Page 1

OMEGA

ENGINEERING, INC.

oium

Al

Behmdogks

FMA-5000 SERIES

Electronic Mass

Flowmeters

CompIqy

Operator’s Manual

Page 2

OMEGAwanamsVlisun~~obeheeddetedsinmaterialsandwakmanshl~andtogivesatlsfactoryseMcefapenod

of

13

one (1) year

coverage

Serwce

exammatlon

WARRANTY is VOID if the

Z3~Kl¶UitOlWCS3Sh

orolheroperat~ngconditionsoutsdedOMEGA ’scontrol.Compo~mtswhichwearorwhlcharedamagedbymlsuse

ara

not warranted.

EVERY PRECAUTION FOR ACCURACY HAS BEEN TAKEN IN THE PREPARATION OF THIS MANUAL,

HOWEVER, OMEGA ENGINEERING, INC. NEITHER ASSUMES

ERRORS THAT MAY APPEAR NOR ASSUMES LIABILITY FOR ANY DAMAGES THAT RESULT FROM THE USE

OF THE PRODUCTS IN ACCORDANCE WITH THE INFORMATION CONTAINED IN THE MANUAL.

dale

m~nthsfrcm

on

Daparfrnenl

of purchase. OMEGA Warranty adds an

product

warranty

,wcduct

will issue an

by OMEGA, if the

These

aner

handling and

to

shculd

unl

If the cad

Aulhortzed

Return (AR) number immediately upon phone or

defecliw

lo

is found

evidenrx

cwent.

be

of having

moustum

0r

unl

unil

shows

camsnm;

include contact points, fuses, and

addiiional

tune.

This ensures that shiing

ba

returned to the

musl

1 malfwUii,

repaired

it

will be

been

tampered with or shows

~mpoper

wbralar;

heat.

of

triacs.

RESPONSIBILR-Y

one (1)

or

replaced

specillcatm:

mooth

faclofy

pertod

grace

ourctiomers

for

al

no charge. However.

FOR ANY OMISSIONS OR

to the normal

recant

waluatan.

Our

wrlllen

betng

of

ewdence

mnap+atkm;

maxlmum

Customer

request.

damaged

mws-9

Upon

the

WARRANTY

Teebwk#lrm

O.UEGA

I.

One

Omega Drive.

Stamford.

Connwtiiu~

Call OMEGA

14DD.8246342 I

Sales:

Customer Service:

Engineering Assistance:

359-1660

(203)

CT:

‘In

And International

Direct all warranty and

telephone number (203)

CONTACT

RETURN (AR) NUMBER. The

the

To avold

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is

possible. That way our customers get the latest in technology and engineering.

OMEGA@is

0

Copyright

in this manual may be reproduced in any manner, either wholly or in part for any purpose whatsoever

without written permission from OMEGA ENGINEERING, INC.

TtfE

return

pa&age.

pmcesslng

1. Returnee ’s name,

2. Model and

Rapalr

3.

a registered trademark of OMEGA ENGINEERING, INC.

Cb&my

Box

4047

C690743D47

Tot1

Free’

-BOO-TC0AEGA

1

l-QQQ-Q22-2378

OMEGA CUSTOMER SERVICE DEPARTMENT TO OBTAIN AN AUTHORIZED

d&y&

Serial

Instructions.

1989

OMEGA ENGINEERING, INC. All rights reserved including illustrations. Nothing

I l-800-622.BEST

l-QW-Q72-94361

CABLE: OMEGA

996404

TELEX:

Return

mquests/lnqulrlm~

mpalr

359.1660.

BEFORE RETURNING ANY INSTRUMENT, PLEASE

designated

AR number should then be marked on the

also please be

addmss,

and phone number.

numben.

l-QDMJSA-WHEN

EASYLINK:

FAX: (203)

RaqueWIlnqulrtas

to OMEGA Customer

oure

to Include:

62968934

35Q-77tX

Servkr Department,

outslde

of

Printed in U.S.A

M698/068

Page 3

SECTION 1

1.1

General Description

TABLE OF CONTENTS

FMA-5000 Series

INTRODUCTION

.

2

. . . . . . . . . . . . . . . . . .

.

2

. . . . . . . . . . . . . . . . .

SECTION

2.1

2.2

2.3

2.4

2.4.1

2 .4 .2

SECTION 3 OPERATION.

3.1

3.2

3.3

SECTION 4 MAINTENANCE

4.1

4.1.1

4.1.2

4.1.3

SECTION 5

5.1

5.2

5.3

2 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . 2

Unpacking

Mechanical Installation

Transducer Connections

Electrical Connections

g-Pin

OEM Electrical Connections

...........................

...................

..................

...................

“D” Connector Pin Assignments

...............

........

........................

Operating Instructions

Notes to Operating Instructions

Principle of Operation

...........................

.....................

........................... .

.....................

