Page 1

®

omega.com

1234.56 GPM

876543.21 >

User’s Guide

Shop online at

Flow

omega.com

TM

®

www.omega.com

e-mail: http://omegamanual.info

For latest information and

product manual visit

www.omegamanual.info.

ISO 9001

CERTIFIED

CORPORATE QUALIT Y

STAMFORD, CT

ISO 9002

CERTIFIED

CORPORATE QUALIT Y

MANCHESTER, UK

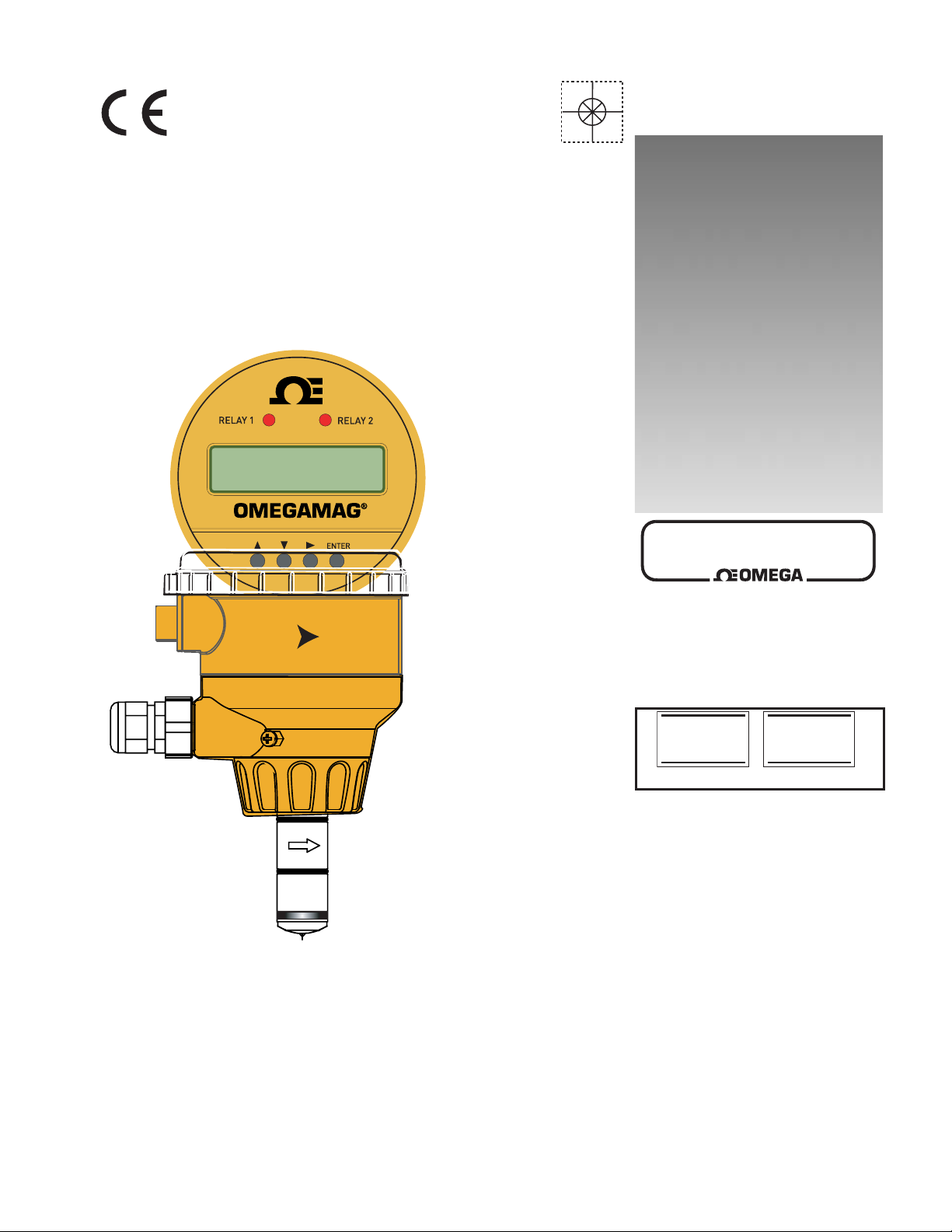

FMG-3000 SERIES Display version

Magmeter

Page 2

omega.com

omega.com

TM

®

OMEGAnet® Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certifi ed Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

®

Mexico: En Español: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé arm

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certifi ed Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-48

e-mail: sales@omega.co.uk

.

dy 1868, 733 01 Karvin. 8

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certifi cation of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certifi cation.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifi cations without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

3000 Series OMEGAMAG display version

6-2551.090-1-OM Rev. A 5/06

SAFETY INSTRUCTIONS

1. Depressurize and vent system prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

1.0 Description

The OMEGAMAG measures the fl ow rate in a full pipe by monitoring the voltage produced when the (conductive) fl uid moves through a

magnetic fi eld.

Output options include a traditional frequency signal and a 4-20 mA output.

The OMEGAMAG is available in two sizes that will accommodate pipes from ½ inch through 8 inch diameters.

Select from three different material combinations to match the magmeter to the application requirements.

Flow

Contents

1.0 Description 1

2.0 Specifi cations 2

3.0 Installation: Pipe fi ttings 3

3.1 Location of Fitting 3

3.2 Empty Pipe Detection 3

4.0 Overview of Display versions 4

5.0 Wiring 5

5.1 Basic Wiring 5

5.2 Wiring: Mirror Relay 1 output 5

5.3 FMG3000 and other manufacturer's instruments 5

5.4 Wiring to Omega Flow Instruments 6

5.5 Wiring Relays 6

6.0 View Menu 7

6.1 Resetting the Resetable Totalizer 7

6.2 Navigating the Menus 8

6.3 Keypad Functions 8

6.4 Security Code 8

7.0 Setup Menu 9

7.1 Averaging and Sensitivity 10

7.2 Bi-Directional Flow 11

7.3 Calibration Data 11

8.0 Calibration Menu 13

8.1 Volume method of calibration 13

8.2Rate method of calibration 13

9.0 Relay Menus 14

9.1 Pulse Relay mode 14

9.2 Total Relay mode 14

9.3 High, Low, or Window Relay modes 15

10.0 Test Menu 16

11.0 Options Menu 16

11.1 Output Modes 16

12.0 Technical Information 17

12.1 Grounding 17

12.2 Maintenance 18

12.3 Troubleshooting 18

13.0 Ordering Information 19

Page 4

2.0 Specifi cations

Wetted Materials:

• Sensor body and Electrodes/Grounding ring:

• -P0, -P1: Polypropylene and 316L Stainless Steel

• -V0, -V1: PVDF and Hastelloy-C

• -W0, -W1: PVDF and 316L Stainless Steel

• O-rings: FPM standard

optional materials: EPDM, Kalrez®

The user is responsible for determining the chemical

suitability of these materials for any specifi c

application.

• Case: PBT

• Display window: Polyamide

Power Requirements

• 4 to 20 mA: 21.6 to 26.4 VDC, 22 mA maximum

400 mV p-p maximum ripple voltage

• Frequency: 5 to 26.4 VDC, 15 mA maximum

• Digital: 4.5 to 6.5 VDC, 15 mA maximum

• Auxiliary: 9 to 24 VDC, 0.4 A maximum

• Reverse polarity and short circuit protected

Performance

• Pipe size range: ½ to 8 in. (DN15 to DN200)

• Flow Range Minimum: ±0.05 m/s (±0.15 ft/s)

(Bi-directional) Maximum: ±10 m/s (±33 ft/s)

• Linearity: ±(1% reading +0.1% of max range)

• Repeatability ±0.5% of reading @ 25°C (77°F)

• Minimum Conductivity: 20 µS/cm

Output Specifi cations

Current output (4 to 20 mA)

• Max Loop Resistance: 300Ω

• Loop Accuracy: 32 µA max. error

(@ 25°C, 24 VDC)

• Temp. drift: ±1 µA per °C max.

• Power supply rejection: ±1 µA per V

• Isolation: Low voltage <48 VAC/DC

from electrodes and aux power

• Maximum cable: 300 m (1000 ft.)

• Error condition: 22 mA

Relay Specifi cations

Relay 1&2 Type: Mechanical SPDT

• Rating: 5A @ 30 VDC max., 5 A @ 250 VAC max

Relay 3 Type: Solid State

• Rating: 50 mA @ 30 VDC, 50 mA @ 42 VAC

Hysteresis: User adjustable, plus delay timer

Trigger Delay: Adjustable

Relay Modes: Off, Low, High, Window, Proportional Pulse

Relay Source: Flow Rate, Resettable Totalizer

Error Condition: Selectable; Fail Open or Closed

Display Specifi cations

Characters: 2 x 16 alpha-numeric

Contrast: User-set in four levels

Backlighting: requires external 9-24 VDC, 0.4 mA max.

