Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

TC-08

8 Channel Thermocouple

USB Data Acquisition Module

Shop online at

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Contents

.....................................................................................................................................11 Introduction

Contents

I

1 Overview

2 Installing the driver

3 Connecting the USB TC-08

4 Safety warning

...........................................................................................................................................1

...........................................................................................................................................1

...........................................................................................................................................1

...........................................................................................................................................4

.....................................................................................................................................52 Product information

1 Specifications

2 How a thermocouple works

...........................................................................................................................................5

...........................................................................................................................................6

.....................................................................................................................................73 Technical reference

1 Introduction

2 Modes of operation

3 Driver routines

4 Programming

5 Troubleshooting

6 Glossary

...........................................................................................................................................7

...........................................................................................................................................7

1 Introduction

2 Streaming mode

3 Get Single mode

4 Legacy mode

...........................................................................................................................................14

1 Introduction

2 New USB mode and legacy mode

3 New USB mode only

4 Legacy mode only

...........................................................................................................................................41

1 Introduction

2 C and C++

3 Delphi

4 Excel

5 LabVIEW

6 Visual Basic

7 Agilent VEE

...........................................................................................................................................43

...........................................................................................................................................44

...........................................................................................................................................7

...........................................................................................................................................8

...........................................................................................................................................10

...........................................................................................................................................12

...........................................................................................................................................14

...........................................................................................................................................15

...........................................................................................................................................29

...........................................................................................................................................34

...........................................................................................................................................41

...........................................................................................................................................41

...........................................................................................................................................41

...........................................................................................................................................42

...........................................................................................................................................42

...........................................................................................................................................42

...........................................................................................................................................42

..............................................................................................................................................47

Index

Page 4

Page 5

Introduction

1

1

1.1

1.2

1.3

Introduction

Overview

The USB TC-08 is a temperature and voltage logger designed to support multiple

thermocouples. With the accompanying TC-08 software, the unit can be used with any

laptop or PC running Windows XP SP2 or Vista. If you are technically-minded and

want to tailor the product to a particular application, you can write your own programs

with the supplied driver.

The driver provides cold junction compensation for thermocouples. The TC-08

software supports up to 20 USB TC-08 devices and the driver can support more (as

many as 64, if you have a high-specification PC).

This manual describes the physical and electrical properties of the USB TC-08, and

provides an explanation of how to use the software drivers. For information on the

USB TC-08 software, please consult the software help file.

Installing the driver

The driver is installed automatically when you install the TC-08 software.

Alternatively, you can download the driver from our website at http://www.omega.com

Connecting the USB TC-08

.

Please note: do not connect the USB TC-08 until you have installed the

software and restarted your PC.

To begin using the USB TC-08, connect it to the USB port on your computer using the

cable provided. Next, connect a thermocouple to one of the thermocouple input

connectors. To complete the installation, select the USB TC-08 unit and thermocouple

type in the TC-08 software as follows:

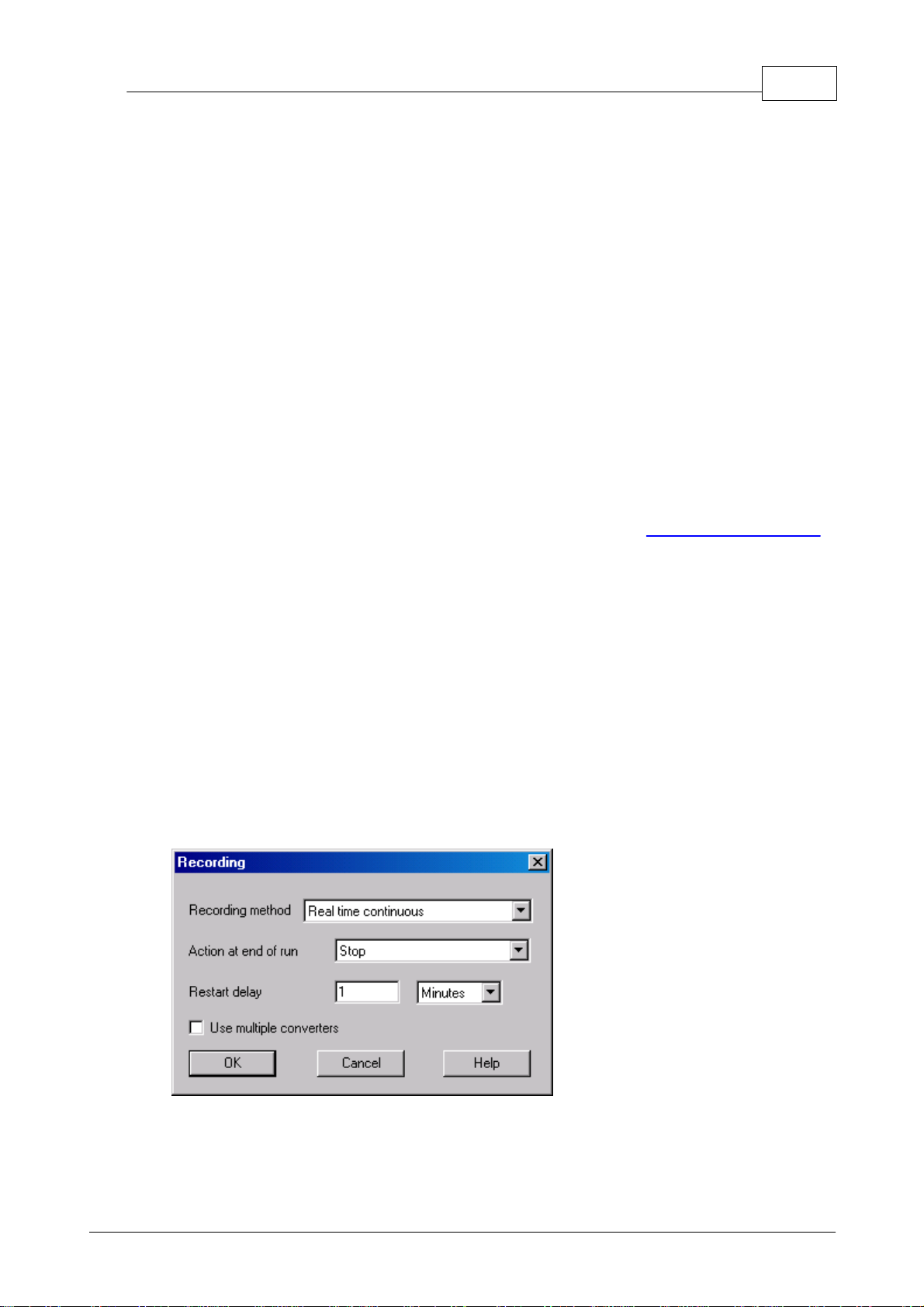

1. Start up the TC-08 Recorder

2. Select New Settings from the File menu.

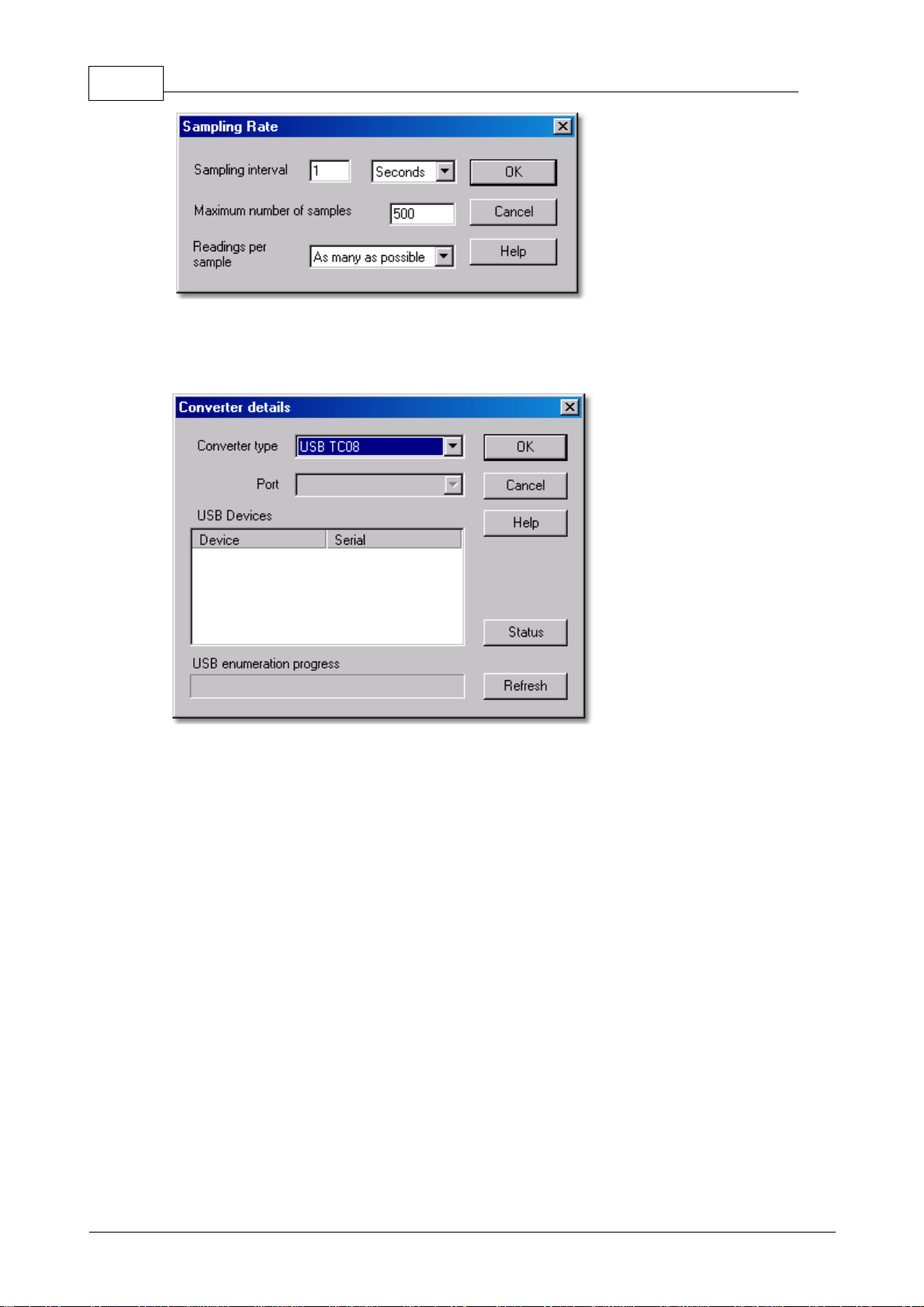

The Recording dialog box appears:

3. Click the OK button.

The Sampling Rate dialog box appears

Page 6

TC-08 User's Guide2

4. Click the OK button.

The Converter details dialog box appears

5. Select USB TC-08 from the drop-down list of converters.

The device name and serial number should appear in the USB Devices pane and

the USB enumeration progress bar gradually expand to 100%. If the progress bar

does not start moving, disconnect and reconnect the USB TC-08, then click

Refresh.

6. In the USB Devices pane, select the USB TC-08. If you are using more than one

USB TC-08, check the serial number on the bottom of the device so that you know

which one to select from the list

7. Click the OK button.

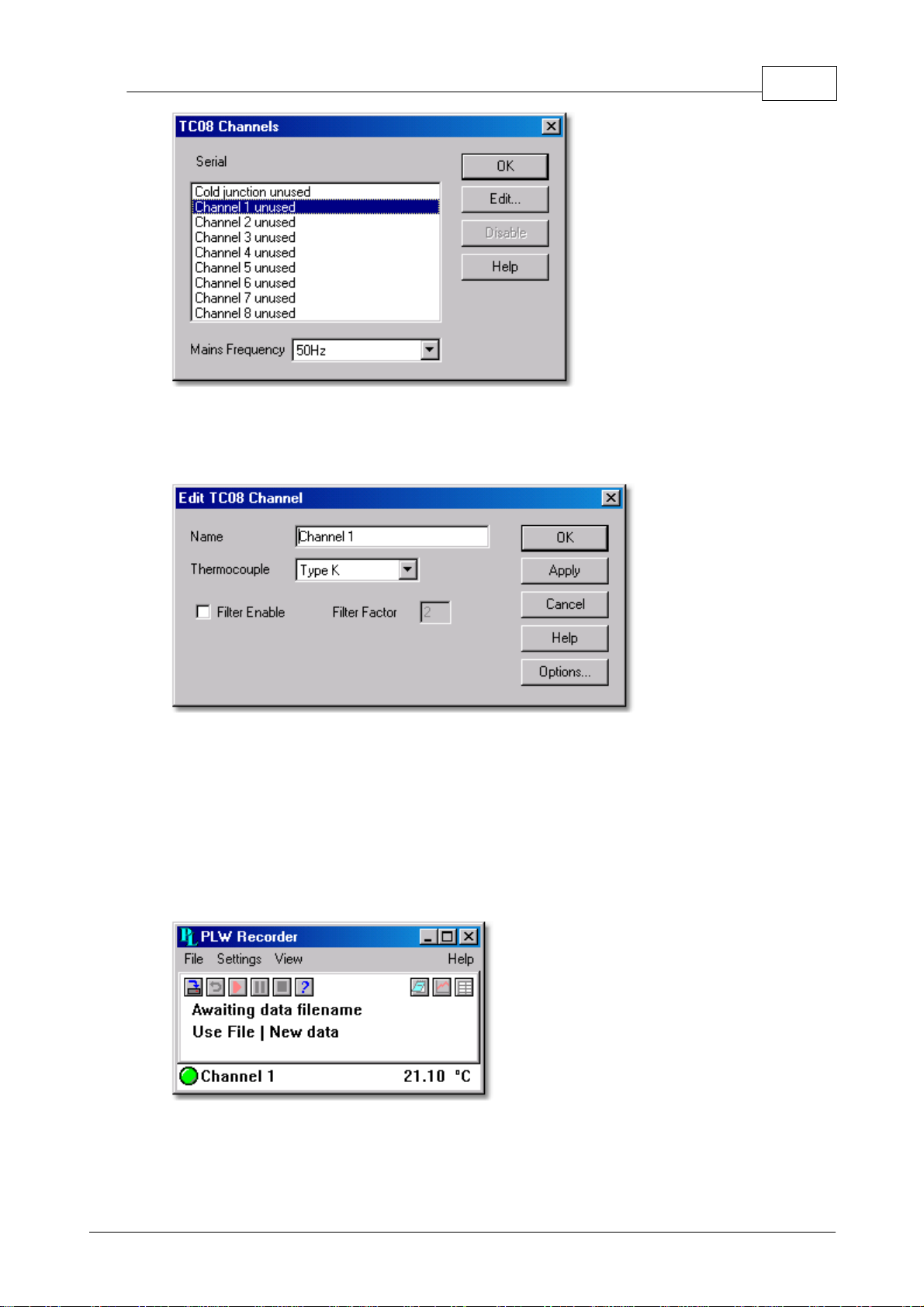

The following dialog box appears

Page 7

Introduction

8. In the TC-08 Channels window, double-click on Channel 1 unused.

The Edit TC-08 Channel dialog box appears

3

9. From the Thermocouple drop-down list, select the type of thermocouple you are

using and click OK.

The TC-08 Channels dialog box reappears.

10. Click OK.

Channel 1 should now appear in the monitor window with the current temperature

reading.

Page 8

TC-08 User's Guide4

1.4

Safety warning

We strongly recommend that you read the general safety information below before

using your product for the first time. If the equipment is not used in the manner

specified, then the protection provided may be impaired. This could result in damage

to your computer and/or injury to yourself or others.

Maximum input range

The USB TC-08 is designed to measure voltages in the range of ±70 mV. Any voltages

in excess of ±30 V may cause permanent damage to the unit.

Mains voltages

These products are not designed for use with mains voltages.

Safety grounding

The ground of every product is connected directly to the ground of your computer

through the interconnecting cable provided. This is done in order to minimise

interference. If the PC (especially laptop) is not grounded, reading stability cannot be

guaranteed and it may be necessary to manually ground the equipment.

Take care to avoid connecting the inputs of the product to anything which may be at a

hazardous voltage. If in doubt, use a meter to check that there is no hazardous AC or

DC voltage. Failure to check may cause damage to the product and/or computer and

could cause injury to yourself or others.

Take great care when measuring temperatures near mains equipment. If a sensor is

accidentally connected to mains voltages, you risk damage to the converter or your

computer and your computer chassis may become live.

You should assume that the product does not have a protective safety earth. Incorrect

configuration or use of the device to measure voltages outside the maximum input

range can be hazardous.

Repairs

The unit contains no user-serviceable parts: repair or calibration of the unit requires

specialised test equipment and must be performed by Omega Engineering.

