Page 1

OPERATING & INSTALLATION

INSTRUCTIONS

RS-7K

DELUXE KEYLESS ENTRY/REMOTE CAR ST ARTER

FOR AUTOMA TIC TRANSMISSION VEHICLES ONL Y

COPYRIGHT: OMEGA RESEARCH & DEVELOPMENT 1999

INTRODUCTION & WARNINGS

Congratulations on your purchase of the RS-7K Remote Car Starter. The RS-7K

will allow you to start your vehicle's engine from the comfort of your home or office,

allowing your vehicle to warm up in winter and cool down in summer. When you

leave your vehicle, simply set the climate controls for what you desire to be operating upon remote start - heater, defroster or air conditioning.

1

INDEX:

Operating Instructions:

Introduction & Warnings ......................................................................... 3

Transmitter Functions ......................................................................... 4-7

Locking & Unlocking The Doors .............................................................. 5

Remote Starting .................................................................................... 6

Remote Trunk Release ............................................................................7

Carfinder Mode ...................................................................................... 7

Valet Override Mode ............................................................................... 8

Installation Instructions:

Warnings ......................................................................................... 9-10

5-Wire Connector ............................................................................ 11-13

3-Wire Blue Connector ..................................................................... 14-15

10-Wire Connector .......................................................................... 16-35

Engine Detect (Smart, Tach, Vacuum) ................................................. 25-27

Door Locks ..................................................................................... 29-35

Receiver Antenna ................................................................................. 36

Programming Button ............................................................................ 36

Transmitter Programming ..................................................................... 37

Features Programing ............................................................................ 38

Wiring Diagram .................................................................................... 39

2

TRANSMITTER FUNCTIONS

The RS-7K comes with two 4-button remote transmitters. Please familiarize yourself with the buttons and operations of the transmitters which are explained in the

following pages.

The RS-7K is a keyless entry/remote start unit designed to be used by itself or

in conjunction with another remote control unit such as a vehicle security system.

We highly recommend that this system be professionally installed, as the complexity of the modern automobile and the nature of circuits to be accessed is often

beyond the abilities of most do-it-yourselfers.

There are several safety considerations with using and installing the RS-7K

Remote Car Starter. Among them are:

- This unit is for Automatic Transmission vehicles only . Installation in a manual

transmission equipped vehicle can result in property damage or personal injury .

- This unit is for fuel injected gasoline engines only.

- Children should not be left unattended in, or be allowed to play with the activating

transmitters of a remote starter equipped vehicle.

- Do not use this unit in an enclosed structure or garage.

