Page 1

DPF6000/DPF5000

Input Options

User’s Guide

Shop on line at

www.omega.com

e-mail: info@omega.com

™

®

Page 2

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter

specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains important

information relating to safety and EMC.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains

important information relating to safety and EMC.

!

®

®

OMEGAnet® On-Line Service

www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

Mexico and TEL: (001)800-TC-OMEGA® FAX: (001) 203-359-7807

Latin America: En Español: (001) 203-359-7803

e-mail: espanol@omega.com

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 20 3472121 FAX: +31 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná

TEL: +420 59 6311899 FAX: +420 59 6311114

e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt

TEL: +33 1 61 37 29 00 FAX: +33 1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 7056 9398-0 FAX: +49 7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive

ISO 9002 Certified River Bend Technology Centre

Northbank, Irlam Manchester M44 5BD United Kingdom

TEL: +44 161 777 6611 FAX: +44 161 777 6622

Toll Free in England: 0800 488 488

e-mail: sales@omega.co.uk

Page 3

i

TABLE OF CONTENTS

The Input Options Manual is divided into three major sections. Each option board

contains circuitry which is exclusive of the others. The main board assembly diagram

is identical for all of the input options, however, and should be referred to when jumper

configuring each option board. This illustration is located in Section 1.10 Drawings.

ISOLATED SIGNAL CONDITIONER OPTION

PAGE

1.1 General ................................................................................................................1

1.2 Mechanical Installation ........................................................................................2

1.3 Electrical Connections ........................................................................................3

1.4 Inputs and Outputs ..............................................................................................5

1.5 Trigger Level Adjustment ....................................................................................7

1.6 Hysteresis Selection ............................................................................................8

1.7 Debouncing Monostable Circuit ..........................................................................8

1.8 Configuration ......................................................................................................9

1.9 Specifications ....................................................................................................10

1.10 Drawings ............................................................................................................11

NON-ISOLATED SIGNAL CONDITIONER OPTION

2.1 General ..............................................................................................................13

2.2 Mechanical Installation ......................................................................................13

2.3 Electrical Connections ......................................................................................14

2.4 Inputs and Outputs ............................................................................................16

2.5 Configuration ....................................................................................................17

2.6 Specifications ....................................................................................................17

2.7 Drawings............................................................................................................18

ANALOG INPUT OPTION

3.1 General ..............................................................................................................19

3.2 Mechanical Installation ......................................................................................20

3.3 Electrical Connection and Configuration ..........................................................21

3.4 Low-Frequency Cutoff ......................................................................................24

3.5 Open Circuit Indication ......................................................................................24

3.6 Power ................................................................................................................24

3.7 Calibration..........................................................................................................25

3.8 Specifications ....................................................................................................25

Page 4

ii

ILLUSTRATIONS PAGE

Figure 1-1 Exploded View ....................................................................................................2

