Omega Products CN2120 Installation Manual

OMEGAnet® On-Line Service

www.omega.com

ServicingServicing

Servicing

ServicingServicing

North America:North America:

North America:

North America:North America:

USA:

ISO 9001 Certified

One Omega Drive, Box 4047

Stamford CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Internet e-mail

info@omega.com

For immediate technical orFor immediate technical or

For immediate technical or

For immediate technical orFor immediate technical or

application assistance:application assistance:

application assistance:

application assistance:application assistance:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico:

En Español: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

®

®

®

Servicing Europe:Servicing Europe:

Servicing Europe:

Benelux:

Postbus 8034, 1180 LA Amstelveen

The Netherlands

Tel: (31) 20 3472121 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic:

Frystatska 184, 733 01 Karviná, Czech Republic

Tel:+420(0)59 6311899 FAX:+420(0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to

the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification. The information contained in this document

is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA,

PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO

AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence. The

purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the following information

available BEFORE contacting OMEGA:

1.Purchase Order number under which the product was PURCHASED,

2.Model and serial number of the product under warranty, and

3.Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2003 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any

electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

France:

11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: 49 (0)7056 9398-0 FAX: 49 (0)7056 9398-29

Toll Free in Germany: 0800 82 66342

e-mail: info@omega.de

Servicing Europe:Servicing Europe:

RETURN REQUESTS / INQUIRIESRETURN REQUESTS / INQUIRIES

RETURN REQUESTS / INQUIRIES

RETURN REQUESTS / INQUIRIESRETURN REQUESTS / INQUIRIES

FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3.Repair instructions and/or specific problems relative to the product.

United Kingdom: ISO 9002 Certified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5BD, United Kingdom

Tel: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. The OMEGA

WARRANTY/DISCLAIMER

Warranty adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number

immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s

WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; or misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors

nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING

ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The

remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event

shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any

nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical

application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and,

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a

manner.

®

Where Do I Find Everything I Need for Process MeasurementWhere Do I Find Everything I Need for Process Measurement

Where Do I Find Everything I Need for Process Measurement

Where Do I Find Everything I Need for Process MeasurementWhere Do I Find Everything I Need for Process Measurement

and Control? OMEGA…Of Course!and Control? OMEGA…Of Course!

and Control? OMEGA…Of Course!

and Control? OMEGA…Of Course!and Control? OMEGA…Of Course!

