Omega Products CN3410 Installation Manual

User’s Guide

http://www.omega.com

e-mail: info@omega.com

CN3410 SERIES

1/8 DIN Panel Mount

Universal T emperature & Pr ocess

Controller

OMEGAnet®On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

SM

Mexico and

Latin America:

Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

SM

SM

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability

for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

GETTING STARTED

This manual is divided into 5 sections which contain all the information needed to

install, configure, set up and operate the instrument. Each section is identified

clearly by a symbol as shown below.

Displays and Function Keys

• Displays and function keys

• LED Indication

• Error Messages

Operator Mode (Level 1)

• Operator menus for:

– Standard controller

– Heat/Cool controller

– Remote Set Point controller

– Profile controller

– Multiple Fixed Set Points controller

• Auto tuning

Set Up Mode (Levels 2, 3 and 4)

• Level 2 – Tuning

8

• Level 3 – Set Points

• Level 4 – Profile

Configuration Mode (Levels 5 and 6)

• Level 5 – Basic hardware and control

functions

• Level 6 – Ranges and passwords

Installation

• Siting

• Mounting

• Electrical connections

Symbol Identification and Section Contents

1

CONTENTS

1 DISPLAYS AND FUNCTION KEYS ............................................................. 3

1.1 Introduction .......................................................................................... 3

1.2 Use of Function Keys .......................................................................... 4

1.3 LED Alarms and Indicators ................................................................. 5

1.4 Error Messages ................................................................................... 6

2 OPERATOR MODE ...................................................................................... 7

2.1 Introduction .......................................................................................... 7

2.2 Standard Controller .............................................................................8

2.3 Heat/Cool Controller............................................................................9

2.4 Remote Set Point Controller .............................................................10

2.5 Profile Controller ............................................................................... 12

2.6 Multiple Fixed Set Points Controller ................................................. 14

2.7 Auto-tune ........................................................................................... 16

3 SET UP MODE ............................................................................................ 18

3.1 Introduction ........................................................................................ 18

3.2 Tuning (Level 2) ................................................................................ 18

3.3 Set Points (Level 3) ........................................................................... 22

3.4 Profile (Level 4) ................................................................................. 25

4 CONFIGURATION MODE .......................................................................... 28

4.1 Introduction ............................................................................................

4.2 Accessing the Configuration Mode ................................................... 28

4.3 Basic Hardware and Configuration (Level 5) ................................... 30

4.4 Ranges and Passwords (Level 6) ..................................................... 40

5 INSTALLATION .......................................................................................... 43

5.1 Siting .................................................................................................. 43

5.2 Mounting ............................................................................................ 45

5.3 Electrical Connections ...................................................................... 47

5.4 Relays, Arc Suppression and Outputs ............................................. 47

Information.

The fold-out page inside on the back cover of this

manual shows all the frames in the programming

levels. Space is provided on the page for writing the

programmed setting or selection for each frame.

