Omega Products CN2116 Installation Manual

Installation and Operating Handbook Contents

MODEL CN2116 PID CONTROLLER

INSTALLATION AND OPERATION HANDBOOK

Contents..............................................................................................................Page

Safety and EMC Information ....................................................................................ii

Chapter 1 INSTALLATION..........................................................................1-1

Chapter 2 OPERATION...............................................................................2-1

Chapter 3 ACCESS LEVELS ......................................................................3-1

Chapter 4 TUNING ......................................................................................4-1

Chapter 5 CONFIGURATION......................................................................5-1

Chapter 6 USER CALIBRATION.................................................................6-1

CN2116 Controller i

Safety Information Installation and Operation Handbook

SAFETY and EMC INFORMATION

Please read this section before installing the controller

This controller meets the requirements of the European Directives on Safety and EMC, however it is the responsibility of the installer to ensure the

safety and EMC compliance of any particular installation.

SAFETY

This controller complies with the European Low Voltage Directive

73/23/EEC, amended by 93/68/EEC, by the application of the safety

standard EN 61010(93).

Electromagnetic compatibility

This controller conforms with the essential protection requirements

of the EMC Directive 89/336/EEC, amended by 93/68/EEC, by the

application of a technical construction file.

Routing of wires

To minimise the pick-up of electrical noise, the logic output wiring

and the sensor input wiring should be routed away from high-current

power cables. Where it is impractical to do this, use shielded cables

with the shield grounded at both ends.

SERVICE AND REPAIR

This controller has no user serviceable parts. Contact Omega

Engineering, Inc. for repair.

INSTALLATION REQUIREMENTS FOR EMC

To ensure compliance with the European EMC directive certain

installation precautions are necessary as follows:

• When using the relay output it may be necessary to fit a filter

suitable for suppressing the emissions. The filter requirements

will depend on the type of load.

ii CN2116 Controller

Installation and Operation Handbook Safety Information

TECHNICAL SPECIFICATION FOR SAFETY PURPOSES.

Equipment ratings

Supply voltage: 100 to 240Vac -15%, +10%

Supply frequency: 48 to 62Hz ac.

Power consumption: 2.5 Watts maximum

Relay output: Maximum of 264Vac. Minimum 30Vac or dc. Maximum current, 2A resistive.

Leakage current: The leakage current through the relay contact suppression components is less than 2mA at 264Vac, 50Hz.

Over current protection: External over current protection devices are required that match the wiring of the installation. A minimum of 0.5mm

or 16awg wire is recommended. Use independent fuses for the instrument supply and the relay output. Suitable fuses

are T type, (IEC 127 time-lag type) as follows; Instrument supply: 85 to 264Vac, 2A, (T). Relay output: 2A (T).

DC Pulse Output

Rating 9Vdc, 18mA (non-isolated)

Application Heating, cooling or alarms

Environmental ratings

Panel sealing: Instruments are intended to be panel mounted. The rating of panel sealing is defined by EN 60529: IP 65.

Operating temperature: 0 to 55oC. Ensure the enclosure provides adequate ventilation.

Relative humidity: 5 to 90%, non condensing.

Atmosphere: The instrument is not suitable for use above 2000m or in explosive or corrosive atmospheres.

Electrical safety

Standard: EN 61010, Installation category II, pollution degree 2.

Installation category II: Voltage transients on any mains power connected to the instrument must not exceed 2.5kV.

Pollution degree 2: Conductive pollution must be excluded from the cabinet in which the instrument is mounted.

Isolation: All inputs and outputs, have a reinforced isolation which provides protection against electric shock, except the Logic

output which is electrically connected to the main process variable input, (thermocouple etc.).

2

CN2116 Controller iii

Safety Information Installation and Operation Handbook

INSTALLATION SAFETY REQUIREMENTS

Personnel

Installation must be carried out by qualified personnel only.

Enclosure of live parts

To prevent hands or metal tools touching parts that may be

electrically live, the controller must be installed in an enclosure.

Wiring

It is important to connect the controller in accordance with the wiring

data given in this handbook. Take particular care not to connect AC

supplies to the low voltage sensor input or the logic output. Wiring

installations must comply with all local wiring regulations.

Isolation

The installation must include a power isolating switch or circuit

breaker. This device should be in close proximity to the controller,

within easy reach of the operator and marked as the disconnecting

device for the instrument.

Overcurrent protection

To protect the internal PCB tracking within the controller against

excess currents, the AC power supply to the controller and relay

output must be wired through the fuse or circuit breaker specified in

the technical specification.

Voltage rating

The maximum continuous voltage applied between any of the

following terminals must not exceed 264Vac:

• power supply to relay, logic or sensor connections;

• relay output to logic or sensor connections;

The controller should not be wired to a three-phase supply with an

ungrounded star connection. Under fault conditions such a supply

could rise above 264Vac with respect to ground and the product

would not be safe.

