Page 1

User's Guide

Shop online at

omega.com

email: Info@omega.com

For latest product manuals:

omegamanual.Info

FMG-1000 SERIES

Municipal/Industrial Magmeter

Page 2

OMEGAnet®Online Service Internet e-mail

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

omega.com i n f o @ o m e g a . c o m

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

TABLE OF CONTENTS

General Information

General Information, Features .........................................................................................................Page 1

Specications

Specications, Flow Range ............................................................................................................Page 2

Installation and Grounding

Positioning the Meter,

Calibration, Chemical Injection, Metal Pipe Installations, Plastic Pipe Installations .............................Page 3

Straight Pipe Recommendations ............................................................................................ Page 4

Full Pipe Recommendations .......................................................................................................Page 5

Inputs/Outputs and Operation

Power, Pulse Output, High Frequency, K-Factor, Display Reading .....................................................Page 6

Connections Diagrams

FMG-1000-MAW, FMG-1000-DL.....................................................................................................Page 7

Straight Pipe Recommendations, Full Pipe Recommendations, Fittings,

Troubleshooting

Problem, Probable Cause, Things to Try ........................................................................................Page 8

TABLES, DIAGRAMS & CHARTS

Features ......................................................................................................................... Page 1

Specifications .................................................................................................................. Page 2

Flow Range .................................................................................................................. Page 2

Metal Pipe Installation, Plastic Pipe Installation ............................................................. Page 3

Straight Pipe Recommendations ........................................................................................ Page 4

Full Pipe Recommendations ........................................................................................... Page 5

High Frequency Output ................................................................................................. Page 6

Display Readings ............................................................................................................. Page 6

Connections Diagrams ...................................................................................................................... Page 7

Troubleshooting ......................................................................................................................... Page 8

Page 4

GENERAL INFORMATION

The FMG-1000 Series are anged electromagnetic

owmeters for use in 4” to 10” pipe in municipal or industrial

water and wastewater applications where propeller meters

have typically been used in the past. Because the FMG1000 has no moving parts and has electrodes designed

to discourage fouling, this magmeter performs well and

requires much less frequent maintenance in applications

where debris or sand would impede propeller meters. There

is no rotor to stop turning or bearings to wear out. Minimal

straight pipe requirements allow FMG-1000 Series meters to

be used in piping congurations where there is little space

between the meter and an elbow.

In chemical injection applications, the meter should be placed

upstream of the injection line or far enough downstream for

thorough mixing to occur before the meter.

Rate and total indication are standard on both models. Flow

measurement units are customer-selected and factory-set

and can only be changed in the eld by an authorized Omega

dealer.

The FMG-1000 is externally powered with 7-26 Vdc at 30 mA

max (see WARNING on Wiring Diagrams).

The 20-foot power cable also provides pulse output for use

with a variety of displays and controls for remote reading,

data logging, pulse-to-analog conversion, and telemetry

applications. Pulse rate is customer-selected and factory-set

and can only be changed in the eld by an authorized Omega

dealer. Default is high frequency for use with 4-20 mA signal

conversion devices.

FEATURES

Rate and total indicator

Powder-coated diecast-aluminum electronics housing

Power/Output cable port

Welded steel epoxy-coated ow tube

316SS electrodes

Dual durometer rubber liner

Flanges, ANSI 150 lb. drilling

Equalization lug

4” 6” 8” 10”

Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec

12 .75 32 2 60 3.8 95 6

500 31.5 1,200 75.7 2,200 138.8 3,500 220.8

Page 1

Page 5

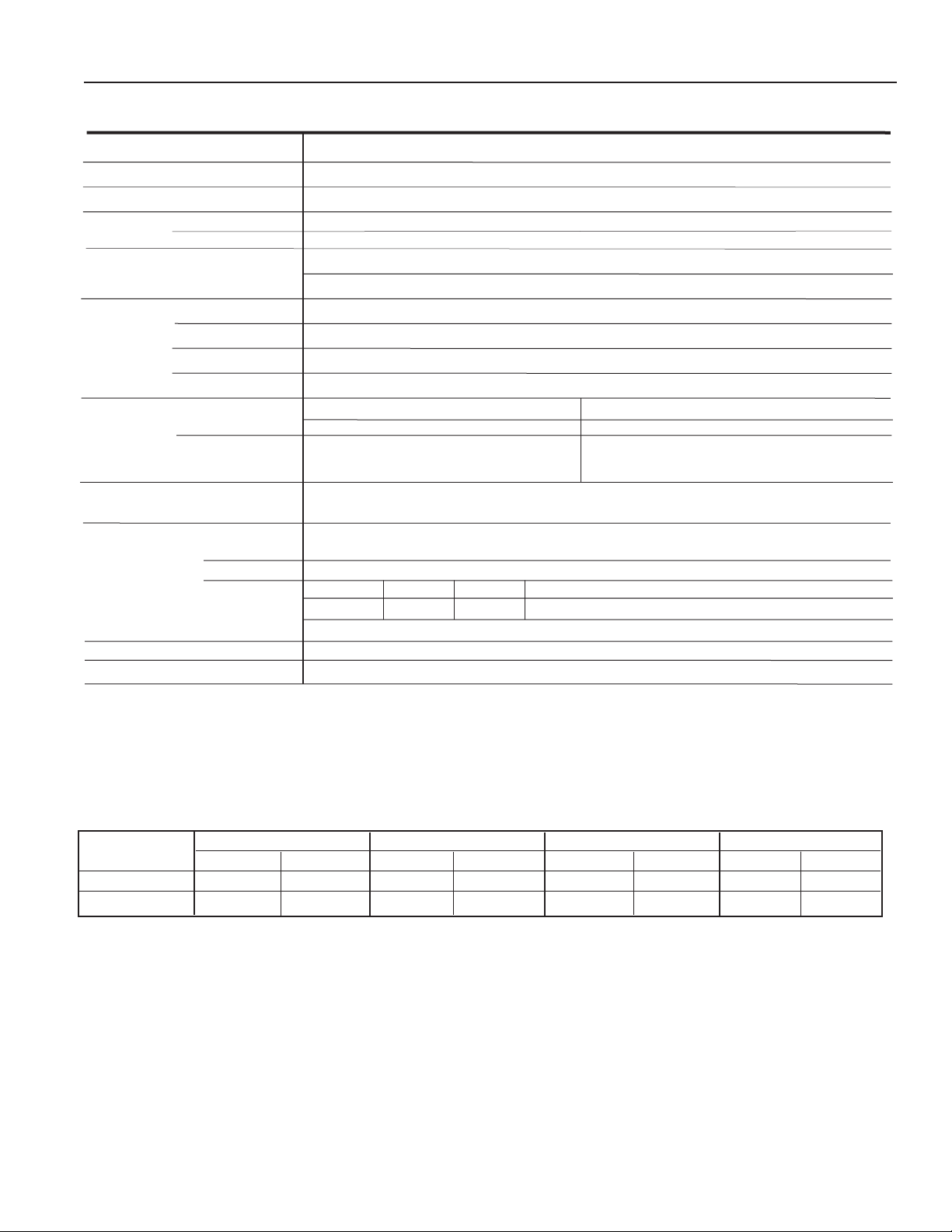

SPECIFICATIONS

SPECIFICATIONS*

Pipe Sizes

Flanges

Pressure

Temperature Operating

Non-Operating

Accuracy

Materials Body

Liner

Electronics Housing

Electrodes

Display

Digits

Units*

Power

Pulse Output Signal

Pulse Rates

High Frequency

(pulse/gal)

Conductivity

Empty Pipe Detection

Environmental

*Specications subject to change.