2

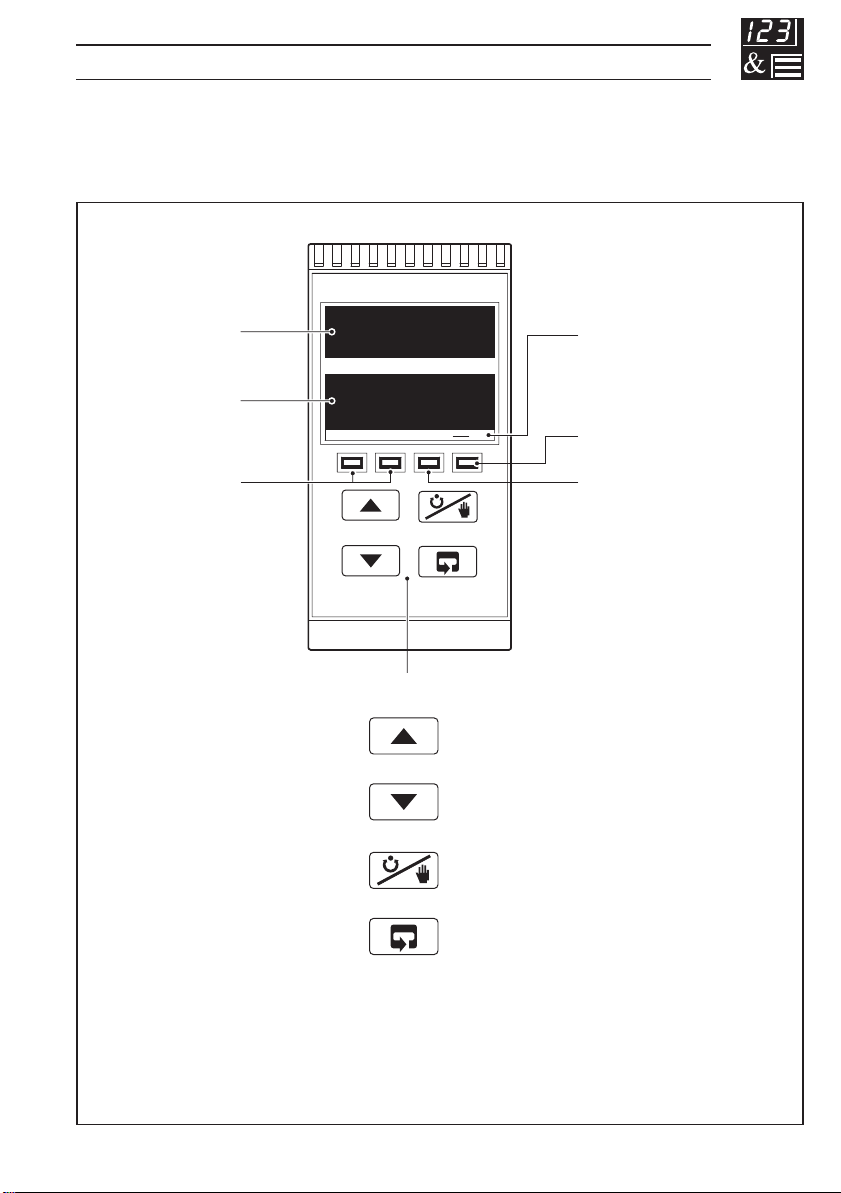

1 DISPLAYS AND FUNCTION KEYS

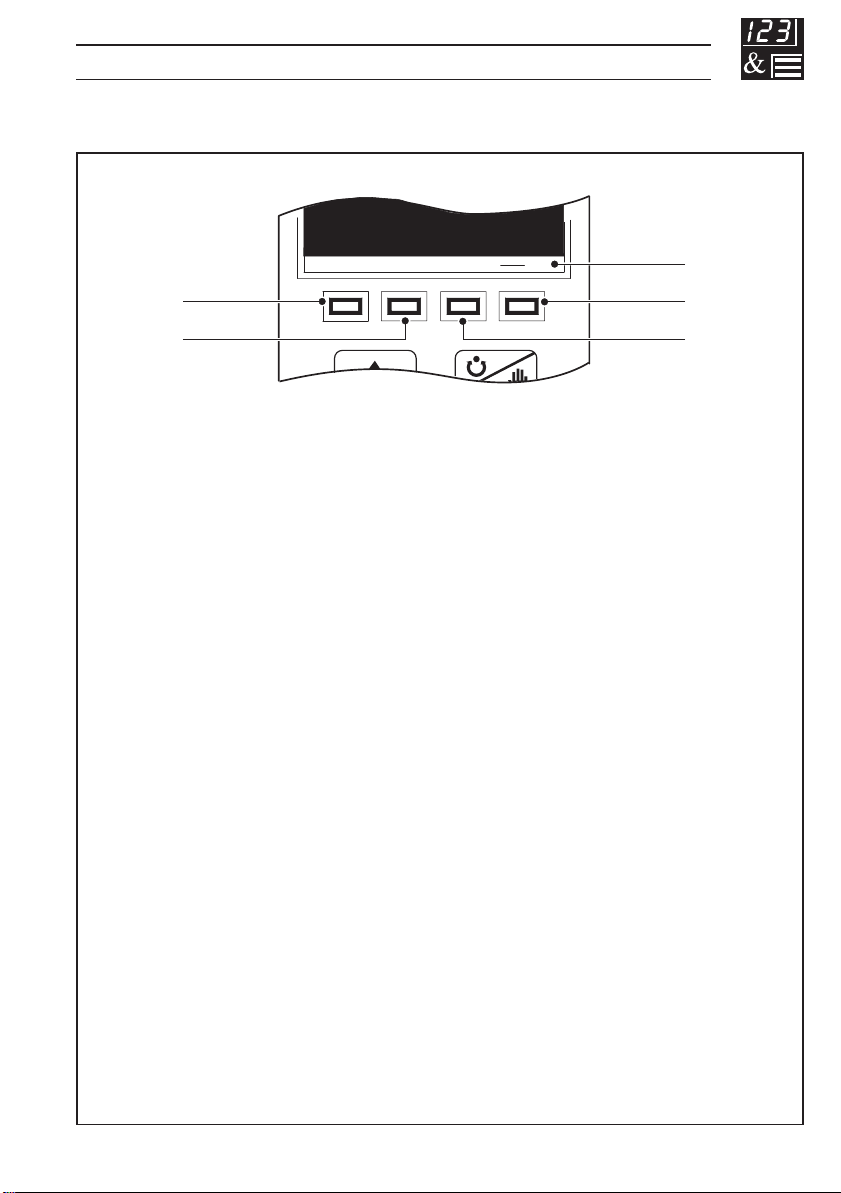

1.1 Introduction – Fig. 1.1

The instrument front panel displays, function keys and LED indicators are shown in

Fig. 1.1.

Upper Display

Lower Display

Alarm LEDs

8888

8888

Function Keys

OP2OP1

MRA1 A2

Raise

Lower

Auto/Manual

Output Value LEDs

(invisible when off)

Manual Control LED

Remote Set Point LED

Parameter Advance

Fig. 1.1 Front Panel Displays, Function Keys and Indicators

3

…1 DISPLAYS AND FUNCTION KEYS

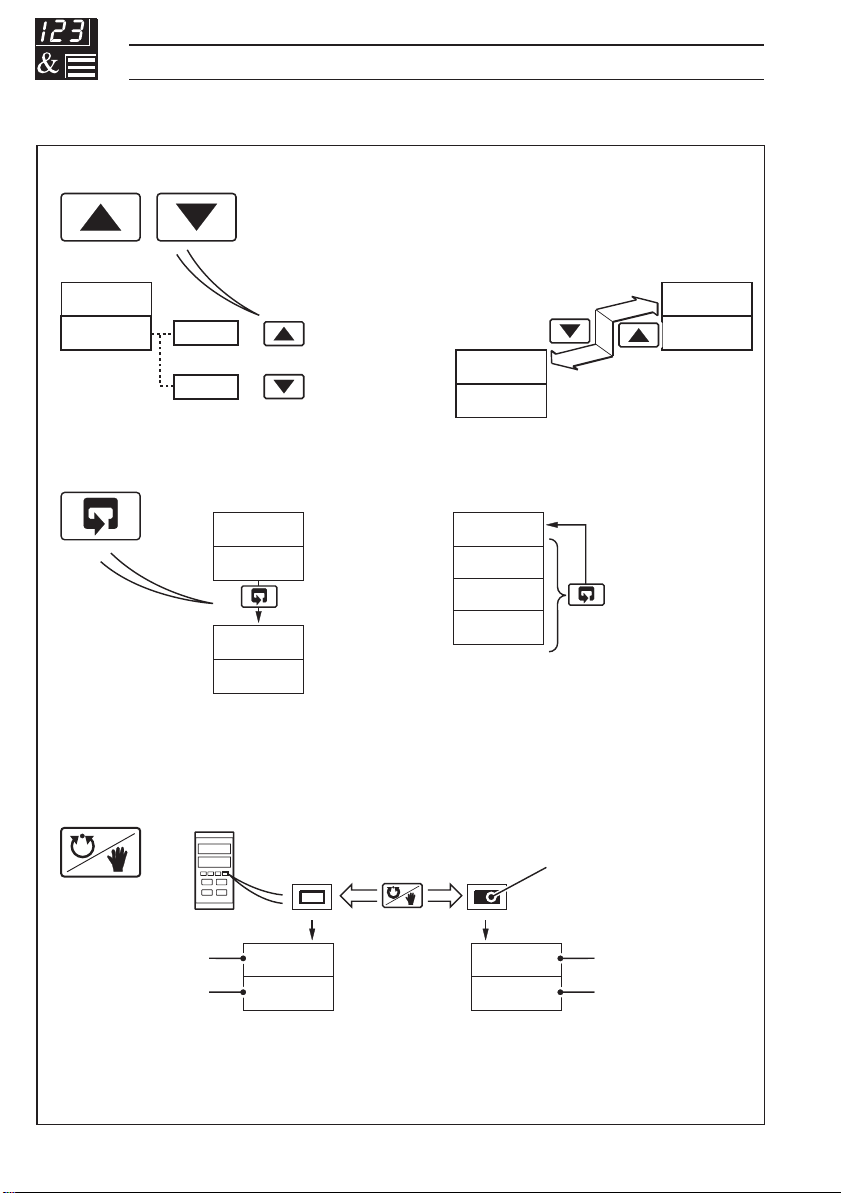

1.2 Use of Function Keys – Fig. 1.2

A – Raise and Lower Keys

bIAS

50.0

51.0

+

LEV1

49.0

–

OPEr

Use to change/set a parameter value… …move between levelsand…

B – Parameter Advance Key

LEV2

tUnE

Frame 1

(top of level)

or…

LEVx

1001

1002

CYCl

Frame 2

1003

5.0

Use to advance to the next

frame within a level…

Note. This key also stores any changes made in the previous frame

C – Auto/Manual Key

Auto

M

…select the top (LEVEL) frame

from within a level

Manual

M

LEV2

tUnE

Press and

hold

Illuminated

Process Variable

Control Set Point

4

125.2

125.8

Use to select Auto or Manual control mode

Fig. 1.2 Use of Function Keys

125.2

70

Process Variable

Control Output (%)

1 DISPLAYS AND FUNCTION KEYS…

1.3 LED Alarms and Indicators

OP2OP1

MRA1 A2

A1

A2

OP1

OP2

M

R

LED Status

All • All LED's flashing – controller is in the Configuration Mode.

