Series unnecessarily.

DON’T

Ground the FMG400 Series independently

from power equipment.

DO

Use crimped terminal lugs for the terminal

board and GND terminal.

DO

or damage to the product, can be

caused.

Modifying or disassembling this

product can cause electric shock,

malfunction of or damage to

this product.

Operating this product without

grounding can cause electric

shock or malfunction.

Loose connections can cause

electric shock, fire from

excessive current or system

malfunction.

The label shown left is placed

near the terminal board for power

input.

(A

black border and symbol on

yellow triangle)

Be alert to electric shock

3

Page 5

SAFETY PRECAUTIONS (continued)

Safety Precautions for Maintenance and Inspection

CAUTION

Do not touch the FMG400 Series

main body when high temperature

fluid is being measured.

The fluid raises the main

body temperature and can

DON’T

Do not conduct wiring work with wet

hands.

cause burns when touched.

Wet hands may result in

electric shock.

DON’T

Do not use a fuse other than the one

specified.

Using a fuse other than the

one specified can cause

DON’T

system failure, damage or

malfunction.

Do not conduct wiring work when

power is applied.

Wiring while power is

applied can cause

DON’T

Use a rated fuse as follows depending

on the power specifications.

• Fuse rating:

1A/250V for 100 to 240 V

• Dimensions:

Diameter 5.2 mm × 20 mm

electric shock.

The label shown left is

placed near the terminal

board for power input.

(A

black border and

symbol on yellow

triangle)

Be alert to electric

shock.

ac

Disclaimer

OMEGA does not accept liability for any damage or loss, material or personal, caused as a

direct or indirect result of the operation of this product in connection with, or due to, the

occurrence of any event of force majeure (including fire or earthquake) or the misuse of this

product, whether intentional or accidental.

4

Page 6

Handling Precautions

To obtain the optimum performance from the FMG400 Series flowmeter for years of

continuous operation, observe the following precautions.

(1) Do not store or install the flowmeter in:

places where there is direct sunlight. If this is unavoidable, use an appropriate

•

sunshade.

places where excessive vibration or mechanical shock occurs.

•

places where high temperature or high humidity conditions obtain.

•

places where corrosive atmospheres obtain.

•

places submerged under water.

•

To put the flowmeter temporarily on the floor, place it carefully with something to

support it so that the flowmeter will not topple over.

(2) Execute wiring securely and correctly.

(3) Seal the cable thoroughly at the cable gland so that the cable is kept airtight.

(4) Ground the flowmeter with 100 ohm or less ground resistance. Avoid a common

ground used with other equipment where earth current may flow. An independent

ground is preferable.

(5) The converter housing covers and the cable glands are tightened securely at the time

of shipment. Do not remove these covers or glands unless it is necessary to wire new

cables or replace old ones.

Otherwise, gradual deterioration of circuit isolation or

damage to this product can be caused. Tighten the covers or cable glands securely

again if they have been removed.

(6) Make sure the fluid to be measured will not freeze in the detector pipe. This can

cause damage to the detector pipe.

(7) Select appropriate wetted materials suited for the process fluid to be measured.

Otherwise, fluid leakage due to corrosion can be caused.

(8) Observe the following precautions when you open the converter housing cover:

Do not open the cover in the open air unprotected against rain or wind. This can

•

cause electric

Do not open the cover under high ambient temperature or high humidity

•

shock or cause damage to the flowmeter electronics.

conditions or in corrosive atmospheres. This can cause deterioration of system

accuracy or cause damage to the flowmeter electronics.

(9) This product may cause interference to radio and television sets if they are used near

the installation site. Use metal conduits etc. for cables to prevent this interference.

5

Page 7

Handling Precautions (continued)

(10) Radio transmitters such as transceivers or cellular phones may cause interference to

the flowmeter if they are used near the installation site. Observe the following

precautions when using them:

Do not use a transceiver whose output power is more than 5 W.

•

Move the antenna of a transceiver or a cellular phone at least 50 cm away from

•

the flowmeter and signal cables when using it. Do not use a radio transmitter or

a cellular phone near the flowmeter while it is operating online. The transmitter

or cellular phone’s output impulse noise may interfere with the flowmeter.

Do not install a radio transmitter antenna near the flowmeter and signal cables.

•

(11) For reasons of flowmeter failure, inappropriate parameters, unsuitable cable

connections or poor installation conditions, the flowmeter may not operate properly.

To prevent any of these problems causing a system failure, it is recommended that

you have preventive measures designed and installed on the flowmeter signal

receiving side.

6

Page 8

Table of Contents

SAFETY PRECAUTIONS 2

Handling Precautions 5

1. Product Inspection and Storage 9

1.1 Product Inspection 9

1.2 Storage 9

2. Overview 10

3. Names of Parts 11

4. Installation 14

4.1 Location 14

4.2 Mounting 15

4.3 Piping Connections 19

5. Wiring 23

5.1 Cables 24

5.2 External Device Connections and Grounding 24

5.3 Digital I/O Connections 26

5.4 Wiring Procedure 27

6. Operation 30

6.1 Preparatory Check 30

6.2 Zero Adjustment 31

7. LCD Display and Controls 32

7.1 Outline 32

7.2 Display Format 34

7.3 Basic Operations 36

7.4 Configuration Items Selection Table 38

8. Configuration Parameter Setting 39

8.1 Configuration Items 39

8.2 Checking or Changing Parameters 40

9. Calibration 70

9.1 Calibration Items 70

9.2 Calibration Using Converter Signal Source 71

10. Digital I/O Functions 75

10.1 Digital I/O Specifications 76

10.2 Totalizer and Pulse Output 77

10.3 Multi-range Functions 79

10.4 High and Low Limit Alarms 84

7

Page 9

10.5 Empty Pipe Alarm 86

10.6 Preset Point Output 87

10.7 Remote Zero Adjustment 89

10.8 Remote Selection of Fixed Value Output 90

10.9 Converter Failure Alarms 91

11. Self-Diagnostics and Alarms 92

11.1 Self-Diagnostics 92

11.2 Output Status for Errors and Alarms 95

12. Maintenance and Troubleshooting 96

12.1 Maintenance 96

12.2 Troubleshooting 98

13. Principle of Operation 101

14. Specifications 102

14.1 Flowmeter Specifications 102

14.2 Specification Code table 106

15. Outline Dimensions . 108

Appendix 1 . Electromagnetic Compatibility and Low Voltage Safety 110

Electromagnetic Compatibility 110

Low Voltage Safety 111

Appendix 2 . Default set value in each configuration item 112

8

Page 10

1. Product Inspection and Storage

Upon arrival of the product package, open the package and check the items contained inside. If

you do not intend to install the product soon after opening the package, store the product and

other related items in a place such as described in 1.2 below.

1.1 Product Inspection

The FMG400 Series flange type electromagnetic flowmeter is shipped in a cardboard container

filled with shock-absorbing materials. Open the package carefully and check as follows:

Make sure the following items are included in the package.

(1) Model FMG400 Series falnge type Electromagnetic Flowmeter......

(2) Instruction Manual ...............................................................

(3) Operation Guide ....................................................................

Inspect the flowmeter for indications of damage that may have occurred during shipment.

Make sure the type and specifications of the flowmeter are in accordance with the

ordered specifications.

If you cannot find the items listed above or any problem exists, contact OMEGA.

1

1

1

1.2 Storage

To store the FMG400 Series flowmeter after opening the package, select a storing place as

follows and keep it under the conditions described below:

(1) Avoid places where there is direct sunlight, rain or wind.

(2) Store the product in a well-ventilated place. Avoid places of extremely high

humidity or extremely high or low temperature. The following environment is

recommended:

•

Humidity range: 10 to 90% RH (no condensation)

•

Storage temperature: –15 to +65° C

(3) Avoid places where vibrations or mechanical shock occurs.

(4) Do not leave the converter housing cover open . Open the cover only when you

actually start wiring cables. Leaving the cover open can cause gradual deterioration

of circuit isolation.

(5) To put the flowmeter temporarily on the floor, place it carefully with something to

support it so that the flowmeter will not topple over.

9

Page 11

2. Overview

The FMG400 Series electromagnetic flowmeter measures the volumetric flow rates of

electrically conductive materials on the basis of Faraday's Law of Electromagnetic induction.

The device consists of two units: the detector, through which the fluid to be measured flows,

and the converter, which receives the electromotive force signals from the detector, then

converts the signals into the 4–20 mA

integrally mounted.

dc signal. These two units for the FMG400 Series are

Features

Every type of electromagnetic flowmeter has the following features:

Fluid flow is not obstructed and pressure loss is negligible.

The process fluid's temperature, pressure, density or flow conditions have no effect on

the accuracy of the flowmeter.

The flowmeter output is directly proportional to the process flow rate, thus it is easy to

read its output.

The FMG400 Series electromagnetic flowmeter has the following additional features:

(1) High accuracy, ±0.5% of rate is possible for 0.3–10 m/s velocity range.

(2) The flowmeter can be used to measure f

luids with solids (such as sludge or slurries)

for the reasons stated below:

The original noise-suppression circuit with signal processing capabilities

•

ensures a stable output.

(3) The flowmeter has various flow measurement output and control functions as standard

specifications and the LCD display for convenient parameter settings.

•

These functions can be selected with control keys on the panel.

(4) An easy-to-read LCD display (2-line × 16-character display)

The backlit LCD display can be read even under poor lighting conditions.