3

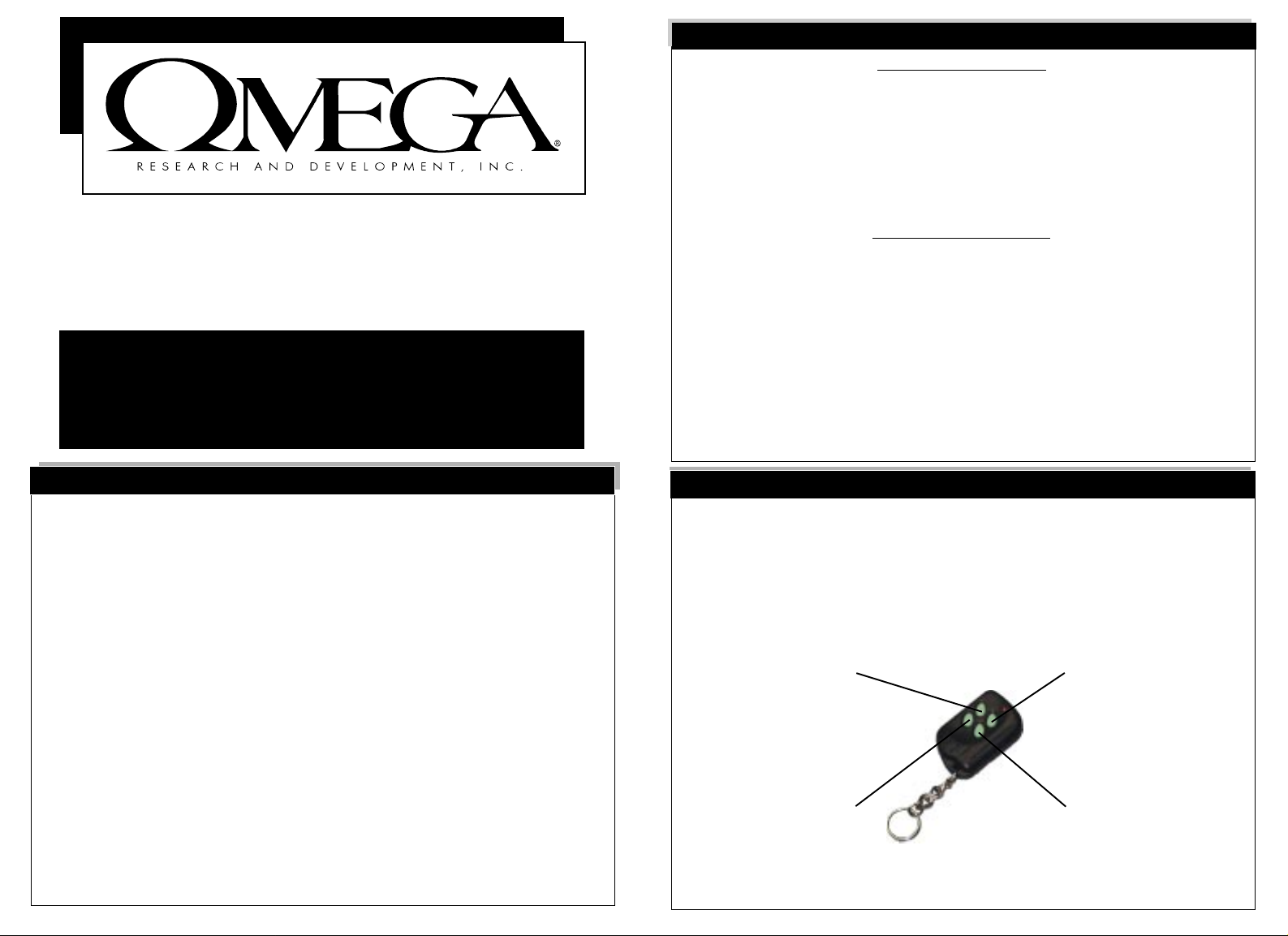

Button #1 •• Button #2

(Lock Doors/ (Unlock Doors)

Carfinder)

Button

#

3 •• Button #4

(Remote Start) (Trunk Release)

4

Page 2

LOCKING & UNLOCKING THE DOORS

To Lock The Vehicle's Doors: Press & Release Transmitter Button #1

- The parking-lights will flash once to confirm and the doors will lock.

THE PARKING-

LIGHTS WILL FLASH

ONCE

THE DOORS WILL LOCK

T o Unlock The V ehicle's Doors: Press & Release T ransmitter Button #2

REMOTE STARTING

To Remote Start The Vehicle: Press & Release Transmitter Button #3

1) The parking-lights will flash once then turn On to confirm Start process.

2) The ignition circuit will turn On.

3) Within 2 seconds the parking lights will turn Off and the starter will engage.

4) The engine will start to run and the starter will be disengaged.

5) The parking lights will stay On while the RS unit is controlling the engine.

6) If the engine stalls, the RS unit will make two attempts to restart it.

7) After 15/30 minutes (programmable) the RS unit will turn the engine off.

- Upon entering the vehicle place the ignition key in the switch and turn it

to the "On" position. Do not turn the key to the "Start" position.

- The parking-lights will flash twice to confirm and the doors will unlock.