A1 • Flashes when Alarm 1 is active (off when inactive).

A2 • Flashes when Alarm 2 is active (off when inactive).

R • On when the controller is operating on the remote set point value.

• Off when the controller is operating using the local set point

value or one of the four fixed set points (in multiple set point mode).

• Flashes when a Ramp/Soak profile is running.

M • On when the controller is operating in Manual control mode.

• Off when the controller is operating in Auto control mode.

• Flashes when the controller is performing an auto-tune.

OP1 • Indicates output 1 (heat) value is displayed in the lower display.

OP2 • Indicates output 2 (cool) value is displayed in the lower display.

Fig. 1.3 LED Alarms and Indicators

5

…1 DISPLAYS AND FUNCTION KEYS

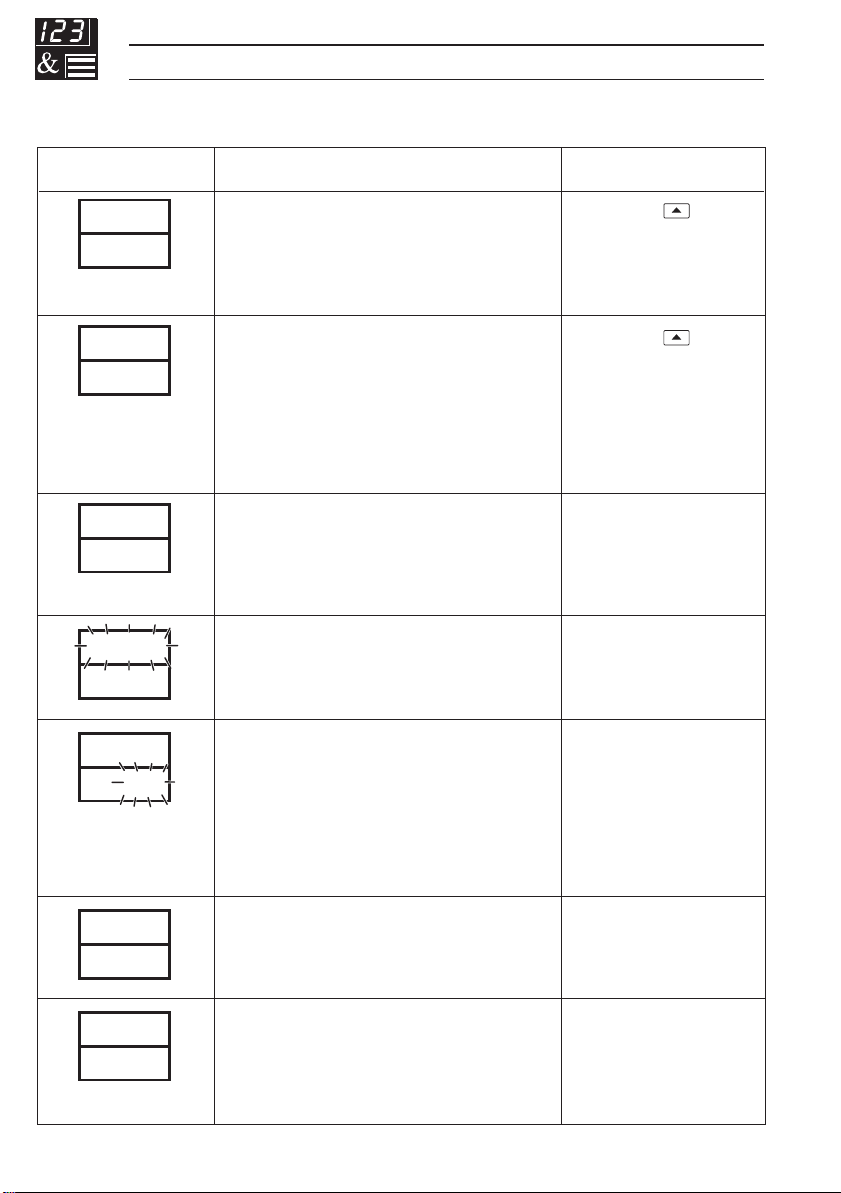

1.4 Error Messages

Display Error/Action

CAL

Err

CnFG

Err

A-d

Err

9999

Calibration error

Turn power off and on again (if the

error persists contact the Supplier).

Configuration error

The configuration and/or setup data

for the instrument is corrupted.

Turn power off and on again (if the

error persists, check configuration/

setup settings).

A to D Converter Fault

The analog to digital converter is

not communicating correctly.

Process Variable Over/Under

Range

70

125.2

70

Remote Set Point Over/Under

Range

The remote set point value is over

or under range. Flashing stops

automatically when the remote set

point input comes back into range.

To Clear Display

Press the

Press the

Turn power off and on

again, if the problem

persists contact the

Supplier

Restore valid input

Select the local set

(rSP.n) in

point

the Operating Page

or the Set Points

Level

key

key

6

OPtn

Err

t.Err

1

Option error

Communications to the option

board have failed.

Auto-tune error

The number displayed indicates the

type of error present – see Table 2.1

in Section 2.7.

Contact the Supplier

Press any key

2 OPERATOR MODE

2.1 Introduction

Operator Mode (Level 1) is the normal day-to-day mode of the instrument.

Frames displayed in level 1 are determined by the control strategy which is

selected during configuration of the instrument – see Section 4.

Note. Only the operating frames relevant to the configured strategy are

displayed in Operator Mode.

