Omega Products CN2204 Installation Manual

Installation and Operation Handbook Contents

MODELS CN2208 and CN2204

TEMPERATURE CONTROLLERS

INSTALLATION AND OPERATION HANDBOOK

Contents Page

Chapter 1 OPERATION................................................................1-1

Chapter 2 INSTALLATION...........................................................2-1

Chapter 3 ACCESS LEVELS.......................................................3-1

Chapter 4 TUNING.......................................................................4-1

Chapter 5 CONFIGURATION.......................................................5-1

Chapter 6 USER CALIBRATION.................................................6-1

Chapter 7 ALARM CONFIGURATION.........................................7-1

Appendix A UNDERSTANDING THE ORDERING ....................... A-1

Appendix B SAFETY & EMC INFORMATION ...............................B-1

TECHNICAL SPECIFICATION ...................................B-5

Issue 1; February 1999 Applies to CN2204 and CN2208 controller software version 3.0 i

Installation and Operation Handbook Operation

Chapter 1 OPERATION

CONTENTS PAGE

Front Panel Layouts............................................................................ 1-2

Getting Started .................................................................................... 1-4

Navigation Diagram .......................................................................... 1-10

Parameter Tables .............................................................................. 1-12

Setting Alarm Levels......................................................................... 1-17

Diagnostic Alarms ............................................................................ 1-18

CN2208 and CN2204 Controller 1-1

Operation Installation and Operation Handbook

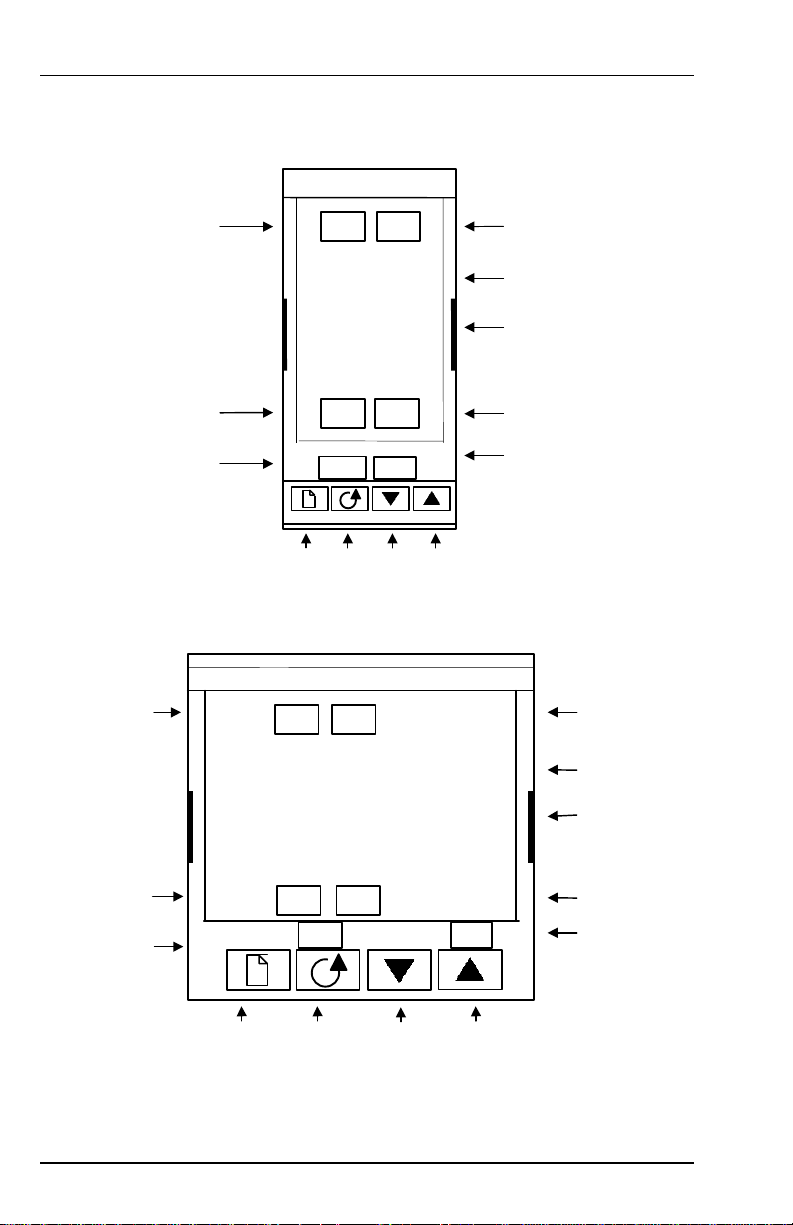

PDLINK Remote Setpoint

Button

Setpoint rate limit active

MAN

RUN

Upper readout

Button

Button

limit active

FRONT PANEL LAYOUT

CN2208

Output 1

Setpoint 2 active

Manual mode

Output 1

OP1 OP2

200.0

200.0

REM

SP2

Scroll

Button

OP2

Down

Button

Page

Button

Fig 1-1 Model CN2208 front panel layout

OP1

Up

CN2204

200.0

Output 2

Upper readout

Lower readout

Output 2

200.0

Setpoint 2

active

Manual mode

Page

Fig 1-2 Model CN2204 front panel layout

1-2 CN2208 and CN2204 Controller

SP2

Scroll

Button

REM

Down

Button

RUNMAN

Up

Lower readout

Remote Setpoint

Setpoint rate

Installation and Operation Handbook Operation

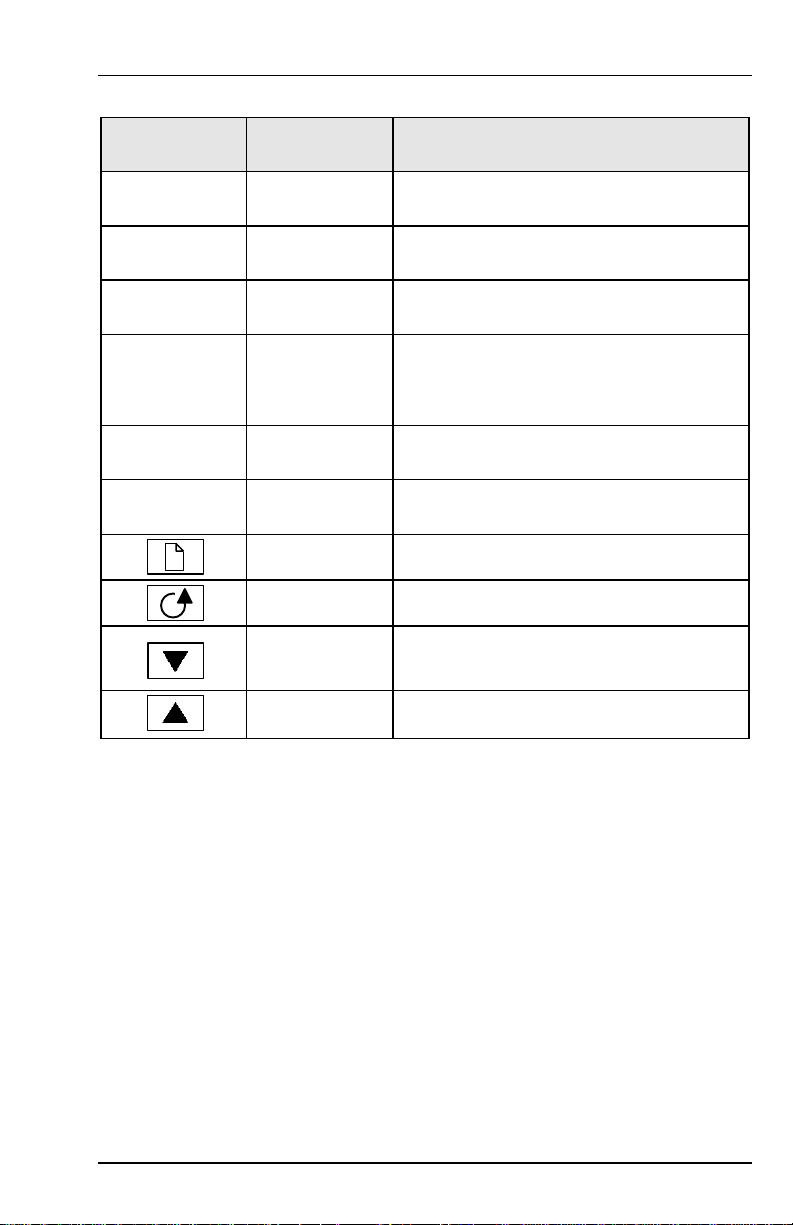

Button or

indicator

OP1 Output 1

OP2 Output 2

SP2 Setpoint 2

REM Remote Setpoint

MAN Manual light

RUN Run light

Name Explanation

Page button Press to select a new list of parameters.

Scroll button Press to select a new parameter in a list.

Down button Press to decrease a value in the lower

When lit, it indicates that output 1 is on. This

is normally the heating output.

When lit, it indicates that output 2 is on. This

is normally the cooling output.

When lit, this indicates that Setpoint 2 has

been selected.

When lit, this indicates that the PDLINK

remote Setpoint input has been selected.

‘REM’ is also used to indicate that user

comms is active.

When lit, it indicates that manual mode has

been selected

When lit, it indicates that Setpoint rate limit is

active.

readout.

Up button Press to increase a value in lower readout.

