Page 1

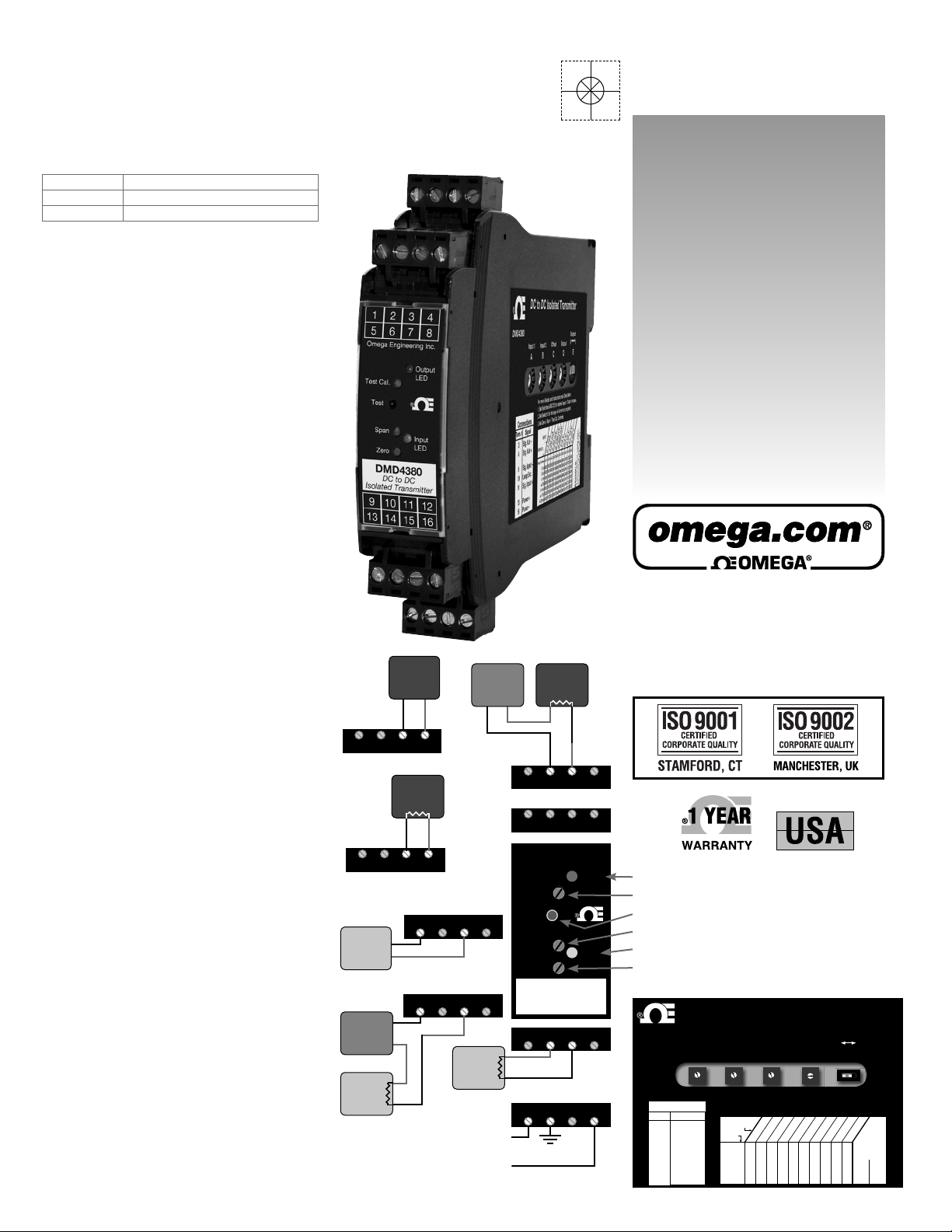

DMD4380 Series

DC-DC Isolated Transmitter

M-5001/1110

Model Power

DMD4380

DMD4380D

Description

The DMD4380 is a field-rangeable signal isolator/transmitter/converter. It accepts a DC voltage or current input and provides an

optically isolated DC voltage or current output that is linearly related

to the input. Full 3-way isolation (input, output, power) makes this

module useful for ground loop elimination, signal conversion and

isolation, common mode signal rejection, or noise pickup reduction.

Standard on the DMD4380 is a 15 VDC loop excitation supply for the

input and a 20 VDC loop excitation supply for the output. These power

supplies can be selectively wired to power passive mA devices.

A green input LED and a red output LED vary in intensity with changes

in the process input and output signals. These provide a quick visual

picture of your process loop at all times.

An output test button provides a fixed output (independent of the

input) when held depressed. The test output level is potentiometer

adjustable from 0 to 100% of output span.

The I/O LEDS and the output test button greatly aid in saving time

during initial startup and/or troubleshooting.