THE PARKING-

LIGHTS WILL FLASH

TWICE

THE DOORS WILL UNLOCK

5

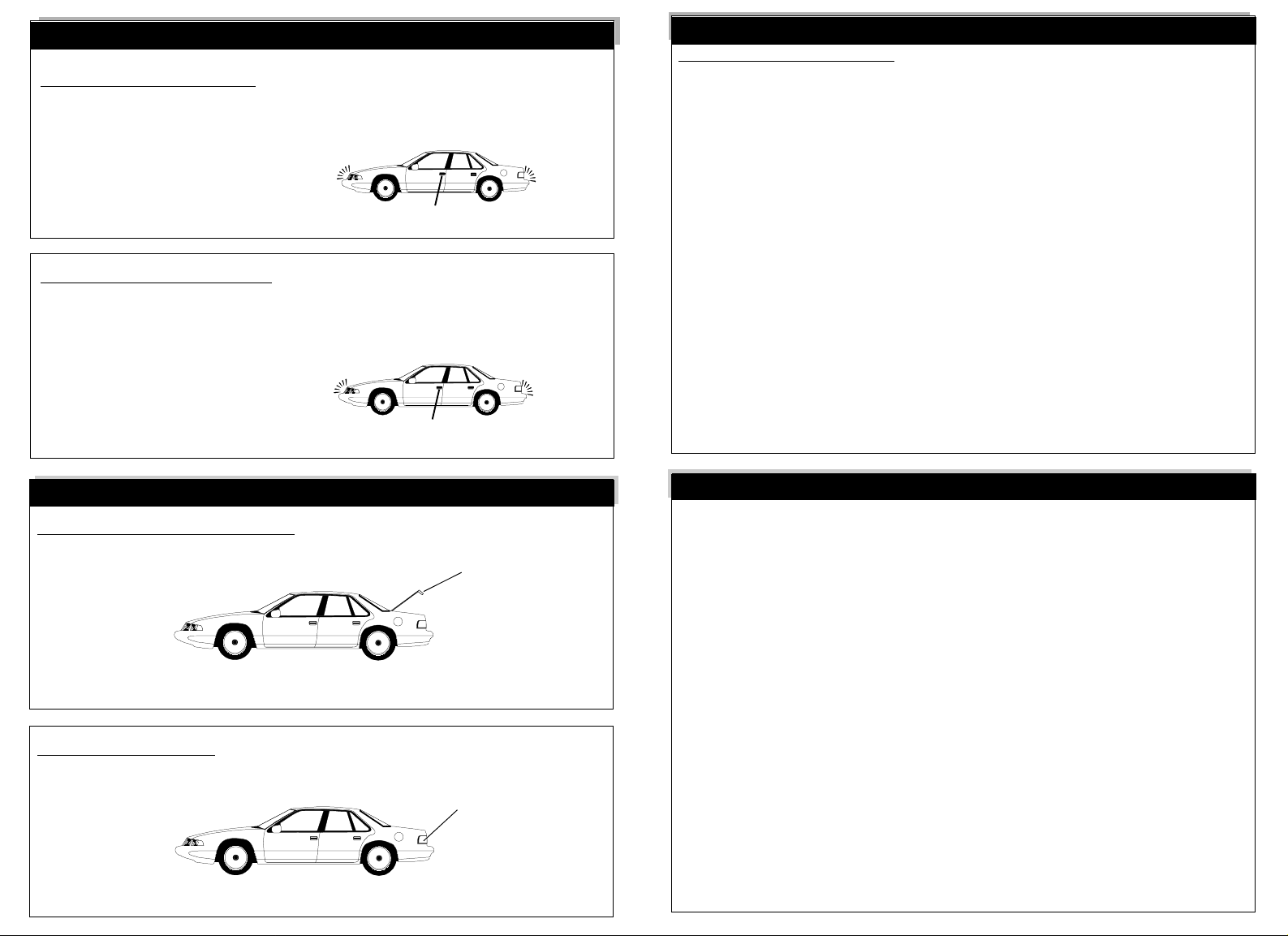

REMOTE TRUNK RELEASE & CARFINDER

To Activate The Trunk Release: Press & Release Transmitter Button

OPERATE OPTIONAL

TRUNK RELEASE

To Activate Carfinder: Press & Hold Transmitter Button

#

1 For 3 Seconds

Safety Features

- The RS unit will only engage if the gear shift selector is in "Park".

- The unit will not engage if the hood is opened.

Deactivation

- T o stop the engine by remote control, simply press transmitter button #3 again.

- Stepping on the brake pedal prior to inserting the key will deactivate the RS unit.

- Opening the hood will deactivate the RS unit.

6

VALET OVERRIDE MODE

#

4

Valet Override: The position of the Override switch allows or prevents the RS unit

from being activated. This feature is used when you do not wish the unit to be

operated, such as when you leave it with a valet parking attendant, mechanic or if

you loan your car to another person.

To engage the Valet Override mode, simply turn the Override Switch OFF. It is

recommended to always turn the Override Switch OFF to prevent unintentional or

unauthorized use of the Remote Car Starter.

Note: Do not confuse the toggle type V alet Override switch with the push button

programming button.

THE PARKING-LIGHTS

WILL FLASH TWICE

7

8

Page 3

INSTALLATION INSTRUCTIONS

!! WARNINGS !!

Do not attempt to install this Remote Car Starter into a manual transmission

vehicle! Doing so could cause serious property damage, personal injury,

and will void all warranties!

Be aware of, and avoid, any airbag circuitry! Due to the fact that an installer

will not be in a normal, upright seated position, severe injury may occur in

an accidental airbag deployment!

The use of a Digital Multimeter (DMM) or V olt-Ohm Meter (VOM) instead of a

standard testlight is recommended. This can greatly reduce the risk of an

accidental airbag deployment or on-board computer damage.

Battery gases are explosive! Avoid sparks and do not smoke while working

near the vehicle's battery!

IMPORTANT!

After reading this manual, start the installation by affixing the

WARNING DECAL to a visible area in the engine compartment!

Installation Considerations: This entire booklet should be read before starting

the installation. An understanding of which control module wires are to be used and

their functions is essential. Installations will vary from car to car, as some control

module wires are required, while others are optional. Before starting the installation, it should be determined which control module wires will be used. Most installers will list these wires, then "map out" the installation by locating and noting the

target wires in the vehicle. This will also determine the best location for the RS

control module, which is mounted upon completion of the installation.

This Remote Start Unit duplicates the actions that occur within the ignition switch

when you use your key to start the engine. Because of this, most of the main wiring

harness connections will be made at the ignition switch harness. The ignition switch

wires usually are high amperage circuits, which means that high reliability connections must be made! We recommend proper soldering of all connections.

Always protect wires ran through the firewall from sharp metal edges and

hot parts of the engine! Always fuse positive wires at the battery or power

source!

9

W I R I N G - 5 WIRE CONNECTOR

Red Wire: (Two 12-Gauge wires)

Connect both Red wires to constant 12 Volts. The most common sources are

the battery's Positive terminal and the ignition switch wiring harness (See diagram

#

1).

Connection Required

Diagram #1

Recommended Locations

Ignition Switch Wire Locations

Caution!

in Yellow or Red tubing or sleeves. Do not use a standard test light, as it can

deploy an airbag or damage on-board computers and sensors.

Green Wire: 12-Gauge

12 volts only when the ignition key is in the "Start" position. This wire is also found

in the ignition switch wiring harness (See diagram

a second Starter wire known as a "Cold Start" wire. When this is encountered, if the

two Starter wires are the same circuit you may connect both of these wires to the

Green wire. If the two Starter wires are separate circuits an optional prewired dual

relay socket and relays are recommended.

