Page 1

omega.com

e-mail: info@omega.com

For latest product manuals

:

omegamanual.info

Shop online at

User’s Guide

DPF500 Series

Ratemeter/Totalize

r

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Table of Contents

i

Page

Chapter 1 Introduction

1.1 Unpacking

1.2 Description

.....................................................................................................................

1.3 Features

1.4 Available Models

............................................................................................................

1.5 Available Options/Accessories

2.1 Battery Installation

2.2 Battery Replacement

.....................................................................................................

2

2.3 Dimensions

2.4 Wiring

............................................................................................................................

4

2.5 Typical Applications/Wiring Diagrams

3.1 20 Point Linearization (-LIN option)

4.1 Explanation of Display Prompts

.....................................................................................

4.2 Programming Flowchart

5.1 General

.........................................................................................................................

5.2 Maintenance

6.1 Error Messages

6.2 Analog Output Calibration

.............................................................................................

7.1 Specifi cations

Page 4

THIS PAGE INTENTIONALLY BLANK

Page 5

shipment, please call OMEGA Customer Service Department.

When you receive the shipment, inspect the container and equipment for any signs of damage. Note any evidence

of rough handling in transit. Immediately report any damage to the shipping agent.

The carrier will not honor any damage claims unless all shipping material is saved for their examination.

After examining and removing contents, save packaging material and carton in the event reshipment is

The following models are available from OMEGA Engineering, Inc.

DPF501 Panel Mount, Battery Powered* Ratemeter and Totalizer (NEMA-4 Front)

DPF502 Wall Mount, Battery Powered* Ratemeter and Totalizer (NEMA-4 Enclosure)

DPF503 Explosion Proof, Battery Powered* Ratemeter and Totalizer

Class I, Division I, Groups B, C & D

Class II, Division I, Groups E, F & G

* All units may be powered from an external 8.5 -30 VDC to prolong internal battery life.

The following options (available at the time of ordering) are available from OMEGA Engineering, Inc.

-MA Loop Powered with 4-20 mA output

-LIN 20-point linearization

-BAT Battery Pack

-ET Extended Temperature Range

The following accessories are available from OMEGA Engineering, Inc.