10

Page 12

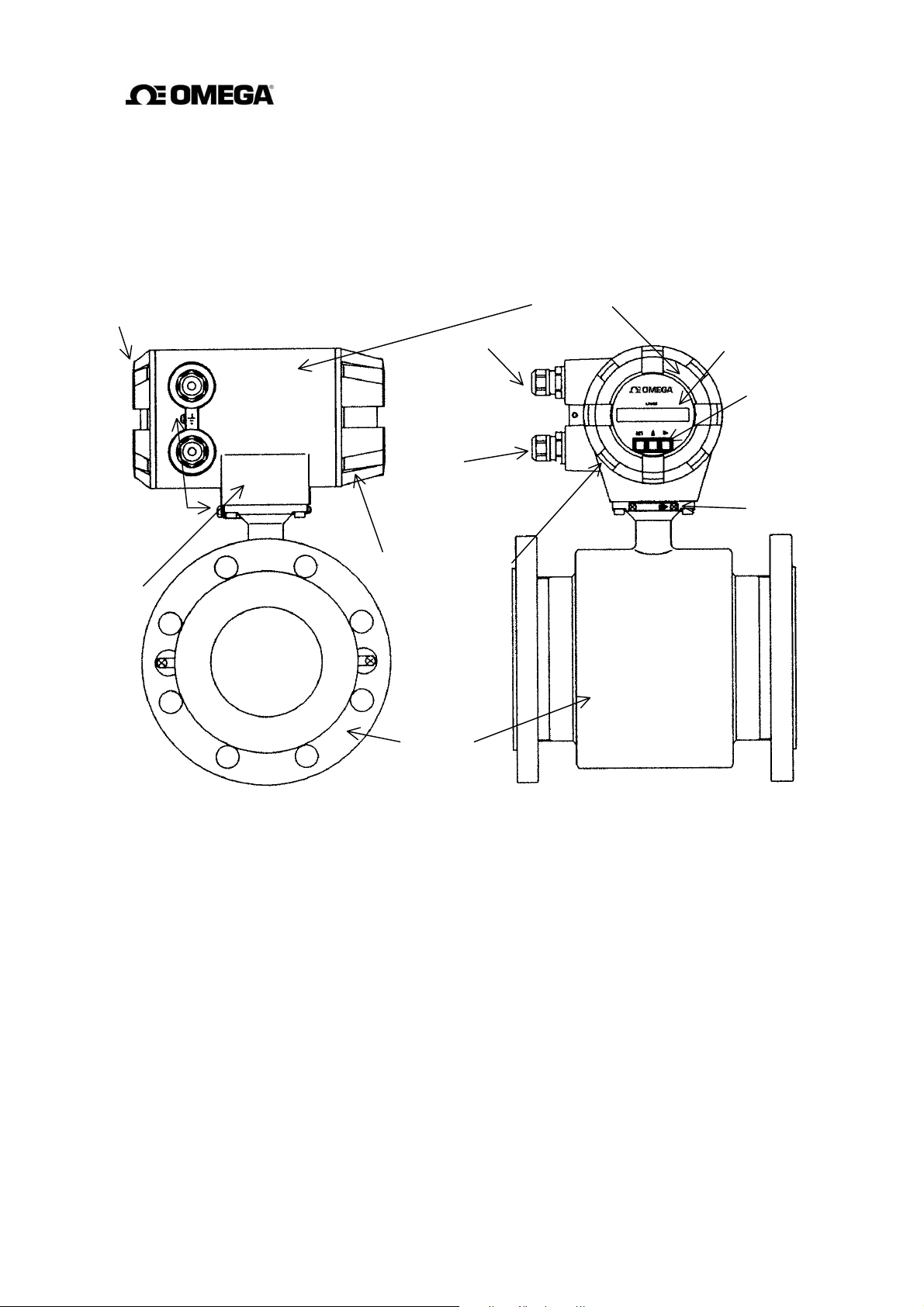

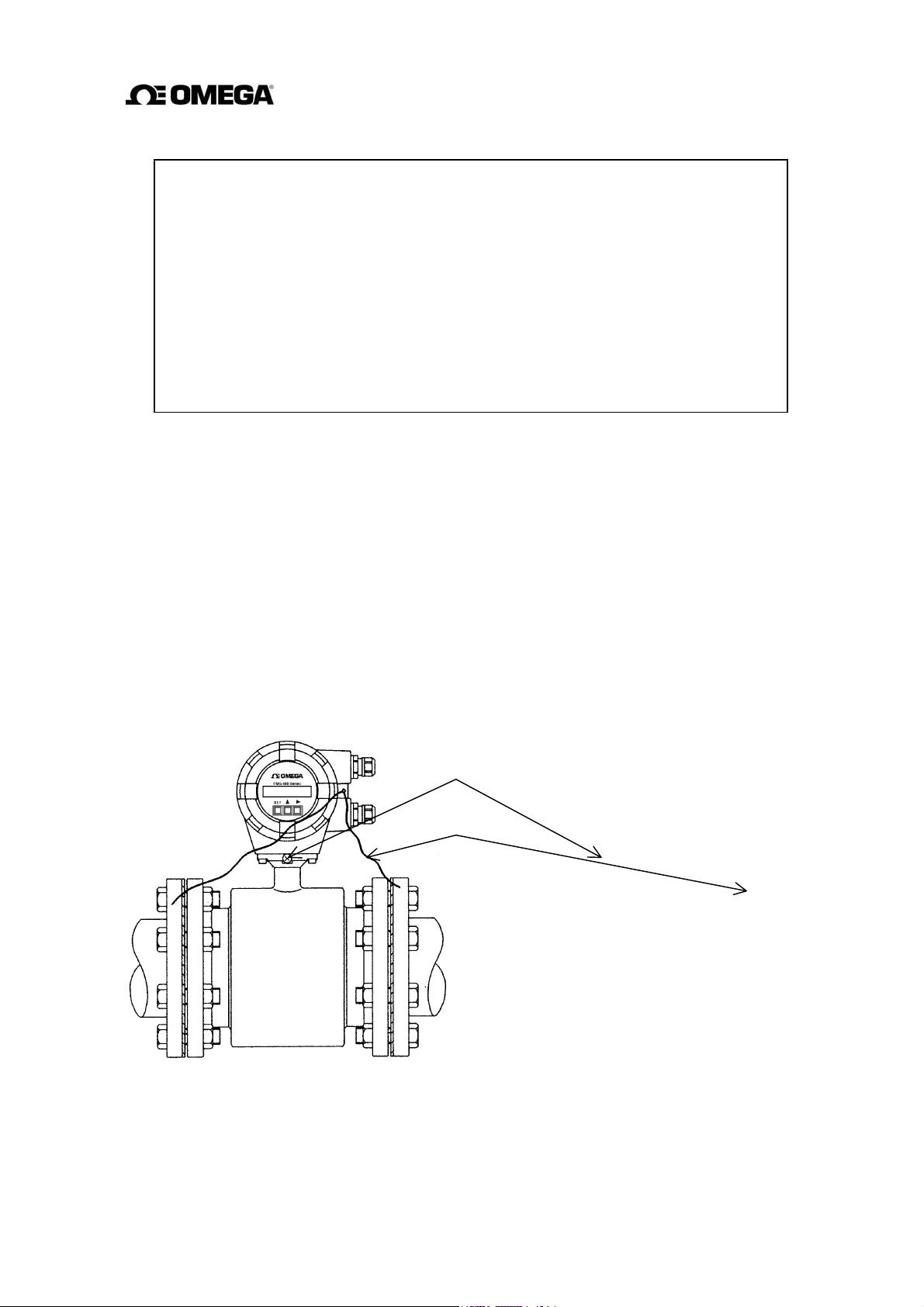

3. Names of Parts

N

play

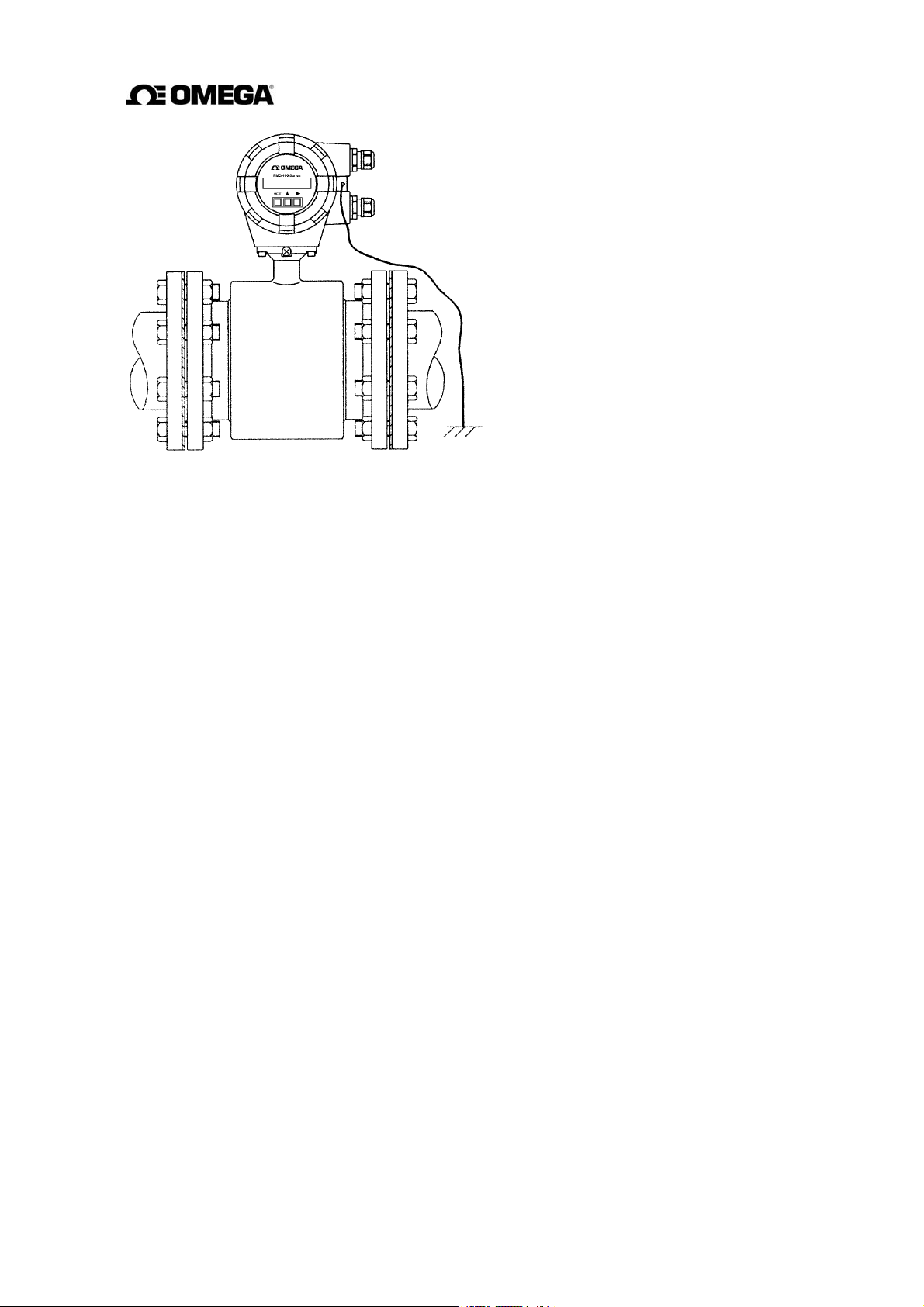

The outline drawing of the FMG400 Series flange type flowmeter is shown in Figure 3.1 and

the internal views of the converter are shown in Figures 3.2 and 3.3.

Outline Drawing

Housing cover

for terminal board

Grounding terminal

ameplate

Port for power cable

Port for I/O

cable

Housing cover for

LCD dis

Detector

Converter

LCD display

Control keys

Flow derection arrow

Figure 3.1 Outline drawing of FMG400 Series flange type Flowmeter

11

Page 13

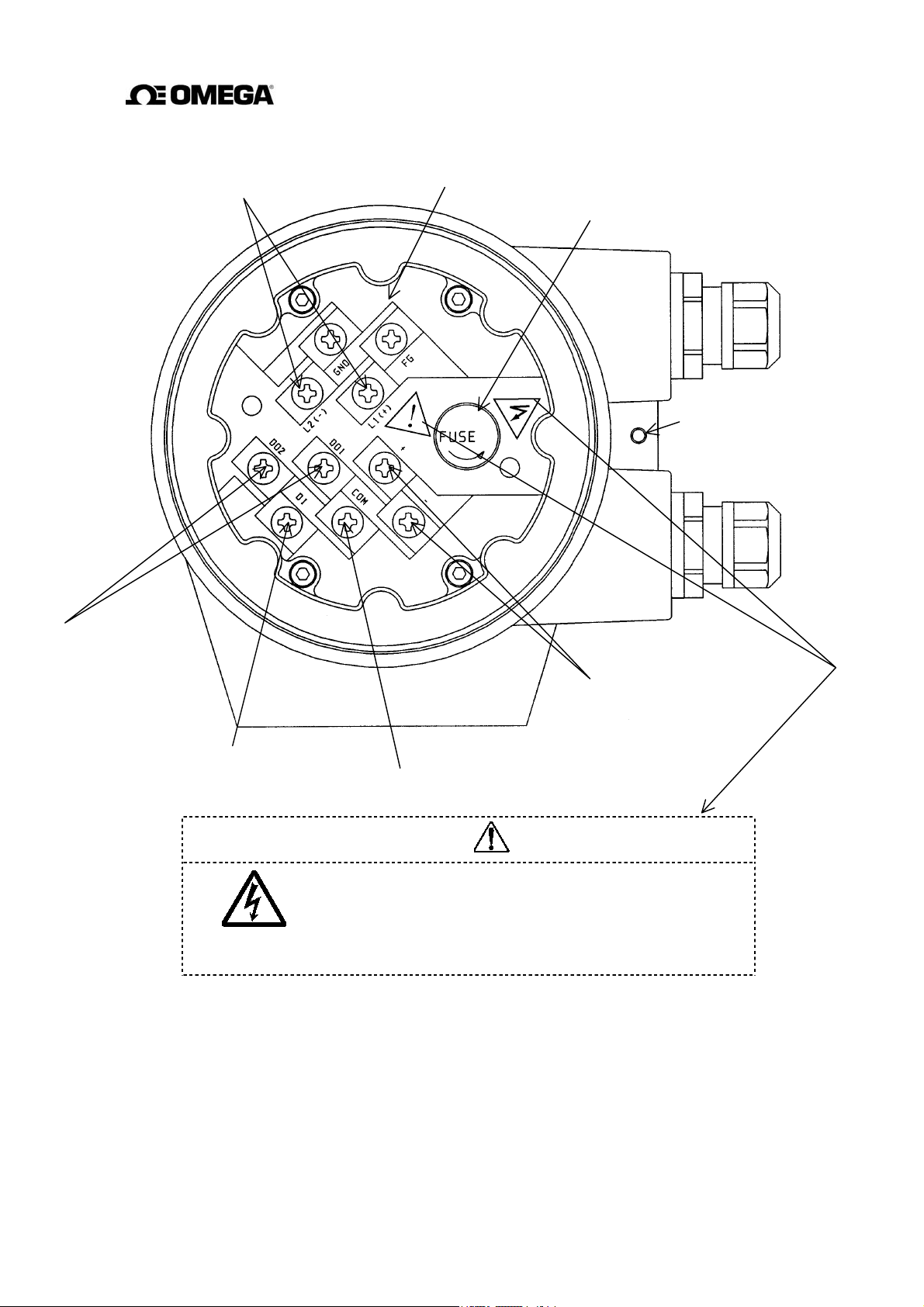

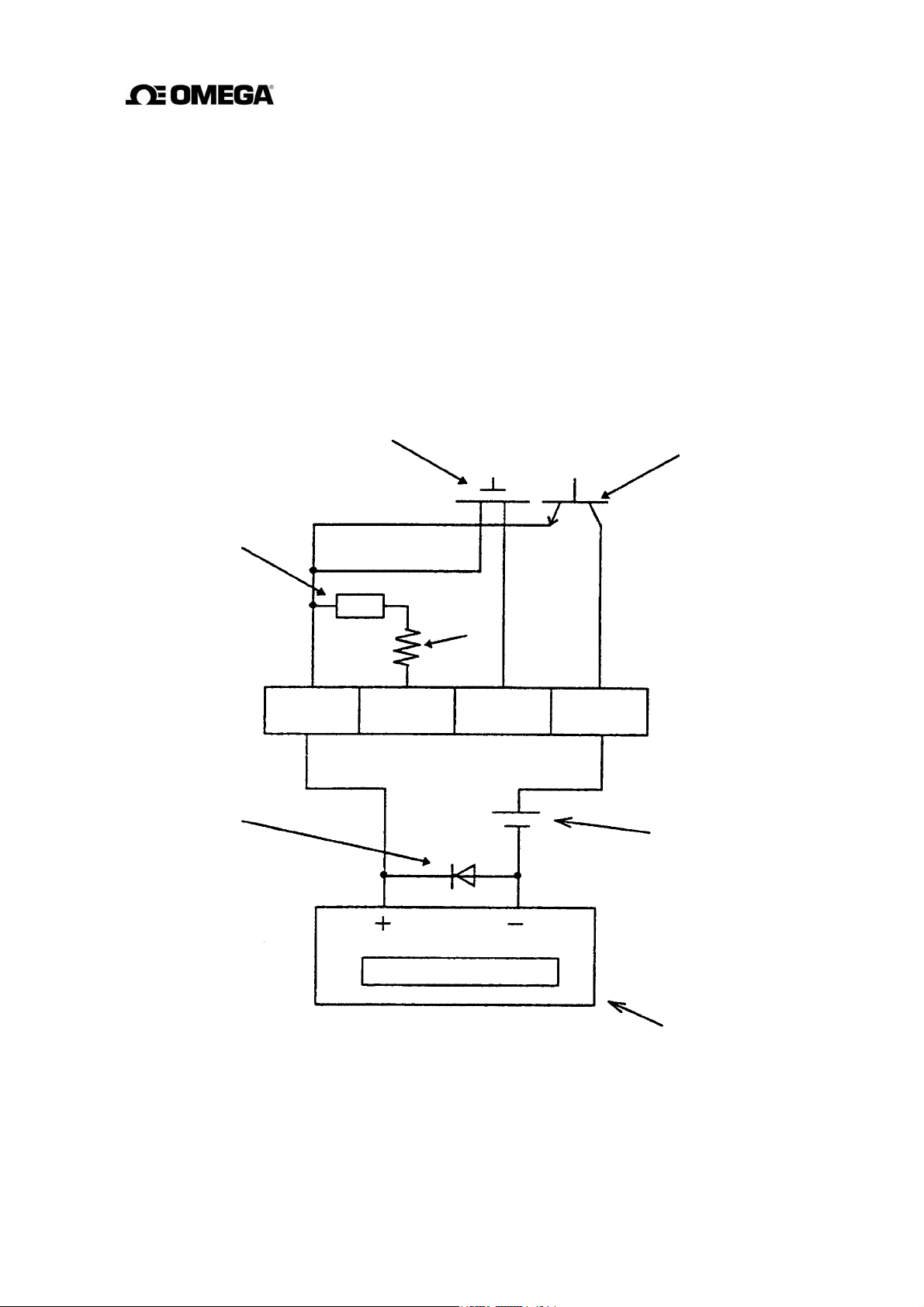

Terminal Board of Converter

Power supply teminals

Internal ground terminal

Fuse

External grounding

terminal

Digital output terminals

Digital input terminal

宜しくお願い致します。

Figure 3.2 Terminal Board of Converter

Current output terminals

Signal COMMON for DI, DO1, DO2

CAUTION

The seal shown in the left figure is attached to near the

power supply wiring terminals. Be careful not to get

electric shock.

