Page 1

http://www.omega.com

e-mail: info@omega.com

®

UserÕs Guide

DRX-ACC, DRX-ACV, DRX-FP,

DRX-PR, DRX-RTD, DRX-ST,

DRX-TC

Communication Manual for

DRX Signal Conditioner Series

Page 2

omega.com

OMEGAnet®On-Line Service Internet e-mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for

any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

This device is marked with the international hazard symbol. It is important to read the Setup Guide before

installing or commissioning this device as it contains important information relating to safety and EMC.

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: TEL: (001)800-TC-OMEGA

®

FAX: (001) 203-359-7807

En Español: (001) 203-359-7803 e-mail: info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800406342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 TC-OMEGA

®

e-mail: germany@omega.com

United Kingdom: One Omega Drive

ISO 9002 Certified River Bend Technology Centre

Northbank, Irlam

Manchester M44 5EX United Kingdom

TEL: +44 (0) 161 777 6611 FAX: +44 (0) 161 777 6622

Toll Free in the UK: 0800 488 488

e-mail: sales@omega.co.uk

OMEGA

®

®

Page 3

TABLE OF CONTENTS

I. WHA

T SIGNAL CONDITIONERS DO: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

II. MODEL OF UNIT : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

III. RS485 SERIAL COMMUNICATION SETUP: . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY CONSIDERATIONS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IV. COMMANDS FOR ACCESSING EEPROM: . . . . . . . . . . . . . . . . . . . . . . . . . . 6

V. DESCRIPTION OF DATA : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VI. COMMANDS FOR MEASUREMENT VALUES: . . . . . . . . . . . . . . . . . . . . . 16

VII. COMMANDS FOR READING MODEL/INPUT TYPE: . . . . . . . . . . . . . . . 16

VIII. RESET COMMANDS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

IX. SAMPLE PROGRAM: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SPECIFICATIONS

DRX-ACC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DRX-ACV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DRX-FP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DRX-PR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DRX-RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DRX-ST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DRX-TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ILLUSTRATIONS:

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Typical Computer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

i

Page 4

ii

NOTES

Page 5

I. WHAT SIGNAL CONDITIONERS DO:

The DRX Series Signal Conditioners are high performance devices used as a front end for PLC’s and

Data Acquisition systems to measure a variety of low level transducer signals with high precision and

accuracy. The DRX Series Signal Conditioners interface directly to transducers and digitize the input

signal. The measured signal is then transmitted to a PLC or a computer using the RS485 Serial

Communication. Up to 32 units may be connected to the same serial RS485 bus, and each unit may

be addressed to transmit the signal being measured under program control, executed on a PLC or a

computer. The key features of the DRX Series Signal Conditioners are the ease of set-up and factory

calibrated ranges. All range switching are done electronically by sending the appropriate command;

therefore, there is no need to remove or open the units when signal input levels are changed. All setup may be done by using the Set-up Software running on a computer or by user supplied programs.

II. MODEL OF UNIT :

There are 7 models available:

THERMOCOUPLE ( DRX-TC )

RTD ( DRX-RTD )

STRAIN ( DRX-ST )

PROCESS ( DRX-PR )

FREQUENCY/PULSE ( DRX-FP )

AC VOLT ( DRX-ACV )

AC CURRENT ( DRX-ACC )

III. RS485 SERIAL COMMUNICATION SETUP:

Communication with the UNIT will be performed via serial communication using RS485 standard

(half duplex). To use the RS485 communication for the Signal Conditioners you’ll need an available

Communication port in your computer and have access to a generic communication software program

(e.g.: Procomm

1

, Windows2HyperTerminal3, etc, see details below for information). A RS485 signal

conditioner communication software program is also available as an option to speed the set-up. A

RS232 to RS485 converter box will also be required if your computer communications port is RS232.

Page 1

1

Procomm is a registered trademark of Datastorm Technologies, Inc.

2

Windows is a registered trademark of Microsoft Corp.

3

HyperTerminal is a registered trademark of Microsoft Corp.

Page 6

For Procomm:

Start the Procomm Program.

Press ALT + P (Select the appropriate communication parameters: Baud Rate, Parity, Data

Bits, Stop Bits.) The default settings may require modifications.

- Factory Default communication settings are as follows:

Baud Rate = 9600

Parity = Odd

Data Bits = 7

Stop Bits = 1

Press ALT + S (To save current communication settings)

Press ALT + O (To go to chat mode)

If the communication port selected is available and the communication parameters of both

the computer and the DRX are matched, then a serial link may be established. To check the

communication any of the commands may be tried i.e. *01X01 would return the current

measured signal value.

For Hyper T

erminal (Windows 95):

Start the Hyper Terminal Program from programs/accessories.

Click on the Properties from the File menu.

Under the Phone Number Menu choose:

Connect using “Direct to COM1 or COM2” whichever that’s available.

Click on Configure Button.

Choose: Baud rate, Data bits, Parity and Stop bits

According to DRX’s settings.

Flow Control = None.

Click “OK” Button.

- Factory Default communication settings are as follows:

Baud Rate = 9600

Parity = Odd

Data Bits = 7

Stop Bits = 1

Under Settings Menu:

Click ASCII Setup Button.

Choose all options except “Force Incoming Data to 7 Bits ASCII”.

Click “OK” Button.

