Page 1

DP21 SERIES

MICROPROCESSOR-BASED

DIGITAL INDICATOR

INSTRUCTION MANUAL

Thank you for purchasing the Omega DP21 Series.

Please check that the delivered product is the correct item you orderd.

Please do not begin operating this product until you have read

this instruction manual thoroughly and understand its contents.

"Notice"

Please ensure that this instruction manual is given to the final user of

the instrument.

Preface

This instruction manual is meant for those who will be involved in the

wiring, installation, operation and routine maintenance of the DP21

series.

This manual describes the care, installation, wiring, function, and

proper procedures for the operation of DP21 series. Keep this manual

at the work site during operation of the DP21 series. While using this

instrument, you should always follow the guidance provided herein.

For matters regarding safety, potential damage to equipment and/or

facilities, additional instructions are indicated by the following

headings:

WARNING

Exercise extreme caution as indicated. This heading indicates

hazardous conditions that could cause injury or death of personnel.

CAUTION

Exercise extreme caution as indicated. This heading indicates

hazardous conditions that could cause damage to equipment and/or

facilities.

NOTE

This heading indicates additional instructions and/or notes.

The mark designates a protective conductor terminal.

Make sure to properly ground it.

DP21 series indicator is designed for indicating temperature,

humidity and other physical subjects. It must not be used in any

way that may adversely affect the safety, health or working

conditions of those who come into contact with the effect of its

usage. When used, adequate and effective safety countermeasures

must be provided at all times. No warranty, express or implied, is

valid in case of using this product without the use of proper

safety countermeasures correspondingly.

WARNING

To avoid damage to the connected equipment, facilities or the

product itself due to a fault of the product, safety

countermeasures must be taken before usage, such as proper

installation of the fuse and the overheating protection device. No

warranty, expressed or implied, is valid in case of usage without

having implemented proper safety countermeasures.

• The mark on the plate affixced to the instrument:

On the terminal nameplate affixed to the case of your instrument,

the mark is printed. This is to warn you of the risk of electrical

shock which may result if the charger is touched while it is

energized.

•A means to allow the power to be turned off, such as a switch or a

breaker, should be installed in the external power circuit to be

connected to the power terminal of the instrument.

Fix the switch or the breaker adjacently to the instrument in a

position which allows it to be operated with ease, and with an

indication that it is a means of turning the power off. The switch

or the breaker should meet the requirements of IEC947, UL489,

UL1066 or CSA C22.2 No.5.1.

•Fuse: Since the instrument does not have a built-in fuse, do not

forget to install a fuse in the power circuit to be connected to the

power terminal.

The fuse should be positioned between the switch or the breaker

and the instrument and be attached to the L side of the power

terminal.

Fuse Rating: 250V AC1.0A/lagged type

Use a fuse which meets the requirements of IEC127, UL248-1~2

48-16 or CSA C22.2 No.926.

•A voltage/current different from that of the input specification

should not be added on the input terminal. It may reduce the life

of the product and/or result in problems with the product.

For the rated voltage/current, see Specifications.

For the rated voltage (mV or V) or current (4-20mA) input, the

input terminal should be connected with a device which meets the

requirements of IEC1010 as input terminals.

•Voltage/current of a load to be connected to the output terminal

and the alarm terminal should be within a reted range. Otherwise,

the temperature will rise and reduce the life of the product and/or

result in problems with the product.

For the rated voltage/current, see Specifications.

The output terminal should be connected with a device which

meets the requirements of IEC1010.

•The DP21 series indicator is provided with a draft hole for heat

discharge. Take care to prevent metal or other foreign matter from

obstructing it. Failure to do so may result in problems with the

product any may even result in fire.

• Do not block the draft hole or allow dust or the like to adhere to

it. Any rise in temperature or insulation failure may result in a

shortening of the life of product and/or problems with the

product.

For spaces between installed instruments, refer to 1. External

Dimensions and Panel Cutout on page 1.

• It should be noted that repeated tolerance tests against voltage,

noise, surge, etc., may lead to deterioration of the instrument.

•User must not modify the instrument or operate it anomalously.

Contents

page

1External Dimensions and Panel Cutout............................................ 1

2 Installation and Matters to be Attended to....................................... 1

2-1 Installation............................................................................... 1

2-2 Matters to be Attended to........................................................ 1

3Connection of Terminals.................................................................. 2

4Wiring.............................................................................................. 3

5Front Panel Information................................................................... 6

6Selection of Measuring Range and Functions.................................. 7

6-1 How to Detach Inner Body...................................................... 7

6-2 Selection of Functions (SW2).................................................. 7

6-3 Selection of Measuring Range................................................ 8

7Parameters....................................................................................... 10

7-1 Display Block......................................................................... 11

7-2 Parameter Setting Block......................................................... 11

7-2-1 Range Block........................................................................ 11

7-2-2 Alarm Block (Additional/Optional function)...................... 11

7-2-3 Communication Block (Additional/Optional function)...... 11

page

8Operating Procedure........................................................................12

8-1 Display when power is applied.............................................. 12

8-2 Display Block (Common to all input types)........................... 12

8-3 Holding PV Value.................................................................. 13

8-4 Release (Reset) of Display of

Maximum/Minimum PV Value.............................................. 13

8-5 Range Block........................................................................... 13

8-5-1 Sensor Compensation Function (Input shift) for Sensor

(thermocouple or R.T.D) Input Type..................................13

8-5-2 Voltage/Current Input Type................................................14

8-5-3 Analog Output Scaling Function........................................15

8-6 Alarm Block........................................................................... 17

8-6-1 Latching alarm (to be designated at the time of ordering)..18

9 Codes for Instrument Selection...................................................... 20

10 Troubleshooting............................................................................. 21

10-1 Identifying cause of trouble............................................... 21

10-2 Display in case of input problems..................................... 21

CAUTION

CAUTION

Page 2

Check before use

This product has been fully checked for quality assurance prior to shipment. Nevertheless, you are requested to make

sure that there is no error, damage or shortage of delivered items by confirming the model codes and checking the

external view of the product and the number of accessories.

Checking accessories:

Instruction manual 1 set

Unit decal 1 sheet

Communication Interface Instruction manual 1 set (Included with the Communication function option)

Connecter (DDK 225M-21421-188) 1 piece (Included with the BCD option)

NOTE: Contact our representative or out local office concerning any problems with the product, accessories or related items.

Caution for use

1) Avoid operating keys of the front panel with hand or sharp objects or motions. Lightly touch the operating keys

with finger tip for operation.

2) Avoid using solvents such as thinner; wipe gently with a dry colth.

2-1 Installation

The installation panel should have a thickness of 1~3.5mm.

The instrument is of a press-and-fit type. Press it from the front so as to fit firmly into the panel hole.

NOTE: The DP21 indicator is of a panel fit-in type. It must be fitted in the panel for use.

2-2 Matters to be Attended to

There is inflammable or corrosive gas, soot or dust to impair insulation.

The ambient temperature is below −10˚C and above +50˚C.

The ambient humidity is above 90% RH and there is dew condensation.

The instrument is subjected to strong vibrations and shocks.

There is a strong electric circuit or a source of inductive interference.

There is exposure to water drops or direct sunlight.

Where the elevation is in excess of 2,000m.

NOTE: The environmental conditions belong to the installation category II of IEC664 and the degree of pollution is 2.

