Page 1

PROGRAMMABLE GAS MASS

FLOWMETERS AND TOTALIZERS

For Clean Gases

FMA-4100/4300 Series

U 23 Selectable

Engineering Units

(Including User Defined)

U Programmable Totalizer

U High and Low Gas

Flow Alarms

U Two Sets Programmable

SPDT Relays with

Latching Feature

U Selectable Analog

0 to 5 Vdc or

4 to 20 mA Outputs

U Internal Conversion

Factors for Up

to 32 Gases

U Digital Interface

RS232 Standard

U Automatic Sensor Zero

Offset Adjustment

(Via Digital Interface

or Local Push Button)

U Self-Diagnostic Tests

U Display Units Include

Adjustable Back Lighting

The FMA-4100/4300 Series flow rate

can be displayed in 23 different

volumetric flow or mass flow

engineering units including a user

specific selection. Flowmeters can

be programmed remotely via

RS232 or RS485 (optional).

FMA-4100/4300 flowmeters

support various functions including,

programmable flow totalizer, high

and low flow alarm, automatic zero

adjustment, 2 relay outputs, jumper

selectable 0 to 5 Vdc or 4 to 20 mA

analog outputs, status LED

diagnostic, storage of up to 10

different gas calibrations, internal

or user-specific K-factors. Display

models have local 2 lines x 16

characters LCD display with

adjustable back light provides flow,

total and diagnostic reading

simultaneously. The digital RS232

or RS485 (optional) interface

provides access to applicable

internal data including, flow, CPU

temperature, auto zero, totalizer

and alarms settings, gas table,

conversion factors and engineering

units selection, dynamic response

compensation and linearization

table adjustment. The analog

interface provides 0 to 5 Vdc or

4 to 20 mA (jumper selectable)

outputs for flow reading.