Figure 1.3 Controller buttons and indicators

CN2208 and CN2204 Controller 1-3

Operation Installation and Operation Handbook

OP1

OP2

G

H

OP1

OP2

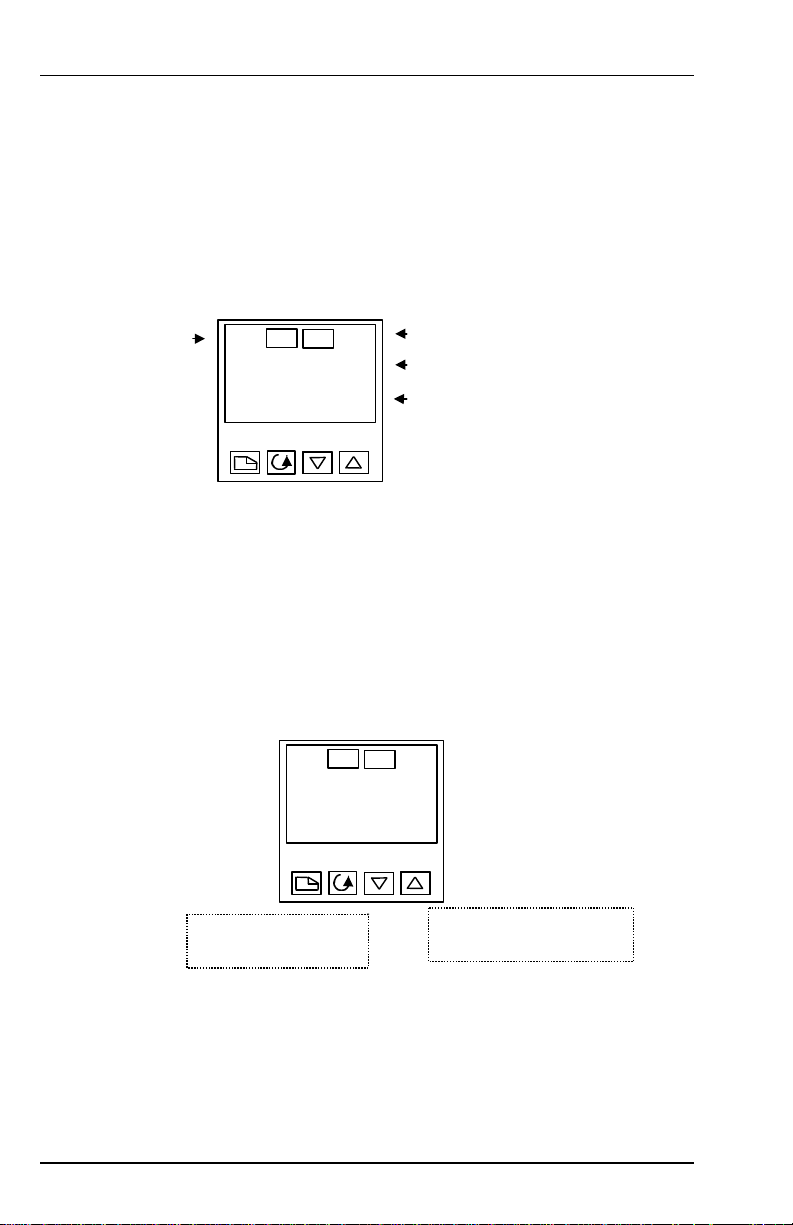

GETTING STARTED

Thank you for selecting the OMEGA CN2208/CN2204 controller.

This section shows the principle of operation.

VIEWING THE PROCESS VALUE and SETPOINT

Install and wire up the controller in accordance with Chapter 2 and switch on.

Following a 3-second self-test sequence, this is the display you will see:

Output 1

20.0

23.0

NOTE

**

TO ADJUST THE SETPOINT

The display may flash an alarm message. Refer to the Parameter Tables later

in this chapter for a complete list and meaning of the messages.

Fig. 1.4 The “Home Display”

Output 2

Actual Temperature (Process Value)

Required Temperature (Setpoint)

20.0

140.0

Press and hold to

decrease temperature

Fig 1.5 The lower readout shows the setpoint

After 2 secs the lower readout will ‘blink’ indicating that the new value has been

accepted. For everyday use you may not need to do anymore than this.

1-4 CN2208 and CN2204 Controller

Press and hold to

increase temperature

Installation and Operation Handbook Operation

No units - Linear Inputs

VIEWING THE DISPLAY UNITS

0.5 sec.

23.0 23.0

23.0

o

C

Display Units

oo

CC Degrees Centigrade

oo

FF Degrees Fahrenheit

oo

KK Degrees Kelvin

140.0140.0

Momentarily

press either

G

NOTE

**

G

If you get lost, pressing and together will return you to the Home

display

Fig. 1.6 Pressing or will flash the display units for 0.05 sec.

button

USE OF THE “SCROLL” BUTTON

Pressing the scroll button will display the output power level. Continued

pressing will display further parameters in what is referred to as the operator

scroll list.

2nd press

OPOP

100.0100.0

Output

Actual output level %

CN2208 and CN2204 Controller 1-5

3rd press

m-A m-A

AutoAuto

Keep pressing to return to

Home display or select further

parameters (if available)

Fig. 1.7 Upper readout is parameter name. Lower is value

Manual/Auto

Actual state

Operation Installation and Operation Handbook

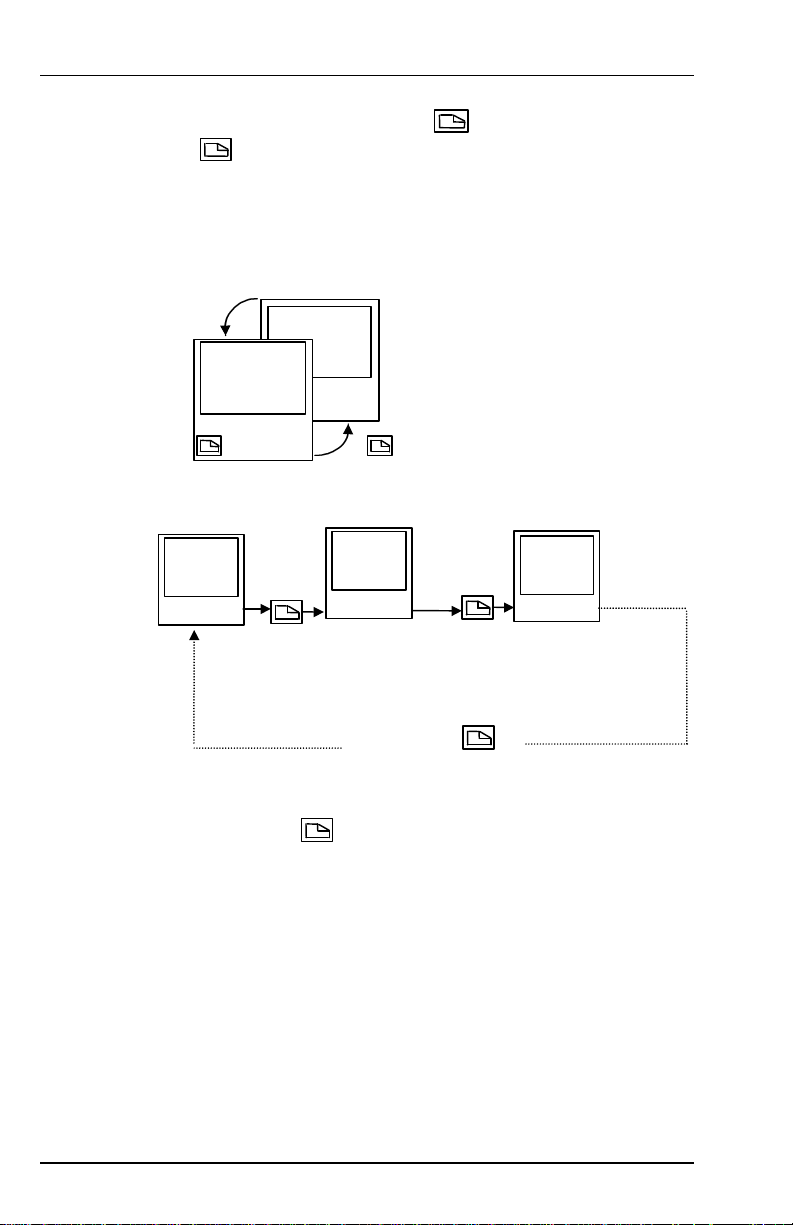

USE OF THE PAGE BUTTON

The “PAGE” button accesses parameter LISTS

Parameters are settings in the instrument which, generally, can be changed by the user to

suit the process. Examples are: Alarms, Self-Tune, etc. They are found under headings

called LISTS and a full set is given later in this chapter.

0.5 sec.

23.0 23.0

o o

23.0 23.0

140.0140.0

CC

1st press

NOTE

**

23.0 23.0

14.0.014.0.0

2nd press

Fig 1.8 Press to choose a parameter list

The actual list headings may be longer or shorter than indicated above and

you can customize this for the operator’s convenience in EDIT level,

Chapter 3.

