Page 1

B

HIGH ACCURACY

PRESSURE TRANSDUCERS

PX409 Series

Starts at

$

475

0.08% BSL Includes

Linearity Hysteresis

and Repeatablity

Broad Temperature

Compensation

Range -29 to 85°C

(-20 to 185°F)

5-Point NIST Traceable

Calibration Included

Outputs:

• mV/V

• 0 to 5 V or 0 to 10 V

• 4 to 20 mA

10 in-H

to 5000 psi Ranges

O

2

RUGGEDIZED DESIGN

For Aerospace,

Automotive, Test and

Industrial Applications

PX409-100GV,

$475, shown

actual size.

PX419-015GV,

$475, shown

actual size.

PX429-030GV, $475,

shown actual size.

Coming Soon!

Differential

Pressure Models

Most Popular

Models in Stock for

Fast Delivery

B-25a

Page 2

SOLID STATE PIEZORESISTIVE DESIGN

WITH HIGH TEMP. PERFORMANCE FOR INDUSTRY,

AUTOMOTIVE, TEST, AND AEROSPACE APPLICATIONS

PX409 Series

mV/V, 0 to 5 Vdc, 0 to 10 Vdc, 4 to 20 mA Outputs

Low Pressure: 10 in-H

O and

2

Standard Ranges: 5 to 5000 psi

Metric Ranges: 25 mbar to 345 bars

Gage or Absolute Pressure

Starts at

$

475

mV/V models

High Accuracy ±0.08% BSL

Includes Linearity, Hysteresis,

and Repeatability

Broad Temperature Compensated Range

-29 to 85°C (-20 to 185°F)

Premium Temperature Performance

Span: ±0.5% over Compensated Range

5-Point NIST Traceable Calibration

Included

Low Pressure Ranges from 10 in-H

All Stainless Steel Wetted Parts

Fast Response Time

Solid State Reliability and Stability

Gage and Absolute Pressures

300% Proof Pressure Minimum

Omega piezoresistive pressure transducers have a

proven record in high performance commercial and

aerospace applications for over 25 years. The

piezoresistive process uses strain gages molecularly

embedded into a highly stable silicon wafer. The silicon

wafer is diced into individual die which each contain a

full strain gage bridge. The die is mounted in a sealed

chamber protected from the environment by glass to

metal seals and a stainless steel diaphragm.

A small volume of silicone oil transfers the pressure

from the diaphragm to the strain bridge. The

construction provides a very rugged transducer with

exceptional accuracy, stability and thermal effects. A

unique design ruggedizes the transducers by providing

secondary fluid containment in the event of a

diaphragm rupture.

At our state-of-the-art facilities, automated test

equipment performs pressure and temperature cycling

on 100% of the PX409 transducers. The transducers

are then calibrated using extremely high accuracy

equipment and a 5-point NIST traceable calibration

All models shown

actual size.

PX409-050GV, $475,

features cable

termination.

PX419-100GI,

$545, features

mini-DIN termination.

PX429-015GI,

twist-lock termination.

O

2

$545, features

Stock Delivery for

most Ranges!

Visit omega.com

0.08%

Accuracy

PX409 SERIES SILICON WAFER TECHNOLOGY

PX409 Series uses a highly stable silicon wafer which is

micro-machined to precision

tolerances and then has

strain gages molecularly

embedded into it.

Strain gages shown

larger than actual size.

certificate is included with each transducer. The

inherent stability of the piezoresistive core provides

excellent long term stability, repeatability and very low

thermal effects at the price of much lower performance

transducers. Standard features of the PX409 Series

also include protective features built into the electronics

and the pressure element. Reverse polarity, EMC, and

power supply fluctuation protection are standard on all

models. Intrinsically Safe and CSA ratings are optional.

The most popular ranges and configurations are

stocked for immediate delivery. All others typically have

very short lead-time.