Page 2

Page 7

Communication Parameter Settings:

Communication settings information are very critical during set-up, if any of the parameters are

changed, it should be recorded on the label for future reference. If the communication parameters

used by the computer does not match the communication parameter of the DRX, then the

communication link may not be established. Hence it is important to record the communication

parameter on the label if different from default.

Resetting Communication Parameters to Factory Defaults

To restore the communication parameters to the factory default settings, two test points must be

shorted together. There are two ways of shorting these test points together, both are detailed below.

Version A-- Test point TP6 must be shorted, by a wire, to test point TP17.

or

Version B-- Newer units have a jumper position S1-A for connecting these two test points together.

Factory Default Settings for Communication:

Baud Rate = 9600

Data Bit = 7

Parity = Odd

Stop Bits = 1

Recognition Character = *

Address = 01

Page 3

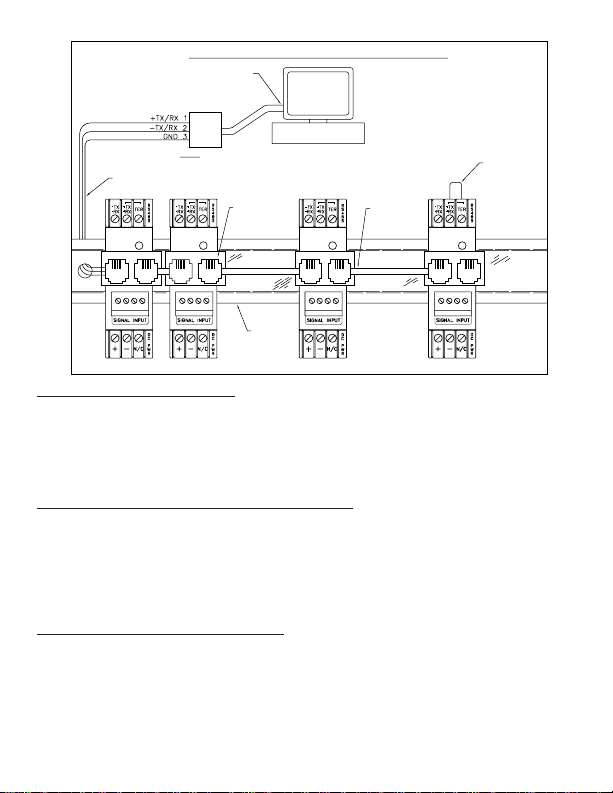

DRX -- SIGNAL CONDITIONERS WITH RS485

SERIAL COMMUNICATION PORT

COMPUTER

RS232 TO

RS485 CONVERTER

HALF—DUPLEX

NOTE: YOU CAN CONNECT A DRX

DIRECTLY TO THE COMPUTER IF YOU

HAVE A RS485 COMMUNICATION

CARD INSTALLED IN THE COMPUTER.

SYSTEM GND

OR SHIELD

FIRST UNIT ON BUS LAST UNIT ON BUS

TEE COUPLER

(JACKS SHOWN

FOR CLARITY)

SHIELDED WIRE

CONNECT LAST

UNIT WITH

JUMPER TO

INCLUDE 120Ω

ON THE BUS

DIN RAIL

Page 8

Page 4

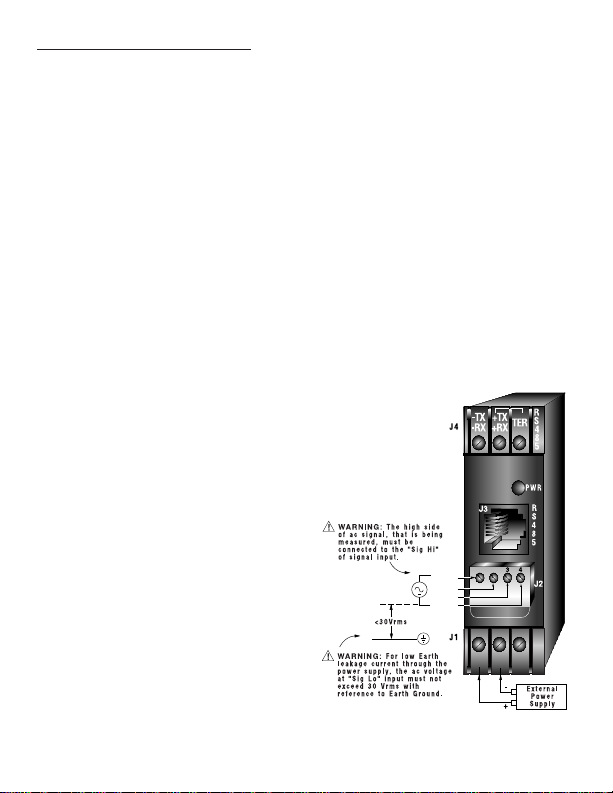

SAFETY CONSIDERATIONS

Unpacking & Inspection

Unpack the instrument and inspect for obvious shipping damage. Do not attempt to

operate the unit if damage is found.

For instruments with AC Voltage and AC Current inputs, observe the input signal

connections in the appropriate section of this manual. These instruments must only

be installed by professional electricians.

• Do not exceed voltage rating on the label located on the instrument housing.

• Always disconnect power before changing signal and power connections.

• Do not use this instrument on a work bench without its case for safety reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure instrument does

not exceed operating temperature rating.

• Use electrical wires with adequate size to handle mechanical strain and power

requirements. Install without exposing bare wire outside the connector to

minimize electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems

persist.

Failure to follow all instructions and warnings may result in injury!