Input Ranges

Field selectable ranges and offsets via switch settings

Voltage: 0-10 mVDC to 0-130 VDC

Bipolar Voltage: ±5 mVDC to ±65 VDC

Current: 0-200 µADC to 0-50 mADC

Input offset: ±100% in 15% increments

Input Impedance (Voltage)

Voltage: 1 M minimum

Current: 50 typical

Voltage Burden: 1 VDC at 20 mA current input

Input Loop Power Supply

15 VDC ±10%, regulated, 25 mADC

May be selectively wired for sinking or sourcing mA input

LED Indicators

Variable brightness LEDs indicate I/O loop level and status

Output Ranges

Field selectable ranges and offsets via switch settings

Voltage (10 mA max): 0-1 VDC to 0-10 VDC

Bipolar Voltage: ±5 VDC or ±10 VDC

Current: 0-2 mADC to 0-20 mADC

20 V compliance, 1000 at 20 mA

Output Linearity

Better than ±0.1% of span

Output Zero and Span

Multi-turn potentiometers to compensate for load and lead variations, ±15% of span adjustment range typical

Output Loop Power Supply

20 VDC nominal, regulated, 25 mADC

May be selectively wired for sinking or sourcing mA output

Output Test

Front button sets output to test level when pressed

Potentiometer adjustable 0-100% of span

Response Time

70 milliseconds typical

Common Mode Rejection

100 dB minimum

Isolation

1200 VRMS minimum

Full isolation: power to input, power to output, input to output

Ambient Temperature Range and Stability

–10°C to +60°C operating ambient

Better than ±0.02% of span per °C stability

Power

80-265 VAC or 48-300 VDC, 2 W maximum

D versions: 9-30 VDC or 10-32 VAC 50/60 Hz, 2 W maximum

Housing

IP 40 ABS/polycarbonate housing mounts to 35 mm DIN rail

Dimensions

0.89" W x 4.62" H x 4.81" D

22.5 mm W x 117 mm H x 122 mm D

Height includes connectors

Connectors

Four 4-terminal removable connectors, 14 AWG max wire size

80-265 VAC or 48-300 VDC

9-30 VDC or 10-32 VAC

Voltage

Output

Switch E

set to “V”

Current

Sourcing

Output

Switch E

set to “I”

Voltage

Xmtr

Loop

Power

Source

mA

Xmtr

Voltage

Input

Device

– +

21 34

mA

Input

Device

– +20V

21 34

–

– +

+

Current Sinking Input

–

– +

+

+

–

Ri

13 Power AC or DC +

14 Earth Ground

16 Power AC or DC –

Switch E

set to “I”

Ri

Voltage Input

1091112

1091112

mA

Xmtr

Loop

Power

Source

Current

Sinking

Output

Omega Engineering Inc.

Test Cal.

Isolated Transmitter

Ri

Current Sourcing Input

mA

Input

Device

Ri

+ –– +

– +

21 3 4

6578

Output

LED

Test

Span

DMD4380

Zero

DC to DC

Input

LED

109 11 12

+15V –

1413 15 16

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

MADE IN

Variable Brightness Output Indicator

Output Test Level Adjustment

Push to Test Output

Output Span Calibration

Variable Brightness Input Indicator

Output Zero Calibration

DC to DC Isolated Transmitter

DMD4380

Connections

Term. #

3

4

9

10

11

13

16

Input 1 Input 2 OutputOffset

ABCDE

4

5

4

4

5

3

2

1

0

F

E

+/-10V

4-20mA

5

6

6

3

2

7

7

1

8

8

0

9

9

F

A

A

E

B

B

C

C

D

D

INPUT

4-20 mA

0-1 mA

0-100 mV

0-50 mV

ABCD

ABCD

ABCD

ABCD

ABCD

4B00

0-1V

0B00

0100

0000

5590

4B09

0-5V

0B09

0109

0009

5599

4B06

1-5V

0B06

0106

0006

5596

4B04

+/-5V

0B04

0104

0004

5594

4B03

0-10V

0B03

0103

0003

5593

4B05

0B05

0105

0005

5595

4B07

0B07

0107

0007

5597

1

0

F

Signal

Sig. Out –

Sig. Out +

Sig. Input –

Loop Exc.

Sig. Input +

Power +

Power –

6

3

2

7

8

9

A

E

B

C

D

For more Details and Instructions see Data Sheet

1. Set Switches A/B/C/D for desired Input / Output ranges.

2. Set Switch E for Voltage or Current as required.

3. Set Zero / Span / Test Cal. Controls

OUTPUT

Rotary Switches

6

5

0-500 mV

ABCD

1490

1499

1496

1494

1493

1495

1497

7

4

1-5 V

Output

V I

8

9

0

1

2

3

+/- 10 V

0-10 V

0-25 V

0-5 V

ABCD

ABCD

ABCD

ABCD

2000

2400

1C30

2800

2009

2409

1C39

2809

2006

2406

1C36

2806

2004

2404

1C34

2804

2003

2403

1C33

2803

2005

2405

1C35

2805

2007

2407

1C37

2807

4-20mA IN/OUT: CODE 5597

Set switch “A” to 5; “B” to 5;

“C” to 9; “D” to 7

EXAMPLE:

Page 2

2

DMD4380 Series DC-DC Isolated Transmitter

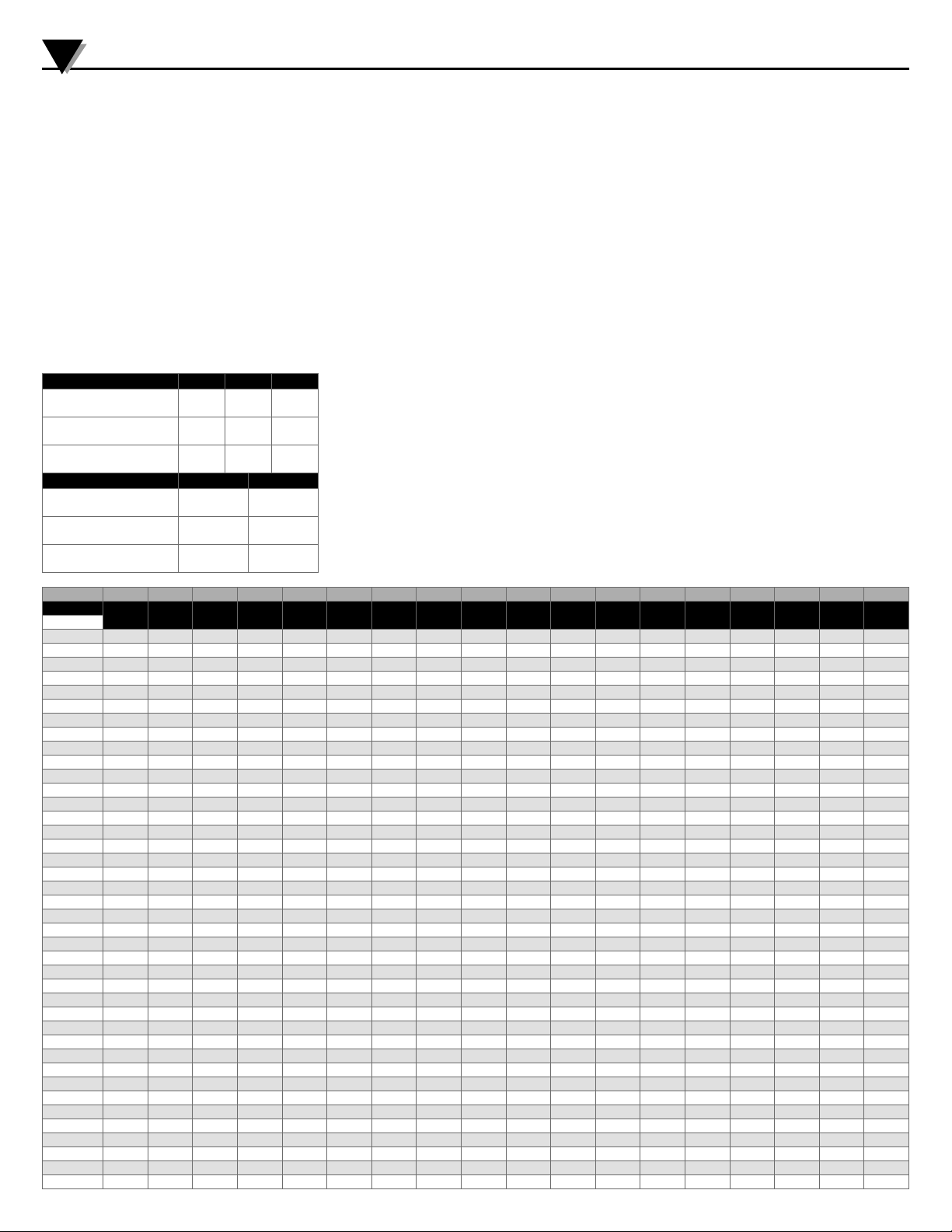

Range Selection

See the tables to select I/O ranges for your application. It is generally

easier to select ranges before installation. The module label lists

common ranges.

For ranges that fall between the listed ranges, use the next highest

setting and trim the output signal with the zero and span potentiometers.

Switches A and B: Input range

Switch C: Input offset

Switch D: Output range

Switch E: “V” for voltage output or “I” for current output

Note that when using a current shunt input, it measures a mV drop

across a fixed resistance, typically 50 mV, 75 mV or 100 mV. The correct input setting would be the appropriate mV range for the shunt.

Electrical Connections

WARNING! All wiring must be performed by a qualified electrician or

instrumentation engineer. Avoid shock hazards! Turn signal input,

output, and power off before connecting or disconnecting wiring,

removing, or installing module.

See diagram for wiring examples. Polarity must be observed for input

and output wiring connections. If the input and/or output do not function, check switch settings and wiring polarity.

Device Connected to Output Terminal Terminal Switch E

(+)

V

I

I

(+)

(+15 V)

Voltage input

Passive mA (current) input.

Module provides loop power

mA (current) input device that

provides loop power.

Device Connected to Input Terminal Terminal

Voltage output

mA (current) output that provides loop power

Passive mA (current) output.

Module provides loop power

3 (–) 4 (+)

(+20 V)

3 (–) 4

2 (–) 3

9 (–) 11 (+)

9 (–) 11

11 (–) 10

Using the Loop Power Supplies with Current Signals

Determine if your device (PLC, display, transmitter etc.) provides

power to the current loop or if the loop must be powered by the

DMD4380. Typical voltage may be 9-24 VDC at your device's terminals if it provides power to the loop.

If your device does not power the current loop, the module can

provide power using the appropriate terminals as indicated on the

wiring diagram.

Module Power

Check white model/serial number label for module operating voltage

to make sure it matches available power.

When using DC power, either polarity is acceptable, but for consistency with similar products, positive (+) can be wired to terminal 13

and negative (–) can be wired to terminal 16.