B-25b

Strain gage

shown magnified

500%

Page 3

B

HIGH ACCURACY

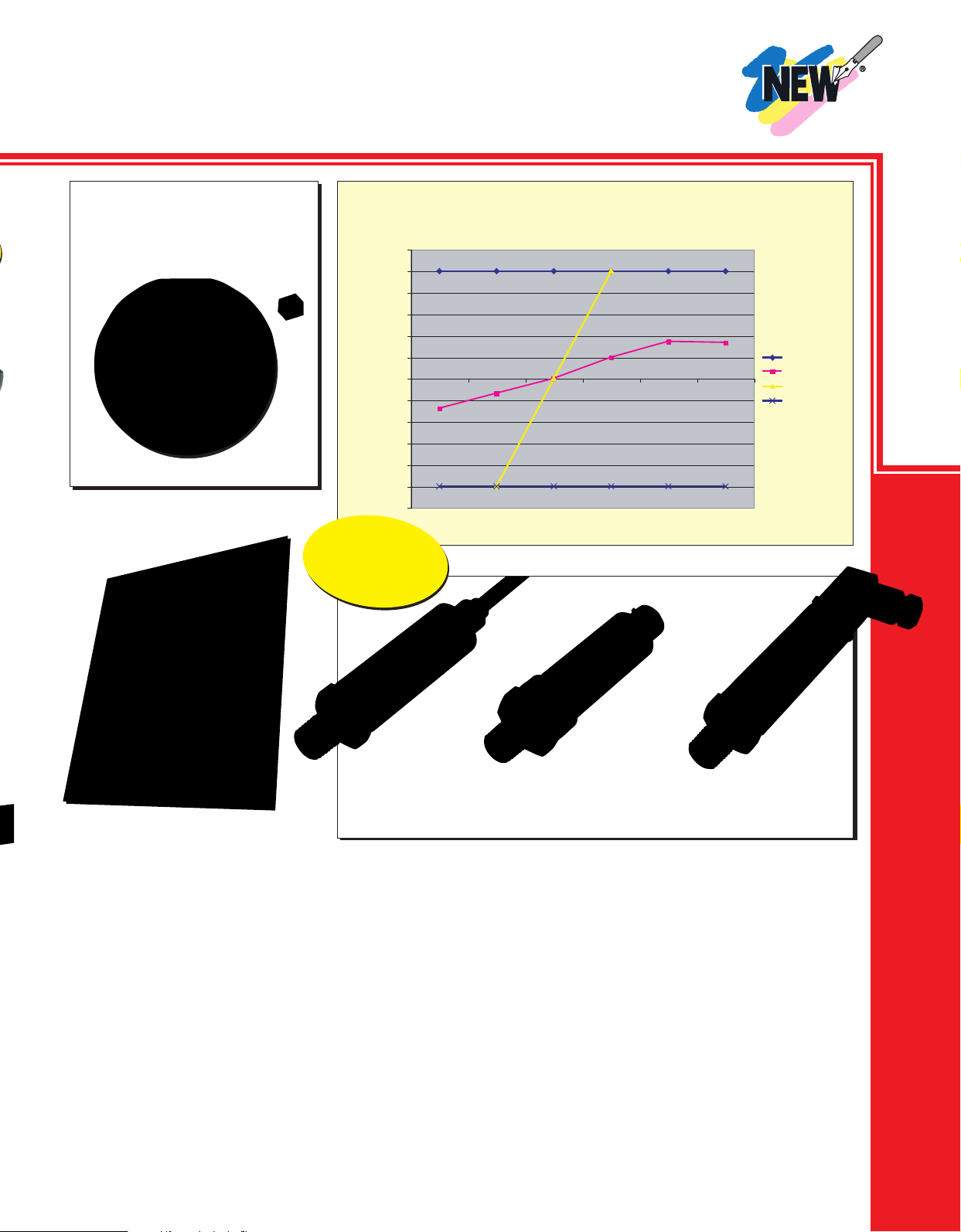

Span Error: 100 psig

-0.60

-0.50

-0.40

-0.30

-0.20

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

0.60

-40 20 80 140 200 220

Tem perature °F

High Limit

PX409

Other Models

Low Limit

Error (% Span)

PRESSURE TRANSDUCERS

PIEZORESISTIVE DESIGN WITH HIGH TEMPERATURE PERFORMANCE

EXCEPTIONAL PERFORMANCE

0.08% STATIC ACCURACY

Micro-Machined Silicon

5-Point NIST Traceable

Calibration Certificate

RUGGEDIZED DESIGN

For Aerospace,

Automotive, Test and

Industrial Applications

Thermal Effects -29 to 85°C (-20 to 185°F)

CUSTOM CONFIGURATIONS AVAILABLE!