4”, 6”, 8”, 10”

ANSI 150 lb. drilling

150 psi (10.3 bar) working pressure

10˚ to 130˚ F (-12˚ to 54˚ C)

-40˚ to 158˚ F (-40˚ to 70˚ C)

+/-1% of reading from 10% to 100% of reading

+/-2% of reading from cutoff to 10% of reading

Welded steel, epoxy-coated

Dual durometer rubber

Diecast aluminum, powder-coated

316 stainless steel

Rate Total

5 8

Gallon/Minute, Liter/Minute, Liter/Second, Gallon, Gallon x 1000, Liter, Liter x 1000, Mega Liter,

Cubic Feet/Minute, Cubic Meter/Hour, Cubic Meter, Cubic Meter x 1000, Cubic Feet,

Million Gallon/Day, Mega Liter/Day Cubic Feet x 1000

7-26 Vdc at 30 mA max

NOTE: Using an unregulated power supply >18 Vdc may damage the meter due to AC line input voltage uctuation

Current sinking pulse, opto-isolated, 30 Vdc at 10 mA max

Pulse output available only with addition of post-factory output cable

High Frequency (default); 10 units/pulse; 100 units/pulse; 1000 units/pulse

4” 6” 8” 10”

16.362 6.307 3.344 2.150

>20 microSiemens

Hardware/software, conductivity-based

NEMA 4X

FLOW RANGE

Minimum

Maximum

Page 2

Page 6

INSTALLATION and GROUNDING

INSTALLATION

Caution: These ow sensors are not recommended

where installation fault may expose the ow sensor to boiler pressure and temperature. Maximum

recommended temperature is 130˚ F.

Positioning the Meter. These meters can be installed

horizontally, vertically, and in any radial position.

Straight Pipe Recommendations. As with most ow meters,

the FMG1000 requires some straight pipe before and/or

after the meter for best accuracy. However, the ability of

electromagnetic meters to average the ow across the entire

pipe allows for shorter straight pipe recommendations than

most mechanical meters (see page 4).

Full Pipe Recommendations. All magmeters require a

method for determining that the pipe is empty, to prevent false

reading. This meter is designed to go to zero reading if one

or more electrodes is exposed. For highest accuracy, install

the meter so that the pipe will be full when there is ow. If air

bubbles may be present in the pipe or sludge accumulation

is an issue, rotate the meter by one ange hole to position

the control housing at a 45˚ angle. See Full Pipe diagrams

on page 5.

