Page 1

DRA-TCI-2D

b

DIN Rail 2-Wire Temperature

Transmitter for

Thermocouple Input

Operator's Manual

CONTENTS:

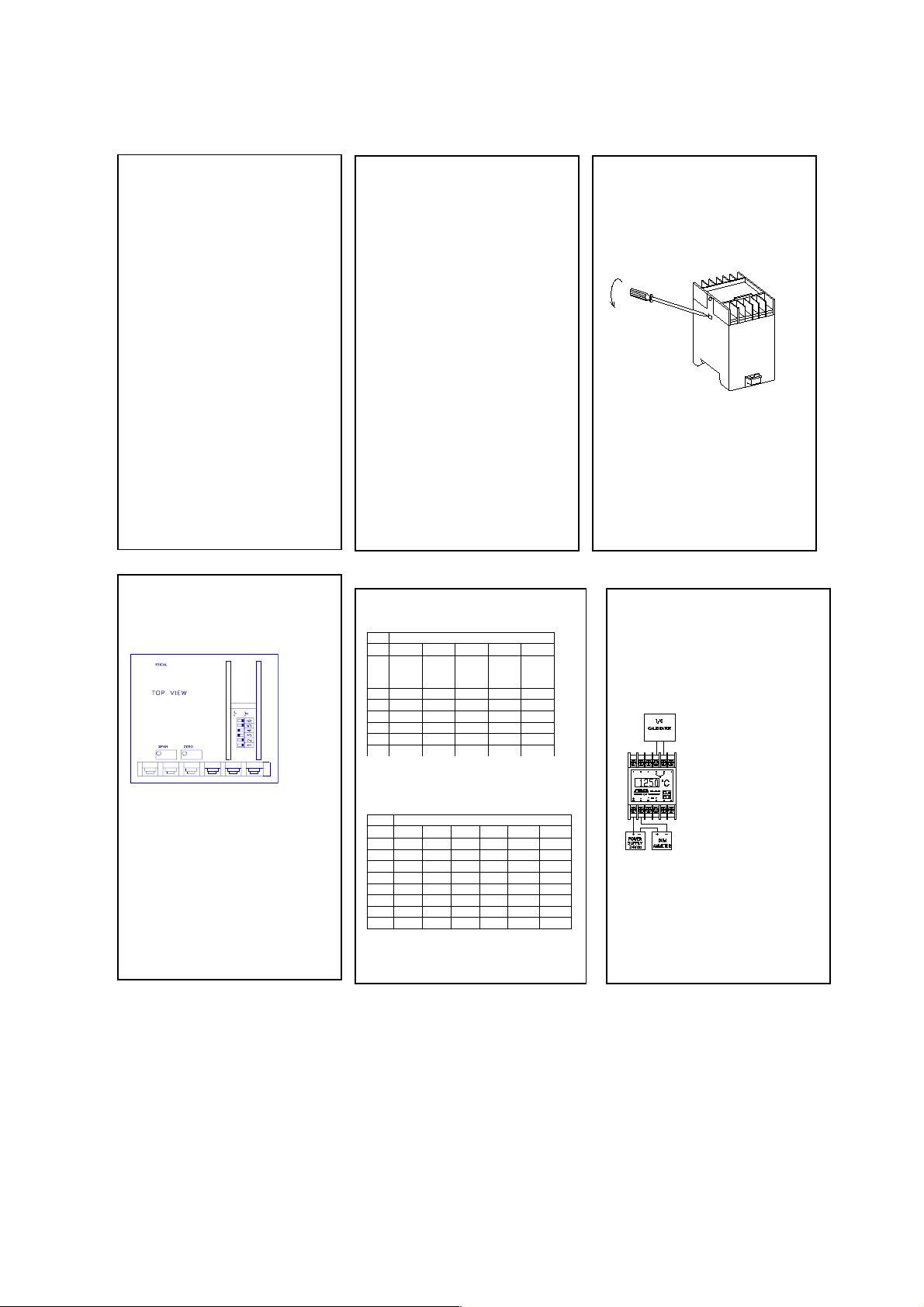

1.OPEN THE HOUSING PROCEDURE

2.TRANSMITTER CALIBRATION

3.DISPLAY CALIBRATION

4.CONNECTION DIAGRAM

5.MECHANICAL DIMENSIONS

6.SPECIFICATIONS

OPEN THE HOUSING PROCEDURE

Carefully insert a proper screwdriver tip into the side

slots. By pressing inwards and rotat ing, the plastic

lock er will rele ase.

Gent ly pull out the unit 's fro nt panel.

Fig 1

To close the unit, insert the printed circuit board in the

proper side guiding slots and push it all the way until the

front panel clicks with the body housing.

1

2. TRANSMITTER CALIBRATION

2.1 Switch Setting

Inside th e enclosure are located six DIP-swit ches for coar se range,

and two multi-turn potentiometers are located on the transmitter

panel for fine-tuning

Fig. 2

Note: The DRA-TCI-2D is ordered for a specific T/C, and

can not be altered.

Note: The following tables indicate coarse ranges. It might

2.1.1. Define the desired range limits:

Tmin - the temperature at which the output current is 4mA.