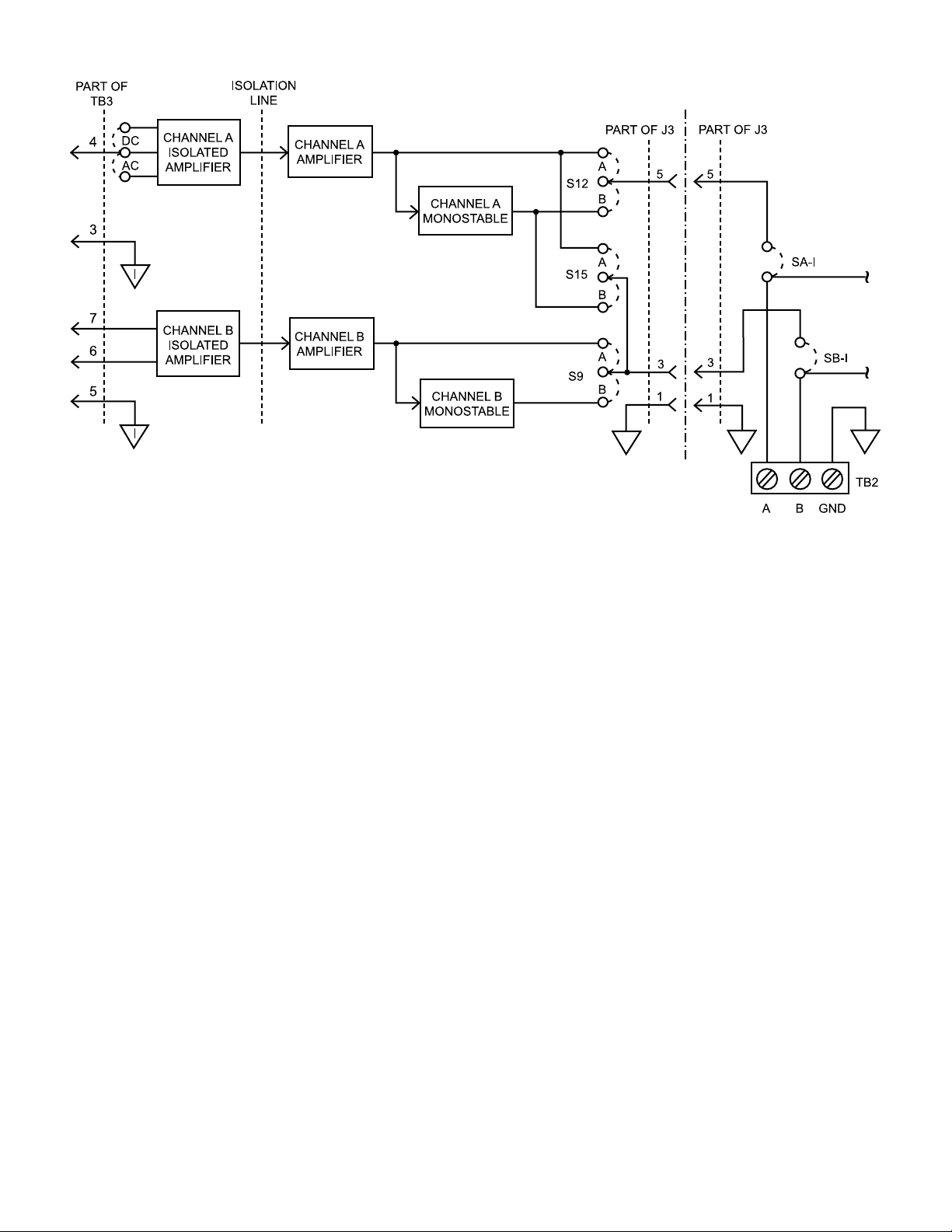

Figure 1-2 Simplified Block Diagram of the Signal Conditioner ............................................6

Figure 1-3 P6A1A Potentiometer/Jumper Locations ............................................................7

Figure 1-4 Debouncing a Mechanical Switch........................................................................8

Figure 1-5 Isolated Signal Conditioner Assembly Diagram ................................................11

Figure 1-8 Main Board Assembly Diagram ........................................................................12

Table 1-1 Wiring and Adjustments for Signal Sources ........................................................4

Table 1-2 Correlation of Sensitivity to Frequency Response ..............................................5

Table 1-3 P6A1A Potentiometer Selection ..........................................................................7

Table 1-4 Jumper Configuration ..........................................................................................9

Figure 2-1 Exploded View ..................................................................................................13

Figure 2-2 Rear View ..........................................................................................................14

Figure 2-3 Non-Isolated Signal Conditioner Assembly Diagram ........................................18

Table 2-1 Required Wiring for Most Commonly Used Sensors ........................................15

Table 2-2 Jumper Configuration ........................................................................................17

Figure 3-1 Exploded View ..................................................................................................20

Figure 3-2 P6A5B Potentiometer/Jumper Locations ..........................................................22

Table 3-1 P6A5A Potentiometer Selection ........................................................................22

Table 3-2 Jumper Positions & Input Wiring For Different Ranges ....................................23

Table 3-3 Cutoff Frequency Selection ..............................................................................24

Table 3-4 Analog Input Signal Range Specifications ........................................................25

Page 5

1

SECTION ONE

ISOLATED SIGNAL CONDITIONER OPTIONS

1.1 GENERAL

The isolated signal conditioner options provide one or two low level, isolated amplifier

channels. Each channel offers:

Adjustable trigger level by a multiturn potentiometer

Three levels of hysteresis, selectable by push-on jumpers

A one-shot (monostable multivibrator) with selectable time for debouncing purposes

Selectable RC filters for contact closure or low frequency applications

High sensitivity (±10 mV) and high protection level (260 V rms) inputs

The above features and the 12.4 V at 20 mA excitation output make this signal conditioner

compatible with a wide range of signal sources such as: contact closure, NPN or PNP opencollector outputs, passive inductive pickups, and most active sensors including NAMUR

standard types.

