Page 1

Series 956

User’s Guide

http://www.omega.com

e-mail: info@omega.com

GP901 Series

Digital Probes

Page 2

OMEGAnet® On-Line Service

http://www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certied Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certied Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

certication of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device

upon certication.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

2

GP901 M-3343 05/08

Page 3

Introduction

The Digital Probe is a gauging transducer combined with conditioning electronics in a permanently

connected ”smart connector” or PIE (Probe Interface Electronics).

The PIE converts and corrects the output from the gauge head and transmits the result in a digital format

using the Orbit protocol. Because the Digital Probe is factory calibrated using a reference Laser, the probe

has a very linear output with position.

The Digital Probe is one of an extensive range of Orbit Modules available for use with the Orbit

Measurement System, which provides an easy way to construct and maintain a complete measurement

system of up to 372 Orbit modules.

The Orbit protocol features an extensive set of commands that enable fast and efficient transmission of

data between the Orbit module and the PC.

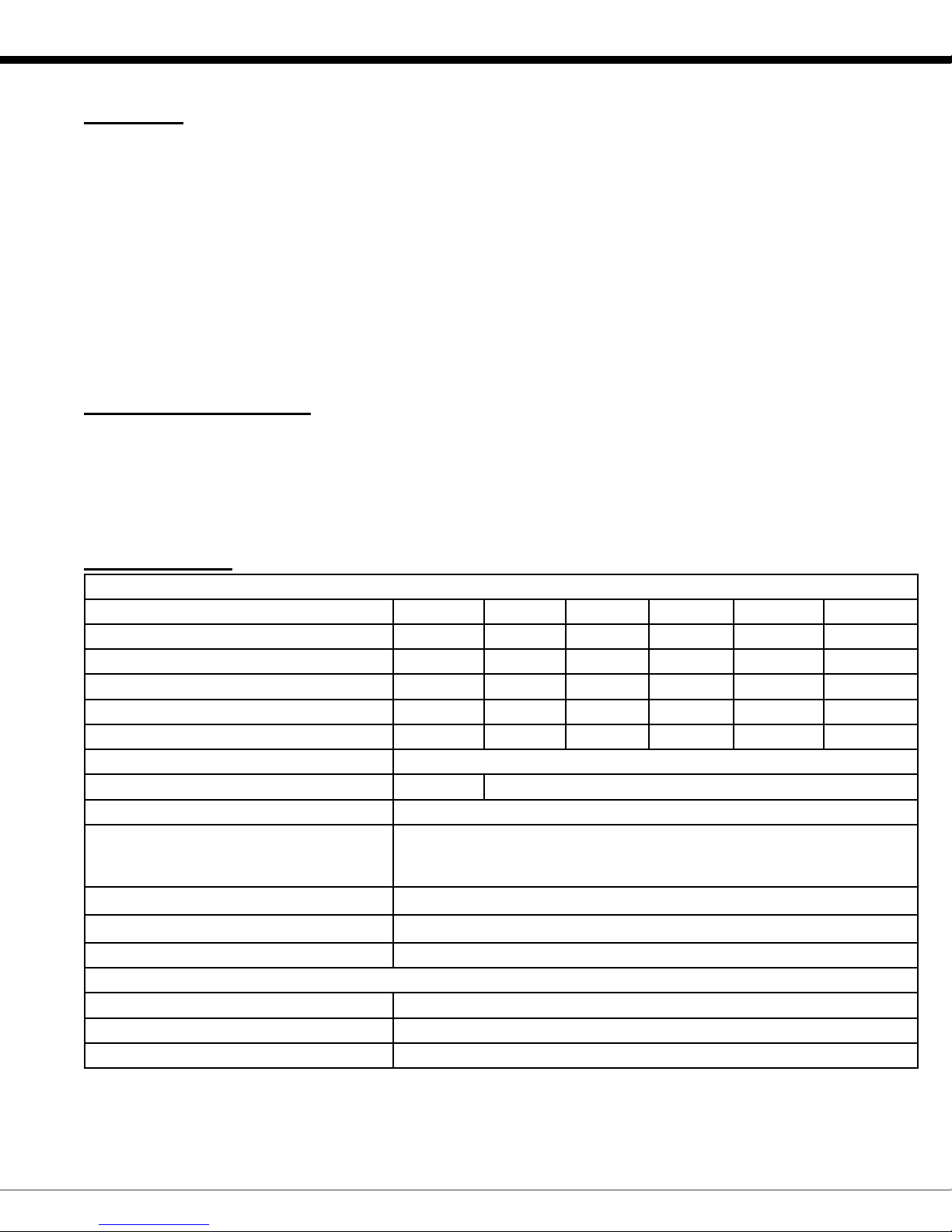

Digital Probe Specifications

This section contains the specifications of the Digital Probe. There are two sections, the first are the

specifications for the complete Digital Probe (PIE + gauge head) and the second is mechanical data

relevant to the gauge head only.