This device is marked with the international Caution symbol. It is important to read

this manual before installing or commissioning this device as it contains important

information relating to Safety and EMC (Electromagnetic Compatibility).

Page 9

SAFETY NOTE: Disconnect all signal input and outputs before attempting this procedure.

Instructions

1) Open the Signal Conditioner Unit—Remove Side Covers from Unit by lifting at the “angled

corners” first, using a flat-head screwdriver. Continue detaching remaining edges of the Cover.

2) Short TP6 & TP17 together, either by wire or, if available, jumper S1-A.

3) After shorting TP6 to TP17, apply power to the unit.

4) The Front Panel Power Indicator (LED) will NOT

turn on.

5) After power has been applied to the unit for about 30 seconds, turn power off.

6) The communication parameters now have been restored to the default settings.

7) Use the DRX Set-up Program to establish communication with the meter.

8) This procedure will not affect calibration. It only resets the communication parameters.

Page 5

Solder wire from

TP6 to TP17 on

Solder side of Board.

Install Jumper onto

S1-A on Component

Side of Board.

Version A Version B

Testpoint/Jumper Locations

Lift Cover at Angled Corners.

Side Cover

Remove to

Access

Testpoints.

Front Panel

Side Cover

Remove to

Access S1-A

Jumper

Six Attachments Per Side

Lift Cover at Angled Corners.

Opening Unit

Page 10

IV. COMMANDS FOR ACCESSING EEPROM:

NO. command letter index meaning # of bytes

1. R,W 01 Input range or function 1

2. R,W 02 Input/output Configuration 1

3. R,W 03 Decimal point 1

4. R,W 04 Filter time constant 1

5. R,W 05 Reading scale 3

6. R,W 06 Reading offset 3

7. R,W 07 Communication parameters 1

8. R,W 08 Communication bus format 1

9. R,W 09 Communication Data format 1

10. R,W 0A Communication device address 1

11. R,W 0B Communication recog. char. 1

12. R,W 0C Unit of measure 3

13. R,W 0D Gate time 1

14. R,W 0E Debounce time 1

15. R,W 0F Transmit time 2

NOTE:

1. Data (Number of hex digits) = 2 * number of bytes

2. command letter

meaning

R Read from EEPROM

W Write to EEPROM

3. "W" commands should be followed by "Z01" command for new values to take ef

fect.

A. COMMAND FORMAT (TRANSMITTING):

*[nn]Cxx[data][hh]<cr>

Note:

Data is required if Command Letter is “W”

B. RESPONSE FORMA

T (RECEIVING):

A. Correct response :

1. If unit is in echo mode

* (see "BUS FORMAT") :

[nn]Cxx[data][hh]<cr>

*echo mode = unit will send back the command.

Page 6

Page 11

2. If unit is not in echo mode :

i. For the commands which require the data to be transmitted by the DRX Signal

Conditioner, data is sent in the following formats:

data[hh]<cr>

ii. For the commands which do not require the data:

NO RESPONSE

B. Error response:

1. If unit is in echo mode

:

[nn]?ee<cr>

2. If unit is not in echo mode

:

?ee<cr>

NOTE :

[ ] : Means will be used wherever applicable.

* : Is the security recognition character(default is “*”).

nn : Is the unit's address in hexadecimal(default is 01).

Address may be from 01 to FF.

C : Is the command letter ( must be capital ).

W : For writing to the EEPROM (requires data)

R : For reading from the EEPROM (doesn’t require data)

xx : Command index is a hexadecimal number from 01 to FF.

data : Is one, two, or three bytes (2,4,6 characters respectively). It will be in

hexadecimal format except when command "X" is executed in which case it

is in decimal format.

hh : Is checksum characters

( Required if Checksum option is on. See “BUS FORMAT”).

The checksum is one byte (two characters) that is the simple hexadecimal

addition of all the previous bytes, ignoring any overflow.

Page 7

Page 12

?ee : Special code indicating an error has occurred as:

?43 : Command error

( occurs if command letters and indexes are invalid)

?46 : Format error

( occurs if length of the data or number of characters is not correct )

?48 : Checksum error

( occurs if checksum is not correct )

?50 : Parity error

( occurs if parity is not correct )

<cr> : Carriage return

Note:

If Baud rate, Recognition character or address are not correct then the UNIT will not

respond.

V. DESCRIPTION OF DATA :

For the following Bit Pattern. The LSB is always bit 0. Bit numbers are always counted from

right to left, with the rightmost digit being bit 0, and the next to the left would be bit 1.

1. INPUT RANGE:

This is one byte data (2 characters). This byte will specify input range and other input

configurations of each model. Bit pattern for different models :

a. INPUT RANGE BYTE VALUE TC ACV ACC

Bits:3210

0000 J 400 mV ac 10 mA

0001 K 4 V ac 100 mA

0010 T 40 V ac 1 A

0011 E 400 V ac 5 A

0100 N ---- ---0101 DIN J ---- ----

0110 R ---- ----

0111 S ---- ---1000 B ---- ----

(1001-1111 not used )

Bit 6-4: not used

Bit 7: 0 Line frequency = 60Hz

1 Line frequency = 50Hz

Page 8

Page 13

b. INPUT RANGE BIT NO. VALUE RTD

Bits:

1-0 00 100 ohms

01 500 ohms

10 1000 ohms

11 10 ohms COPPER

2 0 PLATINUM

1 NICKEL

3 0 DIN STANDARD

1 NIST FOR Pt (SAMA FOR Ni)

5-4 00 2 wire

01 3 wire

10 4 wire

11 not used

6 not used

7 0 Line frequency = 60Hz

1 Line frequency = 50Hz

c. INPUT RANGE BIT NO. VALUE PROCESS (PR) STRAIN (ST)

3-0 0000 0-20 mA 30 mV

0001 400 mV 100 mV

0010 1 V --0011 2 V --0100 5 V --0101 10 V ---

(011 0 - 1111 no t used)

4 0 14V Excit. Internal excit.