Voltage transients across the power supply connections, and between

the power supply and ground, must not exceed 2.5kV. Where

occasional voltage transients over 2.5kV are expected or measured,

the power installation to both the instrument supply and load circuits

should include a transient limiting device.

These units will typically include gas discharge tubes and metal oxide

varistors that limit and control voltage transients on the supply line

due to lightning strikes or inductive load switching. Devices are

available in a range of energy ratings and should be selected to suit

conditions at the installation.

iv CN2116 Controller

Installation and Operation Handbook Safety Information

Conductive pollution

Conductive pollution must be excluded from the cabinet in which the

instrument is mounted. For example, carbon dust is a conducting

pollution. To secure a suitable atmosphere in conditions of

conductive pollution, fit an air filter to the air intake of the cabinet.

Where condensation is likely, for example in low temperatures,

include a thermostatically controlled heater in the cabinet.

Grounding

The logic output is not isolated from the sensor input. Because of

this, two possible conditions need to be considered:

• The temperature sensor may be connected to the electrical

heating element and hence be at the heater supply voltage. The

controller is designed to operate under these conditions but the

logic output will also be at the heater potential. You must ensure

that this will not damage the power control device that is

connected to the logic output and that someone servicing the

equipment does not touch the sensor connections or the logic

output while they are live.

• In some installations it is a requirement to replace the

temperature sensor while the controller is still powered up.

Under these conditions, we recommend that the shield of the

temperature detector is grounded. Do not rely on grounding

through the framework of the machine.

Electrostatic discharge precautions

When the controller is removed from its sleeve, some of the exposed

electronic components are vulnerable to damage by electrostatic

discharge from someone handling the controller. To avoid this, when

handling the unplugged controller you should discharge yourself to

ground through a wrist strap with a 1MΩ series resistor.

Over-temperature protection

When designing any control system it is essential to consider what

will happen if any part of the system should fail. In temperature

control applications the primary danger is that the heating will remain

constantly on. Apart from spoiling the product, this could damage

any process machinery being controlled, or even cause a fire.

Reasons why the heating might remain constantly on include:

• the temperature sensor becoming detached from the process;

• the controller failing with its heating output constantly on;

• an external valve or contactor sticking in the heating condition;

• the controller setpoint set too high.

Where damage or injury is possible, we recommend fitting a separate

over-temperature protection unit, with an independent temperature

sensor, which will isolate the heating circuit.

Please note that using the relay within the controller as an alarm

output will not give protection under all failure conditions.

CN2116 Controller v

Installation and Operation Handbook Installation

Chapter 1 INSTALLATION

The CN2116 controller is a compact 1/16 DIN (48x48mm) PID or

On/Off temperature controller with automatic tuning. It has a single

input, which is configurable on-site for either thermocouple,

resistance thermometer, linear millivolts, or linear milliamps. It has

two outputs: a relay output and a logic output for operating a solid

state relay, either of which is configurable for heating, cooling, or

alarms.

This chapter consists of two parts:

♦ MECHANICAL INSTALLATION

♦ ELECTRICAL INSTALLATION

Before proceeding please read Safety and EMC Information.

WARNING

You must ensure that the controller is correctly configured for your

application. Incorrect configuration could result in damage to the

process being controlled and/or personal injury. It is your responsibility

as the installer to ensure that the configuration is correct. The controller

may either have been configured when ordered, or may need configuring

now. See Chapter 5, Configuration.