Flow Path Cleaning

Inlet and Outlet Screen

Laminar Flow Element

Sensor Tube

FLOW CALIBRATION

General Calibration Procedure

Recalibration over the Same Flow Range

Flow Calibration Over a Different Flow Range and/or Gas

.............................

..........................

(LFE)

........................

.................................

......................

..................

...............

....

SECTION 6 TROUBLESHOOTING. ................ .

6.1

6.2

General......................................1 6

Troubleshooting Guide

...........................

.

.

.

.

.

,12

.12

.12

.13

.14

.16

2

3

3

4

4

6

7

7

7

9

12

14

14

15

16

SECTION 7 SPECIFICATIONS

APPENDICES

1.

2.

3.

4.

Exploded View of Transducer and Parts List

Electrical Schematics

Conversion of Flow Rate

KFactors

............................... .

............................

....................................

....................

.........................

............

.17

..19

.20

.21

.22

.23

Page 4

QUICK OPERATING INSTRUCTIONS

Section 3 for Detailed Operating Instructions)

(See

1.

Install the FMA-5000 Series into the gas flow line. Note the flow

direction arrow on the flowmeter. If you are using

a good quality paste pipe thread sealant for sealing and tighten

one-and-one-half turns only. Do not overtighten.

%

inch pipe, use

I&

.’

II

Overtightening may crack the fittings or shift

calibration.

The line pressure and temperature

(5OY).

150°F

2.

Apply power to the flowmeter. If you are using the FMA-PST

should

not exceed 150 psig

or

Power Supply, just plug the power supply into line power and the

connector into the input power jack on the side of the flowmeter.

If you are providing your own power, use 12 to 15 VDC at 100

mA

maximum. 24 VDC operation is made possible by removing the

0 ohm resistor in the R-10 location and replacing it with a 160

%

watt resistor. The resistor will not fit between the D con-

ohm

nector and DC power jack, so stand it off from the PCB. This is

acceptable since it gets hot in normal operation. Do not supply

+DC power at the D connector while using an FMA-PST power

supply at the DC power jack. The D connector

pinout

is shown

in Section 2.4.

3.

Allow at least 15 minutes for warm-up

4.

After the warm-up period, the flowmeter is monitoring the gas

mass flow rate

5.

Output Signals: The output signal of the flowmeter is either O-5

mA

VDC (standard) or 4-20

(optional). The output is linearly pro-

portional to the gas mass flow rate. The full scale range and gas

are shown on the front label. Section 2.4 describes the electrical

output signal hookup For example, if you have a O-5 VDC output

signal, 5.00 VDC is the output signal for the full scale listed on the

label; 2.50 VDC is for one-half of full scale, and 0.00 VDC is for

mA

zero flow. On the other hand, if you have 4-20

mA

20.00

one-half of full scale, and 4.00

6.

FMA-5000 Series with Integral or Remote Display: The

is the output signal for the full scale; 12.00

mA

is for zero flow.

output signal,

mA

is for

3% digit

LCD reads directly in engineering units or percent of full scale The

full scale range and gas are shown on the front label. The decimal

point for the flow rate is set at the factory and will show

automatically (e.g., 5.54

SLM

or

76.4%).

Page 5

SECTION 1 INTRODUCTION

1.1

GENERAL DESCRIPTION

The OMEGA@ FMA-5000 Series Electronic Mass Flowmeters

measure the mass flow rate of gases in 13 ranges

(standard cubic centimeters per minute), to 040 SLM (standard liters

per minute). Their analog output, integral/remote digital display, in-

sensitivity to temperature and pressure variations, and low cost make

them ideal substitutes for rotameters, and they can also be used to

calibrate rotameters. Other applications include chemical and food

processing, gas chromatography, and leak and filter testing to name

a few.

The FMA-5000 Series are available with or without a digital display.

tiltable

The display is

with 25 feet of cable for remote surface mounting. The flowmeters

require a 14 to 24 VDC external power source that can be provided

by the optional Model FMA-PST Power Supply. A O-5 VDC (standard)

or 4-20

flow rate is provided for recording, datalogging, or control. A

“D” subconnector for the output signal, input power, and remote

display drive is supplied with its mating connector for all FMA-5000

Series units.

All wetted surfaces are constructed of corrosion-resistant glass- filled

nylon plastic,

commodates almost any gas including air, oxygen, process gases,

and even corrosives.

(optional) output signal linearly proportional to gas mass

mA

over

316SS.

and Viton O-rings. This rugged construction ac-

fromO-10

180° for easy viewing and can be ordered

SCCM

g-pin

SECTION 2 INSTALLATION

2.1

UNPACKING

Remove the packing list and verify that all equipment has been receiv-

ed. If there are any questions about the shipment, please call OMEGA

Customer Service Department at (203) 359-1660.

Upon receipt of the shipment, inspect the container and equipment

for any signs of damage Take particular note of any evidence of rough

handling in transit. Immediately report any damage to the shipping

agent.

