Page 1

FTB500 Series

Low Flowrate Meters

Page 2

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

CONTENTS

1. Introduction ....................................................................................2

2. Operation........................................................................................ 3

2.1 Principle.................................................................................3

2.2 Precautions.............................................................................3

3. Installation...................................................................................... 4

3.1 General Piping .......................................................................4

3.2 Strainers/Filters......................................................................5

3.3 Installation Kits......................................................................5

4. Maintenance ...................................................................................6

4.1 General...................................................................................6

4.2 Disassembly...........................................................................6

4.3 Inspection & Repair...............................................................6

4.4 Assembly ...............................................................................8

4.5 Pickup Coil Testing ...............................................................8

4.6 Trouble Shooting .................................................................10

4.7 Spare Parts...........................................................................11

- 1 -

Page 4

1 Introduction

We are proud that you have selected an Omega Low Flowrate

Meter, the finest precision flow transducer on the market.

The Omega FTB500 Series of Low Flowrate Meters are designed

to meet the need for a high quality low flow measurement device

for service in low to moderate viscosity clean liquids and for gas

applications.

The information in this manual is provided to assist in the proper

installation, use, and maintenance of your instrument.

Please take a few minutes to read through this manual before

installing and operating your meter. If you have any problems

with the meter, refer to the maintenance and troubleshooting

sections of this manual.

If you need further assistance, contact your local Omega

Representative or contact the Omega customer service department

by telephone, fax, or email for advice.

- 2 -

Page 5

2 Operation

2.1 Principle

The Omega FTB500 Series of Low Flowrate Meters has been

developed to meet the need for a low flow measurement device

for use with low to moderate viscosity clean liquids and for gas

measurement applications.

The Omega FTB500 Series of Low Flowrate Meters is a family of

low flow rate measurement devices whose design is based on a

Pelton Wheel-like rotor. The measured fluid is directed

tangentially through a velocity nozzle against the rotor causing it

to spin. The pickup coil senses the spinning motion of the rotor

through the housing and converts it into a pulsing electrical

signal. Summation of the pulsing electrical signal relates directly

to the total flow, while the frequency is related to the flow rate.

2.2 Precautions

Do not drop the meter. Dropping the meter may result in

damage to the meter housing and/or internals.

Do not operate the meter at flowrates greater than the

maximum flowrate marked on the meter. Operating at

flowrates greater than the maximum flowrate may overspin the meter. Over-spinning may result in damage to

the meter.

CAUTION: Avoid over-spinning the meter. Over-spinning the meter may

result in damage to the meter internals and lead to meter

failure.

- 3 -

Page 6

3 Installation

Upon receipt of the flowmeter carefully inspected it, checking for

any indications of damage which may have occurred during

shipment. Inspect all packing material carefully for parts or

components which may have been packed with the shipment.

Refer to the packing list/invoice for a detailed list of items

included in the shipment.

3.1 General Piping

The Omega FTB500 Series of Low Flowrate Meters is capable of

sensing fluid flow in one direction only. The meter housing is

marked by a flow direction arrow to indicate the direction of flow

through the meter. The meter must be installed in the piping in th e

correct orientation to ensure the most accurate and reliable

operation. Care should be taken in the proper selection of the

mating fittings. Size, type of material, and pressure rating should

be the same as the flowmeter supplied.

When it is expected that flow will be intermittent, the meter should

not be mounted at a low point in the piping system. Solids which

settle or congeal in the meter may affect meter performance.

In order to achieve optimum electrical signal output from the

flowmeter, due consideration must be given to its isolation from

ambient electrical interference such as nearby motors, transformers, and solenoids.

A typical flowmeter installation is shown below:

Blocking Valve

Strainer

BYPASS RUN

Bypass Valve

Turbine Flowmeter

Blocking Valve

METER RUN

Blocking and Bypass valves should be installed if it is necessary to

do preventive maintenance on the flowmeter without shutting

down the flow system. The Bypass valve can be opened before the

Blocking valves are closed allowing the flow to continue while

removing the turbine flowmeter for service.

- 4 -

Page 7

IMPORTANT

: All flow lines should be purged prior to installing the

meter. To prevent possible damage to the meter, install the

meter ONLY in flow lines that are clean and free of debris.

Upon initial start-up of the system a spool piece should be installed

in place of the flowmeter so that purging of the system can be

performed to remove all particle debris which could cause damage

to the meter internals. In applications where meter flushing is

required after meter service, care should be taken as to not overspin the meter, as severe meter damage may occur.

