Page 1

@a

FTBSOO

Series

Q

a

Low

Flowrate

Meters

(i%%i

OPerator’s

Manual

Page 2

Am

D.aaw.4

OMEGKj

Taek,.l.#hm

c..pmmy

OMEGA To il Free

Canada

Bergar

976

Lava1 (Quebec)

Telephone: (514) 856-6928

FAX: (514)

1-800-TC-OMEGA-‘M

/

l-80%622~BESP

/

I-800-USA-WHENSM

/

ka

Servicing USA and Canada: Call

One

Stamford, CT 06907.0047

Telephone: (203) 359.1660

FAX: (203) 359-7700

USA

Omega

Drive, Box 4047

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

H7L

856-6886

5Al

Servicing Europe: United Kingdom Sales and Distribution Center

Leicestershire

A&y,

25

Telephone: 44 (1455) 285520 FAX: 44 (1455) 283912

The OMEGA

Co m p lete M easure m ent and

Contro l Handbooks

1c

Temperature

V

Pressure, Strain

V

Flow and Level

andconductivitypH W

&

Force

LE9

6TU,

England

&

V

Data Acquisition Systems

V

Electric Heaters

ti

Environmental Monitoring

Swannington Road, Broughton

Encyc loped ias

and Control

Call for Your FREE Handbook Request Form Today: (203)

DFMOSSSFVRIBA

359-RUSH

Page 3

TABLE OF CONTENTS

FTB500 SERIES FLOWMETERS

SECTION

SECTION 1

1.1

I.2

I.3

1.3.1

1.3.2

1.3.3 Viscosity Calibration and UVC Curves

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

Available Models

Theory of Operation

Performance Characteristics

Viscosity Effects

.....................

.................

...............

.........

.................

...

PAGE

.I

.

.

.

.

.

.

.

. .

.

. . .

.

. .

.................

SECTION 2 INSTALLATION

2.1

2.2

2.3

2.4

2.5

Unpacking

Operation

General

Installation Wiring Layout for Interconnections

Installation of the FTB500 Mini Flow Signal Conditioner

.................................

..................................

.................................. .

........

SECTION 3 CALIBRATION

3.1

3.2

3.3

3.4

3.4.1

3.4.2

Introduction

Calibration Procedure

To Confirm

Calibration of FTB500 Analog Output

Setup

Equations

.......................

.................

FTBSOO

Signal Conditioner Offset

........................... .

.........................

SECTION 4 MAINTENANCE

4.1

4.2

Introduction

Servicing and Preventative Maintenance of the

Flowmeter (Ball Bearing Design)

,

.........

...

.. .

.. .

.. .

......

.

. . . . . , . . . . . . . . . . . . . . . .

FTBSOO

. . . . . . . . . . .

SECTION 5 TROUBLESHOOTING AND MAINTENANCE

SECTION 6 RECOMMENDED SPARE PARTS LIST

SECTION 7 ACCESSORIES

SECTION 8 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . .

.6

.

6

7

7

.

.

8

.9

.I2

. . . . . . . . . . . . . . . . , . . . . . . . . .

I2

..

.

12

I3

.

. . .

.

I3

.

13

I3

.

. . . . .

.I5

. . . . . . . . . . . . . . . . . . . . . . . . .

15

I5

.

.I8

. . . . . a

.20

. . . . . . . . . .

.20

. . . . . . . . . . , . . . . . . . . . . . . . .

.21

Page 4

SECTION 1 INTRODUCTION

1.1

DESCRIPTION

OMEGA@

The

low flow measurement of liquids and gases. They utilize a

rotor whose motion is converted into a pulse output proportional to flow

by a pickup coil. They come with an integral signal conditioner, powered

by either 15-35 VDC or 115 VAC (optional) to provide amplified frequency

and analog output. The signal conditioner corrects for the inherent zero off-

set of the flowmeter pulse output. It is mounted in a NEMA 4X, explosion

proof enclosure

II, groups E, F and G.

Features of the FTB500 include:

1.

Integral signal conditioner which provides K-factor offset correction for

the mini-flowmeters.

2. Versatile AC and DC power versions are available.

3. Configurable pulse voltage or analog output options.

FTB500 Series Low Flowmeters offer extremely accurate

(Adalet

XJS DO) rated for class I, groups C and D, and class

pelton

wheel-like

1.2

AVAILABLE MODELS

DESCRIPTION

(LINEAR FLOW RANGE)

STANDARD PART NUMBERS

0.02

to

0.15 GPM

0.025

to

0.25 GPM

0.05

to

0.5 GPM

0.1

to

1.0 GPM

0.2

to

2.0 GPM

OPTIONAL PART NUMBERS

TTL

Pulse output

0-5VDC

output

115VAC

signal conditioner power supply

PSIG

5000

(“CK)

*

Replace

tistokesl

X

1 for 501, 2 for 502, 3 for

in part number with the viscosity (in

of your liquid. The maximum is 25CK.

NOTE

503,4

PART NUMBER*

FTB501-(

FTB502-(

FTB503-(

FTB505-(“CK)

FTB50_X-(*CK)-P

FTB50_X-t”CKb5VDC

FTB5O_X-(*CK)-115VAC

FTB50_X-t*CK)-5KP

“CK)

“CK)

“CK)

‘CK)FTB504-(

for 504, or 5 for 505.