Page 6

2

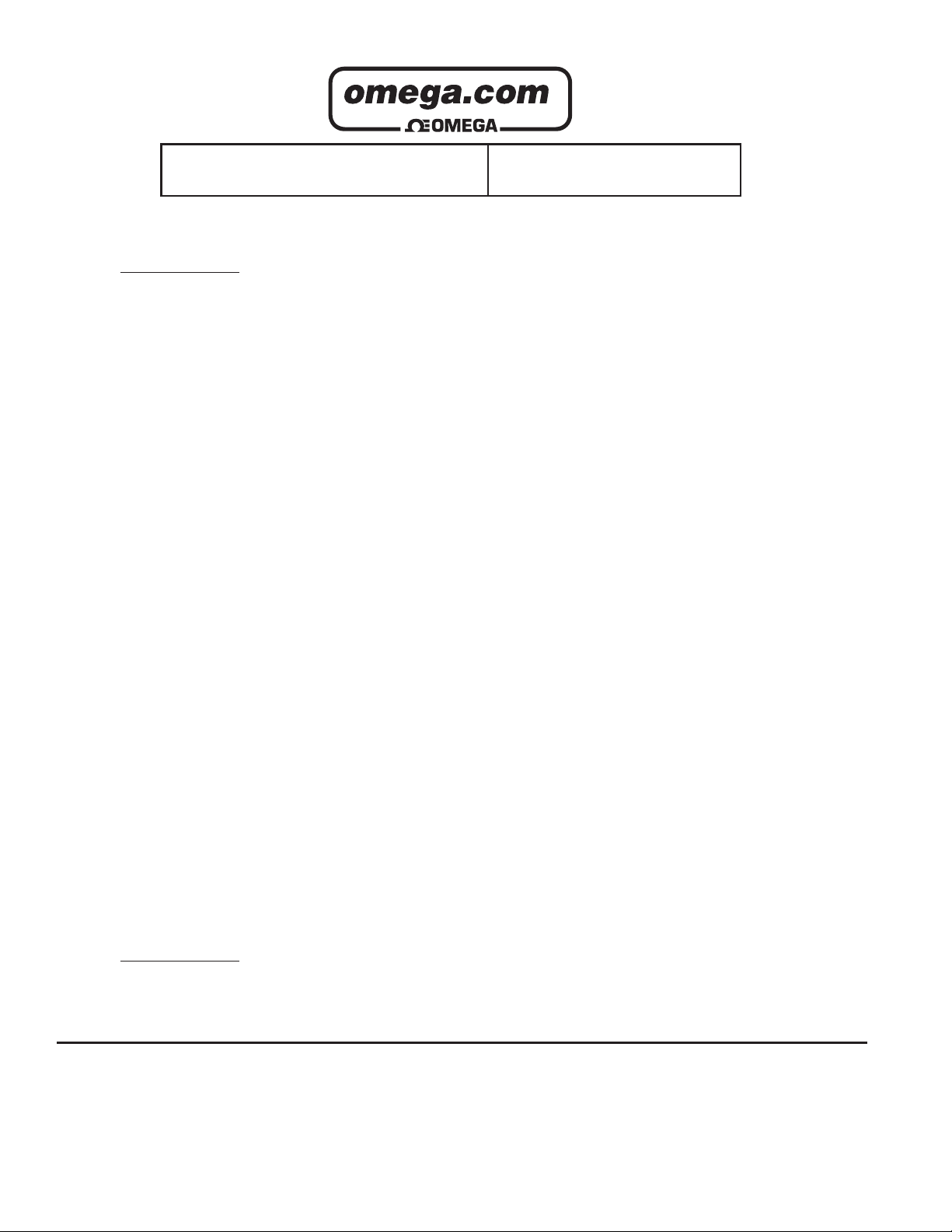

1.2 MECHANICAL INSTALLATION

The signal conditioner board is positioned as a mezzanine, supported by the rear

panel and a slot on the display board (Figure 1-1).

Figure 1-1 Exploded View with Power & Signal Connector

Page 7

3

TO INSTALL:

IMPORTANT: Turn-off the power and input signals from the unit before proceeding.

Failure to do so may result in injury!

CAUTION: The meter has no power-on switch; it will be in operation as soon as you

apply power. To change the factory preset jumpers, disconnect the power from the

unit. Failure to do so may result in injury! The jumpers must be changed by specially

trained personnel.

1. When using a signal conditioning board with the meter, the main board must

be jumper configured prior to installation. For single channel, install SA-I; for dual

channel, install SA-I and SB-I (main board). Refer to Section 1.8 for jumper selection

of input and output features.

2. The insulator board rests atop the lower rear panel, with the two tabs fitting into holes

on the display board.

3. Insert the tab of the signal conditioning board into the slot provided on the display

board.

4. Position J3, an 8-pin connector on the circuit side of the signal conditioner, to mate

with the P3 pins on the main board. Press the board downward until the rear

connectors rest on the lower rear panel.

5. Install the upper rear panel.

1.3 ELECTRICAL CONNECTIONS

Channels A and B of the signal conditioner work separately. The inputs are available on

connector TB3 and are electrically isolated from the counter. The outputs are connected to

the main board with connector J3.

Page 8

4

TYPE REQUIREMENTS WIRING ADJUSTMENTS

1 Passive Inductive Voltage <260 V rms Connect signal wires to Select the hysteresis &

Pickup Voltage >±10 mV TB3-pins 3 & 4. Remove adjust the trigger level

S1, S2, S3, S5, S6, S7. for lowest input voltage

S16 on DC position. (lowest frequency).

2 Active Transducer Operating Voltage = 12.4 V Connect the positive and Select 700 mV hysteresis

(inductive, OPTIC or Operating Current < 20 mA negative supply inputs of (Install S4-A & S8-A).

capacitive) with NPN transducer to the EXC Adjust the multiturn pot

open-collector output. HI & EXC LO, for 0 V trigger level.

respectively. Install S2-A,

S3-A, S6-A, S7-A and

S16-DC.

3 Same as #2, but PNP Same as #2 Same as #2, except Same as #2

open-collector output. install S2-A & S6-A,

remove S3-A & S7-A.

4 TTL- or CMOS- ---- Connect signal output to Select 700 mV hysteresis

compatible signal TB3- pin 4 and Ground to and adjust the trigger

TB3- pin 3. Remove level for 1 V.

jumpers from S2, S3, S6

and S7.

5 Contact Closure Off duration > 100 ms Connect the two ends of Do the #4 adjustments.

(slow) (less than 5 on/off per sec) the contact to TB3-pins 2 Install S1-A and S5-A.

and 4. Install S16-DC. Select the debounce time

Remove S2, S3, S6, S7. if required.

6 Contact Closure Off duration < 100 ms Same as #5 except install Same as #5

(fast) S2-A & S6-A.

