Page 1

DP-7600

High Speed Strain Gauge Readout

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

WARRANTY/ DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s Warranty adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing,

operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of

OMEGA’s control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability

for any damages that result from the use of its products in accordance with information

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth

herein are exclusive, and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall

not exceed the purchase price of the component upon which liability is based. In no event

shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 4

TABLE OF CONTENTS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SWITCH FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

LED INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limit Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Limit One Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Decimal Point Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Filter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Baud Rate Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Echo Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Linefeed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Address Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Legend Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Continuous Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Device Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protection Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protection Code Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Span Number Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dead Weight Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dead Weight Stay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SERIAL COMMUNICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Echo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Line Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Address Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Address Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Read Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Set Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Peak and Runout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remote Tare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page 5

TABLE OF CONTENTS

Test Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Continuous Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Set Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Remote Serial Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Decimal Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reading Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Absolute or Relative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Calibration Span Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Serial Reading Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Limit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

REMOTE INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DP-7600 SENSITIVITY SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . 14

EXCITATION SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DP-7600 BACK VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DP-7600 REAR TERMINATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SCHEMATIC (DP-7600 Top Board) . . . . . . . . . . . . . . . . . . . . . . . . . 16

SCHEMATIC (DP-7600 Bottom Board) . . . . . . . . . . . . . . . . . . . . . . 19

SCHEMATIC (DP-7600 Analog Input Option Board) . . . . . . . . . . . 21

SCHEMATIC (DP-7600 Output Option Board) . . . . . . . . . . . . . . . . 22

SCHEMATIC (DP-7600 RS232/RS485 Option Board) . . . . . . . . . . 23

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Inside Back Cover

Page 6

DESCRIPTION:

The Model DP-7600 is a high speed, high resolution, strain gauge readout. The unit

performs 1000 conversions per second with 15 bits (plus sign) resolution. Limit checking and Peak/Runout tracking are all done at a user selectable rate (from 1 - 500Hz);

meanwhile, the display provides a stable 1Hz filtered data reading. Peak and runout

data can also be displayed using front panel switches. A tare reading of up to 50% of

span can be entered with a single front panel switch press. The tare feature can be

enabled or disabled at any time, without losing the tare value itself, using the unit’s

absolute and relative reading modes. Limit status and display mode settings are always

clearly indicated with front panel LED’s. Programming of the unit is easily performed

using all five of the front panel switches, and calibration requires a security code

which prevents unwanted corruption of calibration data. Remote interfacing is available via RS232/RS485 (optional), or active low logic inputs located on the rear of the

unit.