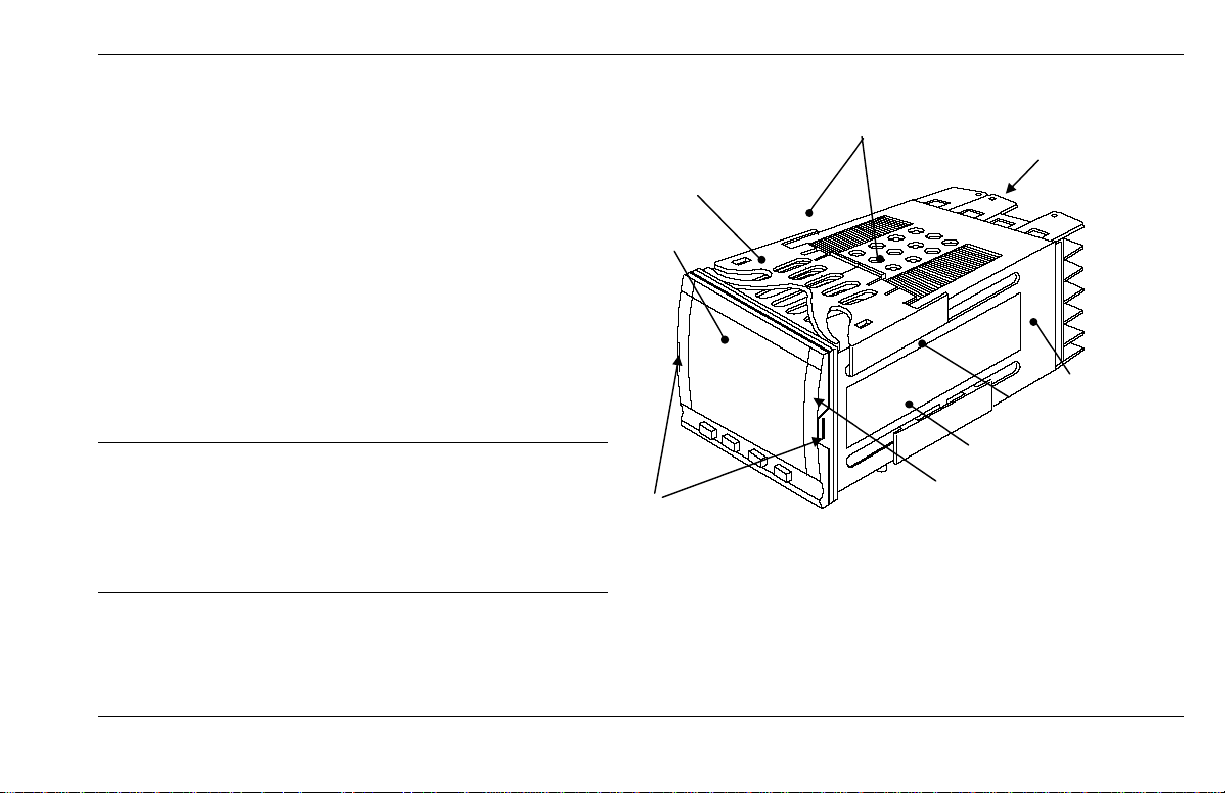

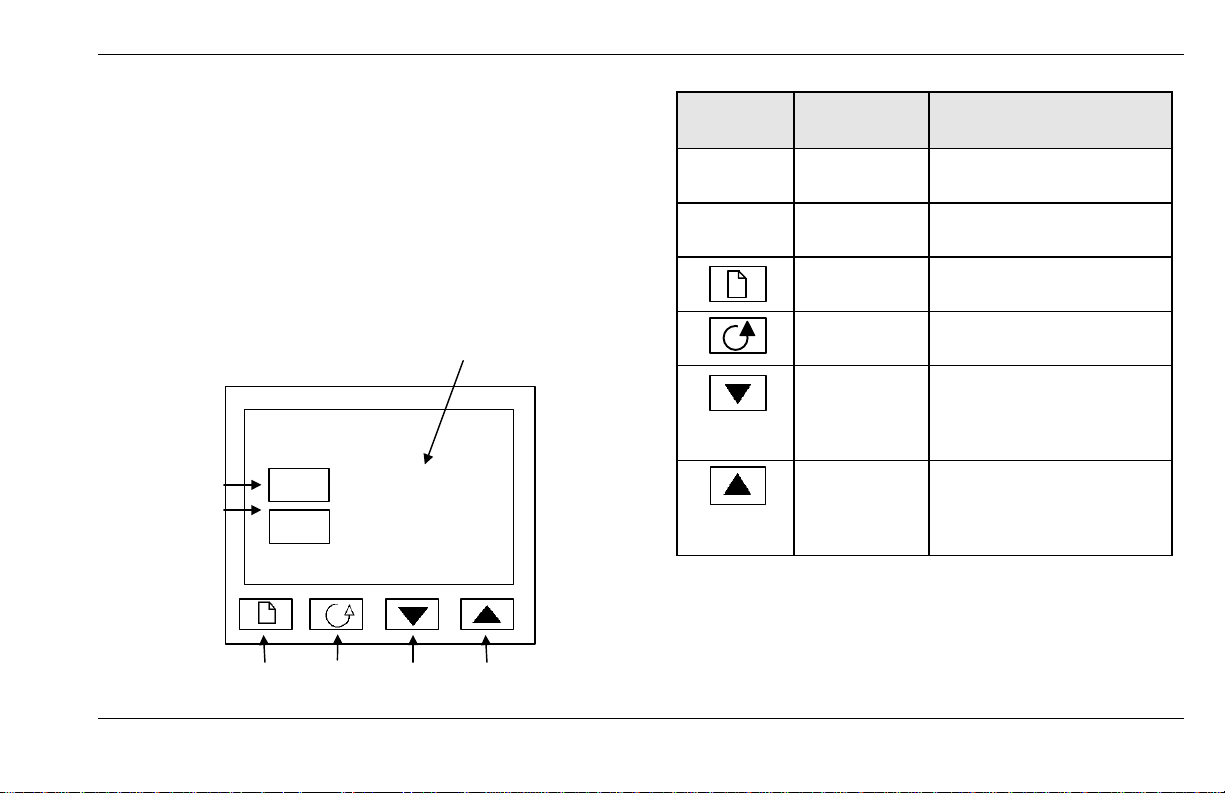

Upper panel

retaining clip

Display screen

Latching

ears

Ratchets

Figure 1-1 CN2116 1/16 DIN controller

Terminal covers

Sleeve

Label

Lower panel

retaining clip

Panel sealing

gasket

CN2116 Controller 1-1

Installation Installation and Operation Handbook

-0.0 +0.6

-0.00 +0.02

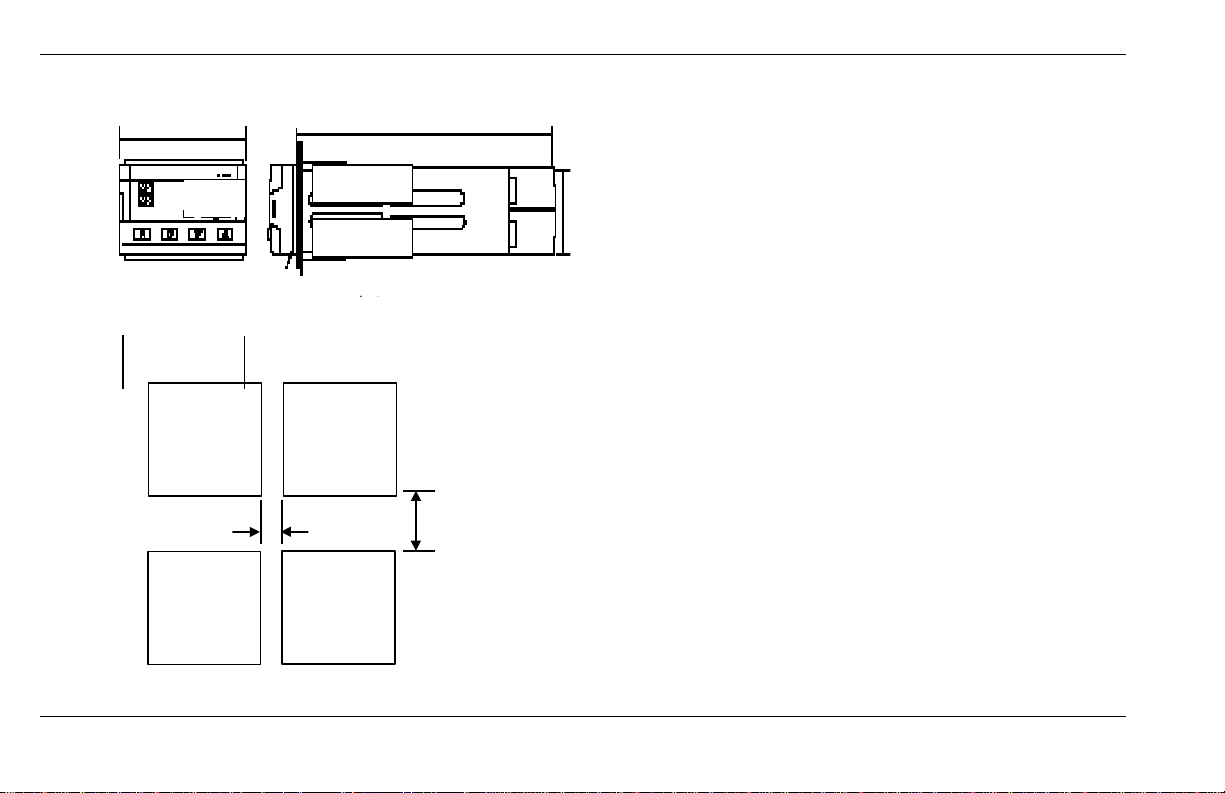

MECHANICAL INSTALLATION

103mm (4.06in)

IP 65, panel sealing

48mm

(1.89in)

CN2116

25.0

48mm (1.89in)

Figure 1-2 Outline dimensions

Panel cut-out and recommended minimum controller

spacings

45 x 45mm

1.78 x 1.78in

10mm (1.5in)

38mm (1.5in)

Unplugging and plugging-in the controller

The electronic assembly of the controller plugs into a rigid plastic

sleeve, which in turn fits into the standard DIN size panel cut-out

shown in Figure 1-3. The controller can be unplugged from it’s

sleeve by easing the latching ears outwards and pulling it forward out

of the sleeve. When plugging the controller back into it’s sleeve,

ensure that the latching ears click into place in order to secure the

IP65 sealing.

To install the controller

1. Prepare the control panel cut-out to the size shown in Figure 1-3.

2. Insert the controller through the panel cut-out.

3. Spring the upper and lower retaining clips in place. Secure

the controller in position by holding it level and pushing both

retaining clips forward.

Note: If you subsequently need to remove the controller sleeve from

the control panel, unhook the retaining clips from the side with either

your fingers or a screwdriver.

