Page 1

MASS AND VOLUMETRIC GAS FLOWMETERS

For Clean Gases

FMA-1611A includes 110 Vac

power supply and a 1.8 m (6') cable

8-pin mini DIN connector, shown actual size.

FMA-1603A includes

110 Vac power supply

and a 1.8 m (6') cable

8-pin mini DIN connector,

shown actual size.

D

FMA-1600A Series

U Ranges of 0 to 0.5 SCCM Up to 0 to 1500 SLM

U Reports Mass Flow, Volumetric Flow,

Temperature, and Pressure

U <10 ms Response Time—Field Adjustable

U 20+ Gas Calibrations, Including Air, Ar,

, CO, CO2, Ethane, H2, He, N2, N2O, Neon,

CH

4

, Propane, Butane, Iso-Butane, Acetylene,

O

2

Ethylene, Krypton, Xenon, and

Sulfur Hexafluoride

U Pressure, Temperature and, Volumetric and

Mass Flow Simultaneously Displayed

U NIST 5-Point Certificate Included

U No Straight Runs of Pipe Required

U No Warm-Up Time

U Turndown Ratio of 100:1 (1% Max Flow)

U RS232 Standard

D-X

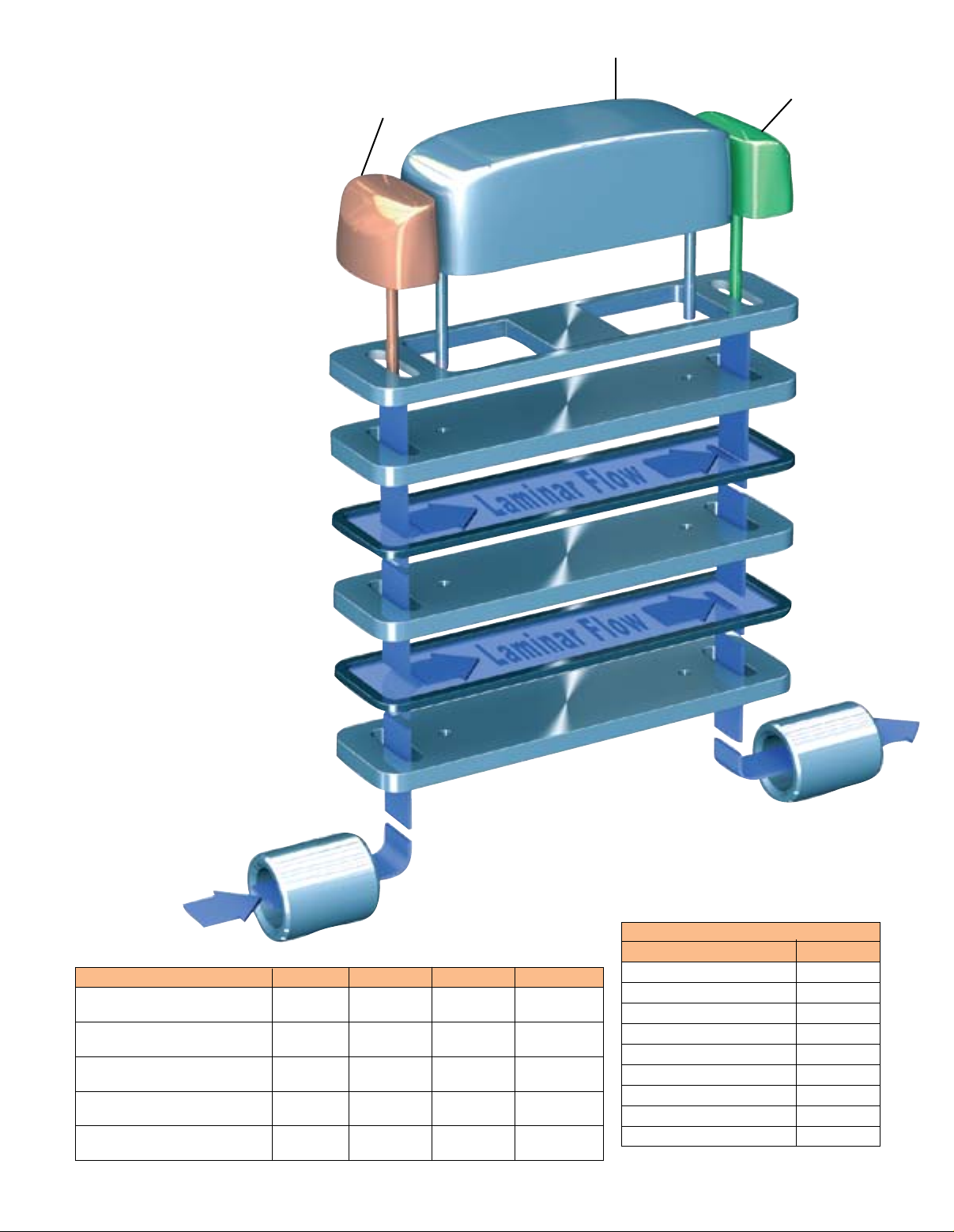

The FMA-1600A Series mass and volumetric

flowmeters use the principle of differential pressure

within a laminar flow field to determine the mass flow

rate. A laminar flow element (LFE) inside the meter

forces the gas into laminar (streamlined) flow. Inside

this region, the Poiseuille equation dictates that the

volumetric flow rate be linearly related to the

pressure drop. A differential pressure sensor is used

to measure the pressure drop along a fixed distance

of the LFE. This, along with the viscosity of the gas, is

used to accurately determine the volumetric flow rate.

Separate absolute temperature and pressure sensors