The carrier will not honor any claims unless all shipping

material is saved for their examination. After examining and

removing contents, save packing material and carton in the

event reshipment is necessary.

NOTE

2

Page 6

2.2

MECHANICAL INSTALLATION

-1

The maximum pressure and temperature

in

the flow line in

which the flowmeter is to be installed should not exceed

(5OOC).

150 psig

In order to

kg/cm2

gage) or

(10

enstire

a successful installation, inlet and outlet tubing or

150°F

piping should be in a clean state prior to installing the flowmeter in-

to the system. The FMA-5000 Series is applicable to clean gas only

because

particulates

tube and laminar flow element over a period of time.

and other foreign matter may clog the sensor

If the gas con-

tains particulate matter, install a high- efficiency, 50 to 100 micron,

in-line filter upstream of the flowmeter.

Do not locate the flowmeter in areas subject to sudden temperature

changes, moisture, or near equipment radiating significant amounts

of heat. Allow adequate space for cable connectors and wiring. Be

sure the arrow on the side of the transducer points in the direction

of flow. If the unit is to be mounted in other than a horizontal posi-

tion, the zero will need adjustment. Refer to Section 5.2.

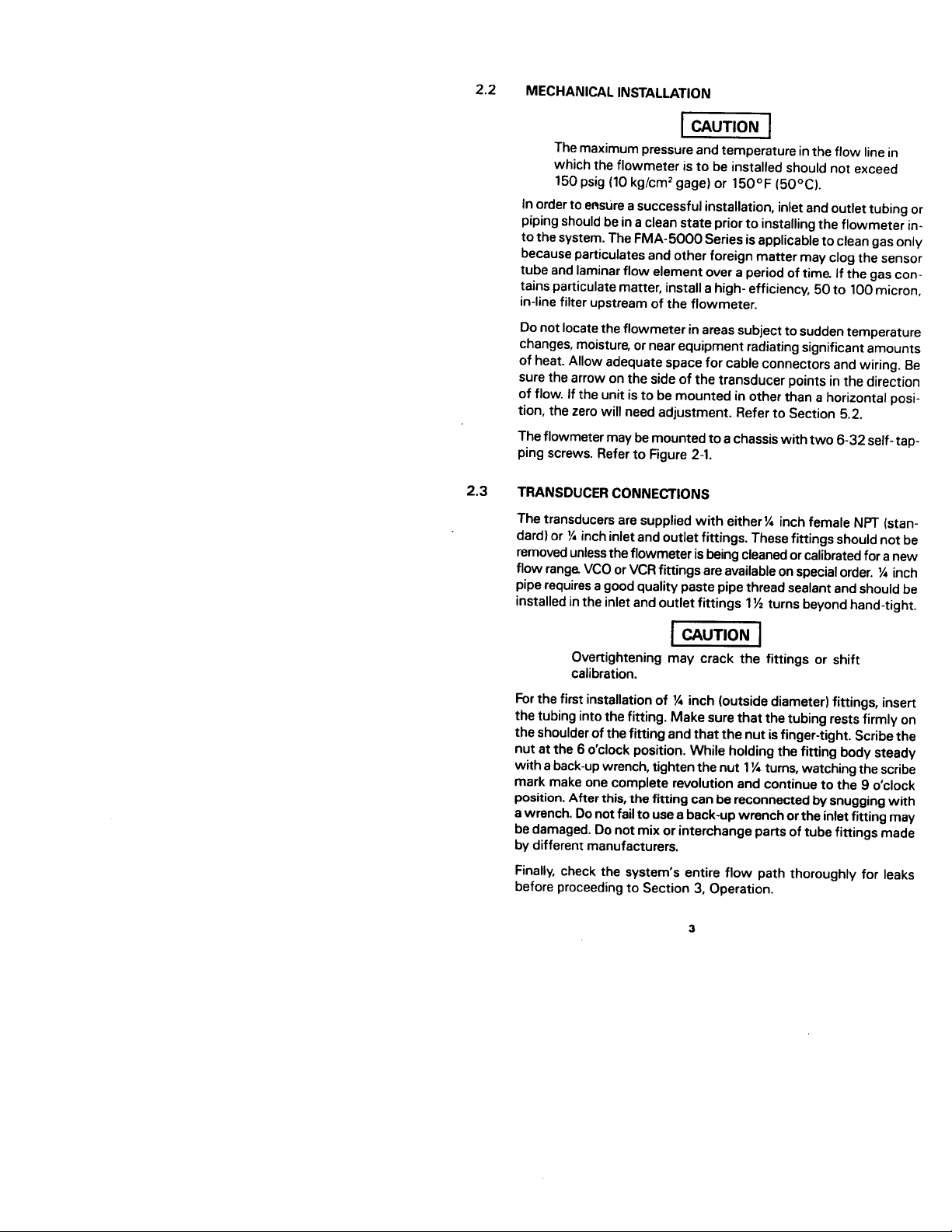

The flowmeter may be mounted to a chassis with two 6-32 self- tap-

ping screws. Refer to Figure 2-l.