Figure 1-3 Panel cut-out and spacings

1-2 CN2116 Controller

Installation and Operation Handbook Installation

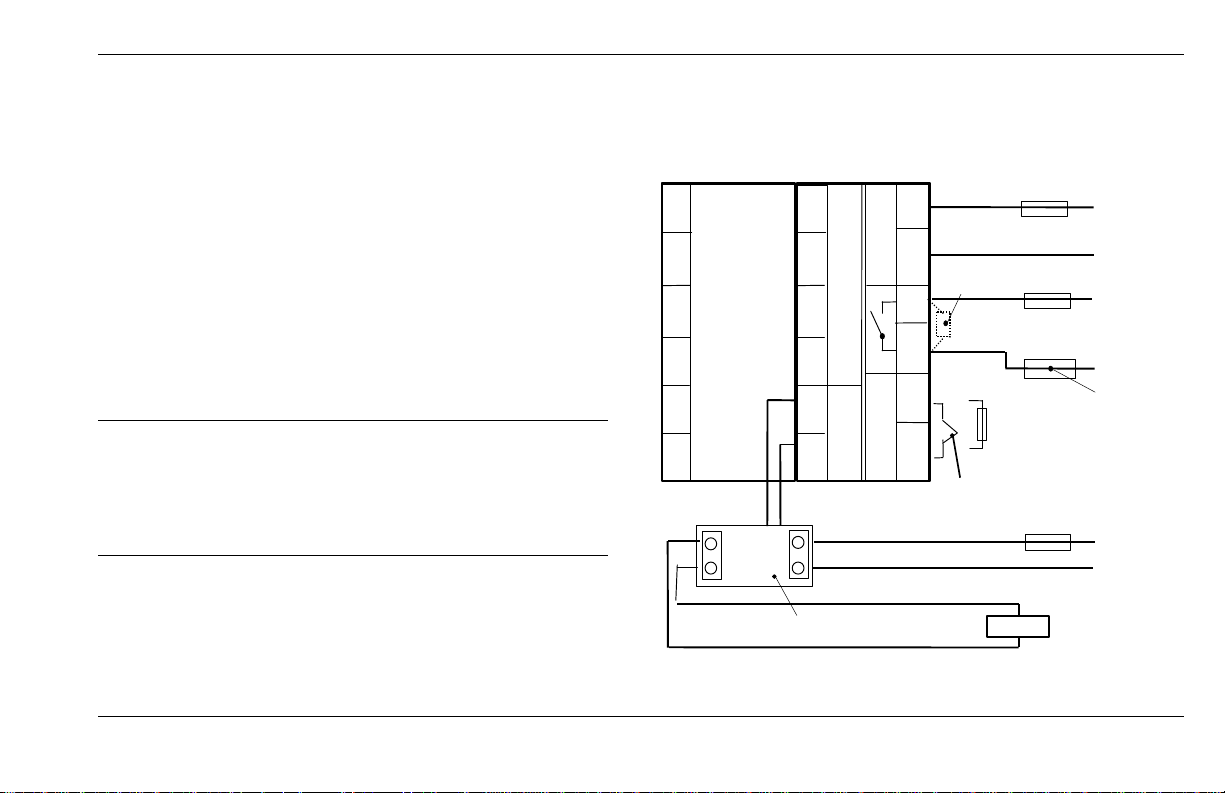

Line

Thermocouple

PT10

2A, 264Vac

2A Fuse

2A Fuse

Snubber

Heater Fuse

Heating

Line

Line

ELECTRICAL INSTALLATION

All electrical connections are made to the screw terminals at the rear

of the controller. If you wish to use crimp connectors, use those

which accept wire sizes from 0.5 to 1.5 mm

Milliamp Inputs

If a milliamp input has been ordered a 2.5Ω sense resistor will be

supplied which must be wired across terminals V- and V+.

Snubber

When switching inductive loads such as contactors and solenoid

valves, the 15nF/100Ω ‘snubber’ provided with the controller should

be wired across the relay terminals AA and AB to prolong contact

life and to suppress interference.

WARNING

When the relay contact is open, the snubber circuit passes 0.6mA at

110Vac and 1.2mA at 240Vac. You must ensure that this current,

2

(16 to 22 awg).

dc pulse

output

9Vdc

18mA

1A

1B

L

U

n

u

s

e

d

n

p

u

85 to 264Vac, 48 to 62Hz

N

AA

AB

I

t

Relay output

V+

RTD/

V-

Neutral

Neutral

Heating,

cooling,

or alarm

contactor

passing through the snubber, will not hold in low power electrical

loads. It is your responsibility as the installer to ensure that this does

not happen.

SSC-TE10S

Neutral

Solid state relay

Figure 1-4 Electrical connections

CN2116 Controller 1-3

Installation and Operation Handbook Operation

button

button

button

Chapter 2 OPERATION

This chapter has six main topics:

• FRONT PANEL LAYOUT

• POWER ON

• PARAMETERS AND HOW TO ACCESS THEM

• PARAMETER NAVIGATION DIAGRAM

• OPERATOR PARAMETER TABLES

• TIMER FUNCTION

• ALARMS

FRONT PANEL LAYOUT

Output 1 on

Output 2 on

OP1

OP2

Readout

CN2116

25.0

Page

Scroll

button

Down

Up

Indicator

or button

OP1 Output 1 When lit, this indicates that

OP2 Output 2 When lit, this indicates that

Figure 2-1 Front Panel Layout

Name Function

the logic output is on.

the relay output is on.