Shop online at www.omega.comShop online at www.omega.com

Shop online at www.omega.com

Shop online at www.omega.comShop online at www.omega.com

TEMPERATURETEMPERATURE

TEMPERATURE

TEMPERATURETEMPERATURE

! Thermocouple, RTD & Thermistor Probes, Connectors, Panels &

Assemblies

! Wire: Thermocouple, RTD & Thermistor

! Calibrators & Ice Point References

! Recorders, Controllers & Process Monitors

! Infrared Pyrometers

PRESSURE, STRAIN AND FORCEPRESSURE, STRAIN AND FORCE

PRESSURE, STRAIN AND FORCE

PRESSURE, STRAIN AND FORCEPRESSURE, STRAIN AND FORCE

! Transducers & Strain Gages

! Load Cells & Pressure Gages

! Displacement Transducers

! Instrumentation & Accessories

FLOW/LEVELFLOW/LEVEL

FLOW/LEVEL

FLOW/LEVELFLOW/LEVEL

! Rotameters, Gas Mass Flowmeters & Flow Computers

! Air Velocity Indicators

! Turbine/Paddlewheel Systems

! Totalizers & Batch Controllers

pH/CONDUCTIVITYpH/CONDUCTIVITY

pH/CONDUCTIVITY

pH/CONDUCTIVITYpH/CONDUCTIVITY

! pH Electrodes, Testers & Accessories

! Benchtop/Laboratory Meters

! Controllers, Calibrators, Simulators & Pumps

! Industrial pH & Conductivity Equipment

DATA ACQUISITIONDATA ACQUISITION

DATA ACQUISITION

DATA ACQUISITIONDATA ACQUISITION

! Data Acquisition & Engineering Software

! Communications-Based Acquisition Systems

! Plug-in Cards for Apple, IBM & Compatibles

! Datalogging Systems

! Recorders, Printers & Plotters

HEATERSHEATERS

HEATERS

HEATERSHEATERS

! Heating Cable

! Cartridge & Strip Heaters

! Immersion & Band Heaters

! Flexible Heaters

! Laboratory Heaters

ENVIRONMENTAL MONITORINGENVIRONMENTAL MONITORING

ENVIRONMENTAL MONITORING

ENVIRONMENTAL MONITORINGENVIRONMENTAL MONITORING

AND CONTROLAND CONTROL

AND CONTROL

AND CONTROLAND CONTROL

! Metering & Control Instrumentation

! Refractometers

! Pumps & Tubing

! Air, Soil & Water Monitors

! Industrial Water & Wastewater Treatment

! pH, Conductivity & Dissolved Oxygen Instruments

INDEXINDEX

INDEX

INDEXINDEX

MOUNTING REQUIREMENTS .................................................... 1

OUTLINE AND CUT OUT DIMENSIONS ..................................... 2

CONNECTION DIAGRAMS........................................................ 3

PRELIMINARY HARDWARE SETTINGS ................................... 18

SECURITY CODE SETTING MODE .......................................... 22

RUN TIME AND CONFIGURATION MODES ............................. 25

GENERAL NOTE ABOUT GRAPHIC SYMBOLS

USED FOR MNEMONIC CODE VISUALIZATION. .............. 25

KEYBOARD DESCRIPTION.............................................. 26

CONFIGURATION MODE ........................................................ 27

MONITOR MODE............................................................. 28

MODIFY MODE ................................................................ 29

RUN TIME MODE .................................................................... 67

PRELIMINARY ................................................................. 67

CONTROL PARAMETERS ............................................... 68

CONTROL PARAMETERS PROTECTION ......................... 68

CONTROL PARAMETERS MODIFICA TION. ...................... 68

PROGRAMMER MODE ..........................................................100

BARGRAPH DESCRIPTION ............................................103

INDICATORS ..................................................................104

DISPLAY FUNCTION DURING

PROGRAMMER MODE ................................................... 105

OUTPUT POWER OFF FUNCTION .................................108

CLOCK CALENDAR .......................................................109

OUT FAILURE DETECTION FUNCTION (OFD).................. 110

SERIAL LINK.................................................................. 110

LAMP TEST ...................................................................111

MANUAL MODE .............................................................111

DIRECT ACCESS TO THE SET POINT ............................112

GENERAL NOTES ABOUT PROGRAM EDITING .............113

EDIT MODE ....................................................................113

SIMPLE PROGRAM MANAGEMENT ...............................121

LINKED PROGRAM MANAGEMENT ...............................124

HOW TO CHECK A PROGRAM......................................125

HOW TO RUN A PROGRAM (SIMPLE OR LINKED) ........126

ACTIONS AVAILABLE DURING RUNNING MODE ...........127

CONTOLLER MODE .............................................................. 130

DISPLAY FUNCTION DURING

CONTROLLER MODE..................................................... 131

INDICATORS FUNCTION DURING

CONTROLLER MODE..................................................... 133

DIRECT ACCESS TO THE SET POINT ............................133

SMART FUNCTION ........................................................134

OUTPUT POWER OFF FUNCTION .................................135

ERROR MESSAGES ..............................................................136

GENERAL INFORMATIONS....................................................141

MAINTENANCE ......................................................................150

DEFAUL T P ARAMETERS........................................................ A.1

CODING .............................................................................. A.15

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

MOUNTING REQUIREMENTS

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

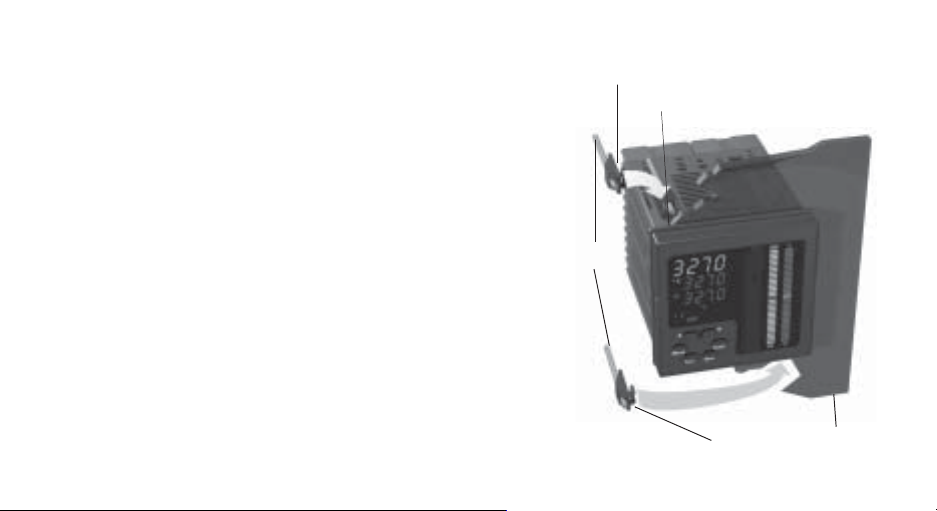

This instrument is intended for permanent installation, for indoor

use only, in an electrical panel which encloses the rear

housing, exposed terminals and wiring on the back.

Select a location, for instrument mounting, where minimum

vibrations are present and the ambient temperature is within 0

and 50 °C (32 and 122 °F).

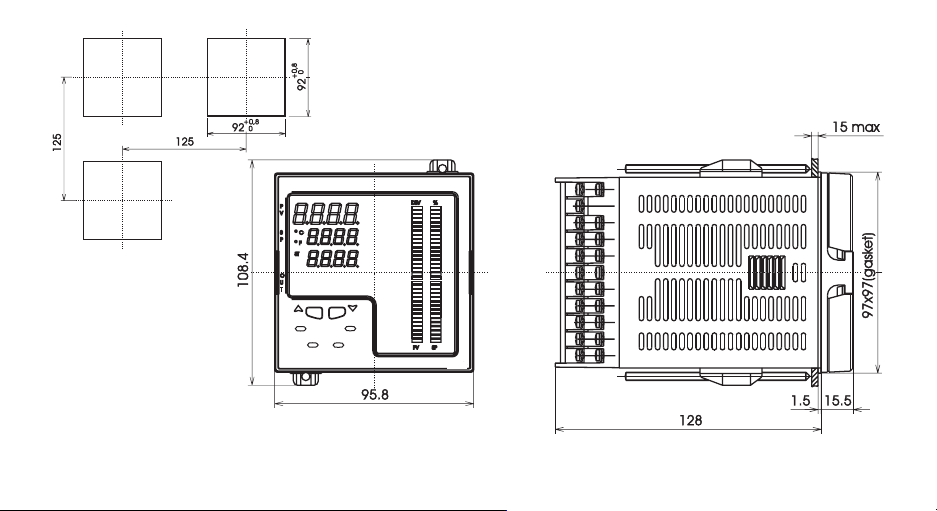

The instrument can be mounted on a panel up to 15 mm thick

with a cutout of 92 x 45 mm (PKP) or 92 x 92 mm (MKP).

For outline and cutout dimensions refer to Fig. 2.

The surface texture of the panel must be better than 6,3 µm.

The instrument is shipped with rubber panel gasket.

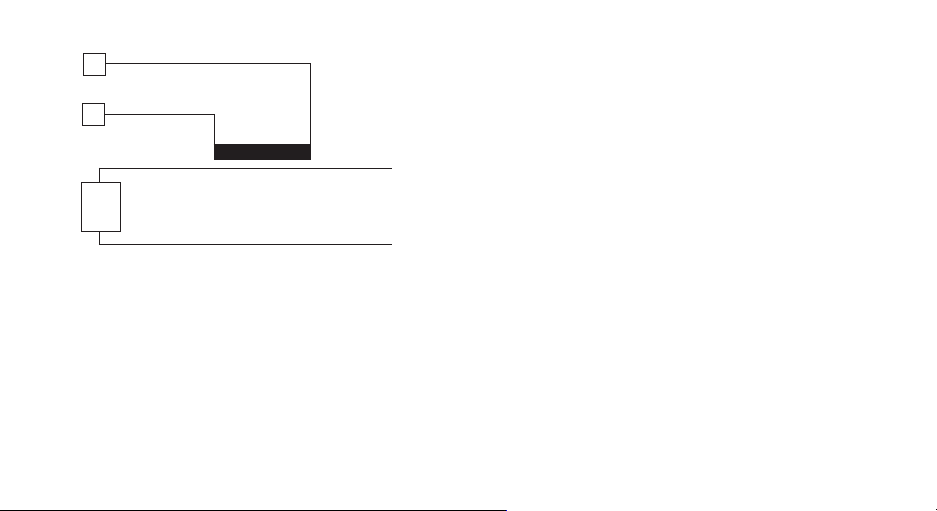

To assure the IP65 and NEMA 4 protection, insert the panel

gasket between the instrument and the panel as shown in fig.

1.

While holding the instrument against the panel proceed as

follows:

1) insert the gasket in the instrument case;

2) insert the instrument in the panel cutout;

3) pushing the instrument against the panel;

4) insert the mounting brackets as shown in fig.1;

5) with a screwdriver, turn the screws with a torque between 0.3

and 0.4 Nm.

bracket

Gasket

Screws

Fig. 1

1

bracket

Panel

Fig. 2 OUTLINE AND CUT-OUT DIMENSIONS FOR MKP MODEL

2

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

CONNECTION DIAGRAMS

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

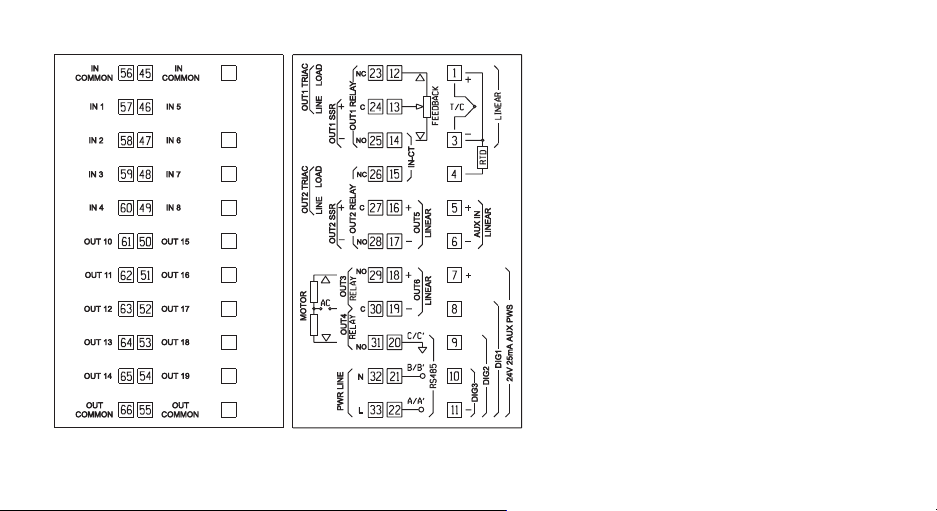

Fig. 3 REAR TERMINAL BLOCK

Connections are to be made with the instrument

housing installed in its proper location.