12

Page 14

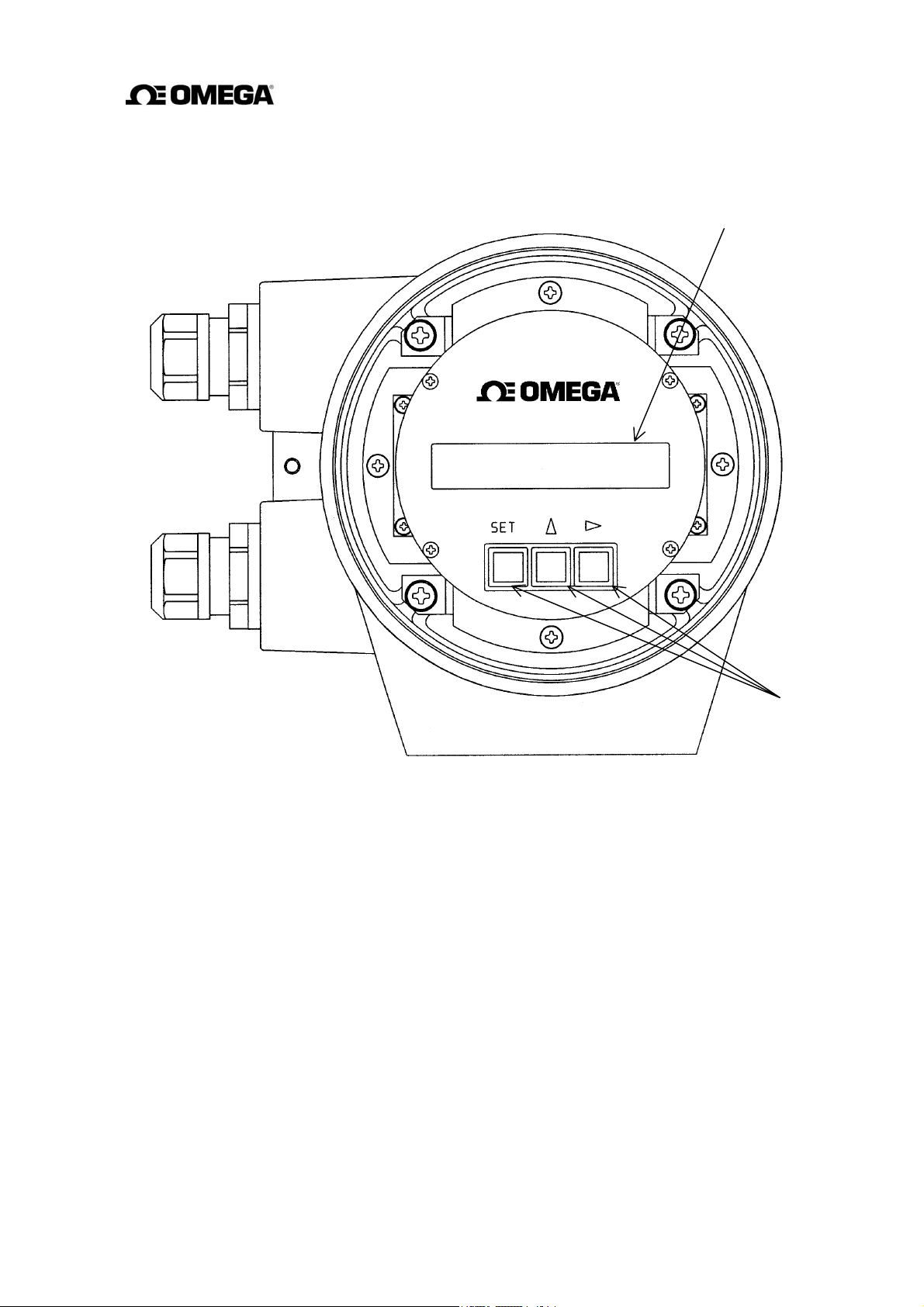

Control switch or keys of Converter

LCD display

Figure 3.3 Control switch or keys of Converter

Control keys

13

Page 15

4. Installation

Safety Precautions for Installation

WARNING

Do not use the FMG400 Series in an

Using this product in an explosive atmosphere can

cause explosion.

explosive atmosphere

DON’T

CAUTION

Install a switch and fuse to isolate the

FMG400 Series from main power.

Power supply from main

power can cause electric

shock or circuit breakdown.

DO

Do not modify or disassemble the

FMG400 Series unnecessarily.

Modifying or disassembling

this product can cause

DON’T

Do not work on piping and wiring with

wet hands.

electric shock,

or damage to this product.

Wet hands may result in

electric shock

malfunction

DON’T

.

Use an appropriate device to carry and

install the FMG400 Series.

If his product falls to the

ground, injury, or malfunction

DO

Ground the FMG400 Series

independently from power equipment.

of or damage to the product,

can be caused.

Operating this product without

grounding can cause electric

shock or malfunction.

DO

The label shown left is placed

near the terminal board for

power input.

(A

black border and symbol on

yellow triangle)

Be alert to electric shock.

4.1 Location

To select the installation site, follow the precautions described below:

Avoid places where fluid runs in a pulsating form.

Avoid places within the immediate proximity of equipment producing electrical

interference (such as motors, transformers, radio transmitters, electrolytic cells, or other

equipment causing electromagnetic or electrostatic interference).

14

Page 16

Avoid places where excessive pipe vibration occurs.

Avoid places where there is direct sunlight. If this is unavoidable, use an appropriate shade

Avoid places where corrosive atmospheres or high humidity conditions obtain.

Avoid places of too great an elevation or constricted areas where clearance for installation

or maintenance work is not provided.

Design piping so that the detector pipe is always filled with fluid, whether the fluid is

flowing or not.

The detector has no adjustable piping mechanism. Install an adjustable short pipe where

needed.

Chemical injections should be conducted on the downstream side of the flowmeter.

* For cautions on piping work such as the installation positions of piping and lengths of

straight pipes, see Section 4.3.

4.2 Mounting

CAUTION

Use an appropriate device to carry

and install the FMG400 Series.

If his product falls to the

ground, injury, of

DO

malfunction of or damage

to the product, can be

caused.

Turn off main power before

working on pipes.

Working on pipes while

power is applied can

DON’T

cause electric shock.

IMPORTANT

When high-temperature fluid is being measured, radiant heat from the detector pipe surface

and adjoining pipes may cause the ambient temperature of the converter to go above 60 °C.

If the ambient temperature goes above 60° C, try to lower the temperature by measures such

as wrapping heat-insulating materials over the detector pipe and adjoining pipes.

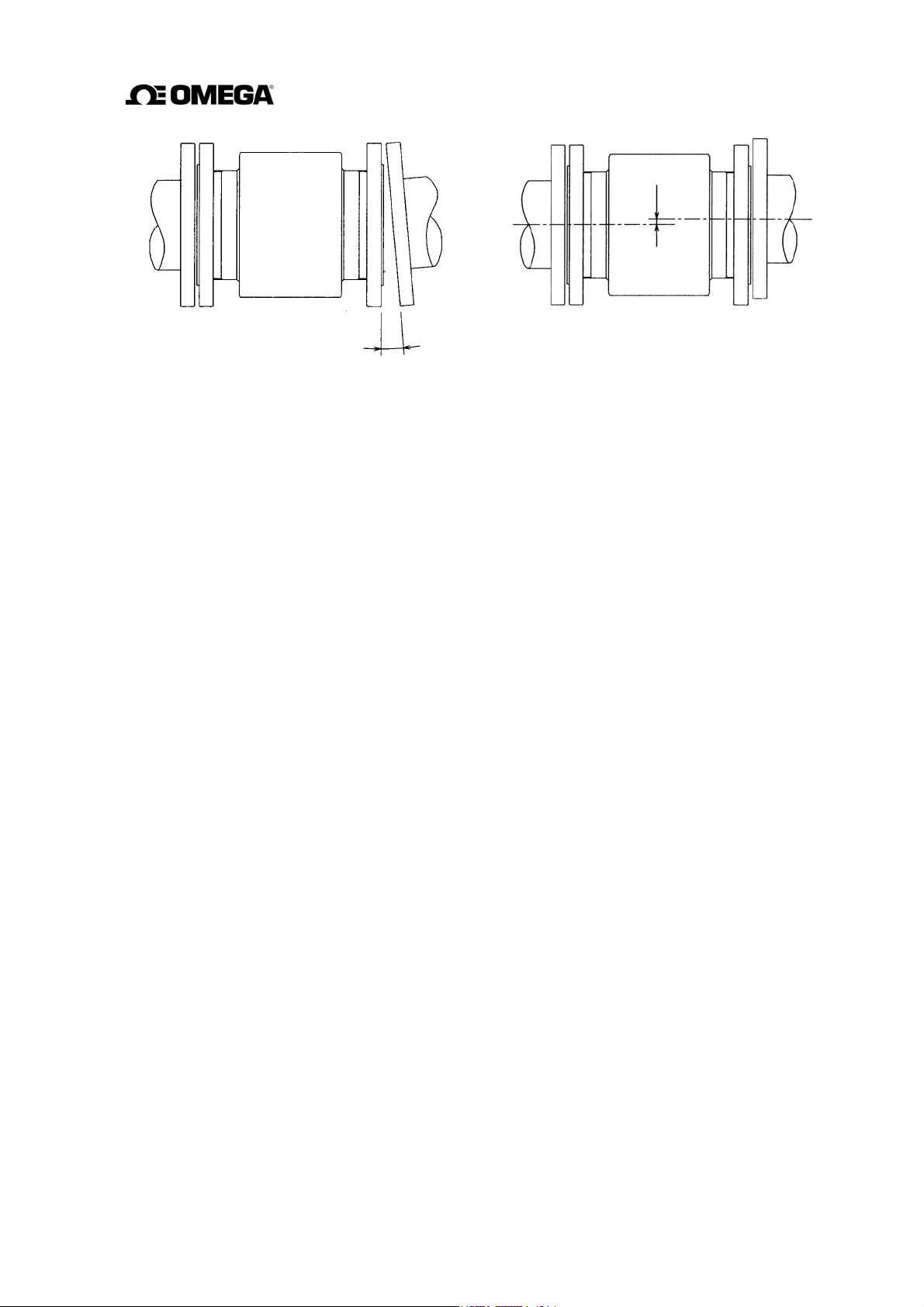

4.2.1 Piping Inspection

Before installing the pipes, make sure that there is no inclination of pipes or tube axial

displacement (eccentricity) as shown in Figure 4.1. Forced installation of the flowmeter in

inclined pipes may cause destruction of the detector or leakage of the fluid. Installing the

flowmeter in pipes with the presence of eccentricity may cause local friction of the lining or

earth ring and measurement errors depending on the properties of the fluid.

Before installing the pipes, flush the pipe interior to remove foreign matters in the pipes.

15

Page 17

Eccentricit

y

Inclination

(a) Inclination of pipe (b) Tube axial displacement

(eccentricity)

Figure 4.1 Bad Examples with Inclination of Pipe and Tube Axial Displacement

(Eccentricity)

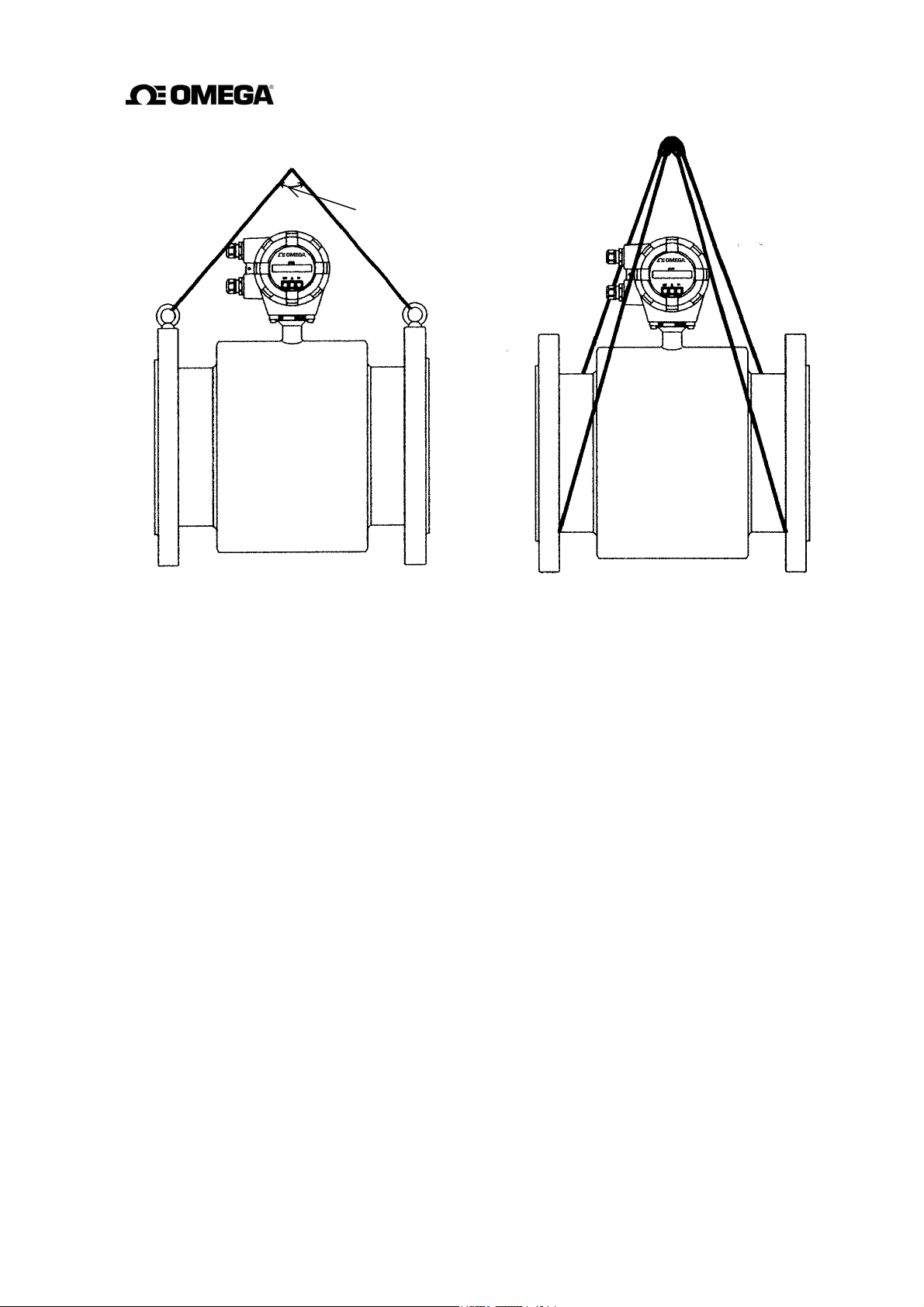

4.2.2 Cautions on Carrying Equipment

In order to prevent damages to the equipment, carry it packed as was at the time of delivery to

the installation location and unpack it there.

As the detector whose nominal diameter is 200 mm comes with eyebolts, lift the equipment as

shown in Figure 4.2 (a).

As the detector whose nominal diameter does not exceed 150 mm comes with no lifting means,

lift the equipment as shown in Figure 4.2 (b). The weights of the detectors with different

nominal diameters are described in Chapter 15 "Outline Dimensions."