The five control strategies are:

• Standard controller – page 8

• Heat/Cool controller – page 9

• Remote Set Point controller – page 10

• Profile controller – page 12

• Multiple Fixed Set Points controller – page 14

7

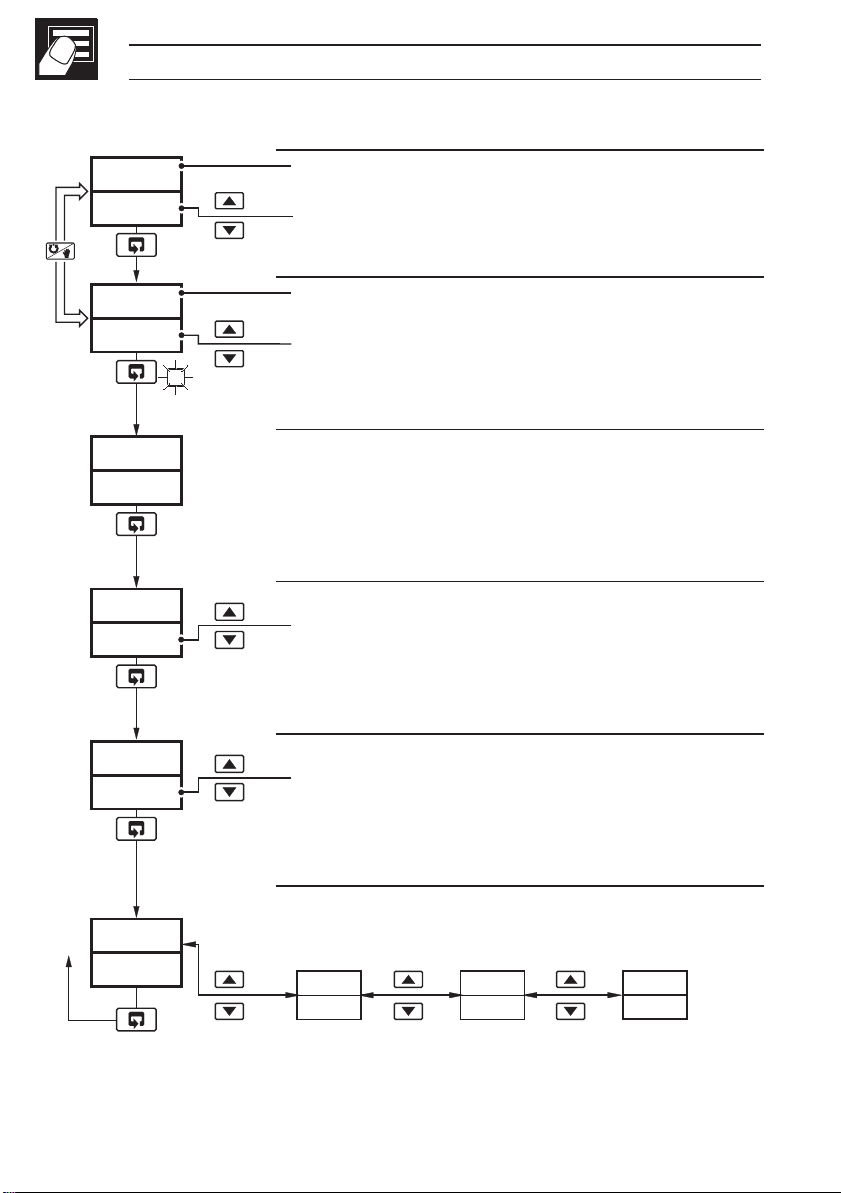

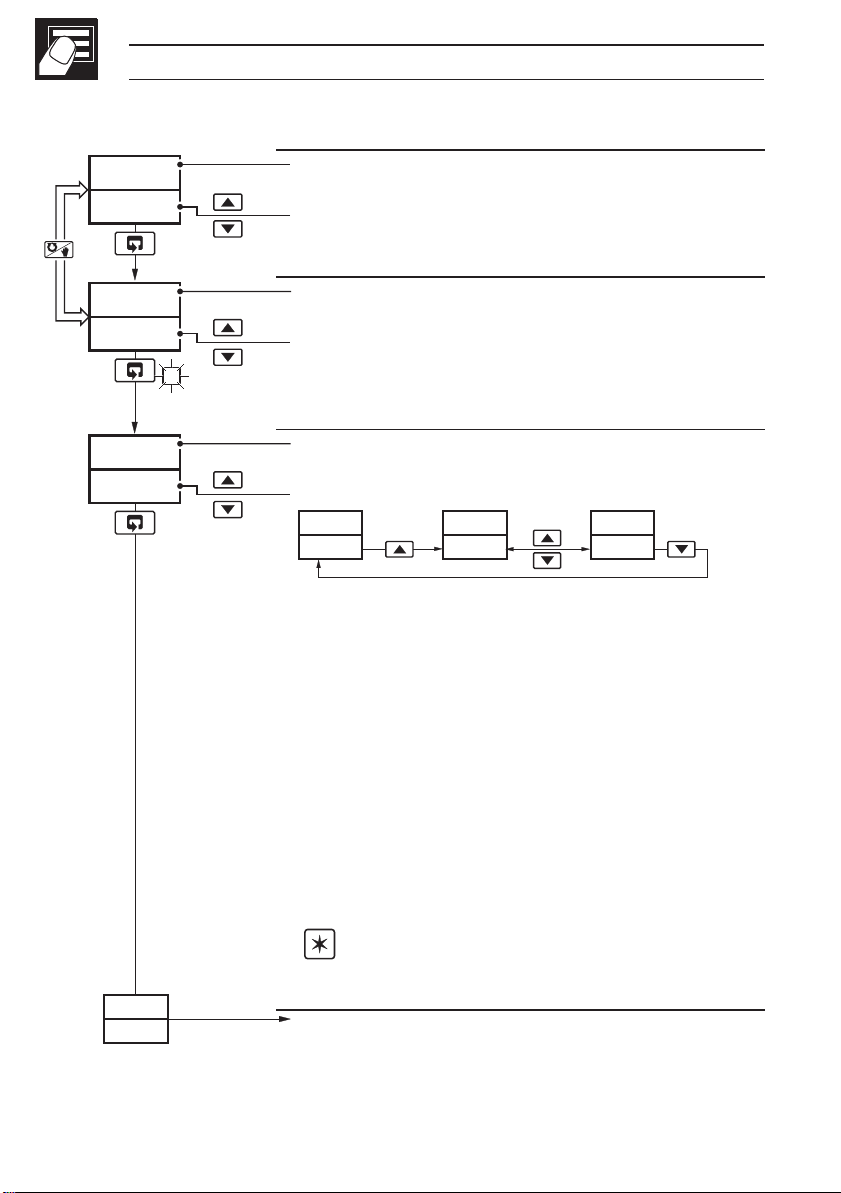

…2 OPERATOR MODE

2.2 Standard Controller

Auto

Man

•1

125.2

125.8

125.2

70

SPrP

120.5

CodE

0

OP1

Process Variable Value

Control Set Point Value (Local set point)

[Set point low limit to set point high limit]

Process Variable Value

Control Output Value (%)

[0 to 100% (–10% to 110% for analog output)]

Adjustable in manual mode only.