1

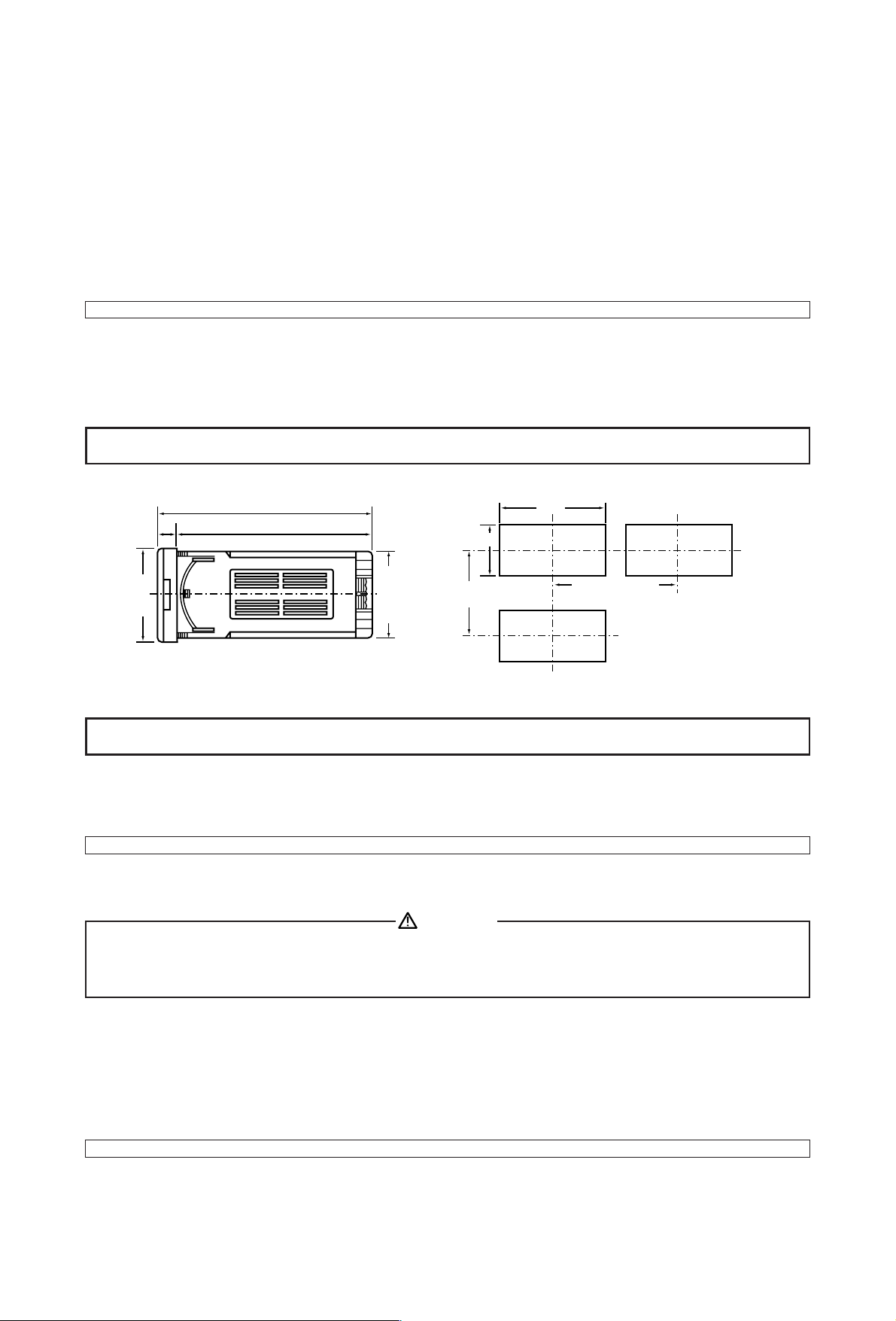

1 External Dimensions and Panel Cutout

2 Installation and Matters to be Attended to

In case where there is an intention to operate this product at one of the following sites, be aware that the occurrence

of life and/or other dangerous situations is considerable.

Exercise caution and avoid these places when selecting an operational site.

Unit: mm

Panel cutout

+08

92

0

10

110

100

45

+06

0

110mm or longer

48 × 96

60mm or

longer

44.6 × 91.6

CAUTION

Page 3

Alarm type such as lower limit alarm or higher limit alarm of alarm 1 and alarm 2 is selected by key

operation.

For both higher limit alarm and lower limit alarm, the C1-NO1 (C2-NO2 in the case of alarm 2) contacts are

closed when the set point of the alarm is reached.

2

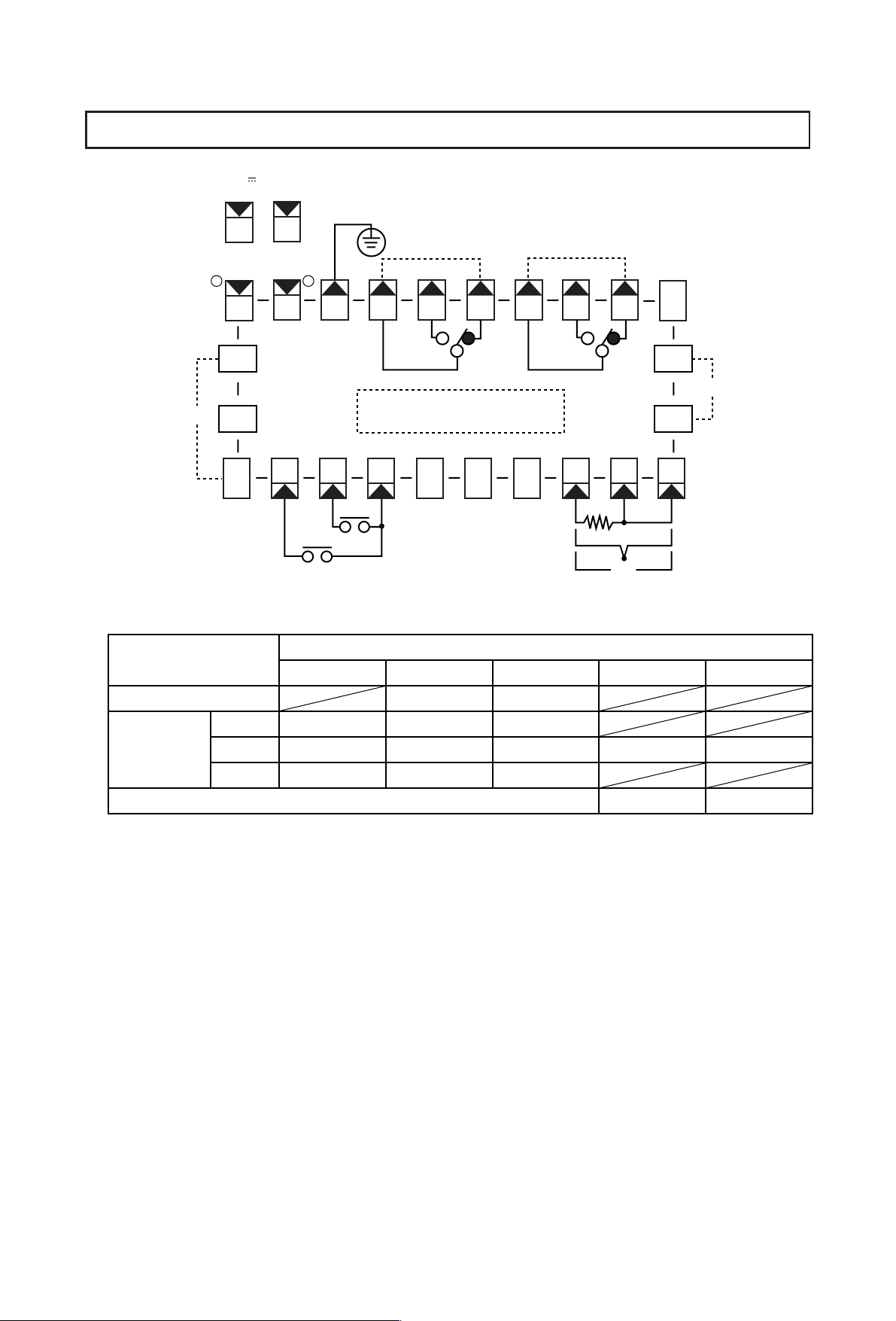

3 Connection of Terminals

24V DC 5W/24V AC

50/60Hz 8VA

+ −

11

100−240V AC ~

50/60Hz 14VA

L N

11

12

12

13

ALARM1

2.5A 240V AC

14 15 16 17 18 19

NO1

22

∗

1

21

BCD OUTPUT

12345678910

RESET

HOLD

∗

1 Wiring Codes/Terminal Numbers for Each Function

Function

121222324

Analog output

−

C1

ALARM2

2.5A 240V AC

NC1

NO2

Terminal Numbers

+

C2

BBA

DC

NC2

−+

−+

20

24

23

∗

1

Communication

RS-232C

RS-422A

RS-485

SG

SG

SG

SD

SD −

−

DC output (24V DC 50mA)