Page 9

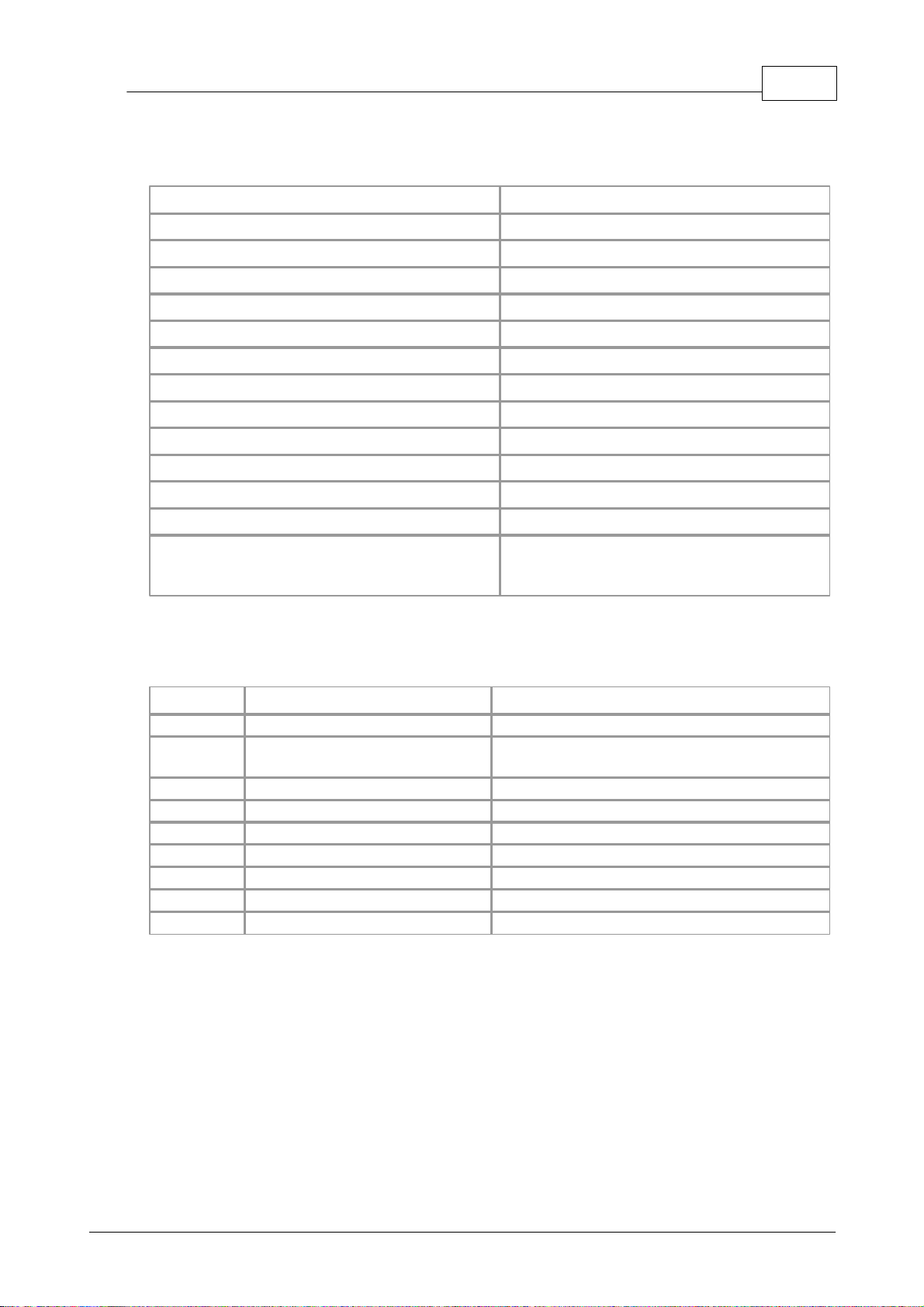

Product information

Resolution

20 bits (16.25 NFR)

Thermocouple types

B,E,J,K,N,R,S,T

Number of input channels

8

Conversion time - per active channel

100 ms

Conversion time - CJC

100 ms

Uncalibrated accuracy

The sum of ±0.2% and ±0.5°C

Full scale input

±70 mV

Common mode range

±7.5 V

Overvoltage protection

±30 V

Input impedance

2 MW

Input connectors

8 x miniature thermocouple

Output connector

USB upstream connector

Power requirements

No power supply required

Environmental conditions

0 to 50°C, 25% to 75% humidity

Quoted accuracy over 20 - 30°C

NOT water-resistant

Actual measurable range

Theoretical ranges

CJC

-5°C to 70°C

N/A

Type B

20°C to 1820°C (CJC must be

>20°C)

0°C to 1820°C

Type E

-270°C to 910°C

-270°C to 1000°C

Type J

-210°C to 1200°C

-210°C to 1200°C

Type K

-270°C to 1370°C

-270°C to 1370°C

Type N

-270°C to 1300°C

-270°C to 1300°C

Type R

-50°C to 1760°C

-50°C to 1760°C

Type S

-50°C to 1760°C

-50°C to 1760°C

Type T

-270°C to 400°C

-270°C to 400°C

5

2

2.1

Product information

Specifications

Note: The resolution and accuracy depend upon the thermocouple type and the

temperature range. Below is a list of the thermocouples and temperature ranges

supported by the USB TC-08.

Page 10

TC-08 User's Guide6

2.2

How a thermocouple works

In a closed circuit of two dissimilar metals (a thermocouple), an electric current flows

when one of the two junctions is heated with respect to the other. The current

continues to flow as long as the two junctions are at different temperatures. The

magnitude and direction of the current is a function of the temperature difference

between the junctions and of the thermal properties of the metals used in the circuit.

This phenomenon is known as the Seebeck Effect.

The conductors can be made of any two dissimilar metals, and when the hot junction

is heated the current flow can be observed. If the positions of the hot and cold

junctions are reversed, current flows in the opposite direction.

A thermocouple circuit actually generates a measurable, low-voltage output that is

almost directly proportional to the temperature difference between the hot junction

and the cold junction. A change in this temperature difference produces some net

change in the voltage.

Note: More information on choosing and using thermocouples can be found at

www.omega.com.

Page 11

Technical reference

7

3

3.1

3.2

3.2.1

Technical reference

Introduction

The USB TC-08 is supplied with driver routines that you can build into your own

programs. The USB TC-08 driver supports Windows XP SP2 and Windows Vista.

Once you have installed the software, the Examples directory will contain the drivers

and a selection of examples of how to use the drivers.

The driver is supplied as a Windows DLL. The DLL uses the C stdcall calling

convention and can be used with C, Delphi and Visual Basic programs. It can also be

used with programs like Microsoft Excel, where the macro language is a form of Visual

Basic.

Modes of operation

Introduction

The USB TC-08 is designed for three specific modes of operation to suit a variety of

applications. The following modes are supported:

Streaming mode

Get Single mode

Legacy mode

Page 12

TC-08 User's Guide8

3.2.2

Streaming mode

Streaming mode is an operational mode in which the USB TC-08 unit samples data

and returns it to the computer in an unbroken sequence, using the onboard clock to

ensure accurate timing.

The unit can buffer up to two sets of readings at once. To avoid loss of readings,

make sure that another application on the PC - including the one you are writing does not prevent the driver from collecting readings for more than three sampling

intervals.

To allow the driver to sample continuously, call the Windows Sleep() function in any

sampling loops (see example below) to make sure that your application does not use

too much processor time.

Hint: Try not to use a Sleep() call for less than 50-100 milliseconds, e.g.,

Sleep(50) or Sleep(100). If you are programming a Windows GUI application, a

good alternative to sampling loops is the WM_TIMER message.