(available on models with relays only)

Environmental

• Enclosure rated NEMA 4X/IP 65

• Storage Temperature: -20°C to 70°C (-4°F to 158°F)

• Relative Humidity: 0 to 95% (non-condensing)

• Operating Temperature

Ambient: -10° to 70°C (14°F to 158°F)

Media: 0° to 85°C (32°F to 185°F)

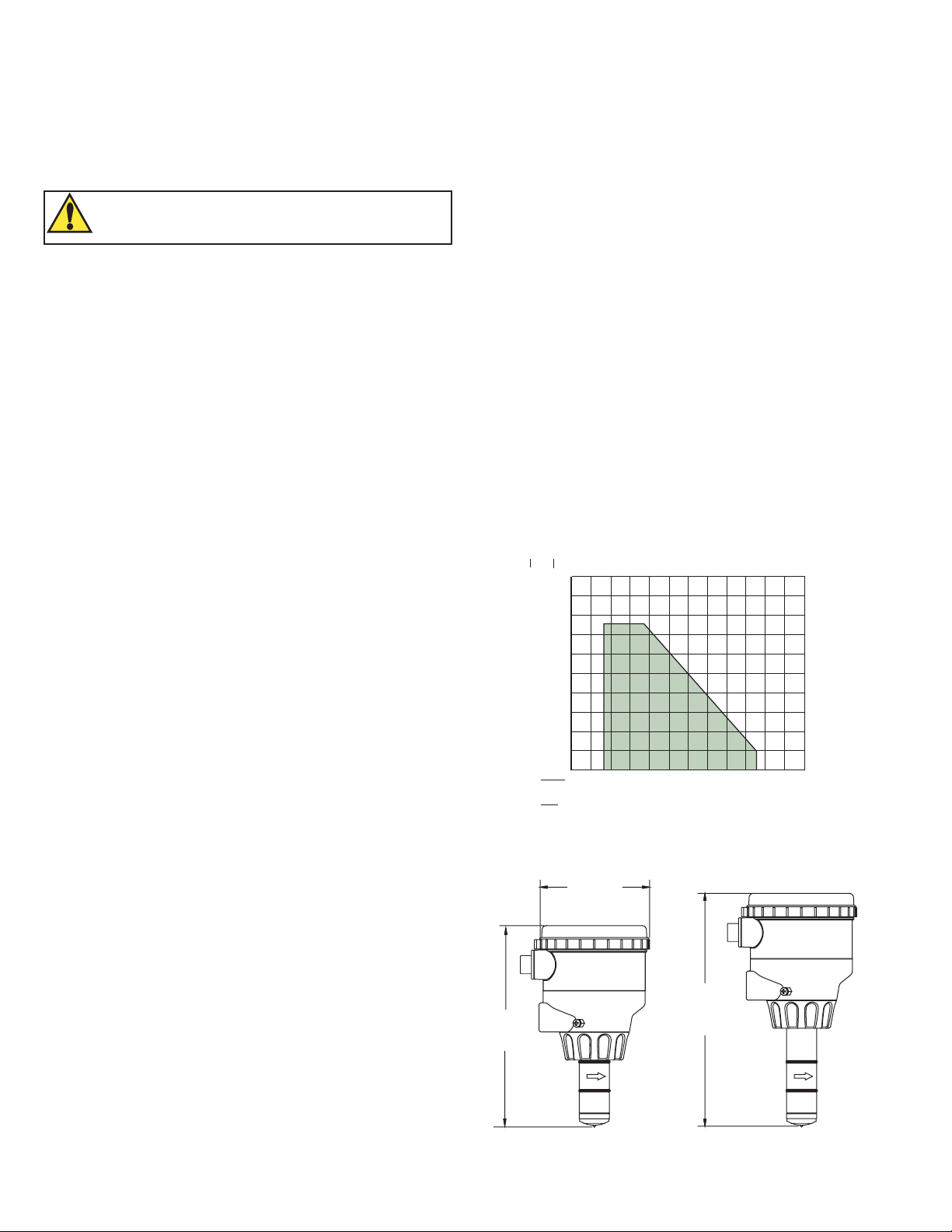

Max. operating pressure: 10.3 bar @ 25°C (150 psi @ 77°F)

1.4 bar @ 85°C (20 psi @ 185°F)

Pressure vs. Temperature

psi

bar

200

14

160

11

8

120

6

80

3

40

Operating Pressure

Acceptable

Media Range

Frequency output:

• Output modes: Freq, Freq÷10, or Mirror Relay 1

• Max. Pullup Voltage: 30 VDC

• On state voltage drop: <0.8 V @ 20 mA

• Short Circuit Protected: ≤30 V @ 0Ω pull-up for one hour

• Reverse Polarity Protected -40 V

• Overvoltage Protected to 40 V with pullup resistor

• Max. Current Sink: 50 mA, current limited

• Maximum cable: 300 m (1000 ft.)

Tests, Approvals & Standards

• UL, CUL listed

• CE:

• EN61326: Immunity & Emissions for Control Equipment

• EN61010: Safety

2

°F

°C

Dimensions

174.5 mm/

6.87 in.

Magmeter w/Display

for ½ in. to 4 in. pipe

0 40 80 120 160 200

-18 4

27

49

71 93

Media Temperature

95.3 mm/

3.75 in.

207.5 mm/

8.17 in.

Magmeter w/Display

for 5 to 8 in. pipe

240

115

Page 5

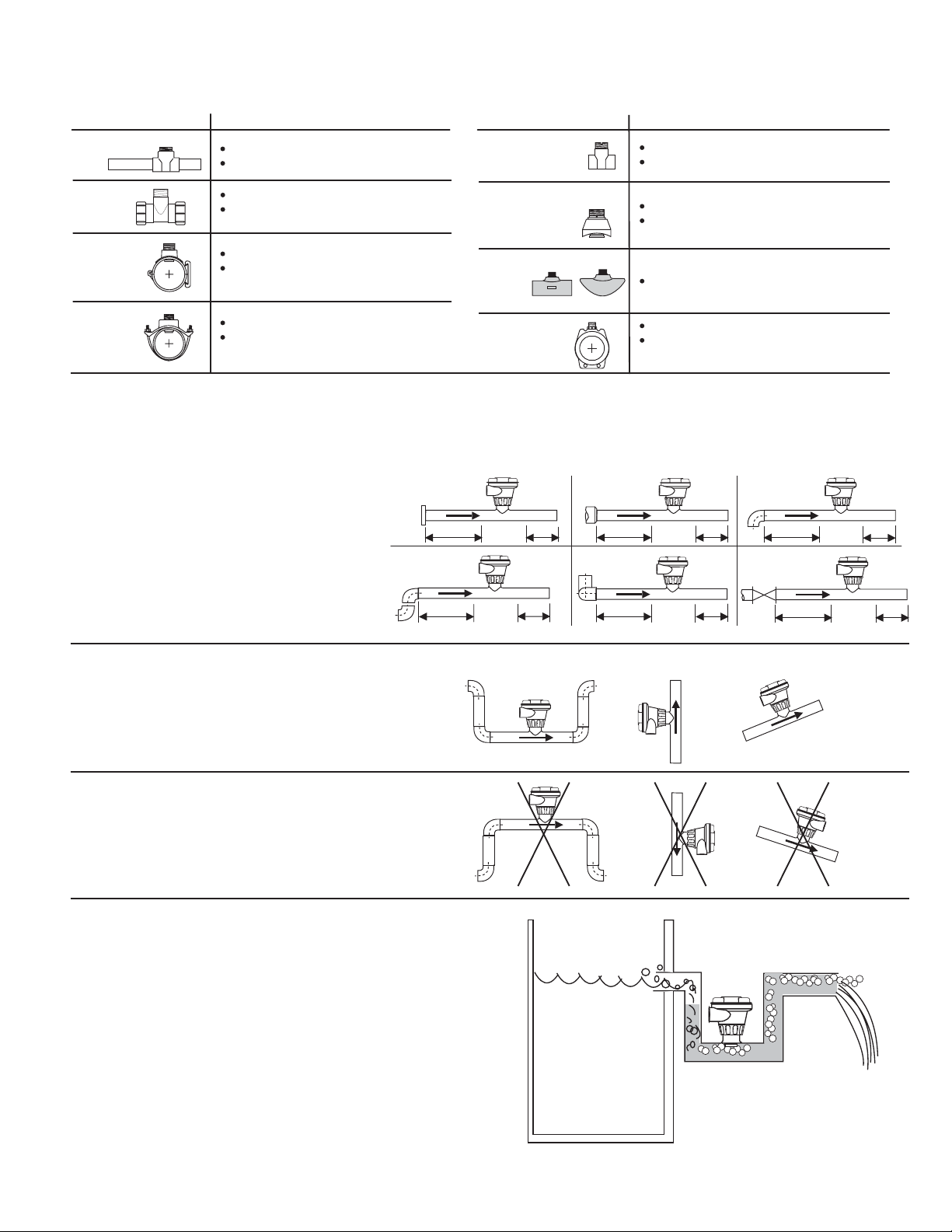

3.0 Installation: Pipe fi ttings

Omega offers a wide selection of installation fi ttings that control the position of the magmeter electrodes in relation to the dimensions of

the pipe. You will fi nd a complete list of order numbers for installation fi ttings in the K-factor table in section 7.3.

Type Description

Plastic tees

0.5 to 4 inch versions

PVC or CPVC

Metric

Union

Fitting

For pipes from DN 15 to 50 mm

PP or PVDF

Type Description

Iron, Carbon Steel,

316 SS Threaded

tees

0.5 to 2 in. versions

Mounts on threaded pipe ends

Carbon steel &

stainless steel

Weld-on

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

Weldolets

PVC

Saddles

Iron

Strap-on

saddles

2 to 4 inch, cut 1-7/16 inch hole in pipe

6 to 8 inch, cut 2-1/8 inch hole in pipe

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

Fiberglass

tees &

saddles:

Metric

Wafer Fitting

FPT

1.5 in. to 8 in. PVDF insert

FPS

For pipes DN 65 to 200 mm

PP or PVDF

3.1 Location of Fitting

The magmeter can only measure fl ow if the pipe is full.

