Page 1

j

MAINTENANCE / ON-SITE - MANUAL

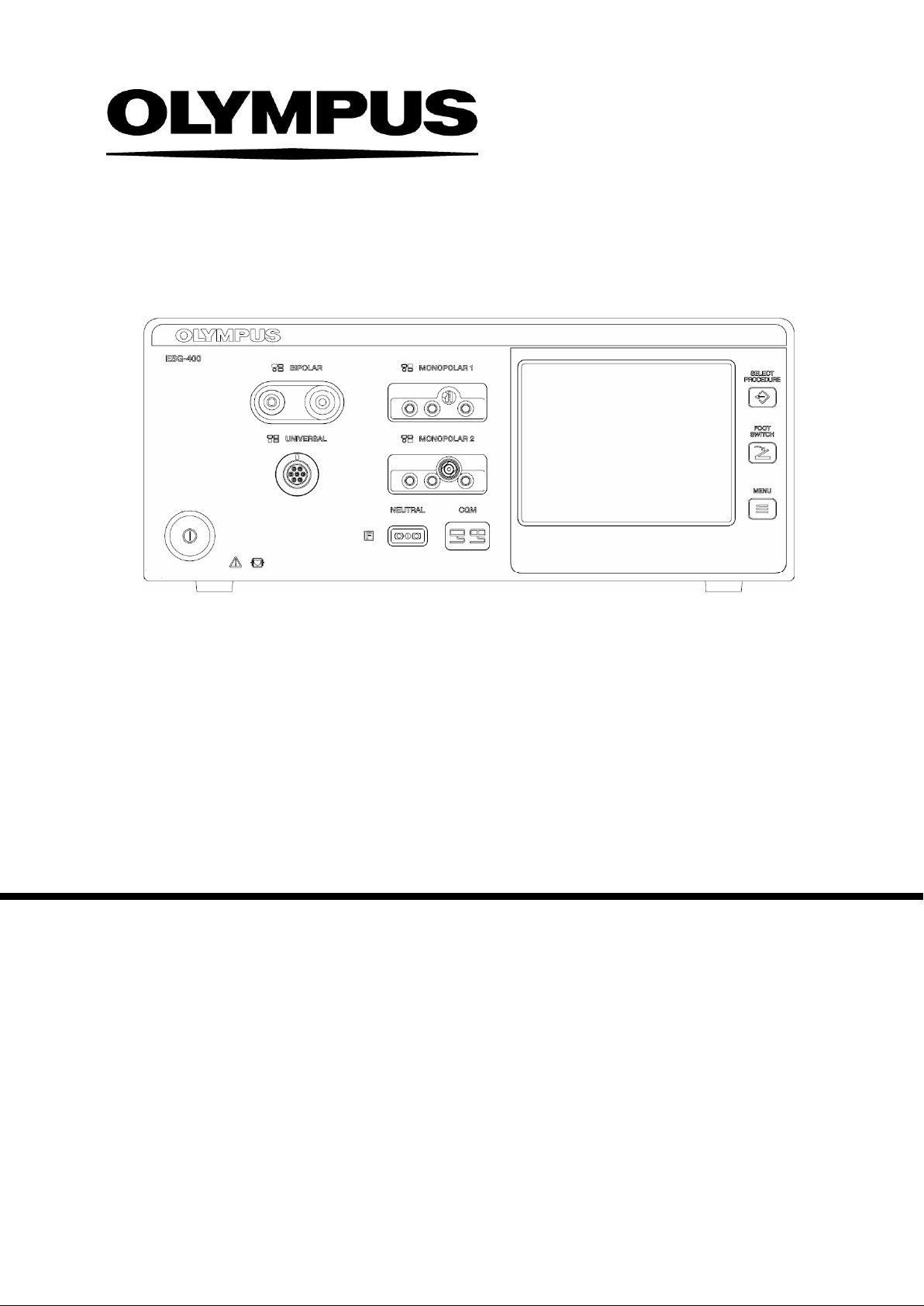

ESG-400

Electro Surgical Generator

7.022.211 / ISSUE 4

Page 2

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

d

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices

or potential equipment damage.

NOTE

Indicates additional helpful information.

NOTE

The user must have received appropriate training in using, servicing,

adjustment, updating and upgrading this electrosurgical generator.

Introduction

The intended use depends on the approval of the country. Refer to the instructions for use of the electrosurgical

unit.

Maintenance instructions

This maintenance manual contains essential information on using and maintaining this electrosurgical

generator safely and effectively. Instructions for the operation of this electrosurgical generator and related

danger, warnings and cautions concerning electrosurgery are beyond the scope of this maintenance manual.

Before using and maintaining, thoroughly review this manual and the instructions for use or maintenance

manuals of all equipment which will be used during maintenance. Use the equipment as instructed. Keep this

manual in a safe, accessible location. If you have any questions or comments about any information in this

maintenance manual, contact Olympus.

Signal words

The following signal words are used throughout this maintenance manual:

ESG-400

INTRODUCTION

User qualifications

The user must have received appropriate training in using this electrosurgical generator. The following

instructions are for use by qualified personnel only. Use of this maintenance manual by other individuals is

prohibited. The training will be provided by authorized representatives of Olympus during installation and

commissioning.

Federal Law of the USA restricts this device to use by, or on the order of, a physician.