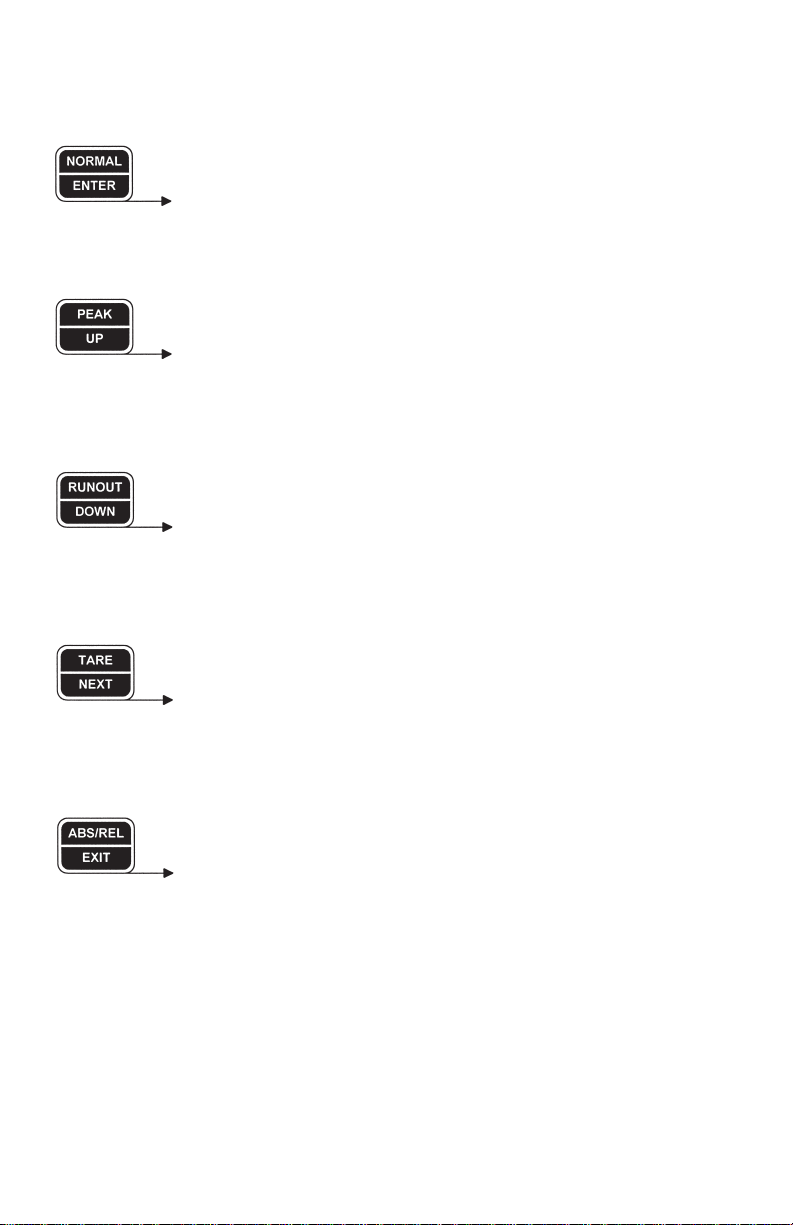

SWITCH FUNCTIONS:

There are five switches located behind the front lens of the model DP-7600. The front

panel switches appear as shown below. The text located at the top half of each switch

(i.e., NORMAL, PEAK, RUNOUT, TARE, ABS/REL) indicates that particular

switch’s function when the unit is in data acquisition and display mode. The text located in the lower half (i.e., ENTER, UP, DOWN, NEXT, EXIT) indicates the switch’s function during setup and calibration. A complete description of each switch is as follows:

1

Page 7

Data Acquisition & Display

: Press to set the display mode for actual reading.

Setup & Calibration Modes

: Press to record a complete setting and advance to the next setup.

Data Acquisition & Display

: Press to set the display mode for peak.

Setup & Calibration Modes

: Press to increment the digit/parameter being set.

Data Acquisition & Display

: Press to set the display mode for runout.

Setup & Calibration Modes

: Press to decrement the digit/parameter being set.

Data Acquisition & Display

: Press to record the current reading as the tare value.

Setup & Calibration Modes

: Press to advance to the next digit to be set.

Data Acquisition & Display

: Press to toggle between absolute and relative reading mode.

Setup & Calibration Modes

: Press to exit the setup or calibration mode at any time (all prior

changes are saved).