Ramping Set Point Value (Read only)

The actual set point value is displayed, i.e. the

instantaneous value the controller is working to.

Security Code

[0 to 9999]

Select the appropriate security code to access:

Auto-tune enable frame (Level 1),

Set Up mode (Levels 2, 3, 4).

AtnE

OFF

LEV1

OPEr

•1 Not displayed if the ramping set point facility is turned off – refer to

Section 3.3.

8

Auto-tune Enable

ON – Auto-tune on

OFF – Auto-tune off

Refer to page 16 for the Auto-tune procedure.

Level 1 (Operator mode)

Refer to Section 3 for levels 2, 3 and 4.

LEV2

LEV3

SEtPtUnE

LEV4

PrFL

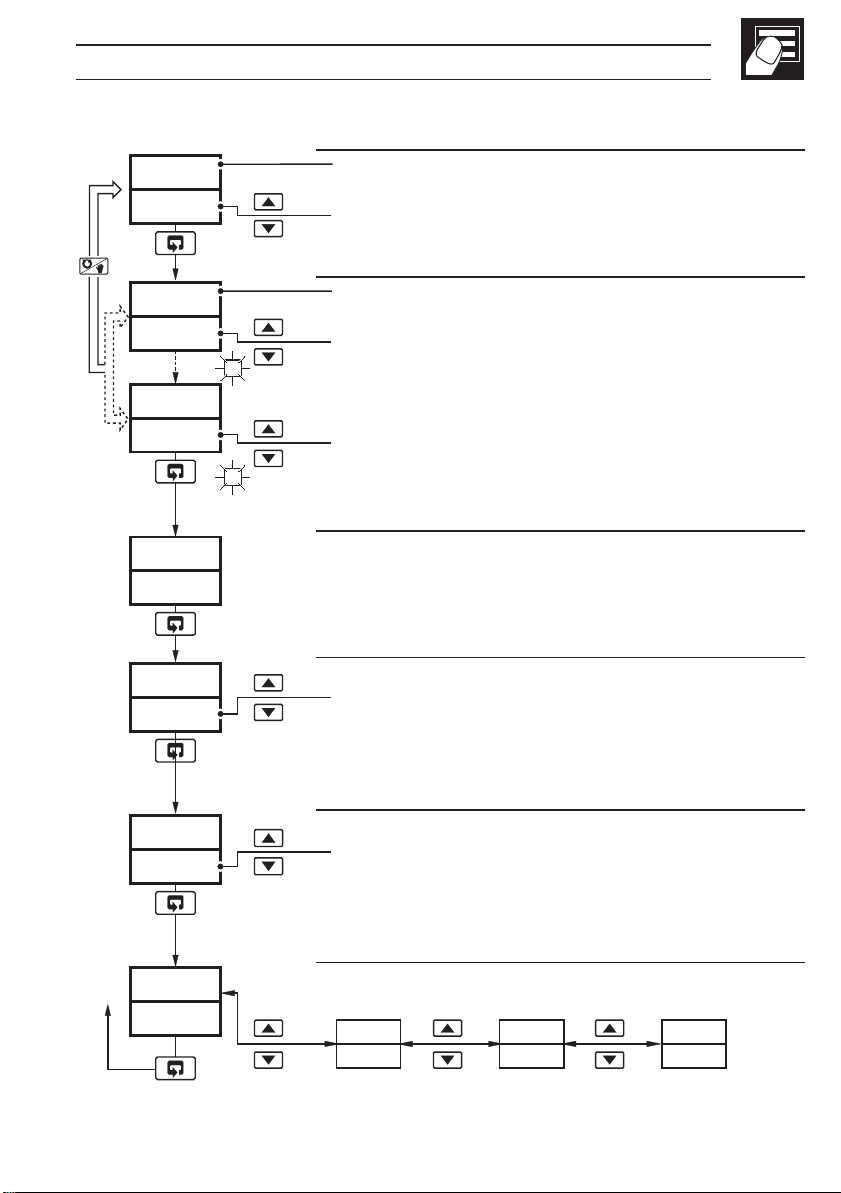

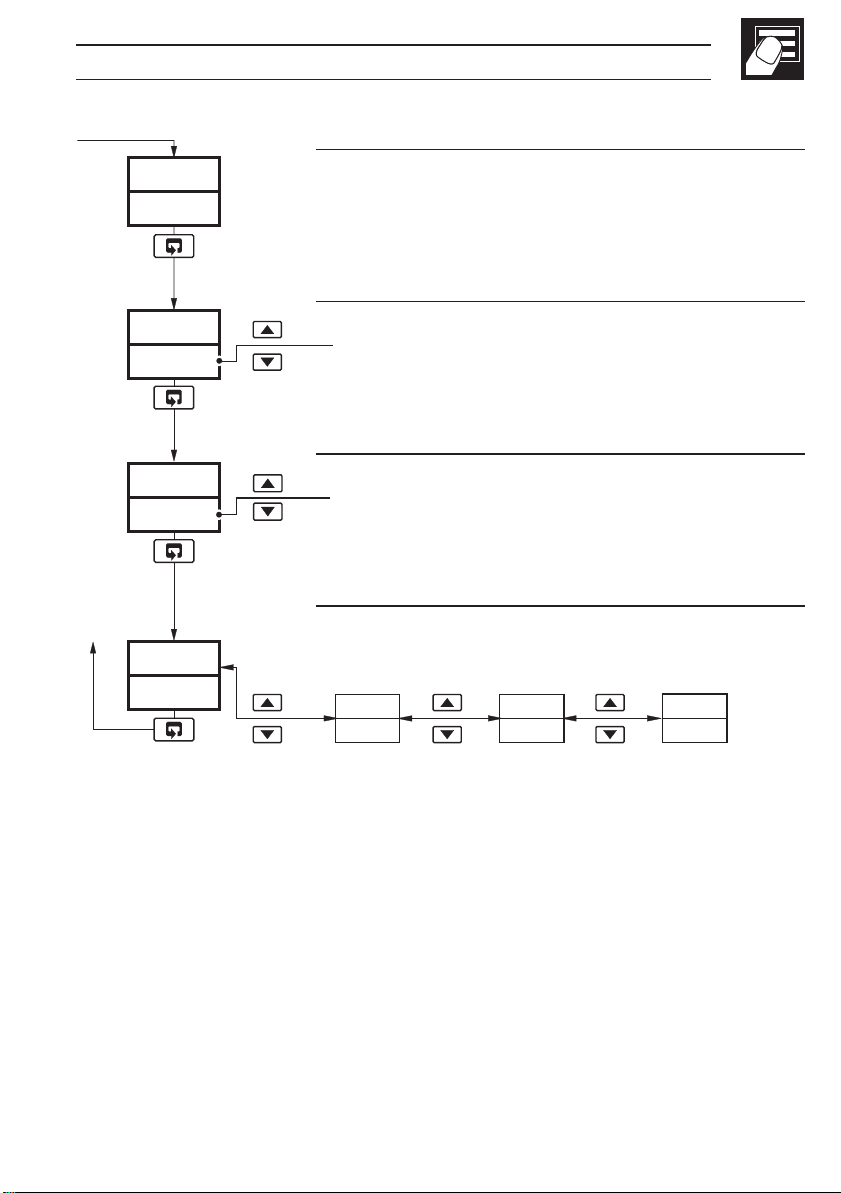

2.3 Heat/Cool Controller

2 OPERATOR MODE…

Auto

Man

•1

125.2

125.8

125.2

70

125.2

-30

SPrP

120.5

COdE

0

OP1 (Heat)