Page button Press to select a new list of

parameters.

Scroll button Press to select a new

parameter in a list.

Down button Press and release to view

the setpoint or a selected

parameter. Keep pressed

to decrease the value.

Up button Press and release to view

the setpoint or a selected

parameter. Keep pressed

to increase the value

Figure 2-2 Indicators and buttons

CN2116 Controller 2-1

Operation Installation and Operation Handbook

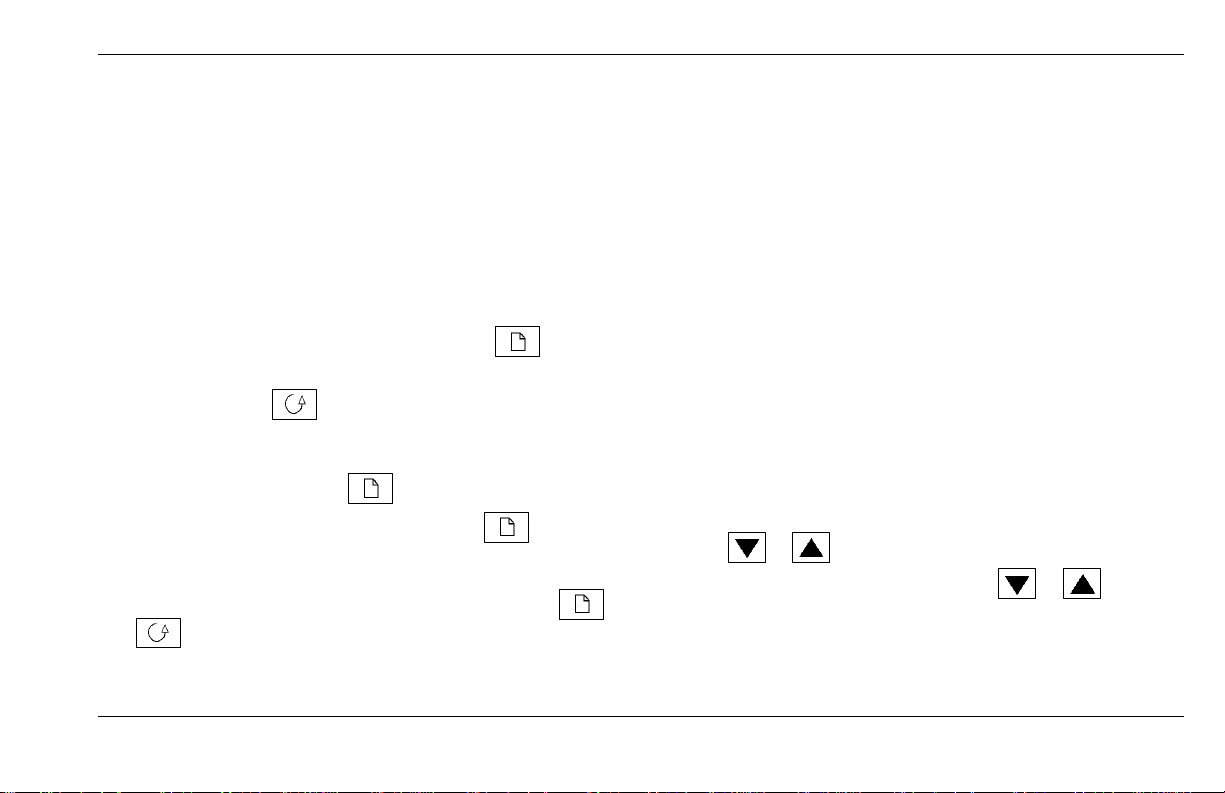

POWER ON

Switch on the power to the controller. It runs through a self-test sequence for about three seconds and then displays the measured value. This is

called the Home display. It is the one you will use most often. From this display you can view and adjust the setpoint as shown below:

The Home display

The measured value is displayed.

Power on

To view the setpoint, press and release either or.

To change the setpoint, keep pressing. Two seconds after releasing

the button, the new value will be accepted and the display will revert

to showing the measured value.

Press the Scroll button once.

X2

OP1

OP2

25.0

OP1

OP2

20.0

Display units

The display units will be shown for 0.5 seconds after which the

display will revert to the Home display.

From the Home Display press the Scroll button twice.

Output power

To view the % output power, press and release or.

This is a read-only value. You cannot change it.

Press and together to return to the Home display.

OP1

OP2

OP

OP1

0

OP2

C

Other parameters

Pressing the Scroll button from the Output Power display may access

further parameters. If setpoint rate limit is enabled then the ‘w. SP’

OP1

OP2

100.0

2-2 CN2116 Controller

display will enable the working setpoint to be accessed. Other

parameters may be in the scroll list if the ‘promote’ feature has been

used (see Edit Level, Chapter 3).