1 10V Excit. External excit.

5 0 Non-ratiometric (PR,ST)

1 Ratiometric (PR,ST)

6 not used

7 0 Line frequency = 60Hz(PR,ST)

1 Line frequency = 50Hz(PR,ST)

Page 9

Page 14

d. INPUT RANGE BIT NO. VALUE FREQUENCY/PULSE (FP)

0 0 ----

1 Low input level

1 0 ----

1 Debounce contact

2 0 ----

1 3K pull up to 5V

3 0 ----

1 1K pull down

5-4 00 12.5V excit.

01 5V excit.

10 8V excit.

11 not used

7-6 not used

2. INPUT/OUTPUT CONFIGURA

TION:

This is one byte data (2 characters).

Bit pattern is:

BIT NO. VALUE MEANING

TC/RTD ACV/ACC/ST PR FP

1-0 00 Degree C ---- ----

01 Degree F ---- Freq. mode

10 Degree K ---- Totalizer ---11 Degree K ---- Totalizer Freq. mode

2 0 Temp. compensation ---- See Note 1 ----

1 No temp compensation---- See Note 1 Quadrature

3 0 ---- ---- See Note 1 ----

1 ---- ---- See Note 1 A-B mode

4 0 ---- ---- ---- ----

1 ---- ---- ---- Totalize mode

5 0 ---- ---- ---- ----

1 ---- ---- Square root ----

7-6 not used set to 0

Page 10

Page 15

Note 1: Bit 2&3 set the speed of process totalize. The time it would take process totalize to

reach the non-totalize reading is shown in the following table:

Bit 3

Bit 2 Time to reach regular reading

0 0 1 minute

0 1 1 hour

1 0 1 day

1 1 30 day

3. DECIMAL

POINT :

This is one byte (2 characters) as:

value

meaning

1 XXXXXX.

2 XXXXX.X

3 XXXX.XX

4 XXX.XXX

5 XX.XXXX

6 X.XXXXX

Note 1:

For TC and RTD models, value must be 1 to 3 only.

4. FIL

TER TIME CONSTANT:

This is one byte (2 characters) as:

value

meaning (per no. of readings)

0 No filtering

12

24

38

416

532

664

7 128

Page 11

Page 16

5. READING SCALE:

Multiplication factor applied to input to get a higher or lower reading.

This is 3 byte data (6 characters) as follows:

- Bits 0 to 18 (19 bits) are value of the scale from 0 to 500000

- Bit 19 is sign, 0 for positive and 1 for negative

- Bits 20 to 23 are for decimal point value = DP

It means as:

Actual decimal value = 10 ** ( 1 - DP )

where ** means "TO THE POWER OF"

example: if scale is -0.000345678.= - 345678 x 10**(-9)

value will be 345678 decimal = 5464E hex

bit 19 =1 for negative

bits 20-23 = DP = 10 = A hex

then data will be AD464E hex

6. READING OFFSET

:

Deviation applied to input to get a higher or lower reading.

This is 3 byte data (6 characters) as follows:

- Bits 0 to 19 are value from 0 to 1000000

- Bit 23 is sign, 0 for positive, 1 for negative

- Bits 20,21,22 are decimal point value = DP

It means as :

Actual decimal value = 10 ** ( 2 - DP )

where ** means "TO THE POWER OF"

example: offset value is 234.089

value of 234089 decimal = 39269 hex

decimal value = 10 ** (-3) then DP=5

then 234.089 decimal = 539269 hex

7. COMMUNICA

TION PARAMETERS:

This is one byte data and specifies

BAUD, PARITY, DATA, and STOP bit.

BAUD = bits 2,1,0 are:

000-001 not used

010 for 1200

011 for 2400

100 for 4800

101 for 9600

110 for 19200

111 not used

Page 12

Page 17

PARITY = bits 4,3 and are:

00 for NO

01 for ODD

10 for EVEN

11 not used

DATA BIT = bit 5 and is:

0 for 7 data

1 for 8 data

STOP BIT = bit 6 and is:

0 for 1 stop

1 for 2 stop

Bit 7 : always 0

Note 1:

Stop bit is always 1. Unless 7 data, no parity is selected then unit will use 2 stop bits.

Note 2:

When 8 Data bit is selected, only NO PARITY is allowed.

8. BUS FORMA

T:

This is one byte data as:

Bit 0 = 0/1 means checksum not included/included

Bit 1 not used

Bit 2 = 0/1 means no echo/echo

Bit 3 = 1 means 485 mode

Bit 4 = 0/1 means continuous/command mode

Bits 7-5 not used

For models (PR/ST/FP):

Bit 7 = 0/1 Enable/Disable peak and valley comparison

NOTE 1 :

ECHO mode means the unit will echo back the command letter and index.

NOTE 2 :

Do not use checksum option unless you have to use it.