OP2 (Cool)

Process Variable Value

Control Set Point Value (Local set point)

[Set point low limit to set point high limit]

Process Variable Value

Control Output Value (Heat %)

[0% to 100% (0% to 110% for analog output)]

If adjusted below 0% the 'Cool' frame is displayed.

Control Output 2 Value (Cool %)

[0% to –100% (0% to –110% for analog output)]

If adjusted above 0% the 'Heat' frame is displayed.

Ramping Set Point Value (Read only)

The actual set point value is displayed i.e. the

instantaneous value the controller is working to.

Security Code

[0 to 9999]

Select the appropriate security code to access:

Auto-tune enable frame (Level 1),

Set Up mode (Levels 2, 3, 4).

AtNE

Auto-tune Enable

ON – Auto-tune on

OFF

LEV1

OPEr

•1 Not displayed if the ramping set point facility is turned off – refer to

Section 3.3.

OFF – Auto-tune off

Refer to page 16 for the Auto-tune procedure.

Level 1 (Operator mode)

See Section 3 for levels 2, 3 and 4.

LEV2

LEV3

SEtPtUnE

LEV4

PrFL

9

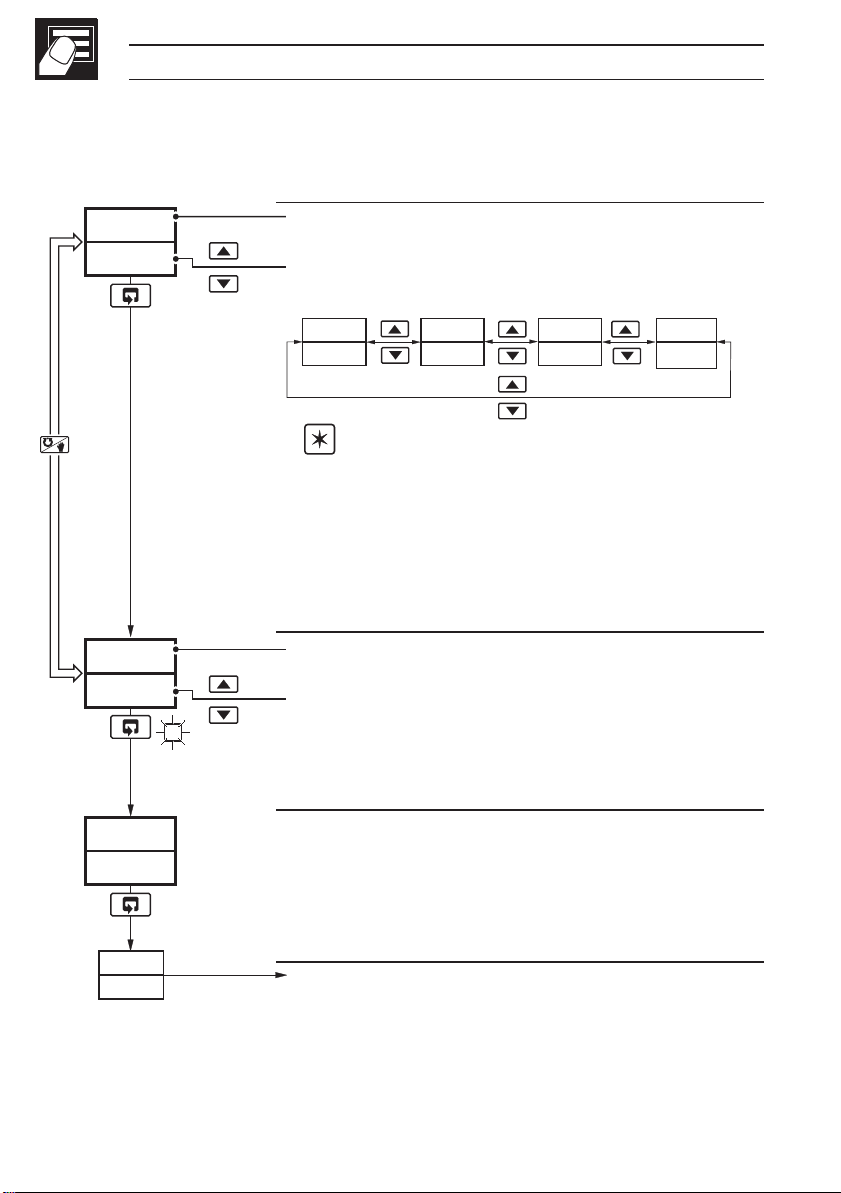

…2 OPERATOR MODE

2.4 Remote Set Point Controller

Auto

Man

125.2

125.8

125.2

70

rSPn

rSPn

123.4

123.4

SPrP

120.5

OP1

Process Variable Value

Control Set Point Value

[Set point low to set point high limit]

Adjustable in local Set Point Mode only.

Process Variable Value

Control Output Value (%)

[0% to 100% (–10% to 110% for analog output)]

Adjustable in manual mode only.

Remote Set Point Selection

rSPY – Remote Set Point

rSPn – Local Set Point

Local or remote set point can also be selected using

a digital input.

The option to change the set point selection at this

frame can be disabled in the configuration level.

Remote Set Point Value (Read only)

Continued on next page…

Note.

If the remote set point input fails while selected, the controller automatically

selects the local set point value. The upper display changes to

lower display flashes. When the fault condition is removed, the remote set point

is re-selected automatically. To clear the error condition while the remote set

point input is still outside its allowed range, select the local set point by pressing

the

10

key (rSP.n is displayed).

rSP.F and the

…2.4 Remote Set Point Controller

•1

SPrP

120.5

CodE

0

AtnE

OFF

LEV1

OPEr

Ramping Set Point Value (Read only)

The actual set point value is displayed, i.e. the

instantaneous value the controller is working to.

Security Code

[0 to 9999]

Select the appropriate security code to access:

Auto-tune enable frame (Level 1),

Set Up mode (Levels 2, 3, 4).

Auto-tune Enable

ON – Auto-tune on

OFF – Auto-tune off

Refer to page 16 for the Auto-tune procedure.