Note: If a security system is present which utilizes a starter interrupt circuit, the

Green wire must be connected to the Starter Motor side of the interrupt.

Blue Wire: 12-Gauge

Ignition)

"Start" positions and no voltage in the "Off" and "Accessory" positions. This wire is

found in the ignition switch wiring harness (See diagram

Note: If two or more Primary Ignition wires are present, you will need to connect an

optional relay(s) to the thin Blue wire located in the 3-pin Blue connector (See dia-

gram

Avoid the Airbag circuit!

Especially avoid any harness or wires encased

10

Connection Required

Connect the Green wire to the vehicle's Starter Motor wire. This wire will show

#1 on

page 11). Some vehicles have

Connection Required

Connect the Blue wire to the vehicle's Ignition #1 wire (also known as Primary

. This wire will show 12 Volts when the ignition key is in the "Run" and

#

1).

#

2 on page 14).

11

12

Page 4

Yellow Wire: 12-Gauge

Connection Required

Connect the Y ellow wire to the vehicle's Accessory wire. This circuit supplies

power to the Heat, Ventilation and Air Conditioning (HVAC) system. This wire will

show 12 Volts when the ignition key is in the "Run" and "Accessory" positions and

No voltage in the "Start" and "Off" positions. The connection point for this wire is

also found in the ignition switch wiring harness (See diagram

#

1).

Note: If two or more Accessory wires are present, you will need to connect an

optional relay(s) to the thin Yellow wire located in the 3-pin Blue connector (See

diagram

#

3 on page 14).

W I R I N G - 3 WIRE "BLUE" CONNECTOR

Blue Wire: (22 Gauge)

The Blue wire will supply a 500ma Negative Ignition output that can be used to

operate an optional relay(s) if two or more Primary Ignition wires are present in the

vehicle. If an optional relay(s) is needed, Connect the Blue wire to the Negative side

of the relay's coil (See diagram

#

2 on page 14).

Red Wire: (22 Gauge)

The Red wire supplies constant 12 Volts that can be used to power the relay's coil.

Warning: DO NOT use the Red wire to power the Ignition or Accessory circuits.

Y ellow Wire: (22 Gauge)

The Y ellow wire will supply a 500ma Negative Accessory output that can be used

to operate an optional relay(s) if two or more Accessory wires are present in the

vehicle. If an optional relay(s) is needed, Connect the Y ellow wire to the Negative

side of the relay's coil (See diagram

#

3 on page 14).

Diagram

Diagram #3

13

Fused

constant

15

12 Volts

85

87

Coil

86

Fused

constant

12 Volts

85

87

Coil

86

87a

30

87a

30

Relay

Ignition Circuit

Relay

Accessory Circuit

Black Wire:

Connect the Black wire to a very good, clean chassis ground. Recommended

areas are to an existing machine thread bolt, either in the driver's kick panel area or

a major structural member behind the dash. Small dash braces are not adequate,

and the area must be clean, bright metal. Use the largest existing machine threaded

bolt available (see diagram #4). Using a sheet metal screw or grounding to sheet

metal is inadequate (see diagram #5 on the page 17).

Diagram #4

Control

#

2

Red Wire

Blue Wire

Yellow Wire

Red Wire

W I R I N G - 10 WIRE CONNECTOR

Black Wire

Module

14

Connection Required

16

Page 5

"Star" Washer

4

4

4

4

4

4

4

4

4

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

Black Wire

Diagram #5

17

Self-Tapping Screw

Ring Terminal

White Wire:

Connection If Desired

The function of the White wire is to supply a 12 Volt signal to the vehicle’s

exterior parking-lights in order to visually confirm system operations.

Connect the White wire to the vehicle's 12 Volt parking-light circuit (See diagram

on page 19).

#

-The correct wire will show 12 Volts only when the headlight switch is in the "Parking

Light" and "Head Light" positions.

-This wire can usually be found at the headlight switch.

Note #1: When such a wire is located, be sure to also test that it is non-rheostated:

While metering the wire, operate the dash light dimmer control. The correct wire will

show no change in voltage when the dimmer is operated.

Note #2: Some vehicles have a parking-light relay which is triggered by a Negative

signal from the headlight switch. In these vehicles, the White wire must be connected

after the relay, usually at the Fuse/Junction Block.

Note #3: Some vehicles are equipped with a split parking light system. In these

vehicles, the use of IN4006 diodes are required (see diagram #7 on page 19).

W ARNING:

- Do NOT connect the white wire directly to the vehicle’s headlights. An external

relay is required.

18

6

Diagram #6

Control

Module

Dash Board

Lights

Control

Module

White Wire

Light

Switch

Diagram #7

Note: Use Two IN4006 Diodes.

White Wire

Right Side Circuit

Light

Switch

Left Side Circuit

Connecting Separate Left And Right Parking Lights Using Two Diodes.

19

Dark Blue Wire:

Connection Required

The hood pin switch must be installed. It prevents operation of the RS unit

23

23

23

23

23

23

23

23

23

if the hood is open.

Connect the Dark Blue wire to the hood pin switch. Carefully route the Dark Blue

wire through the firewall, using an added or existing grommet. Avoid any hot or

moving parts. Mount the switch so that it is open (pin down) when the hood is shut

and closed (pin up) when the hood is open.