Page 13

Technical reference

Example

The following code is a fragment of a C application demonstrating how to use

Streaming mode with the USB TC-08 driver:

//==================================================

// Setting up and running the unit in Streaming mode

//==================================================

usb_tc08_set_mains(handle, 0); // use 50Hz mains noise rejection

for (channel = 0; channel < 9; channel++)

{

// set each channel up as a type K thermocouple

// channel 0 is the cold junction and will be enabled

// by setting the third argument to anything other than ' '

usb_tc08_set_channel(handle, channel, 'K');

}

// find out how fast the unit can sample in its current setup state

minimum_interval = usb_tc08_get_minimum_interval_ms(handle);

usb_tc08_run(handle, minimum_interval); // sample as fast as possible

// not required (just illustrates that the application

// can be idle while the driver collects the readings)

Sleep(10000);

9

// use a two dimensional array with an array of readings for each

channel

// In a real application, this would be a nested loop to regularly poll

// the unit for readings

for (channel = 0; channel < 9; channel++)

{

no_of_readings = usb_tc08_get_temp( handle,

&reading_buffer[channel],

×_buffer[channel],

buffer_length,

&overflows[channel],

channel,

0, // degrees Celsius units

0); // do not fill missing readings

}

// finished polling, now do something with the readings

// if overflows[channel] is high, then one of the readings

// in reading_buffer[channel] has exceeded the input range

// of the USB TC-08

// only stop the unit when we've completely finished streaming

usb_tc08_stop(handle);

Note: You should close down all other applications while you are performing any

timing-critical data logging tasks. Check that the Windows scheduler does not have

any activities planned during the logging session.

Page 14

TC-08 User's Guide10

3.2.3

Get Single mode

Get Single mode is an operational mode in which readings are produced on demand,

using the usb_tc08_get_single function. Since the function relies entirely on the

timing of the calling application, it is ideal for time intervals greater than 1 minute. If

high-speed sampling is required, use Streaming mode.

Note: The function call overhead can be significant, since it takes approximately 360

ms to convert all 9 channels, equating to 40 ms per channel. To reduce this overhead,

disable channels that are not required.

Page 15

Technical reference

Example

The following code is a fragment of a C application demonstrating how to use Get

Single mode with the USB TC-08 driver:

//========================================================

// Setting up and converting readings with Get Single mode

//========================================================

usb_tc08_set_mains (handle, 0); // use 50Hz mains noise rejection

for (channel = 0; channel < 9; channel++)

{

// set each channel up as a type K thermocouple

// channel 0 is the cold junction and will be enabled

// by setting the third argument to anything other than ' '

usb_tc08_set_channel (handle, channel, 'K');

}

// find out the approximate conversion time

// for a call to usb_tc08_get_single

minimum_interval = usb_tc08_get_minimum_interval_ms (handle);

printf("Conversion time: %d\n", minimum_interval);

// Collect 10 readings over approximately 9 minutes

last_time = GetTickCount();

for (i = 0, i < 10, i++)

{

// do the conversion for all channels

usb_tc08_get_single( handle,

value_array, // short value_array[9]

&overflow_flags,

0); // degrees Celsius units

11

// print out the values

printf("\n\nTime: %d minute(s)", i);

for (c = 0; c < 9; c++)

{

// check for overflows on each channel

// with a bitwise & comparator

// shift the comparison bit to match the channel

if (overflow_flags & (1 << c))

{

printf("\nChannel %d overflowed", c);

}

else // no overflow

{

printf("\nChannel %d: %f", c, value_array[c]);

}

}

if (i < 9)

{

while (60000 > (GetTickCount() - last_time)) // 60000ms = 1 minute

{

Sleep(100); // let other applications run

}

last_time = GetTickCount();

}

}

Page 16

TC-08 User's Guide12

3.2.4

Legacy mode

Legacy mode is designed to aid developers who have already written code for the

serial version of the TC-08 and are not yet ready to rewrite their code for the

Streaming or Get Single modes available with the USB version. The legacy support is

going to be phased out and will eventually be removed from the driver altogether. If

you want full support in the future, use the Streaming or Get Single modes.

To allow code to be easily developed for both the serial version and the USB version of

the TC-08, all the function names have been changed. The

usb_tc08_legacy_set_channel function no longer supports offset and gain - this is now

stored only as calibration information in the unit itself. The legacy routines will be

familiar if you previously used the serial TC-08, but the following changes should be

made to convert legacy applications:

Reference the new Header file

Reference the new Library file

Place the new DLL in the directory of the application

Set the mains frequency

Run and stop the unit

Store a handle returned from usb_tc08_open_unit instead of using the serial port

number

Page 17

Technical reference

13

Example

The following code is a fragment of a C application demonstrating how to use legacy

mode with the USB TC-08 driver:

//==========================================================

// Setting up and running the unit in Legacy mode

// This is designed to make it easier to adapt code written

// for the Serial TC08 for use with the USB TC08

//==========================================================

usb_tc08_set_mains(handle, 0); // use 50Hz mains noise rejection

for (channel = 1; channel < 9; channel++)

{

// set each channel up as a type K thermocouple

// switch off filtering for all channels

usb_tc08_legacy_set_channel(handle, channel, 'K', 0);

}

usb_tc08_legacy_run(handle);

last_cycle_no = 0;

no_of_readings = 0;

while (no_of_readings < 50) // collect 50 readings

{

usb_tc08_legacy_get_cycle(handle, &this_cycle_no);

if (last_cycle_no != this_cycle_no)

{

last_cycle_no = this_cycle_no;

no_of_readings++;

for (channel = 1; channel < 9; channel++)

{

usb_tc08_legacy_get_temp( &reading[channel],

handle,

channel,

0);

}

// now do something with the readings

// check that they have not overflowed

// by comparing each reading with 2147483647L

// or LONG_MAX (include limits.h)

usb_tc08_legacy_get_cold_junction(handle, &cold_junction);

// now do something with the cold junction temperature

}

}

usb_tc08_stop(handle);

Page 18

TC-08 User's Guide14

Routine

Description

New USB and serial mode

usb_tc08_open_unit

Opens the USB TC-08 unit and gets a valid USB handle.

usb_tc08_open_unit_async

Opens the unit asynchronously.

usb_tc08_open_unit_progress

Polls the unit's enumeration progress during

asynchronous operation.

usb_tc08_close_unit

Closes the handle.

usb_tc08_stop

Stops the unit streaming.

usb_tc08_set_mains

Sets the mains interference rejection filter to either 50

Hz or 60 Hz.

usb_tc08_get_minimum_interval_ms

Returns the minimum sampling interval for the current

setup.

usb_tc08_get_unit_info

Retrieves information on a particular unit and presents it

as a structure.

usb_tc08_get_formatted_info

Retrieves information on a particular unit and presents it

in string form.

usb_tc08_get_last_error

Returns the last error for a specified unit or for a call to

open a unit.

New USB mode only

usb_tc08_set_channel

Sets up a USB TC-08 channel.

usb_tc08_run

Starts the USB TC-08 unit streaming.

usb_tc08_get_single

Converts readings from currently set up channels on

demand.

usb_tc08_get_temp

In streaming mode, retrieves temperature readings from

a specified channel.

usb_tc08_get_temp_deskew

In streaming mode, retrieves temperature readings from

a specified channel with time deskewed.

Legacy mode only

usb_tc08_legacy_run

Starts the USB TC-08 unit running in legacy mode.

usb_tc08_legacy_set_channel

Sets up a USB TC-08 channel.

usb_tc08_legacy_get_temp

Retrieves temperature readings from a specified channel.

usb_tc08_legacy_get_cold_junction

Retrieves a temperature reading for the cold junction.

usb_tc08_legacy_get_driver_version

Returns the driver version.

usb_tc08_legacy_get_version

Returns the hardware version of the USB TC-08 unit.

usb_tc08_legacy_get_cycle

Returns the number of readings taken so far.

3.3

3.3.1

Driver routines

Introduction

The following table explains each of the USB TC-08 routines:

Page 19

Technical reference

Arguments

None

15

3.3.2

3.3.2.1

New USB mode and legacy mode

usb_tc08_open_unit

short usb_tc08_open_unit (void)

This routine returns a valid handle to the USB TC-08 if the driver successfully opens it.

If the routine fails, see the error code explanations in the usb_tc08_get_last_error

section. If you wish to use more than one USB TC-08, call this routine once for each

unit connected to the PC. The function will return 0 if there are no more units found.

The driver is thread-safe and will not allow access to a single unit from more than one

application. If, therefore, usb_tc08_open_unit does not find a unit, check that

other applications are not using the USB TC-08. This includes applications on other

user accounts on the same computer, where fast user switching is supported.

Note: The usb_tc08_open_unit function provides a simple way to open USB TC-08

units. However, the function call locks up the calling thread until the attached USB

TC-08 unit has been fully enumerated. If a single-threaded application needs to

perform concurrent processing, such as displaying a progress bar, use

usb_tc08_open_unit_async.

Page 20

TC-08 User's Guide16

Returns

Positive short

The handle of a unit.

0

No more units were found.

-1

Unit failed to open. Call usb_tc08_get_last_error

with a handle of 0 to obtain the error code.