Mounting to a DIN Rail

The housing clips to a standard 35 mm DIN rail. The housing is IP40

rated and requires a protective panel or enclosure.

1. Tilt front of module downward and position against DIN rail.

2. Clip lower mount to bottom edge of DIN rail.

3. Push front of module upward until upper mount snaps into place.

Removal

1. Push up on the bottom back of the module.

2. Tilt front of module downward to release upper mount from top

edge of DIN rail.

3. The module can now be removed from the DIN rail.

Calibration

Front-mounted Zero and Span potentiometers are used to calibrate

the output to compensate for load and lead variations.

1. Power up to the module and allow a minimum 20 minute warm

up time.

2. Using an accurate calibration source, provide an input to the

module equal to the minimum input required for the application.

3. Using an accurate measurement device for the output, adjust the

Zero potentiometer for the exact minimum output desired. The

Zero control should only be adjusted when the input signal is at its

minimum. This will produce the corresponding minimum output

signal. Example: for 4-20 mA output, the Zero control will provide

adjustment for the 4 mA or low end of the signal.

4. Set the input at maximum and adjust the Span pot for the

exact maximum output desired. The Span control should only

be adjusted when the input signal is at its maximum. This will

produce the corresponding maximum output signal. Example: for

4-20 mA output, the Span control will provide adjustment for the

20 mA or high end of the signal.

5. Repeat adjustments for maximum accuracy.

Output Test Function

When the Test button is pressed it will drive the output with a known

good signal that can be used as a diagnostic aid during initial start-up

or troubleshooting. When released, the output will return to normal.

The Test Cal. potentiometer is factory set to approximately 50%

output. It can be adjusted to set the test output from 0 to 100% of

the output span. Press and hold the Test button and adjust the Test

Cal. potentiometer for the desired output level.

Operation

The DMD4380 accepts a DC voltage or current input and provides an

optically isolated DC voltage or current output that is linearly related

to the input.

The green input LED provides a visual indication that a signal is being

sensed by the input circuitry of the module. It also indicates the input

signal strength by changing in intensity as the process changes from

minimum to maximum.

If the LED fails to illuminate, or fails to change in intensity as the

process changes, check the module power or signal input wiring. The

red output LED provides a visual indication that the output signal is

functioning. It becomes brighter as the input and the corresponding

output change from minimum to maximum.

For current outputs, the red LED will only light if the output loop

current path is complete. For either current or voltage outputs,

failure to illuminate or a failure to change in intensity as the process

changes may indicate a problem with the module power or signal

output wiring.

Note that it may be difficult to see the LEDs under bright lighting

conditions.

Output 0-1 V 0-2 V 0-4 V 1-5 V 0-5 V 0-8 V 2-10 V 0-10 V ±5 V ±10 V 0-2 mA 0-4 mA 0-8 mA 2-10 mA 0-10 mA 0-16 mA 4-20 mA 0-20 mA