If the piping system has entrained air pockets, take steps to locate the sensor so the air pockets will not contact the electrodes.

Inlet Outlet

Flange

10 x I.D. 5 x I.D.

+GF+

Reducer

15 x I.D. 5 x I.D.

+GF+

90° Elbow

20 x I.D. 5 x I.D.

+GF+

Select a location with suffi cient distance of

straight pipe immediately upstream of the sensor.

2 x 90° Elbow

+GF+

2 x 90° Elbow

3 dimensions

+GF+

Valve/Pump

+GF+

25 x I.D. 5 x I.D.

These confi gurations guarantee that the pipe is always

fi lled. The sensor cannot be exposed to air bubbles.

Avoid these situations unless you are certain that the

sensor will not be exposed to air bubbles.

In a gravity-fl ow system, the tank must be designed so the level

does not drop below the outlet.

This causes the pipe to draw air in from the tank.

If air bubbles pass across the Magmeter electrodes, the output

will become erratic.

3.2 Empty Pipe Detection

40 x I.D. 5 x I.D.

50 x I.D. 5 x I.D.

O.K.O.K. O.K.

+

F

G

+

GF

+GF+

+GF+

+

Vertical flow is OK IF the pipe remains full at all times.

+

GF

+

+GF+

+

+

G

F

+

If the pipe is not full, or the electrodes are not immersed, the

fl ow display will show zero and all output functions will behave

accordingly.

If the magmeter electrodes are exposed to fl ow transitions and air

bubbles, the measurement may be incorrect until the conditions

are stabilized.

3

Page 6

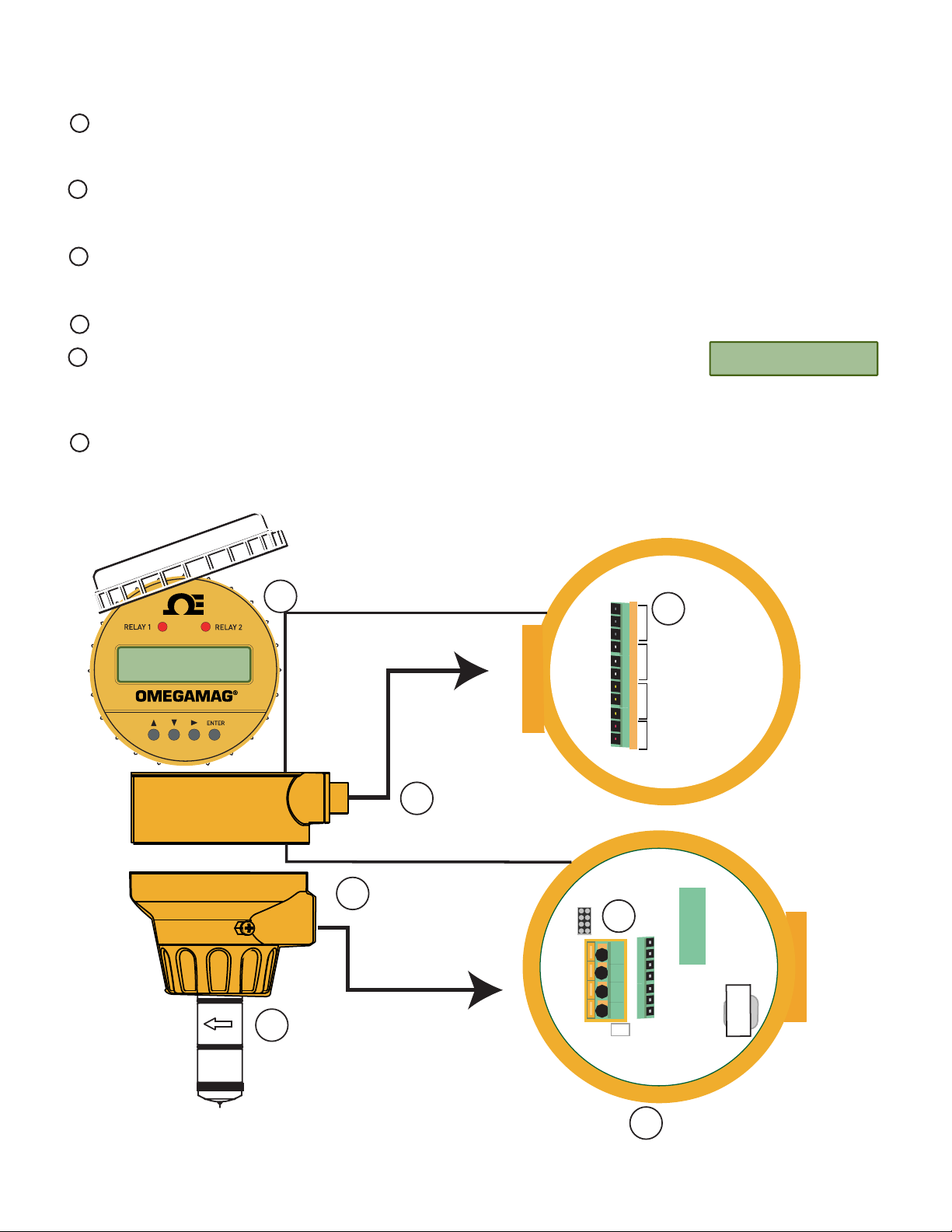

4.0 Overview of Display Magmeter

Display Magmeters use a dual-sided electronics module and dual conduit ports. Unused ports must be sealed to prevent corrosion and

moisture from entering the circuitry.

1. The lower set of conduit ports provide access to the wiring terminals for:

• Loop Power

• Flow Output Signal, whether it is a current loop, a frequency or the Mirror Relay 1 output.

2. The upper set of conduit ports provide access to the wiring terminals for:

• Relay output wiring

• Auxiliary power for relay coils and display backlight

3. The sensor is marked with a directional arrow to indicate the direction identifi ed as forward fl ow.

An adhesive decal is also provided that can be affi xed to the pipe to indicate the direction of forward fl ow.

Flow in the opposite direction from the arrow will be identifi ed as reverse fl ow on the display by a "-" symbol.

4. The terminals in the magmeter are designed to accomodate 14 to 22 AWG conductors.

5. The display includes two LEDs that light when Relay 1 or Relay 2 are activated.

• All three relays can be monitored by scrolling to the Relay Status display located in the View

English >

menu.

• If the Language option has not been made, new magmeters will always open with the Select Language display.

6. The part number, serial number and output type are identifi ed on the electronics module.

®

420 GPM

123456.78 >

5.

Relay Outputs

Auxiliary Power

NO1

NC1

NO2

NC2

NO3

NC3

4.

Relay 1

C1

Relay 2

C2

Relay 3

C3

V+

V-

Aux Pwr

2.

Language

1.

4-20 mA Loop Out

Digital Out

Frequency Out

Mirror Relay 1 Out

3.

4.

4

3

2

1

s/n 60504201234

60504201234

p/n 3-2551-11

3-2551-11

4-20/freq out

6.