Level 1 (Operator mode)

See Section 3 for levels 2, 3 and 4.

LEV2

2 OPERATOR MODE…

LEV3

SEtPtUnE

LEV4

PrFL

•1 Not displayed if the ramping set point facility is turned off – refer to

Section 3.3.

11

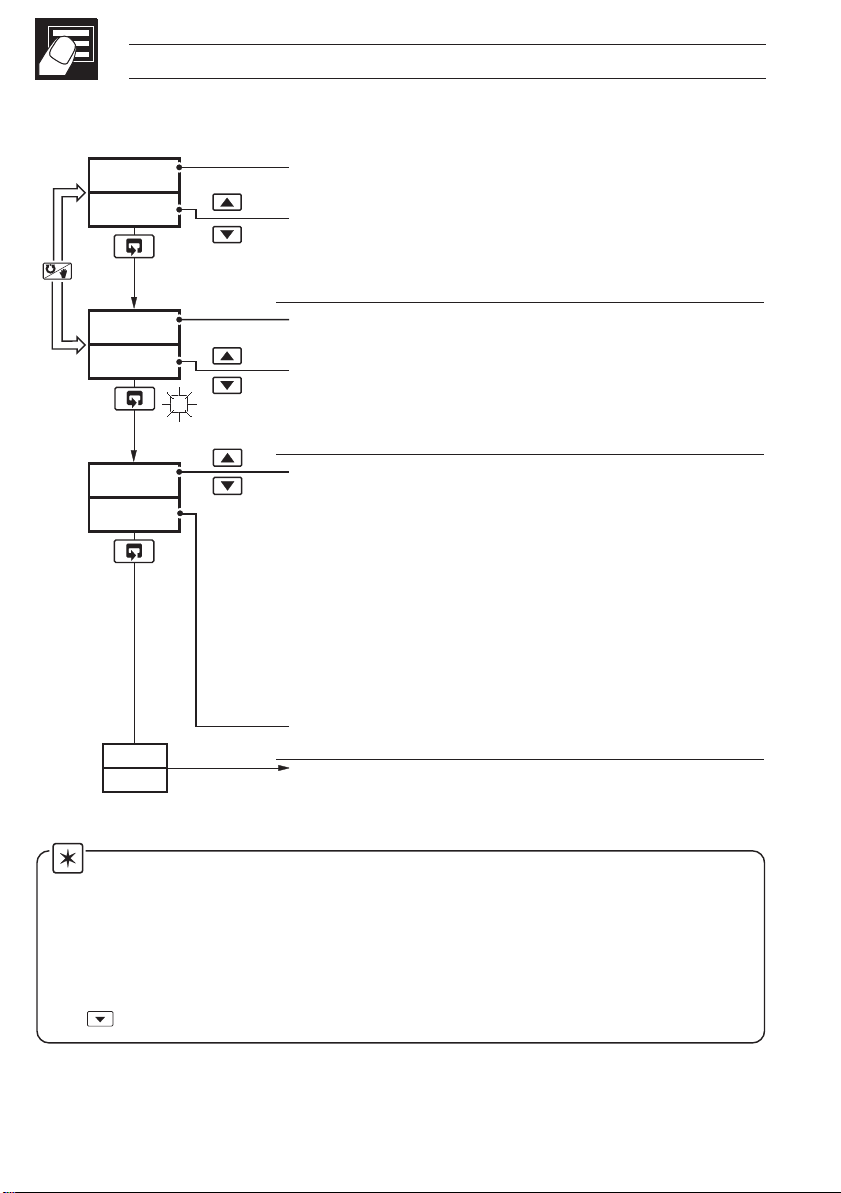

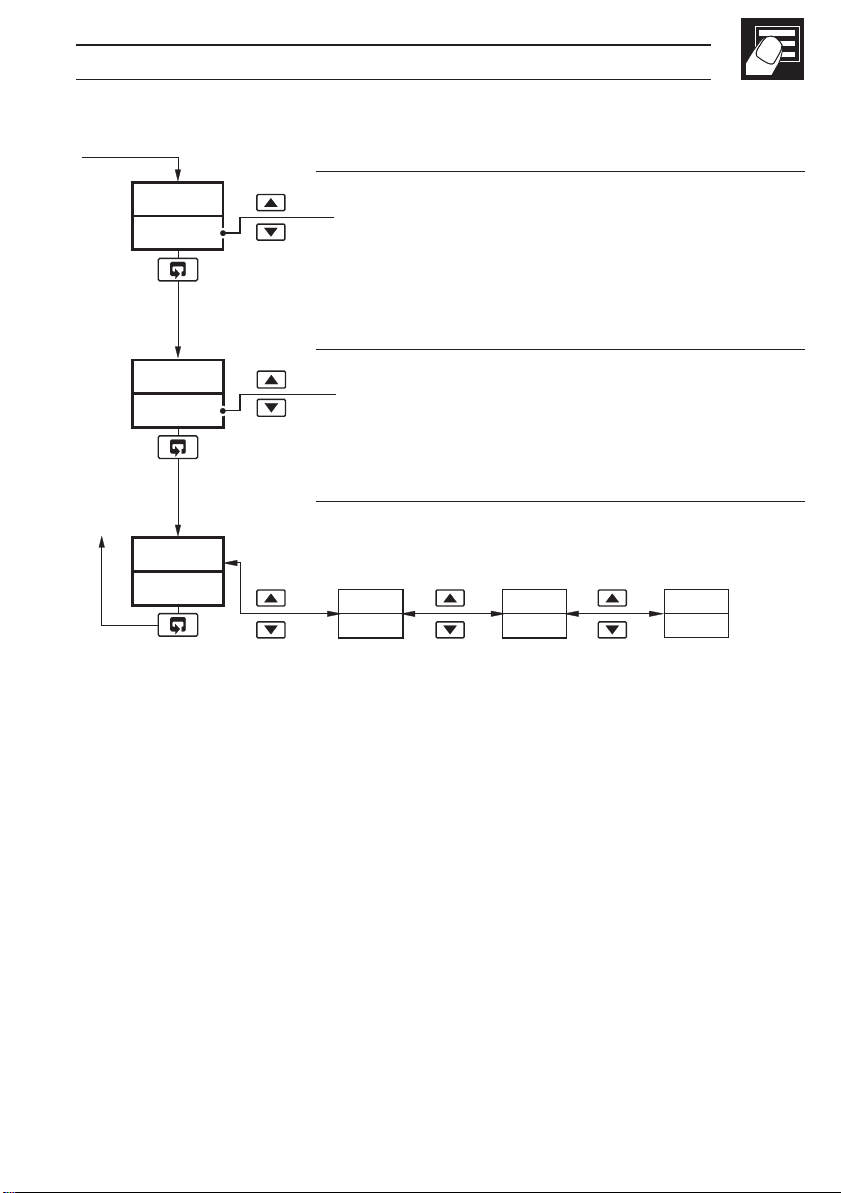

…2 OPERATOR MODE

2.5 Profile Controller

Auto

Man

125.2

125.8

125.2

70

SG 1

StOP

OP1

Process Variable Value

Control Set Point Value

[Set point low limit to set point high limit]

Process Variable Value

Control Output Value (%)

[0% to 100% (–10% to 110% for analog output)]

Adjustable in manual mode only.