Designed to be quickly customized to meet your exacting specifications, often with

fast delivery. Custom variables are available including custom fittings, accuracies,

ranges, calibrations, pressure units, thermal specifications, vibration, operating

temperature and compensated range. Contact OMEGA Pressure Engineering for

more details.

Common Specifications

Gage and Absolute Pressure

Approvals: RoHS compliant

Minimum Isolation Between Case

and Output Terminations:

100M Ω @ 50 Vdc

Pressure Cycles: 1 million, minimum

Long Term Stability (1-Year): ±0.1%

FS typical

Shock: 50 g, 11 mS half sine, vertical

and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute

cycle, Curve L, Mil-Spec 810 figure

514-2-2, vertical and horizontal axis

Bandwidth: DC to 1 kHz typical

Response Time: <1 mS

CE Compliant:

Emissions: IEC550022 Class B

Electrostatic Discharge Immunity:

IEC1000-4-2

EM Field Immunity: IEC61000-4-3

EFT Immunity: IEC61000-4-4

Surge Immunity: IEC61000-4-5

Conducted RF: IEC610000-4-6

Rate Power Frequency Magnetic

Field: IEC61000-4-8

Electrical Termination:

PX409: Integral 2 m (6') cable

PX409C: Integral 2 m (6') cable

with

PX419: mini-DIN

PX429: Twist lock

Environmental Protection:

PX409: IP67

PX409C: IP67

PX419: IP65

PX429: IP65

Overpressure Gage Pressure:

10-in H

1

⁄2 NPT conduit fitting

O: 10 times span

2

B-25c

1 psi: 6 times span

2.5 psi to 3500 psi: 4 times span

5000 psi: 15,000 psi max

Overpressure Absolute Pressure:

5 psia: 6 times span

2.5 psia to 3500 psia: 4 times span

5000 psia: 15000 psi max

Secondary Containment

Gage/Diff/Vac/Compound:

10 in-H2O to 5 psi: To 1000 psi

15 to 1000 psi: To 3000 psi

1500 to 5000 psi: To 15,000 psi

Absolute/Barometric:

5 to 1000 psi: To 6000 psia

1500 to 5000 psi: To 15,000 psia

Wetted Parts: 316 SS

Pressure Port:

1

⁄4–18 NPT male

Weight: 115 to 200 gm (4 to 7 oz)

depending upon configuration

Page 4

mV/V OUTPUT

HIGH PERFORMANCE PRESSURE TRANSDUCERS

PIEZORESISTIVE DESIGN WITH HIGH TEMPERATURE PERFORMANCE

PX409 Series

100 mV Output

2

0-10 in-H

O to 0-5000 psi

25 mb to 345 bar

Starts at

$

475

mV/V Specifications

Output: mV/V, 100 mV @ 10 Vdc

(Ratiometric 5 to 10 Vdc)

Supply Voltage: 10 Vdc

Input/Output Resistance: 5000 Ω

±20% typical

Accuracy (Combined Linearity,

Hysteresis and Repeatability):

±0.08% BSL max

Zero Balance: ±0.5% FS typical

1% max (1% typical, 2% max

for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below)

Calibrated in vertical direction with

fitting down

Operating Temperature Range:

-45 to 121°C (-49 to 250°F)

Compensated Temperature:

Ranges >5 psi: -29 to 85°C

(-20 to 185°F)

Ranges ≤ 5 psi: -17 to 85°C

(0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

PX409-100GV,

$475, shown

actual size.

PX429-015GV,

$475, shown

actual size.

Stock Delivery for

PX419-015GV,

$475, shown

actual size.

most Ranges!