2

Page 8

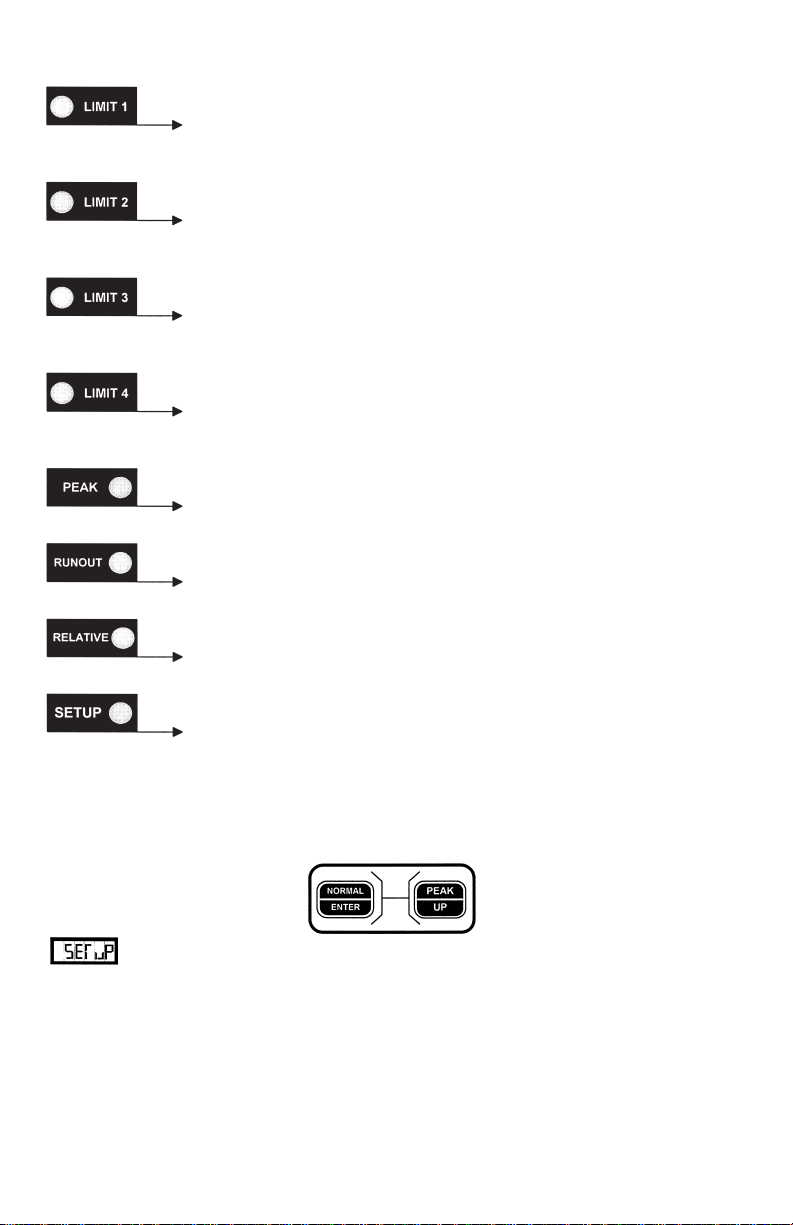

LED INDICATORS:

Limit 1 Illuminates when the display reading exceeds the set limit,

and in the setup mode when establishing the limit.

Limit 2 Illuminates when the display reading exceeds the set limit,

and in the setup mode when establishing the limit.

Limit 3 Illuminates when the display reading exceeds the set limit,

and in the setup mode when establishing the limit.

Limit 4 Illuminates when the display reading exceeds the set limit,

and in the setup mode when establishing the limit.

Peak Illuminates when the display is set in the peak mode.

Runout Illuminates when the display is set in the runout mode.

Relative Illuminates when the display is set in the relative mode.

Setup Illuminates when the display is in the setup mode.

SETUP:

Meter setup is accomplished by using all five of the front panel switches. The setup

m

ode is entered by pressing the Normal [Enter] and Peak [Up] switches simultaneously.

will flash on the display for a second and the setup LED indicator will illuminate. While in the setup mode, programming of the meter functions is accomplished

by setting individual digits of the various parameters (with the exception of baud rate

and decimal point programming). A flashing digit indicates that it is the active digit

being set. The flashing digit can be incremented by pressing the UP switch; conversely,

it can be decremented by pressing the DOWN switch. Once a particular digit has been

set to the desired value the NEXT switch can be pressed to advance to the next digit.

Once all the digits have been set to the proper value the ENTER switch can be pressed

3

Page 9

to advance to the next parameter. At any time during the setup sequence the EXIT

switch can be pressed to leave the setup mode and save the current settings. If the

setup sequence is completed the unit will save all settings and automatically return to

data acquisition and display mode. If a meter setup is started, and a long period

(approximately 100 seconds) of inactivity is detected by the meter, the meter will

return to data acquisition and display mode without saving any new settings.

DISPLAY MODE

Upon entering the setup mode display will flash “d-node” then the unit will

go to one of the following display modes: CH1, CH2, Plus, Minus, Mult or Div. To

select a different mode press RUNOUT [down]. To enter selected display mode and to

go to the next setup option press NORMAL [ENTER].

Note: If no math functions are desired select CH1 or CH2. In normal operation mode:

pressing NORMAL [ENTER] will cycle between the two channels.

If any math function is selected then all math functions are available as well as CH1

and CH2. In normal operation mode: pressing NORMAL [ENTER] will cycle between

the two channels and all math functions.

LIMIT PROGRAMMING

All four limits are programmed in succession (1 through 4) immediately

after entering the setup mode. The corresponding LED illuminates to indicate which

limit is being programmed. All limits can be programmed to any number that is within

the display span (as determined by the meter calibration), and are activated when a

reading that exceeds the programmed limit number is detected.