7.022.211 / ISSUE 4 2 / 99 Introduction

Page 3

Precautions

User-related error prevention

WARNING

Improper use

The safety and effectiveness of electrosurgical interventions depend not only on the design of

the equipment used, but also to a major extent on factors which are under the control of the

user. It is therefore extremely important to read, understand and follow the instructions supplied

with the electrosurgical generator and the accessories in order to ensure safety and

effectiveness.

Always use the electrosurgical generator as outlined in this maintenance manual. Improper use

will not only impede functions and prevent optimum performance, but may cause equipment

damage and / or complications. Before each use, always inspect the equipment as outlined in

this maintenance manual.

WARNING

Annual safety checks / Inspection

The electrosurgical generator and the footswitch must undergo a safety check in yearly intervals

in accordance with the national statutory regulations (refer to chapter 7 “Inspection”).

Environmental conditions

CAUTION

Interference of the unit with other equipment

Be sure that this electrosurgical unit is not used adjacent to or stacked with other equipment

(other than the components of this electrosurgical unit or system) to avoid electromagnetic

interference.

Before use, thoroughly confirm the compatibility of all equipment.

To ensure electrical safety, the electrosurgical unit should not be used in conjunction with:

Electrical equipment whose safety against leakage current is not guaranteed.

Electrosurgical equipment whose safety in combined use is not guaranteed.

The electrosurgical generator complies with the electromagnetic compatibility (EMC) standard.

Nevertheless, when the electrosurgical generator is active it may disturb neighboring electronic

equipment. If an auxiliary computer system is in use together with the electrosurgical generator

and endoscopic imaging techniques, the image on the monitor might freeze or blackout. Follow

the instructions in “Electromagnetic Compatibility (EMC) information” in the Appendix of the

instruction for use regarding electromagnetic ambient conditions.

Never loop the cords (active cord, bipolar cord, neutral electrode cord) or bundle cords together

with cords belonging to other medical equipment. The high frequency signals or spark discharge

noise generated by the unit may interfere with the operation of other medical equipment.

Do not use the electrosurgical unit in a location exposed to strong electromagnetic radiation

(microwave or short-wave medical treatment equipment, Magnetic Resonance Imaging, radio or

mobile phone equipment). Electrosurgical unit malfunction can occur.

CAUTION

Unsuitable temperature and humidity

The electrosurgical generator should only be used under the conditions as described in chapter

1-3 (Limitations). Use under other conditions may impede normal performance and / or result in

equipment damage.

High frequency leakage current or spark discharge may cause user burns.

Follow the dangers, warnings and cautions given below when handling and servicing this electrosurgical unit.

This information is to be supplemented by the dangers, warnings and cautions given in each chapter.

ESG-400

7.022.211 / ISSUE 4 3 / 99 Introduction

Page 4

ESG-400

Accessories

WARNING

Mechanical stress

Do not apply excessive bending, straining, or squeezing force to any cords. It may cause

malfunction.

CAUTION

Non-compatible accessories and accessory damage

The electrosurgical generator shall only be used with compatible accessories. When connecting

accessories (cords, electrodes, HF instruments) avoid output settings where the maximum

output voltage of the electrosurgical generator may exceed the rated accessory voltage (refer to

“Mode characteristics”, “Output characteristics” in the Appendix of the instruction for use, and the

instruction manual of the accessory). For a list of compatible neutral electrodes, refer to

“Specifications” in the Appendix of the instruction for use.

Before use, the electrosurgical unit and accessories must be examined for damage. All

communication cables and its plugs must be free of scratches and cracks. Cables and

accessories with damaged insulation or connections must not be used.

Electric shock

WARNING

Grounding failure

To prevent the risk of electric shock, the housing of the electrosurgical unit must be grounded.

Always connect the power cord plug to a properly grounded wall outlet. Do not use a

3-pin / 2-pin adapter, as it can impair safe operation of the unit.

WARNING

User shock

To prevent user shock, malfunction and damage of the electrosurgical unit, keep liquids away

from all electrical equipment.

When taking measurements or troubleshooting of the electrosurgical unit, take appropriate

precautions, such as using isolated tools and equipment, using the “one hand rule,” etc.

CAUTION

Injury during servicing

When the housing is opened, there is a danger of electric shock. The unit must only be serviced

by authorized technicians.

Burns

WARNING

User

The maximum output voltage characteristics of the electrosurgical generator are shown in the

diagrams in “Output characteristics” in the Appendix of the instruction for use. When setting the

power level, first set it to a low level and increase it gradually. If the output is initially set to a high

level, the electrode’s insulation may be damaged and cause user and / or patient burns.

However, certain modes may present an unacceptable risk at low output power settings. For

example, with the PulseCut fast mode or PulseCut slow mode, the risk of an excessive thermal

effect rises if the output power setting is too low. Therefore, it is recommended that you perform

basic testing before using the electrosurgical generator. If the instruction manual of the HF

instrument to be used stipulate a rated voltage, the output should be set so that it does not

exceed that voltage.

High frequency, high voltage signals that can cause severe burns are present in the

monopolar / bipolar sockets described in this maintenance manual. Take appropriate precautions

when testing and troubleshooting this area of the electrosurgical unit.