Visit omega.com

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

RANGE

psi bar

mV/V OUTPUT, GAGE PRESSURE RANGES

10 in-H2O

1 69 mb PX409-001GV 525 PX419-001GV 525 PX429-001GV 525

2.5 172 mb PX409-2.5GV 525 PX419-2.5GV 525 PX429-2.5GV 525

5 345 mb PX409-005GV 475 PX419-005GV 475 PX429-005GV 475

15 1.0 PX409-015GV 475 PX419-015GV 475 PX429-015GV 475

30 2.1 PX409-030GV 475 PX419-030GV 475 PX429-030GV 475

50 3.4 PX409-050GV 475 PX419-050GV 475 PX429-050GV 475

100 6.9 PX409-100GV 475 PX419-100GV 475 PX429-100GV 475

150 10.3 PX409-150GV 475 PX419-150GV 475 PX429-150GV 475

250 17.2 PX409-250GV 475 PX419-250GV 475 PX429-250GV 475

500 34.5 PX409-500GV 475 PX419-500GV 475 PX429-500GV 475

750 51.7 PX409-750GV 475 PX419-750GV 475 PX429-750GV 475

1000 69 PX409-1.0KGV 475 PX419-1.0KGV 475 PX429-1.0KGV 475

1500 103 PX409-1.5KGV 475 PX419-1.5KGV 475 PX429-1.5KGV 475

2500 172 PX409-2.5KGV 475 PX419-2.5KGV 475 PX429-2.5KGV 475

3500 241 PX409-3.5KGV 475 PX419-3.5KGV 475 PX429-3.5KGV 475

5000 345 PX409-5.0KGV 475 PX419-5.0KGV 475 PX429-5.0KGV 475

mV OUTPUT, ABSOLUTE PRESSURE RANGES

5 345 mb PX409-005AV $520 PX419-005AV $520 PX429-005AV $520

15 1.0 PX409-015AV 520 PX419-015AV 520 PX429-015AV 520

30 2.1 PX409-030AV 520 PX419-030AV 520 PX429-030AV 520

50 3.4 PX409-050AV 520 PX419-050AV 520 PX429-050AV 520

100 6.9 PX409-100AV 520 PX419-100AV 520 PX429-100AV 520

150 10.3 PX409-150AV 520 PX419-150AV 520 PX429-150AV 520

250 17.2 PX409-250AV 520 PX419-250AV 520 PX429-250AV 520

500 34.5 PX409-500AV 520 PX419-500AV 520 PX429-500AV 520

750 51.7 PX409-750AV 520 PX419-750AV 520 PX429-750AV 520

1000 69 PX409-1.0KAV 520 PX419-1.0KAV 520 PX429-1.0KAV 520

Ordering Examples: PX409-1.0KGV, mV output, 1000 psi gage pressure range,

2m (6') cable termination, $475. PX429-015AV, mV output, 15 psi absolute pressure, twist

lock termination, PT06F10-6S, mating twist lock connector (sold separately), and

DP25B-S, 4-digit meter, $520 + 26.50 + 245 = $791.50 system with meter.

(See page B-25h for information on meters).

25 mb PX409-10WGV $525 PX419-10WGV $525 PX429-10WGV $525

2 m (6') CABLE

TERMINATION

B-25d

PRICE

MINI-DIN

TERMINATION

PRICE

TWIST-LOCK

TERMINATION

PRICE

Page 5

0 TO 5 Vdc OUTPUT

HIGH PERFORMANCE PRESSURE TRANSDUCERS

PIEZORESISTIVE DESIGN WITH HIGH TEMPERATURE PERFORMANCE

PX409 Series

0 to 5 Vdc Output

2

0-10 in-H

O to 0-5000 psi

25 mb to 0-345 bar

Starts at

$

545

PX429-015G5V,

$545, shown

actual size.

Amplified Voltage Output

Specifications

Output:

0 to 5 Vdc Supply Voltage:

10 to 30 Vdc@10 mA

0 to 10 Vdc Supply Voltage:

15 to 30 Vdc@10 mA

Accuracy (Combined Linearity,

Hysteresis and Repeatability): ±0.08%

BSL max

Zero Balance: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below).

Calibrated in vertical direction with

fitting down

Operating Temperature Range:

-45 to 115°C (-49 to 240°F)

Compensated Temperature:

Ranges >5 psi: -29 to 85°C

(-20 to 185°F)

Ranges ≤5 psi: -17 to 85°C (0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

PX409-100G5V,

$545, shown

actual size.

Stock Delivery for

most Ranges!

PX419-100G5V,

$545, shown

actual size.