Page 21

Technical reference

17

Example

The following code is a fragment of a C application which demonstrates how to open

multiple units with the USB TC-08 driver. The handles to the open units are stored in

an array for later use:

//======================================================

// Opening multiple units

//======================================================

for (i = 0; (new_handle = usb_tc08_open_unit()) > 0; i++)

{

// store the handle in an array

handle_array[i] = new_handle;

}

no_of_units = i;

// deal with the error if there is one,

// if new_handle was zero, then there was no error

// and we reached the last available unit

if (new_handle == -1)

{

error_code = usb_tc08_get_last_error(0);

printf("Unit failed to open\nThe error code is %d", error_code);

// could terminate the application here

}

//

// Start using the open units

//

Page 22

TC-08 User's Guide18

Arguments

None

Returns

1

The call was successful.

0

No more units were found.

-1

An error occurred, call usb_tc08_get_last_error with a

handle of 0 to obtain the error code.

3.3.2.2

usb_tc08_open_unit_async

short usb_tc08_open_unit_async (void)

This routine begins enumerating USB TC-08 units in the background and provides a

return immediately, so the calling thread can continue executing other code.

Note: The driver is thread safe and will not allow access to a single unit from more

than one application. If, therefore, usb_tc08_open_unit_async does not find a

unit, check that other applications are not using the same USB TC-08. This includes

applications on other user accounts on the same computer, where fast user switching

is supported.

Page 23

Technical reference

19

Example

The following code is a fragment of a C application which demonstrates how to open a

single unit with the asynchronous open unit functions:

//======================================================

// Opening a unit asynchronously

//======================================================

// Tell the driver to start enumerating the unit in the background

// (usb_tc08_open_unit_async returns immediately)

result = usb_tc08_open_unit_async();

// handle any error conditions

if (result == -1)

{

error_code = usb_tc08_get_last_error(0);

printf("Unit failed to open\nThe error code is %d", error_code);

// could terminate the application here

}

else if (result == 0)

{

printf("No USB TC08 units found");

// could terminate the application here

}

// No errors, so start polling usb_tc08_open_unit_progress

// continuously for its enumeration state

do

{

result = usb_tc08_open_unit_progress(&handle, &progress);

switch (result)

{

case USBTC08_PROGRESS_FAIL: // enum equates to: -1

error_code = usb_tc08_get_last_error(0);

printf("Unit failed to open\nThe error code is %d", error_code);

// could terminate the application here

break;

case USBTC08_PROGRESS_PENDING: // enum equates to: 0

printf("\nThe unit is %d percent enumerated", progress);

Sleep(500); // wait for approx. half a second

break;

case USBTC08_PROGRESS_COMPLETE: // enum equates to: 1

printf("\n\nThe unit with handle '%d', opened successfully",

handle);

break;

}

}

while (result == USBTC08_PROGRESS_PENDING);

//

// Start using the open unit

//

Page 24

TC-08 User's Guide20

Arguments

handle

(Out) A handle (positive short) to the unit if the enumeration

is completed. Handle will always be 0 if the enumeration is

incomplete.

progress

(Out) (Optional - can pass NULL) returns a number from 0 to

100 representing the percentage completion of the

enumeration of one unit.

Returns

-1

USBTC08_PROGRESS_FAIL

An error occurred, call

usb_tc08_get_last_error with a

handle of 0 to obtain the error code.

0

USBTC08_PROGRESS_PENDING

Enumeration has not completed

(keep calling

usb_tc08_open_unit_progress).

1

USBTC08_PROGRESS_COMPLETE

Enumeration has completed and the

handle is now valid.

3.3.2.3

usb_tc08_open_unit_progress

short usb_tc08_open_unit_progress

(

short * handle,

short * progress

)

Call this function after usb_tc08_open_unit_async. Repeatedly call it to determine

the state of the background enumeration process. For an example of usage, see

usb_tc08_open_unit_async.

Page 25

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

Returns

0

Use usb_tc08_get_last_error.

1

Unit closed successfully.

21

3.3.2.4

usb_tc08_close_unit

short tc08_close_unit

(

short handle

)

This routine closes the unit for a specified USB handle.

Note: If you successfully open any USB TC-08 units, call usb_tc08_close_unit for each

handle before you exit from your program. If you do not, there is a chance that the

unit will not reopen until it has been disconnected and reconnected.

Page 26

TC-08 User's Guide22

Arguments

handle

Specifies the USB TC-08 unit.

Returns

0

Invalid parameter.

1

Unit stopped streaming successfully.

3.3.2.5

usb_tc08_stop

short usb_tc08_stop

(

short handle

)

This routine stops the unit from running.

Page 27

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

sixty_hertz

Specifies whether to reject 50 Hz or 60 Hz. If set to 1,

the unit will reject 60 Hz, if set to 0, the unit will reject

50 Hz.

Returns

0

Use usb_tc08_get_last_error.

1

Mains rejection set correctly.

23

3.3.2.6

usb_tc08_set_mains

short usb_tc08_set_mains

(

short handle,

short sixty_hertz

)

This routine sets the USB TC-08 to reject either 50 or 60 Hz.

Note: If the rejection is not set correctly the unit will be more susceptible to mains

interference.

Page 28

TC-08 User's Guide24

Arguments

handle

Specifies the USB TC-08 unit.

Returns

0

Use usb_tc08_get_last_error.

Minimum

Interval

Minimum sampling interval for current setup (in

milliseconds).

3.3.2.7

usb_tc08_get_minimum_interval_ms

long usb_tc08_get_minimum_interval_ms

(

short handle

)

This routine returns the minimum sampling interval (or fastest millisecond interval)

that the unit can achieve in its current configuration. The configuration is defined by

calling usb_tc08_set_channel().

Note: The USB TC-08 can sample, from a single channel, at a rate of 10 samples per

second. The absolute minimum sampling interval, with all 8 channels and the cold

junction enabled, is 900 ms. You must set up all the channels that you wish to use

before calling this routine.

Page 29

Technical reference

Arguments

handle

Specifies the TC-08 unit.

info

A pointer to a structure containing unit information.

Returns

0

Use usb_tc08_get_last_error.

1

Routine was successful.

25

3.3.2.8

usb_tc08_get_unit_info

short usb_tc08_get_unit_info

(

short handle,

USBTC08_INFO * info

)

This routine gets the unit information and copies it to the USBTC08_INFO structure,

declared in the usbtc08.h header file. If you pass zero to the function as the handle,

only the driver version member will be valid, but the function will return 1 (success.)

You must assign the correct value to the size field of your USBTC08_INFO structure

before calling this routine. For example, in C, if devinfo is your structure, use this

code:

devinfo.size = sizeof(USBTC08_INFO);

usb_tc08_get_unit_info(hTC08, &devinfo);

Page 30

TC-08 User's Guide26

Arguments

handle

Specifies the USB TC-08 unit.

unit_info

A string where the unit info is to be placed.

string_length

Length of the string to be copied. Should be at least

256 (USBTC08_MAX_INFO_CHARS) characters long.

Returns

0

Too many bytes to copy, will copy as many full lines

as possible.

1

Routine was successful.

3.3.2.9

usb_tc08_get_formatted_info

short usb_get_formatted_info

(

short handle,

char * unit_info,

short string_length

)

This function is similar to the usb_get_unit_info routine, but the unit information is

returned in the form of a formatted character string. The string is separated into the

following elements, each appearing on a different line: driver version; hardware

version; variant info; serial number; calibration date.

Page 31

Technical reference

Error

code

Error

Further information

0

USBTC08_ERROR_OK

No error occurred.

1

USBTC08_ERROR_OS_NOT_SUPPORTED

The driver supports Windows

XP SP2 and Vista.

2

USBTC08_ERROR_NO_CHANNELS_SET

A call to usb_tc08_set_channel

is required.

3

USBTC08_ERROR_INVALID_PARAMETER

One or more of the function

arguments were invalid.

4

USBTC08_ERROR_VARIANT_NOT_SUPPORTED

The hardware version is not

supported. Download the latest

driver.

5

USBTC08_ERROR_INCORRECT_MODE

An incompatible mix of legacy

and non-legacy functions was

called (or usb_tc08_get_single

was called while in streaming

mode.)

6

USBTC08_ERROR_ENUMERATION_INCOMPLETE

usb_tc08_open_unit_async

was called again while a

background enumeration was

already in progress.

27

3.3.2.10

usb_tc08_get_last_error

short usb_tc08_get_last_error

(

short handle

)

This routine returns the last error for the unit specified by handle. If zero is passed

instead of a handle, the function returns the error associated with the last call to

usb_tc08_open_unit or usb_tc08_open_unit_async.