LIMIT ONE DELAY

The limit one delay is a programmable delay, from 0 - 100 seconds, between

the time a reading exceeding the limit one number is detected and when the limit one

output will be activated. Using the delay feature, the limit one output can be tied to the

REMOTE RESET input on the rear of the unit to reset the peak reading so that the

next peak can be properly detected in a process sequence.

DECIMAL POINT POSITION

The calibration span number is displayed with the decimal point shown in its

selected position. The decimal point can be moved across the display to the desired

position using the UP and DOWN switches.

4

Page 10

FILTER SETUP

The digital filter determines the rate at which the limits are checked for output activation, peak/runout tracking, and analog output updates. The digital filter is

programmable from 1 to 500Hz. When stability is more an issue than speed the filter

should be set closer to 1Hz; conversely, when quick detection and activation is more

important the filter should be set closer to 500Hz. Note: Unless the serial option is

installed, the setup sequence is now finished and the unit will return to acquisition

and display mode.

BAUD RATE SELECTION

Program the desired baud rate using the UP or DOWN switches to toggle

through the available settings (300, 600, 1200, 2400, 4800, 9600, 19200, and 38400).

Once the proper baud rate is selected press the ENTER switch to advance to the next

setup.

ECHO SETUP

The model DP-7600 can be programmed to automatically re-transmit (echo)

characters received on its serial communications input. A value of one enables the echo

feature; conversely, programming a zero will disable it.

LINEFEED SETUP

The unit can be programmed to transmit linefeed characters in addition to

the carriage return that is transmitted at the end of data strings. Programming a one

will enable transmission of linefeed characters, while programming a zero will prevent

their transmission.

UNIT ADDRESS SETUP

Multiple DP7600 units can be networked together on a serial bus using the

addressing capability of the unit. Each unit can have a unique address from 0 to 250

(Note: 0 disables the address feature since the unit will respond to all incoming commands/queries).

5

Page 11

LEGEND SETUP

The DP-7600 can append a user selectable engineering units string to readings transmitted from the unit. This feature allows direct terminal readout in engineering units, or easier unit identification in multi-unit applications. Program the legend

number to the number corresponding with desired units as shown in the table below.

Legend T

able

0 - No Legend 4 - kpa.

1 - lbs. 5 - mV.

2 - kgs. 6 - mA.

3 - psi. 7 - V.

CONTINUOUS UPDATE

The model DP-7600 can be programmed to automatically transmit the display reading at selectable time intervals. The update interval can be programmed from

20 times per second (-1) up to a maximum of 3600 seconds (3600). A value of zero

disables the automatic update function.

DEVICE CODE

A non-printable device code allows units to take turns on a serial bus when

daisy chained to a printer or some other data recording device. A value of one enables

transmission of the device code following the reading string; conversely, a value of

zero disables transmission of the device code.

SERIAL COMMAND

A serial command can automatically be executed upon receipt of a nonprintable code (see device code above). A table of numbers associated with each serial

command can be found in the serial communications section of the manual (on page

8). Program to the number associated with the command to be executed when the unit

receives a device code character on its serial communications input.

6

Page 12

CALIBRATION:

The calibration mode is entered by pressing the Normal [Enter] and

ABS/REL [Exit] switches simultaneously. Note: This is the only method to check or

change the calibration of this unit externally.

PROTECTION CODE

Before any calibration can be performed on the unit a unique security code must be

entered. If the code is not entered correctly the unit will automatically revert to display

and acquisition mode; otherwise, the user is allowed to proceed with the calibration

sequence. To enter the code use the standard sequence of operations explained in the

switch functions and setup at the begining of your manual.

PROTECTION CODE PROGRAMMING

A different protection code can be programmed at this time. The code can be

anywhere in the range 0 - 255. If a new code is not required simply press ENTER to

continue with the calibration sequence.

SPAN NUMBER PROGRAMMING

The span number is the display reading that is associated with the input

obtained during the DEAD WEIGHT STAY portion of the calibration sequence (a display reading of zero is automatically associated with the DEAD WEIGHT ZERO calibration step). The span number can be programmed to a maximum of 32767 display

counts. Note: If your deadweight stay calibration will be performed using something

less than the actual expected full-scale input, the desired reading for the dead weight

stay calibration input should still be used as the span number.