7 NAMUR type sensors NAMUR standard Connect the positive Same as #2

(2-wire) sensor input to TB3-pin 4

and the negative sensor

input to TB3-pin 1. Install

S2-A, S3-A, S6-A, S7-A

and S16-DC.

Table 1-1 Wiring and Adjustments for Signal Sources

Page 9

5

1.4 INPUTS AND OUTPUTS

INPUTS

Signal conditioning inputs and excitation outputs are available on TB3, a 7-position header

(shown in Figure 1-1).

Refer to the block diagram in Figure 1-2. Channel A input is available on connector TB3–pin 4.

Pins 6 and 7 are allocated to DC and AC inputs on Channel B. Pins 3 and 5 are isolated

ground (signal return).

TB3 mates with two screw-clamp connectors: a 4-position, TB3J4, and a 3-position, TB3J3.

The 4-position connector may be used with a single or dual-channel signal conditioner; the

3-position may be used only with a dual-channel signal conditioner.

The trigger level can be adjusted between -2 and +2 volts. When the input signal has a large

DC level and does not cross the trigger level range, the AC input should be used. The AC

input is coupled to the DC input with a 0.1 uF capacitor. The maximum non-destructive DC

blocking voltage of this input is 250 V. This input should be left open when not used.

Sensitivity for a Square Frequency Response

Wave Input DC Input AC Input

±10 mV DC - 1 kHz 5 Hz - 1 kHz

±25 mV DC - 20 kHz 2 Hz - 20 kHz

±50 mV DC - 100 kHz 2 Hz - 100 kHz

Table 1-2 Correlation of Sensitivity to Frequency Response

OUTPUTS

The outputs of the signal conditioner channels are connected to the main board through the

J3 connector. These outputs can be connected to the A and B inputs of the meter (pins 1 and 2

of TB2) by installing push-on jumpers on the I positions of SA and SB (Figure 1-2). Each output

can drive 10 LSTTL load (5 LSTTL when debounce monostable is bypassed) and is TTL / 5 V

CMOS compatible

.

In a single-channel signal conditioner (Channel A only), the output can be connected to either

or both A and B outputs by installing jumpers on the appropriate positions of S9, S12 and S15

(see Figure 1-5). However, when a jumper is installed on A or B position of S15, the S9

jumper must be removed.

Page 10

6

Figure 1-2 Simplified Block Diagram of the Signal Conditioner

EXCITATION OUTPUT

A 12.4 V regulated excitation voltage is available on pins 1 and 2 of TB3 (Figure 1-1). This

voltage can be used to drive external transducers with operating currents up to 20 mA.

It should be noted that this voltage is isolated from the main board ground, not from the

isolated ground. Excitation HI and Excitation LO are +6.2 and -6.2 V respectively referenced

to isolated ground.

The EXC LO must not be connected to ISO GND

INPUT FILTER

Jumpers at S1 and S5 connect two .033 uF or .0022 uF capacitors to form an RC low-pass

filter for each input. The time constants of these filters are about 2.5 and .17 milliseconds.

When the input is a contact closure (between EXC HI and ISO DC input), the capacitor is

discharged through a 1 MOhm resistor to ISO GND, providing a time constant of

33 milliseconds. In this case, the trigger level should be adjusted between 0 and +2 V.

Page 11

7

1.5 TRIGGER LEVEL ADJUSTMENT

Two multiturn potentiometers in the Dual-Channel Signal Conditioner (P6A2A) or one

multiturn potentiometer in the Single-Channel Signal Conditioner (P6A1A) are provided to

adjust the trigger level of each channel independently. The P6A2A potentiometers are

accessible through a hole on the top, left-hand side of the case, with the sleeve removed.

The P6A1A has two potentiometers, each in a different location for easy access, depending

on which meter you are using it with. In a P6000A/DPF6000 the potentiometer is accessible

through a hole on the left-hand side of the display board, with the lens removed; S17-B

jumper must be installed.* In a P5000/DPF5000 the potentiometer is accessible through a

hole on the top, left-hand side of the case, with the sleeve removed; S17-A jumper must be

installed. Refer to drawing below and Figure 1-1.

Meter Jumper Position Potentiometer Location

P6000A/DPF6000 S17-B* Through hole in display board

P5000/DPF5000 S17-A Through hole in top of case

Table 1-3 P6A1A Potentiometer Selection

* Factory default position

Figure 1-3 P6A1A Potentiometer/Jumper Locations

When these potentiometers are in their extreme right or left positions, the trigger level may

exceed the maximum positive or negative working voltage of the amplifier.

To adjust the trigger level to about +1 V, turn to the extreme clockwise position of the pot.

Then, turn the pot counter-clockwise six turns. Now the trigger level is about 1 V (1.0 ±.5 V).

To adjust the trigger level to zero, turn the pot counter-clockwise 2.5 more turns.

The positive going trigger level is higher than the negative going trigger level by the selected

hysteresis value.

Page 12

8

1.6 HYSTERESIS SELECTION

The signal conditioner option offers three selectable hysteresis values for each channel.

The hysteresis may be higher than its nominal value when the trigger level is other than zero.

For trigger levels out of the ±2 V range, the hysteresis becomes significantly larger than the

nominal value.

1.7 DEBOUNCING MONOSTABLE CIRCUIT

Each channel contains a monostable circuit with jumper-selectable time constants. Trigger

slope is also selectable. Refer to Section 1.8 Configuration for the jumper settings.