Note: If an invalid handle is passed to a function, the function will fail. The error code,

however, cannot be associated with a unit so usb_tc08_get_last_error will not

retain an error code in this instance. usb_tc08_get_last_error will also fail if the

invalid handle is passed to it.

The error codes, also found in the C header file, are as follows:

User/Developer error codes:

Note: For more details on error codes, see troubleshooting.

Page 32

TC-08 User's Guide28

Error

code

Error

Further information

7

USBTC08_ERROR_NOT_RESPONDING

Cannot get a reply back from a USB

TC-08 unit.

8

USBTC08_ERROR_FW_FAIL

Unable to download firmware.

9

USBTC08_ERROR_CONFIG_FAIL

Missing or corrupted EEPROM.

10

USBTC08_ERROR_NOT_FOUND

Cannot find enumerated device.

11

USBTC08_ERROR_THREAD_FAIL

A threading function failed.

12

USBTC08_ERROR_PIPE_INFO_FAIL

Can not get USB pipe information.

13

USBTC08_ERROR_NOT_CALIBRATED

No calibration date was found.

14

USBTC08_ERROR_PICOPP_TOO_OLD

An old picopp.sys driver was found

on the system.

Arguments

handle

Specifies the USB TC-08 unit.

Returns

-1

Invalid handle.

Error

code

See the error code information above for further

explanation.

Reserved error codes

Note: These reserved error code values are meaningful only to our technical support

staff, but they are supplied to allow developers to display warnings in their

applications. For more details on error codes, see troubleshooting.

Page 33

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

channel

Specifies which channel you want to set the details for: this

should be between 0 - 8 (0 denotes the cold junction.)

tc_type

Specifies what type of thermocouple is connected to this

channel. Set to one of the following characters: 'B', 'E', 'J',

'K', 'N', 'R', 'S', 'T.' Use a space in quotes to disable the

channel. Voltage readings can be obtained by passing 'X' as

the character.

Returns

0

Use usb_tc08_get_last_error.

1

Routine was successful.

29

3.3.3

3.3.3.1

New USB mode only

usb_tc08_set_channel

short usb_tc08_set_channel

(

short handle,

short channel,

char tc_type

)

Call this routine once for each channel that you want to use. You can do this any time

after calling usb_tc08_open_unit

. By default, all channels are disabled.

Note: The CJC is always enabled automatically if a thermocouple is being used. When

no channels are active as thermocouples, the CJC can be optionally enabled or

disabled.

Page 34

TC-08 User's Guide30

Arguments

handle

Specifies the USB TC-08 unit.

interval

Specifies the requested sampling period. You can use

usb_tc08_get_minimum_interval_ms to obtain the smallest

sampling period permitted with the current setup.

Returns

0

Use usb_tc08_get_last_error.

Interval

Actual interval allowed by the driver.

3.3.3.2

usb_tc08_run

long usb_tc08_run

(

short handle,

long interval

)

This routine starts the unit running with a sampling interval, specified in milliseconds.

This routine should be called after usb_tc08_set_channel has been called.

Page 35

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

temp

Pointer to an array of length [9]. There are 9

channels on the USB TC-08 (8 + cold junction) and

the readings are always placed in the array

subscript corresponding to the channel number.

Channels which are not enabled are filled with

QNaN values.

overflow_flags

Pointer to a variable containing a set of bit flags

that are set high when an overflow occurs on a

particular channel. An overflow occurs when the

input signal is higher than the measuring range of

the USB TC-08.

The lowest significant bit (bit 0) represents channel

0 (the cold juction channel) and bit 8 represents

channel 8 (the last thermocouple channel). Bitwise

comparisons should be performed to determine the

overflow state of each channel.

units

Specifies the temperature units for returned data:

0: USBTC08_UNITS_CENTIGRADE

1: USBTC08_UNITS_FAHRENHEIT

2: USBTC08_UNITS_KELVIN

3: USBTC08_UNITS_RANKINE

Returns

0

An error occurred, use usb_tc08_get_last_error to

get the code.

1

The function succeeded.

31

3.3.3.3

usb_tc08_get_single

short usb_tc08_get_single

(

short handle,

float * temp,

short * overflow_flags,

short units

)

You must set up the channels before calling this function. You must not have put the

unit into Streaming mode with usb_tc08_run, as this will cause

usb_tc08_get_single to fail. The function will convert all readings on demand. For

more details and an example see the Get Single mode section.

Page 36

TC-08 User's Guide32

Arguments

handle

Specifies the USB TC-08 unit.

temp_buffer

Pointer to a location where the readings are to be placed.

times_ms_buffer

Returns the time that the first channel was converted

(optional.)

buffer_length

Length of data buffers.

overflow

Pointer to a variable that will be assigned a value of 1 if

an overflow occured on any of the readings copied into

temp_buffer, or 0 if an overflow did not occur. An

overflow occurs when the input signal is higher than the

measuring range of the USB TC-08.

channel

Specifies the channel to read the temperature from.

units

Specifies the temperature units for returned data:

0: USBTC08_UNITS_CENTIGRADE

1: USBTC08_UNITS_FAHRENHEIT

2: USBTC08_UNITS_KELVIN

3: USBTC08_UNITS_RANKINE

Voltages are always returned in millivolts

fill_missing

Choose whether or not to replace QNaN values with the

last known value:

0 - Use QNaNs to represent missing readings

1 - Fill missing readings with previous good reading.

Returns

-1

An error occurred, use usb_tc08_get_last_error to get the

code.

0

Currently no readings to collect.

> 0

Number of readings copied into array (there may still be

more readings in the driver's internal buffer.)

3.3.3.4

usb_tc08_get_temp

long usb_tc08_get_temp

(

short handle,

float * temp_buffer,

long * times_ms_buffer,

long buffer_length,

short * overflow,

short channel,

short units,

short fill_missing

)

Once you open the driver and set up some channels, you can call the usb_tc08_run

routine. The driver will then begin to continually take readings from the USB TC-08.

Use the usb_tc08_get_temp routine to retrieve readings from the driver's buffer

periodically. You must call the function at least once per minute to avoid losing data

(the driver's buffer is circular, so the oldest readings will be overwritten first).

Streaming mode relies on the driver to buffer readings without interruption. If the

driver does not get enough share of the PC's processor time (the most frequent cause

of which is too many applications running at the same time), readings will be dropped

and the sample buffer will be padded with QNaN floating integers.

Warning: The padding of the buffer is also dependent on the performance of the PC

and under very heavy processor loading, padding may not always be accurate.

Page 37

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

temp

Pointer to a location where the temperature is to be

placed.

times_ms_buffer

Returns the exact time that this channel was

converted (optional.)

buffer_length

Specifies the length of the sample buffer.

overflow

Pointer to a variable that will be assigned a value of

1 if an overflow occurred on any of the readings

copied into temp_buffer, or 0 if an overflow did not

occur. An overflow occurs when the input signal is

higher than the measuring range of the USB

TC-08.

channel

Specifies the channel to read the temperature from.

units

Specifies the temperature units in which the data

are returned:

0: USBTC08_UNITS_CENTIGRADE

1: USBTC08_UNITS_FAHRENHEIT

2: USBTC08_UNITS_KELVIN

3: USBTC08_UNITS_RANKINE

Voltages are always returned in millivolts.

fill_missing

Choose whether or not to replace QNaN values

(missing readings) with the last known value:

0 - Use QNaNs to represent missing readings.

1 - Fill missing readings (no QNaNs.)

Returns

-1

An error occurred, use usb_tc08_get_last_error to

get the code.

0

Currently no readings to collect.

> 0

Number of readings copied into array (there may

still be more readings in the driver's internal

buffer.)

33

3.3.3.5

usb_tc08_get_temp_deskew

long usb_tc08_get_temp_deskew

(

short handle,

float * temp,

long * times,

long buffer_length,

short * overflow,

short channel,

short units,

short fill_missing

)

Same as usb_tc08_get_temp but the times take account of small differences caused

by the order in which channels are converted. Note: Unless there is a specific reason

to use the usb_tc08_get_temp_deskewed routine, use usb_tc08_get_temp

instead.

Page 38

TC-08 User's Guide34

Arguments

handle

Specifies the USB TC-08 unit.

Returns

0

Use usb_tc08_get_last_error.

1

Legacy run successful.