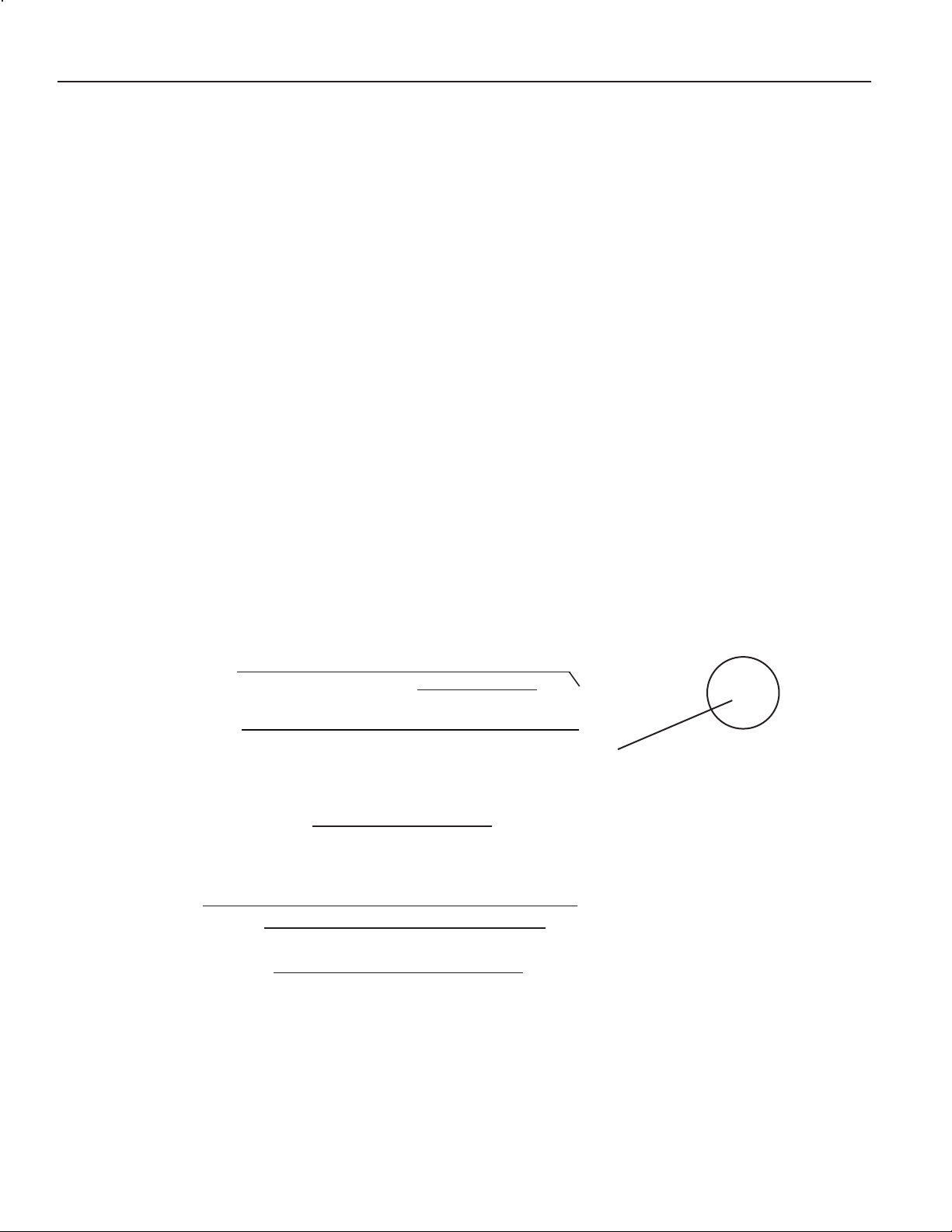

EQUALIZATION AND GROUNDING

Metal Pipe Installations. To equalize the electrical potential

of the uid with the meter, and the surrounding pipe, secure

the ange plates (factory-installed on the equalization lug) to

both pipe anges at one of the bolt holes, as shown below.

Be sure the lockwasher ts between the pipe ange and the

ange plate.

Meter Flange

Pipe Flange

Lockwasher

Flange Plate

Equalization Lug

Metal

Pipe

Meter

Flange

Bolt

Pipe

Flange

Metal

Pipe

Equalization Diagram

Run wire from equalization lug to both pipe anges;

secure ange plates under bolt heads as shown.

Fittings. The anges have standard ANSI 150 lb. drilling and

mate with any other ANSI 150 lb. ange.

Calibration. The FMG-1000 is factory-calibrated and will not

require any form of eld calibration.

Chemical Injection. When any magmeter, by any manufacturer, is used in a chemical injection application, the chemical

injection point must be placed downstream of the magmeter

OR far enough upstream for complete mixing to occur before

the uid reaches the meter. When unmixed chemical alternates with water passing through the meter, the rapid changes

in conductivity may cause sudden spikes and drops in the

meter’s reading, resulting in inaccurate measurement. The

magmeter will restabilize, however, with a steady ow of uid

of uniform conductivity.

Caution: In chemical injection applications, install chemical injection

point downstream of magmeter, or far

enough upstream to allow complete

mixing of uids before the meter.

WARNING: ELECTRICAL SHOCK HAZARD When

the meter is externally AC powered, the piping system must be grounded to meet national and local

electrical safety codes. Failure to do so can result

in electrocution.

Plastic Pipe Installations. When the FMG-1000 is installed

in a plastic piping system, it is not necessary to use the

equalization straps, but very important to ground the meter

to avoid electrical shock hazard and electrostatic interference with meter function.