2.3

TRANSDUCER CONNECTIONS

The transducers are supplied with either% inch female NPT (stan-

dard) or

%

inch inlet and outlet fittings. These fittings should not be

removed unless the flowmeter is being cleaned or calibrated for a new

%

flow range VCO or VCR fittings are available on special order.

inch

pipe requires a good quality paste pipe thread sealant and should be

installed in the inlet and outlet fittings 1% turns beyond hand-tight.

Ovettightening may crack the fittings or shift

calibration.

%

For the first installation of

inch (outside diameter) fittings, insert

the tubing into the fitting. Make sure that the tubing rests firmly on

the shoulder of the fitting and that the nut is finger-tight. Scribe the

nut at the 6 o ’clock position. While holding the fitting body steady

the

with a back-up wrench, tighten

nut 1% turns, watching the scribe

mark make one complete revolution and continue to the 9 o ’clock

position. After this, the fitting can be reconnected by snugging with

a wrench. Do not fail to use a back-up wrench or the inlet fitting may

be damaged. Do not mix or interchange parts of tube fittings made

by different manufacturers.

Finally, check the system’s entire flow path thoroughly for leaks

before proceeding to Section 3, Operation.

Page 7

4.16

(WITHOUT

DISPLAY)

SIDE VIEW

-.

6.66

__

END VIEW

~-

~-

ALL

DIMENSIONS IN INCHES

0.125 DIA. THRU PANEL-2 PLACES.:

PANEL MOUNTING HOLES

ALL DIMENSIONS IN INCHES

BOTTOM VIEW

‘-

6-32 X 0.15 DP.

(SELF TAPPING)

2.4

2.4.1

2-l.

Dimensions

Figure

ELECTRICAL CONNECTIONS

g-Pin

D Connector Pin Assignments

+15 VDC power supply

The flowmeter requires a single

capable of providing a minimum current of 100

configured for

+24

VDC power at 100

is via either the DC power jack or the

+12 to

mA,

and can also be

mA.

Operating power input

g-pin

D connector on the side

of the enclosure. The pin numbers for this D connector are shown in

Figure 2-2 and the pin assignments are given in Table 2-1. The out-

g-pin

put signal is obtained from the

D connector. A O-5 VDC out-

put signal linearly proportional to gas mass flow rate is standard. A

mA

4-20

current loop signal is optionally available.

When the flowmeter is configured for a remote display, connections

are made

D connector. Power connections for the display and

via the

transducer are shared in this mode unless the optional power supp-

ly is used.