ALAL

LiStLiSt

3rd press

Keep pressing to

select more list headings and

continue around a continuous loop

atunatun

LiStLiSt

1-6 CN2208 and CN2204 Controller

Installation and Operation Handbook Operation

G

button

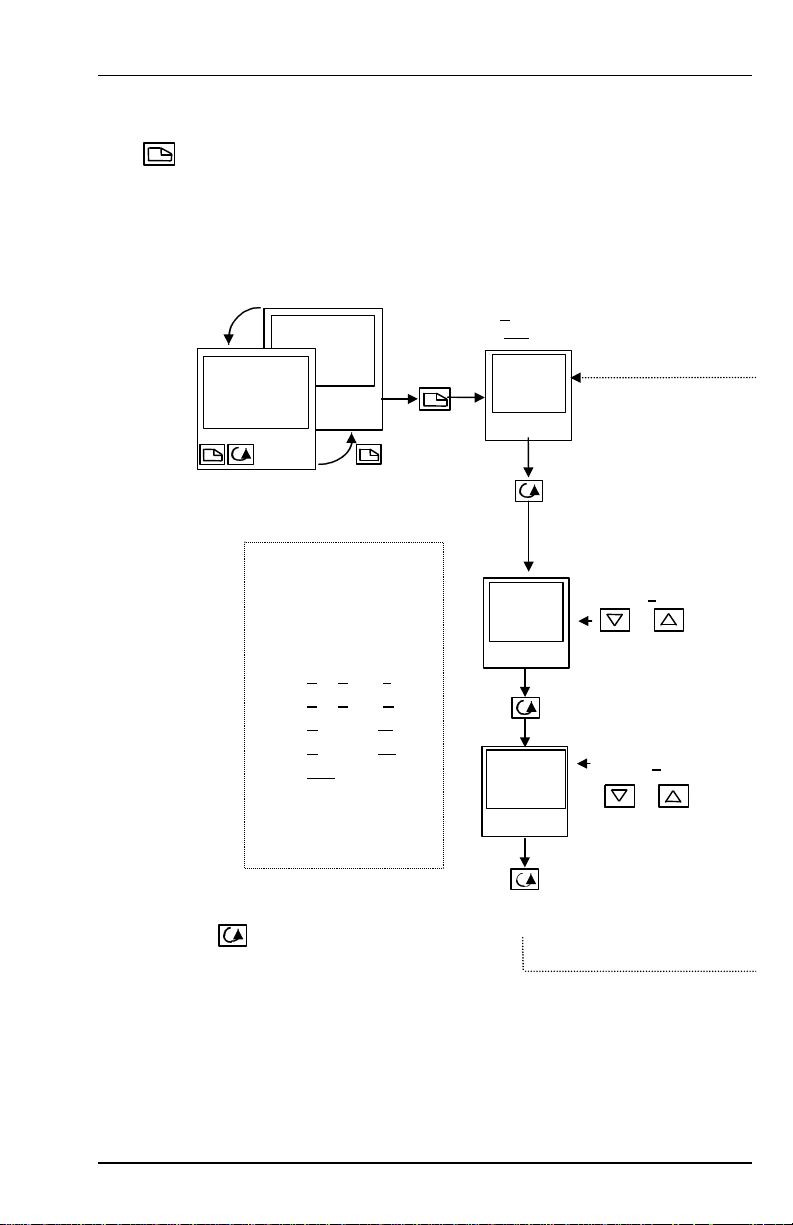

PARAMETER LISTS

Press to choose a LIST - “ALARMS” is a good one. This list allows you to set the

alarm trip levels. The parameters, which appear in the list, will vary according to the

configuration of your controller.

0.5 sec.

23.023.0

o o

23.0

CC

140.0

1st press

Fig. 1.9a Choose a list

There are 4 alarms in the

controller. The first

character is the alarm

number. The following

three letters indicate the

alarm type as follows:

-FSL-FSL Full Scale Low

-FSH-FSH Full Scale High

-dHi-dHi Deviation High

-dLo-dLo Deviation Low

-dEv-dEv Deviation Band

Disabled alarms will not

be displayed.

Chapter 7 gives a full

description of alarms.

Fig. 1.9b Press to select a parameter

Alarm

2nd press

List

ALAL

LiStLiSt

Now press

the SCROLL

1---1---

50.050.0

2---2---

200.0200.0

Keep pressing

1. to scroll through further parameters

2. to return to list header

Alarm 1

or to

change trip level

2nd press

Alarm 2

or to

change trip level

NOTE

If, at any time, no key is pressed within 45 seconds, the display will always

return to the “HOME” display.

**

CN2208 and CN2204 Controller 1-7

Operation Installation and Operation Handbook

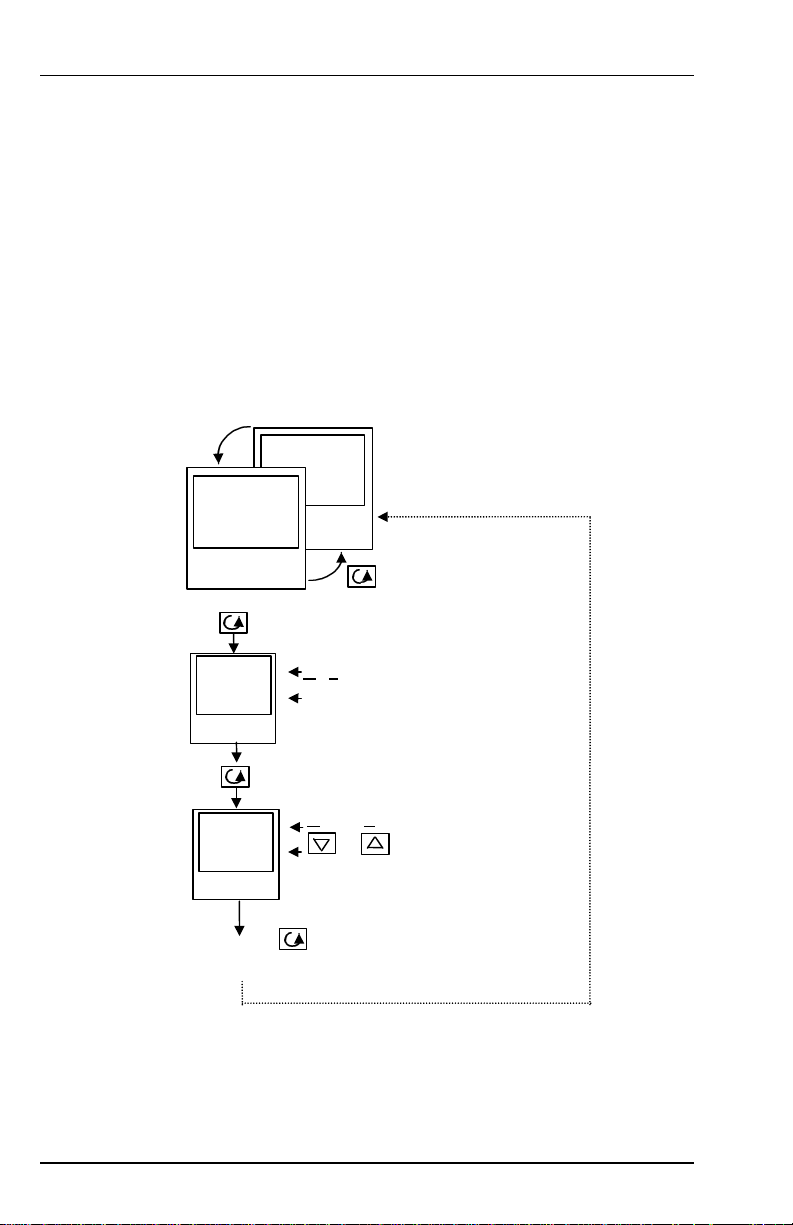

OPERATING MODES

The controller can be used in two modes:

Automatic mode - in which the output power is automatically adjusted to hold the

temperature at the required value. The controller normally operates in this mode.

Manual mode - in which the output is manually adjusted by the Operator. In this mode

the ‘MAN’ light will be on.

One other mode is available:

Remote setpoint - The setpoint is generated as an input signal from a master 2000 series

controller. In this mode the REM light is on.

AUTO or MANUAL SELECT

0.5 sec.

23.023.0

o o

23.0 23.0

CC

140.0140.0

1st press

2nd press

OP OP

100.0100.0

m-A m-A

Output

Actual output level %

3rd press

Manual/Auto

or to select

mAnmAn

AutoAuto automatic mode

ManMan manual mode

Keep pressing

to return to “HOME”

display

Fig. 1.10 Auto/manual select

1-8 CN2208 and CN2204 Controller

Installation and Operation Handbook Operation

OP1

OP2

MAN

G

H

**

MANUAL ADJUSTMENT OF OUTPUT POWER

23.0 23.0

50.050.0

Press and hold to

decrease power

Fig. 1.11 The “Home Display” in manual mode

NOTE

SUMMARY

To step through list headers, press the Page button until the required header is

obtained

To step through parameters within a particular list, press the Scroll button until the

required parameter is obtained

To change the value (or state) of a parameter, press the Raise button or the Lower

button

Manual mode is generally used for test and commissioning purposes, take

care not to leave the controller in this mode since damage or personal

injury could occur.

Actual Temperature (Process Value)

Output Power Demand

Manual Indicator on

Press and hold to

increase power

The remainder of this chapter provides a complete list of all parameters available.