Page 13

Page 18

9. DATA FORMAT:

This is one byte and specifies the data which will be transmitted against the

"V01" command.

Bit pattern:

bit 0 = 0/1 Means do not include/include peak & valley status register.

bit 1 = 0/1 Means do not include/include reading.

For models(TC/R

TD/ACV/ACC):

bit 2 = 0/1 Means do not include/include peak reading.

For models(PR/ST):

bit 2 = 0/1 Means do not include/include process totalize.

For models(TC/R

TD/ACV/ACC):

bit 3 = 0/1 Means do not include/include valley reading.

For models(PR/ST/FP):

bit 3 = 0/1 Means do not include/include peak reading.

For models(TC/R

TD/ACV/ACC):

bits 4 Not used. Set to 0.

For models(PR/ST/FP):

bits 4 = 0/1 Means do not include/include valley reading.

bit 5 Not used. Set to 0.

bit 6 = 0/1 Means do not include/include unit of measure.

bit 7 = 0/1 Means space/carriage return between values.

10. DEVICE ADDRESS :

This is one byte data and specifies the address of the unit when in RS485 multipoint mode.

Addresses are in hexadecimal from 01 to FF.

NOTE:

Address 00 is for broadcasting. All units on the same BUS will perform any

command with this address but will not respond.

11. RECOGNITION CHARACTER:

This is one byte security character.

(Default is *)

Page 14

Page 19

12. UNIT OF MEASURE:

This is 3 bytes. It is ASCII value of unit of measure.

13. GA

TE TIME(For FP model only):

This is 1 byte from 00 to FF.

For value = 00 to F

A:

Each count equals 10ms. If 0 then gate time = 3ms.

Example : 1 second gate time = 64 hex.

For value = FB to FF:

Value Gate time

FB 5 seconds

FC 10 seconds

FD 20 seconds

FE 40 seconds

FF 80 seconds

14. DEBOUNCE TIME(For FP model only):

This is 1 byte from 01 to FF.

Each count equals 5ms. If 0 then error.

15. TRANSMIT TIME:

This is 2 bytes data in second and specifies the time of the transmission by the meter.

Page 15

Page 20

VI. COMMANDS FOR MEASUREMENT VALUES:

Command Receiving value

*01X01 (For all models): Reading value. After reading scale and offset.

Note:

In order to have continuous update on reading. Customer

should send X01 command every time reading is requested.

Models(TC/R

TD/ACV/ACC):

*01X02 Peak reading value.

*01X03 Valley reading.

Models(PR/ST/FP):

*01X03 Peak reading value.

*01X04 Valley reading.

*01V01 (For all models): String of values.

Received values are in decimal with decimal point and no sign for positive and minus sign

for negative.

Example : 00345.6 or -00345.6

If value is overflowed a “?” will be transmitted along with value (?-99999. or ?999999).

VII. COMMANDS FOR READING MODEL/INPUT TYPE:

Command Receiving value

*01U01 One byte for model number

V

ALUE MODEL

00 FP

01 PR

02 ST

03 TC

04 RTD

05 ACV

06 ACC

Page 16

Page 21

VIII. RESET COMMANDS :

*01Z01 (For all models): Hard reset (reading data from EEPROM).

*01Z02 (For all models): Soft reset (Initialize reading).

*01Z03 (For models: TC/RTD/ACV/ACC): Reset peak and valley.

(For models: PR/ST): Reset process totalize value.

*01Z04 (For models: (PR/ST/FP): Reset peak value.

*01Z05 (For models: PR/ST/FP): Reset valley value.

*01Z07 (For models: TC/RTD/ACV/ACC): Reset peak only.

*01Z08 (For models: TC/RTD/ACV/ACC): Reset valley only.

NOTE:

* : Recognition character

01(Follow “*”) : Address

IX. SAMPLE PROGRAM:

' ASSUMING :

' BAUD RATE = 9600

' PARITY = ODD

' DATA BIT = 7

' STOP BIT = 1

' COMM PORT = 1

' ADDRESS = 01

' RECOG. CHAR = *

' SERIAL PORT = COM1

' FOR COMM PORT = 2 -> CHANGE "COM1:" TO "COM2:"

' THIS PROGRAM WILL GET READING AND DISPLAY IT EVERY 1 SECOND

ON ERROR GOTO ER

ON TIMER(1) GOSUB RDG

CLS

CLOSE #1

COLOR 1, 7

LOCATE 22, 30

PRINT "PRESS <ESC> TO END"

OPEN "COM1:" + "9600,O,7,1,CS,DS" FOR RANDOM AS #1

LOCATE 10, 30

PRINT "READING = "

TIMER ON

DO: LOOP UNTIL INKEY$ = CHR$(27)

Page 17

Page 22

COLOR 7, 0

CLS

END

RDG:

PRINT #1, "*01X01"

DAT1$ = ""

DAT$ = ""

T$ = TIME$

T1$ = MID$(T$, LEN(T$) - 1, 2)

T1 = VAL(T1$)

DO

IF LOC(1) > 0 THEN

CNT = 0

DAT1$ = INPUT$(LOC(1), #1)

DAT$ = DAT$ + DAT1$

ELSE

T$ = TIME$

T2$ = MID$(T$, LEN(T$) - 1, 2)

T2 = VAL(T2$)

IF T2 < T1 THEN T2 = T2 + 60

IF T2 - T1 >= 2 THEN CNT = 1

END IF

LOOP UNTIL CNT = 1 OR INSTR(1, DAT$, CHR$(13)) > 0

IF DAT$ = "" THEN

LOCATE 5, 30

COLOR 28

PRINT "COMMUNICATION ERROR!"