(Example: There’s a 10,000 Lbs. load cell but dead weight, the shunt cal resistor available is for only 8000 Lb., calibrate as shown below. Unit will respond to the full scale

of 10,000Lbs. even through unit is calibrated at 8000 Lbs.)

DEAD WEIGHT ZERO

This is the zero (null) point calibration step. Set the transducer or calibrator

for zero output, allow sufficient time for the reading to stabilize, then press the

ENTER switch to store the new zero calibration data.

DEAD WEIGHT STAY

This is the span point calibration step. Check to make sure that MV/V setting and excitation is selected to match the transducer. Set the transducer or calibrator

for full-scale output, allow sufficient time for the reading to stabilize, then press the

ENTER switch to store the new span calibration data.

7

Page 13

SERIAL COMMUNICATIONS:

With the serial communications option installed, the model DP-7600 can easily be

interfaced to a computer, terminal, or printer. The unit can operate in stand-alone mode

or in networked applications. Both RS232 and RS485 serial communication options

are available for the DP-7600. The baud rate is user selectable, and can range from

300 to 38.4K baud. The unit uses a N,8,1 character data format (no parity, 8 data bits,

1 stop bit). All data is transmitted/received as ASCII characters. Characters strings are

transmitted/received with the leftmost character first and are terminated with a carriage return [CR]. Incoming linefeeds are ignored by the unit, and it is optional to

have the unit transmit them. Leading zeros are acceptable for numeric data transmitted

to the unit. Decimal points are ignored by the unit, and are transmitted, when required,

to conform with the selected display format.

Listed below are the available commands for the model DP-7600 (with the associated

command numbers). Following this is a discussion of how commands are interpreted

by the unit along with a brief description for each command.

1 EH Set Echo Mode

2 LF Set Line Feed Mode

3 AE Address Enable

4 AD Address Disable

5 RD Read Display

6 NOT USED

7 NOT USED

8 S1 Set Limit One

9 S2 Set Limit Two

10 S3 Set Limit Three

11 S4 Set Limit Four

12 SP Peak and Runout

13 NOT USED

14 SZ Remote Tare

15 NOT USED

16 NOT USED

17 NOT USED

18 NOT USED

19 TM Test Message

20 NOT USED

21 NOT USED

22 CR Set Continuous Reading Mode

23 NOT USED

24 NOT USED

25 NOT USED

26 LR Set Legend

27 SC Remote Serial Command

28 DP Set Decimal Point Position

29 NOT USED

34 NOT USED

35 PV Set Display Mode

36 AR Absolute or Relative

37 SF Program Filter

8

Page 14

Each DP-7600 command consists of two upper-case alpha ASCII characters. In most

instances, commands can be sent to the unit with a numeric value (ASCII format)

attached for parameter setting. When the unit receives and executes a valid command

it responds by transmitting “ok[CR]”. Commands can also be sent to the unit without

a parameter attached to interegate the current setting for the parameter associated with

that command. In this instance, the unit responds with the equivalent lower-case characters for that particular command along with an ASCII representation for the numeric

value of the parameter in question. The following is an example of a possible exchange

sequence between a model DP-7600 and a host computer:

Exchange 1: HOST SENDS : “AE0[CR]”

DP-7600 RESPONDS WITH : “HELLO ae 0[CR]”

(Note: The unit address is assumed to be set a zero.)

Exchange 2: HOST SENDS : “RD[CR]”

DP-7600 RESPONDS WITH : “99.99lbs[CR]”

(Note: It is assumed the display reading is 99.99 and that the legend is set for lbs.)

Exchange 3 HOST SENDS : “S1 1000[CR]”

DP-7600 RESPONDS WITH : “ok[CR]”

Exchange 4 HOST SENDS : “S1[CR]”

DP-7600 RESPONDS WITH` : “11 1000[CR]”

Exchange 5 HOST SENDS : “AD0[CR]”

DP-7600 RESPONDS WITH : “BYE ad 0[CR]”

Note: Remember [CR] represents a carriage return character.

The following is a list of the serial commands available on the DP-7600. Each command string is shown in quotes, a parameter/number field is represented by X (first) or

Y (second), the sign, where needed, is shown as a lower case s(s). A brief description is

given for each command along with any particular programming instructions.