RD

SD +

+

RD − RD +

− +

Page 4

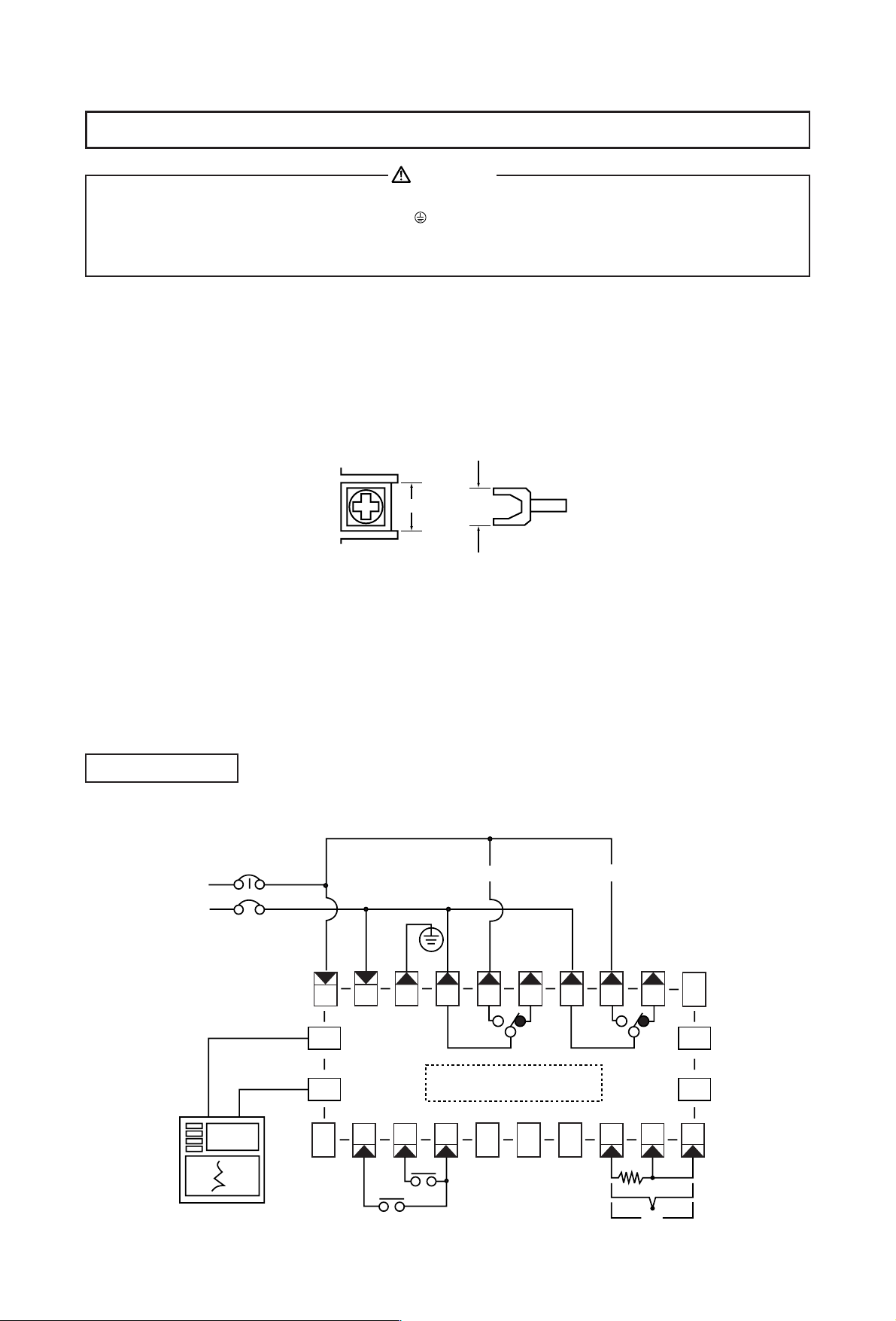

For thermocouple input, use the designated compensating conductor and limit the external resistance to 100Ω or

below.

For R.T.D. input, the lead wire resistance should be 5Ω or less per line, and three lines should have the same

ohmic value.

Use of shielded cable for static induction and twist cable for electromagnetic induction is effective.

Connect the instrument to terminals according to the terminal diagram on page 2 and the wiring diagram attached

onto the instrument case.

Use a suitable press-fit terminal for the M3.5 terminal screw in the wiring for the instrument.

When wiring, use wire (1mm2minimum in sectional area) of 600V grade polyvinyl chloride insulated wire or

equivalent wire which has the same ratings.

NOTE: When the instrument is installed in a place subject to vibrations or shocks, use round press-fit terminals to

prevent disconnection from terminals.

NOTE: For wiring for power supply, etc., use wire as provided in the Electric Supplies Control Act.

Use wire 2mm2or larger for grounding. Grounding resistance should be 100Ω or less. The instrument

should be grounded at one point contact with the GND terminal.

Crossover wiring is not allowed.

•

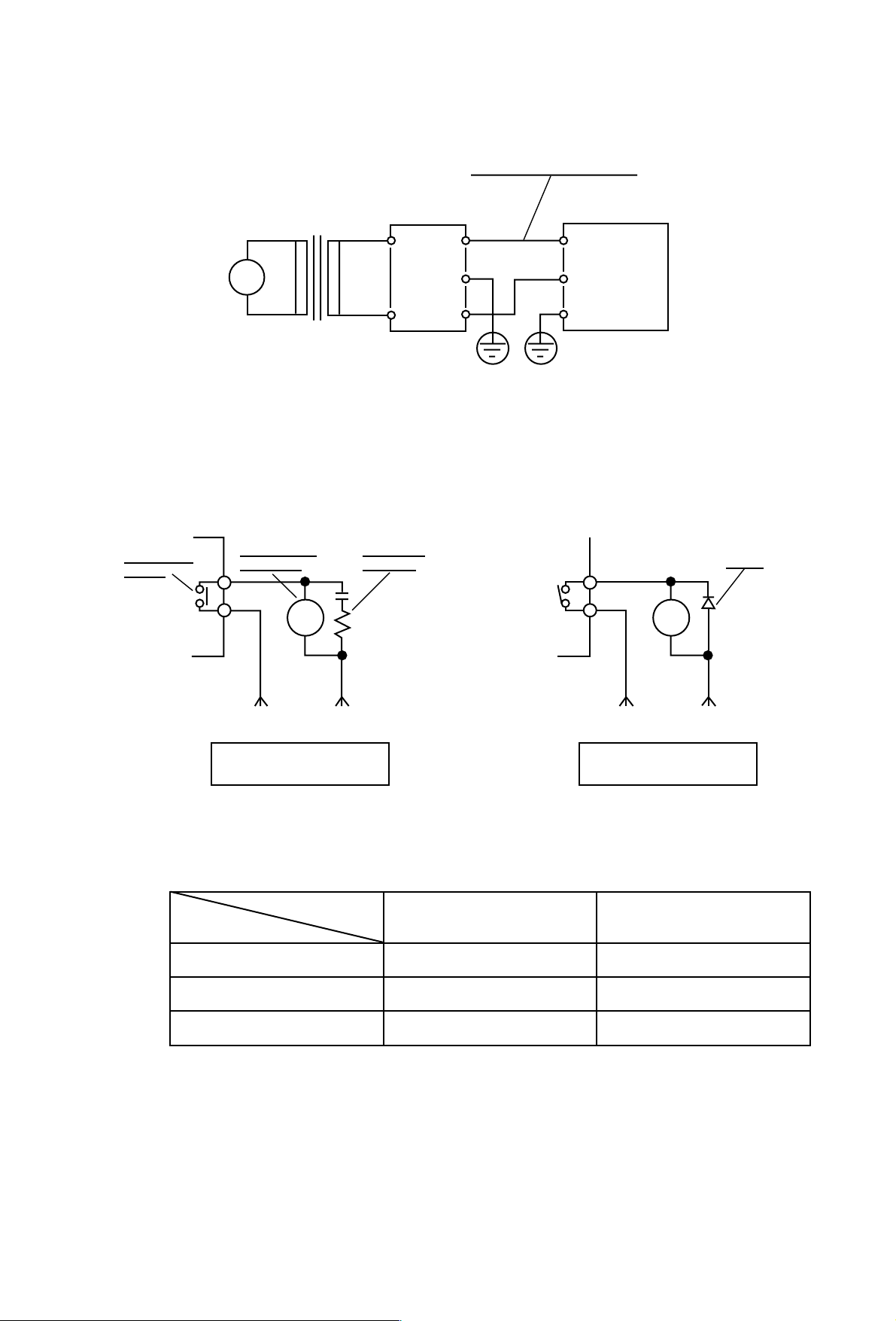

Example for the types with alarm and analog output functions

3

4 Wiring

•

Always disconnect this product from any power source during wiring operation to prevent electrical shock.