A) MEASURING INPUTSA) MEASURING INPUTS

A) MEASURING INPUTS

A) MEASURING INPUTSA) MEASURING INPUTS

NOTENOTE

NOTE: Any external component (like zener

NOTENOTE

barriers etc.) connected between sensor and input

terminals may cause errors in measurement due to

excessive and/or not balanced line resistance or

possible leakage currents.

3

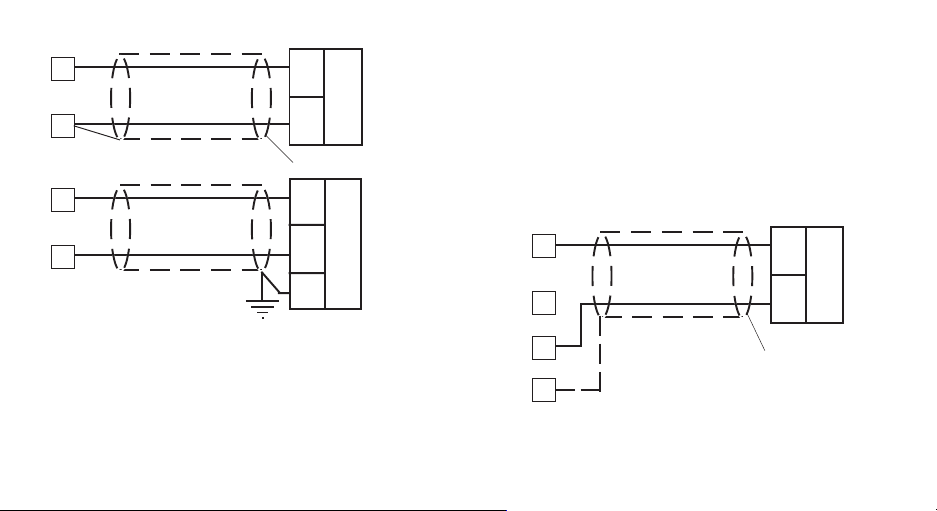

A.1) TC INPUTA.1) TC INPUT

A.1) TC INPUT

A.1) TC INPUTA.1) TC INPUT

1

+

_

3

1

+

_

3

Shield

Shield

A.2) RTD INPUTA.2) RTD INPUT

A.2) RTD INPUT

A.2) RTD INPUTA.2) RTD INPUT

RTD

4

3 4

RTD

1

3

1

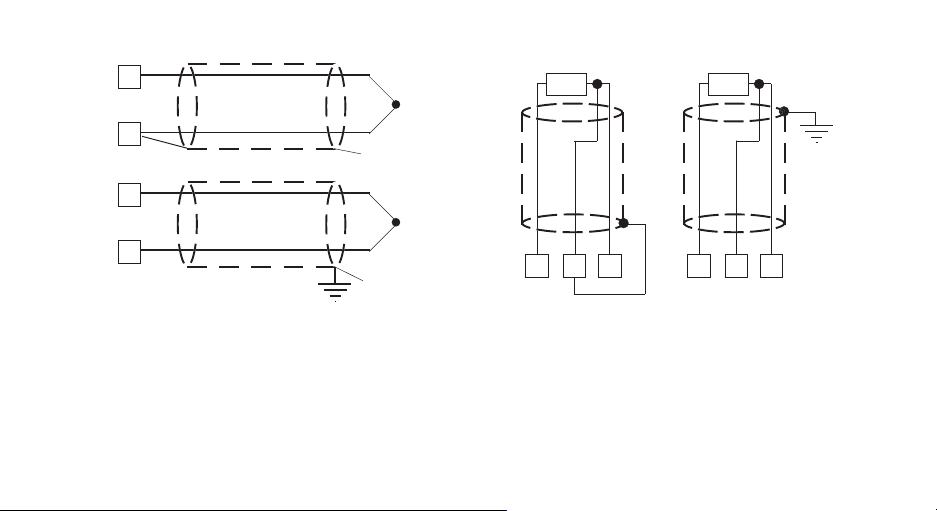

Fig. 4 THERMOCOUPLE INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) For TC wiring use proper compensating cable preferable

shielded.

3) When a shielded cable is used, it should be connected at

one point only.

Fig. 5 RTD INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance

may cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The resistance of the 3 wires must be the same.

4

A.3) LINEAR INPUTA.3) LINEAR INPUT

A.3) LINEAR INPUT

A.3) LINEAR INPUTA.3) LINEAR INPUT

1

3

1

3

+

_

Shield

+

_

G

mA,

mV

or

V

mA

mV

or

V

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is equal to:

< 5 Ω for 20 mA input

> 1 MΩ for 60 mV input

> 200 kΩ for 5 V input

> 400 kΩ for 10 V input

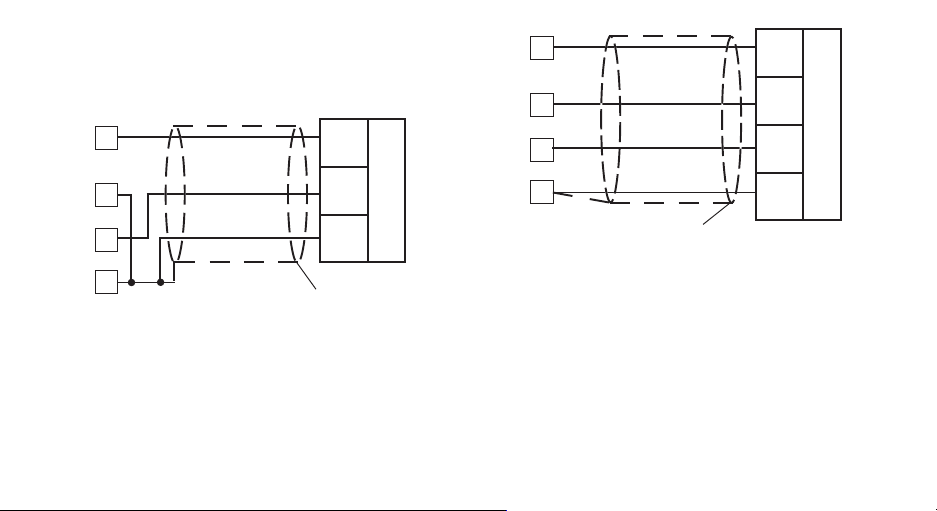

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUTA.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUTA.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

1

3

_

TX

+

Fig. 6 mA, mV AND V INPUTS WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance

may cause measurement errors.

7

Shield

11

Fig. 7.A INPUTS WIRING FOR 2-WIRE TRANSMITTER

5

1

Out

+

Out

3

1

3

7

Out

PWR

+

GND

TX

7

11

Shield

_

PWR

+

PWR

_

TX

11

Fig. 7.B INPUTS WIRING FOR 3-WIRE TRANSMITTER

Shield

Fig. 7.C INPUTS WIRING FOR 4-WIRE TRANSMITTER

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance

may cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is lower than 5 Ω (20 mA input)

6

B) AUXILIARY INPUTB) AUXILIARY INPUT

B) AUXILIARY INPUT

B) AUXILIARY INPUTB) AUXILIARY INPUT

5

6

+

mA

or

_

V

Shield

5

6

+

mA

_

or

V

G

Fig. 8 AUXILIARY INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is

reinforced insulation between instrument output and power

supply must be assured by the external instrument.

2) Don’t run input wires together with power cables.