Switches

Input

±10 mV

±20 mV

±25 mV

±40 mV

±50 mV

±65 mV

±80 mV

±100 mV

±125 mV

±130 mV

±160 mV

±200 mV

±250 mV

±260 mV

±325 mV

±400 mV

±500 mV

±650 mV

±800 mV

±1.25 V

±1.3 V

±1.6 V

±2.5 V

±3.25 V

±6.5 V

±10 V

±12.5 V

±13 V

±16.25 V

±20 V

±25 V

±32.5 V

±50 V

±65 V

ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE

0330V 0338V 0331V 0336V 0339V 0332V 0337V 0333V 0334V 0335V 0330I 0338I 0331I 0336I 0339I 0332I 0337I 0333I

±5 mV

0730V 0738V 0731V 0736V 0739V 0732V 0737V 0733V 0734V 0735V 0730I 0738I 0731I 0736I 0739I 0732I 0737I 0733I

1330V 1338V 1331V 1336V 1339V 1332V 1337V 1333V 1334V 1335V 1333I 1338I 1331I 1336I 1339I 1332I 1337I 1333I

0B30V 0B38V 0B31V 0B36V 0B39V 0B32V 0B37V 0B33V 0B34V 0B35V 0B30I 0B38I 0B31I 0B36I 0B39I 0B32I 0B37I 0B33I

1730V 1738V 1731V 1736V 1739V 1732V 1737V 1733V 1734V 1735V 1730I 1738I 1731I 1736I 1739I 1732I 1737I 1733I

0130V 0138V 0131V 0136V 0139V 0132V 0137V 0133V 0134V 0135V 0130I 0138I 0131I 0136I 0139I 0132I 0137I 0133I

3330V 3338V 3331V 3336V 3339V 3332V 3337V 3333V 3334V 3335V 3330I 3338I 3331I 3336I 3339I 3332I 3337I 3333I

9330V 9338V 9331V 9336V 9339V 9332V 9337V 9333V 9334V 9335V 9330I 9338I 9331I 9336I 9339I 9332I 9337I 9333I

0530V 0538V 0531V 0536V 0539V 0532V 0537V 0533V 0534V 0535V 0530I 0538I 0531I 0536I 0539I 0532I 0537I 0533I

0A30V 0A38V 0A31V 0A36V 0A39V 0A32V 0A37V 0A33V 0A34V 0A35V 0A30I 0A38I 0A31I 0A36I 0A39I 0A32I 0A37I 0A33I

3730V 3738V 3731V 3736V 3739V 3732V 3737V 3733V 3734V 3735V 3730I 3738I 3731I 3736I 3739I 3732I 3737I 3733I

9730V 9738V 9731V 9736V 9739V 9732V 9737V 9733V 9734V 9735V 9730I 9738I 9731I 9736I 9739I 9732I 9737I 9733I

1130V 1138V 1131V 1136V 1139V 1132V 1137V 1133V 1134V 1135V 1130I 1138I 1131I 1136I 1139I 1132I 1137I 1133I

0030V 0038V 0031V 0036V 0039V 0032V 0037V 0033V 0034V 0035V 0030I 0038I 0031I 0036I 0039I 0032I 0037I 0033I

B330V B338V B331V B336V B339V B332V B337V B333V B334V B335V B330I B338I B331I B336I B339I B332I B337I B333I

3B30V 3B38V 3B31V 3B36V 3B39V 3B32V 3B37V 3B33V 3B34V 3B35V 3B30I 3B38I 3B31I 3B36I 3B39I 3B32I 3B37I 3B33I

1530V 1538V 1531V 1536V 1539V 1532V 1537V 1533V 1534V 1535V 1530I 1538I 1531I 1536I 1539I 1532I 1537I 1533I

0430V 0438V 0431V 0436V 0439V 0432V 0437V 0433V 0434V 0435V 0430I 0438I 0431I 0436I 0439I 0432I 0437I 0433I

3130V 3138V 3131V 3136V 3139V 3132V 3137V 3133V 3134V 3135V 3130I 3138I 3131I 3136I 3139I 3132I 3137I 3133I

9130V 9138V 9131V 9136V 9139V 9132V 9137V 9133V 9134V 9135V 9130I 9138I 9131I 9136I 9139I 9132I 9137I 9133I

1030V 1038V 1031V 1036V 1039V 1032V 1037V 1033V 1034V 1035V 1030I 1038I 1031I 1036I 1039I 1032I 1037I 1033I

±1 V

0830V 0838V 0831V 0836V 0839V 0832V 0837V 0833V 0834V 0835V 0830I 0838I 0831I 0836I 0839I 0832I 0837I 0833I

3530V 3538V 3531V 3536V 3539V 3532V 3537V 3533V 3534V 3535V 3530I 3538I 3531I 3536I 3539I 3532I 3537I 3533I

9530V 9538V 9531V 9536V 9539V 9532V 9537V 9533V 9534V 9535V 9530I 9538I 9531I 9536I 9539I 9532I 9537I 9533I

1430V 1438V 1431V 1436V 1439V 1432V 1437V 1333V 1434V 1435V 1430I 1438I 1431I 1436I 1439I 1432I 1437I 1433I

±2 V

2030V 2038V 2031V 2036V 2039V 2032V 2037V 2033V 2034V 2035V 2030I 2038I 2031I 2036I 2039I 2032I 2037I 2033I

3030V 3038V 3031V 3036V 3039V 3032V 3037V 3033V 3034V 3035V 3030I 3038I 3031I 3036I 3039I 3032I 3037I 3033I

9030V 9038V 9031V 9036V 9039V 9032V 9037V 9033V 9034V 9035V 9030I 9038I 9031I 9036I 9039I 9032I 9037I 9033I

±4 V

2430V 2438V 2431V 2436V 2439V 2432V 2437V 2433V 2434V 2435V 2430I 2438I 2431I 2436I 2439I 2432I 2437I 2433I

±5 V

3430V 3438V 3431V 3436V 3439V 3432V 3437V 3433V 3434V 3435V 3430I 3438I 3431I 3436I 3439I 3432I 3437I 3433I

9430V 9438V 9431V 9436V 9439V 9432V 9437V 9433V 9434V 9435V 9430I 9438I 9431I 9436I 9439I 9432I 9437I 9433I

±8 V

1C30V 1C38V 1C31V 1C36V 1C39V 1C32V 1C37V 1C33V 1C34V 1C35V 1C30I 1C38I 1C31I 1C36I 1C39I 1C32I 1C37I 1C33I

2830V 2838V 2831V 2836V 2839V 2832V 2837V 2833V 2834V 2835V 2830I 2838I 2831I 2836I 2839I 2832I 2837I 2833I

B030V B038V B031V B036V B039V B032V B037V B033V B034V B035V B030I B038I B031I B036I B039I B032I B037I B033I

3830V 3838V 3831V 3836V 3839V 3832V 3837V 3833V 3834V 3835V 3830I 3838I 3831I 3836I 3839I 3832I 3837I 3833I

A330V A338V A331V A336V A339V A332V A337V A333V A334V A335V A330I A338I A331I A336I A339I A332I A337I A333I

2C30V 2C38V 2C31V 2C36V 2C39V 2C32V 2C37V 2C33V 2C34V 2C35I 2C30I 2C38I 2C31I 2C36I 2C39I 2C32I 2C37I 2C33I

3C30V 3C38V 3C31V 3C36V 3C39V 3C32V 3C37V 3C33V 3C34V 3C35V 3C30I 3C38I 3C31I 3C36I 3C39I 3C32I 3C37I 3C33I

A830V A838V A831V A836V A839V A832V A837V A833V A834V A835V A830I A838I A831I A836I A839I A832I A837I A833I

B830V B838V B831V B836V B839V B832V B837V B833V B834V B835V B830I B838I B831I B836I B839I B832I B837I B833I

Page 3

DMD4380 Series DC-DC Isolated Transmitter

Output 0-1 V 0-2 V 0-4 V 1-5 V 0-5 V 0-8 V 2-10 V 0-10 V ±5 V ±10 V 0-2 mA 0-4 mA 0-8 mA 2-10 mA 0-10 mA 0-16 mA 4-20 mA 0-20 mA