4

Page 8

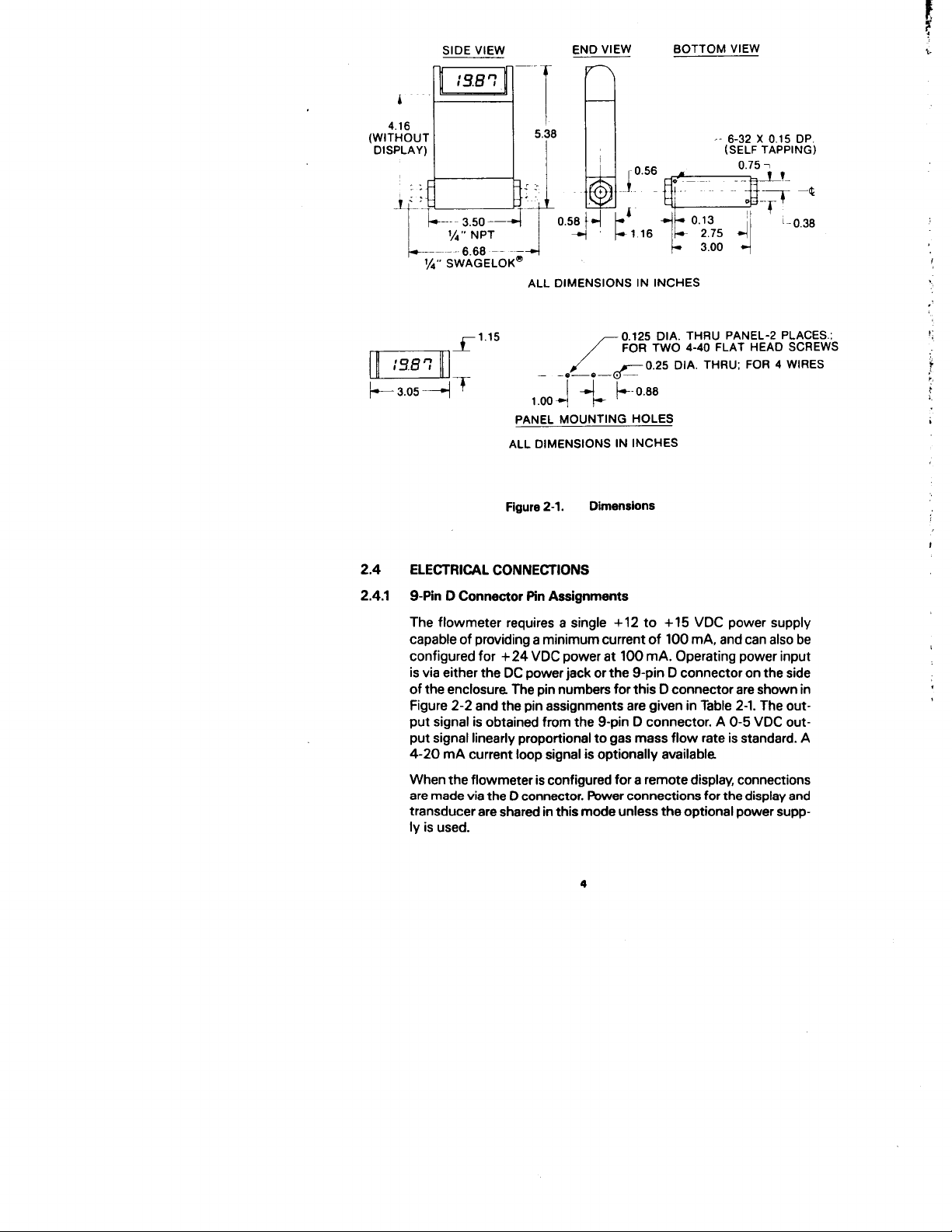

Figure 2-2. D Connector and DC Power Jack

The following connection points can be made through the D connec-

tor or, in OEM applications, made through the circuit board solder pad

connections. The display pad connections are shown for applications

requiring remote mounting of the digital display. The letters appear

on the display circuit board and are shown in Figure 2-3.

PIN NO.

1

2 Signal Common

3

4

5

6

7 Power Common

8

9 4 to 20

FUNCTION DISPLAY PAD

No Connection

N/A

N/A

+

5 VDC Flow Signal

0 to

Supply (12 or 24

VDCl+Power

Remote Display Flow Signal

Remote Display Reference

N/A

(A)

0)

(Cl

(B)

4 to 20

mA

Return (Common)

mA Output

N/A

N/A

Note that the numbers on the connector plug may not agree with the

numbering system as it appears in Figure 2-2. It is important to make

sure that the proper wires are in the proper location.

Page 9

NOTES

g-pin

Remote display connects through the

D connector

only. The pads A-D in the top right of the main circuit

board are for integral display mounting only.

Power supply voltage must be specified at time

Operating a 12

VDC meter at 24 VDC will cause damage.

of

order.

Running a 24 VDC meter at 12 VDC will result in faulty

operation.

Do not supply +DC power at the D connector while

using an FMA-PST power supply at the DC power jack.

Both supplies may be damaged.