3) Pay attention to the line resistance; a high line resistance

may cause measurement errors.

not isolated not isolated

not isolated from measuring input. A double or

not isolated not isolated

4) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

5) The input impedance is equal to:

< 5 Ω for 20 mA input

> 200 kΩ for 5 V input

> 400 kΩ for 10 V input

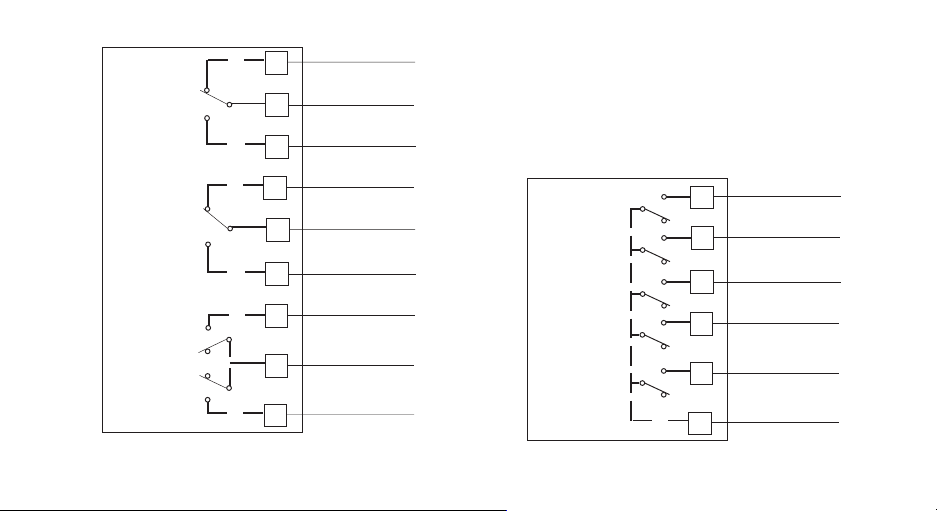

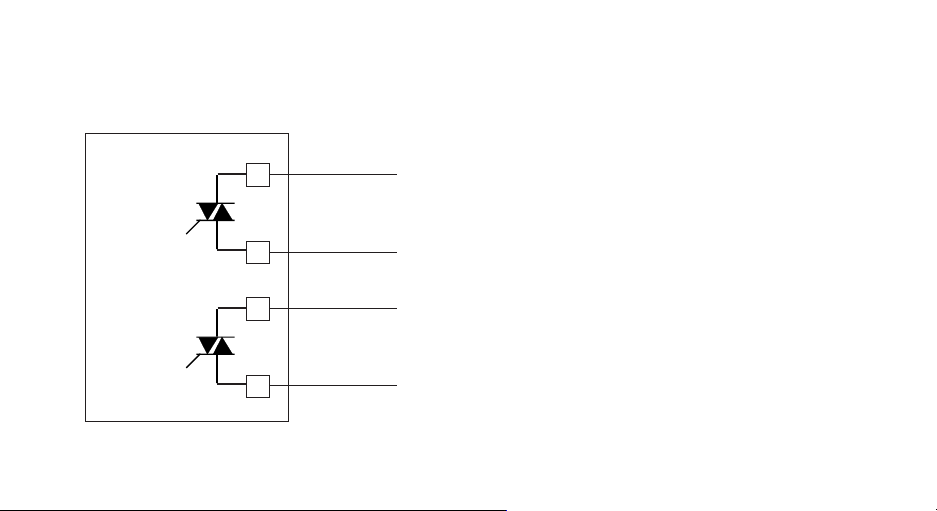

C) LOGIC INPUTSC) LOGIC INPUTS

C) LOGIC INPUTS

C) LOGIC INPUTSC) LOGIC INPUTS

DIG. 1

8

DIG. 2

9

DIG. 3

10

11

Fig. 9.A - LOGIC INPUTS DIG 1, 2, 3 WIRING

7

56

57

58

59

60

IN 1

IN 2

IN 3

IN 4

56

57

58

59

60

IN 5

IN 6

IN 7

IN 8

Fig. 9.B - LOGIC INPUTS IN 1, 2, 3 and 4 WIRING

Fig. 9.C - LOGIC INPUTS IN 5, 6, 7 and 8 WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Do not run logic input wiring together with power cables.

2) Use an external dry contact capable of switching 0.5 mA,

5 V DC.

3) The instrument needs 110 ms to recognize a contact status

variation.

4) The logic inputs are

A double or reinforced insulation between instrument input

and power line must be assured by the external element.

8

NOT NOT

NOT isolated by the measuring input.

NOT NOT

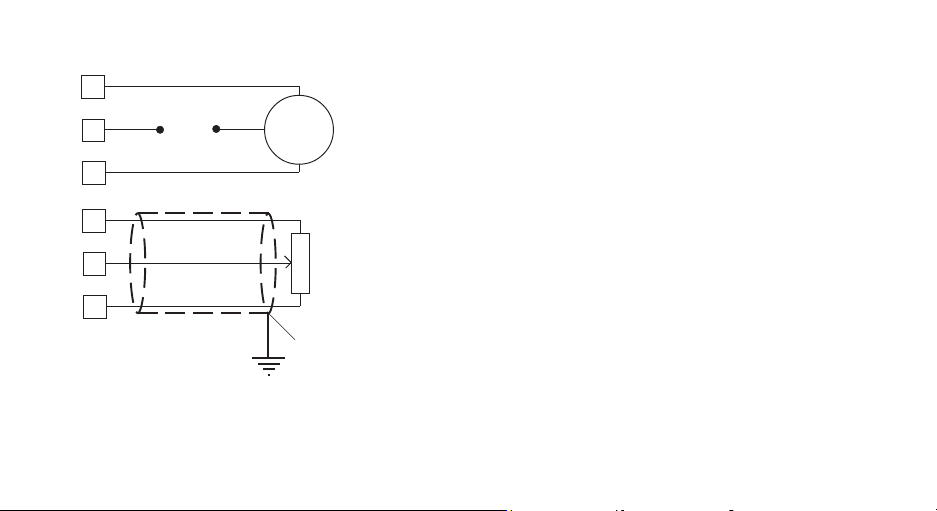

D) CURRENT TRANSFORMER INPUTD) CURRENT TRANSFORMER INPUT

D) CURRENT TRANSFORMER INPUT

D) CURRENT TRANSFORMER INPUTD) CURRENT TRANSFORMER INPUT

14

Current

15

Load

Fig. 10 CURRENT TRANSFORMER INPUT WIRING

This input allows you to measure and display the current

running in the load, driven by a time proportional control output,

during the ON and OFF periods of the output cycle time. By this

feature it is also available the "Output failure detection" function

(see page 110).

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is

2) Do not run current transformer input wiring together with AC

power cables.

not isolated not isolated

not isolated from measuring input.

not isolated not isolated

transformer

3) The minimum active period to perform this measurement is

equal to 120 ms.

4) The input impedance is equal to 20 Ω.