Switches

Input

0-200 µA

0-400 µA

0-800 µA

0-1 mA

0-1.6 mA

0-2 mA

0-2.6 mA

0-3.2 mA

0-4 mA

0-5 mA

0-5.2 mA

0-6.4 mA

0-8 mA

2-10 mA

0-10 mA

0-10.4 mA

0-13 mA

0-16 mA

4-20 mA

0-20 mA

0-20.8 mA

0-26 mA

0-32 mA

0-40 mA

0-50 mA

Output 0-1 V 0-2 V 0-4 V 1-5 V 0-5 V 0-8 V 2-10 V 0-10 V ±5 V ±10 V 0-2 mA 0-4 mA 0-8 mA 2-10 mA 0-10 mA 0-16 mA 4-20 mA 0-20 mA

Switches

Input

0-10 mV

0-20 mV

0-40 mV

0-50 mV

0-80 mV

0-100 mV

0-130 mV

0-160 mV

0-200 mV

0-250 mV

0-260 mV

0-320 mV

0-400 mV

0-500 mV

0-520 mV

0-650 mV

0-800 mV

0-1 V

0-1.04 V

0-1.3 V

0-1.6 V

0-2 V

0-2.5 V

0-2.6 V

0-3.2 V

0-3.25 V

0-4 V

1-5 V

0-5 V

0-5.25 V

0-6.5 V

0-8 V

2-10 V

0-10 V

0-10.4 V

0-13 V

0-16 V

0-20 V

0-25 V

0-26 V

0-32.5 V

0-40 V

0-50 V

0-52 V

0-65 V

0-100 V

0-130 V

ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE

4300V 4308V 4301V 4306V 4309V 4302V 4307V 4303V 4304V 4305V 4300I 4308I 4301I 4306I 4309I 4302I 4307I 4303I

4700V 4708V 4701V 4706V 4709V 4702V 4707V 4703V 4704V 4705V 4700I 4708I 4701I 4706I 4709I 4702I 4707I 4703I

5300V 5308V 5301V 5306V 5309V 5302V 5307V 5303V 5304V 5305V 5300I 5308I 5301I 5306I 5309I 5302I 5307I 5303I

4B00V 4B08V 4B01V 4B06V 4B09V 4B02V 4B07V 4B03V 4B04V 4B05V 4B00I 4B08I 4B01I 4B06I 4B09I 4B02I 4B07I 4B03I

5700V 5708V 5701V 5706V 5709V 5702V 5707V 5703V 5704V 5705V 5700I 5708I 5701I 5706I 5709I 5702I 5707I 5703I

4100V 4108V 4101V 4106V 4109V 4102V 4107V 4103V 4104V 4105V 4100I 4108I 4101I 4106I 4109I 4102I 4107I 4103I

7300V 7308V 7301V 7306V 7309V 7302V 7307V 7303V 7304V 7305V 7300I 7308I 7301I 7306I 7309I 7302I 7307I 7303I

D300V D308V D301V D306V D309V D302V D307V D303V D304V D305V D300I D308I D301I D306I D309I D302I D307I D303I

4500V 4508V 4501V 4506V 4509V 4502V 4507V 4503V 4504V 4505V 4500I 4508I 4501I 4506I 4509I 4502I 4507I 4503I

4A00V 4A08V 4A01V 4A06V 4A09V 4A02V 4A07V 4A03V 4A04V 4A05V 4A00I 4A08I 4A01I 4A06I 4A09I 4A02I 4A07I 4A03I

7700V 7708V 7701V 7706V 7709V 7702V 7707V 7703V 7704V 7705V 7700I 7708I 7701I 7706I 7709I 7702I 7707I 7703I

D700V D708V D701V D706V D709V D702V D707V D703V D704V D705V D700I D708I D701I D706I D709I D702I D707I D703I

5100V 5108V 5101V 5106V 5109V 5102V 5107V 5103V 5104V 5105V 5100I 5108I 5101I 5106I 5109I 5102I 5107I 5103I

5190V 5198V 5191V 5196V 5199V 5192V 5197V 5193V 5194V 5195V 5190I 5198I 5191I 5196I 5199I 5192I 5197I 5193I

4000V 4008V 4001V 4006V 4009V 4002V 4007V 4003V 4004V 4005V 4000I 4008I 4001I 4006I 4009I 4002I 4007I 4003I

F300V F308V F301V F306V F309V F302V F307V F303V F304V F305V F300I F308I F301I F306I F309I F302I F307I F303I

7B00V 7B08V 7B01V 7B06V 7B09V 7B02V 7B07V 7B03V 7B04V 7B05V 7B00I 7B08I 7B01I 7B06I 7B09I 7B02I 7B07I 7B03I

5500V 5508V 5501V 5506V 5509V 5502V 5507V 5503V 5504V 5505V 5500I 5508I 5501I 5506I 5509I 5502I 5507I 5503I

5590V 5598V 5591V 5596V 5599V 5592V 5597V 5593V 5594V 5595V 5590I 5598I 5591I 5596I 5599I 5592I 5597I 5593I

4400V 4408V 4401V 4406V 4409V 4402V 4407V 4403V 4404V 4405V 4400I 4408I 4401I 4406I 4409I 4402I 4407I 4403I

F700V F708V F701V F706V F709V F702V F707V F703V F704V F705V F700I F708I F701I F706I F709I F702I F707I F703I

7100V 7108V 7101V 7106V 7109V 7102V 7107V 7103V 7104V 7105V 7100I 7108I 7101I 7106I 7109I 7102I 7107I 7103I

D100V D108V D101V D106V D109V D102V D107V D103V D104V D105V D100I D108I D101I D106I D109I D102I D107I D103I