,

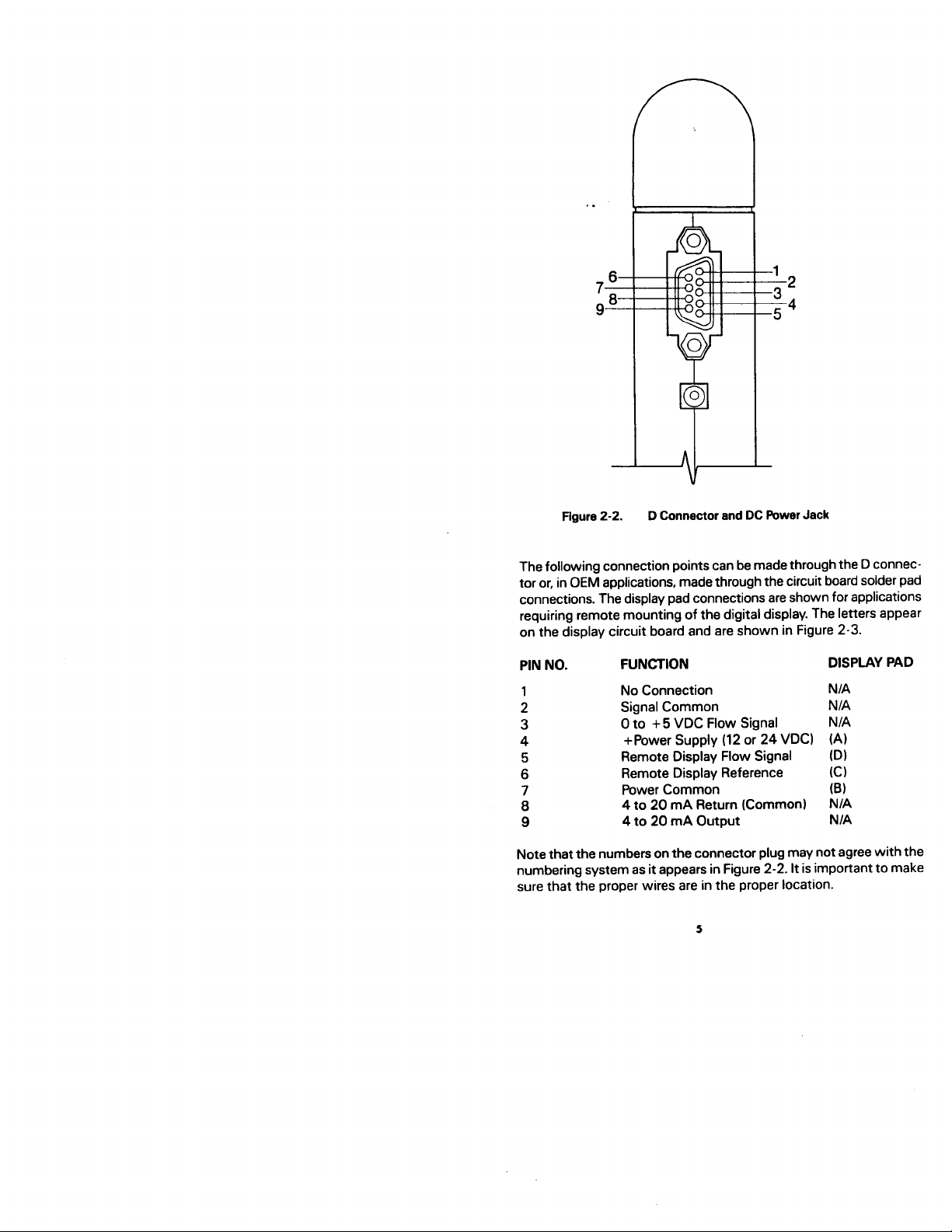

‘ FO R

DIGITAL

DISPLAY

“D”

CONNECTOR

Sdder Pad Assignments

Figure 2-3.

2.4.2

OEM Electrical Connections

-

PCB

FOR

Input/Output

One special design OEM version transducer has an electrical port

(hole) on its side for electrical input/outputs. This port is just above the

input power jack (see the exploded view, item 27, in Appendix 11.

Wires entering via this port are soldered to the printed circuit board

as shown in Figure 2-3. The solder pad assignments are given in Table

2-l.

PC6

To gain access to the

to make the solder connections for special

design applications, refer to the exploded view in Appendix 1 and

follow these steps.

6

Page 10

1.

If the flo wme ter has the digital display:

fro m

F irst, re m ove the

(al

rotating the display

tinue to rotate until this lever-ar m action snaps out the two

yokes holding the display (No. 30). Use extra caution during

this operation as excessive force will break the delicate wire

connections. Carefully m ove the display asse m bly to expose

the

ert excessive force on the display while rotating, as doing so

could crack the LCD display.

Next, re m ove the two screws

(b)

351

enclosure (No.

The top, front and back sides of the enclosure can now be

(cl

re m oved

to the flo w pa th), exposing the PCB.

2. If the flo wme ter does not have the digital display:

(al

Remove the label (No.

expose the two screws.

(b)

Then follow steps lb and

To reasse mb le, reverse this process.

For applications requiring flow totalization or alar m s, it is possible to

connect the F MA -5000 Series to the O MEGA FMA -DV Series elec-

tronics. Contact O MEGA Sa les Depart m ent for special applications.

Zrews

two

and the two screws (also No.

(the

display

until.it

securing the display base

10).

front slides out towards you and perpendicular

291

t he transducer by carefully

hits the top plate and slowly con-

35).

Do not ex-

(No.

21)

in the display base (No.(Na

21)

i n the back o f t he

fro m the plain top cover (No. 281 to

lc above.

SECT ION 3 OPERAT ION

3.1

3.2

QU ICK OPERAT ING INSTRUCT IONS

Qu ick operating instructions are given on the first page of this

m anual.

OPERAT ING NOTES

1. Referencing the Flow Rate to Other Te m perature and Pressure

Conditions

The gas flow rate output of the flow m eter is referenced to standard

(7 OOF )

cond iti ons of

unless you have specified otherwise in your order. Be sure you know

the reference conditions of your unit, because it m ay m ake a dif-

ference if you are co mpa ri ng the ou tpu t w it h ano ther type of

flo wme ter. For exa m ple, the output reading of the F MA -5000 Series

w ill be approxi m ately 7 % lo wer if it is referenced to

‘X. Appendix 3 shows how to convert the flow rate output of your

21

instru m ent to other standard conditions and how to find the flow rate

referenced to the actual te m perature and pressure conditions in the

pipe.

21°C

and 760 mm o f m ercury

7

at mospherel.

(1

O°C

rather than

Page 11

2. Accuracy

The standard accuracy is

*2%

of full scale. A

51% accuracy is

available with special calibration or upon recalibration (See Section

5.2). The

signal is accurate to within

curate to within

signal for zero flow can be as much as

note if

rt2% of full scale accuracy means the O-5 VDC output

mA

kO.1

VDC, and the 4-20

mA.

kO.4

you

get an output signal at zero flow (as long as it is within

This means, for example, that the output

kO.1

VDC or

output is ac-

*0.4mA.