DPF5-BP External battery pack with 2 "C" size batteries and 12" leads

DPF501-BAT Spare battery

FPW-15 15 VDC power supply

Page 6

2

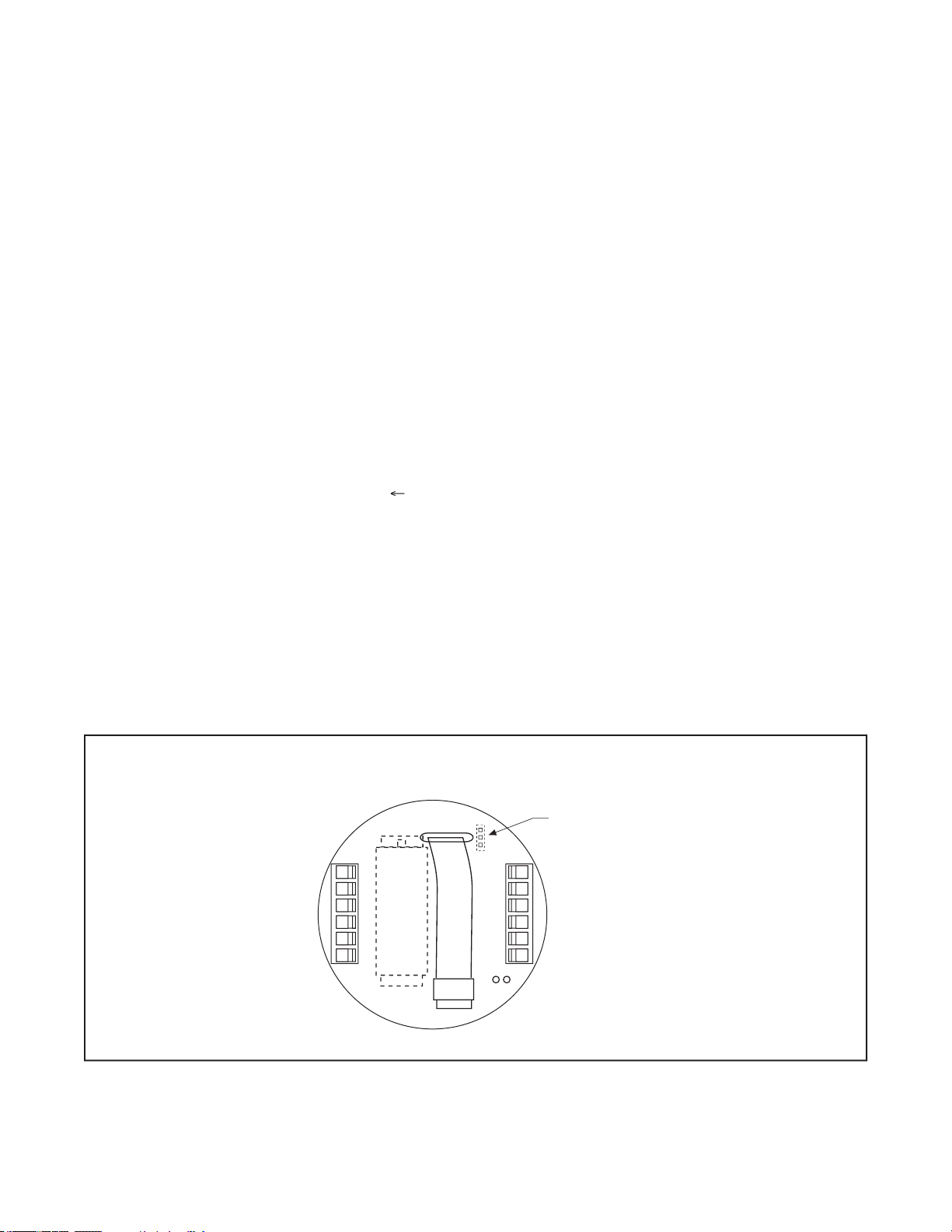

2.1 Battery Installation:

All DPF500 models are shipped without the battery(ies) installed. This preserves battery life when the unit is not in

service. When using external DPF5-BP, mount within 12" and plug connector into 3 position square posts (see Fig

To install the battery, begin by locating the battery holder. The DPF502 and DPF503 require opening the enclosure

cover and removing the DPF500 to expose the battery holder.

The plus terminal of the battery is marked with a (+) symbol stamped into the battery holder. Be sure to install the

2.2 Battery Replacement:

The DPF500 has a battery monitor feature which illuminates when the lithium battery voltage approaches its end

of life. A descriptor, “BAT”, illuminates when the battery voltage falls below this predetermined value. The low bat-

tery detector operates correctly with all power options.

The battery, or batteries, should be replaced within several weeks of the fi rst occurrence of low battery warning,

(left arrow) key to save the totalizer. The display will show "

If the display starts to fl ash after the "

to fl ash memory. At this point you must record the totalizer and setup information and re-enter the setup data after

the new battery(ies) is(are) installed.

6 5 4 3 2 1

Rear View

Battery

789101112

DPF5-BP

Connector

Page 7

DPF5-BP Accessory

2.3 Dimensions

4.92

(125)

4.33

(110)

4.33 (110)

#8 Screw Mounting holes molded directly under cover

screws. Max. screw head .29" (Typ. 4 places)

E

M

.98

(25)

1.97

(50

)

.18 (5)

.43

(11)

BOTTOM VIEW

To access terminals, remove cover

and 4 panel screws. Terminals are

on bottom side of PC board.

Panel Screws

4.92(125)

TOP VIEW (PANEL INSTALLED)

4.63

(117)

3/4 NPT

(2) HLS

5.00

(127)

5/16

4.25

(108)

5.25

(133)

E

M

5.00

(127)

To access terminals, unscrew cover and loosen 2 panel screws.

(If screws are removed, spacers may drop out.) Terminals are on

bottom side of PC board.