3.3.4

3.3.4.1

Legacy mode only

usb_tc08_legacy_run

short usb_tc08_legacy_run

(

short handle

)

This routine starts the sampling thread and forces the specified unit to run in legacy

mode.

Page 39

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

channel

Specifies which channel you want to set the details

for: This should be between 0 and 8.

tc_type

Specifies what type of thermocouple is connected to

this channel. Set to one of the following characters

'B', 'E', 'J', 'K', 'N', 'R', 'S', 'T.' Use a space in quotes

to disable the channel.

filter_factor

Specifies the size of the median filter. Each time the

driver takes a reading from this channel, it updates

the filtered value by adding a reading to a median

filter. The filter factor can be set to any value

between 0 - 255 (0 or 1 turns filtering off).

filter_factor

These parameters are provided for backward

compatibility with the serial TC-08 and have no effect

when used with the USB TC-08.

Returns

0

Use usb_tc08_get_last_error.

1

Legacy set channel successful.

35

3.3.4.2

usb_tc08_legacy_set_channel

short usb_tc08_legacy_set_channel

(

short handle,

short channel,

char tc_type,

short filter_factor,

short offset,

short slope

)

Call this routine once for each channel that you would like to take readings from. You

can do this any time after calling usb_tc08_open_unit.

Note: Do not call this function unless you are operating the USB TC-08 in legacy

mode, having called usb_tc08_legacy_run.

Page 40

TC-08 User's Guide36

Arguments

channel

Specifies from which channel to read temperature. Should

be 0 for CJC, 1 for Channel 1, 2 for Channel 2 and so on.

temp

Pointer to a location where readings are to be placed. Each

reading should be compared with 2147483647L or

LONG_MAX (include limits.h) to check for overflows. An

overflow occurs when the input signal is higher than the

measuring range of the USB TC-08.

filtered

Specifies whether or not to filter the data. The readings

are median filtered if set to 1. 0 causes the unfiltered

temperature to be stored in temp. The filter has a depth

defined by the filter factor, set during a

usb_legacy_set_channel call.

Returns

0

Use usb_tc08_get_last_error.

1

Temperature retrieval successful.

3.3.4.3

usb_tc08_legacy_get_temp

short usb_tc08_legacy_get_temp

(

long * temp,

short handle,

short channel,

short filtered

)

Once you open the driver and define some channels, you can call the

usb_tc08_legacy_run routine. The driver will then constantly take readings from the

USB TC-08. Temperatures are returned in hundredths of a degree Celsius and

voltages are returned in microvolts.

Note: Do not call this function unless you are operating the USB TC-08 in legacy

mode, having called usb_tc08_legacy_run.

Page 41

Technical reference

Arguments

handle

Specifies USB TC-08 unit.

temp

Pointer to a location where the temperature reading is to be

stored.

Returns

0

Use usb_tc08_get_last_error.

1

Retrieval of cold junction temperature reading successful.

37

3.3.4.4

usb_tc08_legacy_get_cold_junction

short usb_tc08_legacy_get_cold_junction

(

long * temp,

short handle

)

This routine retrieves a cold junction temperature reading. This can also be achieved

by passing channel = 0 to usb_tc08_get_temp. Temperatures are returned in

hundredths of a degree Celsius. Normally, you do not need to worry about the cold

junction temperature, as the driver automatically uses it to compensate

thermocouples. You can, however, use it as an indication of ambient temperature.

Page 42

TC-08 User's Guide38

Arguments

none

Returns

Driver version

number

3.3.4.5

usb_tc08_legacy_get_driver_version

short usb_tc08_legacy_get_driver_version

(

void

)

This routine returns the driver version. This is useful when you need to find out if the

latest driver is being used.

Page 43

Technical reference

Arguments

handle

Specifies the USB TC-08 unit.

version

Pointer to a location where the version number is to be

stored.

Returns

0

Invalid handle.

1

Retrieval of version number successful.

39

3.3.4.6

usb_tc08_legacy_get_version

short usb_tc08_legacy_get_version

(

short * version,

short handle

)

This routine sets the 'version' variable to match the version of the USB TC-08

currently being used.

Page 44

TC-08 User's Guide40

Arguments

handle

Specifies a USB TC-08 unit.

cycle

Pointer to a location where the cycle number is to be stored.

Returns

0

Use usb_tc08_get_last_error.

1

Legacy get cycle successful.

3.3.4.7

usb_tc08_legacy_get_cycle

short usb_tc08_legacy_get_cycle

(

long * cycle,

short handle

)

This routine gives the number of complete cycles of readings taken from a particular

USB TC-08. Calling usb_tc08_legacy_get_temp causes the most recent reading for the

specified channel to be returned immediately. If you wish to record values only when

the driver has taken a new reading, you can use this routine to find out how many

complete cycles of readings the driver has taken. Then you can call

usb_tc08_legacy_get_temp, but only when the cycle has been incremented.

Tip: Do not test for an exact cycle number; instead, test for a different cycle number

as your application may have missed readings. See the Legacy mode section for an

example.

Note: Do not call this function unless you are operating the USB TC-08 in legacy

mode, having called usb_tc08_legacy_run.

Page 45

Technical reference

usb_tc08.c

usb_tc08.rc

either

usbtc08bc.lib

(Borland 32-bit applications)

or

usbtc08.lib

(Microsoft Visual C 32-bit applications)

usb_tc08.rch

usbtc08.h

usbtc08.dll

(all 32-bit applications)

41

3.4

3.4.1

3.4.2

Programming

Introduction

We supply examples for the following programming languages:

C and C++

Delphi

Excel

LabVIEW

Visual Basic

Agilent VEE

The example programs are installed in the Examples subdirectory of your TC-08

program directory.

C and C++

C

The C example program is a generic Windows application: it does not use Borland

AppExpert or Microsoft AppWizard. To compile the program, create a new project

containing the following files:

3.4.3

The following files must be in the same directory:

C++

C++ programs can access all versions of the driver. If usbtc08.h is included in a

C++ program, the PREF1 macro expands to extern "C": this disables name-mangling

(or name-decoration), and enables C++ routines to make calls to the driver routines

using C headers.

Delphi

The WIN sub-directory contains a simple program usbtc08.dpr which opens the

drivers and reads temperatures from the three channels. You will need the following

files to build a complete program.

USBTC08FM.dfm

USBTC08FM.PAS

usbtc08.inc

The file usbtc08.inc contains procedure prototypes for the driver routines. You can

include this file in your application.

This example has been tested with Delphi versions 1, 2 and 3.

Page 46

TC-08 User's Guide42

3.4.4

3.4.5

3.4.6

Excel

The easiest way to transfer data to Excel is to use the TC-08 software application.

If, however, you need to do something that is not possible using the TC-08 software,

you can write an Excel macro which calls usbtc08.dll to read in a set of data

values. The Excel Macro language is similar to Visual Basic.

The example usbTC0832.XLS reads in 20 values of the cold junction temperature

and channel 1 temperature, one per second, and assigns them to cells A1..B20.

LabVIEW

While it is possible to access all of the driver routines described earlier, it is easier to

use the special LabVIEW access routine.

To use this routine, copy usbtc08.vi from the Examples subdirectory to your

LabVIEW user.lib directory. You will then need usb_tc08 sub-vi and an example

sub-vi which demonstrate how to use them. You can use one of these sub-vis for each

of the channels that you wish to measure. The sub-vi returns a temperature for

thermocouple types.

Visual Basic

3.4.7

The Examples directory contains the following files, created in Visual Basic 6:

usbtc0832.vbp

usbtc0832.bas

usbtc0832.Frm

usbtc0832.vbw

Agilent VEE

The example program usb_tc08.vee shows how to collect a block of data from the

USB TC-08. There are prototypes in usb_tc08.vh.