Visit omega.com

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

RANGE

psi bar

0 to 5 Vdc OUTPUT, GAGE PRESSURE RANGES

10 in-H2O 25 mb PX409-10WG5V $595 PX419-10WG5V $595 PX429-10WG5V $595

1 69 mb PX409-001G5V 595 PX419-001G5V 595 PX429-001G5V 595

2.5 172 mb PX409-2.5G5V 595 PX419-2.5G5V 595 PX429-2.5G5V 595

5 345 mb PX409-005G5V 545 PX419-005G5V 545 PX429-005G5V 545

15 1.0 PX409-015G5V 545 PX419-015G5V 545 PX429-015G5V 545

30 2.1 PX409-030G5V 545 PX419-030G5V 545 PX429-030G5V 545

50 3.4 PX409-050G5V 545 PX419-050G5V 545 PX429-050G5V 545

100 6.9 PX409-100G5V 545 PX419-100G5V 545 PX429-100G5V 545

150 10.3 PX409-150G5V 545 PX419-150G5V 545 PX429-150G5V 545

250 17.2 PX409-250G5V 545 PX419-250G5V 545 PX429-250G5V 545

500 34.5 PX409-500G5V 545 PX419-500G5V 545 PX429-500G5V 545

750 51.7 PX409-750G5V 545 PX419-750G5V 545 PX429-750G5V 545

1000 69 PX409-1.0KG5V 545 PX419-1.0KG5V 545 PX429-1.0KG5V 545

1500 103 PX409-1.5KG5V 545 PX419-1.5KG5V 545 PX429-1.5KG5V 545

2500 172 PX409-2.5KG5V 545 PX419-2.5KG5V 545 PX429-2.5KG5V 545

3500 241 PX409-3.5KG5V 545 PX419-3.5KG5V 545 PX429-3.5KG5V 545

5000 345 PX409-5.0KG5V 545 PX419-5.0KG5V 545 PX429-5.0KG5V 545

0 to 5 Vdc OUTPUT, ABSOLUTE PRESSURE RANGES

5 345 mb PX409-005A5V $545 PX419-005A5V $545 PX429-005A5V $545

15 1.0 PX409-015A5V 545 PX419-015A5V 545 PX429-015A5V 545

30 2.1 PX409-030A5V 545 PX419-030A5V 545 PX429-030A5V 545

50 3.4 PX409-050A5V 545 PX419-050A5V 545 PX429-050A5V 545

100 6.9 PX409-100A5V 545 PX419-100A5V 545 PX429-100A5V 545

150 10.3 PX409-150A5V 545 PX419-150A5V 545 PX429-150A5V 545

250 17.2 PX409-250A5V 545 PX419-250A5V 545 PX429-250A5V 545

500 34.5 PX409-500A5V 545 PX419-500A5V 545 PX429-500A5V 545

750 51.7 PX409-750A5V 545 PX419-750A5V 545 PX429-750A5V 545

1000 69 PX409-1.0KA5V 545 PX419-1.0KA5V 545 PX429-1.0KA5V 545

Note: To order with 0 to 10 Vdc output, change “5V” to “10V” no extra charge.

Ordering Examples: PX409-1.0KG5V, 5 V output, 1000 psi gage pressure range,

2m (6') cable termination, $545. PX429-015A5V, 5 V output, 15 psi absolute pressure, twist lock

termination, PT06F10-6S, mating twist lock connector (sold separately), and

DP25B-E, 4-digit meter, $545 + 26.50 + 245 = $816.50 system with meter.

(See page B-25h for information on meters).

2 m (6') CABLE

TERMINATION PRICE TERMINATION PRICE TERMINATION PRICE

B-25e

MINI-DIN TWIST-LOCK

B

Page 6

4 TO 20 mA OUTPUT

HIGH PERFORMANCE PRESSURE TRANSMITTERS

PIEZORESISTIVE DESIGN WITH HIGH TEMPERATURE PERFORMANCE

PX409 Series

4 to 20 mA Output

2

0-10 in-H

O to 0-5000 psi

25 mb to 0-345 bar

Starts at

$

545

4 to 20 mA

Specifications

Output: 4 to 20 mA

Supply Voltage: 9 to 30 Vdc

max loop res Ω = (Vs-9)x50

[9 to 20 Vdc above 105°C (229°F)]

Accuracy (Combined Linearity,

Hysteresis and Repeatability): ±0.08%

BSL max

Zero Balance: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below).

Calibrated in vertical direction with

fitting down

Operating Temperature Range:

-45 to 115°C (-49 to 240°F)

Compensated Temperature:

Ranges >5 psi: -29 to 85°C (-20 to 185°F)

Ranges ≤ 5 psi: -17 to 85°C (0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

PX429-015GI,

$545, shown

actual size.

PX409-100GI,

$545, shown

actual size.

Stock Delivery for

most Ranges!

PX419-100GI,

$545, shown

actual size.