These retriggerable monostables can be used for debouncing a mechanical switch (Figure 1-4).

Figure 1-4 Debouncing a Mechanical Switch

ISO IN

ISO OUT

DEBOUNCE TIME

* * *

= TRIGGER EDGE

Page 13

9

1.8 JUMPER CONFIGURATION

FUNCTION CHANNEL A CHANNEL B

Install Remove Install Remove

Input resistance = 1 MΩ pull-down to ISO GND, S2, S3* S6, S7*

max input voltage = 260 V rms

Input resistance = 3 kΩ pull-down to EXC LO, S2-A S3 S6-A S7

max input voltage = +15/-20 V dc

Input resistance = 1 kΩ pull-up to +2 V ref to ISO GND S2-A, S3-A S6-A, S7-A

max input voltage = +15/-10 V dc

No filter S1* S5*

Low pass filter in circuit, time constant = 2.5 ms S1-A S5-A

Low pass filter in circuit, time constant = .17 ms S1-B S5-B

Hysteresis = 700 mV (use when input > 2 V) S4-A S8-A

Hysteresis = 70 mV (use when .2 V < input < 2 V) S4 S8

Hysteresis = 10 mV (use when input <.2 V) S4-B* S8-B*

Monostable trigger on positive edge S14-A* S11-A*

Monostable trigger on negative edge S14-B S11-B

Monostable bypassed (no debounce time) S12-A* S9-A*

Monostable in circuit S12-B S9-B

Debounce time = 120 ms S13-A* S10-A*

Debounce time = 22 ms S13 S10

Debounce time = 1 ms S13-B S10-B

Connects channel A output to channel B, S15-A

monostable bypassed

Connects channel A output to channel B, S15-B*

monostable in circuit

No Connection S15

Channel A, AC coupled S16-AC*

Channel A, DC coupled S16-DC

Table 1-4 Jumper Configuration

* Default position; changes may be required for some applications.

S15 is not supplied in the dual-channel signal conditioners.

Page 14

10

1.9 SPECIFICATIONS

Input impedance Input < ±500 mV: 1 MΩ

(ISO DC INPUT) Input > ±500 mV: More than 70 kΩ

Frequency response for a

square-wave input Input = ±10 mV: 0-1 kHz (min)

Input = ±25 mV: 0-20 kHz (min)

Input = ±50 mV: 0-100 kHz (typ)

Maximum input voltage 260 V rms

Max Common Mode Voltage

(ISO GND refer to GND) 350 V, peak

Max DC blocking voltage

(ISO AC INPUT) 250 V dc

Hysteresis 10, 70 or 700 millivolts

Trigger level (nominal) -2 to +2 V, adjustable

Monostable time constant 1, 22 or 120 milliseconds

Propagation delay

(monostable bypassed) 6-10 microseconds (typ)

Page 15

11

1.10 DRAWINGS

Figure 1-5 Isolated Signal Conditioner Assembly Diagram

R22

R29

R20

R19

S7

TB3

C2

S3

R51

R52

R50

R17

TB3

R16

C12

7

6

L1

S6

E2

R18

R54

R53

C8

AC

R5

R4

C21

C3

CR1

5

4

L2

3

2

C1

C22

S2

S16

DC

R49

R6

CR2

U1

R8

R55

R27

R56

C14

C11

CR7

CR6

CR5

C9

S5

R28

C26

U3

C10

C4

S1

CR4

CR8

CR3

R7

C7

C5

R1

C25

R2

E1

U2

C13

C27

1

C24

C23

8

1

B

A

S17

C19

R34

R32

R25

R43

A

E3

R23

R24

R21

B

S8

R14

U5

R26

R39

R13

R11

S4

R12

R9

R10

C28

U4

U6

C29

R48

R57

R40

R41

U7

R44

R45

R46

C18

C30

R38

R42

A

S14

B

C17

S12

S11

S13

A

B

A

A

B

B

R47

R33

R37

R35

R31

C20

R30

C16

C15

A

S10

B

S15

A

B

S9

R36

A

B

A

B

A

B

AB

S1 A B S15AB

S16

DC

AC

S17 A B

DWG. NO.

11357AY-02 B

S9AB

S8AB

S10AB

S11AB

S12AB

S13AB

S14AB

S2 A

S3 A

S6 A

S7 A

S4 A B

S5 A B

Page 16

12

Figure 1-8 Main Board Assembly Diagram

F

S

F

S

SB

19

SA

I

I

1 2

18

C20

TB2

L2L1

U11

R6R5R4

C3

R2

C2

R1

R10

R3

C23

C22

R31

R30

U10

TF2

C29

R29

U6

U8

Y1

W1

C15

XU5

CR1

C13

P2

CR7

R20

R19

Q1

R22

P1

R12

Q6

R27

R13

C10

CR2

CR3

C11

C5

C12

C17

U1

E1

Q2

R18

C9

R24

C7

R11

R21

R17

R25

R9

C8

U3

Q5

CR4

Q4

R26

R23

P3

E2

C6

C19

C16

U4

R15

U2

R16

U7

U5

U12

C21

C27

C26

TF1

C25

R14

R8

R41

R44

R42

R32

C18

U9

R28

Q9

R33

Q8

Q10

R36

R38

R35

R34

Q11

Q12

R43

R40

R37

R39

R45

Q7

C24

Q13

R7

C14

1 2

C4

C1

Q3

SA

SB

I

S

F

M

I

S

F

M

DWG. NO.