Please

either of these two ranges), it does not mean the flowmeter is

malfunctioning. For models with the digital readout, the accuracy is

simply 2% times the full scale flow rate listed on the front label. For

example, if your full scale is 10 SLM, the digital readout will be ac-

curate to

as

kO.2 SLM, and the reading at zero flow may be as much

-+0.2

SLM and still be within the stated accuracy specification.

3. Overranging

If the flow rate exceeds the full scale range listed on the front label,

the output signal and digital display (if you have it) will read a higher

value.

The FMA-5000 Series has not been calibrated for overranged flows

and probably will be both non-linear and inaccurate. If the supply

voltage is only 12 VDC, the overranged reading may only exceed the

full scale reading by 10% maximum. If the supply voltage is higher,

such as with the 24 VDC option, then the output can exceed full

scale by as much as

50%, or more. If you have the digital display, the

display cannot exceed the four digits 1999. If the flow rate exceeds

1999, the right-most digits will blank and only the left-hand “1” will

appear on the display.

Due to the operating principle of the sensor, if the flow overranges,

the output will become nonlinear and at some point will go “over the

hump”. After this point, the output signal will decrease even though

the flow is increasing. This will not cause any damage and will cor-

rect itself, usually within 30 seconds after the flow is shut off or

returns to within the calibrated range of the meter. In systems where

it is possible for overrange conditions to occur, it is recommended that

a valve or critical orifice be inserted in the line to limit the flow to ap-

proximately 25% above the full scale range.

mA

4. Optional 4-20

mA

The 4-20

output signal current flows from the 4-20

pin on the D connector through the load

Output Signal

mA

output

(50 to 500 ohms) to ground.

Figures 3-l and 3-2 illustrate single and multiple installations with cur-

rent loop outputs.

Page 12

5. Zero and Span Adjustments

The zero and span potentiometers are accessed through marked

+2%

ports

on the right side. If your zero output is more than

scale,

you

may adjust the zero potentiometer when you are absolute-

of full

ly certain that you have zero flow.

Since the output does not indicate negative numbers, it is necessary

tD

adjust down from a slightly positive reading. Slowly rotate the zero

clockwise ’uhtil

pot

a positive reading is indicated. Then turn the pot

counterclockwise slowly just until zero is reached. This completes

the zero adjustment.

Normally,

sp’an

adjustments are not made unless you are calibrating

the flowmeter, as described in Section 5. The span adjustment

should not be used unless you have a known precise non-zero flow

rate that you wish to match.

6. Attitude

Unless specified otherwise, the instrument has been calibrated for

(il5’)

installation with the flow direction in the horizontal plane

with

the enclosure facing upward. If your actual installation orientation is

different, you will have to make a small zero adjustment.

PRINCIPLE OF OPERATION

Gas enters the flow body and divides into two flow paths. Most of

the flow goes through the laminar flow bypass. This creates a

pressure drop that forces a small fraction of the flow through the sen-

sor tube.

The straight sensor tube is mounted on the top of the bypass flow

path. Since both paths are perfectly laminar, the ratio of the total flow

(m)

to the sensed flow (ml) is exactly constant. This contributes to

the flowmeter ’s exceptional accuracy. Two resistance detector

(RTD)

coils around the sensor tube direct a constant amount of heat into

the gas stream.

In actual operation, the gas mass flow carries heat from the upstream

coil to the downstream coil. The resulting temperature difference

T2-Tl

is detected by the RTD coils and gives the output signal. Since

the molecules of gas carry away the heat, the output signal is directly

and linearly proportional to gas mass flow.

The laminar flow bypass makes changing of flow ranges easy with

the proper calibration facilities. Each of the two bypasses in the op-

tional Laminar Flow Bypass Set has a combination of rectangular

slots along its circumference as shown in Figure 3-5 below.

To change the flow rate of the flowmeter, follow the instructions pro-

vided with the Laminar Flow Bypass Set and cut away the gates

leading to the right combination of laminar flow paths in one of the

two bypasses. This procedure requires calibration facilities and

minimal skills in electronics.

9

Page 13

4-20mA

SIGNAL

4-20mA

POWER

SUPPLY

+15v

COM

Ffgure

Figure 3-1.

3-2.

Single Unit 4-20 Hookup

.--

Multiple Installation 4-20 Hookup

10

Page 14

STAAIGHTym

SEN53R

#

LAMINAR FLOW BYPASS

i_L ’

TUBE

Figure 3-3.

SENSOR TUBE

3-4.

Figure

F;;--“GATES”

SECT. A-A

Two Flow paths

‘-ANT HEAT, H

rineasc,

-

RTD COILS

r.#

A

--

A

Figure 3-5.