9

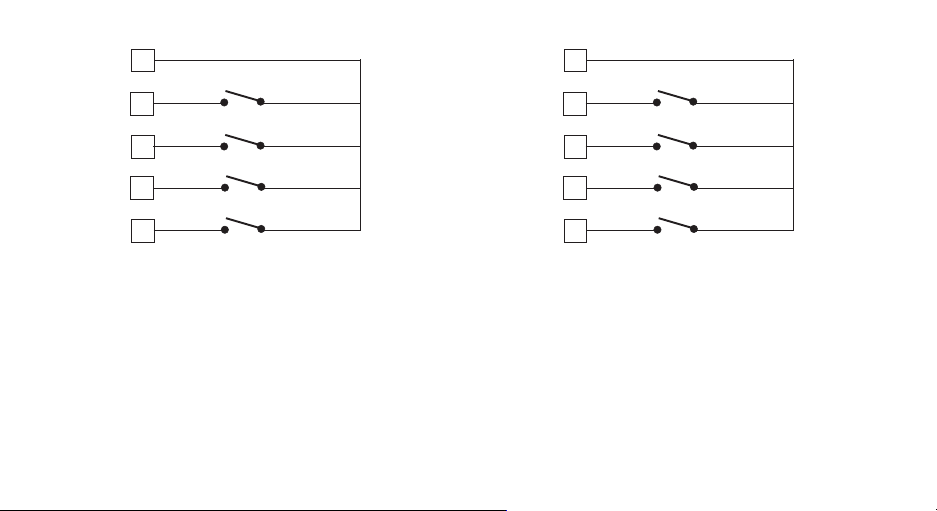

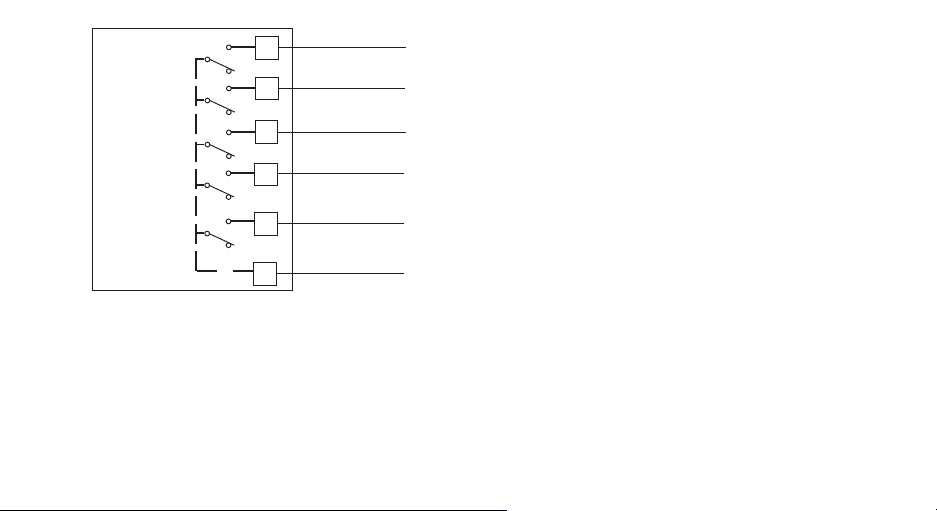

E.1) RELAY OUTPUTSE.1) RELAY OUTPUTS

E.1) RELAY OUTPUTS

E.1) RELAY OUTPUTSE.1) RELAY OUTPUTS

23

OUT 1

24

25

26

OUT 2

27

28

29

OUT 3

30

OUT 4

31

Fig. 11.A RELAY OUTPUTS 1,2,3 and 4 WIRING

NC

C

NO

NC

C

NO

NO - OUT 3

C - OUT 3/4

NO - OUT 4

The outputs from OUT 1 to OUT 4 are equipped with relays

having contact rating equal to 3A/250V AC on resistive load.

WARNINGWARNING

WARNING: When OUT 3 and 4 are used as independent relay

WARNINGWARNING

outputs the addition of the two currents must not exceed 3 A.

NO OUT 10

OUT 10

OUT 11

OUT 12

OUT 13

OUT 14

COMMON

Fig. 11.B RELAY OUTPUTS 10 to 14 WIRING

10

61

62

63

64

65

66

NO OUT 11

NO OUT 12

NO OUT 13

NO OUT 14

COMMON

OUT 15

OUT 16

OUT 17

OUT 18

OUT 19

COMMON

50

51

52

53

54

55

NO OUT 15

NO OUT 16

NO OUT 17

NO OUT 18

NO OUT 19

COMMON

GENERAL NOTES ABOUT RELAY OUTPUT WIRINGGENERAL NOTES ABOUT RELAY OUTPUT WIRING

GENERAL NOTES ABOUT RELAY OUTPUT WIRING

GENERAL NOTES ABOUT RELAY OUTPUT WIRINGGENERAL NOTES ABOUT RELAY OUTPUT WIRING

1) To avoid electrical shock, connect power line at the end of

the wiring procedure.

2) For power connections use No 16 AWG or larger wires rated for

at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

For all relay outputs, the number of operations is 1 x 105 at

specified rating.

All relay contacts are protected by varistor against inductive load

with inductive component up to 0.5 A.

The following recommendations avoid serious problems which

may occur, when using relay output for driving inductive loads.

Fig. 11.C RELAY OUTPUTS 15 to 19 WIRING

The outputs from OUT 10 to 19 are equipped with relays having

contact rating equal to 0.5A/250V AC on resistive load.

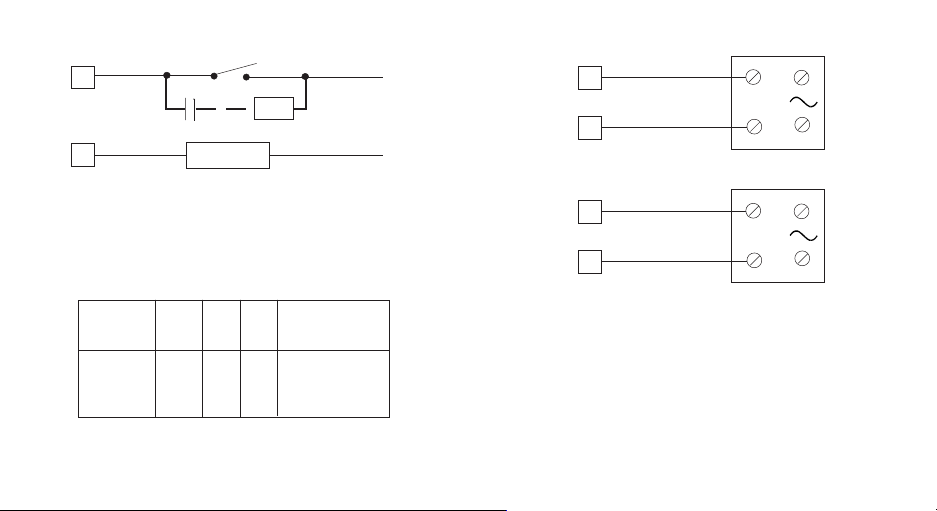

INDUCTIVE LOADSINDUCTIVE LOADS

INDUCTIVE LOADS

INDUCTIVE LOADSINDUCTIVE LOADS

High voltage transients may occur switching inductive loads.

Through the internal contacts these transients may introduce

disturbances which can affect the performance of the

instrument.

For all the outputs, the internal protection (varistor) assures a

correct protection up to 0.5 A of inductive component.

11

The same problem may occur when a switch is used in series

with the internal contacts as shown in Fig. 12.

C

R

LINE

LOAD

Fig. 12 EXTERNAL SWITCH IN SERIES WITH THE

INTERNAL CONTACT

In this case it is recommended to install an additional RC

network across the external contact as shown in Fig. 12

The value of capacitor (C) and resistor (R) are shown in the

following table.

C

LOAD

(mA)

<40 m A

<150 mA

<0.5 A

Anyway the cable involved in relay output wiring must be as far

away as possible from input or communication cables.

(µF)

0.047

0.1

0.33

R

(Ω)

100

22

47

P.

(W)

1/2

2

2

OPERATING

VOLTAGE

260 V AC

260 V AC

260 V AC

E.2) VOLTAGE OUTPUTS FOR SSR DRIVEE.2) VOLTAGE OUTPUTS FOR SSR DRIVE

E.2) VOLTAGE OUTPUTS FOR SSR DRIVE

E.2) VOLTAGE OUTPUTS FOR SSR DRIVEE.2) VOLTAGE OUTPUTS FOR SSR DRIVE

24

OUT 1

+

_

25

27

OUT 2

+

_

28

Fig. 13 SSR DRIVE OUTPUT WIRING

Logic level 0Logic level 0

Logic level 0: Vout < 0.5 V DC.

Logic level 0Logic level 0

Logic level 1Logic level 1

Logic level 1:

Logic level 1Logic level 1

14 V

+ 20 % @ 20 mA

24 V

+ 20 % @ 1 mA.