The FMA-4100/4300 supports

automatic sensor zero offset

adjustment which can be activated

locally via the maintenance push

button or remotely via digital

interface. The auto zero feature

necessitates a condition of

absolutely no flow through the

meter during the adjustment

process. Provisions are made to

either start, read, or save the

current auto zero value via digital

commands. Digital totalizer

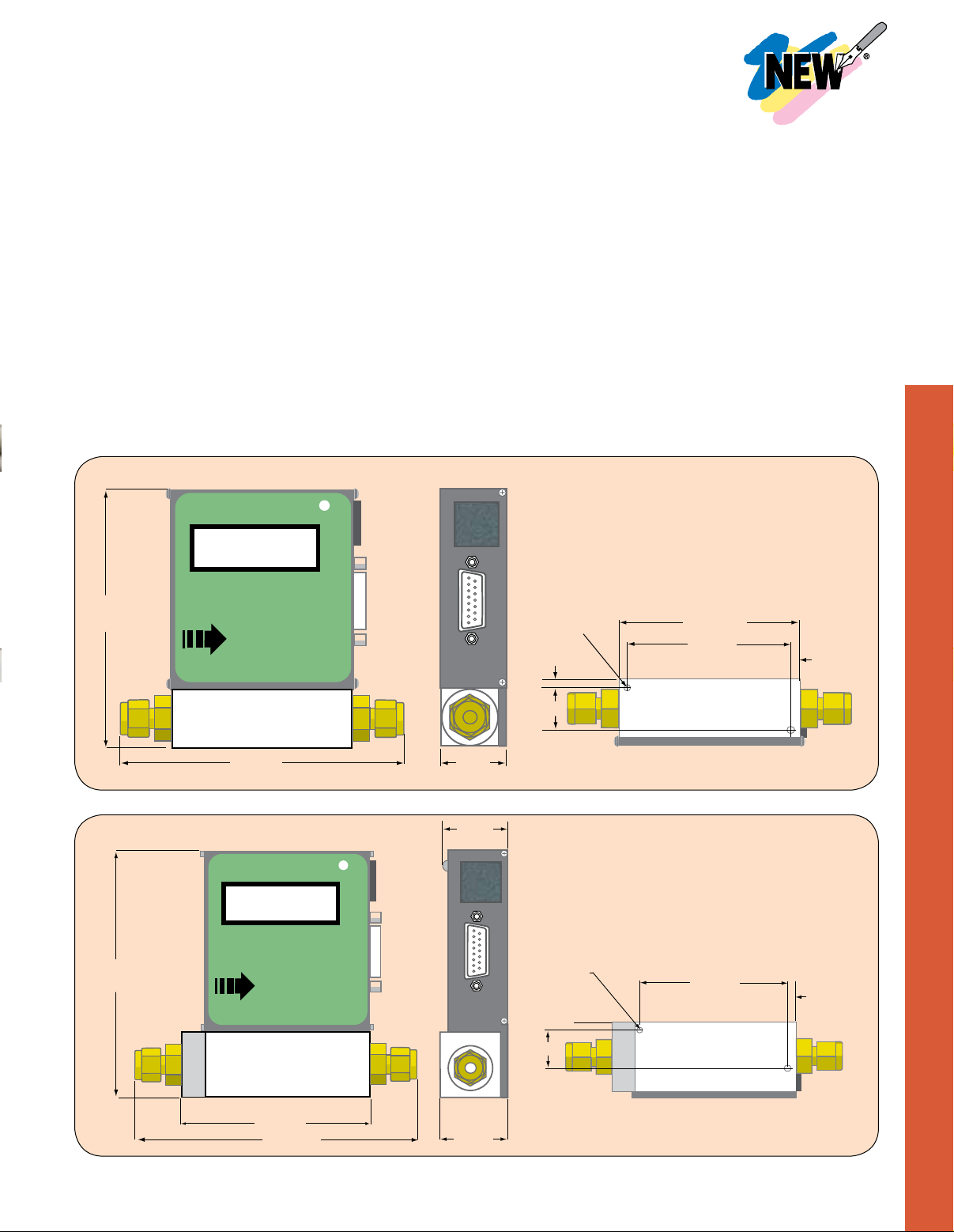

FMA-4303,

shown smaller

than actual size.

commands include: set to zero,

start at a preset flow, assign action

to a preset value, start/stop

totalizing and read. High and Low

gas flow alarm limits can also be

preprogrammed via digital interface.

Alarm action can be assigned with

preset delay interval (0 to 3600

seconds) to activate the contact

closer (separate for high and low

alarm). Latch mode control feature

allows each relay to be latched

on or follow the corresponding

alarm status.

SPECIFICATIONS

Calibrations: Performed at standard

conditions [101.4 kPa (14.7 psia) and

21.1°C (70°F)] unless otherwise

requested or stated

Environmental (PER IEC 664):

Installation Level II; Pollution Degree II

Flow Accuracy (Including Linearity):

±1% of FS at calibration temperature

and pressure

Repeatability: ±0.15% of full scale

Flow Temperature Coefficient:

0.15% of full scale/°C or better

D-9

Page 2

Flow Pressure Coefficient: 0.01% of

DIGITAL

MASS FLOW

METER

STATUS

FLOW

F: O.O1 L/min

T: 34.29 L

TR

DIGITAL

MASS FLOW

METER

STATUS

FLOW

F: O.O1 L/min

T: 34.29 L

TR

full scale/psi (6.895 kPa) or better

Turndown Ratio: 50:1

Flow Response Time: 600 ms time

constant; approximately 2 seconds to

within ±2% of set flow rate for 25 to

100% of full scale flow

Max Gas Pressure: 3447 kPa gauge

(500 psig)

Max Pressure Drop:

Max Flow ≤10 SLM: 1.28 kPa (0.18 psi)

Max Flow >10 SLM: 27.58 kPa (4 psi)

Gas and Ambient Temperature:

5 to 50°C (41 to 122°F)