3.062" (77.77)

Dia. Cutout

3.582" Dia. Bolt Circle

.125" Holes to be 120° Apart

Outside Dotted Line Shows

Outside Panel Dimension

(4.00" Diameter)

120°

.10

(2.54)

4.00

(101.6)

1.7

(43)

2.875

(73)

Panel

Cutout

DPF501

DPF503DPF502

Page 8

4

options may be intermixed in many ways to solve common applications. The isolated pulse output may be freely

terminals (+) 12 and (-) 11. Accidental wiring to (+) 12 and (-)6 should be avoided since excessive current

fl ow may result.

cidental connections to earth may result in erroneous operation of the analog output and/or excessive

current fl ow.

eration of the analog output and/or excessive current fl ow.

2.4 Wiring

2.5 Typical Applications / Wiring Diagrams

+

+

-

1 Mag Input 1

2 Mag Input 2

3 Shield/GND

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

6 5 4 3 2 1

-

To Shield

Pin 3

Flowmeter

with DC Pulse Output

+

-

Strip Chart

Recorder

24 VDC

Power

Supply

+

-

ISOLATED INPUT / 4-20mA LOOP POWERED

NOTE: Separate power supplies

are recommended to isolate output

from input.

If isolation is not a concern, use a

single power supply

4-20mA (+)/DC In (+) 12

4-20mA (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

24 VDC

Power

Supply

PSU-24B

PSU-24

B

Remote

Reset Switch

1 Mag Input 1

2 Mag Input 2

3 Shield/GND

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

Turbine Meter with

Mag Pickup

6 5 4 3 2 1

MAG INPUT / DPF5-BP POWERED

4-20mA (+)/DC In (+) 12

4-20mA (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

DPF5-BP PLUG-IN

CONNECTO

R

DPF5-BP

Remote

Reset Switch

15 VDC

Power

Supply

+

-

1 Mag Input 1

2 Mag Input 2

3 Shield/GND

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

Turbine Meter with

Mag Pickup

6 5 4 3 2 1

MAG INPUT / DC POWERED

4-20mA (+)/DC In (+) 12

4-20mA (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

FPW-15

Flowmeter with

Switch Closure Output

4-20mA (+)/DC In (+) 12

4-20mA (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

1 Mag Input 1

2 Mag Input 2

3 Shield/GND

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

6 5 4 3 2 1

CONTACT INPUT / PULSE OUTPUT / BATTERY POWERED

DPF76 Totalizer

123456

4 1

789101112

Page 9

(-LIN option)

A 20 point linearization table is used to construct a curve describing the relationship of K-Factor and input

frequency. The measured input frequency is used to access the table. A linear interpolation of adjacent

For best performance and resolution choose as many decimal places as possible in the K-

Example: Enter a K-Factor of 1 as 1.000.

4.1 Explanation of Display Prompts

key while the unit is running to save the total value. The display will show

the battery(ies)

key to step to the next digit to the left. Press the

key to enter the 5 digit code. If the entered

code is correct, the display will advance to the next menu prompt (CLr tot). If incorrect, the display will return

to the run mode.

key to clear the total and return to the run mode. Press

the

key to skip and advance to the next menu selection.

of this decimal automatically limits the number of decimal locations allowable in the rate and total to acceptable

key to move the decimal. Press the

key to select the displayed decimal location.

For best performance and resolution choose as many decimal places as possible in the K-Factor.

Example: Enter a K-Factor of 1 as 1.000.

/

tion. The

linearization selection is recommended for fl ow meters whose K-factors change with different

fl ow rates. This selection allows users to enter up to 20 different frequencies with 20 corresponding K-factors for

different fl ow rates. The

setting is used for fl ow meters whose output is linear over its' entire operating

fl ow range. Press the

key to enter the displayed factor type.

/

yes set Pnts

for

to skip and keep the existing values.

for the fl ow sensor. The pulses/unit volume is implied by the totalizer descriptor when a descriptor is used. The

GAL pulses/gallon

LIT pulses/liter

FT3 pulses/ft3

M3 pulses/M3

Factors from 0.0001 to 99999999 may be used. A "0" value for the factor is not allowed and the unit will default

to "1" in LSD if a "0" entry is attempted . The factor is displayed on the subsidiary (lower) display. Press the

key to step to the next digit to the left. Press the

key to enter the

displayed factor.

Page 10

6

4.1 Explanation of Display Prompts

the 20 points (#). Press the

key to step to the next digit to the left.

key to enter the desired frequency for point #.

key to step to the next digit to the left. Press

the

key to enter the desired factor for point #.