PIE is designed to be primarily used with the T-CON connector. Full details of mounting with T-CON refer

to the section of PIE and T-CON installation.

Digital Probe Data

Performance Data

Basic Probe Type GP901-05 GP901-1 GP901-2 GP901-5 GP901-10 GP901-20

Calibrated Stroke mm 0.5 1 2 5 10 20

Full Mechanical Travel 0.58 1.5 3 (*2.5) 6 11 21

Resolution (14 bit over stroke) mm

0.03 0.061 0.122 0.305 0.610 1.22

Resolution (16 bit over stroke) N/A 0.015 0.03 0.076 0.152 0.305

Resolution (18 bit over stroke) N/A N/A N/A 0.019 0.038 0.076

Accuracy mm see Accuracy section below

Repeatability

<0.1 mm <0.15 mm

Reading Rate per Network channel 1000 readings / second minimum

Reading Rate (per PIE) 240 readings / second minimum (4 ms internal update)

in Normal Mode

Up to 3906 readings per second in dynamic (8 probes per network)

Calibration Temperature

Temperature Range

2061°C

0 to 60°C

Warm up Period 30 minutes

General Data

Supply Voltage

5 60.25Vdc

Current Consumption 0.06 A max.

PIE per Orbit channel 31 modules

3GP901 M-3343 05/08

Page 4

Network type Orbit - RS485 2-wire multi-drop (up to 31 per channel)

Network speed 1.5Mbaud, 187.5k Baud or 9600 Baud (do not use 9600

Baud for New Applications as this will be phased out)

Network Control Character Break Character - low (space) of >90 us (187.5k Baud) or

>1.2mS (9600 Baud)

Command Character Format 1 start, 8 data, 1 odd parity, 1 stop bit

Accuracy

The error quoted assumes periodic re-setting against a setting master in accordance with normal gauging

practice (not less than once per day). As the Digital Probe may be used anywhere on its stroke the setting

master itself must be of known dimensions, but does not need to be precisely on its nominal value. The error

quoted for the Digital Probe therefore includes a factor dependant on the distance between the setting master

and the component being gauged.

Where D = difference in mm between setting master and component.