Parking Lights

If there is an existing hood pin switch for an alarm system, you may use it for the

Dark Blue wire connection; diode-isolation is recommended.

Parking Lights

Optional Parts Needed:

Two IN4002 Diodes

To Existing Alarm

Pin

Switch

Instead of using a pin switch to monitor the hood's open or shut status, an Omega

Hood

Diagram #8

Dark Blue Wire

AU-46 Mercury Tilt Switch may used. Connect one of the AU-46's wires to Negative

Chassis Ground and connect the remaining wire to the Dark Blue wire.

20

Page 6

Remote Start Override Mode:

The RS unit can be placed into an "Override" mode which will prevent it from starting the vehicle. This mode is for situations when it is not convenient or safe for the

Remote Start feature to be operable. For example during extended stopovers for

vehicle servicing, maintenance, valet parking, washing, etc.

Connect the Dark Blue wire to one of the included toggle switch's two wires. Connect the toggle switch's remaining wire to ground.

Diagram #9

Ground

Hood

Pin

Switch

Dark Blue Wire

Control

Module

21

Yellow/Black Wire:

Connection

Required

The Yellow/Black wire must be connected. It is part a critical safety feature

which disables the RS unit whenever the brake pedal is pressed.

Connect the Yellow/Black wire to the brake switch wire which shows 12 Volts

when the brake pedal is pressed. The brake switch is typically located above the

brake pedal, and usually mounted to the brake pedal support bracket. Always

make this connection in a fashion ensuring its long-term reliability; soldering is

highly recommended. Upon completing the Y ellow/Black wire's connection, thoroughly test the operation of this circuit.

Pink Wire:

The Pink wire activates the RS Unit. If the Pink wire receives a Negative

pulse, the RS unit will start the vehicle's engine, provided that all safety circuits are

in the proper status. After the engine has been started by remote control, another

Negative pulse on the Pink wire will turn the RS unit off, stopping the engine.

The Pink wire can be connected to an available auxiliary output of an existing

Remote Security System, or the RS-7K's remote control may be used to activate

the unit.

22

Connection If Desired

Gray Wire:

Connection If Desired

The function of the Gray wire is to provide a Negative 500ma auxiliary output

which may be used to operate a trunk release or other interface.

Trunk Release Connection:

1) Connect the Gray wire to pin #85 of the external relay .

2) Connect Constant 12 Volts to pin #86 of the external relay . (Fused)

3) Connect pins #87, 87a & 30 as indicated in diagram #10 on page 24.

23

Diagram #10

Control

Module

Trunk

Switch

Note: In some applications the solenoid wire will rest at ground. In these cases:

- Cut the solenoid wire:

- Connect the switch side to pin

- Connect the solenoid side to pin #30 of the external relay.

- Connect 12 Volts to pin #87 of the external relay (Fused).

Connect to 12 Volts or Negative Ground as needed in the

particular application. (In this case Negative is required)

Gray Wire

85

87

87a

12 Volts

Coil

86

#

87a of the external relay.

Relay

30

24

Release

Solenoid

Page 7

Orange/Black Wire:

Connection Required

The Orange/Black wire is the engine detect wire. The RS unit utilizes three

different methods of monitoring the vehicle during the remote starting process.

Consider all methods before deciding which one to use. Normally the Smart Start

method is used.

1) Vacuum Switch Sensing:

2) Smart Start:

This method uses a voltage sensing circuit which reads the vehicle's voltage before

attempting to start, and then monitors for a voltage increase which occurs when the

alternator has output. The Orange/Black wire connects to a constant 12 Volt source

(i.e.: the vehicle's battery).

Note: When using this method Programmable Jumper #4 will increase/decrease

the starter motor cranking time.

This method uses an optional V acuum switch to verify that the vehicle' engine is

running. The Orange/Black wire connects to one of the Vacuum switch's wires, the

other wire is connected to chassis Ground. Connect the V acuum switch using a

"T" connector to a vacuum hose on the engine's intake manifold.

1) Position the 3-way selector switch for V acuum switch operation (right position).

2) Locate the Smart Start & Tach Sense adjustment screws and LED indicators.

3) Turn BOTH adjustment screws completely counterclockwise.

Note: Using a multimeter set to Ohms, measure the resistance of the Vacuum

switch. The switch should read Zero resistance when the engine is "Off" and read

Maximum resistance (open circuit) when the engine is running. If this is not the

case, relocate the vacuum connection.

25

3) Tach Sense:

If the vehicle is generally hard to start (requiring the starter to be engaged for more

than 1 second)

method the Orange/Black wire reads the engine speed (tach) information from a

wire in the vehicle. The Orange/Black wire connects to the vehicle's tach wire,

which is found in the engine compartment, although in some cases it may also be

located inside the vehicle. T o use a multimeter to verify the correct tach wire, set it

for AC Volts scale. The correct wire will read 1 to 6 volts AC with the engine idling,

and will increase with engine speed.

Note: When using this method Programmable Jumper #1 will increase/decrease

the unit's sensitivity .

1) Position the 3-way selector switch for Tach Sense (left position).

2) Locate the Tach Sense & Smart Start adjustment screws and LED indicators.