•

Be certain that the protective conductor terminal is properly grounded. Otherwise, a serious electric shock

may result.

•

Avoid touching the wired terminal and charged devices while supplying power.

Example of Wiring

WARNING

7.2mm

7.0mm max

Alarm 1 Alarm 2

Power

Analog output signal

0 ~ 10mV or

4 ~ 20mA

SR106

12

HOLD

13

RESET

NO1

C1

BCD OUTPUT

NC1

NO2

NC2

C2

BBA

DC

11

22

−

21

12345678910

14 15 16 17 18 19

20

24

23

−+

−+

Page 5

If there is significant noise from the power line, the installation of an insulating transformer and the use of a noise

filter are recommended.

In case such a load (inductive) as relay, electromagnetic switch or electromagnetic valve is driven via an alarm

relay contact, in order to get rid of sparks. A spark killer, CR (for AC) or diode (for DC) should be connected in

parallel with an exciter coil as shown below.

4

~

Insulating transformer

100/100V

200/200V

Noise filter

ground ground

Wire as short as possible

Indicator

100-240V AC

100-240V AC

50/60Hz

Recommended noise filter: TDK's ZMB2203-13

Alarm output

contact

Auxiliary relay

exciting coil

Spark killer

CR circuit

NO

RY RY

C

AC power supply

When AC supply is used

for auxiliary relay

DC power supply

When DC supply is used

for auxiliary relay

+ −

Diode

Typical Spark Killers (CR Filters)

Manufacturer

Shizuki Denki

Nittsuko

Matsushita Electric

SK25B473MA

CR2E333C121

ECQJ0187X

SK25B104MA

CR2E104C121

ECQJ0186X

Use

Small relay Electromagnetic switch

Page 6

•

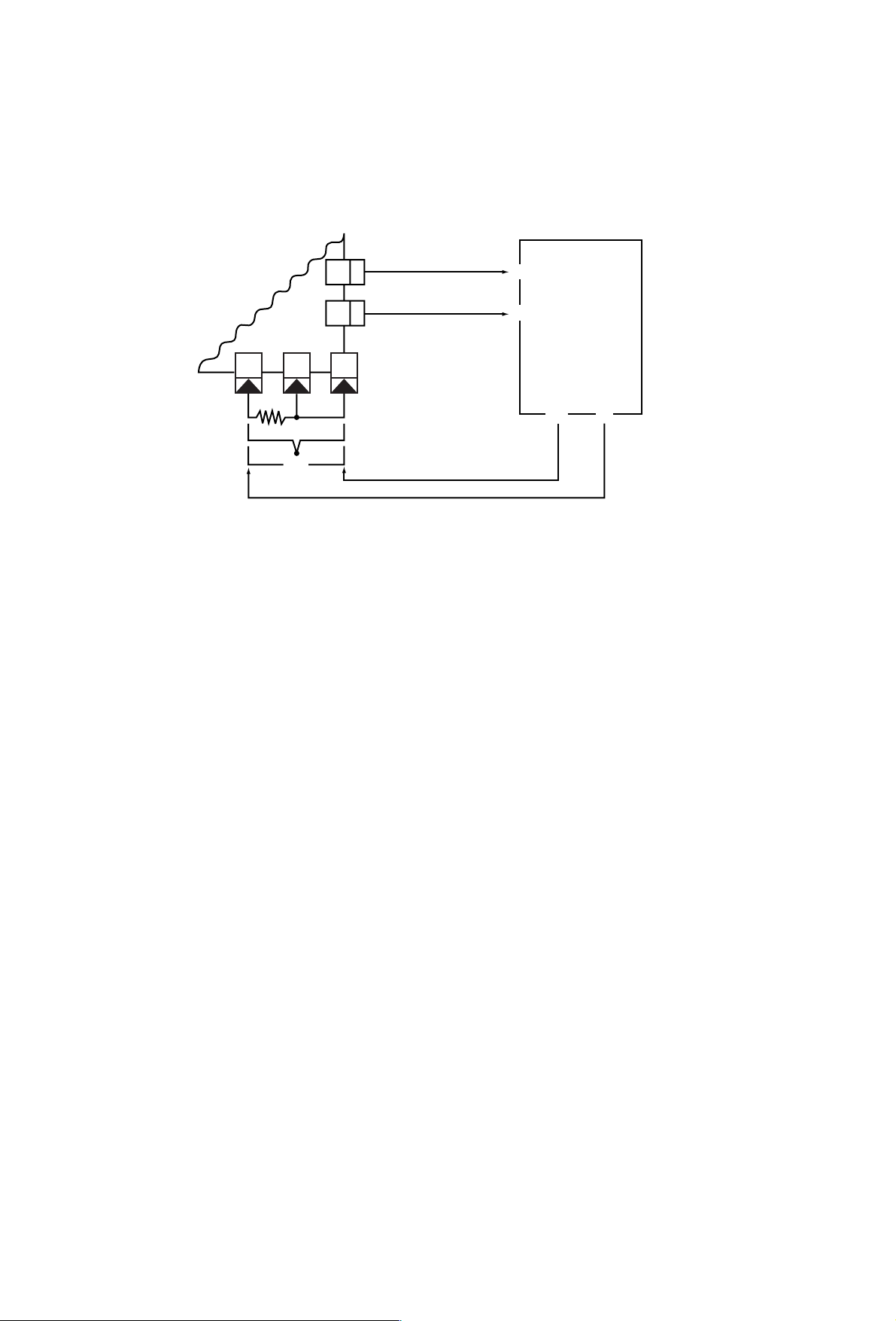

DC power supply for sensor

For this instrument, DC power supply (24V DC 50mA) for sensor can be selected to use an H71 or TH71 series

humidity sensor combinedly. (This can not be used in case of an 24V AC or DC supply.)