Error at calibration temperature: -

0.5 mm Probes i.e. GP901-05-S 6 0.05 mm 6 0.2% x D

1 mm Probes i.e. GP901-1-S 6 0.1 mm 6 0.1% x D

2 mm Probes i.e. GP901-2-S, GP901-2-P 6 0.1 mm 6 0.1% x D

5 mm Probes i.e. GP901-5-S, GP901-5-P 6 0.1 mm 6 0.2% x D

10 mm Probes i.e. GP901-10-S, GP901-10-P 6 0.1 mm 6 0.2% x D

20 mm Probes i.e. GP901-20-S, GP901-20-P 6 0.1 mm 6 0.2% x D

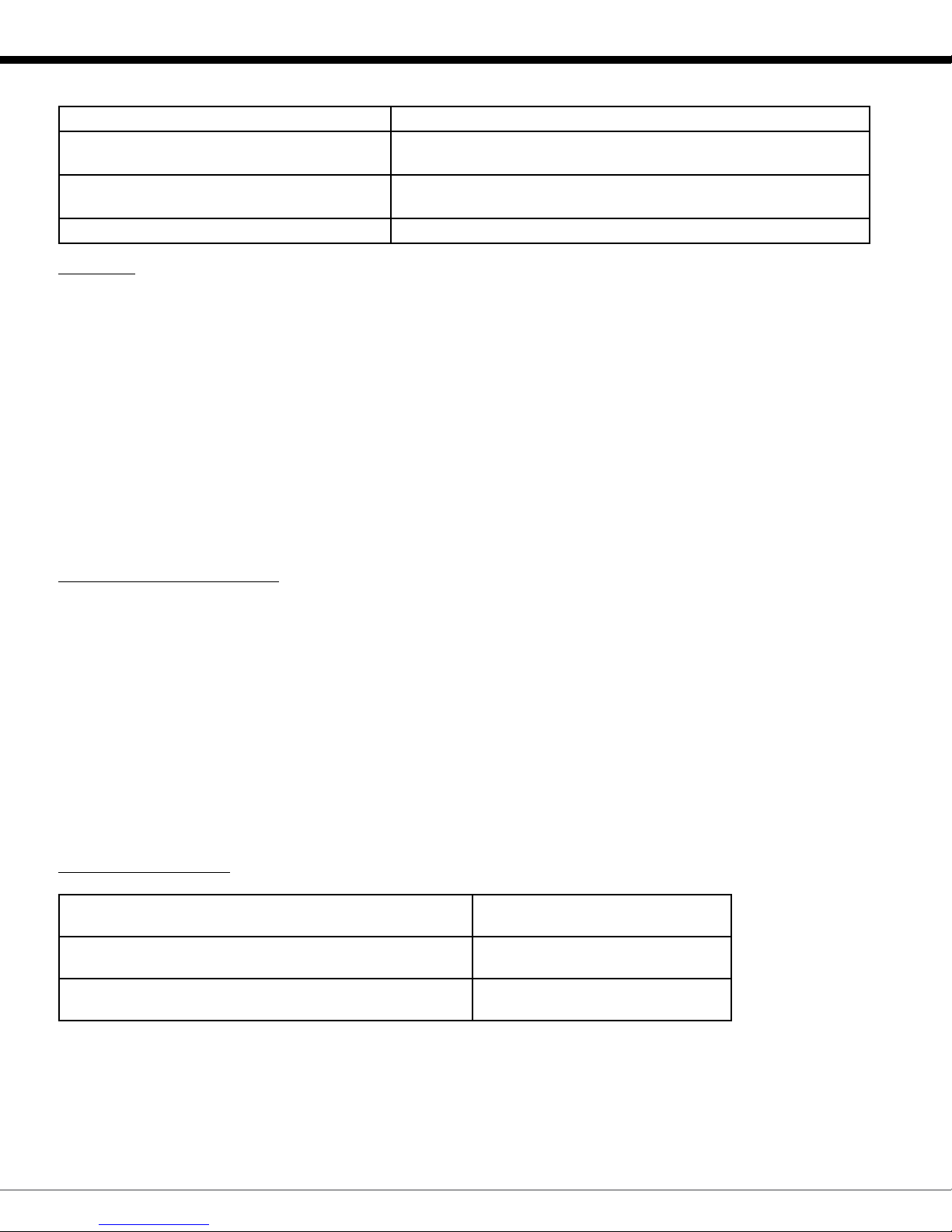

Gauge Head Specications

Specications Common to All Gauge Head Types

Body Material Stainless Steel 400 Series

Probe tips various types available

Non-repeat <0.15 mm

Max. Angular Rotation of Tip 2°

Gaiter Material Viton®

Max. Probe tip tightening Torque 0.22 Nm – M2.5 Thread

(when changing tip please take care not to damage probe) 0.12 Nm – M2 Thread

Storage Temperature Range -20°C to +100°C

Operating Temperature +5°C to +80°C

Environmental Protection (see mounting notes) IP 65 (with gaiter)

Cable Standard (not all types) 2m screened, PUR, insulation

Option (not all types) Standard cable with stainless steel or plastic braid

Pneumatic Operation (Not GP901-05 version)

Minimum operating pressure With Gaiter

(bar) Without Gaiter

Maximum operating pressure With Gaiter

(bar) Without Gaiter

Air leak rate ml/min. at 1.0 bar With Gaiter

Without Gaiter

0.4

0.3

1.0

2.0

<10

<150

4

GP901 M-3343 05/08

Page 5

Gauge Head Application Information

When mounting the Gauge Head in a fixture, care must be taken as the linear bearing assembly at the

tip end is made to very fine tolerances. If a high force is applied to the probe casing performance may be

affected. Ideally probes should be clamped in a yoke, split or collar clamp. If single point screw clamping

is adopted (see diagram), then a tightening torque (in Nm) should be limited to that which will give a

maximum of 50Kg point load. The Gauge Head may be mounted in any attitude.

where d = Screw dia. (mm)

P = Screw pitch (mm)

(assumes a V form thread and 0.15 coefficient of friction).

