Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

FTB600B Series

Ultra-Low Flow Sensors

Shop online at

User’s Guide

Page 2

OMEGAnet®On-Line Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains,and

reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Benelux:

Postbus 8034, 1180 LA Amstelveen

The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic:

Frystatska 184, 733 01 Karvina

´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France:

11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Servicing Europe:

U.S.A. and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

U.S.A.: ISO 9001 Certified

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico:

En Espan~ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: ISO 9002 Certified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Canada:

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Page 3

TABLE OF

CONTENTS

FTB600B Series

Ultra-Low Flow Sensors

i

Section Page

Section 1 Introduction ...................................................................... 1

A. General Description .................................................... 1

B. Principle of Operation ................................................. 1

C. Material Characteristics of PVDF ............................... 2

Section 2 Operation Parameters ..................................................... 3

A. Temperature ................................................................. 3

B. Flow Ranges .................................................................. 3

C. Recommended Viscosity ............................................. 4

D. Filter Recommendations ............................................. 4

E. Cleaning ......................................................................... 5

F. Bi-directional Flow ....................................................... 5

Section 3 Silicone Treatment .......................................................... 6

Section 4 Infrared Sensor ................................................................. 7

A. Supply Voltage ............................................................. 7

B. Frequency Output ........................................................ 7

C. Frequency Ranges ........................................................ 8

D. Cable Requirements .................................................... 8

Section 5 Installation ...................................................................... 10

Section 6 Specifications ................................................................. 14

Section 7 Pressure Drop Curves ................................................... 15

Page 4

ii

FTB600B Series

Ultra-Low Flow Sensors

NOTES:

Page 5

1

1

FTB600B Series

Installation

IMPORTANT: READ INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING FLOW METER

Section 1 - Introduction

A. General Description

The FTB600B Series is an axial paddle wheel turbine type flow meter

based on the pelton wheel principle. This unique patented design

makes the FTB600B Series a very accurate, repeatable, linear device.

Not only is the FTB600B Series precise, but it is also a rugged, troublefree flow meter, which can be used in a wide variety of industries

including: medical, pharmaceutical, chemical processing, pulp & paper,

semiconductor, biotech, agriculture etc.

B. Principle of Operation

Fluid flows through the meter, first passing through a helical nozzle,

which causes flow to spiral, rotating in a helical pattern. The spiraling

fluid then impacts on the flat blade rotor causing the rotor to spin. The

rotor is designed to immediately develop a rotation-induced friction

free fluid bearing, thus eliminating any potential bearing wear. An

infrared electro-optical transmitter and receiver is molded into the

body of the meter along with a pair of miniature circuit boards,

providing voltage stabilizers.* This design inherently bleeds off

entrained gas, improving the accuracy of the meter.

* Clear, transparent & translucent fluids; must transmit infrared light.

Page 6

2

FTB600B Series

Installation

1

C. Material Characteristics of PVDF

(Polyvinylidene Fluoride)

1. Material of construction

Trade name - Kynar

All wetted parts of the FTB600B Series are PVDF, excluding the

O-ring. Wetted parts include any part of the meter that will or could

come in contact with the fluid.

List of wetted parts:

1. Barbed fittings 5. End caps

2. Flow meter body 6. Strainer

3. Rotor 7. Bearings

4. Helical nozzle (Viton O-ring seal)

2. Chemical Composition

Polyvinylidene Fluoride is a fluorpolymer consisting of three basic

materials (carbon, hydrogen and fluorine)

3. Effects of Various Fluids

a . Weak acids - no effects

b. Strong acids - attacked by fuming sulfuric & nitric acids at high

temperature.

c. Weak alkalis - no effects

d. Strong alkalis - no effects

e. Organic solvents - Resistant to most. Slight attack by some.

Imbrittled by some amines, keystone and esters.

Page 7

3

2

FTB600B Series

Operating Parameters

Section 2. - Operating Parameters

A. Temperature

Since the FTB600B Series has printed circuit boards molded into the

body of the meter it is strongly recommended that 180°F not be

exceeded. Exceeding 180°F can cause irreparable damage to the circuit

boards.