4

Page 7

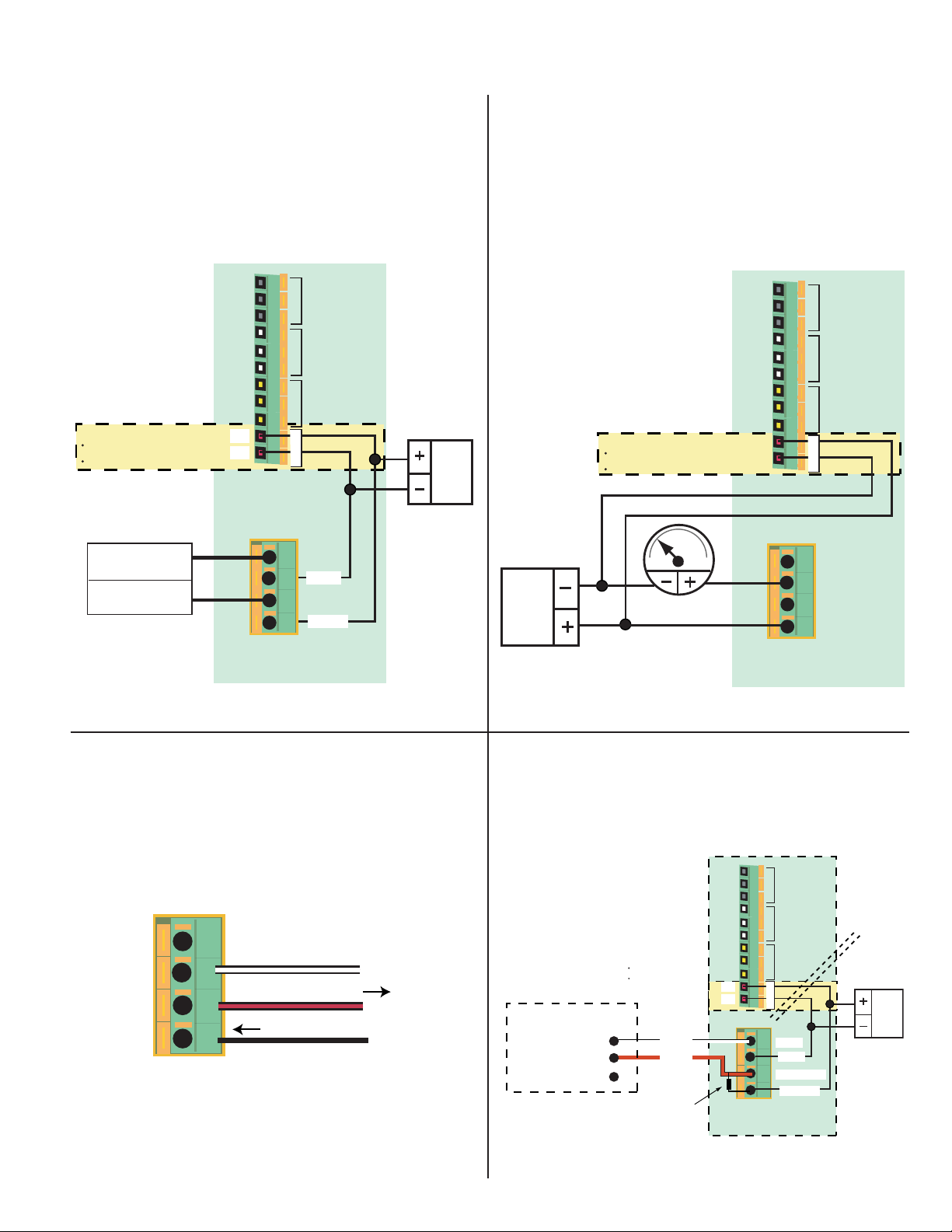

5.0 Wiring

5.1 Basic Wiring

Frequency output

• FMG3001 and FMG3101 OMEGAMAGs may be

programmed to provide an open collector FREQUENCY

output.

• The maximum frequency output is 1000 Hz (@ 10 metres per

second)

• If the Frequency ÷ 10 output is selected, the maximum

frequency is 100 Hz (@ 10 meters per second)

• AUX PWR must be connected to power the display

backlighting and to power the relay coils if included.

NO1

Auxiliary Power for:

Display backlighting

Relay Coils

NC1

C1

NO2

NC2

C2

NO3

NC3

C3

V+

V-

Relay 1

Relay 2

Relay 3

Aux Pwr

VDC

4.5-26.4

4-20 mA output

FMG3002 and FMG3102 OMEGAMAGs provide a passive 4-20

mA loop output.

• External loop power (24 VDC) is required.

• Factory standard calibration is 4 - 20 mA = 0 - 5 m/s.

• The 4-20 mA output can be spanned to any range, from -10

m/s to +10 m/s.

• AUX PWR must be connected to power the display

backlighting and to power to the relay coils if included.

NO1

Auxiliary Power for:

Display backlighting

Relay Coils

NC1

C1

NO2

NC2

C2

NO3

NC3

C3

V+

V-

Relay 1

Relay 2

Relay 3

Aux Pwr

Ground

Signal

Frequency Out

4

- VDC

3

2

+ VDC

1

Frequency ÷ 10 Out

(5 to 26.4 VDC)

Magmeter

5.2 Wiring: Mirror Relay 1 output

The FMG3001 and FMG3101 OMEGAMAGs can be confi gured

to provide an Open Collector output in lieu of the sensor signal

provided by Frequency output selection. The Open Collector

Output can be programmed via the Relay 1 menu.

Magmeter

Not used

4

Ground

3

Open Collector Out

2

1

5-24 VDC

4

3

2

1

- VDC

+ VDC

21.6 to

26.4 VDC

4

20

4-20 mA Loop Output

Magmeter

5.3 The OMEGAMAG and other manufacturer's instruments

When using the magmeter in a system with other manufacturer's

equipment, a pull-up resistor may be required to power the open

collector output.

NO1

Other Manufacturers

Flow Instrument

Ground

Frequency Input

5-24 VDC Out

Auxiliary Power for:

Display backlighting

Relay Coils

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

10 KΩ

Pull-up Resistor

NC1

NO2

NC2

NO3

NC3

C1

C2

C3

V+

V-

Magmeter

Relay 1

Relay 2

Relay 3

Aux Pwr

4

Ground

3

Frequency Out

2

1

24 VDC

Ground

5-24 VDC

5

Page 8

NC3

y

C3

5.4 Wiring to Omega Flow Instruments

The OMEGAMAG and FP90 series Flow Transmitters

When connecting the magmeter to any FP90 model Transmitter, the AUXILIARY power in the FP90 must always be connected.

V+

To

12-24 VDC

Power Source

System Pwr

4

Loop -

System Pwr

3

Loop +

AUX

2

Power -

AUX

1

Power +

Terminals 3-4: 4-20 Loop, Loop Power

Terminals 1-2: Auxiliary Power

FP90 Flow Transmitter

Output -

6

Output +

5

Open Collector

Output

9

8

7

Sensor Input

from

Magmeter

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

V-

Magmeter

Aux Pwr

4

Ground

Ground

3

Frequency Out

2

5-24 VDC

1

24 VDC

OMEGAMAG and FPM5500, FPM9020A

Auxiliary Power for:

Display backlighting

Relay Coils

FPM5500, FPM5600A

12-24 V

10 W

+

-

+

AUX

output

2

+

1

Gnd

Tot a l

reset

4-20

mA

-

12-24 V

10 W

Std. Sensor

Freq. IN

Freq. IN

Sen. Pwr.

Open Collector

Sensor

+

PLS

Iso. Gnd

output

Gnd

5.5 Wiring Relays

Relay 1, Relay 2 Type: Mechanical SPDT

Rating: 5A @ 30 VDC max., 5 A @ 250 VAC max

Relays 1 and 2 are dry contact relays rated for 5 A maximum current.

Relays 1 and 2 are best suited for switching high voltage loads, such as AC

powered pumps and valves.

When used to switch inductive loads, dry contact relays may be damaged by

arcing. Omega recommends the installation of a fi lter device to prevent such

damage.

FP90RC RC Filter kit (for relay use)

C3

V+

V-

Magmeter

NO1

NC1

NO2

NC2

4

3

2

1

C1

C2

Rela

Aux Pwr

Ground

Ground

Frequency Out

5-24 VDC

24 VDC

Relay 1

Mechanical Relays:

5A @ 250 VAC

5A @ 30 VDC

Relay 2

Relay 3 Type: Solid State

Rating: 50 mA @ 30 VDC, 50 mA @ 42 VAC

Relay 3 is a solid state relay. It can be applied exactly the same as a dry

contact relay, but the current rating is 0.2 A (200 mA) maximum. Relay 3 is

best suited to pulse applications and low voltage loads.

Relay Terminal Legend:

NO: Normally Open

NC: Normally Closed

C: Common

6

Auxiliary power must be connected to operate the relays and to

power the display backlighting. Auxiliary power is fully isolated.

The Loop Power supply may be used for Aux power if the power

source provides a suffi cient current rating.

NO3

NC3

C3

V+

V-

Solid State Relay 3:

50 mA max @ 30 VDC

Relay 3

50 mA max @ 42 VAC

Auxiliary Power

9 to 24 VDC

0.4 A Maximum

Page 9

6.0 View Menu

The VIEW menu contains all of the basic information available from the magmeter.

• The normal operating display shows the FLOW RATE on the top line of the display and

the Resetable Totalizer on the lower line of the display.

• The Right Prompt symbol (>) always indicates a sub-menu associated with the current

display. In this display it points the way to the TOTALIZER RESET function. See section

6.1 for detailed instructions.

• With AUXILIARY power connected to the magmeters with Relays, the display will be

backlit. There is no switch to turn the backlight off.

• A fl ashing character or text on the display indicates that the item is being edited.

This manual uses a (red) star to illustrate a fl ashing display.

• The following information is viewed by scrolling UP or DOWN. These displays will remain

in the display for 10 minutes, then the normal operating display will return.

Show the permanent total. This totalizer cannot be reset.

Shows the current output. For 4-20 mA Output models only.

Relay States shown for units with a relay board.

®

1234.56 GPM

876543.21 >

Gallons

Perm 876543.21

Current Output

14.89 mA

Relay 1 2 3

Off Off Off

6.1 Resetting the Resetable Totalizer

®

1234.56 GPM

876543.21 >

1234.56 GPM

876543.21 >

Enter Code

0000

Reset Total ?

Yes No

Enter menus from this display. See section 6.2.

>

Enter Menu

1. From the normal operating display, press the RIGHT arrow key.

2. The resetable totalizer can be confi gured to require the security code before allowing the

reset. If the Total Reset set to "RESET OFF" this display will not appear.

See section 11, Options Menu for instructions.

3. Press any arrow key to toggle the fl ashing selection from NO to YES.

123456.78 GPM

000000.00 >

4. Press the ENTER key. The totalizer will reset to 000000.00 and the display will immediately

return to the normal operating display.

7

Page 10

6.2 Navigating the Menus

Normal Operation Display

The normal operating display shows the Flow Rate on the top line and the Resetable

Totalizer on the bottom line.

• All menu instructions in this manual assume that the instrument is showing this

display.

Menu Directory

The magmeter uses seven main menus to provide access to the calibration and

programming features. Each menu serves a specifi c function.

Starting from the normal operating display, there are two ways to access the menus:

1. Press the UP arrow key to scroll to the Enter Menu display, then press the RIGHT

arrow key.

2. Press the ENTER key and hold it for about three seconds.

Setup Menu

This menu contains all of the settings and information that the magmeter requires to

operate, including the K-factor, the totalizer settings, low fl ow cutoff, and several display

Calibration Menu

The Calibration menu provides two different methods for adjusting the calibration. See

section 8.0 for details related to this menu.