3) Turn BOTH adjustment screws completely counterclockwise.

4) Start the vehicle.

5) Begin tuning the Tach Sense adjustment screw slowly clockwise until the LED

indicator illuminates solid, then turn the vehicle Off.

- T o increase the crank time, tune the adjustment screw counterclockwise.

- To decrease the crank time, tune the adjustment screw clockwise.

this method will produce more consistent remote starting. With this

27

1) Position the 3-way selector switch for Smart Start (center position).

2) Locate the Smart Start & T ach Sense adjustment screws and LED indicators.

3) Turn BOTH adjustment screws completely counterclockwise.

4) Start the vehicle.

5) Begin tuning the Smart Start adjustment screw slowly clockwise until the LED

indicator begins to flash. The flashes confirm that the unit is sensing the engine.

6) Turn the vehicle Off.

7) Confirm that the unit is not picking up noise from other vehicle circuits:

a. Without starting the engine, turn the ignition key to the "On" position.

b. If the LED indicator remains "Off" the unit has been properly tuned.

c. If the LED indicator flashes there is noise on the Orange/Black wire's connec tion and it will be necessary to relocate the connection.

26

Orange Wire:

Connection If Desired

The function of the Orange wire is to provide a Negative 250ma auxiliary output

which may be used to operate a starter motor "Anti-Grind" relay .

Connect "Switch" side of cut wire

to terminal #30 of the relay.

Ignition Switch

Connect "Motor" side of cut wire

87a

87

86

Coil

#

to terminal

Note: Connect 12-gauge

Green starter wire to the

motor side of the cut wire

87a of the relay.

30

85

Orange Wire

Control

Module

Starter Motor

Diagram #11

28

Page 8

Door Locks:

The doorlock interface needed will depend upon the type of power doorlocking system

the vehicle is equipped with.

Note: The vehicle must have existing power doorlocks. The addition of a power

doorlock interface to a vehicle without power locks will not allow the RS unit to operate

the doorlocks. However, power doorlocks may be added to the vehicle in the form of

adding a model DS-2 actuator to each of the doors, along with a doorlock interface.

Green Wire:

The Green wire supplies a negative pulse for locking the vehicle's doors.

Light Blue Wire:

The Light Blue wire supplies a negative pulse for unlocking the vehicle's doors.

Note: Programmable Jumper #2 will allow the RS unit to emit a single or double

unlock pulse.

Connection If Desired

Connection If Desired

3 Wire Negative Pulse Systems

This power doorlock system is simplest of all doorlocking systems. A Negative

pulse system will have only three wires at the doorlock switch.

Examine the wires on the back of the doorlock switch:

1) One wire will show Ground, regardless of the switch's position.

2) One wire will show Ground only when the switch is pushed to "Lock".

3) One wire will show Ground only when the switch is pushed to "Unlock".

Note: The lock & unlock wires coming out of the switch operate the vehicle’s

doorlock relays or a control unit with on-board relays, therefore the lock & unlock

wires will read voltage, up to 12 Volts, when the switch is at rest. The correct

connection point is between the switches and the relays.

The RS unit's Green & Light Blue wires can be connected directly to the vehicle’s

Negative pulse system since only a Negative pulse is required to operate the

vehicle’s on-board doorlocking relays.

Note: If the vehicle’s Negative pulse doorlocking system requires more than 250ma

Negative output, an optional interface must be used.

Negative Pulse System Direct Connection

Green Wire To Switch

Door Lock Wire

Door Lock

Switch

Ground

Control

Module

Blue Wire To Switch

Door Unlock Wire

29

Vehicle's Doorlock

Relay Control Unit

Unlock

Lock

31

+

Doorlock

Actuators

Diagram #12

30

3 Wire Positive Pulse Systems

This doorlock system is similar to the 3 wire negative pulse system except the

doorlock switches provide 12 Volt pulses to operate the doorlock relays/control unit.

Examine the wires on the back of the doorlock switch:

1) One wire will show 12 volts, regardless of the switch's position.

2) One wire will show 12 volts only when the switch is pushed to "lock".

3) One wire will show 12 volts only when the switch is pushed to "unlock".

Warning: The Positive pulse system can be confused with the 5-wire Reversing

Polarity system. This is because both systems emit 12 Volt pulses on the

“Lock” & “Unlock” wires when the vehicle’s switch is pressed respectively . It is

critical to identify which system is present since if 12 Volts are pulsed into a

Reversing polarity system, which rests at ground, a “Short” will occur.

3 main differences between a Positive pulse and a Reversing Polarity system:

1) In a Reversing system the Lock/Unlock wires

Positive system the wires

2) The doorlock switch in a Reversing system will have 5 wires, while a Positive

show partial ground

pulse system the switch will have 3 wires.

3) A

Positive pulse system

system

does not.

uses

factory relays or a control unit, a

32

rest at ground,

while in a

through the relay’s coils.