7.022.211 / ISSUE 4 4 / 99 Introduction

Page 5

ESG-400

Fire / Explosion

DANGER

Ignitable anaesthetics / fire supporting gases

The risk of flammable gases or other materials being ignited exists with any contact of electrical

energy. Precautionary measures must be taken to keep flammable materials and substances

away from an active electrosurgical unit (do not use flammable anesthetics, nitrous oxide or

oxygen). Otherwise, explosion or fire may result and cause serious injuries. This electrosurgical

unit is not explosion-proof. Do not use the unit within an explosion zone.

WARNING

Ignitable cleaning- and disinfection agents

Flammable agents used for cleaning and disinfection must be allowed to evaporate before the

electrosurgical unit is used and serviced.

Non-flammable agents should be used for cleaning and disinfection wherever possible.

WARNING

Risk of fire

Hazards and complications

WARNING

Contamination

The electrosurgical unit may be contaminated with infections materials; therefore, all surfaces of

the unit’s housing should be cleaned before servicing according to chapter 1-8 (Cleaning).

WARNING

Output performance

Should any abnormal output be suspected during operation, immediately terminate the use of

the equipment by releasing the footswitch. If the footswitch does not react, switch off the

electrosurgical unit. Otherwise, malfunction of the equipment may cause an unintended increase

in output.

WARNING

Service persons

Take additional precautions for service technicians, when using the unit’s service operation

mode (see chapter 15, Service operation mode).

CAUTION

Unit defect

To prevent electrosurgical unit damage, never short-circuit electrodes (accessories, neutral

electrodes).

In the event of a defect or malfunction in the unit, an undesirably high output power may be

emitted.

DANGER

Unit defect

Never use the electrosurgical unit if an abnormality is suspected.

Repair and Maintenance

CAUTION

Repair

Repairs must only be carried out by Olympus or a firm authorized by Olympus.

CAUTION

Maintenance

Preventive maintenance (inspection / periodic safety check) must only be carried out by a

qualified person / technician.

7.022.211 / ISSUE 4 5 / 99 Introduction

Page 6

Copyright

©2011 Olympus Winter & Ibe GmbH. All rights reserved.

Unauthorized reproduction or distribution in part or in whole is prohibited.

Trademarks

OLYMPUS is a registered trademark of the Olympus Corporation.

The company names, product names, and proprietary technical terms in this document are the trademarks or

registered trademarks of their respective owners.

ESG-400

7.022.211 / ISSUE 4 6 / 99 Introduction

Page 7

ESG-400

CONTENT

INTRODUCTION ................................................................................................................ 2

CONTENT .......................................................................................................................... 7

CHAPTER 1: PRODUCT SPECIFICATIONS .................................................................... 9

1 OUTLINE ...................................................................................................................... 10

1-1 Intended Use .................................................................................................................................... 10

1-2 Compatibility ..................................................................................................................................... 10

1-3 Expected service life ........................................................................................................................ 10

2 FEATURES ................................................................................................................... 11

2-1 Application Modes ............................................................................................................................ 11

2-2 Accessories ...................................................................................................................................... 12

3 LIMITATIONS ................................................................................................................ 13

4 SPECIFICATIONS ........................................................................................................ 14

4-1 ELECTROSURGICAL GENERATOR ESG-400 (REF: WB91051W) .............................................. 14

4-2 Power cords (4.5 m angled plug) ..................................................................................................... 15

4-3 Footswitch (REF: WB50402W, double pedal) ................................................................................. 16

4-4 Footswitch (REF: WB50403W, single pedal, optional) .................................................................... 16

4-5 Neutral electrode cable “P-cord” (REF: MAJ-814, optional) ............................................................ 16

4-6 Communication cable 0.25 m (REF: MAJ-1871, optional) .............................................................. 17

4-7 Communication cable 10 m (REF: MAJ-1872, optional) ................................................................. 17

4-8 Adapter for UHI-2/3 (REF: MAJ-1873, optional) .............................................................................. 17

5 NAME AND FUNCTION OF EACH PART .................................................................... 18

5-1 Symbols and descriptions ................................................................................................................ 18

5-1-1 Safety related symbols ............................................................................................................ 18

5-1-2 Front panel .............................................................................................................................. 19

5-1-3 Touch screen ........................................................................................................................... 19

5-1-4 Rear panel ............................................................................................................................... 21

5-2 Front panel ....................................................................................................................................... 22

5-3 Rear panel ........................................................................................................................................ 24

5-4 Bottom panel .................................................................................................................................... 25

5-5 All screen ......................................................................................................................................... 25

5-6 Set screen ........................................................................................................................................ 26

5-7 Mode screen .................................................................................................................................... 27

5-8 Footswitch with two pedals .............................................................................................................. 28

5-9 Footswitch with one pedal (optional)................................................................................................ 28

5-10 Neutral electrode cable “P-cord” (optional) ...................................................................................... 29

6 CONNECTOR ................................................................ ................................ ............... 30

6-1 Docking Connector .......................................................................................................................... 30

6-2 Monopolar Standard 1 ...................................................................................................................... 30

6-3 Monoploar Standard 2 (Erbe) ........................................................................................................... 30

6-4 Bipolar Standard 3............................................................................................................................ 30

6-5 Monopolar Neutral Electrode ........................................................................................................... 31