Relay Menus

Each of the available relays in the FMG3001 and FMG3002 are programmed from their

own dedicated menu. See section 9 for details related to these menus.

Note: Menu items associated with Relay 2 and relay 3 are suppressed in models without

relays. See section 9.0 for details related to this menu.

1234.56 GPM

876543.21 >

Enter Menu

>

Enter Menu

Setup >

Enter Menu

Calibration >

Enter Menu

Relay 1 >

Enter Menu

Relay 2 >

®

ENTER

Or

3s

Test Menu

The Test menu is used to manually toggle relays or to induce a known value out of the 420 mA terminals. See section 10.0 for details related to this menu.

Options Menu

The Options menu contains those settings and values that are usually programmed during

the initial installation, and then seldom modifi ed, including the SECURITY CODE (see

section 6.4). See section 11.0 for details related to the Options menu.

6.3 Keypad Functions

6.4 Security Code

The magmeter has a security code that can be programmed to

Scrolls UP through any menu.

If the display shows any fl ashing character or selection,

scrolls UP to the previous value or selection.

any four digit numerical value.

• The factory setting is 0-0-0-0.

• To program the security code go to the Options menu.

• The security code will be required to edit any of the items in

Scrolls DOWN through any menu.

If the display shows any fl ashing character or selection,

scrolls DOWN to the next value or selection.

the menus. It is required only once for each editing session.

• Record the custom security code here or in a safe location.

• If the security code is lost, contact your Omega service

center for instructions.

Press the UP and DOWN keys together to abandon any

unsaved edits and return to the previous display.

Opens the menu currently being displayed.

In Edit modes, advances the fl ashing character.

In menus with only two options (Yes or No, On or Off)

toggles between selections.

Security Code ______ ______ ______ ______

ENTER

Saves a new selection in any menu.

From Normal Operation display, jumps to fi rst selection

in Menu directory (when held for three seconds)

Enter Menu

Relay 3 >

Enter Menu

Test >

Enter Menu

Options >

Enter Code

0000

WRITE IT DOWN!

8

Page 11

7.0 Setup Menu

The Setup menu contains all of the parameters necessary for the OMEGAMAG to begin measuring

fl ow.

®

NOTE: The Security Code must be entered before any changes can be made to the Setup menu.

See the Options menu in section 11 for details.

Enter Menu

Setup >

Enter Code

0000

Use the keypad to navigate through each setting.

ENTER

K-Factor: See the charts in section 7.3 for values in pulses per U.S. Gallon or in pulses

per Liter. To use other units, convert the published values as appropriate.

The values shown for each menu item represent the factory

standard setting. All magmeters are packaged with these

settings.

K-Factor

060.000 >

Pipe Size: Select the pipe size that is nearest to the nominal pipe size.

Pipe Size

2” DN50 >

Flow Units: Set the units for the application. Four characters are available. The fi rst three characters can be set to any symbol or

alpha character, upper or lower case. The following special symbols are located between the upper case and lower case menus:

• (centered dot) µ (micro) _ (blank)

- (dash) / (slash) 3 (for cubic units)

Flow Units

The last character selects the timebase for the fl ow rate measurement.

Select S/s (seconds) M/m (minutes), H/h (hours) or D/d (days)

GPM >

Set 4 mA: In the FMG3002 and FMG3102 versions only, set the fl ow rate where the current

output will be 4 mA.

Set 20 mA: In the FMG3002 and FMG3102 versions only, set the fl ow rate where the

current output will be 20 mA.

The 4-20 mA output may be spanned to monitor forward and reverse fl ow rates.

Total Factor: Set the factor by which the totalizer will count. This setting is made in the

application units (ie; gallons, liters, etc..)

Totalizer Units: Set the Totalizer Units. This setting serves as a label for the totalizer

displays only. It has no effect on the measurement. The special characters listed in the

Total Factor settings are available here also.

Low Flow Cutoff: Set a fl ow rate that the magmeter will use as a minimum threshhold. If

the fl ow rate falls below this value, the magmeter will respond as if the fl ow were zero.

Averaging: Set the averaging period based on the installation and fl ow conditions. Smaller

values allow the magmeter to respond to changes in fl ow rate quickly, while larger values

smooth the fl uctuations caused by installation and fl ow conditions. See section 7.1 for

details.

Set 4 mA

-100 GPM >

Set 20 mA

100.00 GPM >

Total Factor

1000.0 >

Totalizer Units

Gallons >

Low Flow Cutoff

0.5 GPM >

Averaging

25 secs >

Sensitivity: Set a percentage of maximum range by which the fl ow must change to

override the averaging feature and "jump" quickly to the new fl ow rate. See detailed

explanation in section 7.1.

Sensitivity

100% >

9

Page 12

7.1 Averaging and Sensitivity

Even the most carefully engineered fl ow systems may experience

erratic and unstable conditions. If the instability is communicated

to the output functions, the results may create problems for

control devices.

To alleviate these issues, the magmeter provides two adjustments

that operate in tandem. The information here will help in

determining the appropriate settings for any specifi c application.

Averaging

• The AVERAGING setting dictates the time over which the

magmeter will average the fl ow signal.

The LCD display is updated every second. With averaging at

14 seconds, the fl ow rate on the display is an average of the

previous 14 seconds input.

Short averaging times provide the fastest display and output

response to changes in the fl ow rate.

Higher averaging times help to smooth the display and

current output where the fl ow in the pipe is erratic or unstable

due to installation limitations.

Sensitivity

• The SENSITIVITY setting determines how the magmeter

responds to sudden surges in the fl ow rate. It "overrides"

the Averaging function just long enough to allow an actual

change in fl ow rate to be displayed, then resumes the

averaging. The result is a smooth fl ow display and a quick

response to large shifts in the fl ow rate.

No Averaging

With AVERAGING set to zero, the fl ow rate will be displayed

immediately and with no fi ltering. This line represents the

actual output of the fl ow sensor as it responds to unstable fl ow

conditions in the pipe.

Velocity

Time

10 s 20 s 30 s 40 s 50 s 60 s 70 s

Averaging Only

With AVERAGING set to 50 seconds and SENSITIVITY still set to

zero the fl ow rate is stabilized, but a sharp change in fl ow rate is

not represented on the display or at the output for 50 seconds or

longer.

Velocity

The settings for Sensitivity represent a percentage of the

magmeter's maximum range, or 10 m/s.

Example: A sensitivity setting of 25% means that the fl ow

rate must change instantly and by more than 2.5 m/s before

the function is enabled.

NOTE: The SENSITIVITY function is ineffective if the Averaging

function is set to zero.

CAUTION

The SENSITIVITY function changes the response

characteristics of the magmeter. If used as part of a

tuned closed loop control system such a change may be

undesirable.

Time

10 s 20 s 30 s 40 s 50 s 60 s 70 s

Averaging and Sensitivity

With AVERAGING at 50 seconds and SENSITIVITY set to

25%, the fl ow rate is stabilized, while the sudden shift in fl ow is

refl ected very quickly.

Velocity

Time

10 s 20 s 30 s 40 s 50 s 60 s 70 s

10

Page 13

7.2 Bi-Directional Flow

• The magmeter is designed to measure bi-directional fl ow.

• The forward fl ow direction is indicated by the directional arrow molded into the side

Flow

of the magmeter sensor.

• The conduit ports are assembled at the factory to point UPSTREAM. They may be reversed by

disassembling the components of the magmeter and reassembling.

Flow Rate Display: The "+" sign is suppressed during forward fl ow.

"-123.45 GPM" during reverse fl ow.

Totalizer Display: The totalizer will count during forward fl ow conditions only.

During reverse fl ow the totalizer will not increment.

Relay Outputs: May be set to detect reverse fl ow: "Low Setpoint at -25GPM."

4-20 mA output: May be scaled to span any fl ow range:

For example: "4 to 20 mA = -100 GPM to +100 GPM"

Frequency output, Frequency ÷ 10 output: Reverse fl ow is processed same as forward fl ow in the frequency output magmeters.