11364AY-02 B

Page 17

13

SECTION TWO

NON-ISOLATED SIGNAL CONDITIONER OPTION

2.1 GENERAL

This provides a non-isolated amplifier and a debouncing monostable that can be used to

interface a wide range of signal sources to the meter, if isolation is not required. In

addition, a 16 V / 25 mA excitation is available that can be used to power an external active

sensor.

2.2 MECHANICAL INSTALLATION

The signal conditioning board is positioned as a mezzanine and is supported by the rear

panel and P3-J3 header-connector. See Figure 2-1.

Figure 2-1 Exploded View with Power & Signal Connector

Page 18

14

TO INSTALL:

IMPORTANT: Turn-off the power and input signals from the unit before proceeding.

Failure to do so may result in injury!

CAUTION: The meter has no power-on switch; it will be in operation as soon as you

apply power. To change the factory preset jumpers, disconnect the power from the

unit. Failure to do so may result in injury! The jumpers must be changed by specially

trained personnel.

1. When using a signal conditioning board with the meter, the main board must

be jumper configured prior to installation. Install SA-I and SB-I (main board). Refer to

Section 2.5 CONFIGURATION for jumper selection of input and output features.

2. Position J3, an 8-pin connector on the circuit side of the signal conditioner, to mate

with the P3 pins on the main board. Press the board downward until the rear

connectors rest on the lower rear panel.

3. Install the upper rear panel.

2.3 ELECTRICAL CONNECTIONS

The following table provides wiring and jumper configuration for commonly used signal

sources. See Figure 2-2 below for a rear view of the meter. The exploded view and

assembly diagram/schematics further illustrate parts affected, such as connector TB3 for

signal inputs and outputs, jumper locations, or connector P2.

The main assembly diagram is identical for the isolated and non-isolated and non-isolated

signal conditioners. This is located in Section 1.10, Figure 1-8.

Figure 2-2 Rear View

P1

TB1J

BA

TB3J

P2

TB2J

Page 19

15

Input Type Input Requirement Wiring Jumper Position

Passive Inductor Voltage < 60 V rms Connect the signal Remove S4. Install

Pickup High level > 120 mV wires to SIG IN and S1, S2-A and S3-A.

Low level < 20 mV EXC LO

Active Transducer Operating Voltage Connect EXC HI and Remove S1. Install

(inductive, optic or = 16 V (Note 1) LO to the positive S2-A, S3-A and S4-A.

capacitive), with NPN Operating Current and negative supply

open-collector output < 25 mA inputs of transducer.

Connect the output

to SIG IN.

TTL or CMOS- Signal source should Connect the signal Remove S1. Install

compatible signal be powered externally and GND to the SIG S2-A and S3-B. Install

or with +5 V of the IN and EXC LO. S4-A for TTL, remove

main board. S4-A for CMOS.

Contact closure Max of 10 actuation Connect the contact Remove S1. Install

(Slow) per second wires to SIG IN and S2-B, S3-A, and S4-A.

EXC LO.

Contact closure Max of 70 actuation Connect the contact Remove S1 and S2.

(Fast) per second wires to SIG IN and Install S3-A and S3-4.

EXC LO.

NAMUR NAMUR standard Connect the positive Remove S1. Install

and negative inputs S2-A, S3-B, and S4-B.

of sensor to EXC HI

and SIG IN.

Table 2-1 Required Wiring for Most Commonly Used Sensors

Note 1: For 8.2 V excitation, install S3-B; for 20 V excitation, remove S3-A & S3-B.

(Maximum current is 16 mA.)

Page 20

16

2.4 INPUTS AND OUTPUTS

Excitation outputs are available on the TB3 connector, EXC HI (positive) on pin 2 and EXC LO

(negative) on pin 1.

Excitation Output S3 Jumper Position

16 V at 25 mA Install S3-A

(AC-powered units only) 8.2 V at 16 mA Install S3-B

20 V at 16 mA Remove jumper

Signal input, the input of the signal conditioner amplifier, is available on pin 3 of TB3.

RESET output is available on pin 3 of connector TB3. When the input is missing for more

than 1.5 seconds, a negative true pulse is generated on this output that can be used to reset

the meter. To do this, connect this output to the reset input of the meter, P2-pin 18.

Signal output is internally connected to the main board. SA-I must

be installed. Refer to the

drawings section.