5000V 5008V 5001V 5006V 5009V 5002V 5007V 5003V 5004V 5005V 5000I 5008I 5001I 5006I 5009I 5002I 5007I 5003I

4800V 4808V 4801V 4806V 4809V 4802V 4807V 4803V 4804V 4805V 4800I 4808I 4801I 4806I 4809I 4802I 4807I 4803I

ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE ABCDE

0300V 0308V 0301V 0306V 0309V 0302V 0307V 0303V 0304V 0305V 0300I 0308I 0301I 0306I 0309I 0302I 0307I 0303I

0700V 0708V 0701V 0706V 0709V 0702V 0707V 0703V 0704V 0705V 0700I 0708I 0701I 0706I 0709I 0702I 0707I 0703I

1300V 1308V 1301V 1306V 1309V 1302V 1307V 1303V 1304V 1305V 1300I 1308I 1301I 1306I 1309I 1302I 1307I 1303I

0B00V 0B08V 0B01V 0B06V 0B09V 0B02V 0B07V 0B03V 0B04V 0B05V 0B00I 0B08I 0B01I 0B06I 0B09I 0B02I 0B07I 0B03I

1700V 1708V 1701V 1706V 1709V 1702V 1707V 1703V 1704V 1705V 1700I 1708I 1701I 1706I 1709I 1702I 1707I 1703I

0100V 0108V 0101V 0106V 0109V 0102V 0107V 0103V 0104V 0105V 0100I 0108I 0101I 0106I 0109I 0102I 0107I 0103I

3300V 3308V 3301V 3306V 3309V 3302V 3307V 3303V 3304V 3305V 3300I 3308I 3301I 3306I 3309I 3302I 3307I 3303I

9300V 9308V 9301V 9306V 9309V 9302V 9307V 9303V 9304V 9305V 9300I 9308I 9301I 9306I 9309I 9302I 9307I 9303I

0500V 0508V 0501V 0506V 0509V 0502V 0507V 0503V 0504V 0505V 0500I 0508I 0501I 0506I 0509I 0502I 0507I 0503I

0A00V 0A08V 0A01V 0A06V 0A09V 0A02V 0A07V 0A03V 0A04V 0A05V 0A00I 0A08I 0A01I 0A06I 0A09I 0A02I 0A07I 0A03I

3700V 3708V 3701V 3706V 3709V 3702V 3707V 3703V 3704V 3705V 3700I 3708I 3701I 3706I 3709I 3702I 3707I 3703I

9700V 9708V 9701V 9706V 9709V 9702V 9707V 9703V 9704V 9705V 9700I 9708I 9701I 9706I 9709I 9702I 9707I 9703I

1100V 1108V 1101V 1106V 1109V 1102V 1107V 1103V 1104V 1105V 1100I 1108I 1101I 1106I 1109I 1102I 1107I 1103I

0000V 0008V 0001V 0006V 0009V 0002V 0007V 0003V 0004V 0005V 0000I 0008I 0001I 0006I 0009I 0002I 0007I 0003I

B300V B308V B301V B306V B309V B302V B307V B303V B304V B305V B300I B308I B301I B306I B309I B302I B307I B303I

3B00V 3B08V 3B01V 3B06V 3B09V 3B02V 3B07V 3B03V 3B04V 3B05V 3B00I 3B08I 3B01I 3B06I 3B09I 3B02I 3B07I 3B03I

1500V 1508V 1501V 1506V 1509V 1502V 1507V 1503V 1504V 1505V 1500I 1508I 1501I 1506I 1509I 1502I 1507I 1503I

0400V 0408V 0401V 0406V 0409V 0402V 0407V 0403V 0404V 0405V 0400I 0408I 0401I 0406I 0409I 0402I 0407I 0403I

B700V B708V B701V B706V B709V B702V B707V B703V B704V B705V B700I B708I B701I B706I B709I B702I B707I B703I

3100V 3108V 3101V 3106V 3109V 3102V 3107V 3103V 3104V 3105V 3100I 3108I 3101I 3106I 3109I 3102I 3107I 3103I

9100V 9108V 9101V 9106V 9109V 9102V 9107V 9103V 9104V 9105V 9100I 9108I 9101I 9106I 9109I 9102I 9107I 9103I

1000V 1008V 1001V 1006V 1009V 1002V 1007V 1003V 1004V 1005V 1000I 1008I 1001I 1006I 1009I 1002I 1007I 1003I

0800V 0808V 0801V 0806V 0809V 0802V 0807V 0803V 0804V 0805V 0800I 0808I 0801I 0806I 0809I 0802I 0807I 0803I

3500V 3508V 3501V 3506V 3509V 3502V 3507V 3503V 3504V 3505V 3500I 3508I 3501I 3506I 3509I 3502I 3507I 3503I

9500V 9508V 9501V 9506V 9509V 9502V 9507V 9503V 9504V 9505V 9500I 9508I 9501I 9506I 9509I 9502I 9507I 9503I

3A00V 3A08V 3A01V 3A06V 3A09V 3A02V 3A07V 3A03V 3A04V 3A05V 3A00I 3A08I 3A01I 3A06I 3A09I 3A02I 3A07I 3A03I

1400V 1408V 1401V 1406V 1409V 1402V 1407V 1403V 1404V 1405V 1400I 1408I 1401I 1406I 1409I 1402I 1407I 1403I

1490V 1498V 1491V 1496V 1499V 1492V 1497V 1493V 1494V 1495V 1490I 1498I 1491I 1496I 1499I 1492I 1497I 1493I