cen-

1

Page 5

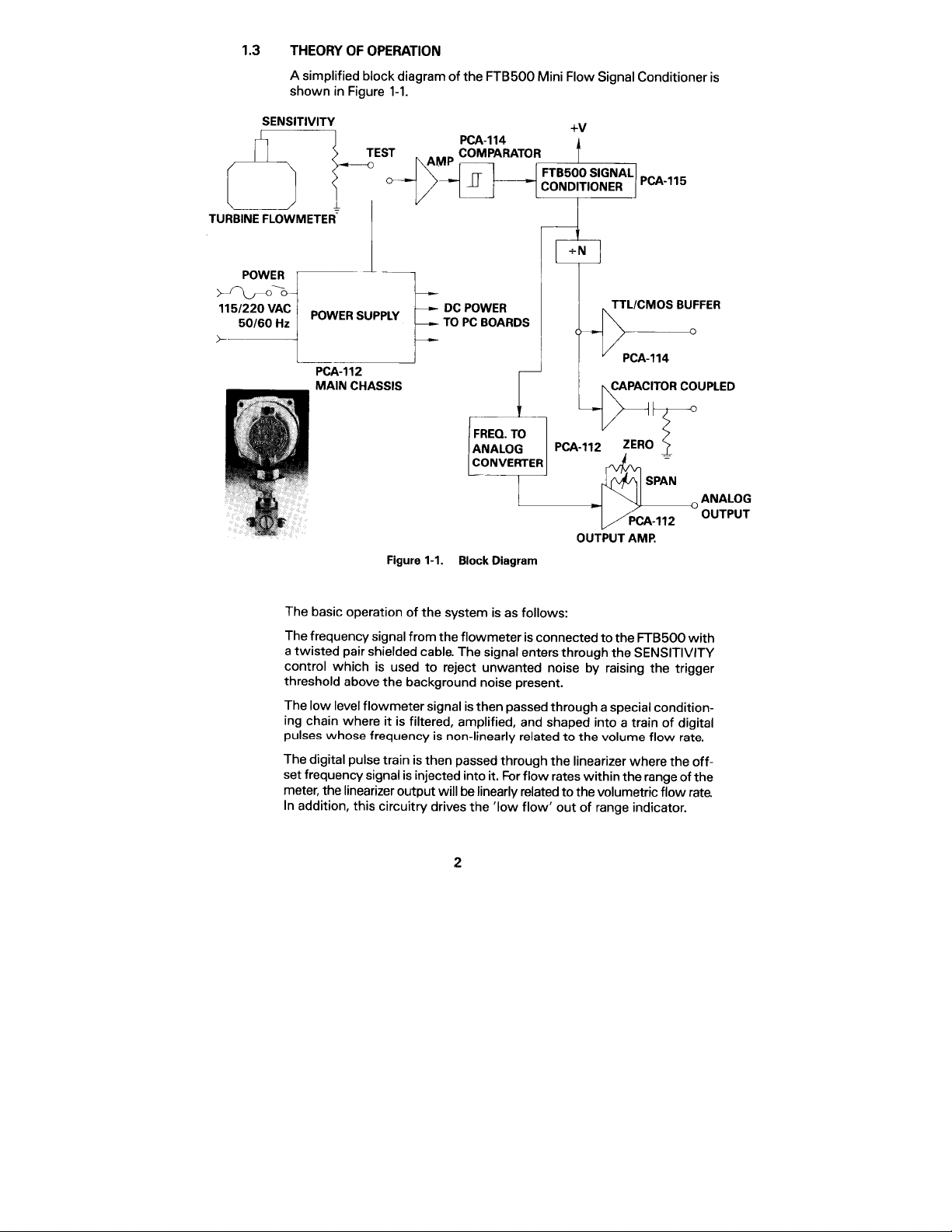

1.3

THEORY OF OPERATION

A simplified block diagram of the FTB500 Mini Flow Signal Conditioner is

shown in Figure 1-I.

SENSITIVITY

TURBINE FLOWMETER=

MAIN CHASSIS

Figure l-l.

FREQ. TO

CONVERTER

- -

Block Diagram

+v

FTBBOO

SIGNAL

CONDITIONER

CAPACITOR COUPLED

OUTPUT

pcA_,,B

ANALOG

OUTPUT

AMP.

The basic operation of the system is as follows:

The frequency signal from the flowmeter is connected to the FTB500 with

a twisted pair shielded cable. The signal enters through the SENSITIVITY

control which is used to reject unwanted noise by raising the trigger

threshold above the background noise present.

The low level flowmeter signal is then passed through a special condition-

ing chain where it is filtered, amplified, and shaped into a train of digital

pulses whose frequency is non-linearly related to the volume flow rate.

The digital pulse train is then passed through the linearizer where the off-

set frequency signal is injected into it. For flow rates within the range of the

meter, the linearizer output will be linearly related to the volumetric flow rate

In addition, this circuitry drives the ‘low flow ’ out of range indicator.

2

Page 6

The signal entering the frequency to analog converter is passed through a

combination of divide by N and DIP switch matrix. The output is chosen

whose pulse rate is between 75 and 150 Hz at the maximum flow rate to

be measured. This scaled pulse rate is fed into a precision monostable cir-

cuit. The output of the monostable is then filtered into an analog voltage

that is proportional to flow.

The output amplifier will take this voltage and perform either a voltage to

voltage amplifier or voltage to current amplifier.

Finally, the output is divided by 8 to reduce irregular pulse spacing. Then,

the pulse train enters a buffer and an attenuator simultaneously. The buf-

fer output produces a square wave pulse which can be used as a

CMOS/lTL

compatible output. The attenuator produces a capacitor coupled AC out-

put which is suitable for driving other signal conditioners, indicators, or con-

trollers which require an AC signal input.

The output frequency from the FTB500 Series Turbine Meter versus flow

flowrate

is essentially a straight line of frequency as a function of

which

does not pass through zero. left uncorrected, this will result in a K-factor

which varies with flow rate.

The

FTBSOO

integral signal conditioner will compensate for the frequen-

cy offset characteristics of the flowmeter, by using the method of offset

frequency injection. Offset frequency injection is implemented electronically

by adding a signal equal to the offset frequency required to linearize the out-

put of the flowmeter. This effectively shifts the output characteristic to that

of the desired ideal. A low-flow cutout feature is provided where the off-

set signal is inhibited during no flow to prevent false outputs from being

generated.

The FTB500 Series Turbine Meter is a family of low flow rate measurement

pelton

devices based on a

tangentially through a velocity nozzle against the

wheel-like rotor. The measured fluid is directed

pelton

rotor causing it to

rotate The motion of the rotor is sensed by the pickup coil and converted

to a pulsing output signal where the frequency is related to the flowrate, and

the accumulated pulses are related to the total volume passing through the

flowmeter.