Laminar

Flow Bypass Set

Page 15

SECTION 4 MAINTENANCE

The FMA-5000 Series essentially requires no maintenance and has

no regular maintenance schedule, other than periodic flow path

cleaning if the gas is dirty. Calibrations may be scheduled once or

twice yearly, depending on the accuracy to be maintained, or as

needed.

4.1

4.1.1

4.1.2

Flow Path Cleaning

The flow path (wetted parts)

(sensor tube1 and Viton O-rings (standard).

If you wish to clean the flowmeter, purge it thoroughly

before disconnecting from the gas line when toxic or cor-

rosive gases are used. Never return the instrument to

OMEGA for repair or calibration without fully neutralizing

any toxic gases trapped inside.

Refer to the exploded drawing of the transducer in Appendix 1 when

performing the following procedures. All cleaning of the flow path

can be accomplished with Freon, alcohol or any cleaner safe for the

listed materials.

Inlet and Outlet Screen

Remove inlet and outlet fittings

12)

and either replace or clean the inlet and outlet screens (No.

(No.

14).

Flow

Laminar

Remove the inlet and outlet fitting as in Section 4.1.1. The LFE has a

slightly tapered shape with the larger diameter upstream (on the in-

let side). To remove the LFE for cleaning, push it out the inlet side from

the outlet side using a blunt object which does not mar the flow chan-

nels. A

to carefully clean all active flow channels in the LFE. When reinstalling

the LFE, it is of utmost importance to press it in the correct distance.

Refer to Figure 4-1.

Element

3/s”

nut driver is perfect for this job. When cleaning, be sure

(LFE)

5% glass-filled Nylon

ale

(Na 13). pull out the LFE hold-downs

6/6;

316 SS

12

Page 16

Figure 4-l.

4.1.3 Sensor Tube

LFE Location Within the Flow Body

Opening

Do not remove the PCB bracket (No.

the

sensor cavity

will shift calibration.

7)

unless it is absolutely

necessary to gain access to the sensor cavity. Doing so will shift the

calibration more than 2%. The remaining parts of the flow path are

disassembled as shown in the exploded view in Appendix 1. Note the

position of the insulation blanket before removal and reinstall in the

same manner. After removal, the sensor tube (No.

ed by purging, washing with a solvent, or by

51

rodding

can be clean-

out the 0.031

inch I.D. tube with a 0.029-0.030 inch O.D. rod or wire. To maximize

the time response, the sensor tube has thin walls. Therefore, when

cleaning, be extremely careful not to bend the sensor tube or to mar

its inlet or outlet edges. It is important when reinstalling the sensor

to make sure that no torque is imparted on the sensor tube. Torque

can be eliminated by using a good quality oxygen compatible grease

on the sensor sealing O-rings. The sensor assembly should slide free-

totwist

ly into the cavity flanges without having

it. Twisting will im-

part undesirable torque on the sensor and could lead to long term shif-

ting of the zero value Also, take care to not disturb or unravel the sen-

sor windings.

13

Page 17

SECTION 5 CALIBRATION

5.1

5.2

GENERAL FLOW CALIBRATION PROCEDURE

Flow calibration requires a calibration standard of at least double ac-

curacy and preferably an order of magnitude better. Most calibrations

can be done using dry nitrogen and the

“K” factors and gas tables

given in Appendix 4.

RECALIBRATION OVER THE SAME FLOW RANGE

Flow recalibration is performed by using the following procedure.

Refer to the electrical schematics in Appendix 2. Calibration checks

and minor adjustments to the zero and full scale may be made via the

access ports in the side of the enclosure. If the linearity needs adjust-

ment (as may be required when installing a different laminar flow ele-

ment bypass to.change the range), go to Step 4.

Step 1

Warm-Up: Plug in the flowmeter to be calibrated and allow

at least 15 minutes warm-up time before attempting any

adjustments.

Step 2

Zero Adjust: Slide open the zero and span access ports on

the side. Using a voltmeter connected to the meter output

Step 3

pins, adjust the zero potentiometer

for 4-20

outputs).

mA

(R5)

for zero flow

Check Full Scale: Generate the full scale flow using a meter-

mA

(4

ing valve in line with the instrument under test. Compare the

indicated flow rate with the flow standard reading. If they

agree to within

ilO%,

adjust the span potentiometer

(R21)

for exact agreement. If the readings do not agree within

*lo%,

attempt to determine the cause of disagreement.

Possibilities are:

Partially clogged or dirty sensor tube

al

Wrong or improper use of K factor

b)

Wrong or improper correction for temperature and

Cl

pressure

Leaks in the system or in the flowmeter

d)

Replacement of parts in the flow path do not exactly

e)

match the original parts.

gD

to

This completes the calibration procedure To adjust linearity,

Step

4.

Step 4

Adjusting Linearity: First gain access to the printed circuit

board inside the enclosure by using the procedure describ-

ed in Section 2.4.3. Orient the meter so that the component

plug

side of the circuit board is facing you.

allow it to

warm up for at least 15 minutes.

in the meter and

14

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Loading...

Loading...