CN2208 and CN2204 Controller 1-9

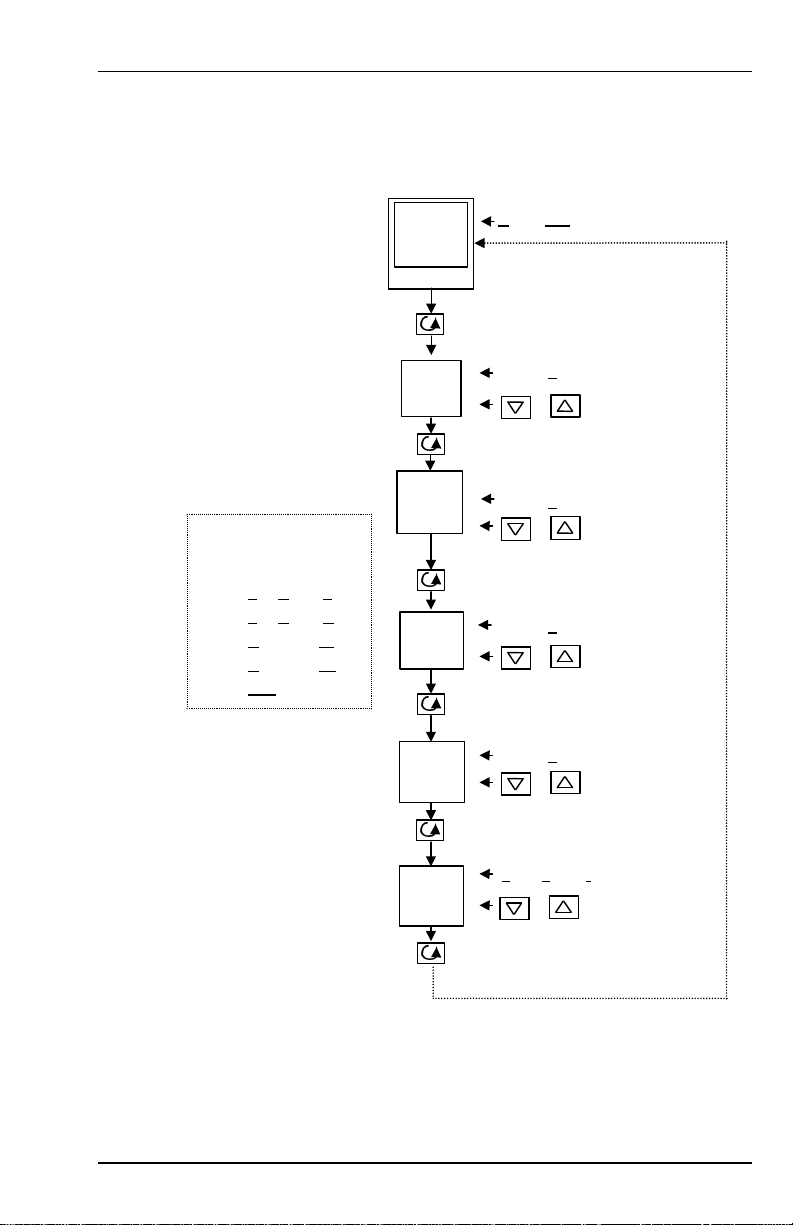

Operation Installation and Operation Handbook

(1)

List

List

List

2

2

2

2

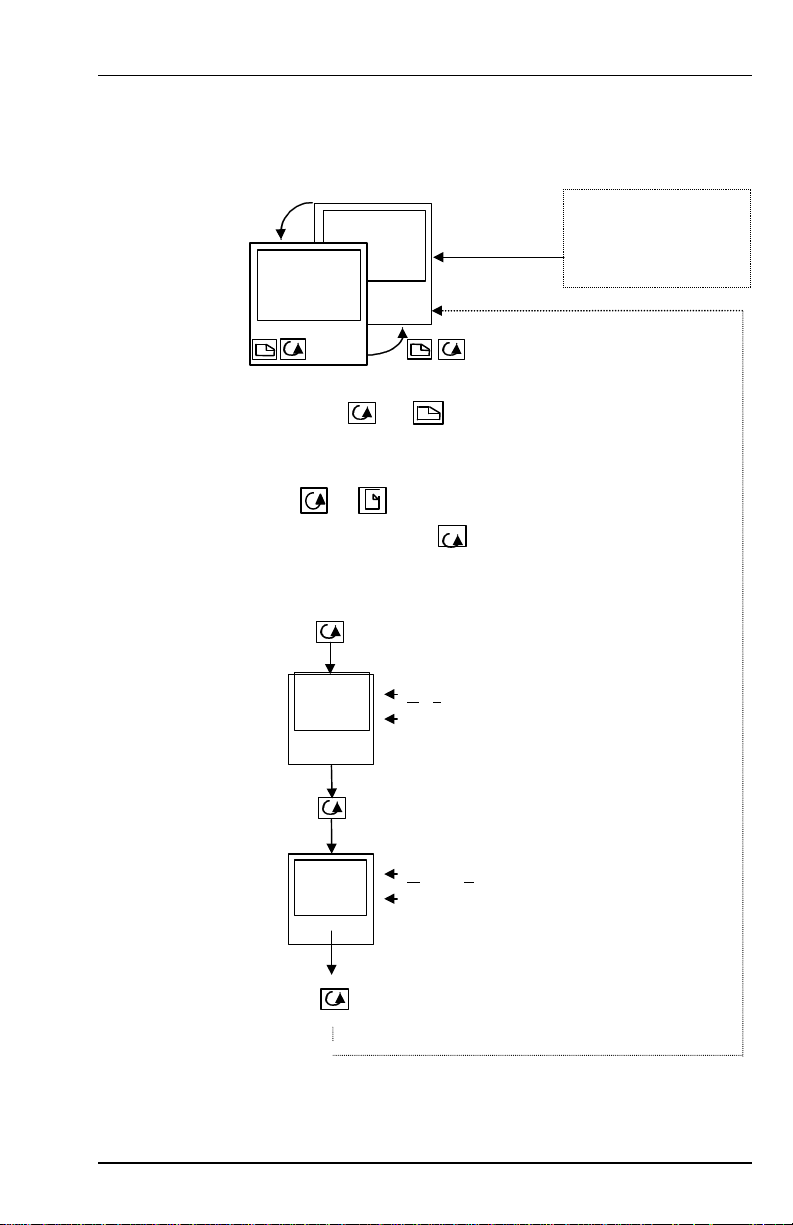

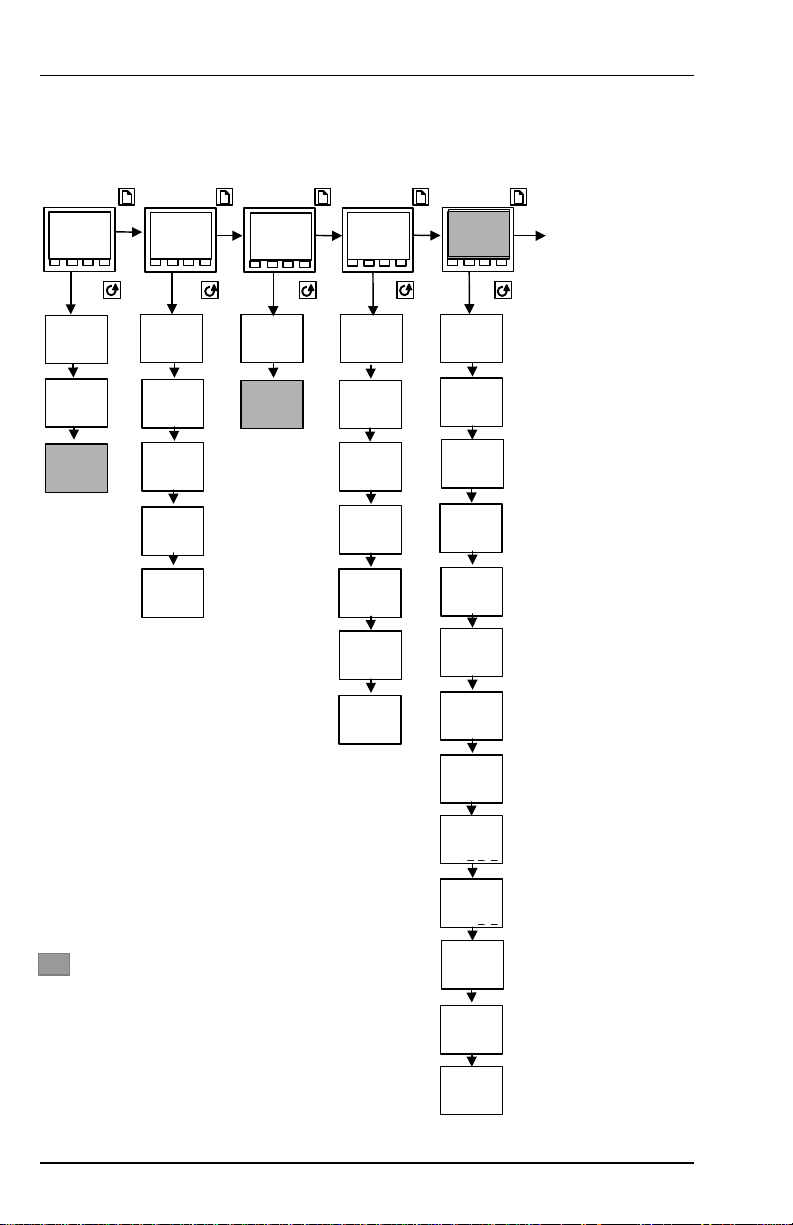

NAVIGATION DIAGRAM (Part A)

Alarm

AL AL

LiStLiSt

1---

100.0

2---

20.00

3---

Autotune

AtunAtun

LiStLiSt

TunE

OFF

Adc

mAn

0

Home

List

20.020.0

20.020.0

OP

100.0

AmPS

5

m-A

Auto

4---

0

Lbt

OFF

The navigation diagram shows a full

list of possible parameters.