Reversing

Page 9

Positive Pulse System Using External Relays

5 Wire Reversing Polarity Systems

Control

Module

Green

Wire

85

Coil

+

Doorlock

Switch

+

87

86

Lite Blue Wire

87a

30

33

++

85

87

Coil

+

86

Vehicle's Doorlock

Relay Control Unit

Unlock

Lock

Reversing Polarity System Using External Relays

Control

Module

Green

Wire

85

Coil

+

86

Lite Blue Wire

87

87a

30

++

85

87

Coil

+

86

Diagram #13

87a

30

87a

30

Doorlock

Actuators

+

This power doorlock system differs from the negative and positive pulse systems in

that there is no doorlock control unit or relays. In this type of system, the switches

themselves supply the positive voltage directly to the doorlock actuators, and, more

importantly, provide the return ground path. It is important to note that the lock &

unlock wires in this system

actually rest at chassis ground.

This means that both the

lock & unlock wires must be "opened", or cut, to make the proper connections.

Examine the wires on the back of the switch. (Normally 5 wires will be found)

1) One wire will show 12 volts, regardless of the switch's position.

2) Two wires will be grounded regardless of the switch's position.

3) One wire will show 12 volts only when the switch is pushed to "Lock".

4) One wire will show 12 volts only when the switch is pushed to "Unlock".

- When the lock /unlock wires are found, they must be cut one at a time. If the correct

wires are cut the door locking system should not operate from the primary switch.

- Notice that in diagram #14 the driver's switch is the primary or “Master” switch (in

some vehicles, the primary switch is on the passenger's side). The half of the cut

wires which come from this primary switch are referred to as the "Switch" side. The

half of the cut wires which go to the secondary switch are referred to as the "Motor"

side even though the cut is made between the switches.

34

Receiver Antenna / Programing Switch:

Receiver Antenna:

The RS unit comes equipped with a plug-in window mount Receiver Antenna. The unit

will not operate unless this receiver antenna is plugged-in.

Select a desired mounting location for the antenna. Make sure the glass surface is

clean and free of dust, grease, or debris. Peel the backing off of the adhesive tape and

affix the antenna. Carefully route the antenna's cable toward the RS control module.

Insert the antenna's Black 3-wire connector into the matching Black port located on

the rear of the RS control module.

Connection Required

Master Doorlock

Switch

Diagram #14

Lock

Unlock

Doorlock Actuators

+

35

Lock

Unlock

Secondary Doorlock

Switch

Programming Button:

Connection Required

The Program button is used in combination with the vehicle’s ignition key to enter the

RS unit into the Transmitter Programing mode. The Program button should be

mounted in a hidden but accessible location. Route the wires to the RS unit's control

module and insert the 2-wire connector into the matching 2-pin port on the control

module.

36

Page 10

TRANSMITTER PROGRAMING

Up to 4 different transmitters may be programmed into the RS units's memory. When

a new transmitter code is programmed, all previous codes will be deleted. If a third

or fourth transmitter is desired, all of the transmitters must be programmed.

T o Program Transmitters:

1) Turn ignition "On".

2) Press & Release Program button 5 times.

- The parking lights will flash 5 times to confirm entry into programing mode.

3) Press any button of new Transmitter to be programed.

- The parking lights will flash to confirm that the Transmitter has been learned.

FEATURES PROGRAMING

The RS unit has four Jumper selectable programmable features. Whenever a

jumper setting is changed, it is necessary to power down the RS unit for the

change to be recognized.

Jumper Jumper

Feature "In" Removed

Jumper #1 T ach Sense Sensitivity Normal High

Jumper #2 Door Unlock Pulse Single Double

Jumper #3 Engine Running Time 15 Minutes 30 Minutes

Jumper #4 Starter Motor Cranking Time 1.2", 1.5", 2" 1", 1.5", 2"

4) T o program additional transmitters, Repeat step

#

3.

5) T urn ignition "Off".

Note 1: It is recommended that all four transmitter memory slots be filled. For

example: If you have two transmitters, program each one twice.

Note 2: The RS unit will automatically exit programing mode if 10 seconds elapse

without receiving a signal from the transmitter(s).