Page 21

17

2.5 CONFIGURATION

FUNCTION PIN JUMPER

GROUP POSITION

Excitation voltage = 16 V, S3* A

max current = 25 mA

Excitation voltage = 8.2 V, S3 B

max current = 16 mA

Excitation voltage = 20 V, S3 None

max current = 16 mA

(AC powered units only)

7.5 k pull-up to +5 V input S4 A

1 k pull-down to EXC LO input S4 B

160 k pull-down to EXC LO S4* None

Debounce time = 15 µsec S2* A

Debounce time = 80 msec S2 B

Debounce time = 10 msec S2 None

Hysteresis = 40 mV, High threshold = 85 mV S1* Installed

Low threshold = 45 mV

Hysteresis = 1.4 V, High threshold = 2.8 V S1 Removed

Low threshold = 1.4 V

* Default Position

Table 2-2 Jumper Configuration

Unless otherwise specified, factory settings are:

16 volts excitation

160 k pull-down to EXC LO

15 microseconds debounce time

40 millivolts hysteresis; high threshold 85 mv, low threshold 45 mv

2.6 SPECIFICATIONS

Input impedance: More than 50 kOhms

Operating frequency: DC to 10 kHz

Hysteresis: 40 mV or 1.4 V, jumper-selectable

Operating input voltage: 0 - 120 mV min; 60 V rms max

(S4 removed)

Page 22

18

2.7 DRAWINGS

Figure 2-3 Non-Isolated Signal Conditioner Assembly Diagram

Page 23

19

SECTION THREE

ANALOG INPUT OPTION

3.1 GENERAL

The P6A5B analog input board allows the meter to serve as a process meter or as

a totalizer for process signals. For instance, it can display watts or totalized kilowatt-hours

based on the 0-1 mA signal from a watt transducer. It can display flow rate in gallons per

minute or totalized gallons based on the 4-20 mA signal from a flow transducer.

The P6A5B converts an input voltage or current to a frequency using a V/F converter. This

frequency can then be processed by the host meter in either the Frequency or

Totalize modes.

The P6A5B can be configured to operate in one of the ranges shown in Table 3-2. The

factory default range setting is 4-20 mA.

Page 24

20

3.2 MECHANICAL INSTALLATION

The analog input board is positioned as a mezzanine inside the case. It is supported by the

rear panel and a slot on the display board.

NOTE: Before installing the Analog input board, install push-on jumpers SA-I and SB-I on

the main board.

Figure 3-1 Exploded View with Power & Signal Connector

Page 25

21

TO INSTALL:

IMPORTANT: Turn-off the power and input signals from the unit before proceeding.

Failure to do so may result in injury!

CAUTION: The meter has no power-on switch; it will be in operation as soon as you

apply power. To change the factory preset jumpers, disconnect the power from the

unit. Failure to do so may result in injury! The jumpers must be changed by specially

trained personnel.

1. Install SA-I and SB-I jumpers on the main board. If not factory-configured, install or

remove jumpers as indicated in Section 3.3.

2. The insulator rests atop the lower rear panel, with the two tabs fitting into holes on the

display board. Insert the tab of the analog input board into the slot provided on the

display board.

3. Position J3, an 8-pin connector on the circuit side of the signal conditioner, to mate

with the P3 pins on the main board. Press the board downward until the rear

connectors rest on the lower rear panel.

4. Install the upper rear panel.

3.3 ELECTRICAL CONNECTION AND CONFIGURATION

The input signal is applied across TB3-7 (SIG HI) and TB3-6 (SIG LO). A 24 V excitation

voltage is available at TB3-5. To use the excitation supply to power the current loop, use

TB3-5 for "+" and TB3-7 for the return (see Table 3-2).

The output frequency of the P6A5B module is internally connected to the A input, TB2-1 of

the main board via the SA-I

jumpers of the main board.

If the P6A5B did not come installed in the meter, the proper ranging/configuring jumpers need

to be installed. Choose the proper range from Table 3-2. The factory calibrates the module to

4-20 mA = 0-10,000 counts by adjusting the offset pot for zero at 4 mA input and writing the

required meter SCALE factor for 10,000 counts on the back of the board. If a different range is

required the scale factor will be different (see Section 3.7, CALIBRATION).

Page 26

22

ZERO ADJUSTMENT

If the P6A5B is to be used in a totalizing application, the multiturn potentiometer must be

adjusted for proper reading when the output frequency of the P6A5B module is low but not

zero. The P6A5B has two potentiometers, each in a different location for easy access,

depending on which meter you are using it with. In a P6000A/DPF6000 meter the zero offset

potentiometer is accessible through a hole on the left-hand side of the display board, with the

lens removed; S3-B jumper must be installed*. In a P5000/DPF5000 meter, the zero offset

potentiometer is accessible through a hole on the top, left-hand side of the case, with the

sleeve removed; S3-A jumper must be installed. Refer to drawing below and Figure 3-1.

Meter Jumper Position Potentiometer Location

P6000A/DPF6000 S3-B* Through hole in display board

P5000/DPF5000 S3-A Through hole in top of case

Table 3-1 P6A5A Potentiometer Selection

* Factory default position

Figure 3-2 P6A5A Potentiometer/Jumper Locations

If the P6A5B is to be used in a non-totalizing application, the zero offset can be adjusted via

the potentiometer, or programmed digitally. In case of programming, it is better to turn the

multiturn potentiometer counter-clockwise to generate an output frequency when the input is

minimum (e.g., 4 mA in 4-20 mA range). This offset, can then be cancelled with a negative

digital offset when the meter is in Frequency mode. This method improves the

display update rate at low frequencies. It also ensures that the frequency output of the P6A5B

module is above the cut-off limit (Section 3.4).

SPAN ADJUSTMENT

Span is adjustable by programming the meter Scale Factor. No potentiometer is

provided.