However, some may not appear

because they are dependent upon

the particular controller variant.

PID

PidPid

LiStLiSt

Pb

50

Ti

300

td

50.0

RES

0.0

Lcb

Auto

Hcb

Auto

REL.C

1.00

Setpoint

List

SPSP

LiStLiSt

SSEL

SP 1

L-r

Loc

SP 1

20.0

SP 2

0.0

Rm.SP

0.0

Loc.t

0.0

SP1.L

3

Notes:

1. Either the PID list or the On/Off list will be

present depending upon the type of control in

use.

2. The last three characters depend upon the type

of alarm configured

3. Absolute setpoint limits are set in configuration,

see Chapter 5.

The shaded boxes are normally hidden in

Operator level. To see all the available

parameters you must select Full level. See

Chapter 3, Access Levels.

Figure 1.12a Navigation diagram

1-10 CN2208 and CN2204 Controller

SP1.H

SP2.L

SP2.H

Loc.L

100.0

Loc.H

0.0

SPrr

OFF

3

3

3

Installation and Operation Handbook Operation

List

Display

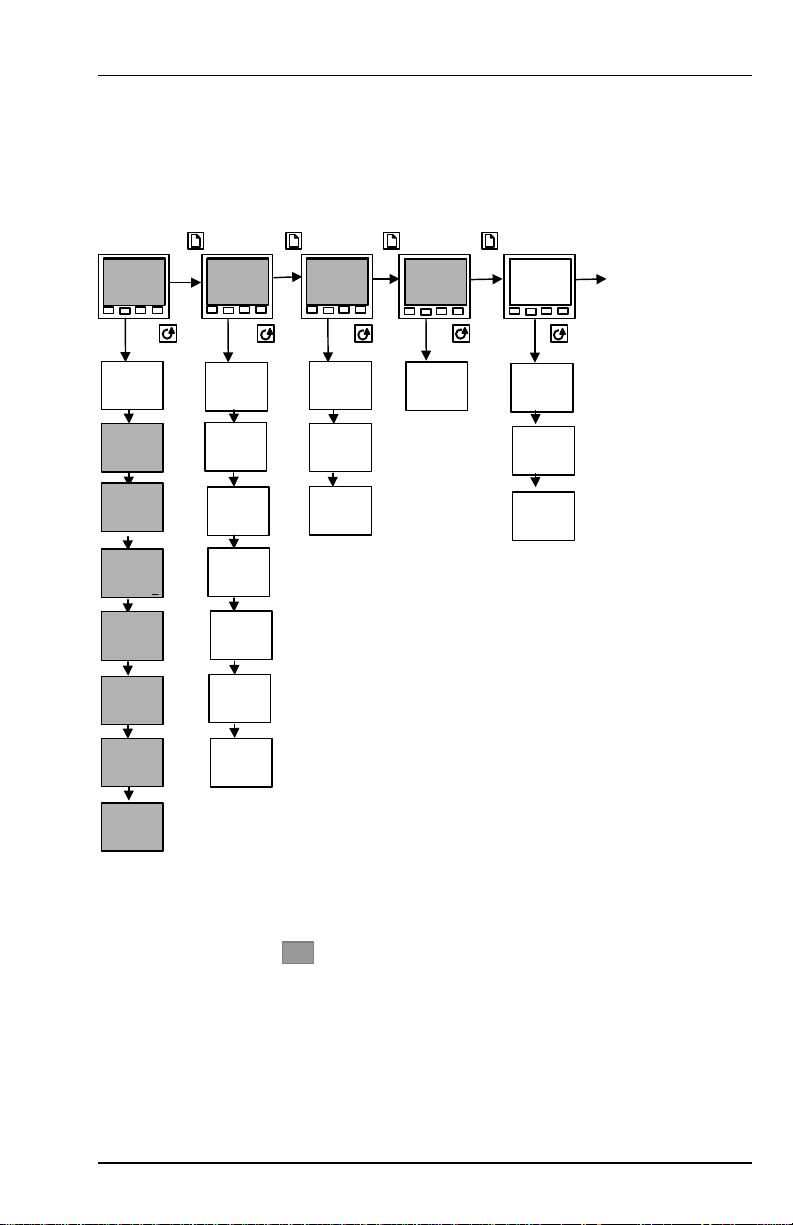

NAVIGATION DIAGRAM (PART B)

Input

iP

LiSt

FiLt

CAL

FACT

CAL.L

Adj.L

CAL.H

Adj.H

CJC

21.0

1.0

no

no

Output

List

oP

LiSt

OP.Lo

100.0

OP.Hi

0.0

Sb.OP

100.0

4

CYC.H

20.0

On Off

(1)

List

OnOF

LiSt

hYS.H

1.0

hYS.C

1.0

HC.db

0.0

Comms

List

CmS

LiSt

Addr

Access

List

ACCS

LiSt

coDE

1

PASS

Goto

OPEr

ConF

Return to

“HOME”

0

CYC.C

5.0

4

Ont.H

1.0

Ont.C

1.0

MV

1.17

Note:

4. Beware! Used for calibration. See Chapter 6.

The shaded boxes are normally hidden in

Operator level. To see all the available

parameters you must select Full level. See

Chapter 3, Access Levels.