6-6 Foot switch 1 (SIP/SOP) .................................................................................................................. 31

6-7 Foot switch 2 (SIP/SOP) .................................................................................................................. 32

7 SYSTEM DIAGRAM ..................................................................................................... 33

8 CLEANING, STORAGE AND DISPOSAL .................................................................... 34

8-1 Cleaning ........................................................................................................................................... 34

8-2 Storage ............................................................................................................................................. 35

8-3 Disposal of the unit .......................................................................................................................... 35

CHAPTER 2: BLOCK DESCRIPTION ............................................................................. 37

1 BLOCK DESCRIPTIONS .............................................................................................. 38

1-1 Motherboard ..................................................................................................................................... 39

1-2 HVPS Board ..................................................................................................................................... 41

1-3 Generator board ............................................................................................................................... 41

1-4 Relay Board ..................................................................................................................................... 41

1-5 Front Panel ....................................................................................................................................... 42

CHAPTER 3: REPAIR SYSTEM ...................................................................................... 43

7.022.211 / ISSUE 4 7 / 99 Content

Page 8

ESG-400

1 ESG-400 MAIN UNIT .................................................................................................... 44

2 BOARD COMPATIBILITY ............................................................................................. 44

3 OPTIONAL ACCESSORIES ......................................................................................... 44

3-1 WB50402W (Footswitch with two pedals) ....................................................................................... 44

3-2 WB50403W (Footswitch with one pedal) ......................................................................................... 44

3-3 MAJ-814 (Neutral electrode cable “P-cord”) .................................................................................... 44

4 PRECAUTIONS ON FUNCTION AND OPERATION SETTINGS ................................. 44

4-1 General Precautions ........................................................................................................................ 44

CHAPTER 4: TROUBLESHOOTING .............................................................................. 45

1 GENERAL ..................................................................................................................... 46

2 NEUTRAL ELECTRODE OPERATION ........................................................................ 47

3 ERROR SCREEN, CODES AND MEASURES ............................................................. 48

3-1 What to do when no error code is displayed .................................................................................... 50

3-2 What to do when an error code is displayed .................................................................................... 54

CHAPTER 5: INSPECTION ............................................................................................. 65

1 JIGS, TOOLS, AND MEASURING EQUIPMENT FOR INSPECTION .......................... 66

2 INSPECTION PROCEDURES ................................................................ ...................... 67

2-1 Visual inspection of the electrosurgical generator and accessories ................................................ 68

2-2 Verifying the contact quality monitor function .................................................................................. 71

2-3 Checking the DC resistance (according to IEC 60601-2-2) ............................................................. 73

2-4 Checking the earth resistance (according to IEC 60601-1 and IEC 62353) .................................... 73

2-5 Checking the earth leakage current (according to IEC 60601-1) .................................................... 73

2-6 Checking the patient leakage current (according to IEC 60601-1) .................................................. 74

2-7 Checking the current and power consumption and output waveform .............................................. 75

2-8 Checking the high frequency leakage current (according to IEC 60601-2-2) .................................. 77

2-8-1 Measurement of the monopolar high frequency leakage current under loaded condition ...... 77

2-8-2 Measurement of the monopolar high frequency leakage current under unloaded condition .. 79

2-8-3 Measurement of the bipolar high frequency leakage current under loaded condition ............ 81

2-8-4 Measurement of the bipolar high frequency leakage current under unloaded condition ........ 83

2-9 Checking the output power .............................................................................................................. 85

2-10 Checking for certain features and error messages .......................................................................... 85

2-11 Final test ........................................................................................................................................... 86

2-11-1 Self test.................................................................................................................................... 86

2-11-2 Display and sound check ........................................................................................................ 86

2-11-3 Functionality of push buttons .................................................................................................. 86

2-11-4 Communication test ................................................................................................................. 86

2-11-5 Restore of output power settings ............................................................................................ 87

2-12 Inspection label (For applicable markets) ........................................................................................ 87

3 INSPECTION CARD ..................................................................................................... 88

CHAPTER 6: DEVICE MENU .......................................................................................... 93

1 SAFETY TEST ................................................................ .............................................. 94

2 SOFTWARE VERSION ................................................................................................. 95

CHAPTER 7: REVISION HISTORY ................................................................................. 97

3 REVISION HISTORY .................................................................................................... 98

7.022.211 / ISSUE 4 8 / 99 Content

Page 9

ESG-400

CHAPTER 1: PRODUCT SPECIFICATIONS

1 OUTLINE ...................................................................................................................... 10

1-1 Intended Use .................................................................................................................................... 10

1-2 Compatibility ..................................................................................................................................... 10

1-3 Expected service life ........................................................................................................................ 10

2 FEATURES ................................................................................................................... 11

2-1 Application Modes ............................................................................................................................ 11

2-2 Accessories ...................................................................................................................................... 12

3 LIMITATIONS ................................................................................................................ 13

4 SPECIFICATIONS ........................................................................................................ 14

4-1 ELECTROSURGICAL GENERATOR ESG-400 (REF: WB91051W) .............................................. 14

4-2 Power cords (4.5 m angled plug) ..................................................................................................... 15

4-3 Footswitch (REF: WB50402W, double pedal) ................................................................................. 16

4-4 Footswitch (REF: WB50403W, single pedal, optional) .................................................................... 16