Visit omega.com

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

RANGE

psi bar

4 to 20 mA OUTPUT, GAGE PRESSURE RANGES

10 in-H2O 25 mb PX409-10WGI $595 PX419-10WGI $595 PX429-10WGI $595

1 69 mb PX409-001GI 595 PX419-001GI 595 PX429-001GI 595

2.5 172 mb PX409-2.5GI 595 PX419-2.5GI 595 PX429-2.5GI 595

5 345 mb PX409-005GI 545 PX419-005GI 545 PX429-005GI 545

15 1.0 PX409-015GI 545 PX419-015GI 545 PX429-015GI 545

30 2.1 PX409-030GI 545 PX419-030GI 545 PX429-030GI 545

50 3.4 PX409-050GI 545 PX419-050GI 545 PX429-050GI 545

100 6.9 PX409-100GI 545 PX419-100GI 545 PX429-100GI 545

150 10.3 PX409-150GI 545 PX419-150GI 545 PX429-150GI 545

250 17.2 PX409-250GI 545 PX419-250GI 545 PX429-250GI 545

500 34.5 PX409-500GI 545 PX419-500GI 545 PX429-500GI 545

750 51.7 PX409-750GI 545 PX419-750GI 545 PX429-750GI 545

1000 69 PX409-1.0KGI 545 PX419-1.0KGI 545 PX429-1.0KGI 545

1500 103 PX409-1.5KGI 545 PX419-1.5KGI 545 PX429-1.5KGI 545

2500 172 PX409-2.5KGI 545 PX419-2.5KGI 545 PX429-2.5KGI 545

3500 241 PX409-3.5KGI 545 PX419-3.5KGI 545 PX429-3.5KGI 545

5000 345 PX409-5.0KGI 545 PX419-5.0KGI 545 PX429-5.0KGI 545

4 to 20 mA ABSOLUTE PRESSURE RANGES

5 345 mb PX409-005AI $545 PX419-005AI $545 PX429-005AI $545

15 1.0 PX409-015AI 545 PX419-015AI 545 PX429-015AI 545

30 2.1 PX409-030AI 545 PX419-030AI 545 PX429-030AI 545

50 3.4 PX409-050AI 545 PX419-050AI 545 PX429-050AI 545

100 6.9 PX409-100AI 545 PX419-100AI 545 PX429-100AI 545

150 10.3 PX409-150AI 545 PX419-150AI 545 PX429-150AI 545

250 17.2 PX409-250AI 545 PX419-250AI 545 PX429-250AI 545

500 34.5 PX409-500AI 545 PX419-500AI 545 PX429-500AI 545

750 51.7 PX409-750AI 545 PX419-750AI 545 PX429-750AI 545

1000 69 PX409-1.0KAI 545 PX419-1.0KAI 545 PX429-1.0KAI 545

Ordering Examples: PX409-1.0KGI, 4 to 20 mA output, 1000 psi gage pressure range,

2m (6') cable termination, $545. PX429-015AI, 4 to 20 mA output, 15 psi absolute pressure,

twist lock termination, PT06F10-6S, mating twist lock connector (sold separately), and DP25B-

E, 4-digit meter, $545 + 26.50 + 245 = $816.50 system with meter.

(See B-25h for information on meters).

2 m (6') CABLE

TERMINATION PRICE TERMINATION PRICE TERMINATION PRICE

B-25f

MINI-DIN

TWIST-LOCK

Page 7

HIGH ACCURACY PRESSURE

Product Label

Hex 22 (0.87) AF

¼-18 NPT

Pressure Adaptor

22

(0.88)

79 (3.1)

79 (3.1)

¼-18 NPT

Pressure Adaptor

Hex 2.5 (1.0) AF

22

(0.88)

Conduit backend PX409C

Integral cable backend PX409

28

(1.1)

5

(0.2)

Twist lock backend PX459

Vent with porous plug

(gage units only)

mini DIN backend PX419

5

(0.2)

5

(0.2)

Vent with porous plug

(gage units only)

TRANSDUCERS

PIEZORESISTIVE DESIGN

WITH HIGH TEMPERATURE PERFORMANCE

PX409-100GI,

$545, shown smaller

than actual size.