P = 1

ELSE

IF P = 1 THEN

LOCATE 15, 30

COLOR 7, 0

PRINT " " ' (24 SPACES)

P = 0

END IF

LOCATE 10, 40

D$ = MID$(DAT$, 6)

DAT$ = LEFT$(D$, LEN(D$) - 1)

COLOR 1, 7

PRINT DAT$; " " ' (2 SPACES)

END IF

RETURN

ER:

RESUME NEXT

Page 18

Page 23

Page 19

DRX-ACC SPECIFICATIONS

INPUT RANGES:

10 mA, 100 mA, 1 Amp, 5 Amp AC current

Dedicated input terminals for (10, 100 mA same

input), 1 Amp and 5 Amp. Return terminal common

to all ranges.

FREQUENCY RANGE:

30 Hz to 1KHz

INPUT IMPEDANCE:

3.3 Ohms for 10, 100 mA input

0.2 Ohms for 1 Amp input

0.04 Ohms for 5 Amp input

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-CURRENT PROTECTION:

10% Above full scale continuously

100% Above full scale for 10 seconds

ANALOG TO DIGITALTECHNIQUE:

Dual slope

READ RATE:

3 readings/second

ACCURACYAT25 °C:

± 0.2% of FS from 30 Hz to 1 KHz

TEMPERATURE STABILITY:

10, 100 mA Range 100 ppm/°C typical

1 Amp Range 150 ppm/°C typical

5 Amp Range 200 ppm/°C typical

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the

<CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

2.4 Watts (100 mA at 24 V DC)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

RETURN

5A

1A

100mA

+

-

N/C

SIGNAL INPUT

D

C

P

W

R

1 2

{

Page 24

Page 20

DRX-ACV SPECIFICATIONS

INPUT RANGES:

400 mV, 4V, 40 Volt, 400 Volt

FREQUENCY RANGE:

30 Hz to 1 KHz

INPUT IMPEDANCE:

2.1 Meg for all ranges.

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-VOLTAGE PROTECTION:

10% Above full scale continuously.

100% Above full scale for 10 seconds.

ANALOG TO DIGITALTECHNIQUE:

Dual slope

READ RATE:

3 readings/second

ACCURACYAT25 °C:

400 mV, 4V, 40V and 400V ranges

49 Hz to 500 Hz ±0.2% of FS

30 Hz to 1KHz ±0.2% of FS ±10 counts

TEMPERATURE STABILITY:

400 mV and 40 Volt range 150 ppm/°C typical

4V and 400 Volt range 100 ppm/°C typical

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the

<CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

2.4 watts (100 mA at 24 Vdc)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

1 2

SIG HI

+

N/C

N/C

SIG LO

SIGNAL INPUT

+

D

C

P

W

N/C

-

R

Page 25

Page 21

DRX-FP SPECIFICATIONS

INPUT TYPE:

Min. Low level signal input (magnetic

pickups) : From 0 mV to 120 mV

Open Collector NPN (Use software to set:

3 KΩpull up to 5V): Max. current source = 1.66 mA

Open Collector PNP (Use software to set: 1KΩ pull down to RTN):

Max. current sink = 12.5 mA

TTL/CMOS Input: (Use software to set: no pull up/down).

Low <= 0.8 V , High >= 3.5 V(For Input: 0.2 Hz to 16 KHz)

Low <= 0.8 V , High >= 12 V( For Input: 0.2 Hz to 50 KHz )

NAMUR Sensors (Use software to set: 1KΩpull

down to RTN and 8.2VExcitation.)

For measuring a low level signal riding on top of a

large DC signal, connect a 0.1 uF capacitor. See

Detail.Use software to set 1KΩ pull down to RTN.

OPERATING MODES:

Frequency: Range = 0.2 Hz to 50 KHz

Max. Input Frequency: 30 KHz. for Input Level: 0-5 V

Max. Input Frequency: 50 KHz. for Input Level: 0-12 V

FREQUENCY

RESOLUTION

0 to 9.99999 Hz 0.00001 Hz

10 to 99.9999 Hz 0.0001 Hz

100 to 999.999 Hz 0.001 Hz

1000 to 9999.99 Hz 0.01 Hz

10000 to 50000.0 Hz 0.1 Hz

0 to 50000 Hz 1 Hz

Totalize with Reset: Range = 0 to 999999*, if reading is larger

than 999999, then reading is converted to floating point

number, i.e. 9.99E9 (maximum).

Max. Input Frequency: 30 KHz. for Input Level: 0-5 V

Max. Input Frequency: 50 KHz. for Input Level: 0-12 V

A-B Totalize (Reset input used as +A input): Range = -99999

to 999999*, if reading is larger than 999999, then reading is

converted to floating point number, i.e. -9.99E9 (minimum),

9.99E9 (maximum).

Max. Input Frequency: 30 KHz. for Input Level: 0-5 V

Max. Input Frequency: 25 KHz. for Input Level: 0-12 V

Quadrature (Reset input used as second input): Range =

-99999 to 999999*, if reading is larger than 999999, then reading

is converted to floating point number, i.e. -9.99E9 (minimum),

9.99E9 (maximum).