B. Flow Ranges

The FTB600B Series is available in six different sizes, which cover a

flow range from 0.1 to 120 lpm.

Specific flow ranges

FTB601B 0.1 to 2 lpm (0.03 to 0.53 gpm)

FTB602B 0.3 to 9 lpm (0.08 to 2.38 gpm)

FTB603B 0.5 to 15 lpm (0.13 to 3.96 gpm)

FTB604B 1.0 to 30 lpm (0.26 to 7.93 gpm)

FTB605B 2.5 to 75 lpm (0.66 to 19.8 gpm)

FTB606B 4.0 to 120 lpm (1.32 to 32 gpm)

Over range may permanently damage the flow meter.

WARNING

Page 8

4

FTB600B Series

Operation Parameters

2

Page 9

5

FTB600B Series

Operating Parameters

2

C. Recommended Viscosity

Range 1-5 cSt (w/o correction)

The effects of changing viscosity on the FTB600B Series are the same as

any other turbine flow meter. It is important to remember that a turbine

meter is a viscosity dependent device, where as the viscosity increases

the linearity of the flow meter will decrease. (Water like viscosities are

ideally suited for use with the FTB600B Series) The FTB600B Series is

factory calibrated with water.

Correction procedure for higher viscosity

For viscosities greater than 5 cSt consult the factory. The FTB600B Series

can be used on fluids greater than 5 cSt. however, the K-factor

(linearity) will change. This requires a recalibration of the FTB600B

Series at the known viscosity to determine the new KFactor.

D. Filter Recommendations

Meter Micron Mesh

FTB601B 35 400

FTB602B 50 300

FTB603B 100 80

FTB604B 100 80

FTB605B 100 80

FTB606B 100 80

Page 10

6

3

FTB600B Series

Silicone Treatment

Section 3 - Silicone Treatment

Silicone treatment is standard for all types of the FTB600B Series series

electronics.

Page 11

7

4

FTB600B Series

Infrared Sensors

Section 4 - Infrared Sensor

A. Supply Voltage

24 Vdc. Do not exceed 24 Vdc. Doing so can cause overheating and

eventual failure of all PC boards. Printed circuit boards are nonrepairable.

B. Frequency Output

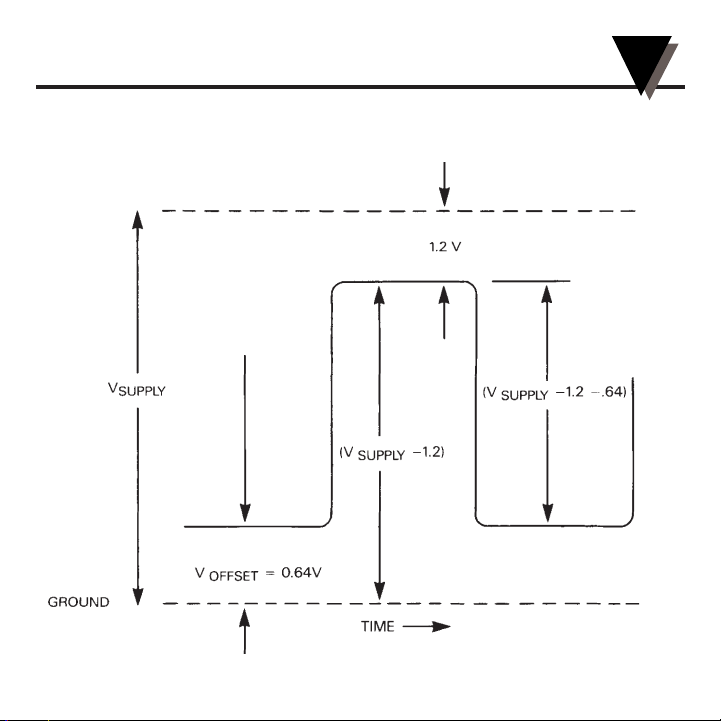

1. Square wave pulse, unscaled (See Figure 4-1)

2. Output impedance 75 ohms

3. Directly proportional to flow rate

4. Output - dc frequency

5. Offset 0.64 volts

6. Peak voltage = Supply voltage - 1.2 volts

7. Peak to peak voltage Supply voltage - 1.2 volts - 0.64 volts

8. Output signal cycle 66.7% (i.e. at 100 Hz there is a 6 millisecond “on”

time and a 4 millisecond “off” time)

9. TTL/CMOS circuit compatibility. The FTB600B Series has an

operational amplifier output, which has a high input impedance and a

low output impedance.