The display will advance to the next point (Fr#) after each entry of the Fr & Fac until all 20 points are com-

and will scale the totalizer display accordingly. (i.e. if the tdec is set in the tenths position (1234567.8), 100 will be

displayed as 100.0). The location of the decimal point allows for greater resolution of both the totalizer display

and the pulse output. The pulse output advances at a rate dependent on the least signifi cant digit of the total-

of totalizer decimal locations allowable is reduced with each decimal place added to the factor decimal. Press

the

key to move the decimal. Press the

key to enter the displayed decimal location.

Note:

The selection of the factor decimal point limits the available selections for the number of decimal

tor. Press the

key to enter the selected descriptor.

key to enter the displayed scale

setting.

A rate descriptor corresponding to the above choice will be illuminated on the display.

a dummy decimal and will scale the rate display accordingly. (i.e. if the r decloc is set in the tenths position

added to the factor decimal. Press the

key to move the decimal. Press the

key to enter the displayed

decimal location.

Note:

The fl ow rate indicator will fl ash “99999” if the computed fl ow rate exceeds the 99999

display capability of the indicator. Choose a new decimal point location to avoid this.

NORMALIZING FACTOR - Normalizes (averages) the data being received. Enter a value from 0 to 9.

("NOR" + 1)

are not detected within this "window", the rate will display 0. The display will update once every second as

key to step to the next digit to the left. Press the

key

to enter the displayed delay value.

output 4mA. Press the

key to step to the next digit to the left. Press

the

key to enter the displayed out lo value.

Page 11

4.1 Explanation of Display Prompts

will output 20 mA. Press the

key to step to the next digit to the left.

key to enter the displayed out hi value.

the selected divider. The pulse out can be divided by 1 (

the divider set at 1, the unit will give a pulse out for every increment of the LSD displayed.

does not exceed the maximum rate of the pulse output. If the pulse output

sage “E PULSE”. Press the “E” key to return to the run mode.

or 0.0625 (8Hz). This menu item is skipped if

is turned off.

to gain access to the menu when the unit is locked. Press the

key

to step to the next digit to the left. Press the

key to enter the displayed code.

Record this number for later use! LOCK CODE:

____________________

key to enter

the displayed selection.

Page 12

8

4.2 Programming Flowchart

TO

CLR ToT

CLEAR T

OT

ACT

OR

ACT

OR

ent Code

correct

20poInt

ACT

OR

TYPE

20poInt

lInear

lInear

selected

20poInt

selected

Continue On

#####

for POINT #

ACT

OR for

AC0-F

AC19)

# = 19

SET pnts

YES

No

SET

20PT

YES

selected

No

selected

The

prompt will only appear if

to bypass the 20 point set up and keep the existing values.

key to choose YES or NO.

to the menu.

key to increment each individual digit of the code.

key to increment each individual digit of the code.

key to advance to the next digit.

to run mode

key to step the factor decimal to the desired location.

to skip and keep the existing location

For best performance and resolution choose as many decimal places as

key to choose factor type (

or

key to increment each individual digit of the factor for point #.

key to increment each individual digit of the factor for point #.

key to advance to the next digit.

key to increment each individual digit of the frequency for point

#.

key to advance to the next digit.

Frequency/factor point pairs must be entered in ascending order of fre-

quency

The

prompt will only appear if

without the 20 point linearization option.

key to increment each individual digit of the factor.

key to increment each individual digit of the factor.

key to advance to the next digit.

Page 13

4.2 Programming Flowchart

key to step the totalizer decimal to the desired location.

key to step to the desired totalizer descriptor.

When option "D" (rate per day) is ordered; selections are:

GAL, BBL, MCF, M3, "blank"

key to step to the desired scale setting.

When option "D" (rate per day) is ordered; selections are:

min, sec, days

key to step the ratemeter decimal to the desired location.

key to increment each individual digit of the delay.

key to increment each individual digit of the delay.

key to advance to the next digit.

key to increment each individual digit of the out low setting (4mA

value).

This will only display on units with Analog Output.