1.3.1

Performance Characteristics

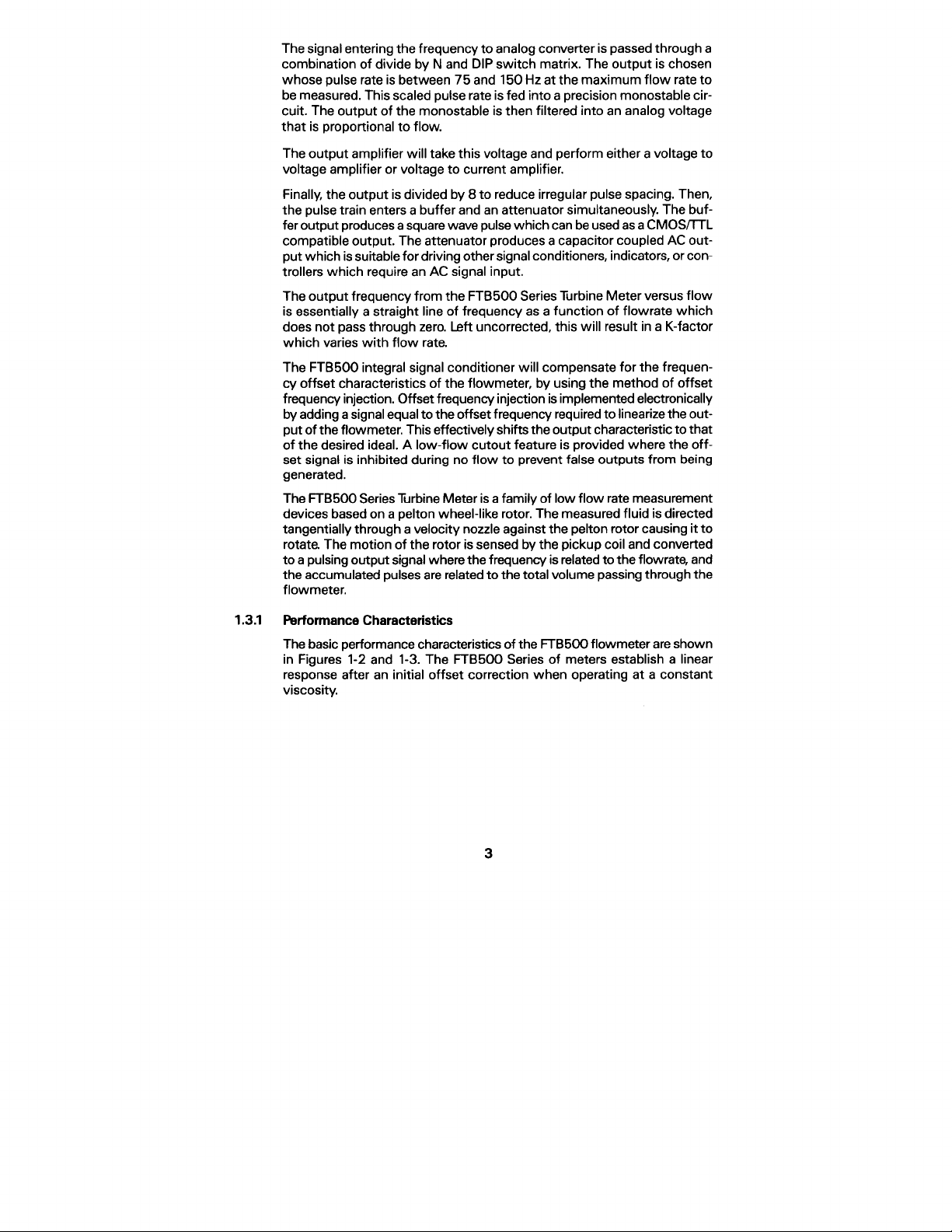

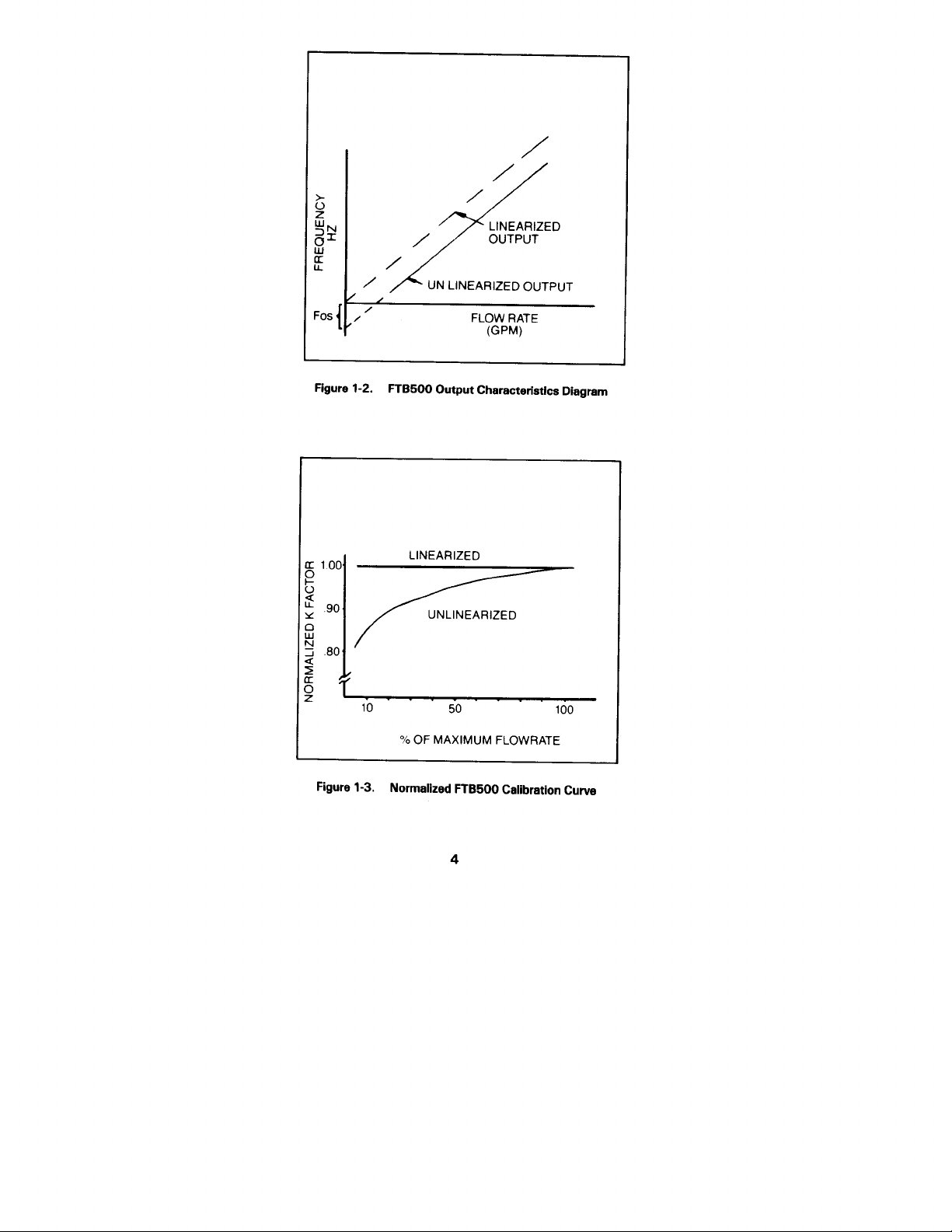

FTBSOO

The basic performance characteristics of the

FTB500

in Figures l-2 and 1-3. The

Series of meters establish a linear

flowmeter are shown

response after an initial offset correction when operating at a constant

viscosity.

3

Page 7

lL

/

UN LINEARIZED OUTPUT

FLOW RATE

(GPM)

Figure 1-2.

8

5

90

!

.80

7

f

1.00

u

Figure 1-3.