Figure 1.12b Navigation diagram

CN2208 and CN2204 Controller 1-11

Operation Installation and Operation Handbook

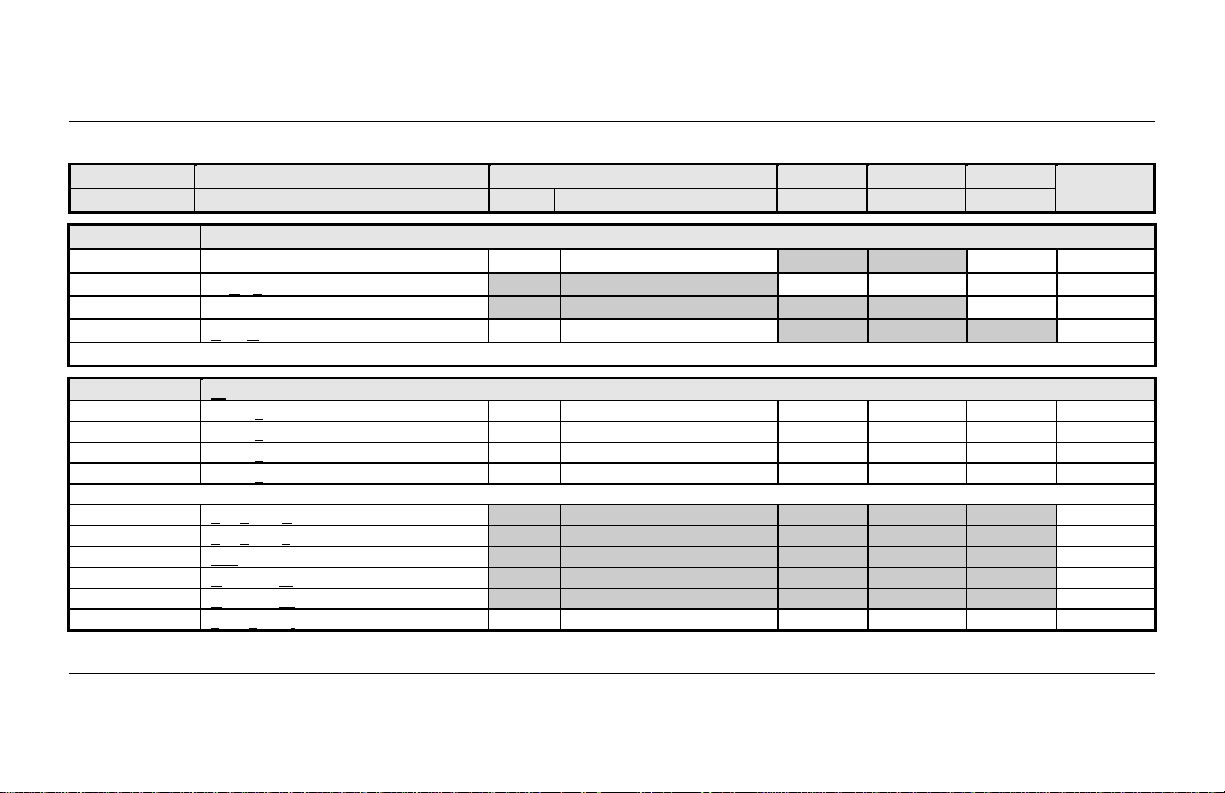

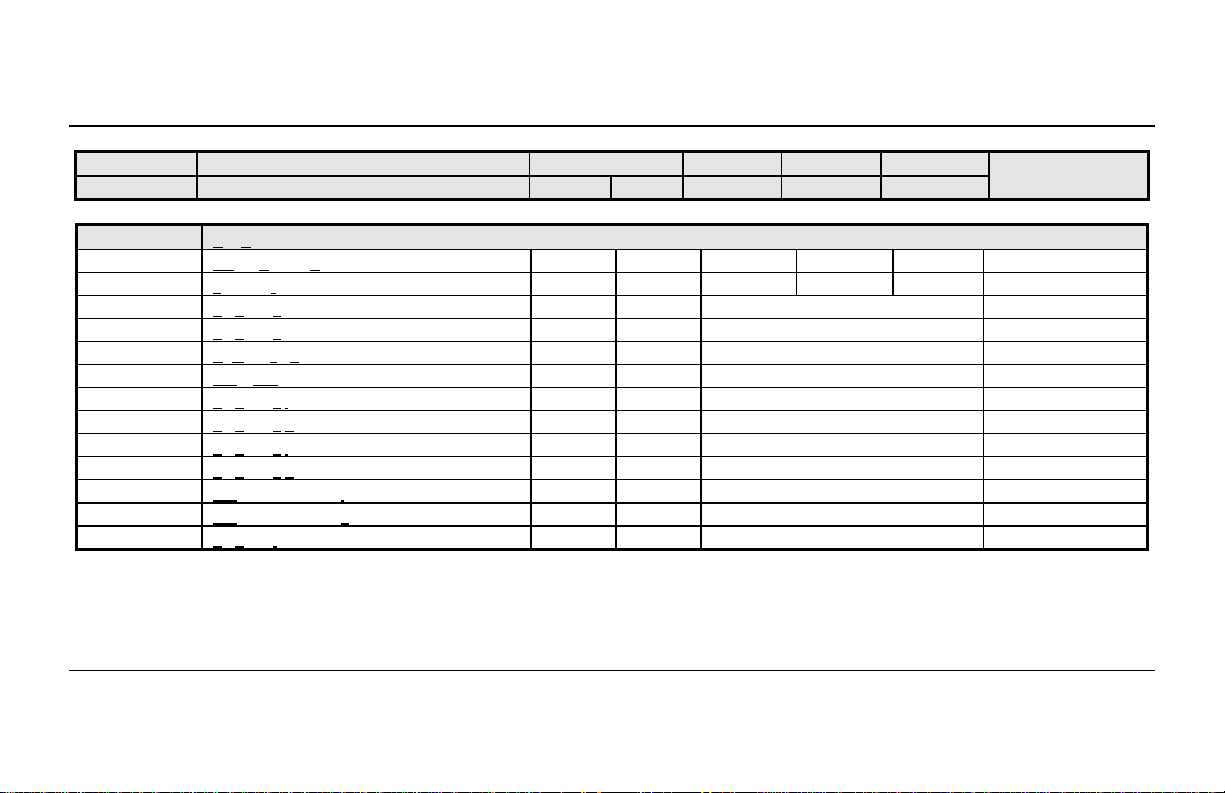

PARAMETER TABLES

Name Parameter Description Default Value Minimum Maximum Units

UK USA Value Value

Home List

Home Measured Value and Setpoint (SP)

OP

AmPS

m-A

Additional parameters may appear in the Home display if the ‘promote’ feature has been used (see Edit Level, Chapter 3).

ALAL

1--2--3--4---

In place of dashes, the last three characters indicate the alarm type, as follows:

-FSH

-FSL

-DEv

-dHi

-dLo

Lbt

% Output Level

Heater current (PDLINK mode 2) Amps

Auto/manual select

Alarm List

Alarm 1 setpoint value

Alarm 2 setpoint value

Alarm 3 setpoint value

Alarm 4 setpoint value

Full Scale High alarm 800

Full Scale Low alarm 32

Deviation band alarm 31

Deviation High alarm 31

Deviation Low alarm 31

Loop break time

SP=25 SP=78

0.00 100.00

Auto Auto

0 Per Alarm See Below 0 9999

0 Per Alarm See Below 0 9999

0 Per Alarm See Below 0 9999

0 Per Alarm See Below 0 9999

OFF OFF 0 9999

as display

%

as display

as display

as display

as display

secs

Customer

Setting

1-12 CN2208 and CN2204 Controller

Installation and Operation Handbook Operation

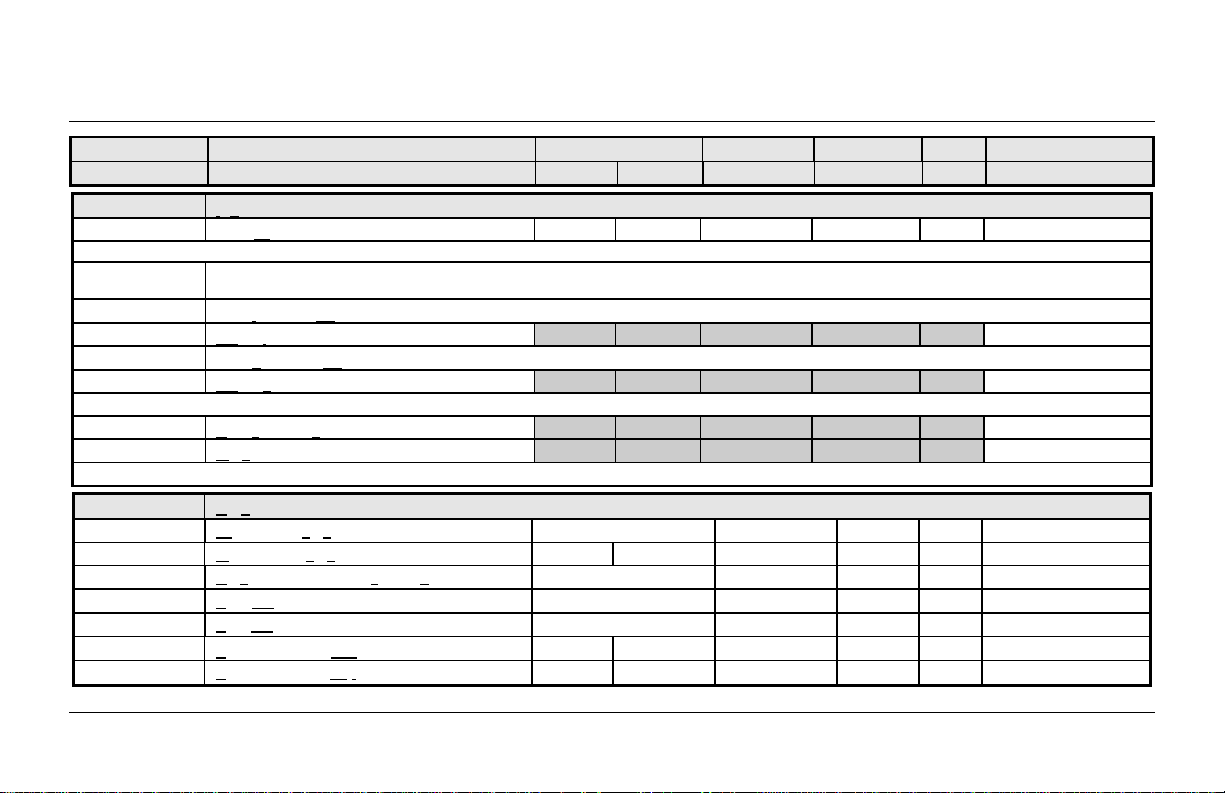

Name Parameter Description Default Value Minimum Maximum Units

UK USA Value Value

AtunAtun

tunE

Adc

PidPid

Pb

ti

td

rES

Lcb

Hcb

rEL.C

Autotune List

Self tune enable

Automatic droop compensation (Manual

Reset) enable (only present if ti set to OFF

PID List

Proportional band

Integral time

Derivative time

Manual reset (appears when ti set to OFF)

Cutback low

Cutback high

Relative cool gain (set 1)