• H71 or TH71 series humidity sensor

5

8910

23

24

BBA

−

−

−

−

+

+

+

+

−+

DC

DP21

24V DC 50mA

POWER

H71/TH71

OUT

CH

Page 7

6

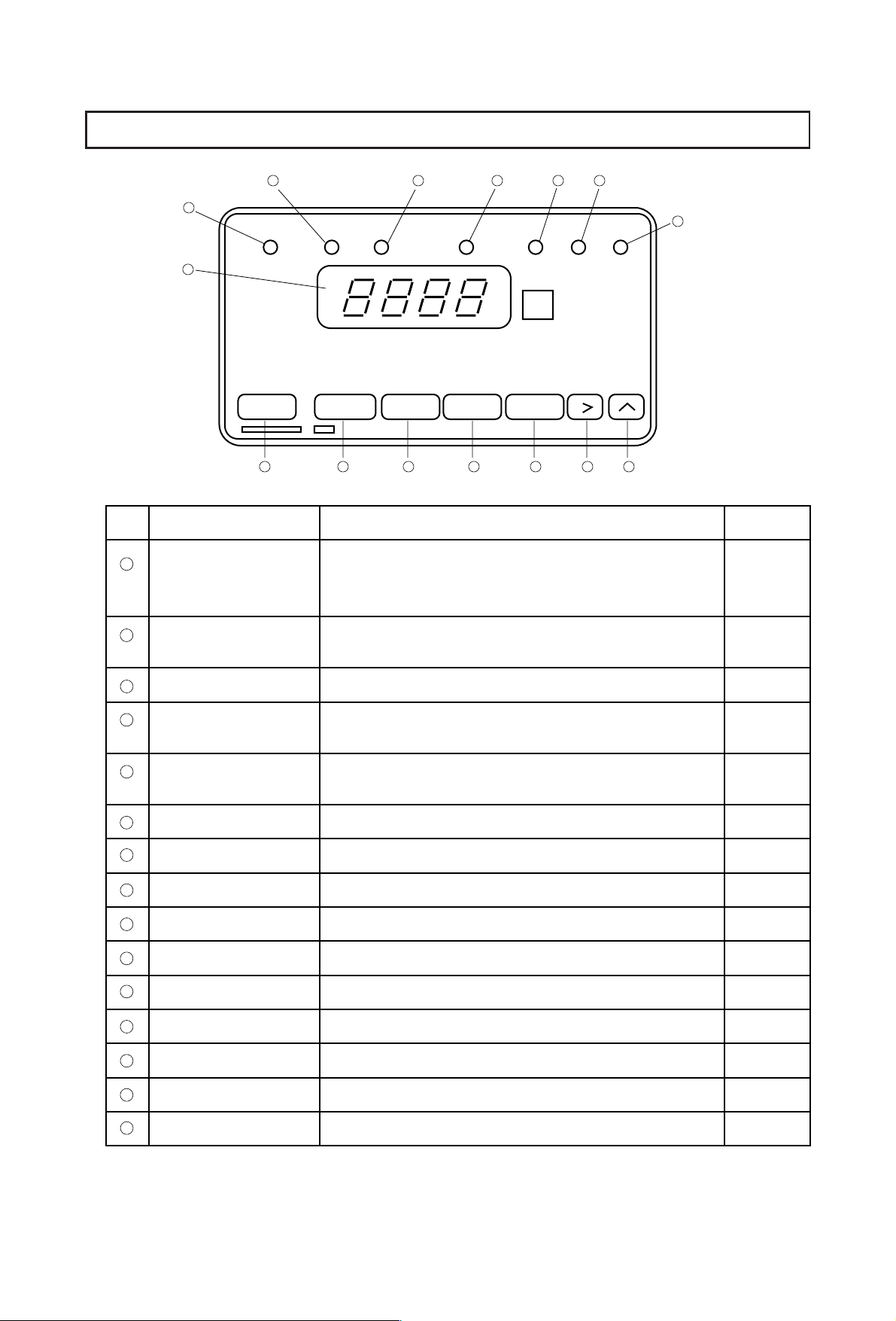

5 Front Panel Information

3 4 5 6 7

Display screen

1

2

Max value lamp

(MAX)

2

1

Max value

lamp

Display key Alarm key

Min value

lamp

Communication key

Hold

lamp

Communication

lamp

Range key Setting key

12131415

Name Function

Displays PVs.

Displays parameters and figures when various functions

are set.

Remains lit while a max value is shown on display

screen by means of display key.

Alarm 1

lamp

Alarm 2

lamp

Range

lamp

9

1011

8

3

Min value lamp (MIN)

4

Hold lamp (HOLD)

5

Communication lamp

(COM)

Alarm 1 lamp (AL1)

6

7

Alarm 2 lamp (AL2)

8

Range lamp (RNG)

9

Up key

Shift key

10

11

Setting (SET) key

Range key

12

Alarm (ALM) key

13

Communication key

14

Remains lit while a min value is shown.

Remains lit while a processing value is held by means of

an external signal.

Remains lit while in the communication mode.

Lights when the alarm 1 function is put to work.

Lights when the alarm 2 function is put to work.

Remains lit while the range block is operated.

Increases a PV.

Takes a figure up or down.

Registers a set value.

Moves to the range block.

Moves to the alarm block.

Moves to the communication block.

Option

Option

Option

Option

Option

15

Display key

Moves to the display block.

Page 8

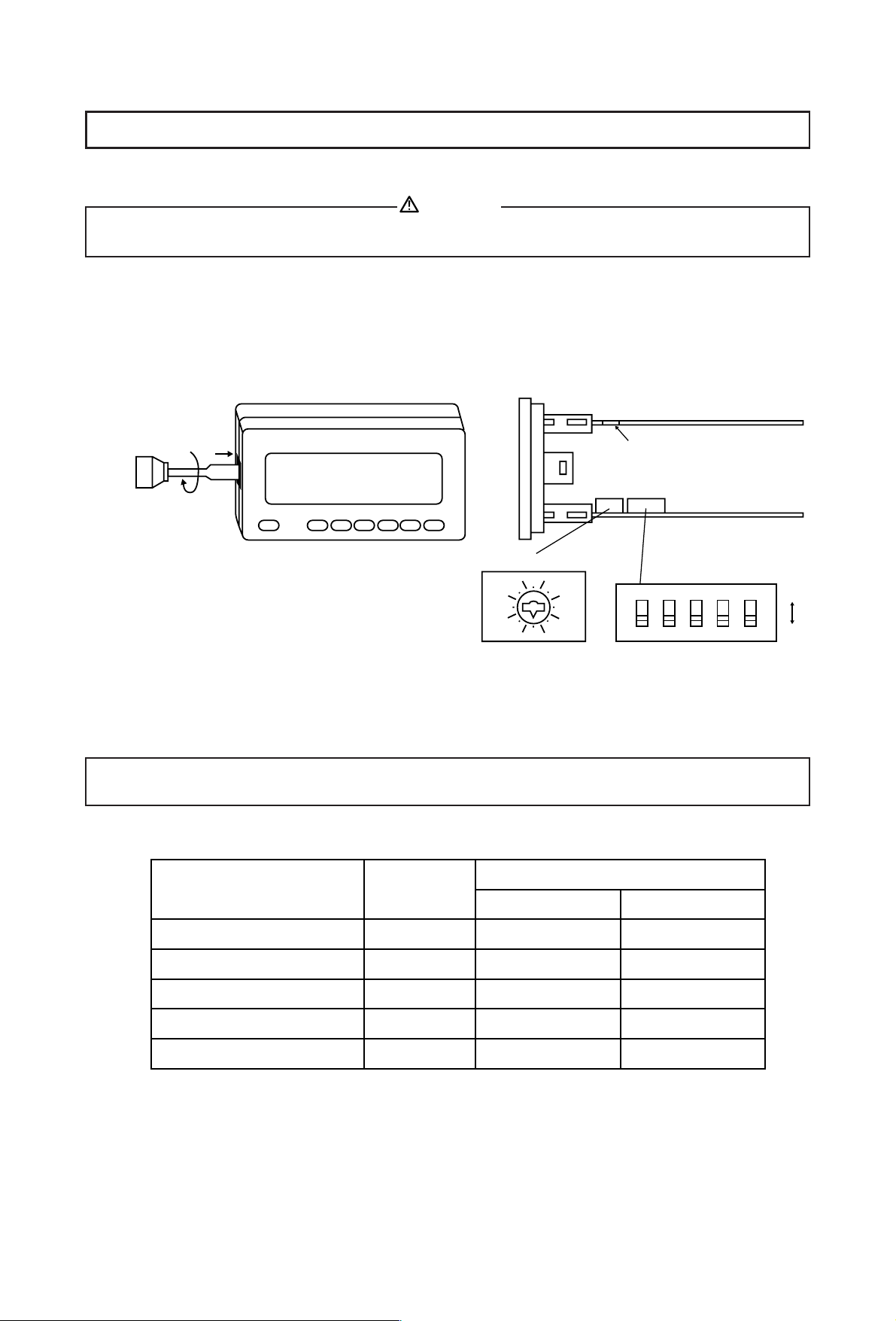

6-1 How to Detach Inner Body

When the instrument is removed/replaced in the case, make sure the power is off. If it is done while the power is

on, it may lead to problems with the product and/or other problems.