This will only display on units with Analog Output.

key to advance to the next digit.

key to increment each individual digit of the out high setting (20mA

value).

This will only display on units with Analog Output.

This will only display on units with Analog Output.

key to advance to the next digit.

key to step to the desired pulse scale divider for the pulse

output.

key to step to the desired pulse width for the pulse output.

This will not display if Pulse Out is turned OFF.

key to increment each individual digit of the "nor" factor.

ToT DESC

r SCALE

TO

T A

DECIMAL

TO

T A

OR

SCALE

SEC

NNIN

HRS

Days

)

GAL

"blank"

R DECLoC

TION

delay

oUT Lo

oUT HI

Pul scale

OUT LOW

OUT HIGH

SCALER

D 1D 1D 1

D 10D 10D 10

D100D100D100

oFFoFFoFF

0.1to 99.9

.5

p uuidth

.5

.25

.125

.0625

WIDTH

nor

TION

Continued From Previous Page

loc code

CODE

loC UnIt

TURN LOCK

ON or OFF

yes

no

key to step to the desired lock setting.

key to increment each individual digit of the lock code.

key to increment each individual digit of the lock code.

key to advance to the next digit.

Page 14

A suitable pulse producing device or fl ow meter is wired to one of the three pulse inputs provided on the DPF500.

terminals 5 and 6. Any high level, DC

The fl ow totalizer is updated once per second* with battery power, instantaneously with DC or loop power. If no

The fl ow total may be cleared by the front panel switch sequence or by a contact closure on the remote reset ter-

To reset the unit from the front panel, the following key sequence is required:

“CLr tot” will be displayed (if the panel lock is on, the display will prompt "

Enter the proper code to advance to the

prompt)

To clear the total. Unit will return to operation

The fl ow rate indicator will measure the fl ow rate once every second* with battery power, 8 times per second with

The analog output will be scaled based on the user selected zero and full scale and the measured fl ow rate. The

analog output is updated at the same time as the rate display.

The pulse output updates at the same rate as the total display in accordance with the instrument setup of pulse

scaling.

* A large delay setting and internal math operations may delay the update rate. A faster update rate occurs when the

The only scheduled maintenance for the DPF500 is periodic replacement of the battery.

Page 15

The DPF500 is provided with extensive self checking which assists the user in the location of setup entry errors

and in reporting malfunctions or unusual operating conditions. When an error occurs, the display will fl ash. Press

any key to see the error message corresponding to the error that has occurred. Press any key again to acknowl-

edge the error. (If the error can be eliminated by a change of setup values, the unit will automatically advance to

the MENU so that the appropriate setup changes can be made).

Table - 1 illustrates the warning message, problem, and recommended corrective actions.

WARNING MESSAGE CAUSE CORRECTIVE ACTION

Rate Low set Set Rate Hi greater

higher than Rate Hi than Rate Lo

Factor = 0 Set in correct Factor

Total rollover None required

Rate exceeds 99999 Use lower rate dec point

Pulse out Overfl ow Use different pulse scaler or

totalizer decimal point

Save to fl ash Write down displayed total and

memory failed setup values if you are changing

the battery. If total wasn't saved,

it will display an arbitrary total

when new battery is installed. In

this case, reset the total to 0 and

check the setup information.

the 4-20 mA has been accurately set to 4.000 and

20.000 mA by the factory. No calibrationshould be required.

The 4-20 mA output may be verifi ed periodically by installing a digital milliamp meter(DMM) in series with the

analog output and simulating a full scale or over range fl ow rate.

with a power supply (8.5 to 30 volts DC) to TB12 (+) and TB11 (–). The output should read 4.000 ma (± 0.005).

down until the output reads 20.000 ma (± 0.005). Press "E" and the unit will return to the "RUN" mode.