Page 27

23

INPUT RANGE SELECTION TB3 WIRING

JUMPERS

4-20 mA S1-A, S1-C, S1-D

(Default)

0-1 mA S1-B, S1-C, S1-E

0-5 V S1 Removed

1-5 V S1-D

0-10 V S1-E

Table 3-2 Jumper Positions and Input Wiring for Different Ranges

Page 28

24

S2 POSITION STORAGE S2-A S2-B S2-C

CUTOFF NO CUTOFF 200-300 Hz 40-60 Hz 8-12 Hz

FREQUENCY (DEFAULT)

Table 3-3 Cutoff Frequency Selection

3.4 LOW FREQUENCY CUTOFF

In some applications, it is desirable to cut off the output frequency below a certain limit to

prevent accumulating a leakage over a long period of time. Table 3-2 lists the cutoff

frequency for different positions of S2.

An active low logic signal is provided on TB3-1 when the output frequency is cut off. This

signal is referenced to Digital GND (TB2-3) and is electrically isolated from the input.

3.5 OPEN CIRCUIT INDICATION

The cutoff signal (available on TB3-1) can be used to show an open current loop in the 4-20 mA

range in rate indication applications. To make sure that the output remains above the cutoff limit

under normal conditions:

1. Turn the offset adjustment pot counter-clockwise until display reads more than 350 counts

with 4 mA input and write down the reading.

2. Program the meter offset to the negative of the above value. The display then

shows zero for 4 mA input.

3.6 POWER

The P6A5B board is powered by the host meter. A 24 V regulated excitation voltage

is available on TB3-5. A maximum of 25 mA may be drawn from this output.

Page 29

25

3.7 CALIBRATION

If the meter is ordered as a configured unit with this option (P6XX4A/P5XX4), the

push-on jumpers and the offset pot are configured for the 4-20 mA range (default). The

meter’s scale factor* is set for a 10,000 reading at full scale input (20 mA). The offset

can be adjusted by the multiturn potentiometer, see section 3.3 for location.

If a different full scale value is all that is desired, simply modify the meter scale factor

as follows:

Required Scale Factor =

Desired Full Scale

x Present Scale Factor

10,000

* This scale factor is also written on the back side of the board.

To calibrate the analog input board in any range

:

1. Put the meter in the Frequency mode, remove the S2 jumper, and apply a high

input (close to full scale), and write down the reading.

2. Apply a low input, about 10% of the input span (e.g., 5.6 mA for 4-20 mA input), and write

down the reading.

3. Calculate and modify the scale factor (A .SC) using this formula:

Scale Factor =

DH - DL

PH - PL

Where: DH = Desired reading with high input

DL = Desired reading with low input

PH = Present reading with high input

PL = Present reading with low input

4. While a low input is applied, adjust the offset using the multiturn potentiometer for the

desired reading, see section 3.3 for location.

In a non-totalizing application (Frequency mode), the meter digital offset

can be programmed instead of adjusting the potentiometer.

Meter’s Offset = Desired Reading - Present Reading

3.8 SPECIFICATIONS

Signal Ranges 4-20 mA 0-1 mA 0-5 V 1-5 V 0-10 V

Resolution 1.6 µA 0.1 µA 0.5 mV 0.4 mV 1.0 mV

Input Resistance 24.3 Ω 381 Ω >10 MΩ >10 MΩ >10 MΩ

Bias Current - - 10-50 nA 10-50 nA 10-50 nA

Absolute Maximum Input 80 mA 20 mA 130 V 130 V 130 V

Table 3-4 Analog Input Signal Range Specifications

Page 30

26

Excitation output 23.5 ± 2 V at 25 mA max.

CMR More than 100 db, DC to 60 Hz

NMR Gate Time = 00.20 sec: 56 db, min

Gate Time = 00.50 sec: 64 db, min

Response Time Gate Time = 00.20 sec: .45 - .65 sec

(to 99.9% of span) Gate Time = 00.50 sec: .75 - 1.25 sec

Accuracy at 25°C 99.95% of the span

(RH 25-75%)

Nonlinearity .02% of full scale, maximum

Typical Temperature stability 0-1 mA ±.010% / °C

of the span, % of FS 4-20 mA: ± .005% / °C

0-5 V, 1-5 V, 0-10 V ± .005% / °C

Temperature stability Less than 0.1 Hz / °C (1 Hz / 10°C)

of the offset

Warm up to rated accuracy: 30 minutes

Full-scale reading Programmable by meter’s scale factor

Full-scale output 6.5 KHz ± 20%

frequency

Overrange capability 10% above full scale, minimum

Offset adjustment with multiturn pot: 5% of span, typ.

with meter’s offset: -99,999 to 999,999

Isolation 350 V dc between output and input

(output is connected to main board)

Operating temperature 0-60°C

Humidity 5-95% non-condensing, 0-40°C

Page 31

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from the date of purchase. OMEGA’s Warranty adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits, improper

repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been

tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current,

heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA

neither assumes responsibility for any omissions or errors nor assumes liability for any damages

that result from the use of its products in accordance with information provided by OMEGA,

either verbal or written. OMEGA warrants only that the parts manufactured by it will be as

specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS

OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of

purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or

otherwise, shall not exceed the purchase price of the component upon which liability is based. In

no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

(2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA

assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and,

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or

damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked

on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2003 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 32

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop on line at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauges

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M912/0103 11357ML-99D

Loading...

Loading...