Installation and Operation Handbook Operation

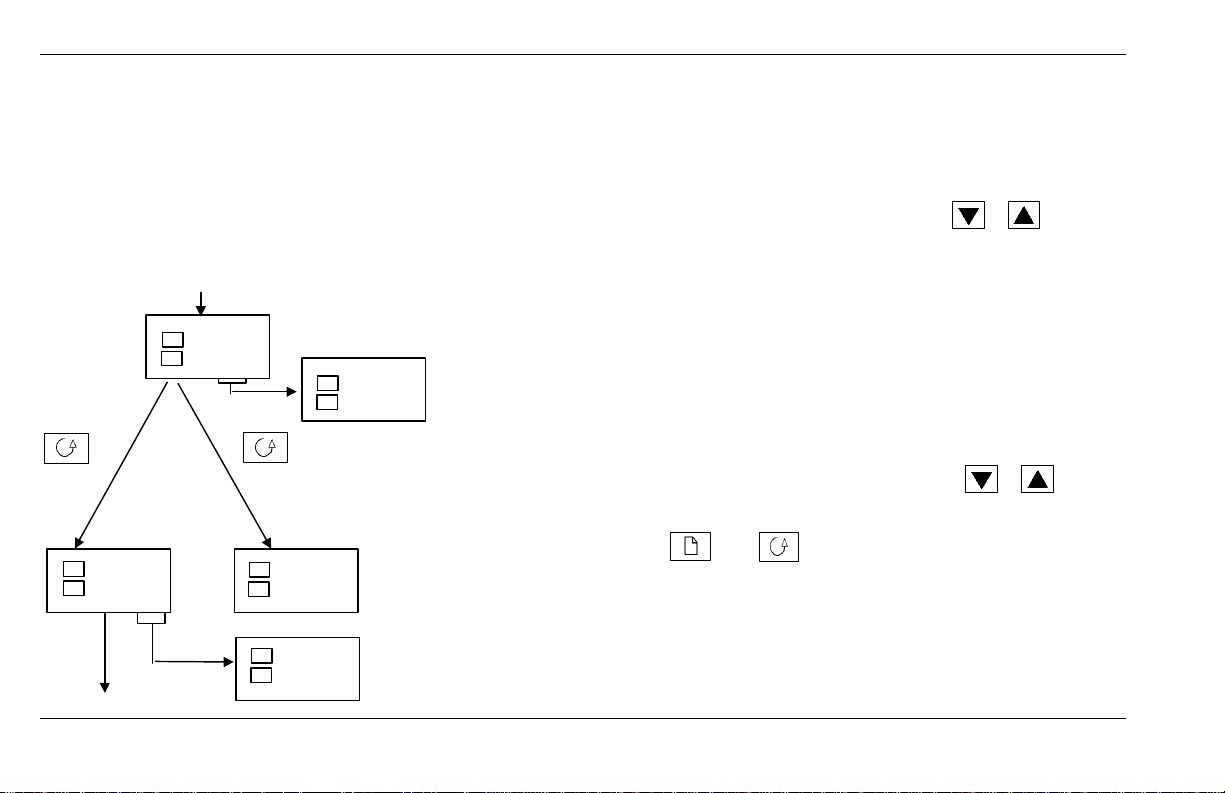

PARAMETERS AND HOW TO ACCESS THEM

Parameters are settings within the controller that determine how the

controller will operate. For example, alarm setpoints are parameters

that set the points at which alarms will occur. For ease of access, the

parameters are arranged in lists, as shown in the navigation diagram

(Figure 2-3). In each list the first item to be displayed is the name of

the list, called the list header. The lists are:

Home list

Alarm list

Autotune list

To step through the list headers press the Page button .

You will eventually return to the Home display.

To step through the parameters within a particular list,

press the Scroll button .

When you reach the end of a parameter list you will return to the list

header. From within a list you can return to the list header at any

time by pressing the Page button.

To step to the next list header press the Page button once

again.

Returning to the Home display

You can get back to the Home display at any time by pressing

and together.

Alternatively, you always get the Home display either if no button is

pressed for 45 seconds or when the power is first turned on.

PID list

Setpoint list

Input list

Output list

On/Off list

Access list.

Parameter names

In the navigation diagram (Figure 2-3) each box depicts the display

for a selected list header or parameter within a list. The Operator

parameter tables later in this chapter list all the parameter names and

their meaning.

The navigation diagram shows all the parameters that potentially can

be present in the controller. In practice, only those associated with a

particular configuration will appear. For example, if no alarms are

configured no alarm parameters will be present and the alarm list will

not appear.

The shaded boxes in the diagram indicate parameters that are hidden

in normal operation. To see all the available parameters, you must

select Full access level. For more information about this, see Chapter

3, Access Levels.

To change the value of a parameter

First, select the required parameter. The parameter name will be

displayed.