7.3 Calibration Data: K-factors

Plastic Installation Fittings:

PVC Tees and Saddles

PIPE SIZE FITTING K-Factor K-Factor

(IN.) TYPE Gallons Liters*

SCH 80 PVC TEES FOR SCH 80 PVC PIPE

½ FP-5305 2289.37 604.85

¾ FP-5307 1430.41 377.92

1 FP-5310 876.86 231.67

1¼ FP-5312 447.06 118.11

1½ FP-5315 324.19 85.65

2 FP-5320 206.69 54.61

2½ FP-5325 131.46 34.73

3 FP-5330 82.52 21.80

4 FP-5340 44.78 11.83

SCH 80 PVC TEES FOR SCH 80 CPVC PIPE

½ FP-5305C 2496.03 659.45

¾ FP-5307C 1381.48 364.99

1 FP-5310C 857.98 226.68

1¼ FP-5312C 445.17 117.61

1½ FP-5315C 325.56 86.01

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE

2 FP-5320S 193.83 51.21

2½ FP-5325S 138.01 36.46

3 FP-5330S 83.89 22.16

4 FP-5340S 40.88 10.80

6 FP-5360S 22.53 5.95

8 FP-5380S 12.52 3.31

SCH 80 PVC SADDLES FOR SCH 40 PVC PIPE

2 FP-5320S 180.01 47.56

2½ FP-5325S 123.72 32.69

3 FP-5330S 75.81 20.03

4 FP-5340S 41.87 11.06

6 FP-5360S 19.71 5.21

8 FP-5380S 11.73 3.10

Carbon Steel Tees and Weld-o-Lets

Stainless Steel Tees and Weld-o-Lets

Galvanized Iron Tees

PIPE SIZE FITTING K-Factor K-Factor

(IN.) TYPE Gallons Liters*

CARBON STEEL TEES ON SCH 40 PIPE

½ FMG-5305CS 1572.66 415.50

¾ FMG-5307CS 1086.73 287.11

1 FMG-5310CS 582.34 153.86

1¼ FMG-5312CS 377.48 99.73

1½ FMG-5315CS 267.79 70.75

2 FMG-5320CS 167.85 44.35

STAINLESS STEEL TEES ON SCH 40 PIPE

½ FMG-5305 1601.26 423.05

¾ FMG-5307 937.78 247.76

1 FMG-5310 606.18 160.15

1¼ FMG-5312 279.68 73.89

1½ FMG-5315 147.65 39.01

2 FMG-5320 111.90 29.56

STAINLESS STEEL WELDOLETS ON SCH 40 PIPE

2½ FMG-5325 106.31 28.09

3 FMG-5330 72.27 19.09

4 FMG-5340 36.84 9.73

4 FMG-5350 29.28 7.73

4 FMG-5360 20.29 5.36

8 FMG-5380 11.73 3.10

CARBON STEEL WELDOLETS ON SCH 40 PIPE

2½ FMG-5325CS 105.70 27.93

3 FMG-5330CS 70.68 18.67

4 FMG-5340CS 36.38 9.61

4 FMG-5350CS 29.28 7.73

6 FMG-5360CS 20.29 5.36

8 FMG-5380CS 11.73 3.10

GALVANIZED IRON TEES ON SCH 40 PIPE

1 FP-5310GI 558.50 147.56

1¼ FP-5312GI 334.45 88.36

1½ FP-5315GI 248.97 65.78

2 FP-5320GIS 146.00 38.57

11

Page 14

7.3 Calibration Data: K-factors

Polypropylene True Union Tees and Wafers

PVDF True Union Tees and Wafers

PVC True Union Tees and Wafers

PIPE SIZE FITTING K-Factor K-Factor

(IN.) TYPE Gallons Liters*

POLYPROPYLENE FITTINGS (DIN/ISO ,BS, ANSI)

1/2" FP-5105PO 2192.73 579.32

3/4" FP-5107PO 1327.81 350.81

1" FP-5110PO 737.16 194.76

1-1/4" FP-5112PO 453.46 119.81

1-1/2" FP-5115PO 275.03 72.66

2" FP-5120PO 156.87 41.45

2-1/2" FP-5125PO 108.80 28.74

3" FP-5130PO 68.50 18.10

4" FP-5140PO 44.38 11.73

5" FP-5150PO 32.30 8.53

6" FP-5160PO 18.37 4.85

8" FP-5180PO 9.80 2.59

PVDF FITTINGS (DIN/ISO ,BS, ANSI)

1/2" FP-5105 1946.49 514.26

3/4" FP-5107 1158.05 305.96

1" FP-5110 749.09 197.91

1-1/4" FP-5112 439.51 116.12

1-1/2" FP-5115 248.93 65.77

2" FP-5120 146.85 38.80

2-1/2" FP-5125 104.84 27.70

3" FP-5130 72.01 19.02

4" FP-5140 46.82 12.37

5" FP-5150 31.93 8.44

6" FP-5160 18.78 4.96

8" FP-5170 11.86 3.13

12

Metal Installation Fittings

Iron Saddles

PIPE SIZE FITTING K-Factor K-Factor

(IN.) TYPE Gallons Liters*

SCH 80 IRON SADDLE ON SCH 80 PIPE

2 FP-5320GI 194.85 51.48

2½ FP-5325GI 142.28 37.59

3 FP-5330GI 87.53 23.13

4 FP-5340GI 40.62 10.73

5 FP-5350GI 29.28 7.74

6 FP-5360GI 22.30 5.89

8 FP-5380GI 12.52 3.31

SCH 80 IRON SADDLE ON SCH 40 PIPE

2 FP-5320GIS 185.35 48.97

2½ FP-5325GI 127.47 33.68

3 FP-5330GI 76.62 20.24

4 FP-5340GI 40.23 10.63

5 FP-5350GI 27.32 7.22

6 FP-5360GI 19.71 5.21

8 FP-5380GI 11.61 3.07

Bronze and Copper

Tees and Brazolets

PIPE SIZE FITTING K-Factor K-Factor

(IN.) TYPE Gallons Liters*

BRONZE TEES ON SCH 40 PIPE

1 FP-5310BR 582.34 153.86

1¼ FP-5312BR 330.54 87.33

1½ FP-5315BR 254.76 67.31

2 FP-5320BR 157.36 41.58

COPPER TEES FITTING ON COPPER PIPE SCH K

½ FP-5305CU 2459.19 649.72

¾ FP-5307CU 1108.02 292.74

1 FP-5310CU 649.87 171.70

1¼ FP-5312CU 422.03 111.50

1½ FP-5315CU 281.43 74.35

2 FP-5320CU 136.02 35.94

COPPER TEES FITTING ON COPPER PIPE SCH L

½ FP-5305CU 2406.30 635.75

¾ FP-5307CU 1174.77 310.37

1 FP-5310CU 672.28 177.62

1¼ FP-5312CU 402.84 106.43

1½ FP-5315CU 294.99 77.94

2 FP-5320CU 149.63 39.53

COPPER/BRONZE BRAZOLET ON SCH 40 PIPE

2½ FP-5325BR 117.31 30.99

3 FP-5330BR 78.62 20.77

4 FP-5340BR 45.13 11.92

5 FP-5350BR 32.79 8.66

6 FP-5360BR 22.73 6.01

8 FP-5380BR 13.14 3.47

Page 15

8.0 Calibration Menu

The K-factors published in this manual assume that the fl ow conditions in the pipe are

ideal.

Many factors that affect the fl ow rate are beyond the control of the magmeter; variations in

actual pipe dimensions, pipe smoothness, and other fl ow conditions will contribute to the

total system error.

Performing a custom calibration with the magmeter in place will adjust the K-factor and

can serve to compensate for installation conditions that may be less than ideal.

Select one of the calibration methods in this menu to achieve the most accurate

measurement possible in a specifi c application.

®

1234.56 GPM

876543.21 >

NOTE: The Security Code must be entered

before selecting the calibration method.

Enter Code

0000

Enter Menu

>

Enter Menu

Or

ENTER

Setup >

Enter Menu

Calibration >

8.1 Volume method of calibration

Use the volume method of calibration if the fl uid passing the magmeter can be measured by a volumetric method (as in a vessel of

known volume, or by weight). It requires the ability to pump a known volume of water past the magmeter, and then input the volume

into the magmeter program. It is most useful for small pipes and lower fl ow rates.

When performed properly, volumetric calibration is the most accurate method. For best results a fi ve minute test period is

recommended, and the test period should be no less than two minutes.

Press Enter

To St art

Press Enter

At START, the magmeter begins counting the fl ow past the sensor.

At STOP, the magmeter stores the total fl ow accumulated since the START.

To Stop

Enter Volume

Enter the VOLUME that has been pumped past the sensor.

000000. GPM

Value must be

more than 0.0

This error message appears if volume entered or the accumulated fl ow is zero. Repeat the

test after checking the system.

This message appears if the new K-Factor is less than 0.0001 or greater than 999999.

K-Factor

Out of Range

To correct the problem, perform the volumetric fl ow again, and be certain that the volume

entered is accurate.

3s

K-Factor

45.6789

Using the information from the VOLUME method, the magmeter will recalculate a new K-Factor.

Press ENTER to accept the new value, or use the keypad to adjust the value.

8.2 Rate method of calibration

Use this method if the magmeter must be calibrated to match a reference fl ow meter. This is the method most commonly used by

monitoring agencies, and for large pipes where volumetric calibration is impractical. The accuracy of this calibration method is largely

dependent on the accuracy of the reference meter and the proximity of the reference to the magmeter.

The fl ow rate shown is based on the existing calibration of the magmeter.

Set New Flowrate

45.6789

K-Factor

Out of Range

K-Factor

56.7890

Use the keypad to modify the fl ow rate to match the reference meter. The magmeter will

automatically calculate a new K-Factor based on the new fl ow rate.

This message appears if the new K-Factor is less than 0.0001 or greater than 999999.

To correct the problem, reexamine the fl ow rate and make certain it is accurate.

Using the information from the RATE MATCHING method, the magmeter will recalculate a new

K-Factor. Press ENTER to accept the new value, or use the keypad to adjust the value.

13

Page 16

9.0 Relay Menus

Magmeter models FMG3001 and FMG3002 have two dry contact

relays (Relays 1 and 2) and one Solid State relay (Relay 3).

®

Any of these relays can be set to any of the operating modes

listed below.

The setpoint values for HIGH, LOW and WINDOW modes can be

set to negative values if required.

For example, a LOW alarm might be set to activate if the fl ow rate

falls below -10 GPM.

Negative values are not available for relays in PULSE or TOTAL

modes.

Off: If a relay is not used, it can be turned Off to prevent contact

wear.

NOTE: The Security Code

must be entered before

modifying the relay menu.