Lifting the detector of any nominal diameter by pressing a bar into the detector pipe may

damage the lining, preventing stable measurement. Never do this under any circumstances.

* Lifting should be performed under instructions of qualified personnel of crane or slinging

work.

16

Page 18

90° or less

(a) With nominal diameter of 200 mm (b) With nominal diameter of 150 mm or

less

Figure 4.2 Lifting Method

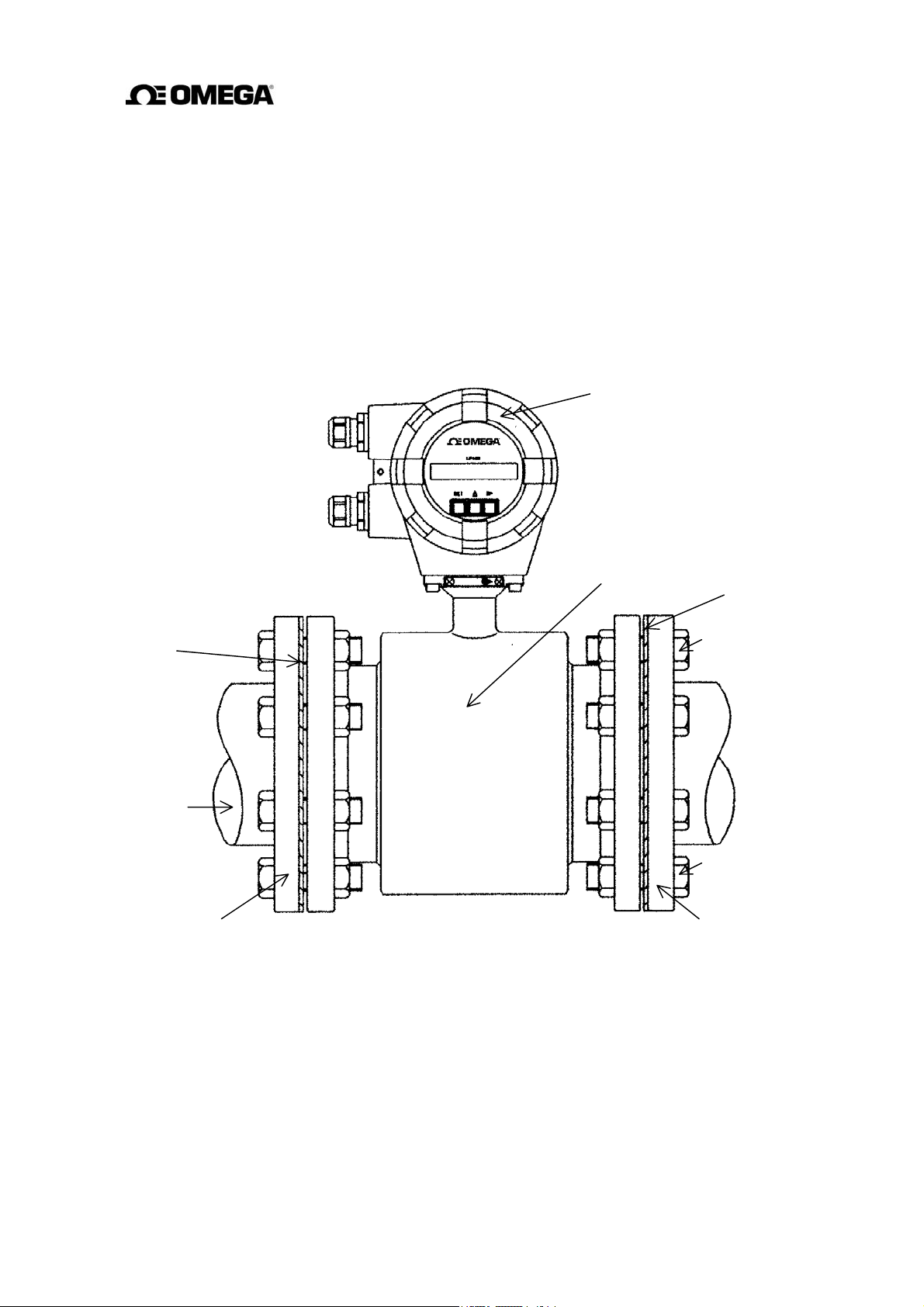

4.2.3 Mounting Procedure

To mount the FMG400 Series flange type, place it between the upstream and downstream pipe

flanges and tighten it with flange bolts and nuts. See Figure 4.3 and follow the procedure

below:

1. Insert two lower mounting bolts through the clearance holes in the upstream (or

downstream) pipe flange.

2. Install a packing next to the upstream (or downstream) flange face and the other packing

next to the downstream (or upstream) pipe flange. The two mounting bolts can now be

guided through the clearance holes in the downstream packing and flange.

3. Place the FMG400 Series flowmeter between the two flange packings, with the flowmeter

detector body above the two bolts. The flowmeter must be oriented in accordance with the

flow direction arrow.

4. Install the two upper mounting bolts through the clearance holes in the upstream and

downstream packings and flanges. Then install the remaining mounting bolts depending

on the flange pattern used.

5. Thread nuts on both ends of the 4 (or more) mounting bolts, finger tight.

17

Page 19

6. While centering the flowmeter with the longitudinal axis of the pipeline, tighten the nuts

g

with a wrench diagonally across in even increments.

Note that the flowmeter detector pipe axis must be aligned with the pipeline axis on both

upstream and downstream sides. This is essential to have stable characteristics of flow

measurement (especially for flowmeters with meter sizes of 50 mm or less).

* In the case of a detector using teflon PFA lining, bolts may get loose with time because of

plastic deformation of teflon. Tighten them periodically.

Converter

Packing

Flow direction

Upstream flange

Detector

Figure 4.3 FMG400 Series flange type flowmeter-piping connections

Packin

Upper mounting bolts

Lower mounting bolts

Downstream flange

18

Page 20

4.3 Piping Connections

(1)

(2)

(3)

)

(1) Required Pipe Length

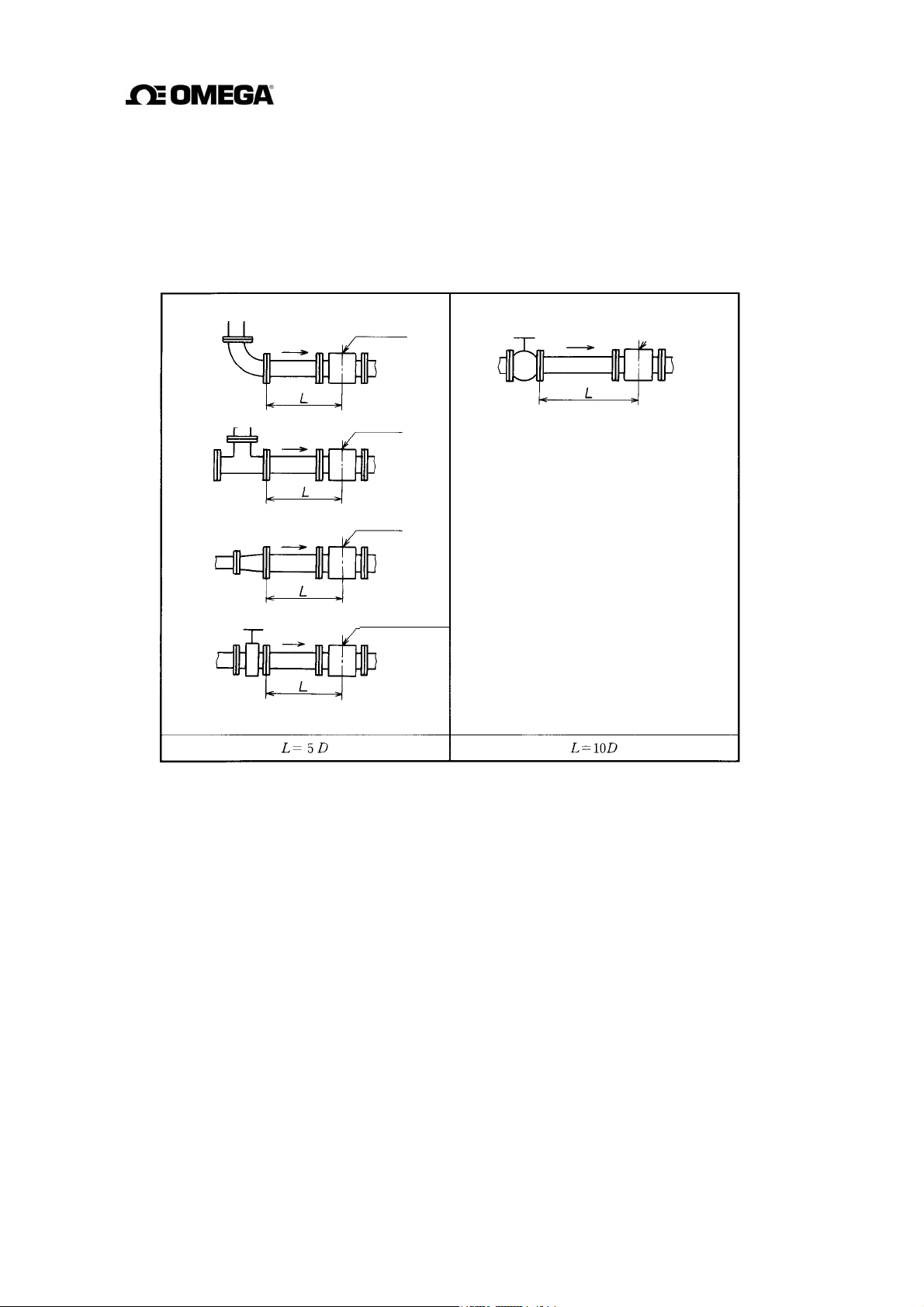

If various joints are used upstream of the detector outlet, the straight pipe length as shown in

Table 4.2 is required.

Table 4.2 Required straight pipe length on the upstream side

90° bent

Tee

Diffuser

(4)Fully opened sluice valve

Detector

Detector

Detector

5. Other valves (not fully opened

Detector

L: Required straight pipe length—straight pipe length plus half-length of the detector.

D: Nominal bore size (diameter)

NOTES

1. The length of a reducer, if connected, can be counted as a part of the straight pipe length.

2. No straight pipe length is needed on the downstream side. If a butterfly valve is installed

downstream of the detector, do not let the valve plate protrude into the pipe of the detector.

19

Page 21

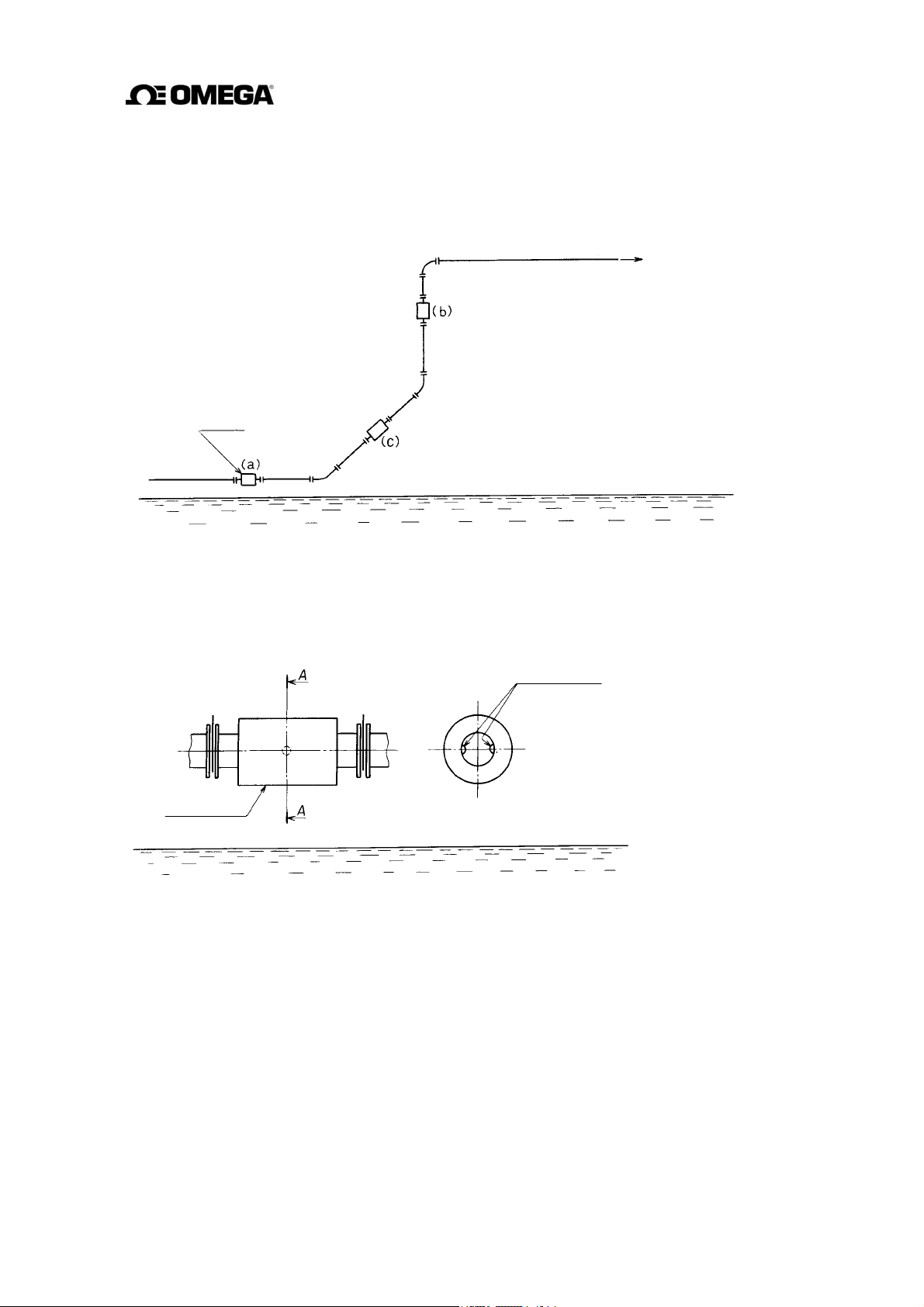

(2) Pipe Orientation

The detector may be installed in horizontal, vertical or sloping pipe runs as shown in Figure 4.4.

However, except for horizontal installation, fluid should flow from lower to upper directions.

See Figure 4.4.

Flow direction

(a) Horizontal pipe installation

(b) Vertical pipe installation

(c) Sloping pipe installation

Detector

Ground surface

Figure 4.4 Detector Piping Orientation

The electrodes should be positioned horizontally against the ground surface in any piping

installation. See Figure 4.5.