FTBSOO

Output Characterlstlcs Diagram

LINEARIZED

UNLINEARIZED

I_7

10 50 100

%

OF MAX IMUM

Normalized

FTBIOO

FLOWRATE

Calibration Curve

4

Page 8

Over the linear flow range, the input/output characteristics takes the form of:

Equation 1

Frequency = C, x Flowrate-C,

FTB500

The

ditioner available in all OMEGA instrumentation. Accuracies of

Series Turbine Meter requires the use of a linearization con-

*l%

of

reading are typical after initial correction for offset. Better accuracies ap-

*2%

proaching

entire characteristics of the

are possible using smart transmitters which can store the

FTB500

Series Turbine Meter.

The K-Factor is the number of pulses per unit volume produced by the

flowmeter under a given set of conditions. Repeatability is a measure of the

stability of the output under a given set of flowing conditions. The

repeatability is defined as the allowable percentage deviation from the

stated K-Factor.

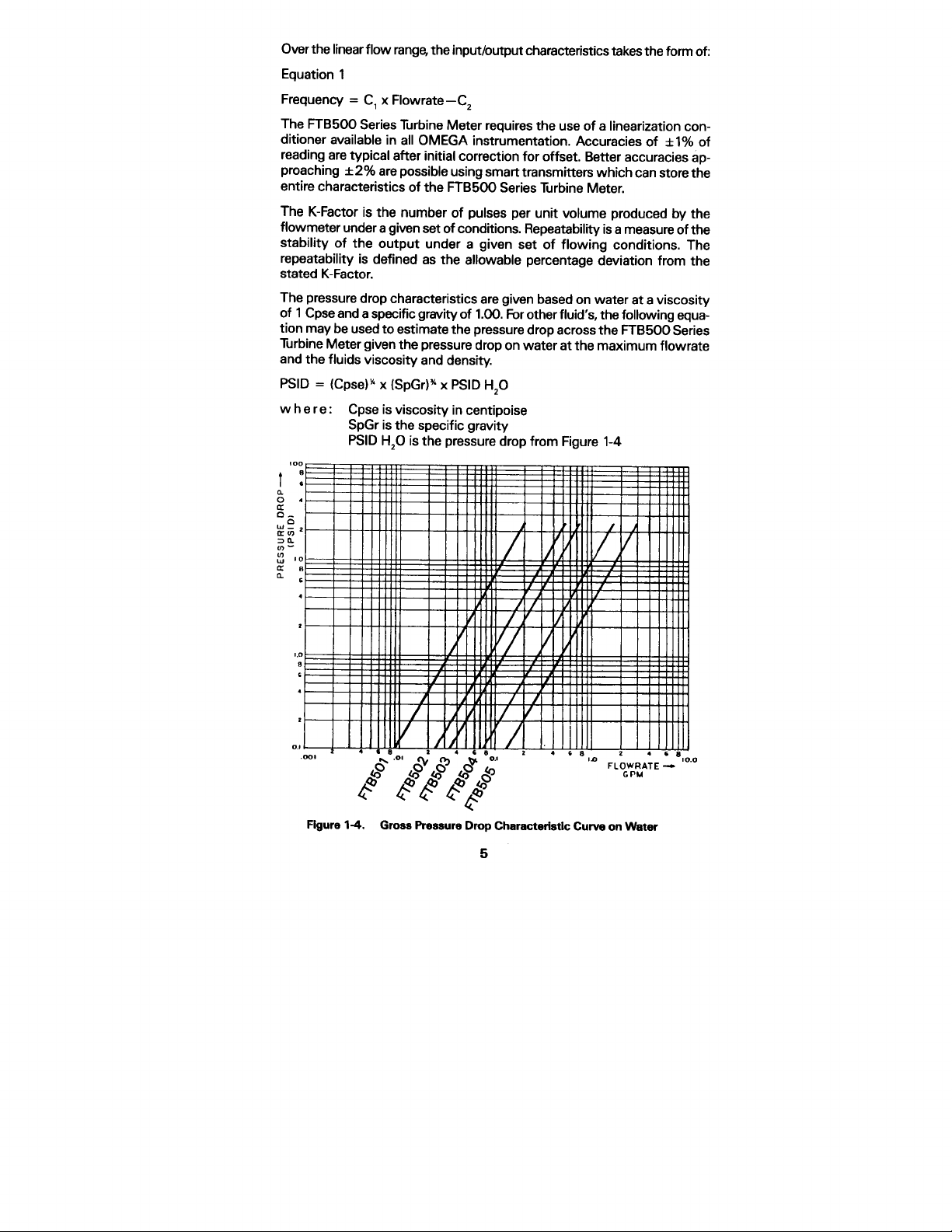

The pressure drop characteristics are given based on water at a viscosity

of 1 Cpse and a specific gravity of 1.00. For other fluid ’s, the following equa-

tion may be used to estimate the pressure drop across the

Turbine Meter given the pressure drop on water at the maximum

FTB500 Series

flowrate

and the fluids viscosity and density.

PSID

=

where:

(Cpsel”

(SpGr)”

x

Cpse is viscosity in centipoise

SpGr

is the specific gravity

H,O

PSID

is the pressure drop from Figure l-4

x

PSID

H,O

Figure 14.

Gross Pressure Drop Characteristic Curve on Water

5

Page 9

1.3.2 Viscosity Effects

An ideal flowmeter may be defined as one in which the output is solely a

function of the fluid flow being measured. Real flowmeters display

dependencies on secondary fluid properties, such as viscosity temperature,

and/or pressure. These effects tend to obscure or degrade the precision of

the flow measurement.

In very few flowmeter designs, the viscosity dependency is well understood

and given suitable documentation, may be compensated for. The OMEGA

instruments are among this select group.

In selecting an

it is generally preferable to size the flowmeter so it will be operating in the

higher portion of its range to minimize viscosity effects in the measurement.

Some loss in flow turndown range may be expected.

FTB500

Series Flowmeter for operation on a viscous fluid,

1.3.3

Viscosity Calibration and UVC Curves

In some flowmeter applications the viscosity is held nearly constant owing

to regulated conditions of temperature and fluid consistency. For such ap-

plications it is only necessary to document the flowmeter ’s performance

at the expected operating viscosity. For such fixed viscosity applications

the standard specifications usually apply.

The

FTB500

Series Turbine Meter may be used over wide viscosity ranges,

since the flowmeter has a unique, documented, Universal Viscosity Curve

(abbreviated UVC) which is accurate to

In some applications, the fluid viscosity is a known function of temperature

A PC could be used to eliminate the otherwise adverse viscosity effect on

the flow measurement.

SECTION 2 INSTALLATION

2.1

UNPACKING

Remove the Packing list and verify that all equipment has been received.

If there are any questions about the shipment, please call the OMEGA

Customer Service.

Upon receipt of shipment, inspect the container and equipment for any

signs of damage. Take particular note of any evidence of rough handling in

transit. Immediately report any damage to the shipping agent.

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing con-

tents, save packing material and carton in the event reshipment

is necessary.

NOTE

*l%

of reading.