CAUTION: Avoid over-spinning the meter. Over-spinning the meter may

result in damage to the meter internals and lead to meter

failure.

3.2 Strainers/Filters

The Omega FTB500 Series of Low Flowrate Meters is designed

for use in a clean fluid service. However, the service fluid may

carry some particulate material which would need to be removed

before reaching the flowmeter. Under these conditions a

strainer/filter may be required to reduce the potential hazard of

fouling or damage that may be caused by foreign matter.

METER SIZE MESH SIZE PARTICLE SIZE

(Maximum)

¼" to ½"

5

/8" to 1¼"

100 .0055

70 .008

1½" to 3"

40 .015

If a strainer/filter is required in the system, it should be located

upstream of the flowmeter taking care that the proper minimum

distance is kept between the strainer and flowmeter.

3.3 Installation Kits

Installation kits for the Omega FTB500 Series of Low Flowrate

Meters consist of two lengths of appropriate tubing cut to a length

appropriate for the upstream and downstream straight pipe run

with appropriate end fittings.

- 5 -

Page 8

4 Maintenance

4.1 General

Preventive maintenance for the Omega FTB500 Series of Low

Flowrate Meters consists of a thorough general inspection.

Remove the meter from the service line and take to a clean work

area. Use the following procedures and exploded component

views to remove, inspect, and reinsert the flowmeter internals.

4.2 Disassembly

1. Hold the meter securely using a vise. Meter orientation

should be such that the threaded plug is facing up. Use

extreme care not to damage the meter housing or piping

connections when placing in the vise.

2. Using a large-blade screwdriver, turn the plug

counterclockwise to remove.

3. To remove the shaft assembly, carefully thread a 10-32

screw into the hole provided in insert. Thread the screw

into the insert until it bottoms out (finger tight only).

4. Turn the housing over and slowly and carefully pu ll the

shaft assembly and internals out of the housing. Take

care not to damage the shaft, rotor, and/or bearings.

5. Remove and discard the gasket/seal.

4.3 Inspection & Repair

1. Examine the flowmeter internals for signs of corrosion

or fouling by foreign materi als.

2. Examine the shaft, rotor, and bearings for signs of wear

and/or damage.

3. If wear or damage is present, replace with new parts.

NOTE: Clean all of the internals in an approved cleaning

solution.