Detector

-

-

Figure 4.5 Installation position of the detector

20

Page 22

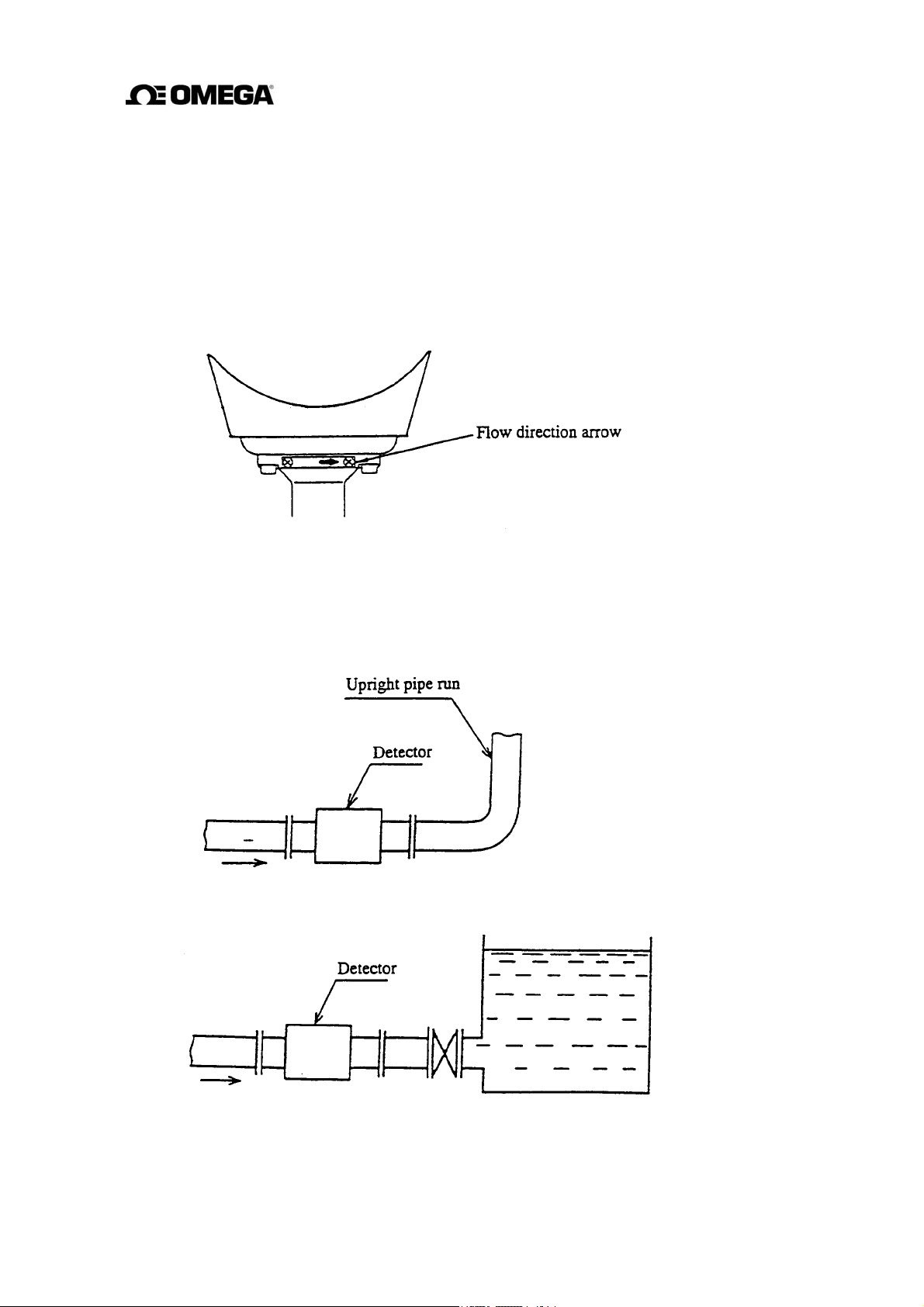

(3) Flow Direction

Install

the detector in accordance with the flow direction arrow on the detector. See Figure 4.6. If

the

actual flow runs opposite to the specified flow direction, the following display and output

appears. (For bi-directional multi-range measurement, see 10.3, “Multi-range Functions.”).

• LCD display : Instantaneous flow rate—indicates negative values,

Totalized flow—no counts added.

• Output: Current output— 4.0 mA output; Pulse output—No pulses

Figure 4.6 Flow direction arrow on the detector

(4) Preventing an Empty Pipe Condition

Design an upright pipe run (Figure 4.7) or sufficient head pressure (Fig. 4.8) at the downstream

detector outlet if there is a possibility of the detector pipe becoming emptied.

Figure 4.7 Detector with an upright pipe run at downstream outlet

Figure 4.8 Detector with sufficient head pressure at downstream outlet

21

Page 23

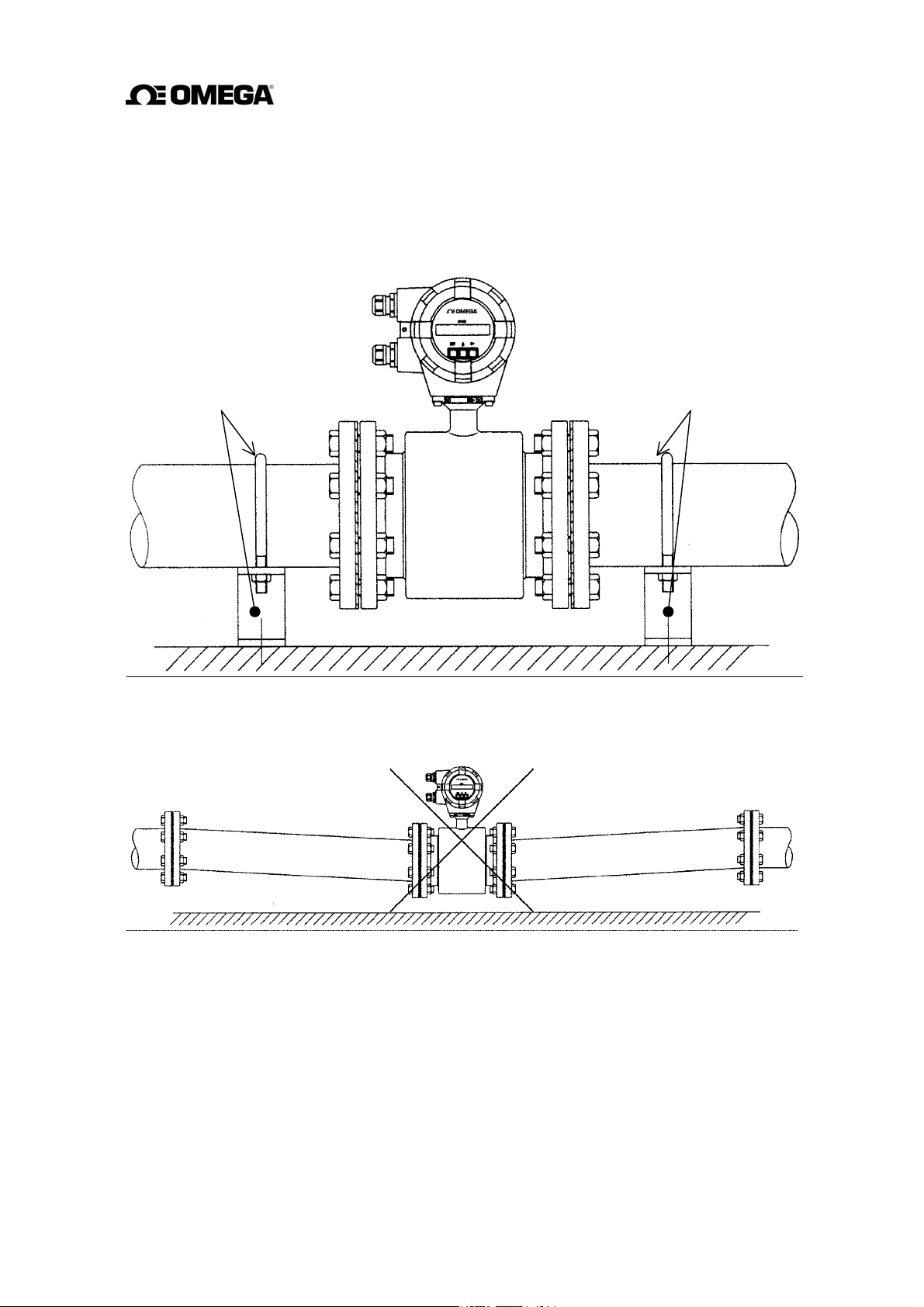

(5) The pipes on both sides of the installation location of the detector should be fixed by attaching

support fittings, etc. Supporting the pipes will not only reduce piping vibration but also

prevent damages to the piping due to dead weight of the electromagnetic flowmeter and

weight of the fluid. (See Figure 4.9 and Figure 4.10.)

Piping support fitting Piping support fitting

Figure 4.9 Example of Pipe Fixing Method

Figure 4.10 Unsupported Piping Model

22

Page 24

5. Wiring

CAUTION

Do not work on piping and wiring with

wet hands.

Wet hands can cause

system failure.

DON’T

Do not modify or disassemble the

FMG400 Series unnecessarily.

Modifying or

disassembling this product

DON’T

Flowmeter accuracy may be affected by the way wiring is executed. Proceed with wiring

taking the following precautions:

(1) Select the cable runs away from electrical equipment (motors, transformers, or radio

transmitters) which causes electromagnetic or electrostatic interference.

(2) Deterioration of flowmeter circuit insulation occurs if the converter interior or cable

ends get wet or humidified. This in turn causes malfunction of the flowmeter or noise

problems. Avoid a rainy day if the flowmeter is to be installed outdoors. Even indoors,

prevent water from splashing over the flowmeter. Try to finish the wiring as quickly as

possible.

can cause electric shock,

malfunction of or damage

to this product.

Ground the FMG400 Series properly.

Operating this product

without a grounding can

DO

cause system malfunction

The label shown left is placed

near the terminal board for

power input.

Be alert to electric shock.

(3) The converter has a surge-absorbing barrier installed inside. Therefore, do not conduct

a withstand voltage test for the converter. To check the insulation of the converter, use

a voltage of 250 V

dc or less.

23

Page 25

5.1 Cables

Use the kind of cables shown in Table 5.1 to wire the converter.

Table 5.1 Cables

Name Cable type

Power cable

Three-wire sheathed

Nominal crosssectional area

2 mm² 11 to 13 mm

Overall

diameter

cable (Note)

I/O cable

The number of wires for the output cable depends on the

system specifications. Use a shielded cable with nominal

cross-sectional area of 1.25 mm² and overall diameter of

11 to 13 mm.

Note: Use a four-wire cable if the arresters are to be used. See Figure 5.1 below.

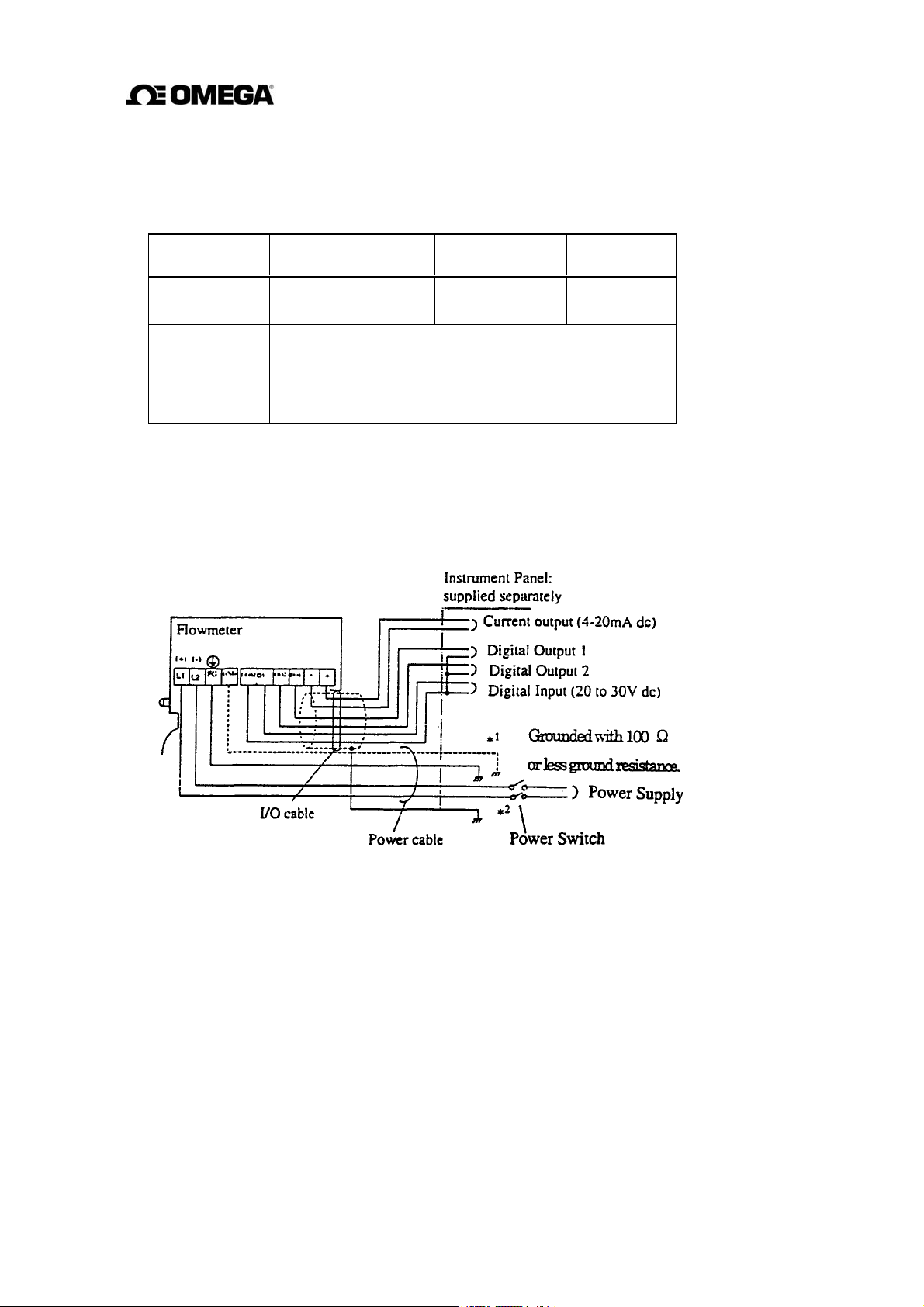

5.2 External Device Connections and Grounding

The terminal board connections of the FMG400 Series flowmeter are shown in Figure 5.1.

Proceed with wiring as described in Section 5.4, “Wiring Procedure.”

If power supply is specified as DC, use L1 as positive (+) and L2 as negative (–) terminals.

1

To use the arresters, ground the GND terminal using a wire shown in broken line.

*

2

Locate an external double-pole power switch on the power line near the flowmeter and within

*

easy operation.

Mark on the switch as the disconnecting device for the flowmeter.