To set a function or to select a measuring range, the inner body has to be drawn out.

Insert a minus screwdriver of 6mm~9mm into the opening (where packing is exposed) of the front case and rotate

the screwdriver while pushing up the lock lever behind the packing. Once the instrument comes out by a few

millimeters, you can remove it by hand.

6-2 Selection of Function (SW2)

Select a function from the table and set it by means of a dip switch (SW2). Unless otherwise designated, all the

switch knobs, codes 1 ~ 5, are pressed down (OFF) in the initial setting.

7

6 Selection of Measuring Range and Functions

NOTE: The switch is set to ON or OFF easily when the switch knob is pressed by means of a thin tool such as a

pincette or a small screwdriver. The switch tends to break if an unnecessarily high force is applied.

CAUTION

How to detach inner body Position of switches (on the right side)

Cut-out portion

Front

panel

SW2

SW1

SW1

8

A

6

4

C

E

2

0

SW2

1

2

3

4

Table for Function Selection

Switch Knob Position

Function/Feature Switch code

Down (OFF) UP (ON)

Display renewal cycle

RTD input standard

Alarm

1

2

3

0.25 sec

JPt (Former JIS)

Non-standby

2.0 sec

Pt (JIS/IEC)

Standby

ON

5

OFF

Key lock

Unit

4

5

Unlocking

˚C

Lock setting

˚F

Page 9

6-3 Selection of Measuring Range

Select a measuring range from the table and set it by turning the rotary switch (SW1).

It is suggested that the set type of input and measuring range would be written on the label on top of the instrument.

When you operate the rotary switch, draw out the apparatus illustrated and

insert a thin minus screwdriver through the cut-out portion on the top into

the groove of the rotary switch. Rotate it to the intended setting point.

Standard Thermocouple RTD

B, R, S, K, E, J, T=JIS/ANSI/DIN/IEC JPt100=(old) JIS

WRe5/26=(Hosking Mfg. Co.) Pt100=(New) JIS/DIN/IEC

U, L=DIN 43710

*1 Thermocouple B: Accuracy not guaranteed below 400˚C (750˚F)

*2 Thermocouple K: 70.0 ~ 400.0 (Unit: Kelvin only) Codes 1K A67 05

*3 RTD: Accuracy ±0.2˚C

8

0

8

A

C

E

6

4

2

Top of the apparatus

Cut-out portion

SW1

Front

panel

1B

1R

1S

1K

1E

1J

1T

1W

1U

1L

1K

2J

2F

32

34

36

41

42

62

64

66

Input

Type Code ˚C Reading Code ˚F Reading Code

Rotary Switch Code

Measuring Range

Thermocouple

RTD

mV

mA

V

B *1

R

S

K

E

J

T

WRe5/26

U

K

K *2

JPt100

(JIS)

Pt100

(JIS/IEC)

0 ~ 10

0 ~ 50

0 ~ 100

0 ~ 20

4 ~ 20

0 ~ 1

0 ~ 5

0 ~ 10

A47

A46

A46

A74

A27

A09

A26

A30

A49

A30

A08

A67

A31

A02

A31

A02

A65

A64

A64

A79

A72

A63

A71

A77

A66

A77

A62

A78

A61

A78

A61

A

8

9

0

1

3

2

4

7

5

6

−

B

C

B

C

D

E

F

E

F

D

E

F

0 ~ 1800

0 ~ 1700

0 ~ 1700

−200 ~ 1200

−100.0 ~ 800.0

0.0 ~ 700.0

−100 ~ 600.0

−199.9 ~ 200.0

0 ~ 2300

−199.9 ~ 200.0

0.0 ~ 600.0

70.0 ~ 400.0

−199.9 ~ 600.0

0.00 ~ 99.99 *3

−199.9 ~ 600.0

0.00 ~ 99.99 *3

32 ~ 3272

32 ~ 3092

32 ~ 3092

−328 ~ 2192

−148 ~ 1472

32 ~ 1292

−148 ~ 1112

−328 ~ 392

32 ~ 4172

−328 ~ 392

32 ~ 1112

−328 ~ 1112

32.0 ~ 212.0

−328 ~ 1112

32.0 ~ 212.0

The scaling function allows you to set a

measuring range freely.

scaling range: −1999 ~ 9999 count

span: 100 ~ 10000 count max

Page 10

Although this series is designed for multirange and programmable range measurement, the instrument has been set

as follows prior to the shipment:

The apparatus is attached with unit display sheets. Use whichever you like.

9

Type of input

Thermocouple

R. T. D.

Voltage

Current

Voltage

JIS K

JIS Pt 100

0 ~ 10mV

4 ~ 20mA

0 ~ 1V

−100.0 ~ 800.0˚C

−199.9 ~ 600.0˚C

0.0 ~ 100.0 without unit

0.0 ~ 100.0 without unit

0.0 ~ 100.0 without unit

Standard/Rating Measurement Range

Unit

3

Unit

3

Unit

3

Code

Nil

˚C

˚F

%RH

%

K

mV

V

mA

A

W

µ S/cm

mbar

bar

psi

Psig

Pa.

kPa

mmH

2O

mH

2O

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

inH

2O

mmHg

cmHg

inHg

1/s

kg/h

kg/cm

2

kgf/cm

2

Torr

mmAq

1/min

1/h

m

3

/min

m3/h

Nm3/min

Nm

3

/h

mm/s

m/s

m/min

m/h

m/s

2

rpm

mm

cm

m

mm

3

cm

3

m

3

in

1b

g

kg

t

1

ppm

pH

cal

kcal

Nil

Nil

Code Code

Page 11

10

7 Parameters

DISPLAY BLOCK

Current PV

display screen

[Communication block]

Communication

Communication

Data bit length Type of Alarm 1

Display

key

Display

key

Maximum value Minimum value

[Parameter setting block]

[Alarm block] [Range block]

value

Alarm 1

hysteresis

Alarm

Alarm

Alarm

Alarm

key

key

key

Position of

decimal point

Display S L side

*1

Display S H side

*1

Communication key key key

Alarm 1 set

mode

Communication key

address

Communication key

Communication key

Display

Input V/I Input TC/RTD

Range

Range

Range

Range

key

Sensor

compensation

key

key

key

Range

Range

key

key

Communication

speed

Communication key

Delay time

Communication key

Release of

latching

Alarm

Alarm 2 set

value

Alarm

Alarm 2

hysteresis

Alarm

Type of Alarm 2

Alarm

Release of

latching

Alarm

key

key

key

key

key

Analog S L side

*2

Analog S H side

*2

Range

Range

Parameters enclosed by

dotted lines are for

additional (optional) functions.

key

key

*1 Display S: Display scaling

*2 Analog S: Analog output scaling

Page 12

The parameters of the DP21 series indicator are shown on page 10.

They are divided to the display block and the parameter setting block, which is further divided into three sections.

7-1 Display Block

Pressing the display (DISP) key repeatedly shows PV value → maximum value → minimum value.

7-2 Parameter Setting Block

7-2-1 Range Block

In the case of DC voltage or current input, higher and lower limit values of display range and the position of

decimal point are set. In the case of sensor input, a sensor compensation and an output range if the optional

analog output function is included, are set.

7-2-2 Alarm Block (Additional/optional function)

An action type of Alarm 1 or 2, hysteresis, action point and release of latching (holding of alarm action) are

set.

7-2-3 Communication Block (Additional/Optional function)

Communication mode, communication address, the length of data bit, the speed of communication and the

time of delay are set. (For details, please refer to the instruction manual for communication interface.)

11

Page 13

8-1 Display when power is applied

When power is applied to the instrument, the following characters and figures appear on the display screen at

intervals of about one second, and then the current processed value is displayed.

8-2 Display Block (Common to all input types)

Repeatedly pressing the key brings PV, maximum and minimum values onto display.

When the key is pressed while operation is going on by means of any key other than the key, the

processed value display is returned.