Page 16

OPERATING TEMPERATURE

-4°F (-20°C) to + 158°F (70°C)

Extended Temp: -22°F (-30°C) to + 158°F (70°C)

0 - 90% Noncondensing

- Panel Mount - NEMA 4X Front

2

- Wall Mount - NEMA 4X Enclosure

(keypad mounted behind clear cover)

3

- Explosion Proof - Class I, Division I, Groups B, C & D

Class II, Division I, Groups E, F & G

Frequency Range: 0 to 3500 Hz

Trigger Sensitivity: 30 mV p-p (10 mV p-p on special order)

Over Voltage Protected: ± 30 VDC

OPTO-ISOLATED DC PULSE INPUT

High (logic 1): 4-30 VDC

Low (logic 0): Less Than 1 VDC

Minimum Current: .5 mA

Hysteresis: 0.4 VDC

Frequency Range: 0 to 5 kHz

Min. Pulse Width: 0.1 msec

Internal Pullup Resistor: 100 KΩ to +3.6 VDC

High (logic 1): Open or 4-30 VDC

Low (logic 0): Less Than .5 VDC

Internal Switch Debounce Filter: 0 to 40 Hz

battery life.

Internal Pullup Resistor: 100 KΩ to +3.6 VDC

High (logic 1): Open or 4-30 VDC

Low (logic 0): Less Than .5 VDC

Minimum On : 25 msec

battery life.

Range: 0.001 to 99999999

Decimal Point Locations: XXXX.XXXX to XXXXXXXX

20 POINT LINEARIZATION -LIN OPTION

This feature allows the user to enter 20 different frequencies

with 20 different corresponding K-Factors to linearize non linear

signals.

ANALOG OUTPUT -MA OPTION:

Type: 4-20 mA follows rate display, Two wire hookup

Accuracy: 0.025% Full Scale at 20° C

Temperature Drift: 50 ppm/°C Typical

Reverse Polarity Protected

Update Rate: 8 times/second

The DPF500 uses the 4-20 mA loop power as its primary

Setup Information: Stored in fl ash memory

Totalizer: Stored in battery backed RAM but can be saved to

fl ash memory by operator for recall after battery change out.

Supplied with 1 or 2 C size Lithium battery pack.

Voltage: 8.5 to 30 VDC

Current: Less than 5 mA

Supplied with 1 C size lithium battery

Protection: Reverse Polarity Protection on DC Power Input

Voltage: 8.5 to 30 VDC

Supplied with 1 or 2 C size lithium battery(ies)

Protection: Reverse Polarity Protection on Current Loop

Loop Burden: 8.5V maximum

tions at equipment duty cycles

Idle 2hrs/day 8hrs/day 24hrs/day

-BAT* 10 yrs 10 yrs 10 yrs 9.1 yrs

-BAT-LIN 10 yrs 10 yrs 10 yrs 8.4 yrs

Standard unit 10 yrs 10 yrs 10 yrs 10 yrs

and -MA

Standard unit Indefi nite operation when externally powered

and -MA

* -BAT option contains DPF5-BP battery pack

Battery shelf life is rated at 10 years by manufacturer

Life expectancy based on rated battery capacity at 20°C

The above table is shown with pulse output inactive. Use

of pulse output shortens battery life.

Example: A pulse output of 0.06 sec. duration, once per

second, would derate the battery life by 20%.

5 Digits (99999), 0.35" High, Display updates once per second

with battery power, 8X per second with DC or Loop power

Rate Descriptors: /SEC, /MIN, /HR

Min. Input Frequency: 0.01 Hz to 10 Hz (selectable delay of 0.1

to 99.9 seconds)*

Selectable Rate Display Damping

Totalizer Display: (selectable decimal)

8 Digits (99999999), 0.2" High

Totalizer Descriptors: GAL, LIT, FT3, M3, "blank"

Warning Displays: Low battery warning

The pulse output advances with the least signifi cant digit of the

totalizer or decimal multiples there of (see Pulse scale divider).

Type: Isolated photomos relay

Max. voltage (off state): 30 VDC

Current (on state): 100mA

Pulse Duration: Selectable 0.5, 0.25, 0.125, 0.0625 seconds

Pulse Scale divider (Pulscale): User selectable, ÷1, ÷10, ÷100

or OFF

NOTE: Select OFF for max. battery life.

ACCURACY

0.01% Reading, ±1 count

Temperature Drift: 50 ppm/°C Worst Case

* A large delay setting and internal math operations may delay the update rate.

-BAT* 10 yrs 10 yrs 10 yrs 9.1 yrs

Page 17

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 18

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M1896/0705

Loading...

Loading...