Maximum current = 20 mA.

12

+

__

_

__

SOLID STATE

RELAY

+

__

_

__

SOLID STATE

RELAY

NOTENOTE

NOTE: This output is not isolated.

NOTENOTE

A double or reinforced insulation between instrument output

and power supply must be assured by the external solid state

relay.

E.3) TRIAC OUTPUTSE.3) TRIAC OUTPUTS

E.3) TRIAC OUTPUTS

E.3) TRIAC OUTPUTSE.3) TRIAC OUTPUTS

24

Line

OUT 1

23

Load

Switching modeSwitching mode

Switching mode: isolated zero crossing type.

Switching modeSwitching mode

Rated currentRated current

Rated current: from 50 mA to 1 A.

Rated currentRated current

Rated voltageRated voltage

Rated voltage: from 24 V

Rated voltageRated voltage

60Hz)

Load typeLoad type

Load type: resistive load only

Load typeLoad type

NOTESNOTES

NOTES 1) To avoid electrical shock, connect power line at

NOTESNOTES

the end of the wiring procedure.

2) For power connections use No 16 AWG or larger

wires rated for at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

5) This output is not fuse protected. Please, provide it

externally using a fuse with a I2t equal to128.

to 240 V

RMS

-10 % +15 % (50/

RMS

27

OUT 2

26

Fig. 14 TRIAC OUTPUT WIRING

Line

Load

13

E.4) SERVOMOTOR OUTPUTE.4) SERVOMOTOR OUTPUT

E.4) SERVOMOTOR OUTPUT

E.4) SERVOMOTOR OUTPUTE.4) SERVOMOTOR OUTPUT

! (Open the valve)

29

30

31

" (Close the valve)

12

Power

line

Servo-

motor

! (Open)

13

14

Fig. 15 SERVOMOTOR OUTPUT WIRING

" (Close)

Shield

Feedback

potentiometer

The two relay output must be interlocked (see chapter

"Preliminary hardware setting" paragraph "Out 3 and 4

selection").

NOTESNOTES

NOTES:

NOTESNOTES

1) Before connecting the instrument to the power line, make sure

that line voltage and the load current are in accordance with the

contact rating (3A/250V AC on resistive load).

2) To avoid electric shock, connect power line at the end of the

wiring procedure.

3) For servomotor connections use No 16 AWG or larger wires

rated for at last 75 °C.

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For feedback potentiometer, use shielded cable with the shield

connected to the earth at one point only.

7) The relay outputs are protected by varistors against

inductive load with inductive component up to 0.5 A.

14

E.5) ANALOG OUTPUTSE.5) ANALOG OUTPUTS

E.5) ANALOG OUTPUTS

E.5) ANALOG OUTPUTSE.5) ANALOG OUTPUTS

+

16

OUT 5

_

17

+

16

OUT 5

_

17

+

_

Shield

+

_

20 mA20 mA

OUT 6

OUT 6

18

19

18

19

+

+

_

20 mA

_

Shield

+

_

+

_

20 mA

G

Fig. 16.A OUTPUT 5 WIRING

G

Fig. 16.B OUTPUT 6 WIRING

NOTENOTE

NOTE:

NOTENOTE

1) Do not run analog output wirings together with AC power

cables.

2) Out 5 and 6 are isolated outputs.

3) The maximum load is equal to 600 Ω.

15

F) SERIAL INTERFACEF) SERIAL INTERFACE

F) SERIAL INTERFACE

F) SERIAL INTERFACEF) SERIAL INTERFACE

I

N

S

T

R

U

M

E

N

T

Fig. 17 - RS-485 WIRING

The cable length must not exceed 1.5 km at 9600 BAUD.

NOTESNOTES

NOTES:

NOTESNOTES

1) This is an isolated RS-485 serial interface.

2) The following report describes the signal sense of the

voltage appearing across the interconnection cable as

defined by EIA for RS-485.

a) The ” A ” terminal of the generator shall be negative with

respect to the ” B ” terminal for a binary 1 (MARK or OFF) state.

b) The ” A ” terminal of the generator shall be positive with

respect to the ” B ” terminal for a binary 0 (SPACE or ON).

22

21

20

A/A'

B/B'

COMMON

A'/A

B'/B

M

A

S

T

E

R

3) The EIA standard establishes that by RS-485 interface it is

possible to connect up to 30 devices with one remote master

unit.

The serial interface of these instruments is based on “High

input impedance” transceivers; this solution allows you to

connect up to 127 devices (based on the same transceiver

type) with one remote master unit.

16

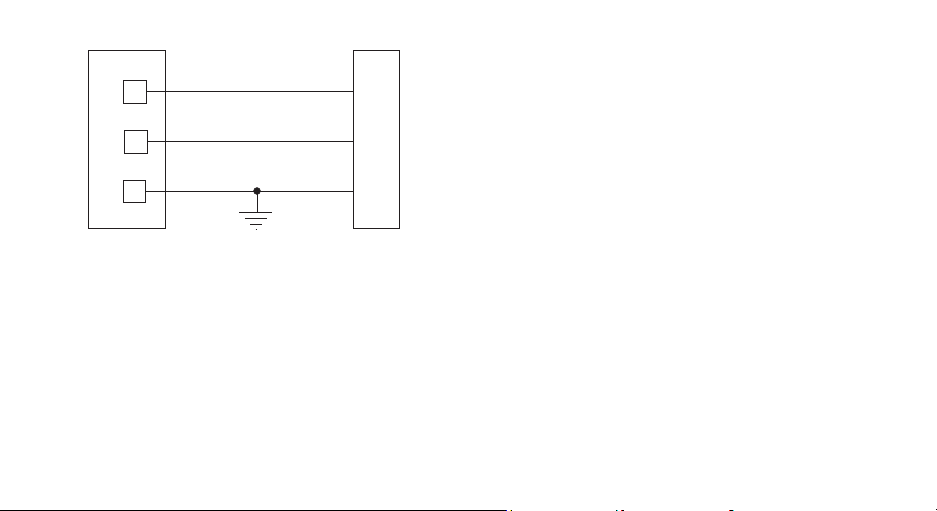

G) POWER LINE WIRINGG) POWER LINE WIRING

G) POWER LINE WIRING

G) POWER LINE WIRINGG) POWER LINE WIRING

N (L2)

32

POWER LINE 100 V to

240 V A.C (50/60Hz)

L (L1)

or 24 V AC/DC

Line

Neutral

33

Fig. 18 POWER LINE WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Before connecting the instrument to the power line, make sure

that line voltage corresponds to the description on the identification label.

2) To avoid electrical shock, connect power line at the end of the

wiring procedure.

3) For supply connections use No 16 AWG or larger wires rated for

at last 75 °C.

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For 24 V DC the polarity is a not care condition.

7) The power supply input is fuse protected by a sub miniature

fuse rated T, 1A, 250 V.

When fuse is damaged, it is advisable to verify the power supply

circuit, so that it is necessary to send back the instrument to

your supplier.

8) The safety requirements for Permanently Connected

Equipment say:

- a switch or circuit-breaker shall be included in the building

installation;

- it shall be in close proximity to the equipment and within

easy reach of the operator;

- it shall be marked as the disconnecting device for the

equipment.

NOTENOTE

NOTE: a single switch or circuit-breaker can drive more than

NOTENOTE

one instrument.

9) When a neutral line is present please connect it to the 32

terminal.