Enter Code

0000

9.1 Pulse Relay mode

Program a relay to activate for a fi xed period, for each volume of

fl uid that passes the sensor.

For example, program the relay to pulse once for 100 ms for

every 3 gallons that pass by the sensor.

1234.56 GPM

876543.21 >

Enter Menu

>

Enter Menu

Setup >

Enter Menu

Calibration >

Enter Menu

Relay 1 >

ENTER

Or

3s

Relay Volume: Set the volume of fl uid that the magmeter must

Relay 1 Mode

Pulse >

Relay 1 Volume

0.0000 Gal >

Relay 1 Width

0.1 secs >

measure before activating the relay for one pulse.

Pulse Width: Adjust the length of time the relay will remain

activated. The pulse width setting is dependent on the type of

external equipment being connected to the relay.

9.2 Total Relay mode

Program a relay to activate when the Resetable totalizer reaches a specifi c value. The maximum setting is 999999.

Application example: A fi lter must be replaced in a R.O. system every 10000 gallons. The service representative that installs a new

fi lter sets relay 3 to Total mode, sets the setpoint at 10000 and resets the totalizer to 000000.00. When the totalizer is reset, the relay

will be deactivated and the process begins anew.

Every time the Totalizer reaches 10000, the relay activates and lights a message indicator to remind the operator to contact the service

representative to replace the fi lter.

Relay 1 Mode

Total >

Relay 1 Set High

000000 >

14

Page 17

9.3 High, Low, or Window Relay modes

Program the relay to activate when the fl ow rate reaches a setpoint (High or Low) or when the fl ow

rate moves outside of a prescribed range (Window).

Reverse Flow

The setpoint values for HIGH, LOW and WINDOW modes can be set to negative values if required.

For example, a LOW alarm might be set to activate if the fl ow rate falls to -10 GPM.

Process

Hysteresis

Relay behavior with LOW Setpoint

Low Setpoint

Time

1234.56 GPM

876543.21 >

Enter Menu

>

Enter Menu

Setup >

®

ENTER

Or

3s

Process

High Setpoint

Relay behavior with HIGH Setpoint

Hysteresis

Time

Process

High Limit

Window

Low Limit

Hysteresis

Relay behavior with WINDOW Setpoints

Hysteresis

Time

Relay activated

Relay deactivated

Set Low: Set the fl ow rate where a Low relay will be activated.

Set High: Set the fl ow rate where a High relay will be activated.

Set Window: Set a range where the relay will be deactivated. If

the fl ow rate moves outside of the low or high boundaries the

relay will be activated.

Hysteresis: Set a fl ow rate increment where the relay will be

deactivated. The hysteresis setting serves to prevent relay

"chatter" when the fl ow rate recovers from an alarm condition by

requiring the fl ow rate to move substantially within the setpoint.

Example: If high setpoint is 100 GPM, and hysteresis is 5 GPM,

the relay will be activated if fl ow rate reaches 100.1 GPM, but will

only be deactivated when the fl ow rate is 95 GPM (5 GPM inside

the setpoint.)

Delay: Set a time period for the relay to wait after reaching

the setpoint. This delay serves to prevent the relay "chatter" by

allowing the fl ow rate time to move back within the setpoint.

Enter Menu

Calibration >

Enter Menu

Relay 1 >

NOTE: The Security

Code must be entered

before modifying the

relay menu.

Enter Code

0000

The values shown for each menu item represent the factory

standard setting. All magmeters are packaged with these

settings.

Relay 1 Mode

Low >

Relay 1 Mode

High >

Relay 1 Mode

Window >

Relay 1 Set Low

00.000 GPM >

Relay 1 Hys

00.000 GPM >

Relay 1 Delay

0.1 secs >

Relay 1 Set High

00.000 GPM >

Relay 1 Hys

00.000 GPM >

Relay 1 Delay

0.1 secs >

Relay 1 Set Low

00.000 GPM >

Relay 1 Set High

00.000 GPM >

Relay 1 Hys

00.000 GPM >

Example: If the delay is set to 5 seconds, in the example above

the relay will not be activated until the fl ow rate exceeds 100 GPM

for 5 seconds.

Relay 1 Delay

0.1 secs >

The menu repeats for Relay 2 and Relay 3.

15

Page 18

10.0 Test Menu

The Test menu provides a simple method to verify that the system is operating properly. Auxiliary power MUST be connected to the

magmeter to activate the relays

Shown for 4-20 mA models Only

Use the keypad to enter any current output from 4.0 mA minimum

to 22.1 mA maximum.

Shown for Relay models Only

Toggle any of these relays ON and OFF to verify that the system

®

Enter Menu

Test >

Test Output

4.20 mA >

Test Relay 1

Open Closed >

is operating properly.

Test Relay 2

Open Closed >

Test Relay 3

Open Closed >

Auxiliary power MUST be

connected to the magmeter to

test the relays.

V+

Auxiliary Power

V-

9 to 24 VDC

0.4 A Maximum

11.0 Options Menu

The Options Menu contains those features and settings that will normally be set one time and then seldom changed. These include

language preference, decimal placement, Security Code assignment, etc.

®

Enter Menu

Options >

Language

English >

Security Code

**** >

Contrast

2 >

Select from English, German, French or Spanish.

This Selection will be displayed at fi rst power-up of a new magmeter.

Security Code can be set to any four digit number. Factory standard

setting is 0000.

Set for best view after the magmeter is installed. Larger number

means display appears darker.

The values shown for each

menu item represent the

factory standard setting. All

magmeters are packaged

with these settings.

Total Reset

Lock On >

Noise Rejection

60 Hz >

Flow Decimal

****.** >

Total Decimal

******.** >

Separator

ddd.d >

Lock ON requires the Security Code before resetting the Resetable

Totalizer. Lock OFF reset with no security code.

Filters out common 50 or 60 Hz electrical noise.

Set the maximum resolution for the FLOW RATE display by limiting

the decimal to this point. The Flow Rate display will auto-scale from

this resolution up to whole units.

Set the maximum resolution for the TOTALIZER display by limiting

the decimal to this point. The Totalizer display will always show this

resolution.

Select decimal point or comma for use in numeric displays.

Output Mode

Frequency >

For Frequency/Digital models only: Select Freq output, Freq ÷ 10

output, Mirror Relay 1 output or Digital output.

11.1 Output Modes

In FREQUENCY output mode, the OMEGAMAG serves as a traditional fl ow sensor and provides an output pulse that is compatible

with most Omega POWERED fl ow instruments. It is not compatible with the FPM5800 Self-Powered Flow Meter or the FPM5750

series Battery-powered fl ow totalizer. The frequency output range is from 0 Hz to 1000 Hz.

The FREQUENCY ÷ 10 output mode reduces the output frequency of the OMEGAMAG to a range that is useful for some

programmable logic controllers (PLC). The frequency output range is from 0 Hz to 100 Hz. This shift does not affect the stated

accuracy of the magmeter's frequency output.

The MIRROR RELAY 1 output mode allows Frequency models to use the Open Collector Output like a relay that can be programmed

via the Relay 1 menu.

If the magmeter is equipped with relays, this mode will mirror the settings of Relay 1.

If the magmeter is not equipped with relays, this mode can still be selected and programmed via the Relay 1 menu.