OFF OFF OFF ON

MAN MAN MAN CALC

20.0 46 0.0 9999

360 360 OFF 9999

60 60 OFF 9999

0.0 0.0 0.00 100.0

Auto Auto 0 9999

Auto Auto 0 9999

1.00 1.00 0.01 9.99

as display

seconds

seconds

%

as display

as display

Customer Setting

CN2208 and CN2204 Controller 1-13

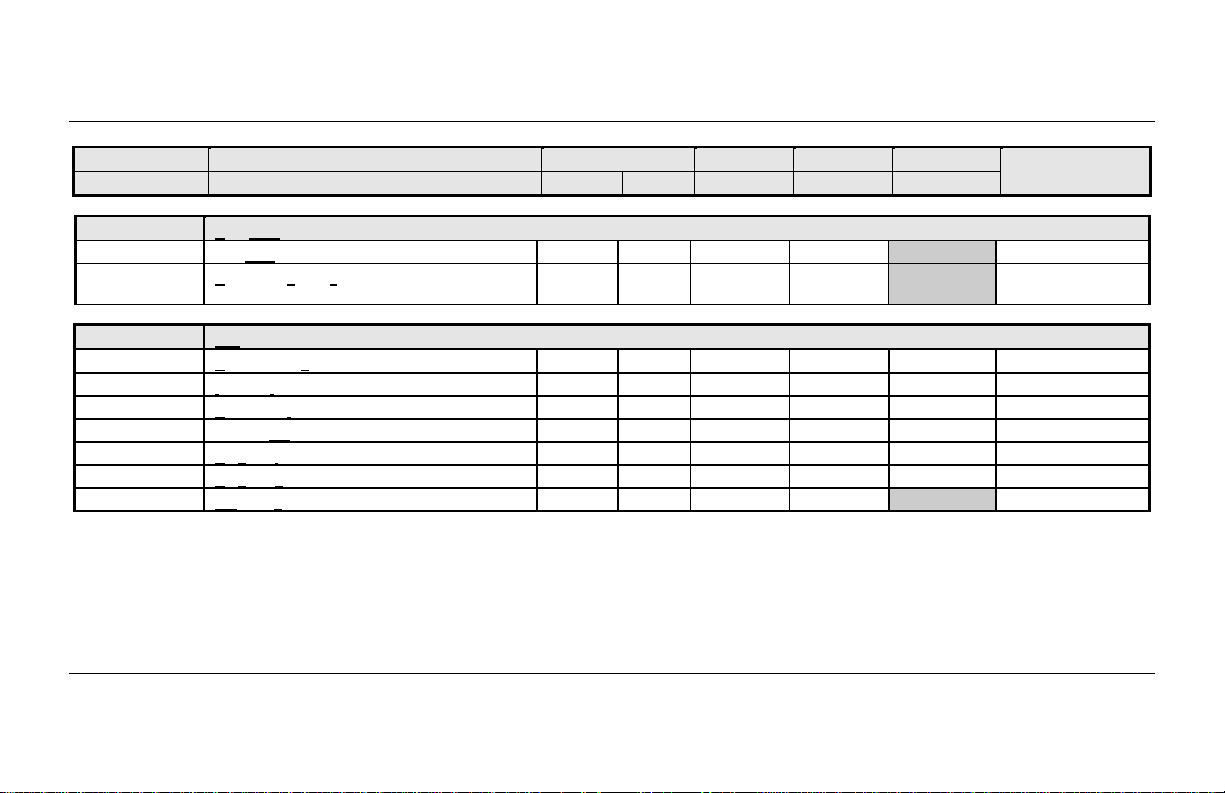

Operation Installation and Operation Handbook

Name Parameter Description Default Value Minimum Maximum Units

UK USA Value Value

SPSP

SSEL

L-r

SP1

SP2

rm.SP

Loc.t

SP1.L

SP1.H

SP2.L

SP2.H

Loc.L

Loc.H

SPrr

Set Point List

Select SP1 or SP2

Local or remote setpoint select *

Setpoint 1 value

Setpoint 2 value

Remote setpoint

Local trim

Setpoint 1 low limit

Setpoint 1 high limit

Setpoint 2 low limit

Setpoint 2 high limit

Local setpoint trim low limit

Local setpoint trim high limit

Setpoint rate limit

SP1 SP1 SP1 SP2

Loc Loc Loc rmt

25

25

0

0

0

1000

0

1000

-210

1200

OFF

78 As display range

78 As display range

32 As display range

0 As display range

32 As display range

800 As display range

32 As display range

800 As display range

-340 As display range

2192 As display range

OFF As display range

Customer Setting

* Only appears if PDLINK fitted and configured in the HA comms slot.

1-14 CN2208 and CN2204 Controller

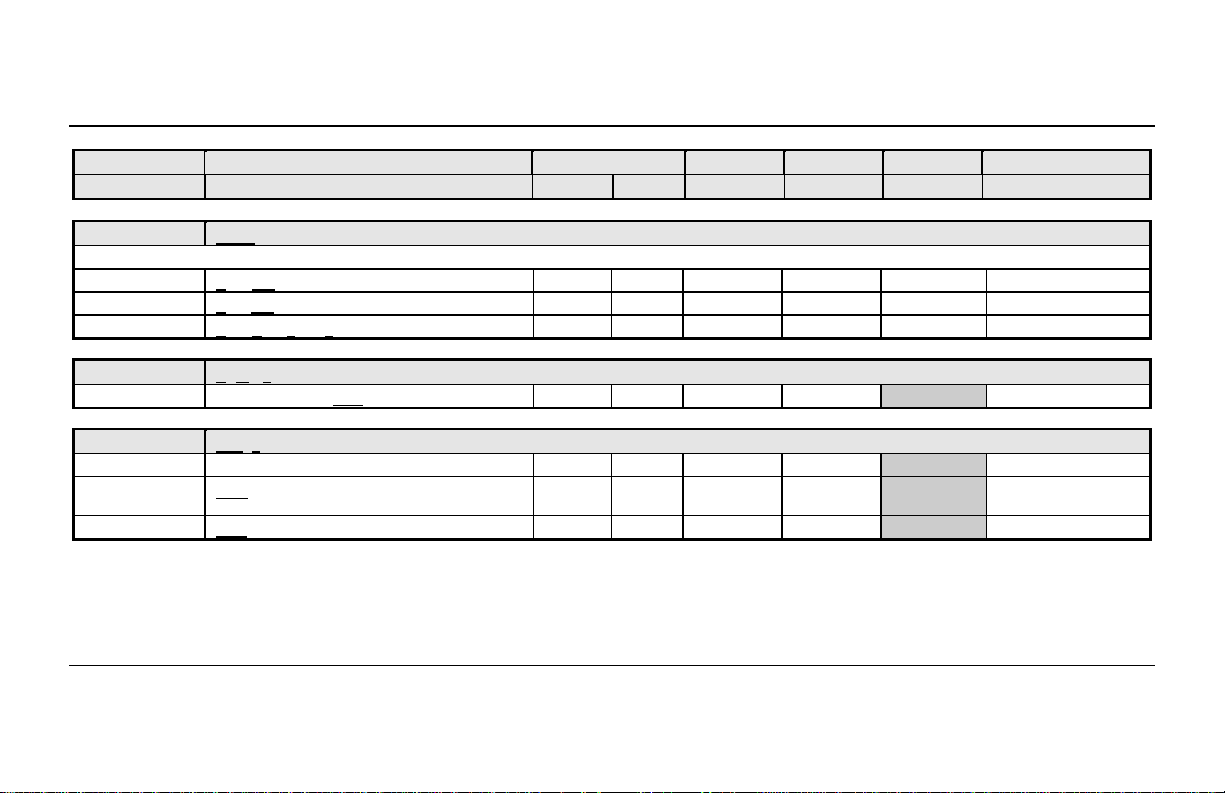

Installation and Operation Handbook Operation

Name Parameter Description Default Value Minimum Maximum Units Customer Settings

UK USA Value Value

iPiP

FiLt

Input list

Input filter time constant

1.6 1.6 1.0 999.9

secs

The next 5 parameters will appear if User calibration has been enabled in configuration level. To perform a user calibration, refer to Ch 6.

CAL

FACt will re-instate factory settings and disable User Calibration. Default setting FACt

USEr will re-instate any previously set User Calibration offsets and make available User Calibration parameters as follows:

CAL.L User low point calibration if YES allows access to next parameter. if no the next parameter is hidden

AdJ.L

*

Adjust low point to calibrated ref. source

CAL.H User high point calibration if YES allows access to the next parameter if no the next parameter is hidden

AdJ.H

*

Adjust high point to calibrated ref. source

The following two parameters are always present in Full Access level but not in Operator level

o

CJC

mV

*

Do not make adjustments to the AdJ.L or AdJ.H parameters unless you wish to offset the controller calibration

Cold Junction compensation temperature

Millivolt input

oPoP Output list Note; If On/Off control is configured only Sb.OP, ont.H and ont.C will appear in the following list