Use the proper switch as follows.

Recommended switch rating; Rating AC250V 6A or more

Inrush current 15A or more

Figure 5.1 Terminal Board Connections

24

Page 26

IMPORTANT

(1) The grounding terminal of the FMG400 Series flowmeter should be grounded with

100 ohm or less ground resistance. Use a heavy copper braid or wire (cross-sectional

area 5.5 mm

terminal is M4 size and an M4-size crimped ring lug should be used to connect the

wire to the terminal. Avoid a common ground where earth current may flow.

independent

and non-conductive pipeline grounding procedures.

(2) To prevent a two-point grounding, ground the shielded cable on the receiving

instrument side.

2

minimum) to ground the terminal and make it as short as possible. The

An

ground is preferable. See Figure 5.2. for a conductive pipeline grounding

If connection pipe is conductive:

(1) Connect between the grounding

terminal

and both ends of the mating

flanges with a heavy copper braid or

wire (cross sectional area 5.5 mm

minimum).

(2) If the conductive pipe is not

grounded

to a

good earth ground, use

the same type of copper braid or

wire

to

ground the terminal with 100

ohm or less ground resistance.

Grounding terminal

Grounding wire

If connection pipe is non-conductive:

(1) Use a heavy copper braid or wire

(cross sectional area 5.5 mm²

minimum) to ground he terminal with

2

100 ohm or less ground resistance.

25

Page 27

Figure 5.2 Grounding Procedure

26

Page 28

5.3 Digital I/O Connections

(

)

r

Digital I/O terminals consist of contact output terminals, voltage signal input terminal (DI), and

signal common terminal (COM). Each terminal (DO1, DO2 and DI) is isolated from internal

circuits. Terminal (COM) is the signal common for the other three terminals (DO1, DO2 and

DI).

Functions can be assigned for each terminal with the LCD control keys. See Chapter 10,

“Digital I/O Functions.”

To connect an electromagnetic relay or counter to the contact output terminal (DO1 or DO2),

put a surge-absorbing diode into the input circuit of the relay or counter. See Figure 5.3 for an

example of electromagnetic counter connection.

Solid-state relay Transistor open collector

Resisto

COM DI DO2 DO1

Diode

Note

* Note. Be sure to use a surge absorption diode with a rated current of 1 A and rated withstand

voltage of 200 V Min.

Figure 5.3 Electromagnetic Counter Connection Example

Power supply

27

Page 29

5.4 Wiring Procedure

Cable termination and cable connections are described below.

5.4.1 Cable Termination

CAUTION

Do not conduct wiring work when

power is applied.

Wiring while power is

applied can cause electric

DON’T

Use cables as specified in Table 5.1. Remove about 30 mm of the end of cable sheath to expose

the two coated wires and then strip the wires about 10 mm. Then attach an M4-size crimped

ring-lug to the end of each wire using a compression tool. The crimped ring-lug should be of

the kinds with insulated sleeve to prevent shorts between adjacent terminals. The overall length

of the wire with the M4-size ring-lug attached should be about 35 mm. See Figure 5.4.

shock.

35 mm

Do not work on piping and wiring

with wet hands.

Wet hands may result in

electric shock.

DON’T

Figure 5.4 Termination of cables

5.4.2 Cable Connections

Connect the terminated cable wires to the terminal board as described below.

IMPORTANT

Connect the wires securely to the terminal board. A loose connection may result in

unsatisfactory flowmeter performance. Make sure the wires are securely connected.

28

Page 30

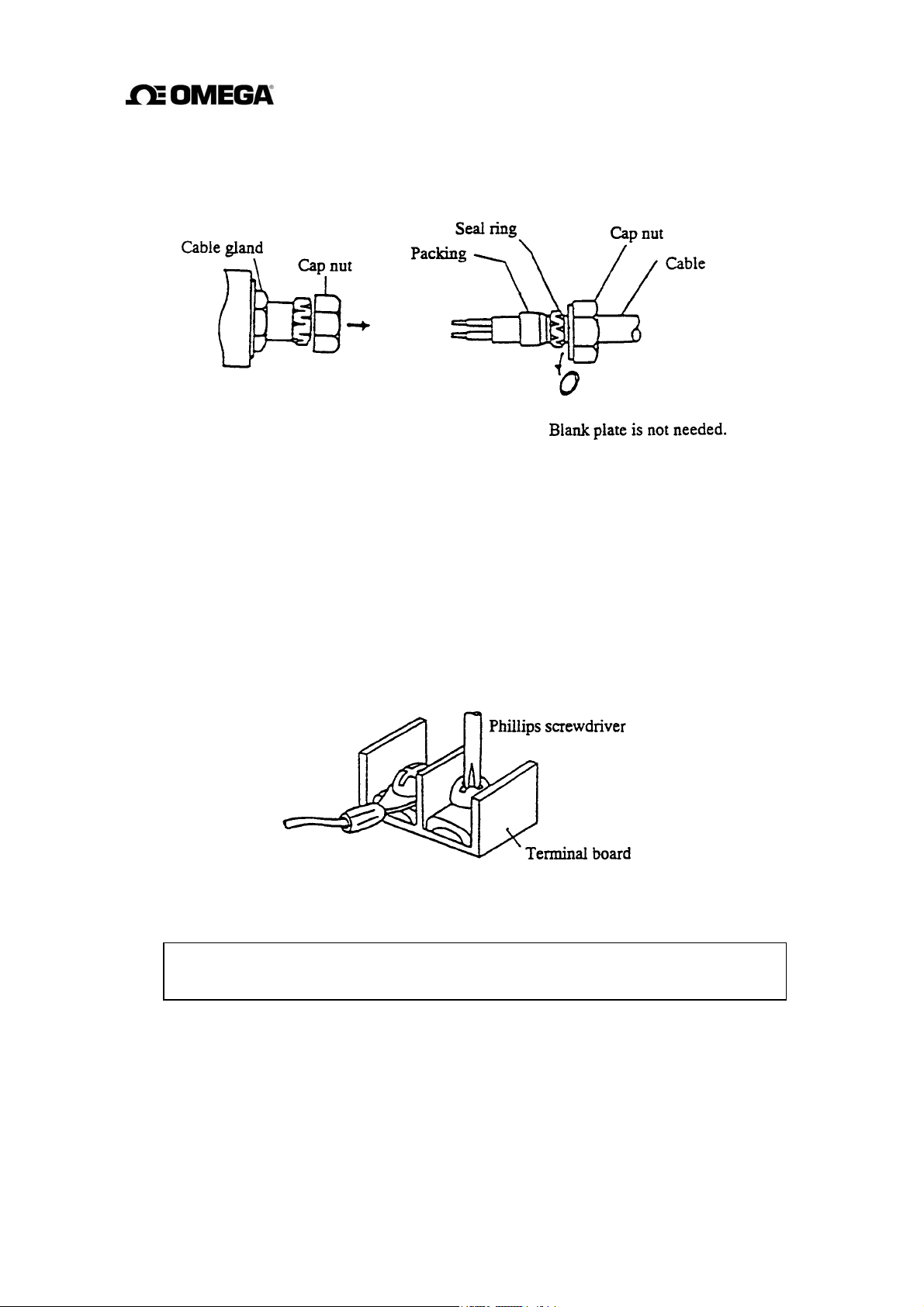

(1) Remove the cap nut from the cable gland and put the terminated cable through the cap nut,

seal ring, and packing as shown in Figure 5.5 on the right. The blank plate inside the cable

gland used when shipped is not needed once the cable is wired.

Figure 5.5 Cable connections

(2) Remove the housing cover for the terminal board shown in Figure 3.1. The terminal board is

located inside the converter as shown in Figure 3.2. Connect the crimped terminal of each

wire to the specified pin of the terminal board. See Figure 5.1 for the terminal board

configuration. Tighten each crimped terminal to the terminal board with a screw using a

Phillips screwdriver as shown in Figure 5.6. Loose connection may result in unsatisfactory

flowmeter performance. Make sure the wire is securely connected.

Figure 5.6 Terminal board connections

NOTE

The appropriate torque for tightening the terminal board screws is 1.2 Nm (12 kgf·cm).

29

Page 31

(3) After the terminal board connection, pull the cable a little so that the cable runs straight from

the terminal board without unnecessary winding.

However, if the sheath-removed part goes as far as where the packing is located, air may

leave through there and the airtight structure may not function. See the incorrect example in

Figure 5.7. Then tighten the cap nut with a wrench.

Figure 5.7 Cabling Procedure

(4) Attach the terminal cover and screw the housing cover for the terminal board. To keep the

housing seal, tighten the cover securely, using a tool fitting with the groove on the cover.

30

Page 32

6. Operation

CAUTION

Do not touch the FMG400 Series main

body when high temperature fluid is

being measured.

The fluid raises the main

body temperature and can

DON’T

6.1 Preparatory check

Follow the procedure described below to prepare before starting the flow measurement.

System Check

Check the wiring between the converter and related instruments.

Make sure all the bolts of connection flanges on which the flowmeter is

mounted securely tightened.

Make sure the direction of flow arrow is in accordance with actual flow.

Make sure the flowmeter is grounded with 100 ohm or less ground resistance.

cause burns when touched.

Make sure the converter housing covers are securely tightened.

Placing System On-Stream

Let the fluid go through the detector pipe. When the detector is filled with the

fluid, stop the fluid and keep it still in the detector pipe.

Supplying Electric Power

Make sure the power supply is as specified.

Checking Converter Parameters

Check the configuration parameter settings. Refer to Chapter 7, “LCD

Display and Controls,” along with Chapter 8, “Configuration Parameter

Setting”.

Zero Adjustment

Wait for 30 minutes to warm up the flowmeter. Then making sure the fluid

holds still in the detector pipe, starts the zero adjustment. Refer to 6.2, “Zero

Adjustment.”

On-line measurement

After checking the items and conducting the zero adjustment as listed above,

let the fluid go through the detector pipe. Output (4–20 mA dc) directly

proportional to the flow rate can be obtained.

31

Page 33

6.2 Zero Adjustment

To conduct zero adjustment of the flowmeter, the fluid in the detector pipe must be held still.

To start the zero adjustment is pressing a combination of control keys for the model with LCD

display (see 8.2.8, “Zero Adjustment”).

Press the zero adjustment switch for more than 3 seconds.

(Note that once the zero adjustment is started, there is no way to cancel the zero adjustment

sequence.)

An LED lamp is ON during zero point adjustment.

Then the LED indicator lights and the zero adjustment sequence will start. The zero

adjustment sequence lasts about 3 to 6 seconds. (Zero adjustment duration depends on the

excitation current frequency. It takes about 3 seconds for 24 Hz setting and about 6

seconds for 12 Hz and 6 Hz settings.)

When the zero adjustment sequence ends, the LED indicator goes off.

To conduct the zero adjustment, it is necessary to open the converter housing cover and press

the switch. Observe the following precautions when you open the housing cover:

(1) Do not open the cover in the open air unprotected against rain or wind.

If you adjust the flowmeter in the rain, this can cause electric shock or damage to the

flowmeter electronics. If wind blows against the internal circuitry of the converter, output

may fluctuate and fail to indicate correct measuring values.

(2) Do not conduct the zero adjustment when the ambient humidity is high. By opening the

cover in high humidity conditions, the measuring accuracy may be reduced or damage

caused to the flowmeter electronics.

32

Page 34

7. LCD Display and Controls

You can select the operation mode, change the configuration parameters or execute

operation-specific functions using the control keys on the panel. How to operate these

keys is described in this chapter.

7.1 Outline

The Converter has a LCD display. The LCD display can be used to set and indicate various

configuration parameters. Figure 7.1 shows the front view of LCD display.

FMG400 Series

LCD display

Figure 7.1 Converter with LCD display

LCD display (2-line × 16-character)

The backlit display enables an easy-to-read indication even under poor lighting conditions.

Instantaneous flow rates or totalized flow in the measurement mode, or configuration

parameters in the setting mode can be displayed.

33

Control keys

Page 35

Control Keys

Changing the operation mode, checking or changing parameters can be done with these keys.

To operate these keys, you have to open the converter housing cover. Observe the following

precautions when you open the housing cover:

(1) Do not open the housing cover in the open air unprotected against rain or wind.

If you open the housing cover in the rain, it can cause electric shock or damage to the

flowmeter electronics. If wind blows against the internal circuitry of the converter, output

may fluctuate and fails to indicate correct measuring values.

(2) Do not open the housing cover when the ambient humidity is high. By opening the cover

in high humidity conditions, the measuring accuracy may be reduced or damage caused to

the flowmeter electronics.

Functions of each control key when pressed are shown in the table below.

Control keys Basic functions of control keys

Goes into the item selection sequence.

SET

5

4

Goes into the detailed-item specifying sequence for each selected item in

measurement, setting or calibration modes.

Stores the selected data in the setting mode.

Changes items (alphabet letter and number) in the items selection

sequence, and changes parameters (numbers and/or units) in the detaileditem specifying sequence in measurement, setting or calibration modes.

Starts and stops the totalizer in the measurement mode. (Note)

Changes digits (alphabet letter and number) in the items selection

sequence, and starts the detailed-item specifying sequence by indicating

the left-most digit with the cursor.

Moves the cursor from left to right (from the right end reverts to the left

end) in the above sequence.

Resets the totalizer in the measurement mode. (Note)

Note: To operate the totalizer, it is preferable to set the indicating unit (UNIT 1 and/or UNIT 2)

to one of the units appropriate for totalization just to make sure it is operating correctly. See 10.2,

“Totalizer and Pulse Output.”

34

Page 36

7.2 Display Format

In the measurement mode, measured data are displayed in UNIT 1 (primary indicating unit)

and UNIT 2 (secondary indicating unit). As to indicating units, see 8.2.4, “Indicating Unit.”

Display Format

Measured Value Display Forma

(1) Flow rate

t

35

Page 37

(2) Totalizer

(3) Volumetric flow

“C” is indicated when totalized flow is counted.

Increments per counting rate. Refer to 8.2.10,

“Counting Rate.”

Wraps around after 99999999.

“F” for forward and “R” for reverse direction flow

will be displayed

Displays down to the smallest digit of

“C” is indicated when volumetric flow is counted.

The unit of flow

8 digits (99999999) maximum including decimal point

(4) % display

If the flow count exceeds 99999999, wraps around.

“F” for forward and “R” for reverse direction flow

will not displayed.

Displayed down to 0.1 %.

Displays up to 125.0 %.

Flow direction: Forward “

“ (blank space);

Reverse “-“

36

Page 38

7.3 Basic operations

Flow measurement in the measurement mode, checking or changing configuration

parameters in the setting mode and a converter unit check in the calibration mode are

the basic operations of the converter.

7.3.1 Mode Change

The converter has three operation modes: measurement, setting and calibration. The system

stays in the measurement mode after the power is turned on. To change the mode to the setting

or calibration mode, press [SET] and select the desired item using

return to the measurement mode, select “0” (MEASURE MODE) for the number column of

configuration items (such as A0 or B0) . See 7.4, “Configuration Items Selection Table.”