To view the parameter value, press and release

either

or .

To change the parameter value, press either or .

In this adjustment, pressing once changes the value by one digit.

Keeping the button pressed speeds up the rate of change.

Two seconds after releasing either button, the readout blinks to show

that the controller has accepted the new value.

CN2116 Controller 2-3

Operation Installation and Operation Handbook

List

(1)

(2)

(2)

(1)

List

3)

(4)

(2)

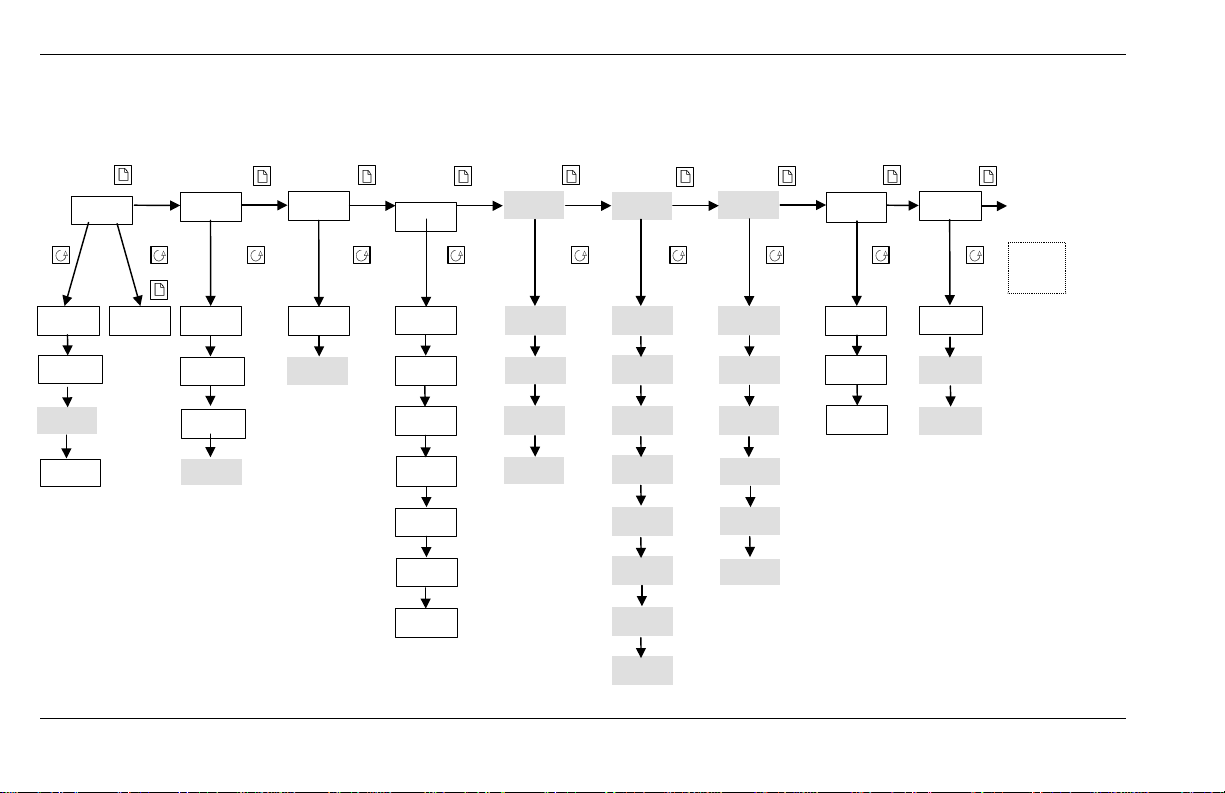

PARAMETER NAVIGATION DIAGRAM

Home

List x2

20.0

Alarm

List

AL

or

x2

oP ºC/F/k

w.SP

m - A ConF

???

Notes:

1. Either the PID list or the On/Off list will be present.

This is dependent upon the control type in use.

2. The last three characters depend upon the type of

alarm configured.

3. If setpoint rate limit is active ‘w.SP’ will be

displayed.

4. Other parameters may appear if the ‘promote’

feature has been used (see Edit Level, Chapter 3).

The shaded boxes are normally hidden in Operator level

2-4 CN2116 Controller

1FSH

2FSL

3dEv

Lb t

Autotune

Atun

tunE

AdC

PID

List

PID

Pb

ti

td

rES

Lcb

Hcb

rEL.C

Setpoint

SP

SP L

SP H

SPrr CYC.H

dwell

Input

List

iP

FiLt

CAL

CAL.L

AdJ.L

CAL.H

Adj.H

Output

List

oP

OP.Lo

OP.Hi

CYC.C

ont.H

ont.C

CJC

Figure 2-3 Operator parameters navigation diagram

mV

On-Off

List

on.OF

hYS.H

hYS.C

HC.db

Access

List

ACCS

Home

List

codE

Goto

Loading...

Loading...