Tmax - the temperature at which the output current is 20mA.

Tspan - t he difference between Tm ax and Tmin.

According to the following tables, set switches no. 4 to 6 for the

Zero (Tmin), and set switches 1 to 3 for the Span (Tspan).

Note: "1" represent the switch "ON" state.

.

occur that the proper range can be obtained with

adjacent switch combinations.

2

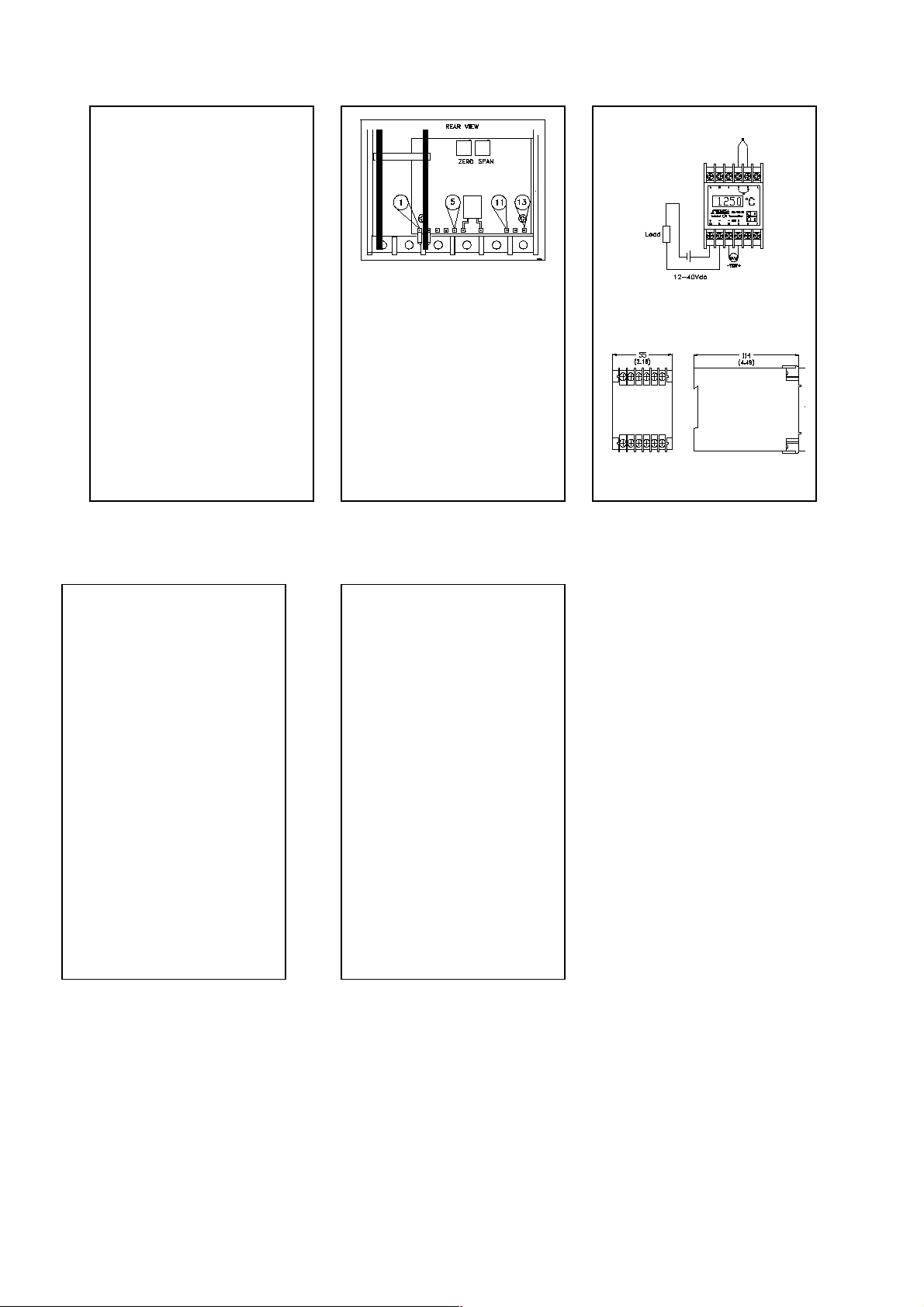

CALIBRATION TABLES

2.2.1 "Span" Table

SW. T/C Type

3 – 2 - 1

K (°C) J (°C) T (°C) E (°C) B, R, S (°C)

1 1 1 50...95 50...95 600...1100

1 1 0 90...18 0 1000..1700

1 0 0 90...175

0 1 1 175...360 93...200 50...95

0 1 0 250...440 140...248 60...11 5 160..280

0 0 1 440...850 230...480 112...215 270...575

0 0 0 850..1350 450...760 200...400 530...1100

"Zero" T able

SW. T/C Type

4 – 5 - 6

K (°C) J (°C) T (°C) E (°C) B (°C) R & S (°C)