Relative Gas Humidity: Up to 70%

Leak Integrity: 1 x 10

-9

SCCS He max

to the outside environment

Attitude Sensitivity: Deviation of up to

1% from stated accuracy, after re-zeroing

Output Signals: Linear 0 to 5 Vdc

(3000 Ω min load impedance); Linear

4 to 20 mA (500 Ω max loop

resistance). Max noise 20 mV

peak to peak (for 0 to 5 Vdc output)

Dimensions: mm (in)

Relay: SPDT (30 Vdc, 1A)

Transducer Input Power:

11 to 26 Vdc, 100 mV max peak to

peak output noise

Power Consumption: +12 Vdc

(200 mA max); +24 Vdc (100 mA max);

Circuit board has built-in polarity reversal protection, 300 mA resettable fuse

provide power input protection

Wetted Materials:

Standard Aluminum Models:

Anodized aluminum, brass,

316 stainless steel, FKM O-rings

Optional Stainless Steel Models:

316 stainless steel, FKM O-rings

Optional O-ring Materials:

Buna, EPR (Ethylene Propylene),

or perfluoroelastomer

Inlet and Outlet Connections:

Model FMA-4100/4300: Standard

6.35 mm (

1

⁄4") compression fittings,

for units 60 SLM and larger

9.53 mm (3⁄8")

Optional: 3.18 or 9.53 mm (1⁄8 or 3⁄8")

compression fittings

Display (FMA-4300 Models): Local

2 lines x 16 characters LCD with

adjustable backlight (2-lines of text)

Calibration Options: Standard is one

10-points NIST traceable calibration.

Optional, up to 9 additional calibrations

may be ordered at additional charge.

Contact OMEGA for additional

information

CE Compliance: EMC compliance with

89/336/EEC as amended

Emission Standard: EN 55011:1991,

Group 1

Class A Immunity Standard:

EN 55082-1:1992

D

113

(4.425)

Dimensions: mm (in)

121.2

(4.800)

124

(4.882)

90.1

(3.575)

136.2

(5.363)

28.5

(1.125)

31.2

(1.230)

35

(1.375)

Mounting

Holes 6-32

3.5

(0.140)

18

(0.720)

Mounting

Holes 6-32

3.5

(0.140)

18

(0.720)

79

(3.094)

72

(2.814)

Units ≤10 SLM Full Scale

72

(2.814)

Units >10 SLM Full Scale

(0.140)

(0.140)