ECHO: “EH X[CR]”

The echo command allows enabling or disabling of the unit’s echo feature. When the

echo feature is turned on the unit automatically echo’s all received characters.

X = 1 echo ON

X = 0 echo OFF

9

Page 15

LINE FEED: “LF X[CR]”

The unit can be set to send a line feed character following each transmitted string.

X = 1 line feeds are transmitted.

X = 0 line feeds are not transmitted

ADDRESS ENABLE: “AE XXX[CR]”

The address enable command, in conjunction with the address disable command, can

be used to network multiple DP-7600 units. Once a unit’s address has been enabled it

will respond to all incoming commands until the unit’s address is disabled. When the

address enabled command is executed by a DP-7600 it responds with “HELLO ae

XXX[CR].” Note: a unit address of zero (0) disables the addressing feature and the

address enable command is not required.

ADDRESS DISABLE: “AD XXX[CR]”, or “AD[CR]”

This command disables the unit at the specified address, or when an address in not

attached, all units on the network. When the command is successfully executed the

unit will respond with “BYE ad XXX[CR]”.

READ DISPLAY: “RD[C.R.]”

Requests transmission of the current DP-7600 display reading. The type of reading

returned (i.e. peak, runout, or current input) will depend upon the display reading

mode selected. The unit will format the reading with sign and decimal point as needed.

SET LIMIT: “S# XXXXX[CR]”

Allows remote setting of the DP-7600 limit numbers. The # should be replaced in the

string with the number of the limit to be set (1 through 4).

PEAK AND RUNOUT: “SP[CR]”

When this command is received the peak and runout reading are then reset.

REMOTE TARE: “SZ X[CR]”

The remote tare command allows tare “capture” similar to that performed by the front

panel TARE switch. When a number is attached to the command a new tare value is

captured.

10

Page 16

TEST MESSAGE: “TM[CR]”

The test message is primarily a diagnostic aid. When the test message command is

received the unit will respond by outputting information particular to the model number and software version/revision.

CONTINUOUS READING: “CR XXXX[CR]”

The continuous reading command allows setting of the automatic update feature of the

DP-7600.

X = -1 - readings are transmitted 20 times per second

X = 0 - automatic updates disabled

XXXX = 1 - 3600 -number of seconds between updates

SET LEGEND: “LR X[CR]”

The set legend command allows a unit indicator to be attached to readings transmitted

by the unit.

X = ? legend number (from table) for reading units

REMOTE SERIAL COMMAND: “SC X YY[CR]”

In data logging applications, involving several units daisy-chained together, a problem

arises when it is desired to have several units automatically transmit readings at the

same time interval (since contention could result in scrambled data at the printer). To

compensate for this, the model DP-7600 allows unit to “take turns” on the same serial

bus. This is done by enabling transmission of a special non-printable character at the

end of a reading string; which, when received by the following unit will cause it to

execute a serial command (RD would be most common). The second unit can have

the device code enabled and so on. Note: all units should have the echo function

enable so that messages will pass along to the following units in the chain.

DECIMAL POSITION: “DP X[CR]”

The display decimal point can be positioned using this command.

X = 0 88888 (no decimal point)

X = 1 8888.8

X = 2 888.88

X = 3 88.888

X = 4 8.8888

X = 5 .88888

11

Page 17

READING MODE: “PV X[CR]”

The display reading mode can be set using this command.

X = 0: Display is set for reading only

X = 1: Display is set for peak

X = 2: Display is set for runout

ABSOLUTE OR RELATIVE “AR X[CR]”

Allows changing of the display mode between absolute and relative.

X = 0 Absolute measurement only (tare is disabled)

X = 1 Relative measurement (tare enabled)

SET FILTER “SF XXX[CR]”

The set filter command can be used to remotely set the rate at which limit detection,

peak/runout tracking, and analog output updates are performed.