4-5 Neutral electrode cable “P-cord” (REF: MAJ-814, optional) ............................................................ 16

4-6 Communication cable 0.25 m (REF: MAJ-1871, optional) .............................................................. 17

4-7 Communication cable 10 m (REF: MAJ-1872, optional) ................................................................. 17

4-8 Adapter for UHI-2/3 (REF: MAJ-1873, optional) .............................................................................. 17

5 NAME AND FUNCTION OF EACH PART .................................................................... 18

5-1 Symbols and descriptions ................................................................................................................ 18

5-1-1 Safety related symbols ............................................................................................................ 18

5-1-2 Front panel .............................................................................................................................. 19

5-1-3 Touch screen ........................................................................................................................... 19

5-1-4 Rear panel ............................................................................................................................... 21

5-2 Front panel ....................................................................................................................................... 22

5-3 Rear panel ........................................................................................................................................ 24

5-4 Bottom panel .................................................................................................................................... 25

5-5 All screen ......................................................................................................................................... 25

5-6 Set screen ........................................................................................................................................ 26

5-7 Mode screen .................................................................................................................................... 27

5-8 Footswitch with two pedals .............................................................................................................. 28

5-9 Footswitch with one pedal (optional)................................................................................................ 28

5-10 Neutral electrode cable “P-cord” (optional) ...................................................................................... 29

6 CONNECTOR ................................................................ ................................ ............... 30

6-1 Docking Connector .......................................................................................................................... 30

6-2 Monopolar Standard 1 ...................................................................................................................... 30

6-3 Monoploar Standard 2 (Erbe) ........................................................................................................... 30

6-4 Bipolar Standard 3............................................................................................................................ 30

6-5 Monopolar Neutral Electrode ........................................................................................................... 31

6-6 Foot switch 1 (SIP/SOP) .................................................................................................................. 31

6-7 Foot switch 2 (SIP/SOP) .................................................................................................................. 32

7 SYSTEM DIAGRAM ..................................................................................................... 33

8 CLEANING, STORAGE AND DISPOSAL .................................................................... 34

8-1 Cleaning ........................................................................................................................................... 34

8-2 Storage ............................................................................................................................................. 35

8-3 Disposal of the unit .......................................................................................................................... 35

7.022.211 / ISSUE 4 9 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 10

1-1 Intended Use

The intended use depends on the approval of the country. Refer to the instructions for use of the electrosurgical

generator.

1-2 Compatibility

This product can be used in combination with the products listed in compatibility table.

1-3 Expected service life

The expected service life is 10 years.

ESG-400

1 Outline

7.022.211 / ISSUE 4 10 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 11

ESG-400

2 Features

The ESG-400 is a reusable, non-sterile electrosurgical generator with different mono- and bipolar cutting and

coagulation modes. The maximum output power is 320 W.

On the front side it features a touch screen display that displays the connection status of accessories and

peripherals connected to the electrosurgical generator. It is also used to show and modify the output settings

(e.g. mode, output power, effect) as well as to control other functions (e.g. save settings).

In addition the ESG-400 has a bipolar socket, two monopolar sockets, a neutral electrode socket, and a

universal socket to connect applicators with instrument recognition. The power switch turns the generator on

and off.

Two contact quality indicators (one for split and one for non-split electrodes) are green illuminated if neutral

electrodes are correctly connected. Three additional push buttons allow recalling a previously saved setting

(Select Procedure), to assign the footswitches to specific output sockets (Footswitch), and to control several

other functions (Menu), e.g. select language, touch tone control, output volume, or brightness.

On the rear panel the volume control, a ventilation hole, the equipotential bonding point, the AC power socket,

and two footswitch sockets can be found. Furthermore, for the connection of peripheral equipment 26-pin plugs

respectively 14-pin plugs can be connected to the LINK-IN or to the LINK-OUT socket.

On the bottom panel, a docking socket is featured. It can be used to connect the ESG-400 directly to the

USG-400 and upcoming devices. The ESG-400 is compatible with the new USG-400 ultrasonic generator to

enable the use of combined (US + HF) instruments.

2-1 Application Modes

Monopolar Cut:

PureCut (Cutting of varying tissue structures; 3 Effects)

BlendCut (Cutting of varying tissue structures; 3 Effects)

PulseCut slow (Intermittent cutting; 3 Effects)

PulseCut fast (Intermittent cutting; 3 Effects)

Monopolar Coagulation:

SoftCoag (Coagulation of tissue with little sticking and carbonization; 3 Effects)

ForcedCoag (Fast and effective coagulation; 3 Effects)

SprayCoag (Contact-free surface coagulation with little penetration depth; 3 Effects)

PowerCoag (Fast and effective coagulation with increased dissection capabilities; 3 Effects)

Bipolar Cut:

BipolarCut (All bipolar cutting procedures of tissue structures; 3 Effects)

SalineCut (Cutting in conductive fluid; 3 Effects; only available via UNIVERSAL socket )

Bipolar Coagulation:

BiSoftCoag (Coagulation with little sticking and carbonization; 3 Effects)

AutoCoag (Coagulation with little sticking and carbonization; 3 Effects)

SalineCoag (Coagulation in conductive fluid; 3 Effects; only available via UNIVERSAL socket )

7.022.211 / ISSUE 4 11 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 12

HardCoag (Controlled tissue coagulation; 3 Effects)

RFCoag (Controlled deep tissue coagulation; with and without RCAP) FineCoag (Coagulation of

tissue with little sticking and carbonization; 1 Effect)

The modes have preset power levels that may be customized by the user in a defined range.