3.5

3.5

D-10

Page 3

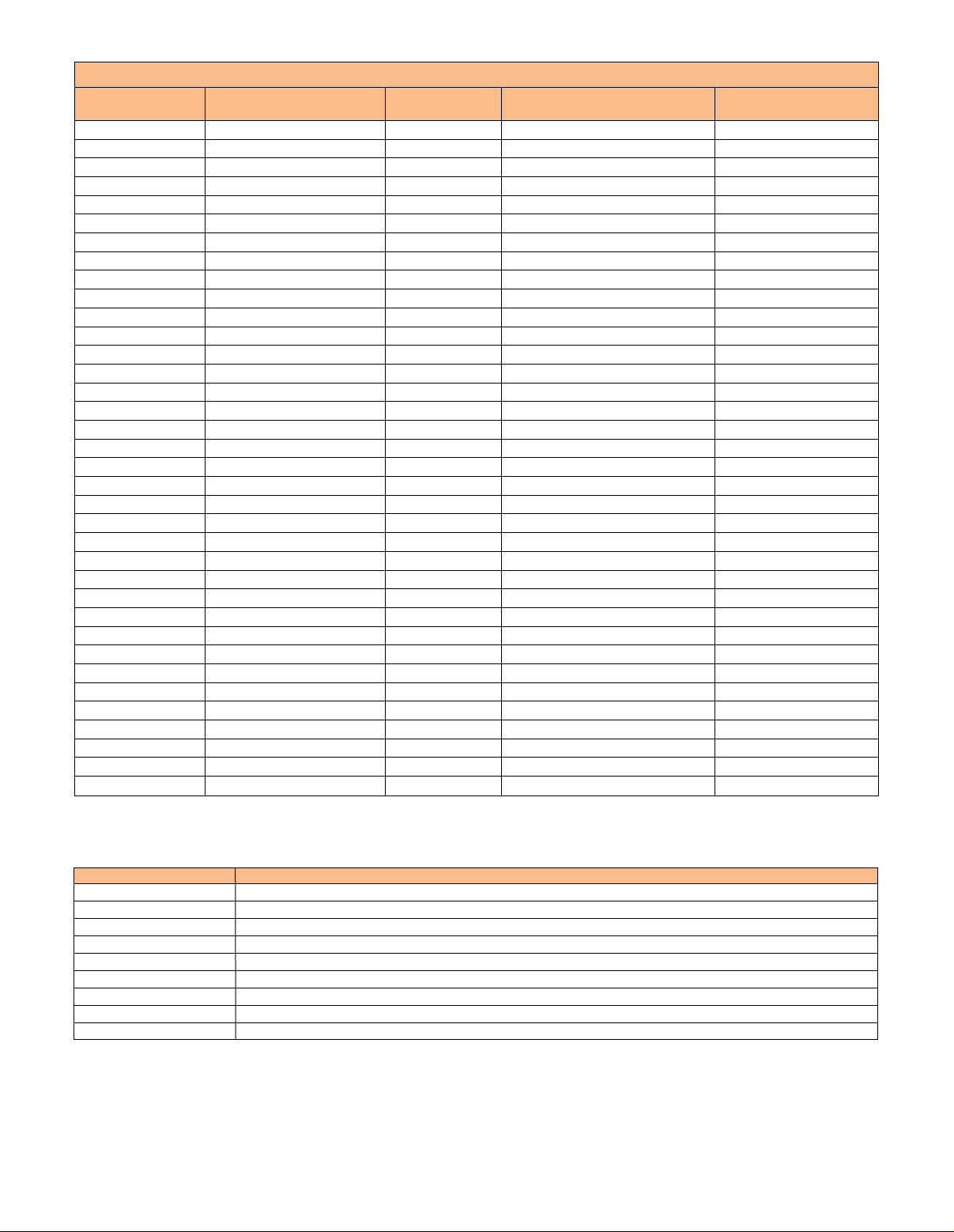

To Order Visit omega.com/fma4100_4300 for Pricing and Details

Integral Inlet and Outlet Compression

Model No. Body Display Fittings mm (inch) Range

FMA-4102 Aluminum - 6.35 (¹⁄₄) 0 to 5 SCCM

FMA-4103 Aluminum - 6.35 (¹⁄₄) 0 to 10 SCCM

FMA-4104 Aluminum - 6.35 (¹⁄₄) 0 to 20 SCCM

FMA-4105 Aluminum - 6.35 (¹⁄₄) 0 to 50 SCCM

FMA-4106 Aluminum - 6.35 (¹⁄₄) 0 to 100 SCCM

FMA-4107 Aluminum - 6.35 (¹⁄₄) 0 to 200 SCCM

FMA-4108 Aluminum - 6.35 (¹⁄₄) 0 to 500 SCCM

FMA-4109 Aluminum - 6.35 (¹⁄₄) 0 to 1 SLM

FMA-4110 Aluminum - 6.35 (¹⁄₄) 0 to 2 SLM

FMA-4111 Aluminum - 6.35 (¹⁄₄) 0 to 5 SLM

FMA-4112 Aluminum - 6.35 (¹⁄₄) 0 to 10 SLM

FMA-4113 Aluminum - 6.35 (¹⁄₄) 0 to 20 SLM

FMA-4114 Aluminum - 6.35 (¹⁄₄) 0 to 30 SLM

FMA-4115 Aluminum - 6.35 (¹⁄₄) 0 to 40 SLM

FMA-4116 Aluminum - 6.35 (¹⁄₄) 0 to 50 SLM

FMA-4117 Aluminum - 9.53 (³⁄₈) 0 to 60 SLM

FMA-4118 Aluminum - 9.53 (³⁄₈) 0 to 80 SLM

FMA-4119 Aluminum - 9.53 (³⁄₈) 0 to 100 SLM

FMA-4302 Aluminum Y 6.35 (¹⁄₄) 0 to 5 SCCM

FMA-4303 Aluminum Y 6.35 (¹⁄₄) 0 to 10 SCCM

FMA-4304 Aluminum Y 6.35 (¹⁄₄) 0 to 20 SCCM

FMA-4305 Aluminum Y 6.35 (¹⁄₄) 0 to 50 SCCM

FMA-4306 Aluminum Y 6.35 (¹⁄₄) 0 to 100 SCCM

FMA-4307 Aluminum Y 6.35 (¹⁄₄) 0 to 200 SCCM

FMA-4308 Aluminum Y 6.35 (¹⁄₄) 0 to 500 SCCM

FMA-4309 Aluminum Y 6.35 (¹⁄₄) 0 to 1 SLM

FMA-4310 Aluminum Y 6.35 (¹⁄₄) 0 to 2 SLM

FMA-4311 Aluminum Y 6.35 (¹⁄₄) 0 to 5 SLM

FMA-4312 Aluminum Y 6.35 (¹⁄₄) 0 to 10 SLM

FMA-4313 Aluminum Y 6.35 (¹⁄₄) 0 to 20 SLM

FMA-4314 Aluminum Y 6.35 (¹⁄₄) 0 to 30 SLM

FMA-4315 Aluminum Y 6.35 (¹⁄₄) 0 to 40 SLM