- 6 -

Page 9

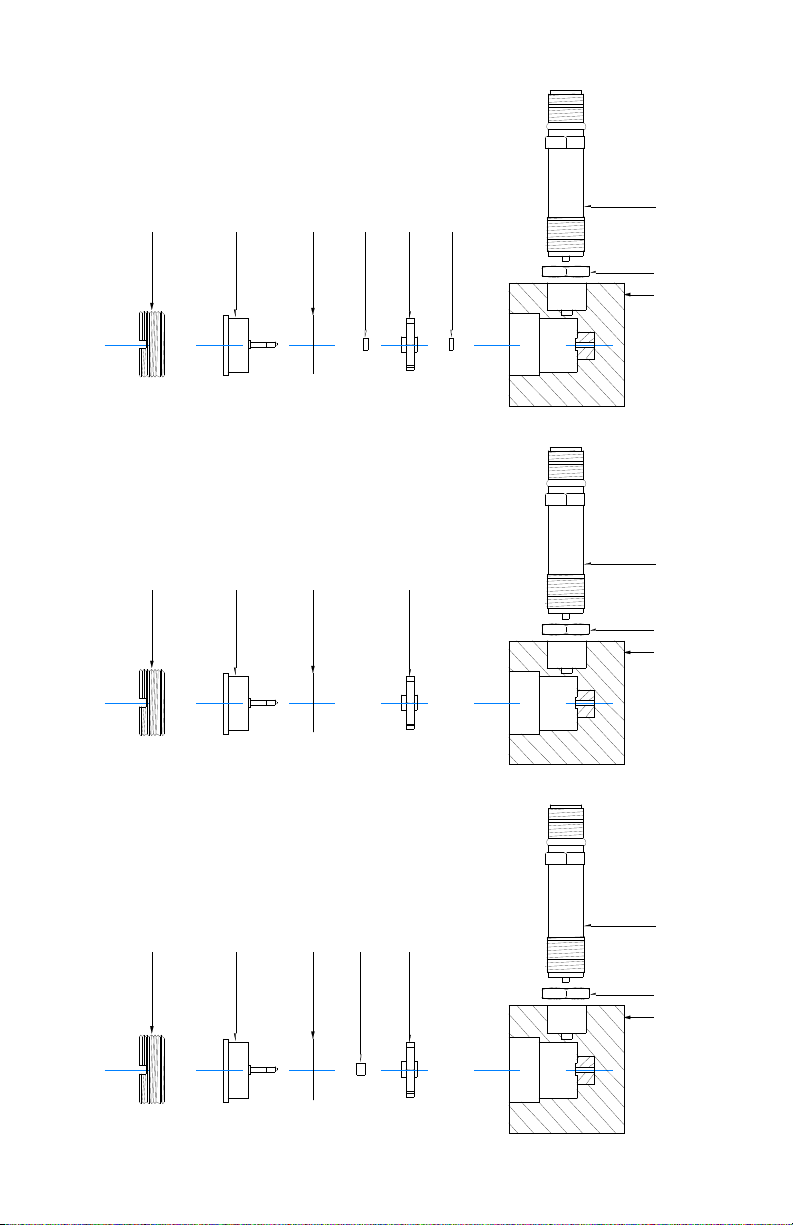

Exploded View:

BB - Ball Bearing Models

Exploded View:

C – Hard Carbon Bearing Models

Shaft AssemblyThreaded Plug Seal Ball Bearing Ball Bearing

Shaft AssemblyThreaded Plug Seal

Rotor

Rotor

Pickup Coil

Coil Locknut

Housing

Pickup Coil

Coil Locknut

Housing

Exploded View:

TC - Tungsten Carbide Sleeve Models

Shaft AssemblyThreaded Plug Seal

TC Journal

Rotor

- 7 -

Pickup Coil

Coil Locknut

Housing

Page 10

4.4 Assembly

1. Install any new parts.

2. Guide the rotor and bearing assembly onto the shaft.

Make sure the rotor is installed with the cup side of the

Pelton wheel facing the “IN” side of the housing.

3. Place a new gasket on the insert. Always use a new

gasket.

4. Place the shaft assembly insert, gasket, and rotor

assembly back into housing by inverting the housing to

keep gasket and rotor assembly in place.

5. Install the threaded plug and tighten to 50 ft-lb.

4.5 Pickup Coil Testing

Testing the MAG and MCP (RF) coils consists of measuring the

resistance with an ohmmeter. Resistance measurements are to be

made when there is no flow through the meter or with the coil

removed from the meter housing.

1. Measure the resistance between pin A and pin B. The

resistance should be approximately as listed in the

following table of some common coils.

2. The resistance from any pin to the case should be greater

than 1 Mohm.

COIL

MC2PAHT

MCP3A

PC13-74G

PC13-74S

PC24-45G

PC24-45S

PC28-13G

PC28-14G

DC RESISTANCE

(Ohms)

15.0 10%

11.5 10%

1800 10%

1850 15%

1350 10%

1850 15%

120 20%

180 20%

- 8 -

Page 11

If either resistance measurement fails, replace the pickup coil.

Firmly seat the new coil in the flowmeter and tighten the locking

nut.

- 9 -

Page 12

4.6 Trouble Shooting

Refer to the following troubleshooting guide for assistance with

possible meter malfunctions:

TROUBLE CAUSE REMEDY

Fluid will not flow Meter clogged. Clear meter.

through the meter Line to meter

blocked.

Reduced flow through

the meter

Line to meter

Meter readings

inaccurate

Meter drag due to

Meter not giving pulse Faulty pickup coil. Replace pickup coil.

signal Meter internals not

Meter partially

clogged.

partially blocked.

Fluid flowrate is

not within meter

flow range.

worn or damaged

parts.

turning due to

worn or damaged

parts.

Clear line to meter.

Clear meter.

Clear line to meter.

See “Specifications” for

min and max flowrates.

Replace worn or

damaged parts.

Replace worn or

damaged parts.

- 10 -

Page 13

4.7 Spare Parts

The following table contains the suggested spare parts for the

Omega FTB500 Series of Low Flowrate Meters:

Item No. Qty Part Description

1 1 Pickup Coil

1 1 Seal/Gasket

1 1 Rotor Assembly

1 1 Bearings

1 1 Shaft Assembly

Specific meter parts are dependent upon the meter size and model,

always have the complete meter model number or serial number

available when consulting the factory.

- 11 -

Page 14

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds

an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of theproduct, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 15

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

SM

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Data Logging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M-0968/1212

Loading...

Loading...