2-2 Accessories

Footswitch Double Pedal (WB50402W): It has a blue pedal that is used to activate the selected coagulation

mode and a yellow pedal that is used to activate the selected cutting mode.

Footswitch Single Pedal (optional; WB50403W): It has a blue pedal that is used to activate the selected

coagulation mode

P-Cord (optional; MAJ-814): The P-cord is used to connect a patient plate to the ESG-400.

ESG-400

7.022.211 / ISSUE 4 12 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 13

3 Limitations

Operation

environment

Temperature

+ 10…+ 40°C

Relative humidity

30…85%, non-condensing

Atmospheric pressure

70…106 kPa

Transportation and

storage

environment

Temperature

- 25…+ 60°C

Relative humidity

10…85%, non-condensing

Atmospheric pressure

50…106 kPa

(1) Use this product under the supervision of a doctor at a medical facility.

(2) Do not use this product in combination with the products other than those designated by Olympus.

(3) This product shoul be used, transported or stored in the following environment.

ESG-400

7.022.211 / ISSUE 4 13 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 14

4 Specifications

Power supply

Voltage range

100…120 V~ / 220…240 V~

Frequency

50 / 60 Hz

Maximum input power

1500 VA

Power fuse

10 A (only FST-series from

Schurter)

Power connection line

IEC 60320-1 / C13

Maximum length: 4.5 m

Terminal for potential

equalization

Yes

Size, weight and

packaging

Width x Depth x Height

370 × 465 × 156 mm

Volume

25752 cm³

Weight of generator

12.5 kg

Weight of packaging

2.3 kg

Type of packaging

Cardboard and expanded

polypropylene material

Classification

Protection class according

to IEC 60601-1

CF, Class I

Classification according to

MDD 93/42/EEC

IIb

Output

High frequency functions

Monopolar / Bipolar

High frequency

430 kHz ±20%

Maximum high frequency

power

320 W

All modes

25% duty cycle

(e.g. 10 s activated / 30 s

deactivated)

RFCoag (with or without

RCAP)

100% duty cycle

4-1 ELECTROSURGICAL GENERATOR ESG-400 (REF: WB91051W)

ESG-400

7.022.211 / ISSUE 4 14 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 15

ESG-400

Sockets

MONOPOLAR 1

3-pin ( 4 mm),

Valleylab standard;

coaxial ( 8 mm),

Bovie standard

MONOPOLAR 2

3-pin ( 4 mm),

Valleylab standard;

coaxial ( 5 / 9 mm),

Erbe standard

BIPOLAR

2-pin ( 4 mm,

pin spacing 28.8 mm),

Valleylab standard;

coaxial

(

inner

8 mm,

outer

4 mm),

Erbe standard

UNIVERSAL

7-pin, Olympus standard

Neutral electrode

Single or split, 10 mm plug

Contact quality

monitor (CQM)

Allowable resistance range

for split type neutral

electrodes

10...155 Ω ±15 Ω

Allowable resistance range

for non-split type neutral

electrodes

< 10 Ω ±5 Ω

Power cords

WA95621A

Many European countries

Type E/F

WA95622A

USA, Canada and other

countries

Type B

WA95623A

United Kingdom and other

countries

Type G

4-2 Power cords (4.5 m angled plug)

7.022.211 / ISSUE 4 15 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 16

4-3 Footswitch (REF: WB50402W, double pedal)

Classification

Protection class according

to IEC 60529

IPX8 (except the plug section)

Size, weight and

packaging

Width x Depth x Height

350 × 185 × 65 mm

Weight of footswitch

1.9 kg

Length of cord

4 m

Weight of packaging

0.5 kg

Type of packaging

Cardboard material

Classification

Protection class according

to IEC 60529

IPX8 (except the plug section)

Size, weight and

packaging

Width x Depth x Height

175 × 185 × 50 mm

Weight of footswitch

1.6 kg

Length of cord

4 m

Weight of packaging

0.5 kg

Type of packaging

Cardboard material

Size

Weight

0.14 kg

Length of cord

3.1 m

4-4 Footswitch (REF: WB50403W, single pedal, optional)

ESG-400

4-5 Neutral electrode cable “P-cord” (REF: MAJ-814, optional)

7.022.211 / ISSUE 4 16 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 17

4-6 Communication cable 0.25 m (REF: MAJ-1871, optional)

Size

Weight

0.05 kg

Length of cord

0.25 m

Size

Weight

0.5 kg

Length of cord

10 m

Size

Width x Depth x Height

100 × 77 × 42 mm

Weight

0.35 kg

Compatible cables

MAJ-1871, MAJ-1872

4-7 Communication cable 10 m (REF: MAJ-1872, optional)

4-8 Adapter for UHI-2/3 (REF: MAJ-1873, optional)

