Page 1

omega.com info@omega.com

Servicing North America:

U.S.A. :Omega Engineering, Inc.

Headquarters: Toll-Free: 1-800-826-6342 (USA & Canada only)

Customer Service: 1-800-622-2378 (USA & Canada only)

Engineering Service: 1-800-872-9436 (USA & Canada only)

Tel: (203) 359-1660 Fax: (203) 359-7700

e-mail: info@omega.com

For Other Locations Visit omega.com/worldwide

Operating Instructions of Solid State Relay SSR530 and SSRL530 Series

1. Manufacturer has made great effort on product quality and reliability, but improper

selection or use may result in irreversible damage of internal power semiconductor

devices in solid state relay. In addition, due to the voltage fluctuation of the power grid

(usually + + + 10%) and the differences in inductance and capacitance, a certain safety

factor must be taken into account when selecting the type. For example, the long-term

working current of electric heating should not exceed 60% of the rated SSR current, and

the rated current of the motor should not exceed 1/7 of ssr current.

2. When the long-term working current is greater than 5A, it must be equipped with the

supporting radiator. Radiator slab temperature shall not exceed 80 ℃.

If the ambient temperature is too high, air cooling must be adopted to accelerate air flow for

better cooling effect.

3. In order to ensure the closely contact of solid state relay with the radiator during the

installation process and to achieve more ideal cooling effect, our company equipped with

special thermal conductive film or special thermal conductive silicone according to the

different level of current. When installing, please parallel the heat conduction film to the

solid state relay, between the bottom plate of the solid state relay and the radiator, and

install the mounting screws.

4. When the module is fastened to the surface of the radiator, it adopts M3, M4, M5 screws and

spring washers, and is fastened with 4-6nm torque. After 3 hours, it is fastened with the

same torque. Recommended tightening torque 0.8- 1 Nm for the controlling end M3 screw,

1.9 -2.1 Nm for loading end M5 screw.

5. In order to prevent the breakdown of solid state relay caused by short circuit, overload of

voltage or current, we strongly recommended installing relevant fast acting fuse (our

company can provide supporting services).

For the inductive load, it is also necessary to install the pressure-sensitive resistance and

RC absorption circuit at the solid-state output end. For the dc solid-state relay, if it is the

inductive load, it is necessary to install the relay diode protection.

6. Solid state relays must operate with sufficient voltage and current values that do not exceed

the nominal trigger voltage and current value. For example, the control end is "3-32vdc", that

Page 2

is, the minimum input voltage shall not be less than 3VDC and the maximum shall not

IN PUT

IN PUT

IN PUT

380V IN PUT

exceed 32VDC.Therefore, special attention should be paid to meet the triggering

requirements of solid state relay in series or in parallel circuit.

7. In order to improve the efficiency and avoid the trouble of disassembling the input and output

screws of solid-state relay when installing SSR, our company specially places the input and

output screws of SSR separately, which is more convenient for installation and use.

8. The storage requirements of solid state relays shall be moisture-proof, moisture-proof, rainproof, avoid falling and violent collision. Should be stored in a ventilated, dry, non-corrosive

gas environment, the humidity of the environment must be less than 80%.

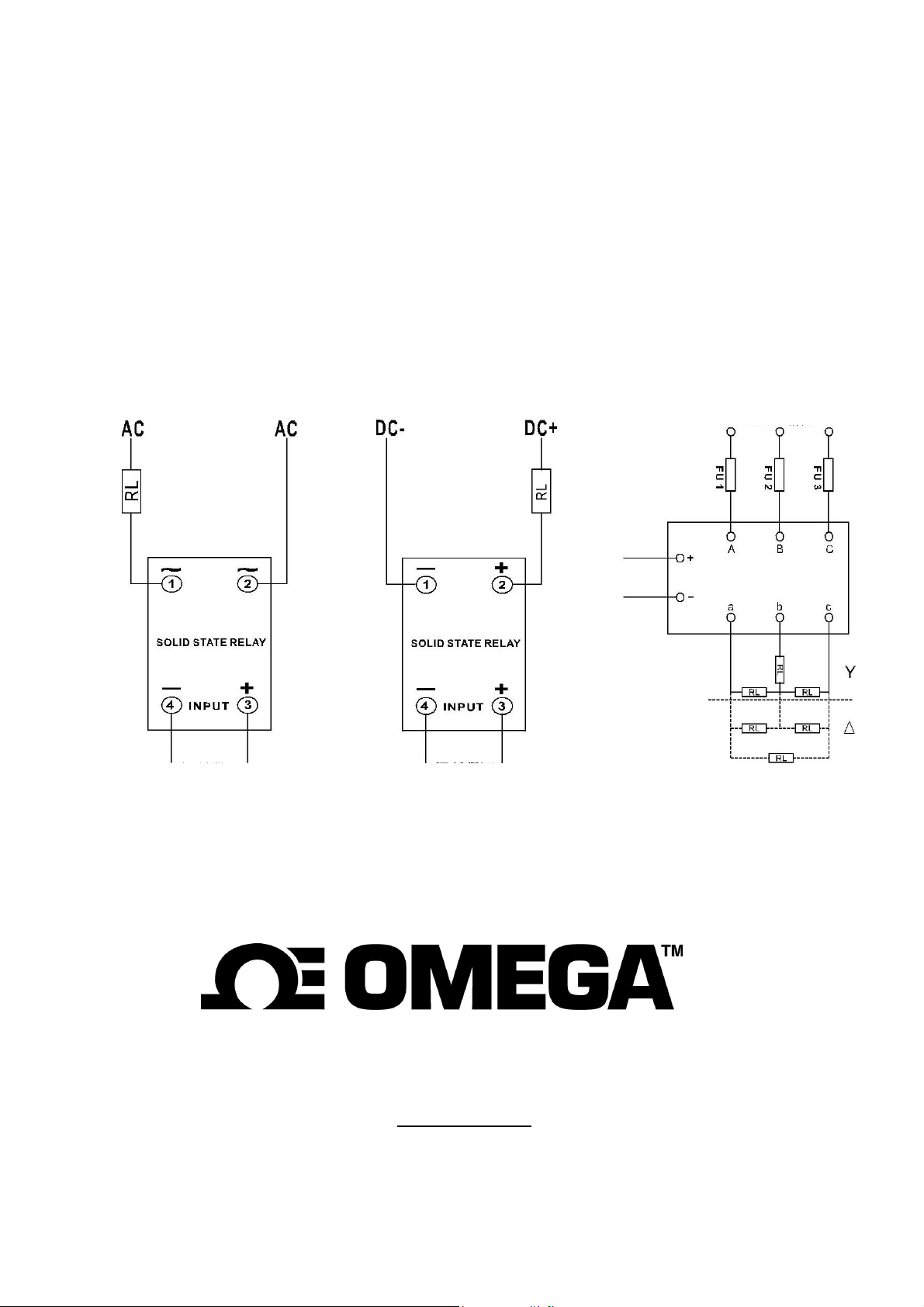

9. Wiring diagram

AC SSR DC SSR 3-phase SSR

Shop on line at omega.com email:info@omega.com

Please download the latest user manual from

the website www.omega.com and search

related products

Loading...

Loading...