17

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

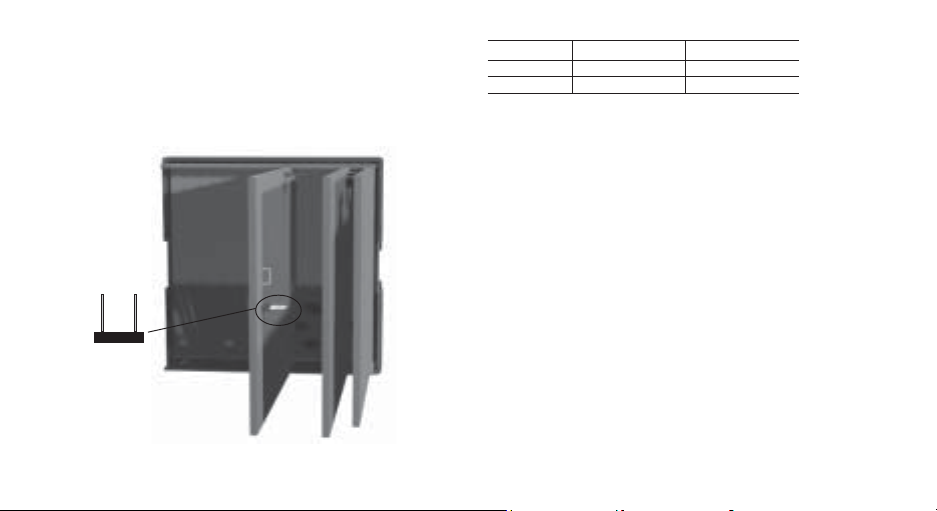

How to remove the instrument from its caseHow to remove the instrument from its case

How to remove the instrument from its case

How to remove the instrument from its caseHow to remove the instrument from its case

1) Switch off the instrument.

2) Push gently the lock A on the right.

3) While the lock A is maintained out, slide out the right side of

the instrument (see fig. 19.a)

B

4) Push gently the lock C on the left.

5) While the lock C is maintained out, slide out the instrument

(see fig. 19.b)

D

C

A

D

Fig. 19.a Fig. 19.b

B

18

MAIN INPUT SELECTIONMAIN INPUT SELECTION

MAIN INPUT SELECTION

MAIN INPUT SELECTIONMAIN INPUT SELECTION

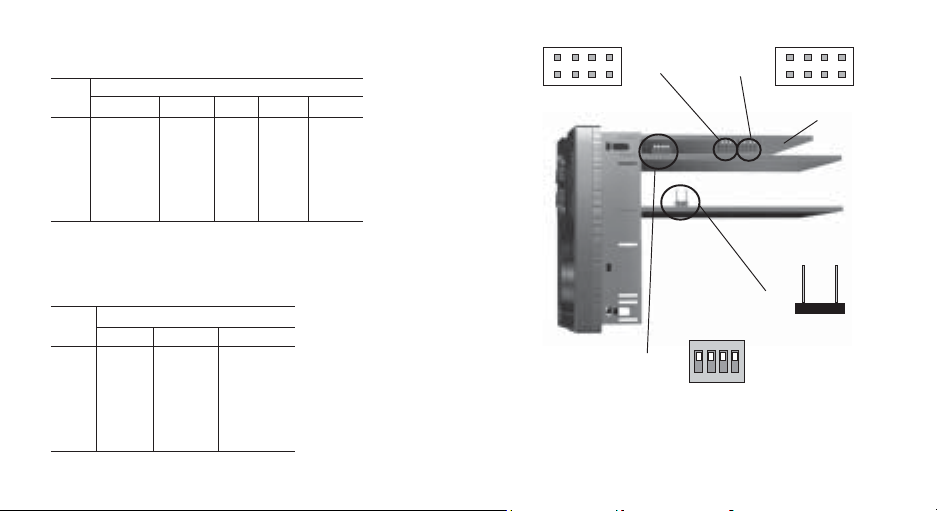

Set J103 (see fig. 20) according to the desired input type as

shown in the following table.

J103 INPUT TYPE

T/C, RTD 60 mV 5 V 10 V 20 mA

1-2 open open close open open

3-4 open open close close open

5-6 open open open open close

7-8 open open open open close

5-7 close close open close open

6-8 close close open open open

AUXILIARY INPUT SELECTION (option)AUXILIARY INPUT SELECTION (option)

AUXILIARY INPUT SELECTION (option)

AUXILIARY INPUT SELECTION (option)AUXILIARY INPUT SELECTION (option)

Set J102 (see fig. 20) according to the desired input type as

shown in the following table.

J102 INPUT TYPE

5 V 10 V 20 mA

1-2 close open open

3-4 close close open

5-6 open open close

7-8 open open close

5-7 open close open

6-8 open open open

1 3 5 7

J102

2 4 6 8

1 3 5 7

J103

2 4 6 8

CPU

card

J205

ON DIP

V301

1 2 3 4

Fig. 20

19

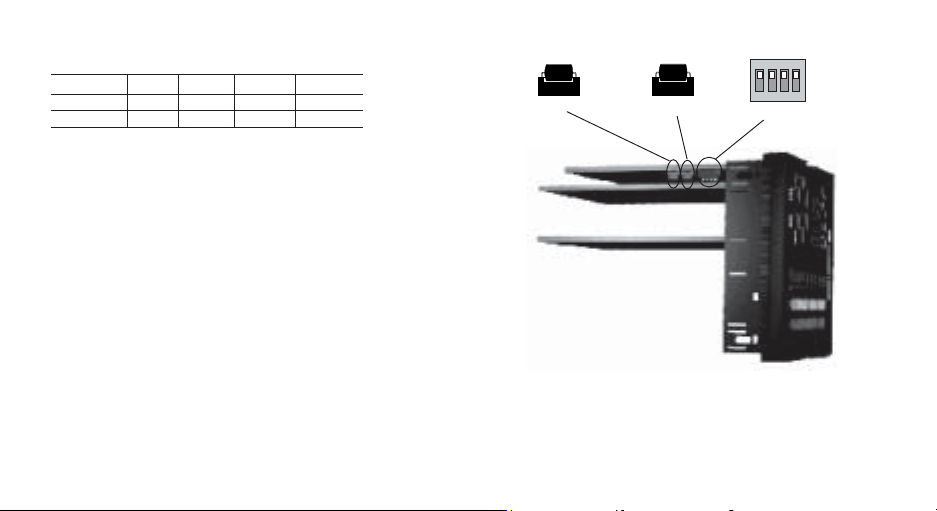

OUTPUT 3 AND 4 SELECTIONOUTPUT 3 AND 4 SELECTION

OUTPUT 3 AND 4 SELECTION

OUTPUT 3 AND 4 SELECTIONOUTPUT 3 AND 4 SELECTION

Output 3 and 4 can be set as:

- 2 independent relay outputs

- 1 servomotor output with interlocked contact.

Set J204 (see fig. 21) and J205 (see fig. 20) according to the

desired output type as shown in the following table.

J204

Fig.21

Output J 204 J 205

Relay close open

Servo open close

NOTENOTE

NOTE: when the servomotor close loop or the servomotor open

NOTENOTE

loop with valve position indication outputs is required, it will be

necessary to set also V301 (see "IN CT/Feedback selection"

paragraph)

IN CT / FEEDBACK SELECTIONIN CT / FEEDBACK SELECTION

IN CT / FEEDBACK SELECTION

IN CT / FEEDBACK SELECTIONIN CT / FEEDBACK SELECTION

This instrument can use the "IN CT" input or the "Feedback"

input; the two inputs are not contemporarily.

The current transformer input allows you to measure and

display the current running in a load driven by a time proportional control output during the ON and OFF periods of the

output cycle time. By this feature it is also available the "Out

failure detection" function (see page 111).

The feedback input is used when the servomotor close loop or

the servomotor open loop with valve position indication outputs

is required.

20

To select the desired input type, set V301 (see fig. 20) as

detailed in the following table:

Input V301.1 V301.2 V301.3 V301.4

IN CT ON OFF ON ON

Feedback OF F ON OFF ON

OPTION CHECKOPTION CHECK

OPTION CHECK

OPTION CHECKOPTION CHECK

This instrument can be supplied with several options.