1 1 1 0 ~ .25 0 ~ 42 -50 ~ -30 -100 ~ -52

1 1 0 25 ~ 60 30 ~ 85 -45 ~ -15 100 ~ 465 0 ~ 180

1 0 1 45 ~ .90 70 ~ 125 -15 ~ .5 -52 ~ 56 120 ~ 280

1 0 0 80 ~ 120 110 ~ 175 5 ~ 40 460 ~ 870 240 ~ 380

0 1 1 115 ~ 160 165 ~ 215 30 ~ 58 56 ~ 162 340 ~ 480

0 1 0 150 ~ 190 200 ~ 265 50 ~ 74 865 ~ 1270 440 ~ 580

0 0 1 190 ~ 230 250 ~ 300 65 ~ 88 162 ~ 269 540 ~ 680

0 0 0 225 ~ 265 280 ~ 350 82 ~ 108 215 ~ 320 1270 ~ 1670 640 ~ 800

5

3

2.3 Calibration instrumentation:

2.3.1. 24Vdc Power Supply

2.3.2 T/C calibrator

2.3,3 High accuracy DVM

2.3.4 Small screwdriver

Connect the transmitter to be calibrated according to Fig #3.

Fig 3

2.4 CALIBRATION STEPS

a. Set the calibrator to Tmin.

. Adjust the Zero for 4mA.

c. Set the calibrator to Tmax.

d.Adjust the Span for 20mA.

Repeat steps a to d until satisfactory results are achieved.

Page 2

2.4.1..................... Calibration example:

j

b

Needed: T/C Type K ranged for: 200 to 500°C

Tmin: 200°C

Tspan: 500 – 200 = 300°C

1. Set the DIP switch to: 0,1,0,0,0,1 (sw1..sw6)

2. Set the calibrator for 200°C, calibrate "Z" to 4.000mA.

3. Set for 500°C and calibrate "S" to 20.000mA.

4

. Repeat steps 2, 3 until satisfactory results are obtained.

3. DISPLAY CALIBRATION

The display calibration is performed by setting two jumpers and

two trimmers (Zero and Span).

The display has 3½ digits, i.e it can display from -1999 to 1999.

Three decimal positions can be obtained using one of the two

umpers.

Jumper position over pins #1 to #5 sets the decimal point.

No jumper - 1999

Pins #1-#2 - 199.9

Pins #3-#4 - 19.99

Pins #4-#5 - 1.999

Jumper over pins #11 to #13 sets the display range according to:

No jumper 1000 to 1999

Pins #12-#13 500 to 1000

Pins #11-#12 200 to 500

Fig. 4

3.1 CALIBRATION PROCEDURE

a. Set the transmitter to exactly 4-20mA.

. Place th e jumpers for desired r ange.

c. Adjust the display Zero trimmer for 000 at 4mA.

d. Adjust the display Span trimmer for desired span.

e. Adjust the display Zero trimmer for Tmin at 4mA.

Example:

required -100°C to +750°C. The span is 850°C.

Set the display (at -100°C) to 000 by the Zero potentiometer. Set

the display (at +750°C) to 850 by the Span potentiometer. Set the

display (at -100°C) to -100 by the Zero potentiometer

4. CONNECTION DIAGRAM

Fig. 5

MECHANICAL DIMENSIONS, mm (in )

Fig. 6

9

6. SPECIFICATIONS

INPUT: Thermocouple type B, E, J, K, R, S T

BURNOUT PROTECTION: Upscale

MINIMUM INPUT SPAN: 4mV

OUTPUT: 4 - 20 mA, (25 mA limited)

LOOP RESISTANCE: Rmax(W) = (Vsupply-12)/.02

ISOLATION: 1500 Vdc or peak ac

RESPONSE TIME: 160 msec (0-98%)

CALIBRATI ON:

Span Calibration: Three DIP switches and "Span" potentiometer

Zero Calibration: Three DIP switches and "Zero" potentiometer

COLD JUNCTION COMPENSATION ERROR: Typical ±0.9°C

for 0-60°C change (±3°C for B, R and S)

ACCURACY (linearity, hysteresis and repeatability):

± 0.1% of span for type K,

± 0.1% to ± 0.2% for other thermocouple types, typical

TEST TERMINALS: 40 to 200 mV represent 4-20 mA

SUPPLY VOLTAGE: 12 - 40 Vdc reverse polar ity protected

SUPPLY AND LOAD VARIATION EFFECT: < ±0.03% of span

for full change

CMR: 127db typical dc to 60 Hz

DISPLAY: 0.3" 3½ digit back-illuminated, LCD

LCD DISPLAY RANGE: -1999 to 1999.

DISPLAY CALIBRATION: Internal Zero & Span potentiometers.

TEMPERATURE STABILITY: ±0.01% of span /1°C

10

OPERATING TEMPERATURE: -20 to +70°C (-4 to 158°F)

STORAGE TEMPERATURE: -30 to +85°C (-22 to 185°F)

HUMIDITY: 5 - 95% relative humidity, non-condensing

HOUSING: Plastic polycarbonate

PROTECTION LEVEL:

Housing: According to IP-40

Terminals: According to IP-20

MOUNTING: Standar d 35 mm DIN rail

WEIGHT: 200 grams (7 oz)

11

Page 3

.

Page 4

Loading...

Loading...