Meter Equalization Lug

Plastic Pipe Plastic Pipe

Exothermically weld when

corrosion is a concern

#6 AWG Stranded

Copper Ground Wire

Ground Clamp

Earth

8’ Ground Rod

Page 3

Page 7

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

1X

2X

Meter

1X

2X

Meter

1X

2X

Expanded Pipe

Swirling Flow

Propeller Meter

5X

5X

Meter

Meter

5X

1X

1X

Meter

1X

Swirling Flow

Partially Open

Buttery Valve

Meter

Page 4

Page 8

FULL PIPE RECOMMENDATIONS

Recommended:

Keep pipe full at meter for accuracy

Meter

Meter

Not Ideal:

Allows air pockets to form at meter

Meter

Recommended:

Keeps pipe full at meter for accuracy

Meter

Recommended:

Allows air to bleed off

Intermittent air

Electrode

moved from

top by rotating

meter

Meter

miss electrode

Electrodes free

from sediment

bubbles

build-up

Meter

Not Ideal:

Post-valve cavitation can create air pocket

Meter

Not Ideal:

Air can be trapped

Intermittent air

bubbles

pass over

electrode

Possible

sediment

build-up

Meter

Page 5

Recommended:

Improved accuracy results from

unimpeded electrodes

Not Ideal:

Air bubbles and sediment on the

electrodes can affect accuracy

Page 9

INPUTS/OUTPUTS and OPERATION

INPUTS/OUTPUTS

Power. The FMG-1000 operates on 7-26 Vdc at 30 mA max

external power (see WARNING in wiring diagrams). The display

reads “P” when external power is in use (see illustration below).

Pulse Output. The cable also provides pulse output that

can be used for remote reading, 4-20 mA signal conversion,

datalogging, and telemetry applications. See page 7 for

connection diagrams to Omega controls and displays.

Pulse rates are selected by the customer at time of order,

factory-set, and can only be changed in the field by an

authorized Omega dealer. Three pulse rates are possible:

One pulse per ten gallons (or liters), one pulse per thousand

gallons (or liters), or High Frequency (required for use with

4-20 mA converters; see below):

High Frequency Output/K-Factor

Meter Size Pulses per Gallon Pulses per Liter

4” 16.362 4.323

6” 6.307 1.666

8” 3.344 0.883

10” 2.150 0.568

OPERATION

Caution: There are no user-adjustable

connections or settings inside the display

housing. Use caution when opening the

housing for a battery change, to avoid

damage to internal components.

Display Reading. The FMG-1000 display has two lines, the

bottom line for ow rate and the top line for accumulated total.

Measurement units are pre-ordered and factory-set and can

be changed in the eld only by an authorized individual.

Refer to the diagrams below to read your display.

External Power Indicator

No Power

Meter Installed Backwards

Empty Pipe

Page 6

Page 10

CONNECTIONS DIAGRAMS

The FMG-1000 requires a power source of 7 to 26 Vdc at

30 mA max (see WARNING). The power cable also serves as

a pulse output if needed for remote reading, data logging,

signal conversion, or telemetry.

FMG-1000-MAW

Blue

Do

Not

{

Orange

Use

4-20 mA

Power

5

6

4

3

2

1

0

Frequency

5

6

4

4

7

8

9

7

3

3

8

2

2

9

1

0

S

Sensor

Not

Used

5

5

6

6

4

7

7

3

8

8

2

9

9

1

1

0

0

Pulse-to-Analog Converter

Power Supply

at 30 mA max

(see WARNING)

White (-)

Green (+)

Black

Red

(-) (+)

7-26 Vdc

FMG1000 Cable Color Codes

Orange and Blue: Serial Output (Do Not Use)

Green (+) and White (-): Isolated solid-state contact closure pulse

output, 30 Vdc max, 10 mA max

Red (+) and Black (-): External Power, 7-26 Vdc at 30 mA max

Drain: Connect to earth ground (see WARNING)

Cable

Shielded

Drain Wire

Direct Burial Cable

22 AWG Stranded

WARNING: Using an unregulated power

supply >18 Vdc may damage the meter

due to AC line input voltage uctuation.