Page 47

Technical reference

Error code

Description

Category

1

USBTC08_ERROR_OS_NOT_SUPPORTED

P*

2

USBTC08_ERROR_NO_CHANNELS_SET

P

3

USBTC08_ERROR_INVALID_PARAMETER

P

4

USBTC08_ERROR_VARIANT_NOT_SUPPORTED

P*

5

USBTC08_ERROR_INCORRECT_MODE

P

6

USBTC08_ERROR_ENUMERATION_INCOMPLETE

S

7

USBTC08_ERROR_NOT_RESPONDING

S

8

USBTC08_ERROR_FW_FAIL

S

9

USBTC08_ERROR_CONFIG_FAIL

S

10

USBTC08_ERROR_NOT_FOUND

S

11

USBTC08_ERROR_THREAD_FAIL

S

12

USBTC08_ERROR_PIPE_INFO_FAIL

S

13

USBTC08_ERROR_NOT_CALIBRATED

S

14

USBTC08_ERROR_PICOPP_TOO_OLD

S

Key

S

Errors in this category indicate that a fault has occurred with the USB

TC-08 unit or your PC. Try disconnecting the USB TC-08, then

reconnecting it. If this does not work, restart your PC. If this does not

work, do the following:

1. Uninstall the software and restart the PC

2. Reinstall the software and restart the PC

3. If this does not work, download the latest version of the software

from http://www.omega.com and install this, then restart the PC

4. If this does not work, contact das@omega.com

PP*Errors in this category are handled internally within software

applications, and only developers need to be aware of their meanings.

Find a routine which fails with one of these error codes.

Errors in this category are user-dependent and developers should make

sure that their application provides suitable error messages for users to

read in the event of an error occurring.

43

3.5

Troubleshooting

The following table lists each of the error codes described in the

usb_tc08_get_last_error section, and divides them into categories, so that you know

what to do in the event of a particular error occurring.

Page 48

TC-08 User's Guide44

3.6

Glossary

CJC. A method of compensating for ambient temperature variations in thermocouple

circuits.

Cold junction compensation. See CJC.

Common mode range. The voltage range, relative to the ground of the data logger,

within which both inputs of a differential measurement must lie in order to achieve an

accurate measurement.

DLL. Dynamic Link Library. Files with this file extension contain a collection of

Windows functions designed to perform a specific class of operations.

Input impedance. The resistance measured between the input terminals of a

circuit.

NFR. Noise-Free Resolution. The effective number of bits of resolution that can be

considered noise-free.

Overvoltage protection. The maximum input voltage that can be applied without

damaging the unit.

QNaN. Quiet Not a Number. In the context of the USB TC-08, QNaNs are numbers

created artificially to fill in gaps in sampling. These gaps are interruptions caused by

lack of available PC or laptop processor time, normally caused by too many

applications being open simultaneously. QNaNs are defined in the IEEE 754-1985

ISO standard and are indeterminate, meaning no two QNaNs have the same value.

In C/C++, the int _isnan(double) function in the <float.h> header can be used to

identify QNaN float representations, cast to a double first. QNaNs will not cause an

error if arithmetic operations are performed on them - however, the results will

remain indeterminate.

Resolution. A value in bits, related to the number of increments of an analog input

signal that can be detected by a digital measurement system. A high-resolution

measurement system detects smaller signal increments than a low-resolution

measurement system.

Thermocouple. A device consisting of two dissimilar metals joined together. The

thermoelectric voltage developed between the two junctions is proportional to the

temperature difference between the junctions.

Type B thermocouple. Type B thermocouples are made from platinum and rhodium

and are suitable for high temperature measurements of up to 1820°C. Unusually, due

to the shape of their temperature / voltage curve, type B thermocouples give the

same output at 0°C as at 42°C.

Type E thermocouple. Type E thermocouples are made from chromel and

constantan. They have a high output (68 uV/°C), making them well suited to

low-temperature (cryogenic) use. They are non-magnetic.

Type J thermocouple. Type J thermocouples are made from iron and constantan.

They measure temperatures in the range -210 to +1200°C. The main application is

with old equipment that can not accept the more modern thermocouple. J types

should not be used above 760°C, as an abrupt magnetic transformation will cause

permanent decalibration.

Page 49

Technical reference

Type K thermocouple. Type K thermocouples are low-cost, general-purpose

thermocouples, made from chromel and alumel, operating in the -270°C to +1370°C

temperature range. Sensitivity is approx 41 uV/°C.

Type N thermocouple. Type N thermocouples are made from nicrosil and nisil. The

high stability and resistance to high-temperature oxidation of these thermocouples

make them suitable for measuring high temperatures. They are less expensive than

platinum types B,R, and S and were designed to be an improved type K.

Type R thermocouple. Type R thermocouples are made from platinum and

rhodium, and are suitable for high-temperature measurements of up to 1760°C. Low

sensitivity (10 uV/°C) and high cost make them unsuitable for general purpose use.

Type S thermocouple. Type S thermocouples are made from platinum and

rhodium, and are suitable for high-temperature measurements of up to 1760°C. Low

sensitivity (10 uV/vC) and high cost make these thermocouples unsuitable for general

purpose use. Due to their high stability, type S thermocouples are used as the

standard of calibration for the melting point of gold.

Type T thermocouple. Type T thermocouples are made from copper and

constantan, are highly accurate, and operate in the -270°C to +400°C temperature

range.

45

USB. Universal Serial Bus. This is a standard port that enables you to connect

external devices to PCs. A typical USB 1.1 port supports a data transfer rate of 12

Mbps (12 megabits per second), and is much faster than a COM port.

USBTC08_INFO. This structure is used to receive information from the

usb_tc08_get_unit_info function and is defined in the usbtc08.h header file. Note: If

the programming language you are using does not support structures, use the

usb_tc08_get_formatted_info function.

typedef struct tUSBTC08Info

{

short size;

short DriverVersion;

short PicoppVersion;

short HardwareVersion;

short Variant;

char szSerial[USBTC08_MAX_SERIAL_CHARS];

char szCalDate[USBTC08_MAX_DATE_CHARS];

} USBTC08_INFO, *LPUSBTC08_INFO;

Page 50

Page 51

Index

A

AgilentVEE 42

C

H

Hot junction 6

I

Impedance 5

Installation 1

Index

47

C 41

C++ 41

Cold junction 6

Connection 1

D

Delphi 41

DLLs 7

Driver routines 14

usb_tc08_close_unit 14, 21

usb_tc08_get_formatted_info 14, 26

usb_tc08_get_last_error 14, 27

usb_tc08_get_minimum_interval_ms 14, 24

usb_tc08_get_single 14, 31

usb_tc08_get_temp 14, 32

usb_tc08_get_temp_deskew 14

usb_tc08_get_unit_info 14, 25

usb_tc08_legacy_get_cold_junction 14, 37

usb_tc08_legacy_get_cycle 14, 40

usb_tc08_legacy_get_driver_version 14, 38

usb_tc08_legacy_get_temp 14, 36

usb_tc08_legacy_get_version 14, 39

usb_tc08_legacy_run 14, 34

usb_tc08_legacy_set_channel 14, 35

usb_tc08_open_unit 14, 15

usb_tc08_open_unit_async 14, 18

usb_tc08_open_unit_progress 14, 20

usb_tc08_run 14, 30

usb_tc08_set_channel 14, 29

usb_tc08_set_mains 14, 23

usb_tc08_stop 14, 22

usb_tc08_temp_deskew 33

E

Error codes 27, 43

Excel 42

L

LabVIEW 42

Legacy mode 7, 12

M

Modes of operation

Get single 7, 10

Legacy 7, 12

Streaming 7, 8

MS Excel 42

P

Programming 7, 41

Agilent VEE 42

C 41

C++ 41

Delphi 41

LabVIEW 42

Visual Basic 42

Q

QNaN 32, 33

R

Repairs 4

Resolution 5

S

Safety 4

Specification 5

Streaming mode 7, 8

T

G

Get single mode 7, 10

Thermocouple 6

Troubleshooting 43

Page 52

TC-08 User's Guide48

U

usb_tc08_close_unit 14, 21

usb_tc08_get_formatted_info 14, 26

usb_tc08_get_last_error 14, 27

usb_tc08_get_minimum_interval_ms 14, 24

usb_tc08_get_single 14, 31

usb_tc08_get_temp 14, 32

usb_tc08_get_temp_deskew 14

usb_tc08_get_unit_info 14, 25

usb_tc08_legacy_get_cold_junction 14, 37

usb_tc08_legacy_get_cycle 14, 40

usb_tc08_legacy_get_driver_version 14, 38

usb_tc08_legacy_get_temp 14, 36

usb_tc08_legacy_get_version 14, 39

usb_tc08_legacy_run 14, 34

usb_tc08_legacy_set_channel 14, 35

usb_tc08_open_unit 14, 15

usb_tc08_open_unit_async 14, 18

usb_tc08_open_unit_progress 14, 20

usb_tc08_run 14, 30

usb_tc08_set_channel 14, 29

usb_tc08_set_mains 14, 23

usb_tc08_stop 14, 22

usb_tc08_temp_deskew 33

V

Visual Basic 42

Page 53

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2007 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 54

M4525/0707

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...