Page 12

8

FTB600B Series

Infrared Sensors

4

C. Frequency Ranges for

(non-cartridge models) pulses/l

Model Frequency (Hz) K-Factor

FTB601B 60 to 1200 36,000

FTB602B 40 to 1200 8,000

FTB603B 27 to 800 3,200

FTB604B 20 to 600 1,200

FTB605B 18.75 to 562 450

FTB606B 15 to 450 225

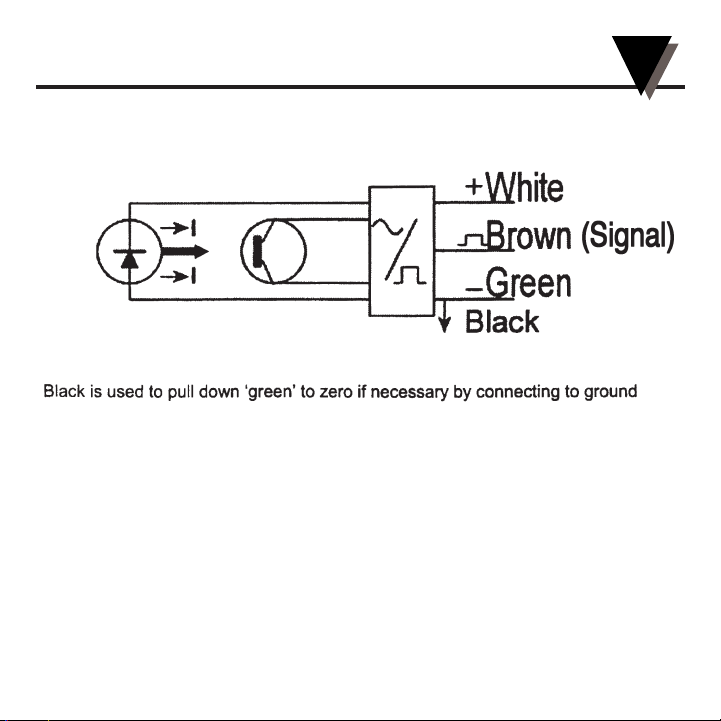

D. Cable Requirements

1. 20 to 22 AWG (American Wire Gauge)

2. 4 conductor-shielded cable.

Avoid influences of strong electromagnetic forces as they

can damage components on the PC boards.

NOTE

Page 13

9

FTB600B Series

Infrared Sensors

4

Figure 4-1. Output Frequency Waveforms

Page 14

10

5

FTB600B Series

Installation

Section 5 - Installing the FTB600B Series in the fluid line.

A. Make sure the fluid is compatible with PVDF (polyvinylidene fluoride)

and meets viscosity, pressure and temperature parameters of the

FTB600B Series. The fluid must also meet filtration requirements as

listed in 3D.

B. Install the FTB600B series in the fluid line with the arrow pointing in

the direction of the flow.

C. While installing the FTB600B Series in the fluid line be careful not to

over-torque the end caps (on hose-barbed flowmeters) or other

fittings on the flowmeter. Due to the relatively soft composition of

PVDF the body or threads can be permanently distorted.

D. Attach wires to the readout display with the display and power off.

Not only will this help to avoid a potential shock hazard, but it can

also help prevent an error in hooking the flow meter to an incorrect

115 Vac supply.

E. Connect digital display to power supply and enter scaling factors for

both the rate and total. Follow the manufacturers instructions for

programming the digital display.