Two integrated circuits (KY101 and KY103), located as shown

in fig. 22 and inserted in a socket, give you the possibility to

verify if your instrument is equipped with the desired option.

When KY101 is present the auxiliary input and the digital inputs

are present.

When KY103 is present the auxiliary power supply option is

present.

ON DIP

KY101

KY103

1 2 3 4

V101

Fig. 22

21

Operative mode and Hardware lockOperative mode and Hardware lock

Operative mode and Hardware lock

Operative mode and Hardware lockOperative mode and Hardware lock

By V101 (see fig 22) it is possible to select one of the following

operative modes:

a) run time mode without configuration mode

b) run time and configuration modes

c) security code setting mode

Set V101 according to the following table:

Modes V101.1 V101.2 V101.3 V101.4

a OFF ON ON ON

b OFF ON OFF ON

c OFF ON OFF OFF

All the others switch combinations are reserved.

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

SECURITY CODE SETTING MODE

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

General notesGeneral notes

General notes

General notesGeneral notes

The instrument parameters are divided in two families and each

family is divided in groups.

- The first family encompasses all the run time parameters.

- The second family comprises all the configuration parameters.

A specific security code enables the parameter modification of

each family.

For run time parameters, it is possible to select which groups of

them will be protected by the security code and in this case, it

is necessary to set the run time security code before to modify

one or more parameters of a protected group.

The configuration security code protects all configuration

parameters and it will be necessary to set the configuration

security code before to start the configuration parameters

modification.

For configuration parameters an hardware lock is also

available.

22

Security code settingSecurity code setting

Security code setting:

Security code settingSecurity code setting

1) Remove the instrument from its case.

2) Set the internal dip switch V101 as follows:

- V101.1 = OFF- V101.2 = ON

- V101.3 = OFF- V101.4 = OFF

3) Re-insert the instrument.

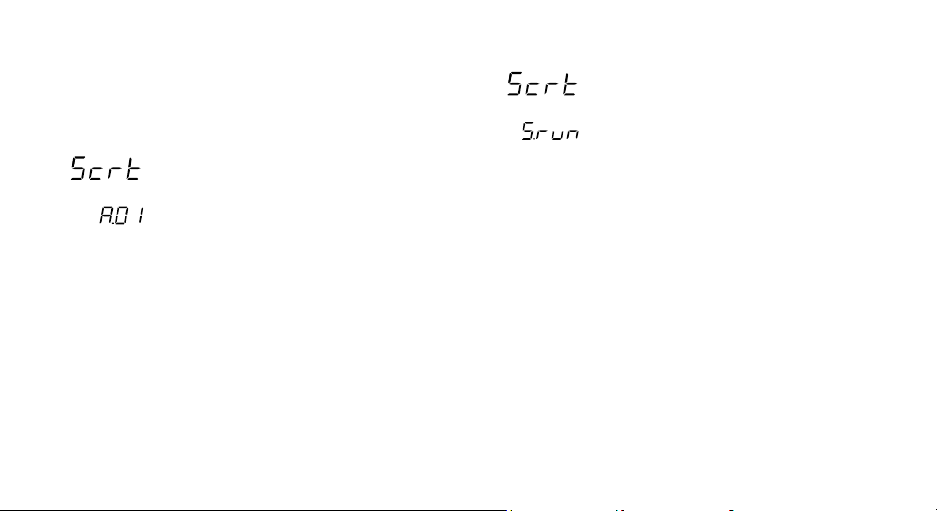

4) Switch on the instrument. The display will show:

The upper display shows that the security code setting mode

is selected while the lower display shows the firmware

version.

5) Push the FUNC pushbutton.

Run time security codeRun time security code

Run time security code

Run time security codeRun time security code

The display will show:

NoteNote

Note: the middle display shows the current status of the run

NoteNote

time security code ("0", "1" or "On").

By ! and " push-button, set "S.run" parameter as follows:

0 No protection (it is ever possible to modify all run

time parameters);

1 ever protected (it is never possible to modify a run

time parameter);

from 2 to 250 security code for run time parameter

protection.

NOTESNOTES

NOTES:

NOTESNOTES

1) The selected value of a security code cannot be displayed

anymore and, coming back to the "S.run" parameter, the

display will show :

- "On" when "S.run" is different from 0 or 1

- "0" when "S.run" is equal to 0

- "1" when "S.run" is equal to 1.

When the security code is forgotten, a new value can be set.

2) When "S.run" is different from 0 or 1, the "run time default "

23

and the "run time hidden" groups are ever protected by

security code.

Run time groups protected by security codeRun time groups protected by security code

Run time groups protected by security code

Run time groups protected by security codeRun time groups protected by security code

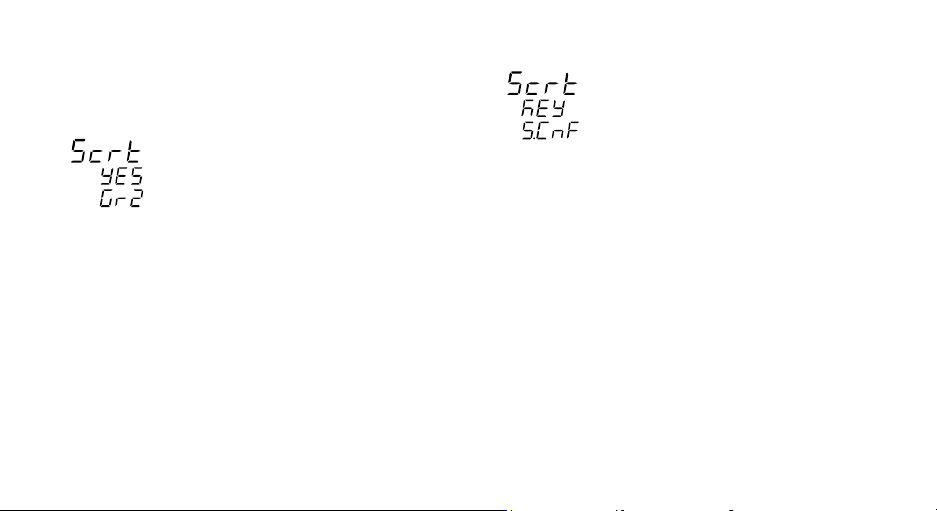

The display will show:

By this parameter it is possible to set if the run time group 2 will

be protected or not by the run time security code.

By ! and " push-button, set "Gr2" parameter as follows:

nO No protection (it is always possible to modify run time

group 2 parameters)

Ye s the run time group 1 parameter modification will be

protected by security code.

Push the FUNC push-button; the instrument memorizes the

new setting and goes to the next parameter.

NOTESNOTES

NOTES:1)This selection may be carried out only if a run time

NOTESNOTES

security code has been set (from 2 to 250).

2) The above described selection may be repeated for

all groups of the run time mode.

Configuration security codeConfiguration security code

Configuration security code

Configuration security codeConfiguration security code

The display will show:

NoteNote

Note: the middle display shows the current status of the

NoteNote

configuration security code ("0", "1" or "On").

By ! and " push-button, set "S.CnF" parameter as follows:

0 No protection (it is ever possible to modify all

configuration parameters);

1 ever protected (it is never possible to modify a

configuration parameter);

from 2 to 250 security code for configuration parameter

protection.

NOTENOTE

NOTE: the selected value of a security code cannot be

NOTENOTE

displayed anymore and, coming back on the "S.CnF"

parameter, the display will show "On" when "S.CnF" is

different from 0 or 1, "0" when "S.CnF" is equal to 0,

"1" when "S.CnF" is equal to 1.

When the security code is forgotten, a new value can

be set.

24

Loading...

Loading...