ESG-400

7.022.211 / ISSUE 4 17 / 99 Chapter 1: PRODUCT SPECIFICATIONs

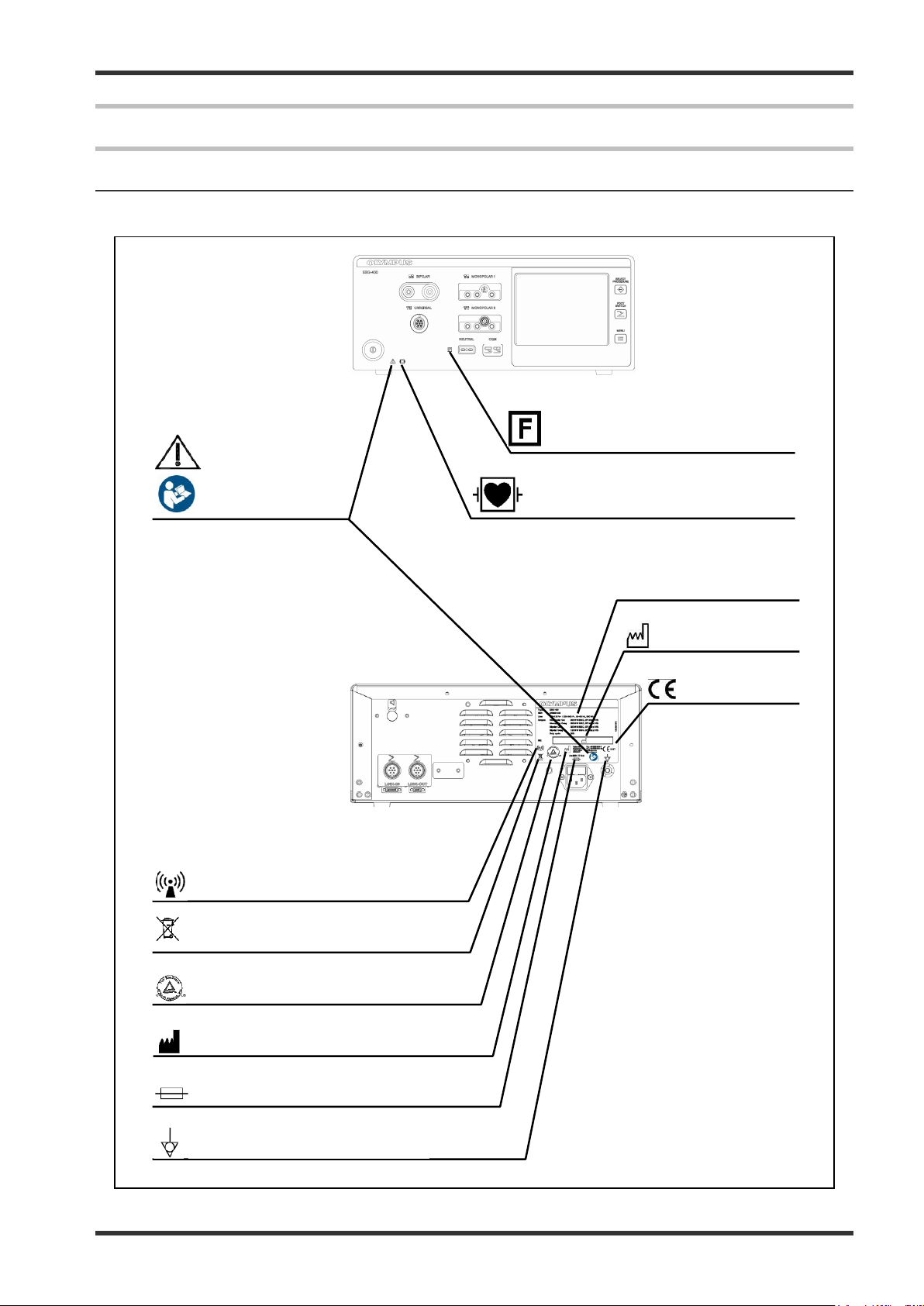

Page 18

Date of

manufacture

CE marking

Non-ionizing electromagnetic radiation

Output insulated from earth

(connection for neutral electrode)

Caution, read

instructions

Refer to

instructions

Defibrillation proof type CF applied

part (cardiac application)