are incorporated and correct the volumetric flow rate

to a set of standard conditions. This standardized flow

rate is commonly called the mass flow rate and is

reported in units such as standard cubic feet per

minute (SCFM) or standard liters per minute (SLM).

Standard units include a 0 to 5 V output (4 to 20 mA

optional) and RS232 communications. The gas select

feature can be adjusted from the front keypad or via

RS232 communications. Volumetric flow, mass flow,

Page 2

absolute pressure, and

temperature can all be viewed

or recorded through the RS232

connection. It is also possible

to multi-drop up to 26 units on

the same serial connection to a

distance of 38 m (125'). These

flowmeters can be powered

by the optional battery pack

FMA1600-BP for use in the field.

SPECIFICATIONS

Accuracy: ±(0.8% of rdg

+ 0.2% FS)

Repeatability: ±0.2%

Turndown Ratio: 100:1

Response Time: 10 ms typical

default response time for 63.2% of

a step change. A variable register

allows response time to be field

adjustable to a certain extent via

RS232 communications. The

primary trade-off for response

time is signal noise

Output: 0 to 5 Vdc standard

Operating Temperature:

-10 to 50°C (14 to 122°F)

Zero Shift: 0.02% FS/°C/atm

Span Shift: 0.02% FS/°C/atm

Humidity Range: 0 to 100%

non-condensing

Pressure (Max): 145 psig

Measurable Flow Rate:

125% FS

Supply Voltage: 7 to 30 Vdc

(15 to 30 Vdc for 4 to 20 mA

output)

Supply Current: 35 mA typical

current draw; 100 mA available

supply recommended

Cable Connection:

8-pin mini DIN

Wetted Parts: 302 and 303 SS,

FKM, silicone RTV, nylon

aluminum

616,

Absolute Pressure

Sensor

Exploded View of Internal

Laminar Flow Elements

Differential Pressure

Sensor

Temperature

Sensor

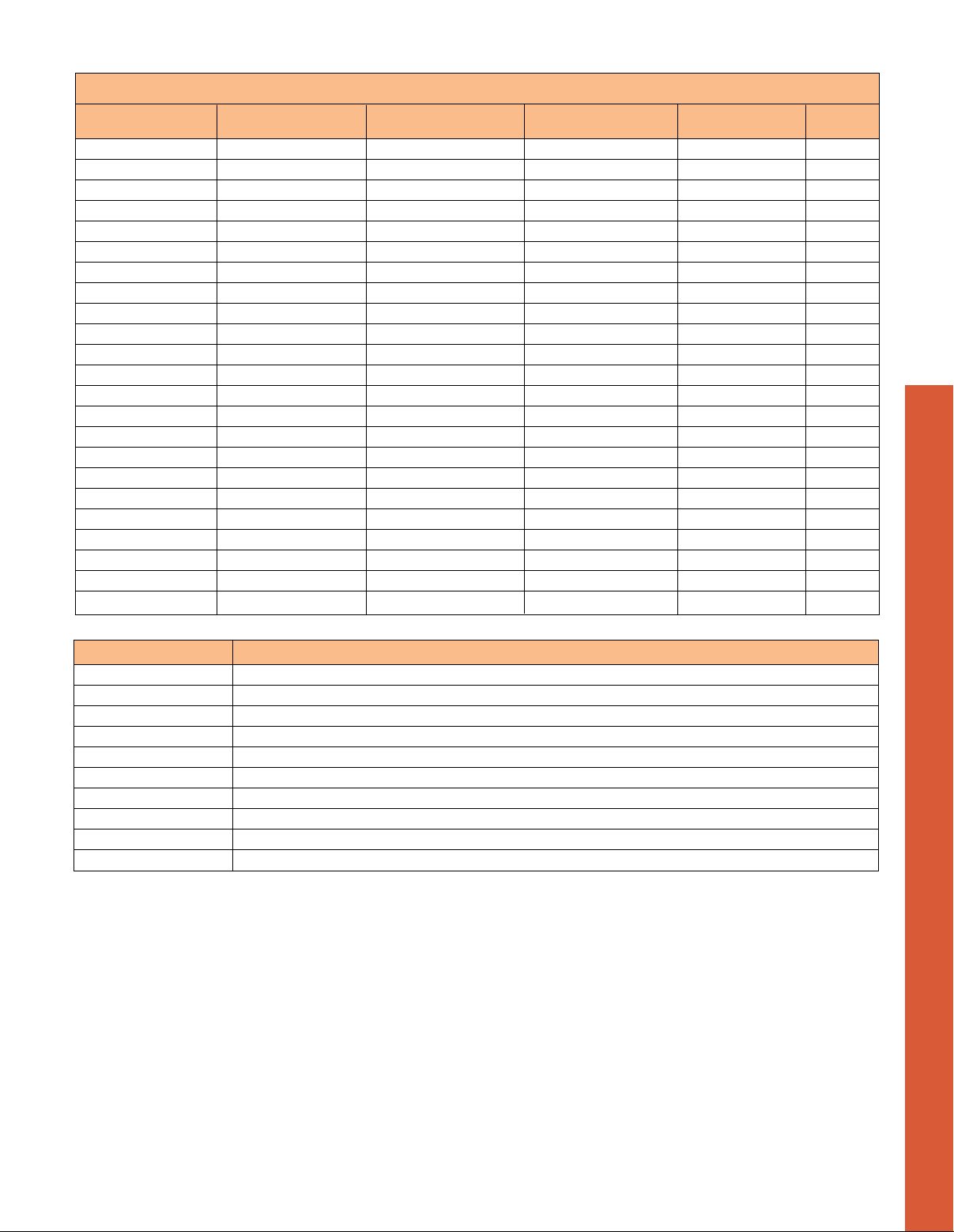

Dimensions: mm (inch)

Flow Range Height Length Depth Port Size

0.5 to 50 SCCM 98.98 60.33 26.67 10-32

(3.897) (2.375) (1.05) UNF

100 to 500 SCCM and 103.30 60.33 26.67 ¹⁄₈ FNPT

1 to 20 SLM (4.067) (2.375) (1.05)

50 and 100 SLM 110.92 101.60 40.64 ¹⁄₄ FNPT

(4.367) (4.0) (1.6)

250 SLM 126.16 101.60 40.64 ¹⁄₂ FNPT

(4.967) (4.0) (1.6)

500 to 1500 SLM 126.16 101.60 40.64 ³⁄₄ FNPT

(4.967) (4.0) (1.6)

D-X

Standard Pressure Drops

†

Full Scale Flow Rate psid

0.5 to 50 SCCM 1

100 SCCM to 10 SLM 1

20 SLM 1

50 SLM 2

100 SLM 2.5

250 SLM 4.0

500 SLM 5.5

1000 SLM 6.0

1500 SLM 9.0

† Venting to atmosphere.