Measurement mode:

process values. The flowmeter can measure the flow velocity, flow rates, or totalized flow.

The flowmeter first goes into this mode when power is turned on.

Setting mode:

measurement mode. These parameter values are displayed while checking or changing these

values but the flowmeter outputs the measured process values as in the measurement mode.

See 7.4, “Configuration Items Selection Table” and 8.2, “Checking or Changing

Parameters” for details. Configuration items are from A1, A2, A3 to M1.

Calibration mode:

simulation signal is used to check the measuring span and excitation current value. The

current output of the flowmeter changes in accordance with the simulation signal. The

status of each digital output is held to the value just before the system moved into the

calibration mode. See 7.4, “Configuration Items Selection Table” and Chapter 9,

“Calibration” for details. Configuration items are from N1 to N4.

used to check or change various configuration parameters used in the

measures the process flow and displays and outputs the measured

used to check the converter internal circuits. The internally generated

[4]

and

[5]

keys. To

37

Page 39

7.3.2 Configuration Parameter Selection in Setting and Calibration Modes

Follow the procedure described below to select configuration items in the setting and

calibration modes. The key on the left should be pressed to start each sequence described on

the right.

Measurement mode

Goes into the item selection sequence. In this sequence, each

SET

4

item is indicated by a combination of an alphabet letter and a

number.

Selects the desired item (indicated by an alphabet letter and a

number) first by selecting the digit (alphabet or number) with

[4]

and then changing the value with

[5]

5

SET

4

4

5

SET

SET

SET

Displays the parameter for the selected item.

Goes into the parameter changing sequence. The digit

indicated by the cursor can be changed.

Changes

the cursor) using

with

Flickers the selected value and/or unit to confirm changes

made for the selected item.

Stores the indicated value and/or unit and stops flickering of

the data.

Returns to the items selection sequence.

the value and/or unit first by selecting the digit (with

[4]

and then changing the value or unit

[5].

(Note 2)

(Note 1)

Notes

1. To return to the measurement mode, select “0” (MEASURE MODE) for the number

column of any items (such as A0 or B0).

2. To return to the parameter changing sequence, press

38

[5].

Page 40

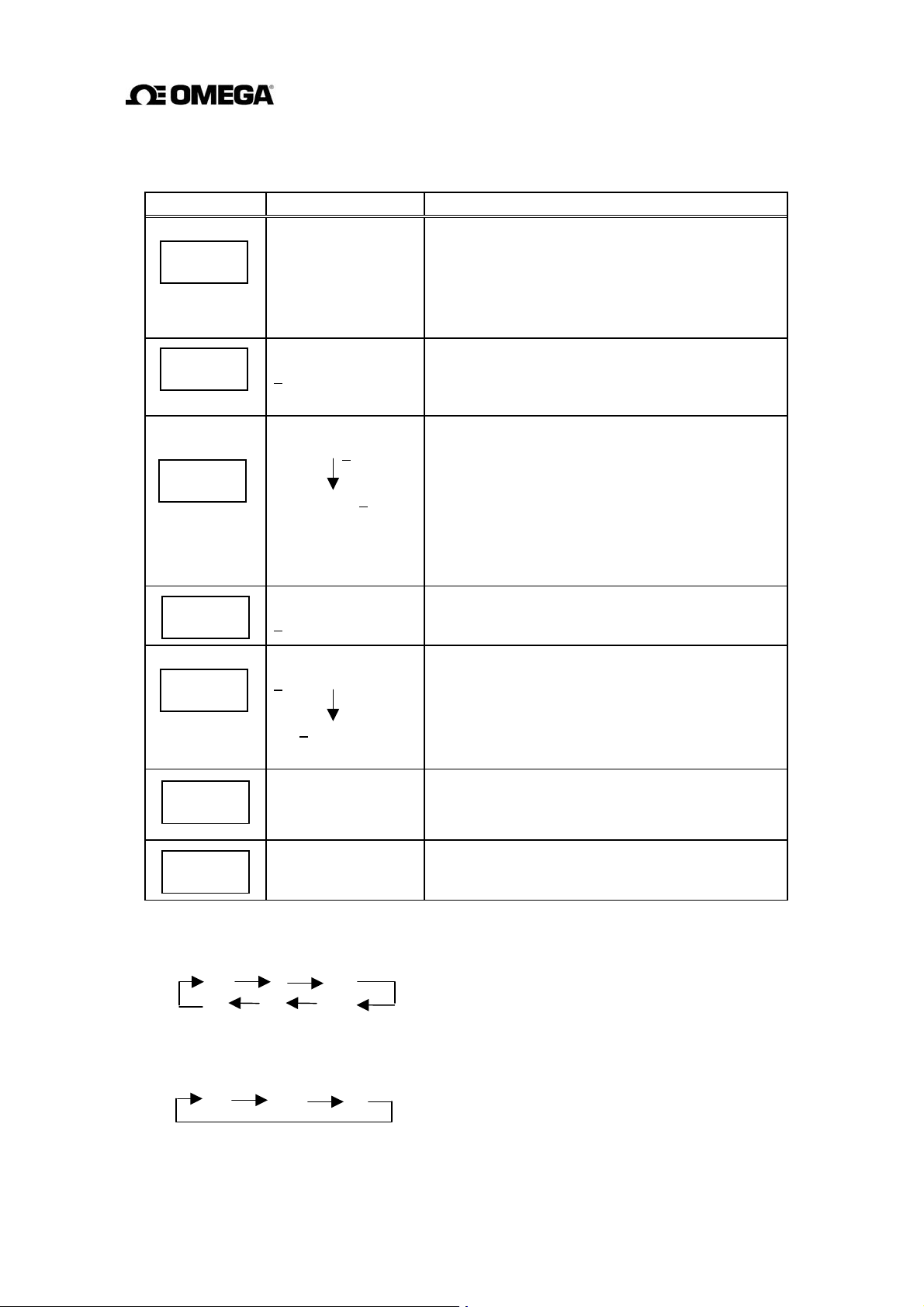

7.4 Configuration Items Selection Table

In the setting and calibration modes, configuration items can be selected as shown below. For

example, the excitation current can be selected by the item A1. To change the parameters for

the selected items, see the following chapters. To return to the measurement mode, select “0”

for the number (such as A0 or B0).

Setting mode items (A1, A2, A3 to M1): See Chapter 8, “Configuration Parameter Setting.”

Calibration mode item (N1 to N4): See Chapter 9, “Calibration.”

0123456

Excitation

*

A

Current

Indicating

*

B

Unit 1

Range Type Range 1 Range 2 Range 3 Range 4 Range

*

C

Damping

*

D

Constant

Zero

*

E

Adjustment

DO1

*

F

Function

Counting

*

G

Rate

Preset Count

*

H

High Alarm

*

I

Set

Meter Size Excitation

Frequency

Indicating

Unit 2

Low Cutoff

DO2

Function

Pulse Width

High Alarm

Value

DI Function

Low Alarm

Set

Hysteresis

Low Alarm

Value

Empty Pipe

*

J

Alarm

Rate-of-

*

K

change Limit

Fixed-value

*

L

Output

Zero Offset

*

M

Adjustment

Flow Rate

*

N

Cal 0%

* Returns to the measurement mode.

Control Limit

Time

Fixed-current

Output

Flow Rate

Cal 50%

Fixed-pulse

Output

Flow Rate

Cal 100%

39

Page 41

8. Configuration Parameter Setting

8.1 Configuration Items

To check or change parameters, first select the desired configuration item as described in 7.3.2.

The configuration items are listed below. See each section for detailed procedure.

The default set value in each configuration item is shown in Appendix 2.

Section Configuration item Display example Page

8.2.1

8.2.2

8.2.3

8.2.4

8.2.5

8.2.6

8.2.7

8.2.8

8.2.9

8.2.10

8.2.11

8.2.12

Excitation Current

Meter Size

Excitation Frequency

Indicating unit

Range Type

Span (range)

Hysteresis

Damping Constant

Low Cutoff

Zero Adjustment

Digital I/O

Counting Rate

Pulse Width

Preset Count

High/Low Alarm

Alarm Limit Value

A1: EX. CURR. 0.2100 A

A2: METER SIZE 50 mm

A3: EX. FREQ. 24 Hz

B1: UNIT 1 m/s

C1: RANGE TYPE

C2: RANGE 1

C3: RANGE HYST

D1: DAMPING 05.0 SEC

D2: LOW CUT 05.0 %

E1: ZERO ADJUST 00.1 %

F1: DO1 FUNC. 1: H ALM

G1: COUNT RATE

G2: PLS. EIDTH

H1: PRESET 009000

I1: H. ALARM SET

I2: H. ALARM VAL

1:SINGLE

01.000 m/s

05.0 %

6.00E-1l

020 m/s

ON

+100.0 %

40

41

42

44

46

51

52

53

54

56

58

59

8.2.13

8.2.14

8.2.15

8.2.16

Empty Pipe Alarm

Rate-of-change Limit

Control Limit Time

Fixed-value Output

Zero Offset Adjustment

J1: EMPTY ALM ON

K1: LIMIT RATE

K2: LIMIT TIME

L1: FIXED OUT OFF

M1: MANUAL ZERO -000.1 %

40

05.5 %

01 SEC

62

63

65

68

Page 42

8.2 Checking or Changing Parameters

8.2.1 Excitation Current

Proceed as follows to check or change the excitation current setting value.

To check the exciting current setting value:

Key operation Display example Description

A1: EX. CURR.

0.2100A

SET

SET

To change the excitation current setting value:

A1: EX. CURR.

Press [SET] first to start the item selection sequence

and select

configuration items using

Then press [SET] again to display the exciting

current setting value.

Pressing [SET], the system returns to the items

selection sequence.

A1: EX. CURR.

[5]

from among the

[4]

and

keys.

IMPORTANT

The exciting current value is factory set when shipped. Do not change the value unless the

value differs from that written on the nameplate of the flowmeter.

The following example shows how to change the excitation current setting value from 0.1900A

to 0.2150A.

Key operation Display example Description

SET

4

5

A1: EX. CURR.

0.1900A

A1: EX. CURR.

0.1900A

A1: EX. CURR.

0.2900A

0.2100A

0.2150A

Press [SET] first to start the item selection sequence

and select

configuration items using

Then press [SET] again to display the excitation

current setting value (0.1900 A in this example).

Pressing

as many times as necessary to move the cursor to

the digit to be changed.

Change the value by pressing

cursor to another digit by pressing

the value. In this example repeat this process until

the display shows “0.2150A.”

A1: EX. CURR

[4]

, the cursor appears. Then press

from among the

[4]

and

[5].

(Note)

[5]

keys.

Then move the

[4]

and change

[4]

A1: EX. CURR.

SET

SET

Note:

The valid range is from 0.0500A to 0.2300A. If you try to set the value above 0.2300A,

the error message

A1: EX. CURR.

*

H. OVER SPEC appears. Set the value within the valid range.

0.2150A

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to save

the value.

Pressing [SET], the system returns to the items

selection sequence.

41

Page 43

8.2.2 Meter Size

Proceed as follows to check or change the meter size of the detector.

To check the meter size:

Key operation Display example Description

A2: METER SIZE

50 mm

SET

SET

To change the meter size:

IMPORTANT

Meter size is factory set when shipped. Do not change the meter size unless it differs from

the specified value.

The following example shows how to change the meter size from 50 mm to 100 mm.

Key operation Display example Description

SET

4

A2: METER SIZE

A2: METER SIZE

50 mm

A2: METER SIZE

50 mm

Press [SET] first to start the items selection

sequence

the configuration items using

Then press [SET] again to display the current

meter size.

Pressing [SET], the system returns to the items

selection sequence.

Press [SET] first to start the items selection

sequence

the configuration items using

keys. Press [SET] again to display the current

meter size (50 mm in this example).

Pressing

and select

and select

[4]

A2: METER SIZE

[4]

A2: METER SIZE

the cursor appears.

and

[4]

from among

[5]

keys

from among

[5]

and

A2: METER SIZE

5

A2: METER SIZE

SET

SET

Note:

The meter size is changed as shown below by pressing

the range between 15 mm (0.5 in) and 100 mm (4in).

2.5 mm 15 mm 100 mm 400 mm 0.1 in 0.5 in 4 in 16 in

If the meter size has been changed, other setting values (such as span and counting rate) will be

affected depending on the measuring unit used. Therefore, check those setting values if you

have changed the meter size.

A2: METER SIZE

100 mm

100 mm

Select “100 mm” by pressing

as necessary.

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

save the value.

Pressing [SET], the system returns to the items

selection sequence.

(Note)

[5].

[5]

as many times

However, select a size in

42

Page 44

8.2.3 Excitation Frequency

Proceed as follows to check or change the excitation frequency.

To check the excitation frequency:

Key operation Display example Description

A3: EX. FREQ.

24 Hz

SET

A3: EX. FREQ.

SET

To change the excitation frequency:

The excitation frequency can be selected from 6 , 12 and 24 Hz. The characteristics of the

flowmeter change in accordance with the selected frequency as shown below. 24 Hz is the

default setting when shipped from the factory.

Excitation frequency 6 Hz 12 Hz 24 Hz

Zero point stability Good

Press [SET] first to start the item selection

sequence and select

the configuration items using

keys. Then press [SET] again to display the

current excitation frequency.

Pressing [SET], the system returns to the items

selection sequence.

A3: EX. FREQ.

[4]

from among

and

[5]

Response time Good

Fluid noise resistant Good

43

Page 45

The following example shows how to change the excitation frequency from 24 Hz to 12 Hz.

Key operation Display example Description

SET

4

5

SET

SET

A3: EX. FREQ.

24 Hz

A3: EX. FREQ.

24 Hz

A3: EX. FREQ.

12 Hz

A3: EX. FREQ.

12 Hz

A3: EX. FREQ.

Press [SET] first to start the item selection

sequence and select

the configuration items using

keys. Press [SET] again to display the current

excitation frequency (24 Hz in this example).

Pressing

Select “12 Hz” by pressing

excitation frequency changes as follows:

6 Hz 12 Hz 24 Hz

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

save the value.

Pressing [SET], the system returns to the items

selection sequence.

[4],

A3: EX. FREQ.

the cursor appears.

[5]

from among

[4]

and

twice. The

[5]

44

Page 46

8.2.4 Indicating Unit

You can select one of the 16 engineering units listed below as an indicating unit.

Flow velocity:

•

Flow rate:

•

m/s, (ft/s)

m³/s, m³/min, m³/h

l

/s, l/min, l/h

ml/s, ml/min, ml/h

(gal/s), (gal/min), (gal/h)

Volumetric flow:

•

(totalized flow)

Other units:

•

m³, l, ml, (ga

%, COUNT (totalized flow without a unit), RANGE (1 to 4)

l)

Notes

1.