Page 10

2.2

OPERATION

Perform any purging of piping with spool piece in place. Once completed,

install the flowmeter and connect cabling to pickup coil.

With the FTB500 Mini Flow Signal Conditioner properly installed and

calibrated, verify the following performance.

With the power ON and no flow through the flowmeter, there should be no

pulse output from the unit. To verify this, connect either a digital Frequen-

cy Counter or an AC voltmeter.

If using a Digital Frequency Counter, the display should display zero. If some

other constant or varying indication occurs, noise may be present.

Slowly turn the SENSITIVITY threshold control counter-clockwise until in-

dication stops.

Turning the sensitivity control FULLY counter-clockwise will

render the outputs inoperative. Turn potentiometer clockwise to

return to normal operation.

If using an AC voltmeter, the meter should be at zera If noise is present, the

voltmeter will deflect and swing from 0 to

Slowly turn the SENSITIVITY threshold control counter-clockwise until in-

dication stops.

NOTE

2.5V.

2.3

GENERAL

Proper application of the turbine flowmeter requires a suitable piping installa-

tion in order to achieve accurate and reliable operation. Refer to Figure 2-l.

Vl, V2 = BLOCKING VALVE

V3

= BYPASS VALVE

S = STRAINER

FS = FLOW STRAIGHTENER

TFM = TURBINE FLOWMETER

2-I.

Figure

BYPASS RUN

FS

t

TFM

METER RUN

Typical Turbine Meter Installation

-

7

v2

I

Page 11

The piping configuration immediately

flowmeter is termed the meter run.

-In

METER RUN

inner diameter as the meter bore. A minimum of IO pipe diameters of

straight pipe upstream and 5 pipe diameters downstream are required.

Where this optimum line configuration can not be implemented, it is ad-

visable to install a flow straightener properly positioned upstream of the

flowmeter. Orientation is not a critical factor, however, horizontal is a pre-

ferred orientation.

RELATIVE-The performance of the turbine flowmeter is affected by fluid

swirl and non-uniform velocity profiles. The following recommendation will

reduce such flow irregularities.

It is advisable not to locate the meter run immediately downstream of

pumps, partially opened valves, bends or other similar piping configurations.

In addition, the area surrounding the flowmeter should be free of sources

of electrical noise such as motors, solinoids, transformers and power lines

which may be coupled to the

The metering section should not be subjected to excessive vibration or

shock. Such a condition may result in a mechanically induced output signal

from the

BYPASS RUN -A properly sized bypass run with suitable blocking valves

may be equipped where an interruption in fluid flow for turbine meters ser-

vicing can not be tolerated.

STRAINER-A strainer, filter and/or air eliminator is recommended to reduce

the potential of fouling or damage Recommended mesh size is at least 100

microns. Finer filters are preferred.

On initial startup of a line, it is advisable to install a spool piece purging the

line to eliminate damaging the flowmeter, due to flux, tape, solder, welds

or other contaminants carried along by the fluid stream.

general, the meter run should be chosen to have the same

pickoff

pickoff

device.

preceeding

device.

and following the

2.4

INSTALLATION

In considering the interconnections between the flowmeter and the flow

measurement system some attention must be given to anticipated noise

sources and to the coupling of these noise sources to the interconnecting

wiring.

Noise signals may be coupled inductively or capacitively into the wiring bet-

ween the flowmeter and the electronic measuring systems. In general, utiliz-

ing a shielded, twisted pair for the interconnection greatly reduces this

coupling. The shield should be grounded on one end of the cable only. In

general, grounding only on the electronic measuring system is best.

However, even with proper interconnecting cabling cross talk with other

signal lines or power lines may still occur and should be avoided. Physical

isolation in the manner in which the wiring is run reduces the chance of

potential problems.

WIRING LAYOUT FOR INTERCONNECTIONS

B

Page 12

It is common to transmit the low level output signal from the flowmeter

several hundred feet through a shielded, twisted pair instrument cable.

Where a noisy environment is suspect, it is recommended that a pre-

amplifier be installed on or near the flowmeter to assure the preservation

of flow information from the flowmeter to the electronic measuring system.

Suitable accessory models are available from the manufacturer.

2.5

FTB500

INSTALLATION OF THE

FTB500

The

for easy opening of the enclosure Refer to Figure 2-2 for the mounting draw-

ing for the FTB500.

Drill appropriate mounting holes as required. Mount the unit to the panel.

Refer to Figure 2-3 for DC hookup or Figure 2-4 for

appropriate terminals for installation. Connect the flowmeter cable to the

FTB500 including shield.

should be placed in a convenient location with sufficient room

“0” RING

a--+------_,

MINI FLOW SIGNAL CONDITIONER

115VAC

(optional) for

REMOVABLE COVER

/-

Tl=t.aJ

Figure 2-2.

35/4”

NPT

FOR

Mounting Holes Location Diagram

”

I.D. CONDUIT

H

9

Page 13

To

PICKUPCOIL

--

-\-

I

A

i:

B:,’

.-

7x

1I

1I

:,’

--_

0

0

ANALOG OUTPUT

(STANDARD)

1

PULSE OUTPUT

1-P

OPTION)

DC VOLTAGE

INPUT

1234567 8

+

-

+

_

SIGNAL

RETURN

SIGNAL

COMMON

F(TEBT)

@

0

@

0

@

TERMINAL

BLOCK 1

-

TERMINAL

BLOCK 2

NOTE

Lo

FTB500

THE

CALIBRATION SIGNAL. TO INJECT THIS TEST

SIGNAL, INSTALL A JUMPER FROM TERMINAL

8 TO TERMINAL 1.

EQUlPPED WITH AN INTEGRAL

IS

Figure 2-3. DC Input Installation

10

Wiring

Diagram

Page 14

Xl

PICKUP COIL

Ayy==+--~

TERMINAL

BLOCK 1

IIBVAC

50160 Hz

INPUT

F(TEST)

(NEUTRALS

E

THE

FTB500

CALIBRE

SIGNAL,

IS EQUIPPED WITH AN INTEGRAL

\TlON

SIGNAL.

INSTALL A JUMPER FROM TERMINAL

8 TO TERMINAL 1.

@

u

TERMINAL

BLOCK 2

NOTE

TO INJECT THIS TEST

Figure 24.

115VAC

Input Installation Wiring Diagram

11

Page 15

Connect the line power and ground to appropriate terminals. The line power

should be an ‘instrument grade ’ line whose various loads do not contain

solenoids, valves or other similar transient producing load which might

adversely affect the operation of the system.

Connect the cabling to the pulse output and to the inputs of the final

measurement system. Observe same precautions listed for interconnecting

cabling.