Max. Input Frequency: 30 KHz. for Input Level: 0-5 V

Max. Input Frequency: 25 KHz. for Input Level: 0-12 V

* Resolution is 1 count.

ISOLATION:

Dielectric strength to 1000 Vrms transient per 1 minute test

based on EN 61010 for 50 Vdc or Vrms working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT IMPEDANCE:

Input: 1MΩ to +EXC

Reset: 100K to +5V

INPUT OVER-VOLTAGE PROTECTION:

With 1K pull down: 14V

With 3K pull up: 20V

Without pull up/down: 60V

EXCITATION:

5, 8.2 or 12.5V at 25mA, programmable

ACCURACYAT 25 °C:

± 0.1% of FS Crystal time base accuracy: ± 50 ppm

TEMPERATURE STABILITY:

± 50 ppm/°C typical Time base stability: ±1ppm/°C

STEP RESPONSE FOR RS485 OUTPUT:

0.1 second to 99% of the final value

(Filter time constant = 0, Gate time = 0.05 Sec)

RESPONSE TIME:

To verify the response time, check the carriage return <CR>, it will be

sent at the end of the response. You can send another command after

you receive the <CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: Only for reading (X01 command).

01 is address.

Frequency mode: response time is controlled by the gate time. If

gate time is increased then response time is longer. Other modes:

response time is not controlled by the gate time.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

3 Watts (125mAat 24V DC)

OPERATING AMBIENT :

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

+EXC

+IN

RST

RTN

Frequency Mode/

Excitation

NPN open

Collector

Totalize Mode

with Reset (example)

+

-

N/C

SIGNAL INPUT

D

C

P

W

R

1 2

J4

J2

J3

J1

34

PWR

R

S

4

8

5

-TX

-RX

+TX

+RX

TER

R

S

4

8

5

1 2 3 4

+EXC

+IN

RST

RTN

J2

1 2 3 4

+EXC

+IN

RST

RTN

J2

Quadrature Mode

Excitation

Quadrature

Encoder

A

B

EXC

EXC

A

B

Totalize (A-B) Mode

J1

120mV

ø

0.1uF

+IN

1 2 3 4

RTN

Page 26

Page 22

DRX-PR SPECIFICATIONS

INPUT RANGES:

±20mA; ±400mV, ±1V, ±2V, ±5V, and ±10V

Ratiometric or nonratiometric

EXCITATION:

14V or 10V @ 25mA

INPUT IMPEDANCE:

Voltage Range: 1MΩ

Current Range: 10Ω

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-RANGE PROTECTION:

Voltage input: 50V

Current input: 50mA

MODE:

Linear, Square root, Linear totalize,

Square root totalize

ANALOG TO DIGITALTECHNIQUE:

Multiple slopes

READ RATE:

8 readings/second, automatic polarity

ACCURACY AT 25 °C:

±0.1% of FS ± 2 counts

TEMPERATURE STABILITY:

100 ppm/°C typical

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the

<CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

3 watts (125 mA at 24Vdc)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

+

-

N/C

SIGNAL INPUT

D

C

P

W

R

1 2 3 4

J4

J2

J3

J1

PWR

R

S

4

8

5

-TX

-RX

+TX

+RX

TER

R

S

4

8

5

+

EXC

+

V IN

+

I IN

RTN

++

+

1 2 3 4

+

EXC

+

V IN

+

I IN

RTN

J2

Excitation

COM

SIG

1 2 3 4

J2

+

EXC

+

V IN

+

I IN

RTN

(+)

MAX.

20mA

1 2 3 4

J2

+

EXC

+

V IN

+

I IN

RTN

(+)

(-)

(

-

)

-

-

+

(4-20)

-

-

Page 27

Page 23

DRX-RTD SPECIFICATIONS

SPECIFICATIONS:

100, 500, 1000 Ohm platinum RTD with both

European (alpha=0.00385) and American

(alpha=0.00392) curves.

Input Type:

100 Ohm -328 to 1562 °F -200 to 850 °C

500 Ohm -328 to 1562 °F -200 to 850 °C

1000 Ohm -328 to 1562 °F -200 to 850 °C

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-VOLTAGE PROTECTION:

250 V AC for 1 Minute

ANALOG TO DIGITALTECHNIQUE:

Dual slope

READ RATE:

3 readings/second, automatic polarity

ACCURACYAT25 °C:

±0.5 °C for platinum RTD’s

TEMPERATURE STABILITY:

0.05 °C/°C

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the <CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

2.4 Watts (100 mA at 24 V DC)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

J2

J2

1 2 3 4

1 2 3 4

+

-

N/C

SIGNAL INPUT

D

C

P

W

R

J4

J2

J3

J1

PWR

R

S

4

8

5

-TX

-RX

+TX

+RX

TER

R

S

4

8

5

1 2 34

+EXC

+SIG

-SIG

-EXC

+EXC

+SIG

-SIG

-EXC

+EXC

+SIG

-SIG

-EXC

2 WIRE

3 WIRE

4 WIRE

RTD

RTD

RTD

Page 28

Page 24

DRX-ST SPECIFICATIONS

INPUT RANGE:

±30mV/ ±100mV

Ratiometric or nonratiometric

EXCITATION:

10V @ 30mA or external

INPUT IMPEDANCE:

More than 1MΩ

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-RANGE PROTECTION:

Voltage input: From -10 to +20V

ANALOG TO DIGITALTECHNIQUE:

Multiple slopes

READ RATE:

8 readings/second, automatic polarity

ACCURACYAT25 °C:

±0.2% of FS ± 2 counts

TEMPERATURE STABILITY:

75 ppm/°C typical

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the

<CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

3 watts (125 mA at 24Vdc)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

+

-

N/C

SIGNAL INPUT

D

C

P

W

R

1 2 3 4

J4

J2

J3

J1

PWR

R

S

4

8

5

-TX

-RX

+TX

+RX

TER

R

S

4

8

5

+EXC

+SIG

-SIG

-EXC

+EXC

-SIG

-EXC

V+ (external)

+EXC

+SIG

-SIG

-EXC

+SIG

Page 29

Page 25

DRX-TC SPECIFICATIONS

INPUT TYPE:

Type J,K,T,E,R,S,B,N, J DIN

Input Type Range °F Range °C

J -346 to 1400°F -210 to 760 °C

K -454 to 2500°F -270 to 1372 °C

T -454 to 752 °F -270 to 400 °C

E -454 to 1832 °F -270 to 1000 °C

R S -58 to 3214 °F -50 to 1768 °C

B +212 to 3300 °F +100 to 1820 °C

N -454 to 2372°F -270 to 1300 °C

J DIN -328 to 1652 °F -200 to 900 °C

ISOLATION:

Dielectric strength to 1000 Vrms transient per

1 minute test based on EN 61010 for 50 Vdc or Vrms

working voltage.

Three way Isolation:

• Power to input

• Power to analog output/communication

• Input to analog output/communication

INPUT OVER-VOLTAGE PROTECTION:

250 V AC for 1 minute

ANALOG TO DIGITALTECHNIQUE:

Dual slope

READ RATE:

3 readings/second, automatic polarity

ACCURACYAT25 °C:

±1°C for temperature above -150 °C

±2°C for temperature below -150 °C

TEMPERATURE STABILITY:

0.05 °C/°C

STEP RESPONSE FOR RS485 OUTPUT:

2 seconds to 99% of the final value

(Filter time constant = 64)

RESPONSE TIME:

To verify the response time, check the carriage return

<CR>, it will be sent at the end of the response. You

can send another command after you receive the

<CR>.

i.e. send: *01X01

response: 01X01<DATA><CR>

Note: 01 is address.

WARM UPTO RATED ACCURACY:

30 minutes

INPUT POWER:

10 to 32 Volt DC

POWER CONSUMPTION:

2.4 Watts (100 mA at 24 V DC)

OPERATING AMBIENT:

-5 to +55 °C

STORAGE TEMPERATURE:

-40 to +85 °C

RELATIVE HUMIDITY:

90% at 40 °C non-condensing

PWR

R

S

4

8

5

-TX

-RX

+TX

+RX

TER

R

S

4

8

5

Page 30

Page 26

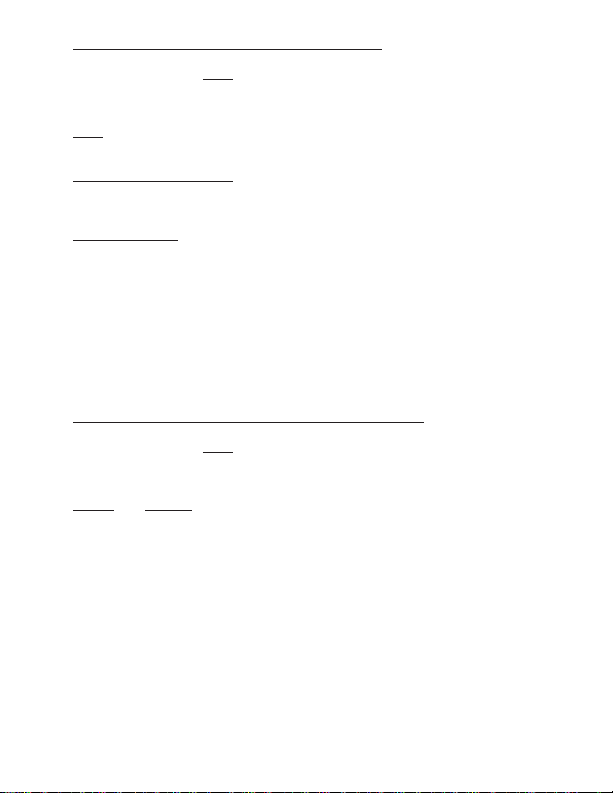

DIMENSIONS:

TYPICAL COMPUTER SETUP:

RS232 to

RS485 Converter

Half-Duplex

0.89[22.5]

2.95[75.0]

PWR

PWR

4.77[121.1]

COMPUTER

CONNECTION

(DB9 OR DB25)

COMPUTER

POWER

CONNECTION

RJ12 CONNECTOR

WITH CABLE

ADAPTER

(DB9/25 TO RJ12)

P

P

W

W

R

R

Page 31

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at

no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of being damaged as a result of excessive corrosion; or

current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2000 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

PATENT NOTICE: This product is covered by one or more of the following patents: U.S. Patents Des. 336,895; 5,274,577

/ FRANCE Brevet No. 91 12756 / SPAIN 2039150; 2048066 / U.K. Patent No. GB2 248 954; GB2 249 837 / CANADA

2052599; 2052600 / ITALY 1249456; 1250938 / GERMANY DE 41 34398 C2. Used under license.

Page 32

13047ML-99E M2769/1000

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gauges

䡺⻬

Load Cells & Pressure Gauges

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...