2000V 2008V 2001V 2006V 2009V 2002V 2007V 2003V 2004V 2005V 2000I 2008I 2001I 2006I 2009I 2002I 2007I 2003I

B100V B108V B101V B106V B109V B102V B107V B103V B104V B105V B100I B108I B101I B106I B109I B102I B107I B103I

3000V 3008V 3001V 3006V 3009V 3002V 3007V 3003V 3004V 3005V 3000I 3008I 3001I 3006I 3009I 3002I 3007I 3003I

9000V 9008V 9001V 9006V 9009V 9002V 9007V 9003V 9004V 9005V 9000I 9008I 9001I 9006I 9009I 9002I 9007I 9003I

9090V 9098V 9091V 9096V 9099V 9092V 9097V 9093V 9094V 9095V 9090I 9098I 9091I 9096I 9099I 9092I 9097I 9093I

2400V 2408V 2401V 2406V 2409V 2402V 2407V 2403V 2404V 2405V 2400I 2408I 2401I 2406I 2409I 2402I 2407I 2403I

B500V B508V B501V B506V B509V B502V B507V B503V B504V B505V B500I B508I B501I B506I B509I B502I B507I B503I

3400V 3408V 3401V 3406V 3409V 3402V 3407V 3403V 3404V 3405V 3400I 3408I 3401I 3406I 3409I 3402I 3407I 3403I

9400V 9408V 9401V 9406V 9409V 9402V 9407V 9403V 9404V 9405V 9400I 9408I 9401I 9406I 9409I 9402I 9407I 9403I

1C00V 1C08V 1C01V 1C06V 1C09V 1C02V 1C07V 1C03V 1C04V 1C05V 1C00I 1C08I 1C01I 1C06I 1C09I 1C02I 1C07I 1C03I

2800V 2808V 2801V 2806V 2809V 2802V 2807V 2803V 2804V 2805V 2800I 2808I 2801I 2806I 2809I 2802I 2807I 2803I

B000V B008V B001V B006V B009V B002V B007V B003V B004V B005V B000I B008I B001I B006I B009I B002I B007I B003I

3800V 3808V 3801V 3806V 3809V 3802V 3807V 3803V 3804V 3805V 3800I 3808I 3801I 3806I 3809I 3802I 3807I 3803I

A300V A308V A301V A306V A309V A302V A307V A303V A304V A305V A300I A308I A301I A306I A309I A302I A307I A303I

2C00V 2C08V 2C01V 2C06V 2C09V 2C02V 2C07V 2C03V 2C04V 2C05V 2C00I 2C08I 2C01I 2C06I 2C09I 2C02I 2C07I 2C03I

B400V B408V B401V B406V B409V B402V B407V B403V B404V B405V B400I B408I B401I B406I B409I B402I B407I B403I

3C00V 3C08V 3C01V 3C06V 3C09V 3C02V 3C07V 3C03V 3C04V 3C05V 3C00I 3C08I 3C01I 3C06I 3C09I 3C02I 3C07I 3C03I

A800V A808V A801V A806V A809V A802V A807V A803V A804V A805V A800I A808I A801I A806I A809I A802I A807I A803I

B800V B808V B801V B806V B809V B802V B807V B803V B804V B805V B800I B808I B801I B806I B809I B802I B807I B803I

3

Page 4

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

OMEGAnet

www.omega.com info@omega.com

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Canada: 976 Bergar

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail:espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, human applications.

®

Online Service Internet e-mail

Servicing North America:

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

Toll Free in Benelux: 0800 0993344

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

®

M44 5BD United Kingdom

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

e-mail: sales@omegaeng.nl

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping

time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors

nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies

of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used

in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

PATENT NOTICE: U. S. Pat. No. 6,074,089; 5,465,838 / Canada 2,228,333; 2,116,055 / UK GB 2,321,712 / Holland 1008153 / Israel 123052 / France

2 762 908 / EPO 0614194. Other patents pending.

FOR WARRANTY RETURNS, please have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

M-5001/1110

RETURN REQUESTS / INQUIRIES

Loading...

Loading...