37

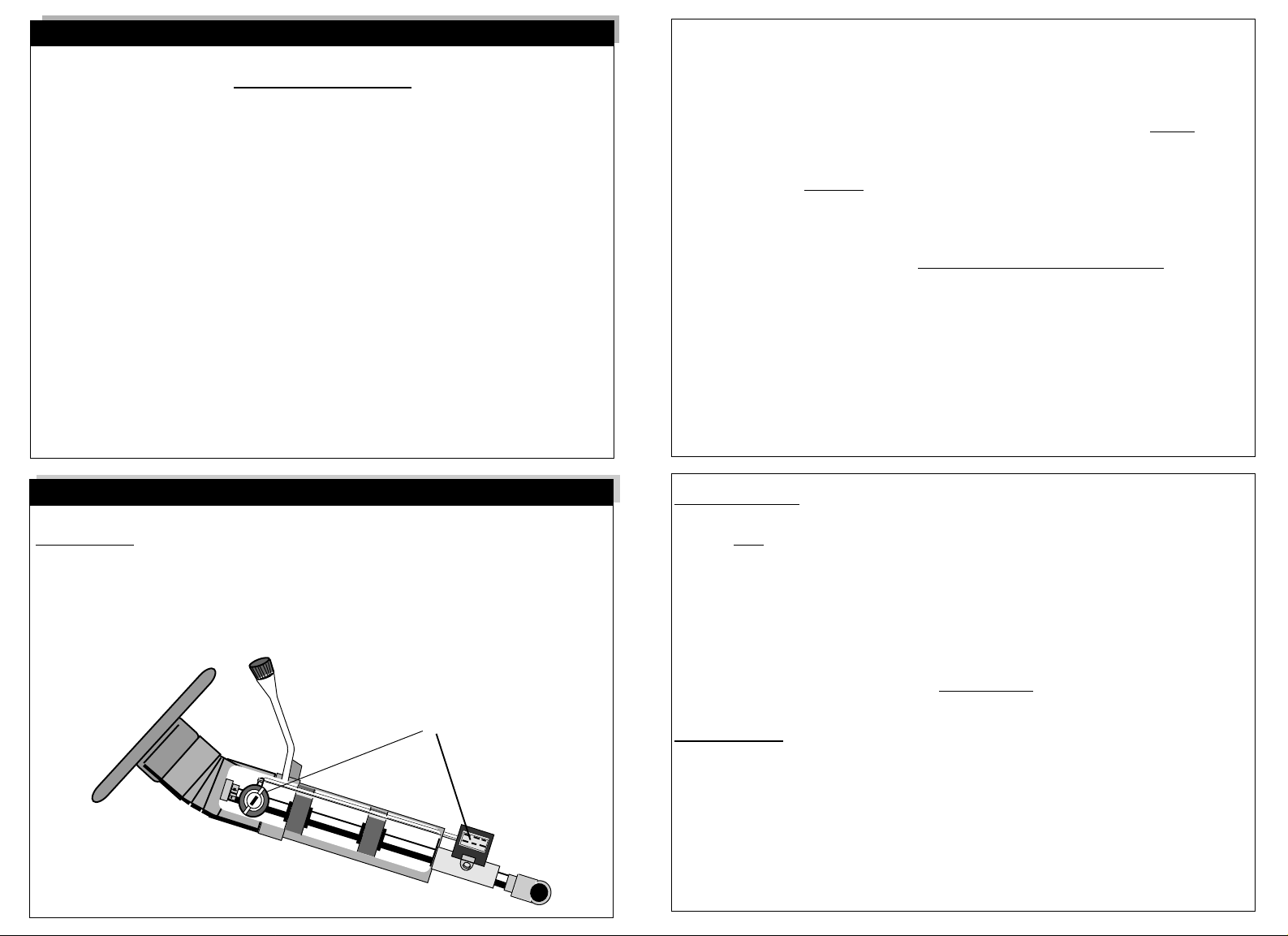

Green = Starter

Yellow = Accessory

5 Wire Connector

3-Wire Blue Connector

Antenna Port

10-Wire Connector

Engine Detect Selector Switch

Trap Door

Jumpers

4 3 2 1

Program Button

Smart Start

Tuner & LED

Tach Sense

Tuner & LED

39

Red = +12 Volts

Red = +12 Volts

Blue = Ignition 1

Yellow = - Accessory 2 Output

Red = Constant +12 Volts Output

Blue = - Ignition 2 Output

Black = Chassis Ground

White = + Parking Lights Output

Dark Blue = - Hood Pin Switch Input

Yellow/Black = + Brake Pedal Input

Pink = - Activation Input

Gray = - Auxiliary Output

Light Blue = - Unlock Output

Green = - Lock Output

Orange/Black = Engine Detect Wire

Orange = Anti-Grind Output

Vacuum Sensing

Smart Start

Tach Sensing

38

LIMITED LIFETIME WARRANTY

Products manufactured and sold by OMEGA RESEARCH & DEVELOPMENT, INC. (the Company), are

warranted to be free from defects in materials and workmanship under normal use. If a product sold

by the Company proves to be defective, the Company will repair or replace it free of charge within

the first year and thereafter all parts to be repaired will be free with only a nominal charge for Omega

Research and Development, Inc.'s labor and return shipping, to the original owner during the lifetime

of the car in which it was originally installed.

All products for warranty repair must be sent postage prepaid to Omega Research &

Development, Inc., P.O. Box 508, Douglasville, Georgia 30133, with bill of sale or other dated proof

of purchase. This warranty is nontransferable and does not apply to any product damaged by

accident, physical or electrical misuse or abuse, improper installation, alteration, any use contrary to

its intended function, unauthorized service, fire, flood, lightning, or other acts of God.

This warranty limits the Company's liability to the repair or replacement of the product. The

Company shall not be responsible for removal and/or reinstallation charges, damage to or theft of the

vehicle or its contents, or any incidental or consequential damages caused by any failure or alleged

failure of the product to function properly. Under No Circumstances Should This Warranty, Or The

Product Covered By It, Be Construed As A Guarantee Or Insurance Policy Against Loss. The Company

neither assumes nor authorizes any person or organization to make any Warranties or assume any

liability in connection with the sale, installation, or use of this product.

This device complies with F.C.C Rules part 15. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference and, (2) This device must accept any interference

that may be received, including interference that may cause undesired operation.

The manufacturer is not responsible for any radio TV interference caused by unauthorized

modifications to this equipment. Such modifications could void the user’s authority to operate the

equipment.

40

Loading...

Loading...