Units in parentheses, such as “gal” and “ft” are shown only when the meter size is

selected in inches. They are not shown when the meter size is selected in mm.

2.

If COUNT or RANGE is selected, the display is shown as follows:

COUNT: displays totalized flow counts (8 digits) without a unit.

RANGE: displays the range number (1 to 4).

Two indicating units (primary unit: UNIT 1, secondary unit: UNIT 2) can be selected.

Proceed as follows to check or change these two indicating units.

To check the indicating units:

Key operation Display example Description

B1: UNIT 1

%

SET

B1: UNIT 1

SET

Press [SET] first to start the items selection

sequence and select

configuration items using

Then press [SET] again to display the current

primary indicating unit.

Pressing [SET], the system returns to the items

selection sequence.

B1: UNIT 1

[4]

from among the

and

[5]

keys.

Primary indicating unit and secondary indicating unit can be selected by the following

configuration items:

B1: UNIT 1 primary indicating unit

B2: UNIT 2 secondary indicating unit

45

Page 47

To change the indicating unit:

The following example shows how to change the primary indicating unit from % to ml/s.

Key operation Display example Description

SET

4

5

4

5

SET

SET

B1: UNIT 1

%

B1: UNIT 1

%

B1: UNIT 1

ml

B1: UNIT 1

ml _

B1: UNIT 1

ml/s

B1: UNIT 1

ml/s

B1: UNIT 1

Press [SET] first to start the items selection

sequence to select

configuration items using

Then press [SET] again to display the current

primary indicating unit (% in this example).

Pressing

Select “ml” as the first unit of primary indicating

unit by pressing

(Note1)

Pressing [

(time unit) of primary indicating unit.

Select “s” as the second unit (time unit) of primary

indicating unit by pressing

necessary.

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

save the unit.

Pressing [SET], the system returns to the item

selection sequence.

[4]

4

], the cursor moves to the second unit

(Note 2)

B1: UNIT 1

[4]

, the cursor appears.

[5]

as many times as necessary.

[5]

from among the

and

as many times as

[5]

keys

Notes

1. The first unit (volumetric units etc.) changes as shown below:

% m³

RANGE COUNT (ft/s) m/s

Units in parentheses, such as “gal” and “ft” are shown only when the meter size is

selected in inches. They are not shown when the meter size is selected in mm.

2. The second unit (time unit) changes as shown below:

/s /min /h __

l ml

(gal)

46

Page 48

8.2.5 Span (range)

You can set the following constants in this setting item:

1. Range type

2. Span

3. Unit of span (can be changed only in range 1)

4. Hysteresis

(1) Range type

You can select a single range or multiple ranges. Select one from five types shown below:

Range type Description

1. SINGLE Single range

2. 4F-0R Unidirectional flow, automatic selection of multiple ranges

3. 2F-2R Bi-directional flows, automatic selection of multiple ranges

4. EXT.2F-0R

5. EXT.2F-2R

Unidirectional flow, multiple ranges selected by external

signal

Bi-directional flows, multiple ranges selected by external

signal

(2) Span (range)

Span can be set and displayed as follows for flow velocity and flow rates:

•

Flow velocity: 01.000 m/s (three digits after the decimal point)

•

Flow rates: 2.83E+3 m³/H (three digits and exponential)

Valid range of span is 0.1 m/s to 10 m/s in terms of flow velocity.

If you try to set the span outside of this range, one of the following messages appears:

*

H. OVER SPEC. (if the set value exceeds 10 m/s)

*

L. OVER SPEC. (if the set value is less than 0.1 m/s)

Try again to set the span within the specified range.

When multiple ranges are used, the following must be observed:

•

Range 1 > Range 2 > Range 3 > Range 4 (unidirectional flow, multiple ranges)

•

Range 1 > Range 2, Range 3 > Range 4 (bi-directional flows, multiple ranges)

If you try to set the ranges not conforming to the above, the following message appears:

*

MULTI RNG ERR

Try again to set the ranges as specified above.

Totalization counting rate

If you have changed the span while the counting rate is set for totalization, the counting

rate for 100% output may have exceeded the maximum counting capacity.

In this kind of event, the following message appears and the system goes to the counting

rate setting sequence.

*

H. OVER C RATE or L. OVER C RATE

Set the counting rate for the newly set span.

47

Page 49

(3) Unit of span

You can select one of the following 10 engineering units as a unit for the span. The unit is

set for the range 1 and the same unit applies automatically to other ranges—range 2, range

3 and range 4.

•

Flow velocity:

•

Flow rate:

m/s, (ft/s)

m³/s, m³/min, m³/h

l

/s, l/min, l/h

ml/s, ml/min, ml/h

(gal/s), (gal/min), (gal/h)

Units in parentheses, such as “gal” and “ft” are shown only when the meter size is selected

in inches. They are not shown when the meter size is selected in mm.

If you change the unit, the new span based on the newly set unit will be automatically

displayed.

(4) Hysteresis

The hysteresis is the dead band used when multiple ranges are switched. The hysteresis can

be set from 0 to 25% in increments of 0.1%. The hysteresis setting is needed only when

automatic selection of multiple ranges is used.

[The setting sequence]

The following is the setting sequence of span (range).

Span (range) item selection

Range type setting

Range 1 span and unit setting

Range 2 span setting

Range 3 span setting

Range 4 span setting

Hysteresis setting

If a single range is selected, range 2 to range 4 and hysteresis settings will be bypassed.

Proceed as follows to check or change each constant.

48

Page 50

To check each constant:

Key operation Display example Description

C2: RANGE 1

02.000 m/s

SET

C2: RANGE 1

SET

Range type, Span. Hysteresis can be selected by the configuration items as follows:

Range type C1: RANGE TYPE

Span of Range 1 C2: RANGE 1

Span of Range 2 C3: RANGE 2

Span of Range 3 C4: RANGE 3

Span of Range 4 C5: RANGE 4

Hysteresis C6: RANGE HYST

To change the range type:

Range type should be changed before changing the span.

Press [SET] first to start the items selection

sequence

configuration items using

Then press [SET] again to display the current span

for Range 1.

Pressing [SET], the system returns to the items

selection sequence.

and select

C2: RANGE 1

[4]

and

from among the

[5]

keys.

The following example shows how to change the range type from 1 to 3.

Key operation Display example Description

SET

4

5

SET

SET

C1: RANGE TYPE

1:SINGLE

C1: RANGE TYPE

1: SINGLE

C1: RANGE TYPE

3:2F-2R

C1: RANGE TYPE

3:2F-2R

C1: RANGE TYPE

Press [SET] first to start the items selection

sequence

among the configuration items using

[5]

current range type.

Pressing

Select Range type 3 (3: 2F-2R) by pressing

twice.

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

store the changed type.

Pressing [SET], the system returns to the items

selection sequence.

and select

keys. Then press [SET] again to display the

[4],

C1: RANGE TYPE

the cursor appears.

[4]

from

and

[5]

49

Page 51

To change the span (range):

The following example shows how to change the span of Range 1 from 2.0 m/s to 100 l/min.

Key operation Display example Description

SET

4

5

4

5

SET

SET

C2: RANGE 1

02.000 m/s

C2: RANGE 1

02.000 m/s

C2: RANGE 1

3.93E+0 l/s

2.36E+2 l/min

C2: RANGE 1

2.36E+2 l/min

C2: RANGE 1

1.36E+2 l/min

1.00E+2 l/min

C2: RANGE 1

1.00E+2 l/min

C2: RANGE 1

Press [SET] first to start the items selection

sequence and select

configuration items using

Then press [SET] again to display the current span

of Range 1 (2.0 m/s in this example).

Pressing

[4]

cursor to the position for the measuring unit.

Select “l” as the first unit of the measuring unit by

pressing

(Note1)

cursor to the second unit (time unit), select “min.”

(Note 2)

changes in accordance with the newly selected

unit.)

Press

the cursor to the digit of span to be changed.

Change the value by pressing

the cursor

change the value. In this example repeat this

process until the display shows “1.00E+2”(=100)

l

/m.

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

store the changed span and unit.

Pressing [SET], the system returns to the items

selection sequence.

[4],

as many times as necessary to move the

[5]

Similarly, pressing

(The displayed span automatically

[4]

as many times as necessary to move

to

C2: RANGE 1

[4]

the cursor appears. Then press

as many times as necessary.

another digit by pressing

from among the

[5]

and

[4]

to move the

[5]

Then move

[4]

keys.

and

Notes

1.

The first unit of the measuring unit changes as shown below:

m³ l m

m (ft) (gal)

Units in parentheses (ft and gal) are shown only when the meter size is selected in inches.

2. The second unit of the measuring unit changes as shown below:

/s /min /h

However, the following first and second unit combinations cannot be selected:

m/min, m/h, ft/min, ft/h.

l

50

Page 52

To change the hysteresis:

The hysteresis is set at 3% (default) when shipped from the factory.

The following example shows how to change the hysteresis from 3% to 5%.

Key operation Display example Description

SET

4

4

5

SET

SET

C6: RANGE HYST

03.0 %

C6: RANGE HYST

03.0 %

C6: RANGE HYST

03.0 %

C6: RANGE HYST

05.0 %

C6: RANGE HYST

05.0 %

C6: RANGE HYST

Press [SET] first to start the items selection

sequence

the configuration items using

Then press [SET] again to display the current

hysteresis (3.0% in this example).

Pressing

Press

to change.

Change the value to “5” by pressing [

(if necessary, move the cursor to another digit and

change the value).

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

store the changed hysteresis.

Pressing [SET], the system returns to the item

selection sequence.

and select

[4]

[4]

to move the cursor to the desired digit

C6: RANGE HYST

[4]

the cursor appears.

(Note)

from among

5]

and [

5]

keys.

twice.

Note:

If you try to set the hysteresis above 25.0 %, an error message “* H. OVER SPEC.”

appears. Try again to set the value within the specified range.

51

Page 53

8.2.6 Damping Constant

The damping constant is used to moderate output fluctuations. (The larger the damping

constant, the more the output is averaged. But the response to an input change will be slower.)

The damping constant can be set as follows:

0.0 sec, 0.5 sec and 1 to 60 sec (in increments of 1 second)

Note:

0.0 sec setting will work as equal to 0.1 sec damping constant.

Setting value exceeding 60 sec will be automatically set to 60 sec.

Proceed as follows to check or change the damping constant.

To check the damping constant:

Key operation Display example Description

D1: DAMPING

SET

D1: DAMPING

SET

To change the damping constant:

The following example shows how to change the damping constant from 0.5 sec to 10 sec.

Key operation Display example Description

D1: DAMPING

SET

D1: DAMPING

4

D1: DAMPING

02.0 S

00.5 S

00.5 S

10.5 S

5

10.0 S

D1: DAMPING

SET

D1: DAMPING

SET

10.0 S

Press [SET] first to start the items selection

sequence and select

the configuration items using [

keys. Then press [SET] again to display the

current damping constant.

Pressing [SET], the system returns to the items

selection sequence.

Press [SET] first to start the items selection

sequence and select

the configuration items using [

keys. Then press [SET] again to display the

current damping constant (0.5 S.)

Pressing [

(If necessary, press [

the digit to be changed.)

Change the value to “1” by pressing [

move the cursor to another digit by pressing

4]

[

repeat this process until the display shows “10.0

S.”

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

store this data..

Pressing [SET], the system returns to the items

selection sequence.

4],

and change the value. In this example

(Note)

D1: DAMPING

4]

D1: DAMPING

the cursor appears.

4]

to move the cursor to

from among

and [

from among

4]

and [

5].

5]

5]

Then

52

Page 54

8.2.7 Low Cutoff

The low cutoff is the value set just above 0% flow rate. Flow rates below this level are treated

as 0% and subsequent outputs as 0% current output. The low cutoff can be set from 0 to 10%

of the span and in increments of 0.1%.

Proceed as follows to check or change the low cutoff value.

To check the low cutoff value:

Key operation Display example Description

D2: LOW CUT

01.0 %

SET

D2: LOW CUT

SET

To change the low cutoff value:

The following example shows how to change the low cutoff value from 1.0 % to 3.0 %.

Key operation Display example Description

D2: LOW CUT

01.0 %

SET

D2: LOW CUT

01.0 %

4

Press [SET] first to start the items selection

sequence to select

configuration items using

Press [SET] again to display the current low cutoff

value.

Pressing [SET], the system returns to the items

selection sequence.

Press [SET] first to start the items selection

sequence and select

the configuration items using

keys. Press [SET] again to display the current low

cutoff value (1.0% in this example).

Pressing

[4]

changed.

[4]

to move the cursor to the digit to be

D2: LOW CUT

D2: LOW CUT

from among the

[4]

and

from among

[4]

the cursor appears. Then press

[5]

and

keys.

[5]

D2: LOW CUT

03.0 %

5

D2: LOW CUT

SET

D2: LOW CUT

SET

Note:

If you try to set the low cutoff value above 10 % of the span, an error message

*

H. OVER SPEC appears. Set the value within the specified range.

03.0 %

Change the value to “3” by pressing

(Note)

(If necessary, move the cursor to another digit by

[4]

pressing

Pressing [SET], the cursor disappears and the

changed display flickers. Press [SET] again to

store the value.

Pressing [SET], the system returns to the items

selection sequence.

53

and change the value.)

[5]

twice.

Page 55

8.2.8 Zero Adjustment

To conduct the zero adjustment of the flowmeter, the fluid in the detector pipe must be held

still. (If the fluid cannot be stilled by any means, see 8.2.16, “Zero Offset Adjustment.”)

To start the zero adjustment, follow the procedure described below.

Key operation Display example Description

E1: ZERO ADJUST

01.0 %

SET

ADJUST READY

4

* ZERO ADJUST

SET

SET

Notes

1. To cancel the zero adjustment, press

E1: ZERO ADJUST

E1: ZERO ADJUST

01.1 %

00.0 %

Press [SET] first to start the items selection

sequence

among the configuration items using

[5]

current flow rate (1.0% in this example).

Pressing

shown left and the system is ready for zero

adjustment.

Pressing [SET], “

shown left and the system starts the zero

adjustment. The zero adjustment takes about 3 to

6 seconds.

Newly adjusted zero point appears.

Pressing [SET], the system returns to the items

selection sequence.

[5]

and select

keys. Then press [SET] again to display the

[4]

(Note 1)

(Note 2)

. The system returns to the point where zero

E1: ZERO ADJUST

ADJUST READY

, “

* ZERO ADJUST

from

[4]

and

” appears as

” appears as

point is displayed.

2. Zero adjustment duration depends on the excitation frequency (24 Hz: 3 sec, 12 Hz and

6 Hz: 6 sec).

54

Page 56

8.2.9 Digital I/O

You can select the various digital I/O functions shown below. See Chapter 10 ,”Digital I/O

Functions.” for details.