PX409 CABLE CONNECTION

COLOR mV 5/10V mA

Black – EXC Common – Supply

White + SIG + Output NC

Green – SIG NC NC

Red + EXC + EXC + Supply

Dimensions: mm (in)

Hex = 0.87

1

⁄2 x 14 NPT

PIN mV 5/10V mA

1 + EXC + EXC + Supply

2–EXC Common – Supply

3 + SIG + Output NC

4–SIG NC NC

PX419-100GI, $545,

shown smaller than actual size.

PX419 MINI-DIN PIN OUT

PX429-015GI,

$545, shown smaller

than actual size.

PX429 TWIST LOCK PINOUT

PIN mV 5/10V mA

PIN mV 5/10V mA

A + EXC + EXC + Supply

B–EXC Common – Supply

C + SIG + Output NC

D–SIG NC NC

E NC NC NC

F NC NC NC

B

COMPATIBLE METERS AND ACCESSORIES

METERS

MODEL NO. PRICE DESCRIPTION

DP41-S $545 6-digit high accuracy (0.005%) strain meter for use with mV/V output models

DP41-E 545 6-digit high accuracy (0.005%) process meter for use with voltage and current output models

DP41-B 595

DP25B-S 245 4-digit precision strain meter for use with mV/V output models

DP25B-E 245 4-digit precision process meter for use with voltage and current output models

ACCESSORIES

CX5302 $15.00 Extra mini-DIN connector for PX419 Series

PT06F10-6S 26.50 Mating twist lock connector for PX429 Series

PS-4G 10.00 Pressure snubber for air/gaseous media

PS-4E 10.00 Pressure snubber for water or light oils

PS-4D 10.00 Pressure snubber for dense liquids (motor oil)

6-digit high accuracy (0.005%) universal meter for use with voltage and current output models

also accepts thermocouple and RTD inputs

B-25g

PX409 Series pressure ranges >15 psi

to 1000 psig for pressure ranges

above 1000 psi consult factory.

PX409 Series pressure ranges

15 psi and below.

MOST POPULAR LISTED!

Page 8

COMPATIBLE METER

DP25B

4-Digit Precision Meter

All Models

$

245

function for weighing applications,

mV, V, mA,

Strain Gage Inputs

Full Process Unit Scaling

Built-In Transducer Power

Process and Strain Models

Because they accept a wide range

of DC voltage and current inputs,

the DP25-B-E strain meters can

handle most process and strain

applications. Features include easy

front-panel scaling to virtually any

engineering units, a remote tare

OMEGA Pressure and Strain

Measurement Handbook

and a hardware lockout to prevent

unauthorized changes in setup. In

addition, the DP25B-E meters

feature built-in excitation in

To Order (Specify Model Number)

MODEL NO. PRICE DESCRIPTION

DP25B-E $245 Voltage/current input with excitation

DP25B-S 245 mV input in excitation

Comes complete with operator’s manual.

Ordering Examples: DP25B-E, voltage/current input meter for use with 0 to 5 V, 0 to 10 V, 4 to

20 mA output PX409 Series transducers, $245. DP25B-S, mV input meter for use with mV/V

output PX409 Series transducers, $245.

PATENTED

Covered by U.S. and

International patents and

pending applications

DP25B, $245, shown close to actual size.

4 user-selectable voltages, which

makes them compatible with most

transducers and transmitters.

IN STOCK FOR FAST DELIVERY

HOT OFF THE

HOT OFF THE

PRESS!

The omegadyne.com

®

New Horizons®in Strain Gages

®

PRESS!

Pressure

Transducers

Strain Gages

Force & Load Cells

Torque

Pressure Gauges

(Digital & Analog)

Displacement —

LVDT and

Potentiometers

Proximity

Pressure Switches

Accelerometers

Dynamic Pressure

Dynamic Load

Pressure Valves

and Regulators

Request Your FREE Copy of the OMEGA

Complete Pressure, Strain and Force

Measurement Handbook and Encyclopedia

Handbook Cover Art: Based on an original Norman Rockwell illustration ©The Curtis Publishing Company

Precision Gages

Transducer Quality

Gages

Karma Gages

Strain Gage

Accessories

Custom Designs

Available

OEM Pricing

Request Your FREE

Copy Today!

Dilbert © United Feature Syndicate, Inc.

®

For Sales and Service, Call TOLL FREE

B-25h

©COPYRIGHT 2008 OMEGA ENGINEERING, INC. ALL RIGHTS RESERVED.

Shop Online at

Page 9

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...