FMA-4316 Aluminum Y 6.35 (¹⁄₄) 0 to 50 SLM

FMA-4317 Aluminum Y 9.53 (³⁄₈) 0 to 60 SLM

FMA-4318 Aluminum Y 9.53 (³⁄₈) 0 to 80 SLM

FMA-4319 Aluminum Y 9.53 (³⁄₈) 0 to 100 SLM

Accessories

Model No. Description

FMA-4000PS-NA Power supply 110 Vac, N American plug

FMA-4000PS-EU Power supply 230 Vac, European plug

FMA-4000PS-UK Power supply 240 Vac, U.K. plug

FMA-4000PS-AU Power supply 240 Vac, Australian plug

FMA-4000PS-NA-A Power supply 110 Vac, N American plug with analog wires

FMA-4000PS-EU-A Power supply 230 Vac, European plug with analog wires

FMA-4000PS-UK-A Power supply 240 Vac, U.K. plug with analog wires

FMA-4000PS-AU-A Power supply 240 Vac, Australian plug with analog wires

FMA-4000C 15-pin D pre-wired 1.8 m (6') to PC, 0.9 m (3') to power supply

Comes complete with software CD (operator’s manual included on CD), 15-pin D pre-wired 1.8 m (6') cable, and NIST certificate.

Power supplies sold separately. Power supplies also include cable.

For models with stainless steel body, add suffix, “-ST” to model number, consult Flow Engineering for price.

To replace the RS232 communications with RS485, add suffix “-RS485” to model number, no additional cost.

For units with

For units with

Ordering Examples: FMA-4308, aluminum flowmeter with display, 0 to 500 SCCM and FMA-400PS-NA, 110 vac plug-in power supply.

FMA-4102, aluminum flowmeter without display, 0 to 5 SCCM.

1

⁄8" compression fittings, add suffix “-1/8” to model number, no additional cost.

3

⁄8" compression fittings, add suffix “-3/8” to model number, no additional cost.

D-11

Loading...

Loading...