FMG-1000

FMG-1000-DL

Battery

Data Logger

Blue

Do

Not

{

Orange

Use

-

S

+

Not

Used

Power Supply

at 30 mA max

(see WARNING)

(-) (+)

7-26 Vdc

Green (+)

Black

Red

Drain Wire

White (-)

Shielded

Direct Burial Cable

22 AWG Stranded

Cable

FMG-1000

WARNING: Using an unregulated power

supply >18 Vdc may damage the meter

due to AC line input voltage uctuation.

Page 7

Page 11

TROUBLESHOOTING

Problem

Blank Display

Flow rate steadily reads

zero when there is ow

Flow rate intermittently

drops when there is ow

Probable Cause Try...

No power

Flow is below cutoff (very low)

Pipe not full

Meter is installed backwards

(display reads [ - ] )

Power connections reversed

Fluid conductivity <20mSiemens/cm

Pipe not full

Check power connections

Reading will resume when ow increases

Reposition meter for full pipe (see page 4)

Note ow direction arrow, reverse meter

Change power connections

Select another ow meter

Reposition meter for full pipe (see page 4)

Jumpy reading

Meter reads, but no

pulse output

Output pulses missing

Missing or incorrect ground wire

Rapidly changing conductivity

(in chemical injection applications)

External device needs pull-up resistor

Reversed leads (polarity sensitive)

Meter not reading

Check for proper ground

Install chemical injection line downstream

of meter (or far enough upstream to allow

complete mixing of uids before meter)

Add pull-up resistor

Change output connections

Check display

Page 8

Page 12

WARRANTY/DISCLAIMER

FOR NON-WARRANTY REPAIRS,

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months f rom date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be re t u rned to the factory for evaluation. O M E G A’s Customer Serv i c e

D e p a rtm ent will issue an Authorized Return (AR) number immediately upon phone or written re q u e s t .

Upon examination by OMEGA, if the unit is found to be defective, it will be re p a i red or replaced at no

c h a rge. O M E G A’s WARRANTY does not apply to defects resulting from any action of the purc h a s e r ,

including but not limited to mishandling, improper interfacing, operation outside of desi

i m p roper re p a i r, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corro s i o n ;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s c o n t r ol. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or e

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

R E P R E S E N T ATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY W

AND FITNESS FOR A PA R TICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

L I A B I L I T Y: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this ord e r , whether based on contract, warr a n t y, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

compone nt upo n wh ic h li abili ty is based. In no even t shall OMEGA be li able for

co

nsequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

a c t i v i t y , medical application, used on humans, or misused in any way, OMEGA assumes no re s p o n s i b i l i t y

as set forth in our basic WA R R A N T Y/ D ISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA h a rmless from any liability or damage whatsoever arising out of the use of the

P roduct(s) in such a manner.

rrors nor assumes liability for any

ARRANTY OF MERCHANTA B I L I T Y

gn limits,

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR

) NUMB ER FROM OM EGA’S C U STOM E R SERVICE DE PA R TMEN T ( IN ORDE R T O AV O I D

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

WARRANTY RETURNS, please have the

FOR

following information available BEFORE

contacting OMEGA:

1 . P u r chase Order number under which the pro d u c t

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 13

Notes

Page 14

W h e r e Do I Find Eve rything I Need for

P r ocess Measurement and Control?

OME GA…Of Cours e !

Shop online at omega.com

T E M P E R A T U R E

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FO R C E

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

F L OW / L E V E L

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

p H / C O N D U C T I V I T Y

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equi

pment

DATA AC Q U I S I T I O N

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

H E A T E R S

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

E N V I R O N M E N T A L

M O N I T ORING AND CONTRO L

Metering & Control Instrumentation

R e f r a c t o m e t e r s

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

PL-OM-65200291-080311

8/3/2011

M-4332/0111

Loading...

Loading...