16

Page 19

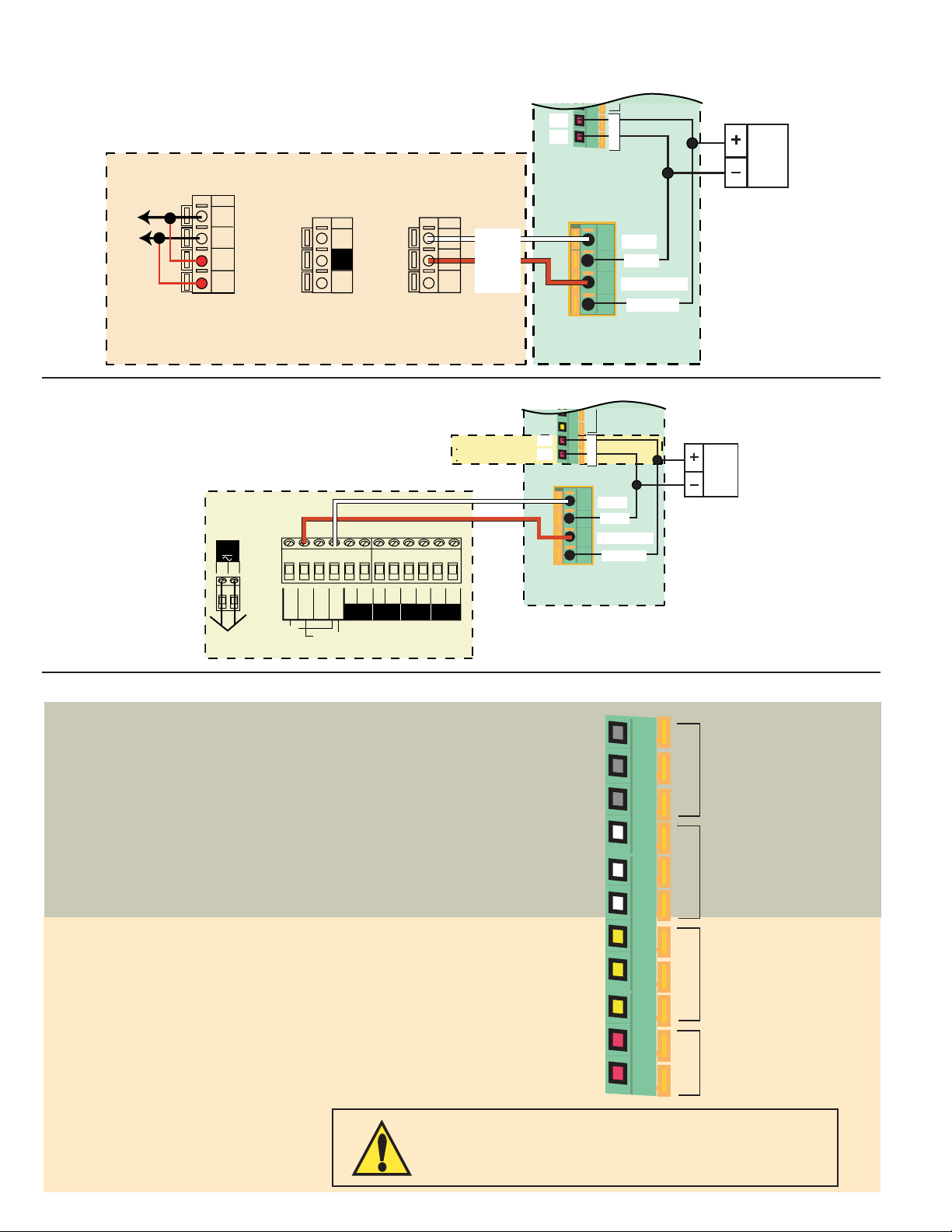

12.0 Technical Information

12.1 Grounding

Precalibration conditioning: The magmeter may appear to be unstable immediately after installation. Allow the sensor to sit in a full

pipe for 24 hours before beginning calibration and operation.

• Use a cable gland or a liquid tight connector to seal the cable ports from water intrusion.

• Use Tefl on tape or a suitable sealant on cable ports.

• The magmeter must be carefully grounded to eliminate electrical noise that may interfere with the measurement.

• Grounding requirements will vary with each installation.

• The following recommendations should be applied in sequence until the interference is eliminated.

The ground terminal on the outside of the yellow housing is connected internally to the grounding ring at the tip of the sensor.

Connect a conductor (14 AWG/2.08 mm2 wire recommended) from this terminal directly to Earth ground to prevent electrical noise

from interfering with the magmeter signal.

If the interference persists, apply step #2:

Connect grounding rings, metal clamps or grounding electrodes to the pipe immediately upstream and downstream of the

magmeter sensor location. These devices must be in contact with the fl uid.

If the interference persists, apply step #3:

The shield from the output cable must be terminated at the remote instrument ONLY.

This shield must not be connected at both ends!

If the interference persists, apply step #4:

Connect an additional wire (minimum AWG 14/2.08 mm

2

) from the remote instrument ground to the magmeter ground terminal.

Instrument

Do not terminate

shield at Magmeter

3.

1.

4.

Sensor

Grounding ring

Earth ground

4 in. to 50 in.

(10 cm to 1.3 m)

Grounding rings on plastic pipe

(Install between flanges)

metal straps on metal pipe

4 in. to 50 in.

(10 cm to 1.3 m)

2.2.

or

Page 20

12.2 Maintenance

The OMEGAMAG requires very little maintenance. There are no user-serviceable components in the magmeter.

• If the fl uid contains deposits and solids that may coat the electrodes, a regular cleaning regimen is recommended.

• Do not use abrasive materials on the metal electrodes. Clean with soft cloth and mild detergent only.

• Use a cotton swab and mild detergent to remove deposits on the metal electrodes.

Environmental Recommendations:

• When used properly, this product presents no inherent danger to the environment.

• Please follow local ordinance when disposing of this or any product with electronic components.

12.3 Troubleshooting

Symptom Possible Cause Solution

• Output is erratic and unstable.

• Output is not 0 when fl ow is stopped.

• No 4-20 mA output.

• 4-20 mA current output is incorrect.

• No Frequency output.

• Magmeter installed too close to

upstream obstruction.

• Magmeter located in area exposed to

air bubbles/pockets.

• Magmeter is installed in pipe

backwards.

• Electrical noise is interfering with the

measurement.

• Electrodes are coated with deposits

or chemical oxide layers.

• Electrodes not adequately conditioned

in fl uid.

• Fluid is moving inside the pipe.

• Loop power not connected correctly.

• 4-20 mA is not scaled properly.

• Magmeter is wrong model.

• Incorrect setting in Options Menu.

• Wiring is not correct.

• Frequency input to other

manufacturer's fl ow instrument does

not have pull-up resistor.

• Relocate the magmeter to have

straight uninterrupted pipe upstream

of the sensor for at least 10 x the pipe

diameter.

• Eliminate air bubbles in the pipe.

• Remove the magmeter and reinstall

with the fl ow direction arrow on the

sensor body pointed DOWNSTREAM.

• Review the grounding of the

magmeter and the pipe. Install

adequate Earth ground to allow the

magmeter to operate properly.

• Allow the sensor to sit in full pipe for

24 hours then restart.

• Increase the Low Flow Cutoff.

(section 7.0)

• Connect 24 VDC ±10% connected to

loop terminals 1 and 3.

• Check and reset in the Setup Menu.

• Frequency model:

FMG3001 or FMG3101

• Select Frequency in the Options

menu.

• Check wiring, make corrections.

• Install 10kΩ resistor. (section 5.1)

• No fl ow rate, current output is 22 mA.

• Blank display, no backlighting, no

relay LEDS, but external equipment

using output signal is still working.

• Error Message:

"Error Not Saved"

18

• The fl uid is too clean for magmeter.

• Electronic component failure.

• Magmeter AUX power is not connected.

• Main power is below specifi cation • Correct the main power defi ciency

• Unsuitable application for magmeter.

• Return magmeter to factory.

• Connect AUX power (section 5.5)

(9 to 24 VDC, 0.4 A max.)

Page 21

13.0 Ordering Information

Frequency output Magmeters

OMEGAMAG, PP/FREQ, ½ to 4 in. FMG3001-PP

OMEGAMAG,PVDF/FREQ, ½ to 4 in. FMG-3001-PVDF

OMEGAMAG, PP/FREQ, ½ to 4 in. FMG3001-PP-D

OMEGAMAG,PVDF/FREQ, ½ to 4 in. FMG-3001-PVDF-D

OMEGAMAG,PVDF/FREQ, 5 to 8 in. FMG3101-PVDF-D

OMEGAMAG,PP/FREQ, 5 to 8 in. FMG3101-PP

OMEGAMAG,PVDF/FREQ, 5 to 8 in. FMG3101-PVDF

OMEGAMAG, PP/FREQ, 5 to 8 in. FMG3101-PP-D

4-20 mA Loop output Magmeters

OMEGAMAG,PP/4-20, ½ to 4 in. FMG3002-PP

OMEGAMAG,PVDF/4-20, ½ to 4 in. FMG3002-PVDF

OMEGAMAG, PP/4-20, ½ to 4 in. FMG3002-PP-D

OMEGAMAG,PVDF/4-20, ½ to 4 in. FMG3002-PVDF-D

OMEGAMAG,PVDF/4-20, 5 to 8 in. FMG3102-PVDF-D

OMEGAMAG,PP/4-20, 5 to 8 in. FMG3102-PP

OMEGAMAG,PVDF/4-20, 5 to 8 in. FMG3102-PVDF

OMEGAMAG, PP/4-20, 5 to 8 in. FMG3102-PP-D

Replacement Parts and Accessories

Miscellaneous

O-ring, FPM (Viton®) FMG3000-VO

O-ring, EPDM FMG3000-EO

O-ring, FFPM (Kalrez®) FMG3000-KO

Liquid Tight Connector FP-LTC

19

Page 22

Notes:

20

Page 23

SA

MAD E

IN

IN

USA

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period

to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it

will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT

OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in

our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold

OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a

manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specifi c problems relative

to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of

OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specifi c problems relative

to the product.

consult OMEGA for

Page 24

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

•

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

•

Wire: Thermocouple, RTD & Thermistor

•

Calibrators & Ice Point References

•

Recorders, Controllers & Process Monitors

•

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

•

Transducers & Strain Gages

•

Load Cells & Pressure Gages

•

Displacement Transducers

•

Instrumentation & Accessories

FLOW/LEVEL

•

Rotameters, Gas Mass Flowmeters & Flow Computers

•

Air Velocity Indicators

•

Turbine/Paddlewheel Systems

•

Totalizers & Batch Controllers

pH/CONDUCTIVITY

•

pH Electrodes, Testers & Accessories

•

Benchtop/Laboratory Meters

•

Controllers, Calibrators, Simulators & Pumps

•

Industrial pH & Conductivity Equipment

DATA ACQUISITION

•

Data Acquisition & Engineering Software

•

Communications-Based Acquisition Systems

•

Plug-in Cards for Apple, IBM & Compatibles

•

Datalogging Systems

•

Recorders, Printers & Plotters

HEATERS

•

Heating Cable

•

Cartridge & Strip Heaters

•

Immersion & Band Heaters

•

Flexible Heaters

•

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

•

Metering & Control Instrumentation

•

Refractometers

•

Pumps & Tubing

•

Air, Soil & Water Monitors

•

Industrial Water & Wastewater Treatment

•

pH, Conductivity & Dissolved Oxygen Instruments

6-2551.090-1-OM (A-5/06) M-4334/0506

Loading...

Loading...