Typical maximum torque is 0.27 Nm (i.e. M5 x 0.8 steel or 10-32 UNF steel)

A clearance hole in the fixturing of 9.5 mm F is desirable around the gaiter for satisfactory operation.

Tip

Generally, where piece parts are automatically loaded into a fixture, or where there is the possibility of

severe side loads, the use of pneumatically operated transducers is strongly recommended.

To remove the tip, the shaft should be fully retracted into the body before unscrewing.

Pneumatic Gage Heads

The tip of a pneumatic Gage Head is normally biased in the inward direction and the extension of the tip is

achieved by applying air pressure to the Gauge Head nozzle.

Air pressure may be varied within the specified limits to achieve the desired tip force at zero. The

pneumatic Gage Heads are designed to be leak free and of small volume to minimise the air flow

requirements and maintain a consistent tip force. Care must be taken not to damage the gaiter seal as the

satisfactory operation of the Gage Head is entirely dependent on this component. A clearance hole in the

fixturing of 9.5 mm F is desirable around the gaiter for satisfactory operation.

To maximise working life of the Gage Heads the air supply should be both clean and dry for continual

reliable operation. Maximum relative humidity of 60 % RH and filtered to better than 5 µm particle size.

Environmental Considerations

Most Gage Heads are designed to be used with a gaiter and are designed to withstand the rigours of

in-process gauging and will operate satisfactorily in the presence of copious amounts of coolants and

cleaning solvents.

For Gage Heads without a gaiter such as Feather touch or in situations where removal of the gaiter is

necessary (i.e. at low temperatures where stiffening of the gaiter may be a problem) then the working

atmosphere must be both clean and dry. Ingress of dirt or fluids may interfere with the performance of the

probe or even cause damage.

5GP901 M-3343 05/08

Page 6

Cable

The Gage Head cable is custom made to achieve the optimum balance between flexibility, flex life,

chemical resistance, abrasion resistance electrical and electrical screening.

To minimise transducer failure due to cable damage cable runs should be positioned well clear of moving

components and vulnerable working areas. If the cable is in a flex situation then a minimum bend radius

of 150 mm should be maintained, the vacuum and pneumatic options should not be flexed from the

transducer cable entry, but should be anchored separately at a position of 50 - 70 mm from the end cap.

If the cable of a Digital probe is damaged it is not possible to repair it without affecting probe calibration. It

must be replaced.

Connections

The PIE is designed to be used with the T-CON connector and allows for fast network configuration. All

connections are via the 9-way sub D-type connector.

The Orbit Network has been designed to meet EMC requirements EN50081-1 for emissions and

EN50082-1 for immunity when properly installed. The T-CON case should be connected to a good electrical ground. The mounting option using the captive nuts is the preferred method. Ensure screws make

good contact with the mounting surface. If the mounting option using plastic feet is used paint should be

removed from the T-CON base pads to ensure good electrical contact with mounting surfaces.

6

GP901 M-3343 05/08

Page 7

PIE and T-CON Installation

7GP901 M-3343 05/08

Page 8

This Page Intentionally Left Blank

8

GP901 M-3343 05/08

Page 9

This Page Intentionally Left Blank

9GP901 M-3343 05/08

Page 10

This Page Intentionally Left Blank

10

GP901 M-3343 05/08

Page 11

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for

a period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This ensures

that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits, improper

repair, or unauthorized modication. This WARRANTY is VOID if the unit shows evidence of having been

tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current,

heat, moisture or vibration; improper specication; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA

neither assumes responsibility for any omissions or errors nor assumes liability for any damages

that result from the use of its products in accordance with information provided by OMEGA, either

verbal or written. OMEGA warrants only that the parts manufactured by it will be as specied and

free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth

herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on

contract, warranty, negligence, indemnication, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable

for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in

medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no

responsibility as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser

will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of

the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED

RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO

AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the

return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specic problems

FOR NON-WARRANTY REPAIRS, consult OMEGA

for current repair charges. Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specic problems

relative to the product.

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in

whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

11GP901 M-3343 05/08

Page 12

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

12

GP901 M-3343 05/08

Loading...

Loading...