SECTION 3 CALIBRATION

3.1

INTRODUCTION

FTB500

In general, all

flowmeter systems supplied by OMEGA Engineering,

Inc. have been factory calibrated at the time of purchase

All systems which were factory calibrated have a calibration card attached

prior to shipment. This card contains the flow rate, offset frequency

and low flow setpoint.

Field calibration is only required when a change has occurred. Such a

change may be due to repair, replacement or recalibration of the flowmeter.

F(OSl

3.2

CALIBRATION PROCEDURE

Before calibrating the FTB500 flowmeter, analog outputs, be sure the

response time adjustment potentiometer is turned fully clockwise for

fastest response time (0.5 seconds nominal). This potentiometer is found

inside the signal conditioner, inside the rectangular case, on the top printed

circuit board, just beneath terminal I. Slowest response time, with poten-

tiometer fully counter-clockwise, is 2 seconds. Increasing the response time

can act to reduce “jitter” in the analog output.

Begin by determining the offset frequency of the mini flowmeter. This is sup-

plied on the calibration card

[F(OSl].

The mini flow signal conditioner may be calibrated with the internal TEST

frequency used in conjunction with a frequency counter.

jumpered

The TEST switch, when

8 to Terminal 1, refer to Figure 2-3 or

to the input terminal (connecting Terminal

2-41,

injects an internally generated

frequency. When using this feature, F (TEST) is equal to 120 Hz.

F(OS)l

F(OUT)

where:

= 1.8

FfOUTl

FfTEST)

FfOSl

[F(TEST)

+

is the output frequency of the linearizer

is the test frequency

is the offset frequency

12

Page 16

3.3

FTBSOO

l7I

CONFIRM

1. Connect frequency counter to the offset frequency test point of the unit.

Inject the TEST frequency and observe that the frequency equals 10

2.

F(OS).

x

For analog, go to Section 3.4.

For pulse, continue to step 3.

3.

Connect frequency counter to the output of the unit and with an in-

jected TEST frequency, verify that the output frequency equals

in the equation stated above.

SIGNAL CONDITIONER OFFSET

F(OUT)

3.4

3.4.1 Set Up

3.4.2 Equations

CALIBRATION OF

The signal conditioner may be calibrated with an internal “TEST” frequency

or an external oscillator used in conjunction with a frequency counter.

METHOD 1

As stated before, the “TEST” frequency

tied to Terminal

When using this feature, F (TEST) is equal to 120 Hz and is used in the

following equation.

Alternate or external oscillator may be used to supply a test frequency. In

this method, the external oscillator is connected to the signal input ter-

minals. The oscillator ’s output frequency is set to equal F (MAX) as in-

dicated on the frequency counter. For this approach, use F (MAX) in the

following equations for F (TEST).

Regardless of the method used, begin by calculating the following set points

indicated by Equation I through Equation 3. Use the frequency F (TEST)

depending on calibration method chosen above

Equation

Equation 2

Equation 3

FTBBOO

ANALOG OUTPUT

jumpered

11,

injects an internally generated frequency into the unit.

F(MAX)

1

= K FACTOR x R (MAX) _

60

Set (ZERO) = SET TO NO FLOW CONDITION

Set (SPAN) =

i.e.,

[F

(TEST) + F

5mA,

4mA,

[F(MAXl

to the input (Terminal 8

or OV

(OS11

x SPAN +

(OS)1

+ F

F(GS)

ZERO

13

Page 17

where:

F(TEST)

F(OSl

F(MAX)

= test frequency used

= offset frequency

= the flowmeter output frequency at

R(MAXl when

at the reference condition at which the relation with

F(MAX)

was defined.

ifi,

K Factor

SPAN

ZERO

= in units of readout,

= varying component of analog output. For example,

mA

for 4 to 20

16

= fixed offset component of analog output. For

example, 4

mA

PULSE/GAL

mA

output, 5V for 0 to 5V output

mA

for 4 to 20

output, OV for 0 to

5v output.

1.

The Range Adjustment is accomplished by selecting a switch position

on a DIP switch located on the PCA-112 printed circuit card depending

on the model. Refer to Table 3-l to determine required switch position,

and select the switch position on the top printed circuit board adjacent

to the zero adjust potentiometer.

TABLE 3-1

RANGE SELECT SWITCHES

F (MAX)

300 to 600

600 to 1200

1200 to 2400

2400 to 4800

2.

Turn the “SPAN” potentiometer fully counter-clockwise until slippage

RANGE SELECT

SWITCH

POSITION

3

4

5

6

is felt or 25 turns. Refer to Figure 3-1.

* EQUIPPED FOR ANALOG OUTPUT OPTION

Figure 3-1.

Dimensions and

Potentiometer

locations

’

14

Page 18

FOR CURRENT OUTPUT OPTION ONLY

Connect a digital

3.

put terminals.

Adjust “ZERO” potentiometer (refer to Figure

4.

current (i.e., 4

Inject the test frequency while adjusting “SPAN” potentiometer (refer

5.

to Figure

Repeat steps 4 and 5 until no change is observed.

6.

FOR VOLTAGE OUTPUT OPTION ONLY

Connect a digital voltmeter across the voltage output terminals.

7.

8. Inject the test frequency while adjusting “SPAN” potentiometer so

voltage equals to SET (SPAN).

SECTION 4 MAINTENANCE

4.1

INTRODUCTION

OMEGA ’s Flow

vice life. However, problems do occur from time to time and the following

points should be considered for preventative maintenance and repairs.

The bearing type used in the flowmeter was chosen to give compromise

between long life, chemical resistance, ease of maintenance and perfor-

mance. A preventative maintenance schedule should be established to

determine the amount of wear which has occurred since last overhaul.

In case the flow measurement system malfunctions or becomes in-

operative, refer to the Troubleshooting Guide in Section 5.

mA).

3-l) so the current equals to SET (SPAN).

Measurement_Systems

milli-ammeter

or equivalent, across the current out-

3-l) for desired “ZERO”

are constructed to give a long ser-

4.2

SERVICING AND PREVENTATIVE MAINTENANCE OF THE

FLOWMETER (BALL BEARING DESIGN)

Preventative maintenance requires that the Mini Flowmeter under go a

general inspection. Refer to Figure 4-I and the following procedure to

remove the flowmeter internals from the housing. A clean work area is

required.

15

FTBBOO

Page 19

CORRECT

ORIENTATION

ROTOR

OF

WHEN LOOKING

DOWN FROM TOP

FLOW-8

WELO-

Figure 4-1.

FL OW -

DETAIL OF ROTOR

Standard Ball Bearing Cutaway Diagram

16

Page 20

FTB500

The

1.

Flow m eter m ust be held in place by a vise. Me ter orien-

tation should be such that the threaded plug is facing upwards.

Using a screwdriver and turning counter clockwise, break the seal and

2.

re move the plug.

Using tweezers or needle nose pliers, slowly pull the insert out, while

3.

taking care not to da m age the shaft or lose the thrust stop.