Profile Segment Number (1 to 4) currently active

Profile Status

SG 1

StOP

SG 1

rUN

SG 1

HOLd

StOP – Profile inactive – the control set point

is equal to the local set point value

when the profile is not running.

rUN – Profile active – currently operating on

the segment indicated.

HOLd – Profile hold – pauses the current ramp

or soak mode by putting it into 'Hold'

mode. The guaranteed ramp soak

feature can also be used to put the profile

into a 'Hold' mode until the process

variable comes back within the

hysteresis band.

12

SPrP

120.5

Note. The profile status can be changed using

a digital input.

Continued on next page…

…2.5 Profile Controller

2 OPERATOR MODE…

•1

SPrP

120.5

CodE

0

AtnE

OFF

LEV1

OPEr

Ramping Set Point Value (Read only)

The actual set point value is displayed, i.e. the

instantaneous value the controller is working to.

Security Code

[0 to 9999]

Select the appropriate security code to access:

Auto-tune enable frame (Level 1),

Set Up mode (Levels 2, 3, 4).

Auto-tune Enable

ON – Auto-tune on

OFF – Auto-tune off

Refer to page 16 for the Auto-tune procedure.

Level 1 (Operator mode)

See Section 3 for levels 2, 3 and 4.

LEV2

LEV3

SEtPtUnE

LEV4

PrFL

•1 Not displayed if the ramping set point facility is turned off – refer to

Section 3.3.

13

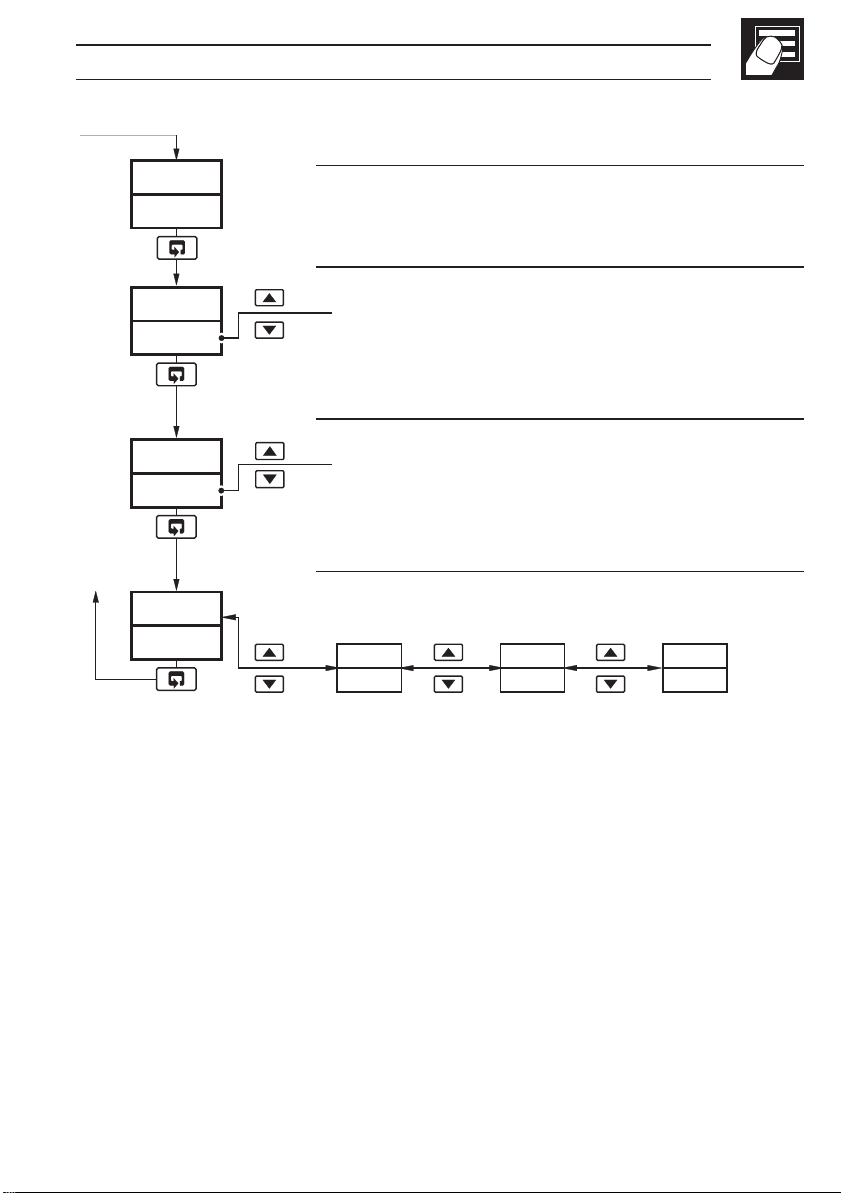

…2 OPERATOR MODE

2.6 Multiple Fixed Set Points Controller

If the Multiple Fixed Set Points Controller type is selected during configuration, four

fixed control set points can be set – see Section 4.4.

Auto

Man

125.2

125.8

125.2

70

OP1

Process Variable Value

Fixed Control Set Point Selected

SP-1

100.3

Notes.

a) The top display momentarily displays the set

point selected before reverting to the display

of the process variable value.

b) A digital input can also be used to select the

fixed set points.

Process Variable Value

Control Output Value (%)

[0% to 100% (–10% to 110% for analog output)]

Adjustable in manual mode only.

SP-2

200.1

SP-3

300.2

SP-4

400.5

•1

SPrP

12.05

Ramping Set Point Value (Read only)

The actual set point value is displayed, i.e. the

instantaneous value the controller is working to.

CodE

0

•1 Not displayed if the ramping set point facility is turned off – refer to

Section 3.3.

14

Continued on next page…

2 OPERATOR MODE…

…2.6 Multiple Fixed Set Points Controller

CodE

0

AtnE

OFF

LEV1

OPEr

Security Code

[0 to 9999]

Select the appropriate security code to access:

Auto-tune enable frame (Level 1),

Set Up Mode (Levels 2, 3, 4).

Auto-tune Enable

ON – Auto-tune on

OFF – Auto-tune off

Refer to page 16 for the Auto-tune procedure.

Level 1 (Operator mode)

See Section 3 for Levels 2, 3 and 4.

LEV2

LEV3

SEtPtUnE

LEV4

PrFL

15

Loading...

Loading...