F. The FTB600B Series is now ready for use.

G. See Table 5-1 for straight pipe recommendations.

Page 15

11

FTB600B Series

Installation

5

Figure 5-1. Supply Voltage and Signal Output Connections

Page 16

12

FTB600B Series

Installation

5

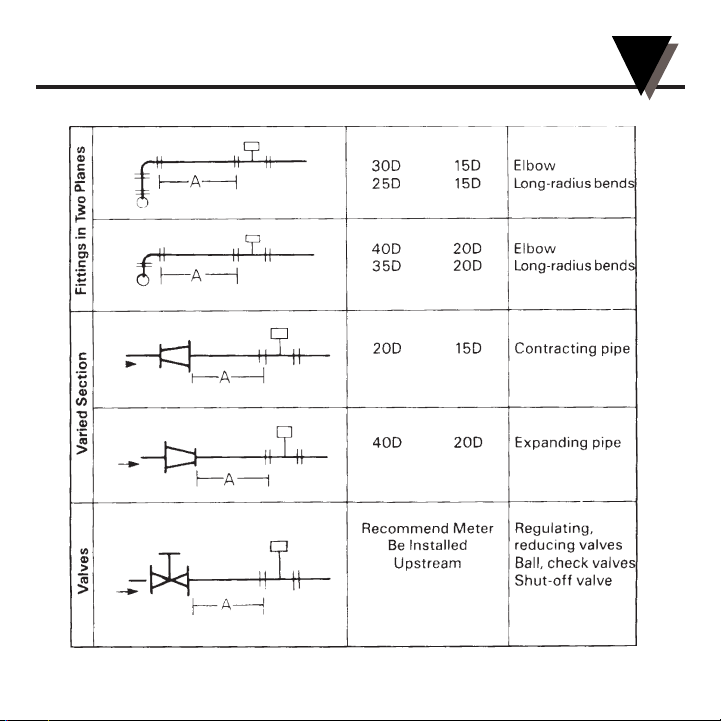

Table 5-1. Piping Table

Page 17

13

FTB600B Series

Installation

5

Table 5-1. Piping Table Con't.

Page 18

14

6

FTB600B Series

Specifications

Section 6 - Specifications

Accuracy: ±3% of reading

Repeatability: ±0.1% of reading

Linearity: ±1% of reading

Viscosity Range: 1 to 15 centistokes

Working Pressure: 150 PSIG at 175°F

Wetted Materials: PVDF

Power Supply: 5 to 18 Vdc, 6 to 33 mA

Output Signal: Unscaled square wave

Pressure Drop: See Section 7

Page 19

15

7

FTB600B Series

Pressure Drop Curves

Section 7 - Pressure Drop Curves

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB601

50

0.50 1.0

Liters/minute

kPa

1.5 2.0

45

40

35

30

25

20

15

10

5

0

Page 20

16

FTB600B Series

Pressure Drop Curves

7

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB602

250

2.00 4.0

Liters/minute

kPa

8.06.0 10.0

200

150

100

50

0

Page 21

17

FTB600B Series

Pressure Drop Curves

7

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB603

200

510150

Liters/minute

kPa

160

180

140

100

80

60

40

20

120

0

Page 22

18

FTB600B Series

Pressure Drop Curves

7

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB604

200

10 20 300

Liters/minute

kPa

160

180

140

100

80

60

40

20

120

0

Page 23

19

FTB600B Series

Pressure Drop Curves

7

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB605A

160

140

120

100

80

60

40

20

10 20 30 40 50 600

Liters/minute

kPa

0

Page 24

20

FTB600B Series

Pressure Drop Curves

7

Pressure Drop FTB600B Series Liquid Turbine - Flowmeter FTB606A

180

160

140

120

100

80

60

40

20

10 20 30 40 50 60 70 80900

Liters/minute

kPa

0

Page 25

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

WARRANTY / DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to

the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue

an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is

found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having

been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat,

moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by the company will be as specified and

free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein

are exclusive, and the total liability of OMEGA with respect to this order, whether based on

contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our

basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA

harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

Page 26

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor

Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN

AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters

& Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators

& Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition &

Engineering Software

䡺⻬

Communications-Based

Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM

& Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater

Treatment

䡺⻬

pH, Conductivity & Dissolved

Oxygen Instruments

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

M1132/0405

Loading...

Loading...