4.

Remove the rotor by using a pair of tweezers.

5.

Remove the shaft asse m bly with s m ooth needle nose pliers. Care

should be taken in not defor m ing the shaft and loss of any parts.

Exa m ine the flo wme ter internals for signs of corrosion or fouling by

6.

foreign m aterials.

7.

Exa m ine the shaft and bearings for signs of wear or corrosion on the

m ating surface.

If wear or corrosion is present in bearings, obtain new bearings fro m

8.

stock of the m anufacturer.

9.

Insert ball bearings in rotor.

10.

Gu ide the rotor bearing asse m bly onto the shaft. Make sure to orient

the rotor so the cup side of the

pelton

whee l faces the IN side of the

housing. Refer to Figure 4-1 detail.

NOTE

IF THE ROTOR IS INSTALLED BACKWARDS , THE METER W ILL

NOT G IVE YOU THE ACCURACY YOU REQU IRE . REFER TO THE

DETA IL CLOSELY.

Il.

Install a new Viton “0” ring

#77-545-018 or equivalent on the insert.

NOTE

“0” ring should be lightly lubricated with “0” ring lubrication

wh ich is silicone based.

12.

P lace insert on the shaft. W hen properly seated gently push the

insert back on the shaft.

13.

Install and tighten the threaded plug. Tighten plug until snug. Do

not over tighten.

The flow m eter is ready for service W hen installing the flow m eter be sure

to orient the input and output correctly.

17

Page 21

TO PICKUP

COIL

PCA-112

11

COIL-1

11-1

PCA-115

ANALOG

OUPUT

COMMON

PULSE

OUTPUT

COMMON

FiTESTi

ACIDC

POWER

SUPPLY

ANALOG

OUTPUT

-

@.

@

0

I

BLK

WHT

GRN

Figure 5-1.

I-II-

Wiring

Internal

FTBSOO

SIGNAL

CONDITIONER

Page 22

TROUBLESHOOTING GUIDE

In case of an inoperable or malfunctioning system the following procedures

can be used to isolate the faulty wiring, printed circuit boards and/or alter-

nate causes. The majority of repairs can be made in the field thereby reduc-

ing the time a unit is out of service

A recommended spare parts list is given in Section 6. The necessary

documentation is contained within this manual with the exception of the

calibration data sheet for the turbine flowmeter. This calibration is supplied

separately.

To test the

Refer to Section 3.2, Calibration Procedure Failure conditions are listed and

the possible corrective actions are given to eliminate the observed problems.

FTB500,

(Cont ’d)

an internal 120 Hz test frequency has been provided.

TROUBLESHOUTING

OBSERVED CONDITION

Unit repeatedly blows fuses.

Unit gives no pulse output

with flow present.

Unit gives pulse output with

no flow present

GU IDE

CORRECTIVE ACTION

1.

Inspect terminal strip wiring for conformi-

ty to the installation instructions and for

acceptable workmanship

2. Verify correct fuse size.

3.

Replace PCA-112.

4. Replace PCA-115.

5. Replace PCA-114.

If unit continues to blow fuses it is

advisable to return it to the factory.

This defect is difficult to diagnose in

an assembled system.

1. Turn sensitivity

clockwise

2. Replace pickup coil and/or interconnec-

ting wiring.

3. Replace PCA-114.

4. Replace PCA-115.

5. Replace PCA-112.

1. Noise pickup, turn sensitivity adjust

counter clockwise until correct zero flow

indication is obtained.

2. Replace pickup coil.

3. Replace PCA-115.

4. Replace PCA-114.

NOTE

(SENS)

potentiometer

19

Page 23

TROUBLESHOOTING GUIDE

(Cont ’dl

OBSERVED CONDITION

Unit does not function

Analog output.

Analog output with no flow.

SECTION 6

PART NUMBER

PCA-112

PCA-II4

RECOMMENDED SPARE PARTS LIST

DESCRIRTION

POWER SUPPLY/ANALOG OUTPUT CARD

SIGNAL CONDITIONER CARD

(MAGNETIC PICKUP COIL)

PCA-115

LINEARIZE AND FLOW DRIVE,

PLUG-IN CARD

‘/4

SLO BLO

FUSES, POWER SUPPLY

CORRECTIVE ACTION

I. PCA-115 has incorrect offset frequency

setting.

2. Replace PCA-115.

3. Flowmeter used below or above normal

range. Obtain correct flowmeter.

1. Replace PCA-112.

(SENS)

1. Turn sensitivity

potentiometer

slowly ccw.

Fully CCW will make the unit inoper-

ative.

2. Replace PCA-112.

NOTE

QTY

1

I

I

1 BOX

SECTION 7 ACCESSORIES

DESCRIPTION

n

MNPT adaptor kit with

%

w

MS flare to

%

10” upstream and 5” downstream straight

SS tubing

PART NUMBER

FTB500-ADP

20

Page 24

SECTION 8 SPECIFICATIONS

INPUT POWER OPTION:

INPUT

METHOD:

OFFSET FREQUENCY:

THERMAL STABILITY:

LOW FLOW ADJUSTMENT

LOW FLOW INDICATION:

ACCURACY:

REPEATABILITY:

MAX. PRESSURE DROP AT

MAX. PRESSURE:

FREQUENCY OUTPUT AT FULL

bP

FLOW

SECTION 1.2):

ANALOG OUTPUTS

OPTION, REFER TO

CURRENT OUTPUT (STANDARD):

ACCURACY:

RANGE:

RESPONSE TIME:

VOLTAGE OUTPUT (OPTIONAL):

ACCURACY:

RANGE:

IMPEDANCE:

RESPONSE TIME:

I

ICSTK:

SCALE-

mA

15 to 35 VDC at 75

115VAC,

50/60 Hz (optional)

(standard)

Input protected, RF and band pass

filtered, adjustable trigger level.

Input impedance-4OkQ

Trigger sensitivity-IOmV,,,(minimum)

10 Hz to 1000 Hz

Over

voltage-120V,,,

absolute

(maximum)

Frequency injection of offset frequency

with post scaling and low flow alarm

7 to 150 Hz

200 parts per

million/°C

20 to 200 Hz (based on comparison with

input flowmeter frequency)

None

+

1% of reading for pulse

*0.25%

of reading

PSID

IO

PSIG

PSIG

standard

optional

1000

5000

125 Hz nominal

+0.05%

+200

of full scale,

PPM/OC.

4 to 20mA into 375X max.

0.5 seconds for

IO-go%.

Adjustable from 0.5 to 2 seconds.

Output suitable for driving grounded or

floating load types

PPM/OC.

*200

*0.05%

of full scale;

o-5v.