Page 3

To Order Visit omega.com/fma1600 for Pricing and Details

Mass Flowmeter 4 to 20 mA Output

Model No. Model No. Model No.** Model No.** Connection Max Flow

FMA-1601A FMA-1601A-I FMA-1601A-I2 FMA-1601A-V2 10 to 32 thread 0.5 SCCM

FMA-1602A FMA-1602A-I FMA-1602A-I2 FMA-1602A-V2 10 to 32 thread 1 SCCM

FMA-1614A FMA-1614A-I FMA-1614A-I2 FMA-1614A-V2 10 to 32 thread 2 SCCM

FMA-1615A FMA-1615A-I FMA-1615A-I2 FMA-1615A-V2 10 to 32 thread 5 SCCM

FMA-1603A FMA-1603A-I FMA-1603A-I2 FMA-1603A-V2 10 to 32 thread 10 SCCM

FMA-1616A FMA-1616A-I FMA-1616A-I2 FMA-1616A-V2 10 to 32 thread 20 SCCM

FMA-1604A FMA-1604A-I FMA-1604A-I2 FMA-1604A-V2 10 to 32 thread 50 SCCM

FMA-1617A FMA-1617A-I FMA-1617A-I2 FMA-1617A-V2 ¹⁄₈ FNPT 100 SCCM

FMA-1618A FMA-1618A-I FMA-1618A-I2 FMA-1618A-V2 ¹⁄₈ FNPT 200 SCCM

FMA-1619A FMA-1619A-I FMA-1619A-I2 FMA-1619A-V2 ¹⁄₈ FNPT 500 SCCM

FMA-1620A FMA-1620A-I FMA-1620A-I2 FMA-1620A-V2 ¹⁄₈ FNPT 1 SLM

FMA-1605A FMA-1605A-I FMA-1605A-I2 FMA-1605A-V2 ¹⁄₈ FNPT 2 SLM

FMA-1606A FMA-1606A-I FMA-1606A-I2 FMA-1606A-V2 ¹⁄₈ FNPT 5 SLM

FMA-1607A FMA-1607A-I FMA-1607A-I2 FMA-1607A-V2 ¹⁄₈ FNPT 10 SLM

FMA-1608A FMA-1608A-I FMA-1608A-I2 FMA-1608A-V2 ¹⁄₈ FNPT 20 SLM

FMA-1609A FMA-1609A-I FMA-1609A-I2 FMA-1609A-V2 ¹⁄₄ FNPT 50 SLM

FMA-1610A FMA-1610A-I FMA-1610A-I2 FMA-1610A-V2 ¹⁄₄ FNPT 100 SLM

FMA-1611A FMA-1611A-I FMA-1611A-I2 FMA-1611A-V2 ¹⁄₂ FNPT 250 SLM

FMA-1612A FMA-1612A-I FMA-1612A-I2 FMA-1612A-V2 ³⁄₄ FNPT 500 SLM

FMA-1613A FMA-1613A-I FMA-1613A-I2 FMA-1613A-V2 ³⁄₄ FNPT 1000 SLM

FMA-1621A FMA-1621A-I FMA-1621A-I2 FMA-1621A-V2 ³⁄₄ FNPT 1500 SLM

FMA-1622A FMA-1622A-I FMA-1622A-I2 FMA-1622A-V2 ³⁄₄ FNPT 2000 SLM

FMA-1623A FMA-1623A-I FMA-1623A-I2 FMA-1623A-V2 1¹⁄₄ FNPT 3000 SLM

Two 4 to 20 mA Output

Two 0 to 5V Output

D

Accessories for FMA-1600A Series

Model No. Description

FMA1600-C1 Replacement 8-pin male mini DIN connector cable, single ended, 1.83 m (6')

FMA1600-C1-25 FT 8-pin male mini DIN connector cable, single ended, 7.62 m (25')

FMA1600-C2 8-pin male mini DIN connector cable, double ended, 1.83 m (6')

FMA1600-C2-25FT 8-pin male mini DIN connector cable, double ended, 7.62 m (25')

FMA1600-C3 8-pin male mini DIN to DB9 female adaptor, 1.83 m (6')

FMA1600-CRA 8-pin male right-angle mini DIN cable, single ended, 7.83 m (6')

FMA1600-MDB Multi-drop box

FMA1600-PSU Universal 100 to 240 Vac to 24 Vdc power supply adaptor

MN1604 Replacement 9V battery for “-B” portable meters

FMA1600-BP Battery cradle (not for use with “-B” models)

Comes complete with 24 Vdc universal power supply, 1.8m (6') cable, 8-pin male Mini- DIN connector, operator’s manual, and NIST certificate.

Units are calibrated to air @ 5 psig for 0 to 1 LPM, 15 psig for 2 to 10 LPM, 30 psig for 20 to 100 LPM, and 50 psig for 200 LPM and greater.

Calibrations done at ambient (21C/70F) temperature only.

To replace the standard RS232 communications with RS485, add suffix “-RS485” to the model number; for additional cost.

Standard input is 0 to 5V, for optional 4 to 20 mA input add suffix “-IN” to the model number; no additional cost.

Standard output is scaled to the mass flow rate. For volumetric flow rate as standard output add suffix “-VOL” to the model number; no additional cost.

Standard output is 0 to 5V, for optional 4 to 20 mA output, add suffix, “-I” to model number; for additional cost.

For two 4 to 20 mA output, add suffix “-I2” to model number; for additional cost.

For two 0 to 5V output, add suffix “V2” to model number; for additional cost.

**Optional secondary output are scaled the same as the primary output scale. For an alternate output scale add suffix “-T” to the model number

for temperature or “-P” for pressure; no additional cost.

For a portable version of the meter add suffix “-B” to the model number; for additional cost. Portable versions have an integral battery compartment

on the meter and come with one 9V battery installed. Option not available on “-I” or “I2” models where 4 to 20mA is the chosen output.

For units scaled in SCFH, add suffix “-SCFH” to model number; no additional cost. Please specify the desired range in SCFH.

For totalizer option, add suffix “-TOT” to the model number; for additional cost. Please specify resolution.

This is a 6-digit counter. Examples: For totalizing in liters with 1/100 liter resolution, the max count would be 9999.99. For totalizing in liters with 1

liter resolution, the max count would be 999999.

Ordering Examples: FMA-1601A, 0.5 SCCM mass flowmeter, FMA-1600-BP, battery pack.

FVL-1619A-VOL, 500 SCCM volumetric flowmeter.

D-20

Loading...

Loading...