When any key other than the key is operated and that operation is interrupted for more than a minute, the

processed value returns to the display.

While the maximum processed value is on display, the maximum value lamp remains lit.

While the minimum processed value is on display, the minimum value lamp remains lit.

DISP

DISP

DISP

DISP

12

8 Operating Procedure

Applying

power

Name of series

No. of software

Lower limit of measuring range

Lower limit of measuring range

Contents of functions included in the instrument

Function without

Alarm

Analog output

BCD code

Communication

0

0

0

0

with

1

1

1

1

Processed value

Page 14

8-3 Holding PV Value

When the terminals #2 and #4 are short-circuited by an external contact signal, the processed value at the time of

short-circuiting is held and displayed prior to the current processed value. (The hold lamp lights.)

Even while the hold lamp is lit, the maximum and minimum values can be displayed by operating the key.

8-4 Release (Reset) of Display of Maximum/Minimum PV Values

When the terminals #2 and #4 are short-circuited by an external contact signal, display data of maximum and

minimum values are released (reset).

Releasing (Reset) by Keyboard Operation

Pressing the entry ( ) key twice consecutively when the maximum value is on display also functions to release.

* Maximum/minimum processed values are initialized (reset) upon turning power ON.

8-5 Range Block

8-5-1 Sensor Compensation Function (Input shift) for Sensor

(thermocouple or R.T. D.) Input Type

SET

DISP

13

Type of Displays in Display Block

Current processed value display

key

DISP

Maximum (peak) processed value display

key

DISP

Minimum (bottom) processed value display

key

DISP

Sensor compensation

Processed value

key

RNG

Sensor compensation

The range lamp lights.

Entry ( ) key

SET

Compensation value set by means of the and keys

Registration by means of the entry ( ) key

key

DISP

SET

Processed value (after sensor compensation)

The range lamp goes out.

Page 15

Setting Range of Sensor Compensation

Thermocouple input: ±99.9 or ±999 Unit

R.T.D. input: ±99.9 or ±9.99 Unit

Sensor compensation function

This is the function for displaying input as value added with a predetermined bias. It is used when a

processed value is lower than the actual value due to sensor error, etc., or compensation is necessary for a

processed value which is within the precision range but varies from the value(s) obtained by other

instrument(s).

8-5-2 Voltage/Current Input Type

(1) Setting decimal point

Pressing the range key when the processed value is on display brings the characters onto display,

allowing selection or setting of the position of decimal point.

* When the decimal point is set at the third position from the right, the display shows .000, not 0.000.

(2) Setting lower limit of measuring range

Display scaling function

Setting range: −1999 ~ 9899 Initial Value: 0.0

Pressing the range key twice in the current measuring range display screen brings the characters

(lower limit of measuring range) onto display.

When the setting key is pressed, the display changes to figures.

Use the and keys to set a desired value in the place of the flashing figure and register it by the use

of the entry key.

14

RNG

key

SET

DISP

key

Processed value display

Decimal point flashes (change of position allowed)

Processed value display

Setting the position of decimal point

The range lamp lights.

Desired position is set by the use of key and register it by the use

of the entry key (completion of position change).

The range lamp goes out. Pressing the key calls the processed

value back onto display.

Entry ( ) key

Page 16

* Scaling of Measuring Range

Measuring range: −1999 ~ 9999

Tha span between the lower and higher limits can be set as desired in a range from 100 to 10000 counts.

(3) Setting higher limit of measuring range

Display scaling function

Setting range: −1899 ~ 9999 Initial value: 100.0

Pressing the key in the preceding screen for measuring range lower limit setting calls the

(measuring range higher limit setting) screen.

For setting, follow the same steps as measuring range lower limit setting in (2) above.

8-5-3 Analog Output Scaling Function

Additional (optional) function/range block

Analog Output

This is the function to output an analog voltage or current correspondingly to the processed value. The output

can be used as an input signal into a recorder or a data collector.

(1) Analog output scaling lower limit setting

Setting range: within measuring range

Initial value: the same as measuring range

(This display does not appear if the function is not added.)

RNG

15

RNG

key

RNG

key

SET

DISP key

Processed value display

Measuring range lower limit setting screen

Current lower limit value is displayed

Processed value display screen (Completion of setting)

Setting by the use of and keys and registration by the

use of entry key.

Entry ( ) key

Page 17

(2) Analog output scaling higher limit setting

Setting range: −1999 ~ 9999

Initial value: same as measuring range

Pressing the key in the preceding screen for analog output lower limit setting calls the

(analog output scaling higher limit) setting screen.

For setting, follow the same steps as lower limit setting in (1) above.

RNG

16

RNG

SET

twice (ShFt→AoL/Sensor input)

4 times (dp→Sc_L→Sc_H→Ao_L/V,I input)

Analog output lower limit processed value

Analog output lower limit measuring value

Analog output

Scaling lower limit setting screen

Use the and keys to set a desired value in the place of

flashing number and register it by the entry key.

Entry ( ) key

SET

Entry ( ) key

Press ( ) key

*

Scaling Output

100%

Analog

output

0%

Setting range

An analog signal corresponding to PV is output

within a measuring range defined by and

.

* When you have changed the measuring

range, make sure to confirm the scaling

value of the analog signal.

Page 18

8-6 Alarm Block

The instrument can be added with the two optional alarm functions, Alarm 1 (AL_1) and Alarm 2 (AL_2).

* The deviation in Alarm 2 is relative to the set value in Alarm 1.

* If (the amount of deviation) is set at a low value and hysteresis is large in the (deviation

higher/lower limit) mode, alarm actions overlap and it may happen that releasing will not be possible once an

alarm is output.

Therefore, values have to be set lest hysteresis should overlap.

17

Setting of alarm

Type 1

Setting of alarm

Type 2

[ ]

Absolute value higher limit alarm

[ ]

Absolute value lower limit alarm

[ ]

Deviation higher limit alarm

[ ]

Deviation lower limit alarm

[ ]

Deviation higher and lower limit alarm

[ ]

Absolute value higher limit alarm

[ ]

Absolute value lower limit alarm

ON

ON

ON

ON

ON

ON

ON

ON

PV

Alarm Function

Alarm 1 set point Alarm 2 set point

Page 19

8-6-1 Latching alarm (to be designated at the time of ordering)

Once an alarm is output, the state of output is maintained after the processed value gets out of the alarm action

range. It is released by operating the front keyboard (See the "Releasing Latching Action" section).

18

ALM SET

ALM SET

ALM SET

ALM SET

ALM SET

ALM SET

ALM SET

ALM SET

ALM

Processed value display

Alarm 2

Alarm setting 2

Alarm setting 1

Hysteresis

setting 1

Hysteresis

setting 2

Alarm type

selection 1

Alarm type

selection 2

Latching

action release 1

Latching

action release 2

Set desired value in the place

of flashing figure by means of

the and keys.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Register by means

of the entry key.

Set desired value in the place

of flashing figure by means of

the and keys.

Set desired value in the place

of flashing figure by means of

the and keys.

Set desired value in the place

of flashing figure by means of

the and keys.

Select one out of 5 types by

means of the key.

key key

key key

key

,

,

,

Parameters in Alarm Block

ON

ON

OFF

OFF

OFF

OFF

Ordinary alarm

Latching alarm

Lower limit alarm

Alarm set point

Hysteresis

Higher limit alarm

Latching in action

Latching released by key

Range in which latching can be released.

Latching actions

movement of PV

Page 20

19

Releasing Latching Action

(An example of release of latching/releasing not possible while an alarm is output.)

Pressing the alarm key four times consecutively brings the parameter onto the display.

Then, pressing the setting/entry key brings onto display flashes when the key is pressed to indicate that

this state can be changed now. Pressing the key again changes the display to which flashes. When the

entry/setting key is pressed, it stops flashing and the alarm latching action is released.

ALM

SET

REGDISP

ALM

Processed value display

4 times

Setting release of latching 1

Latching in action

The "rSEt" state possible to

be changed.

The "KEEP" state possible to

be changed.