<IO9

0.5 seconds for IO-90%

21

Page 25

SPECIFICATIONS (Cont ’d)

PULSE OUTPUTS (OPTIONAL):

ENVIRONMENTAL

OPERATING AMBIENT TEMPERATURE:

FLUID TEMPERATURE RANGE:

STORAGE TEMPERATURE:

MATERIALS OF CONSTRUCTION

HOUSING:

BALL BEARINGS:

ROTOR:

SEALS:

CONNECTIONS:

CONTROLS AND ADJUSTMENTS

FUSE:

SENS:

OFFSET FREQUENCY:

LOW FLOW ADJUST:

RANGE:

ZERO:

STANDARD OPTION

-TTUCMOS

fanout

of IO TTL/CMOS loads. AC capacitively

coupled square wave.

OPTIONAL-Open collector -adjustable

V,,,

transistor

2N6660. Maximum OFF

state voltage 60 VDC. Maximum ON cur-

I.OA.

rent

to

176OF

+450°F

to

150°C

-4O

-450°

-65” to

316 Stainless Steel

44oc

17-4 PH

Viton

37O

flare per MS-33656-8

n %

II

MNPT adaptor kit optional

%

A circuit protection device located inter-

nally. Check main schematic for proper

size and type.

A single control used to set the threshold

sensitivity level above the ambient noise

pickup.

An internal 20 turn adjustment on the

PCA-II5 printed circuit card used to ad-

just the equivalent offset frequency of the

FTB500, 7 to 150 Hz.

An internal adjustment on the PCA-115

printed circuit card which is factory set to

turn off the offset frequency oscillator at

no flow.

A dual-in-line (DIP) switch located on a

PCA-112 board which is used to program

the module to accept an input frequency

range.

A multiple turn adjustment potentiometer

which is used to set the current/voltage

output signal with no flow to the desired

mA).mA

“zero” value (i.e., 4

or 100

Page 26

SPECIFICATIONS (Cont ’d)

SPAN:

RESPONSE:

SCALING FACTOR:

A multiple turn adjustment potentiometer

which is used to set the current/voltage

output signal to the desired span cor-

mA

responding to

(i.e., 4 to 20

responding to

equivalent flow range

1OV

mA

or 0 to

cor-

O-100GPM).

A multiple turn adjustment potentiometer

which is used to dampen the response at

the analog output.

A dual-in-line (DIP) switch located on the

PCA-112 board which is used to select the

desired pulse output scaling factor.

23

Page 27

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to give

satisfactory service for a period of

adds an additional one

warranty to cover handling and shipping time. This ensures that

receive maximum coverage on each product. If the unit should malfunction, it must be

returned to the factory for evaluation.

an Authorized Return (AR) number immediately upon phone or written request Upon

examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at

no charge. However, this WARRANTY is VOID if the unit shows evidence of having been

tampered with or shows evidence of being damaged as a result of excessive corrosion; or

current, heat, moisture or vibration; improper specification; misapplication; misuse or

other operating conditions outside of OMEGA ’s control. Components which wear or which

are damaged by misuse are not warranted. These include contact points, fuses, and

13

(1)

month grace period to the normal

months from date of purchase. OMEGA Warranty

OMEGA’s

@zz

(11

year

one

OMEGA ’s

Customer Service Department will

product

customers

issue

triacs.

OMEGA is glad to offer suggestions on the use of its various products.

Nevertheless, OMEGA only warrants that the parts manufactured by it will be as

specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

FlTNESS

AND

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence, indemnification, strict liability or

otherwise, shall not exceed the purchase price of the component upon which

liability is based. In no event shall OMEGA be liable for consequential, incidental

or special damages.

Every precaution for accuracy has been taken in the preparation of this manual; however,

OMEGA ENGINEERING, INC. neither assumes responsibility for any omissions or errors

that may appear nor assumes liability for any damages that result from the use of the

products in accordance with the information contained in the manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear installation or

activity, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or

damage whatsoever arising out of the use of the equipment in such a manner.

~~~?~~~~~,$~~~~~~~~~~~.~~~

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer

Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER

MUST OBTAIN AN AUTHORIZED RETURN

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any corre-

spondence.

FOR

the following information available

BEFORE contacting OMEGA:

1. P.O. number under which the product

was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific 2. Model and serial number of product, and

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improve-

ment is possible. This affords our customers rhe latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

0

Copyright 1995 OMEGA ENGINEERING, INC. All rights reserved. This documentation

may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without prior written consent of

OMEGA ENGINEERING, INC.

FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

lNQUlR[ES

/

RETURN

REQUESTS

WARRANTY RETURNS, please have

(AR)

NUMBER FROM OMEGA ’S CUSTOMER

FOR NON-WARRANN REPAIRS OR

BRATIDN, consult OMEGA for current

repair/calibration charges. Have the following

information available BEFORE contacting

OMEGA:

1. P.O. number to cover the COST of the

repair/ calibration,

3. Repair instructions and/or specific

problems relative to the product.

~$%~~~y~~~~~%

CALI_

Page 28

I

I

Find Everything Where Do

Need for

Process Measurement and Control?

OMEGA...Of Course!

TEMPERATURE

&

&

m

Thermocouple, RTD

m

Wire: Thermocouple, RTD & Thermistor

@’

Calibrators

m

Recorders, Controllers

B

Infrared Pyrometers

&

Ice Point References

Thermistor Probes, Connectors, Panels

&

Process Monitors

Assemblies

PRESSURE/STRAIN FORCE

&

b8

Transducers

B

Load Cells

m

Displacement Transducers

k?

Instrumentation

FLOW

@

Rotameters, Gas Mass Flowmeters

@’

Air Velocity Indicators

Turbine/Paddlewheel

@’

@’ Totalizers

Strain Gages

&

Pressure Gauges

/

LEVEL

&

Batch Controllers

&

Accessories

Systems

&

Flow

Computers

H/CONDUCTIVITY

&

pH

Electrodes, Testers

g

m

Benchtop/Laboratory Meters

m

Controllers, Calibrators, Simulators

m

Industrial

&

Conductivity Equipment

pH

Accessories

&

Pumps

DATA ACQUISITION

m

Data

m

i$?

ij?

m

Acquisition and Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM

Datalogging Systems

Recorders, Printers

&

Plotters

Bs

Compatibles

HEATERS

bd’

Heating Cable

k?

Cartridge

m

Immersion

k?

Flexible Heaters

m

Laboratory Heaters

&

Strip Heaters

&

Band Heaters

ENV IRONMENTAL MON ITORING AND CONTROL

&

D

Metering

b?

Refractometers

iZ!’

Pumps

m

Air, Soil &Water Monitors

m

Industrial Water

pH,

Control Instrumentation

&

Tubing

Conductivity k!’

&

Wastewater Treatment

&

Dissolved Oxygen Instruments

MO968

/0992

Loading...

Loading...