OP.Lo

OP.Hi

Sb.OP

CYC.H

CYC.C

ont.H

ont.C

Low (power) output limit

High (power) output limit

Output setting when in sensor break

Heat cycle time

Cool cycle time

Heat output min. on time

Cool output min. on time

0.0 or -100.0 (cool) -100.0 100.0

100.0 100.0 -100.0 100.0

0.0 or -100.0 (cool) -100.0 100.0

1.0 (dc pulse) 20 (relay) 0.2 999.9

1.0 (dc pulse) 20 (relay) 0.2 999.9

0.1 0.1 Auto (50mS) 1.0

0.1 0.5 Auto (50mS) 1.0

%

%

%

secs

secs

mins

mins

CN2208 and CN2204 Controller 1-15

Operation Installation and Operation Handbook

Name Parameter Description Default Value Minimum Maximum Units Customer Settings

UK USA Value Value

OnOfOnOf

This set of parameters only appear if On/Off control has been configured

hYS.H

hYS.C

HC.db

cmScmS

Addr

ACCSACCS

codE

Goto Goto level -OPEr,FuLL,Edit,or

ConF

On/off list

Heat hysteresis

Cool hysteresis

Heat/Cool dead band

Comms list

Communications address

Access list

Full and Edit level password

conF

Configuration level password

0 0 0 9999

0 0 0 9999

1 1 0 9999

1 1 1 254

1 1 0 9999

OPEr OPEr OPEr conF

2 2 0 9999

as display

as display

as display

1-16 CN2208 and CN2204 Controller

Installation and Operation Handbook Operation

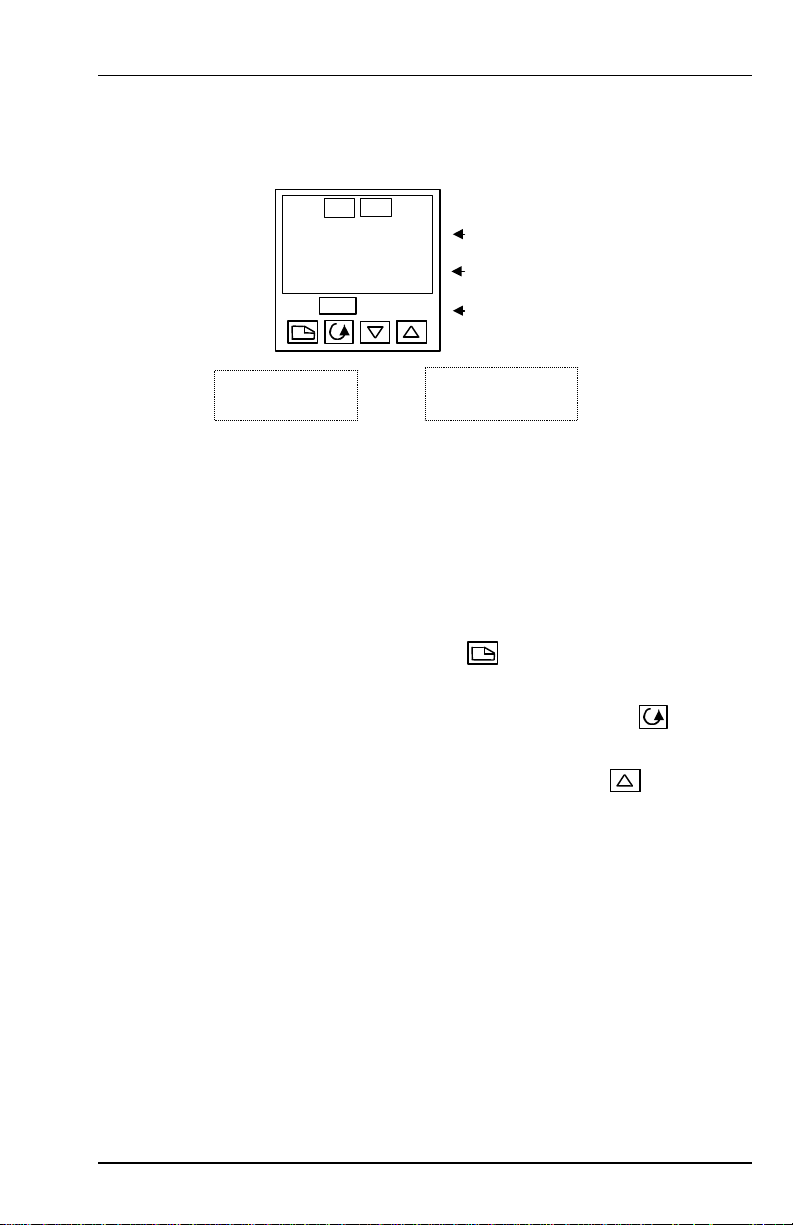

SETTING ALARM LEVELS

Up to 4 Alarms may be configured. Each alarm is given a name to describe its function see table below. If an alarm is not used it does not appear in the list below.

In place of dashes,

letters indicate alarm

type as follows:

-FSL Full S

-FSH Full Scale High

-dHi Deviation High

-dLo Deviation Low

-dEv Deviation Band

cale Low

ALAL

LiStLiSt

1--1-100100

2---2---

200200

3---3---

4---4---

00

00

Alarm List

Alarm 1

or to change

2nd press

Alarm 2

or to change

3rd press

Alarm 3

or to change

4th press

Alarm 4

or to change

5th press

Lb tLb t

OFFOFF

Press to return

to list header

CN2208 and CN2204 Controller 1-17

Loop break time

or to change

Operation Installation and Operation Handbook

Diagnostic alarms

These indicate that a fault exists in either the controller or the connected devices.

Table 1.1a Diagnostic alarms

Display

shows

EE.Er

S.br

L.br

Ld.F

SSr.F

What it means What to do about it

Electrically Erasable

Memory Error:

The value of an operator

or configuration

parameter has been

corrupted.

Sensor Break:

Input sensor is unreliable

or the input signal is out

of range.

Loop Break:

The feedback loop is

open circuit.

Load failure

Indication that there is a

fault in the heating circuit

or the solid state relay.

Solid state relay failure

Indication that there is a

fault in the solid state

relay

This fault will automatically take you into

configuration level. Check all of the

configuration parameters before returning to

operator level. Once in operator level, check

all of the operator parameters before

resuming normal operation. If the fault

persists or occurs frequently, contact Omega

Engineering, Inc.

Check that the sensor is correctly connected.

Check that the heating and cooling circuits

are working properly.

This is an alarm generated by feedback from

a Omega SSC-TE10S solid state relay (SSR)

operating in PDLINK mode 1-see Electrical

installation Chapter 2. It indicates either an

open or short circuit SSR, blown fuse, missing

supply or open circuit heater.

This is an alarm generated by feedback from

a Omega SSC-TE10S solid state relay (SSR)

operating in PDLINK mode 2 -see Electrical

installation Chapter 2. It indicates either an

open or short circuit condition in the SSR.

Htr.F

HW.Er

1-18 CN2208 and CN2204 Controller

Heater failure

Indication that there is a

fault in heating circuit

Hardware error

Indication that a module

is of the wrong type,

missing or faulty

This is an alarm generated by feedback from

a Omega SSC-TE10S solid state relay (SSR)

operating in PDLINK mode 2 -see Electrical

installation Chapter 2. It indicates either a

blown fuse, missing supply or open circuit

heater.

Check that the correct modules are fitted.

Installation and Operation Handbook Operation

Diagnostic alarms continued

These indicate that a fault exists in either the controller or the connected devices.

Table 1.1b Diagnostic alarms

Display

shows

rmt.F

LLLL

HHHH

Err1

Err2

Err3

Err4

Err5

Pwr.F

What it means What to do about it

Remote input failure. The

PDLINK input is open

circuit

Out of Display range, low

reading

Out of Display range, high

reading

Error 1: ROM self-test fail

Error 2: RAM self-test fail

Error 3: Watchdog fail

Error 4: Keyboard failure

Stuck buttons, or a button

was pressed during power

up.

Error 5: Input circuit failure

Power failure. The line

voltage is too low

Check for open or short circuit wiring on the

PDLINK input

Check the value of the display range

Check the value of the display range

Return the controller for repair

Return the controller for repair

Return the controller for repair

Switch the power off and then on without

touching any of the controller buttons.

Return the controller for repair

Check that the supply to the controller is

within the rated limits

CN2208 and CN2204 Controller 1-19

Installation and Operation Handbook Installation

8

3

7

8

4

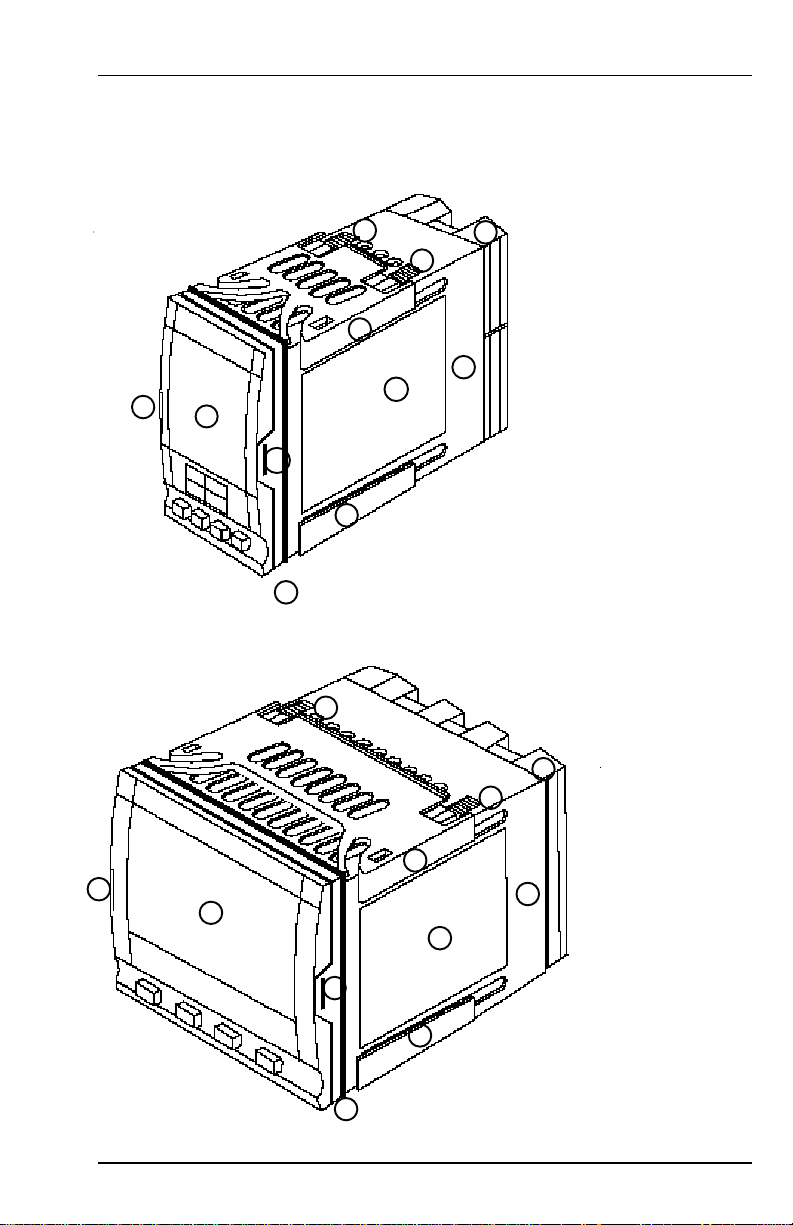

Chapter 2 INSTALLATION

8

6

2

1

2

Figure 2-1 CN2208 1/8 DIN controller

5

KEY

1. Display screen

2. Latching ears

3. Panel sealing gasket

4. Panel retaining clips

5. Label

6. Sleeve

7. Terminal covers

8. Ratchets

7

8

4

2

6

1

5

2

4

3

Figure 2-2 CN2404 ¼ DIN controller

CN2208 and CN2204 Controller 2-1

Loading...

Loading...