Release of latching

Flow Chart of Releasing Latching Alarm

Page 21

NOTE: If BCD output function is added, CE marking does not apply.

20

9 Codes for Instrument Selection

Item Code Specification

1. SeriesDP21-48 × 96 DIN Size Digital Instruction Scale

2. Input ThermocoupleB, R, S, K, E, J, T, WRe5-26, U, L Multi-input

RTD Jpt 100/Pt 100 Multi-input

Voltage (mV) 0~10, 0~50, 0~100mV DC

Current (mA) 0~20, 4~20mA DC

Voltage (V) 0~1, 0~5.0, 0~10V DC

K. T. C. (Thermocouple) for Kelvin (K) Unit (Measuring 70.0~400.0K)

3. Power Supply 90 -

10 02 -

100−240V AC ±10% 50/60Hz

24V AC ±10% (50/60Hz)

24V AC ±10%

4. Alarm None

None

Japanese

English

Without

With

24V DC 50mA

None

0~10mV DC Output resistance 10Ω

4~20mA DC load resistance below 300Ω

0~10V DC max load current below 2mA

RS-485

RS-422A

RS-232C

BCD

Individual settings and outputs 2 points (1c contact)

contact capacity = 250V AC 2.5A/resistive load

Scaling

(within measuring range)

When communication function is

selected, Item 6. DC power supply

for sensor cannot be selected.

Same as above with latching function

5. Analog output and

communication function

6. DC power for sensor

(Selection not possible in case

power supply is 24V AC or DC)

7. Front sheet letter

8. Remarks

1

2

3

4

6

8

00

00

03

04

06

15

16

17

20

J

E

0

9

00 24 -

10

11

Multi-input programmable range

Scaling range: −1999~9999 counts

Span: within a range count from

100~10000

When 24V DC or AC is selected, Item 6.

DC power for sensor cannot be selected.

Page 22

10-1 Identifying cause of trouble

If something goes out of order, (A) investigate input/output, (B) confirm that the wiring and terminals are in order

and not loose, and (C) check the relevant settings. If you have any queries regarding problems or the handling of the

instrument, please call our company.

10-2 Display in case of input problems

21

10 Troubleshooting

Type of Input

Problem Display

Thermocouple disconnection

Cold contact compensation

rose to +80˚C or more.

Cold contact compensation

down to −20˚C or lower.

10000 ~ 10999 counts when

input is within +10% of

measuring range.

Input is +10% or more above

measuring range.

−2000 ~ −2999 counts

when input is within −10%

of measuring range.

Input is −10% below

measuring range.

Thermo-

couple

input type

RTD

input type

Voltage/

current

input type

Terminal No.

A

B

B

disconnection of

terminal number 8

8

disconnection of

terminal number 9

9

disconnection of

10

terminal number 10

Error in display

Page 23

22

SPECIFICATIONS

•

Display:

· Range Display: 7-segment LED (4-digit)

· Displays: Measuring range, max. hold, bottom hold

· Display Accuracy: ±0.25% + 1 digit of measuring range

(Thermocouple B: Accuracy not guaranted

below 400˚C (700˚F))

· Display Cycle Range: 0.25 sec. or 2 sec. (by internal switch)

· Legend Change: ˚C and ˚F (by internal switch)

· Monitor Display: Max., min., hold, communication, alarm

and range

•

Setting:

· Setting Method: By front key

· Setting Keys: Display, Communication, Alarm, Range,

Setting, Shift and Up

· Type of Setting: Position of decimal point, display scaling,

sensor compensation, analog output

scaling, alarm, alarm sensitivity, latching

OFF, communications (interface), etc.

•

Input:

· Sampling Cycle: 0.25 sec.

· Thermocouples: T, J, E, K, R, S, B, WRe5-26, DIN 43710

U & L

Kelvin Legend: 70.0~400.0K (available only T/C 'K',

option)

Input Resistance 500kΩmin.

External Resistance

Allowable Range: 100Ω max.

Sensor Compensation: ±99.9 or ±999 Unit (depending on

communication signal)

Burnout Scaling: Up-scale (standard feature)

· R.T.D.: JPt100/Pt100 (DIN/JIS) changeable

Rated Amperage: Approx. 0.5mA

Lead Wire Resistance: 5Ω max. per wire

Sensor Compensation: ±99.9 or ±9.99 Unit (dependeng on

communication signal)

· Voltage: 0~10mV, 0~50mV or 0~100mV DC

changeable

0~1V, 0~5V, 0~10V DC changeable

Input Resistance: 500kΩ min.

· Current: 4~20mA or 0~20mA DC changeable

Receiving Resistance: 250Ω

· Display Scaling: Only voltage and current inputs available

(−1999~+9999, 100~10000 counts)

Setting Method & Decimal Point Position: By front key

· Isolation: Between input and internal circuit

•

External Control

· HOLD: Present value is maintained by external

contact signal

· RESET: Maximun value or minimum value is

released by external contact signal.

· Isolation: External contact signal input is isolated

from the system and various types of

output (not isolated from sensor input,

however)

•

Data storage: By non-volatile memory (EEPROM)

•

Operating Ambient Conditions

Operating ambient temperature/humidity ranges:

−10 to +50˚C / 90% max. (no dew

condenstation)

Limit in altitude: 2000 meters above sea level or lower

Category: II

Degree of pollution: 2

•

Applicable standards: Safety: IEC1010-1 and EN61010-1

EMC: EN61326

During EMC testing, the apparatus

continues to operate at a measurement

accuracy within ± 10%FS.

•

Optional Functions:

Alarm:

· Alarm Points: 2 Point

· Alarm Method: Individual Setting/individual output

· Alarm 1: Absolute value high limit or absolute value

low limit (selectable)

· Alarm 2: Absolute value high limit, absolute value

low limit,

deviation high limit, deviation low limit or

deviation high/low limit (selectable)

Deviation high limit, deviation low limit

and deviation high/low limit alarm can be

selected deviation for alarm 1.

· Alarm Setting Range: −1999~9999 (absolute value high limit,

absolute value low limit, deviation high

limit and deviation low limit)

1~9999 (deviation high/low limit)

· Alarm Setting: By front key

· Alarm Sensitivity: 0.2~9.9 or 2~99 by front key

· Alarm Output: 1c contact, 250V AC, 2.5A/Resistive load

· Inhibit/Non-Inhibit: Selectable by internal switch

· Latching Alarm: Available as option

•

Analog Output:

· Output: 0~10mV DC (output resistance: 10Ω)

0~10V DC (load current: 2mA max.)

4~20mA DC (load resistance: 300Ω max.)

· Output Accuracy: ±0.25%FS of diplay value

· Resolution: Approx. 0.0125FS (1/8000)

· Isolation: Isolated between input and internal circuit

· Output Scaling: By front key

•

Interface:

· Type of Interface: RS-232C, RS422A or RS-485

· Speed: 1200, 2400, 4800, or 9600 bps selectable

· Data Bit: 7-bit odd-parity or 8-bit w/o parity

selectable

· Address: 0~31

· Code: ASCII Code

· Isolation: Isolated between input and internal circuit

•

Sensor Power Supply: 24V DC (±3V) 50mA

•

Power Supply: 100-240V, AC, 50/60Hz, 24V AC or 24V DC

Power Consumption: 100-240V, AC: approx. 14VA

24V AC: approx. 8VA, 24V DC: approx. 5W

•

Insulation Resistance: 500V DC 20MΩ between input terminal

and power supply terminal

500V DC 20MΩ between input terminal

and protective conductor terminal

•

Dielectric Strength: One minute at 2300V AC between input

terminal and power supply terminal

One minute at 1500V AC between power

supply terminal and protective terminal

•

Protective strength: Only front panel has simple dust-proof and

drip-proof structure

•

Material: Resin molding

•

External Dimensions: 48(H) × 96(W) × 110(D) mm

•

Mounting: Push in panel (one-touch mount)

•

Panel thickness: 1.0~3.5mm

•

Size of mounting hole: H45 × W92mm

•

Weight: Approx. 300g

Page 24

23

M E M O

Loading...

Loading...