XXX = 1 - 500 (Hz)

CALIBRATION SPAN NUMBER “SN X YYYY[CR]”

X = Channel number (1 or 2)

YYYY = Calibration span number

SERIAL READING MODE “SM X[CR]”

X = 0 : Serial read outputs channel #1 (display reading)

X = 1 : Serial read outputs channel #2 reading

X = 2 : Serial read outputs channel #2 peak

X = 3 : Serial read outputs channel #2 runout

LIMIT MODE “LM X N[CR]”

X = Limit number

N = Limit mode, bit defined as follows:

Normal - 01 HEX

Peak - 02 HEX

Runout - 03 HEX

Channel #2 - 04 HEX

High limit - 08 HEX

12

Page 18

Example: Assume we want a high limit, normal (reading), active on channel one; then,

YY = 01 OR’ed 08 = 09 HEX (NOTE: unlike most serial command parameters, this

is not ASCII).

REMOTE INPUTS:

Seven logic level, active-low, remote inputs are located on the rear of the unit for interfacing to programmable logic controllers etc.. The remote inputs can be used to duplicate many of the front panel switch functions of the unit. A brief description of each

input follows below:

NORMAL MODE (remote input #1) --sets the display mode to reading only.

DATA REQUEST (remote input #2) --requests a serial transmission of the

display reading

RESET P/R (remote input #3) --resets the peak and runout readings

DATA HOLD (remote input #4) --A/D samples are ignored while this

input is active

RUNOUT MODE (remote input #5) --sets the display mode to runout

PEAK MODE (remote input #6) --sets the display mode to peak

CAPTURE TARE (remote input #7) --sets the tare value to the current

display reading

All remote inputs must be active for a minimum of 50mS (with the exception of DATA

HOLD which only needs to be held active a minimum of 1mS for detection).

13

Page 19

SENSITIVITY PROGRAMMING:

Pick a sensitivity setting that is as close as possible, without going under, the expected

full-scale output from the transducer being used.

Example: Assume that a 10,000 pound capacity load cell with an output of .5mV/V

full-scale is going to be used with the DP-7600. Also assume that the excitation

required 10V; therefore, the full-scale input to the unit will be 5mV at 10,000 pound,

and the sensitivity switches located on the rear of the DP-7600 should be set for 5.1mV

full-scale (S1 - S3 open).

DP-7600 BACK VIEW

EXCITATION

SETTINGS

DP-7600 SENSITIVITY SETTINGS

14

Page 20

DP-7600 REAR TERMINATIONS

TB1 (POWER INPUT - BOTTOM BOARD)

(1) AC LINE

(2) AC NEUTRAL

(3) EARTH GROUND

TB2 (TOP BOARD) TB3 (BOTTOM BOARD)

(1) LIMIT 1 SHIELD

(2) LIMIT 2 -15V

(3) LIMIT 3 ANALOG OUTPUT

(4) LIMIT 4 -RCAL2

(5) NORMAL MODE +RCAL2

(6) DATA REQUEST -SIGNAL2

(7) RESET P/R +SIGNAL2

(8) DATA HOLD -RCAL1

(9) RUNOUT MODE +RCAL1

(10) PEAK MODE -EXCITATION

(11) CAPTURE TARE -SENSE

(12) +5V -SIGNAL1

(13) ISOLATED POWER +SIGNAL1

(14) ISOLATED GROUND +SENSE

(15) INSTRUMENT GROUND +EXCITATION

J3 (RJ11 - TOP BOARD)

(1) RS485 SERIAL

(2) RS485 TERMINATION RESISTOR

(3) RS232 RX

(4) RS232 TX

(5) RS232 - GROUND

(6) RS485 ~SERIAL

15

Page 21

SCHEMATIC (DP-7600 Top Board)

16

Page 22

SCHEMATIC (DP-7600 Top Board)

17

Page 23

SCHEMATIC (DP-7600 Top Board)

18

Page 24

SCHEMATIC (DP-7600 Bottom Board)

19

Page 25

SCHEMATIC (DP-7600 Bottom Board)

20

Page 26

SCHEMATIC (DP-7600 Analog Input Option Board)

21

Page 27

SCHEMATIC (DP-7600 Output Option Board)

22

Page 28

SCHEMATIC (DP-7600 RS232/RS485 Option Board)

23

Page 29

DIMENSIONS

24

6”

INCLUDING I/O CONNECTOR

Page 30

MOUNTING

Customers Panel with Cutout

to mount Omega Instrument

I/O Connectors Supplied by

Omega Number and Style Vary

Mounting Straps Supplied by Omega

25

Page 31

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M2838/0624

Loading...

Loading...