Waste electrical and electronic

equipment

cTUVus marking

Manufacturer

Potential equalization terminal

Fuse rating

Type plate

5 Name and Function of each part

5-1 Symbols and descriptions

5-1-1 Safety related symbols

ESG-400

7.022.211 / ISSUE 4 18 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 19

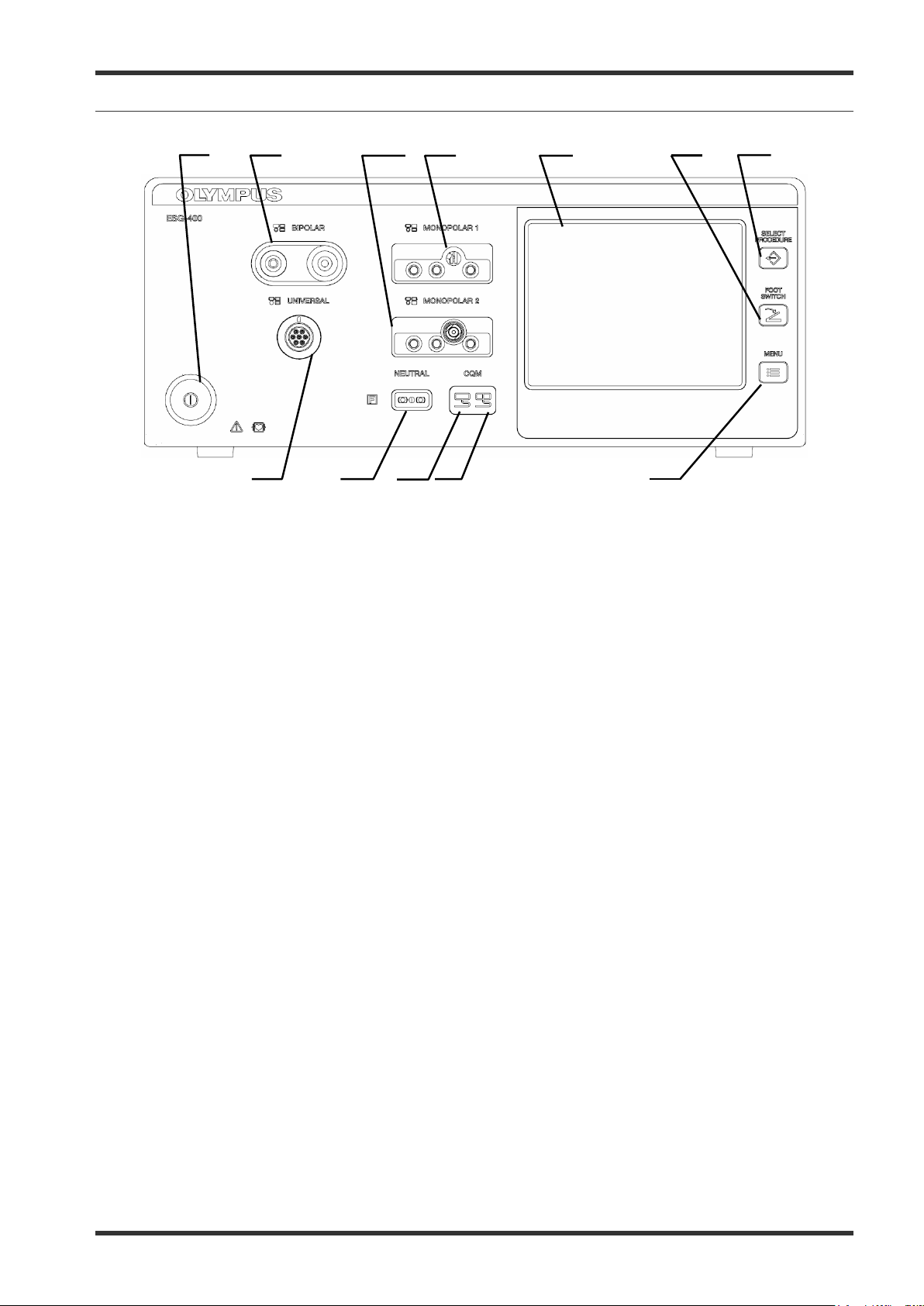

5-1-2 Front panel

Power on / off

Neutral electrode – non-split type

Neutral electrode – split type

Select procedure

Footswitch

Menu

BIPOLAR socket

MONOPOLAR 1 socket

UNIVERSAL socket

MONOPOLAR 2 socket

Double footswitch

Single footswitch

Autostart

Plus

Minus

Return

OK Cancel

ESG-400

5-1-3 Touch screen

7.022.211 / ISSUE 4 19 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 20

ESG-400

Save procedure

Delete procedure

Languages

Touch tone on

Touch tone off

Software version

Safety test

Service

Volume

Brightness

Select procedure (in title line)

Menu (in title line)

Toggle

Previous

Next

Numeric

Alphabetic

Uppercase / lowercase

Backspace

Caution

Communication indicator

7.022.211 / ISSUE 4 20 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 21

Reset

RCAP

Resistance Controlled Automatic Power

Reference to BIPOLAR socket

Reference to MONOPOLAR 1 socket

Reference to UNIVERSAL socket

Reference to MONOPOLAR 2 socket

Volume

Footswitch

LINK-IN

LINK-IN socket

LINK-OUT

LINK-OUT socket

5-1-4 Rear panel

ESG-400

7.022.211 / ISSUE 4 21 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 22

5-2 Front panel

1.

Power switch

This switch turns the electrosurgical generator on and off.

2.

BIPOLAR socket

This socket connects the plug of a bipolar HF instrument.

3.

MONOPOLAR 2 socket

This socket connects the plug of a monopolar HF instrument.

4.

MONOPOLAR 1 socket

This socket connects the plug of a monopolar HF instrument.

5.

Touch-screen

Displays the connection status of the accessories and peripherals connected to the electrosurgical

generator. It is also used to show and modify the output settings (e.g. mode, output power, effect) as

well as to control other functions (e.g. save procedures, delete procedures).

6.

FOOTSWITCH push button

This button is used to open the “Footswitch screen” to assign one or two footswitch(es) or the autostart

function to a specific output socket.

7.

SELECT PROCEDURE push button

This button is used to open the “Select Procedure screen” to recall saved settings.

8.

MENU push button

This button is used to open the “Menu screen” to control several functions (save or delete a procedure,

control the touch tone, output volume and brightness as well as other functions).

8.

6.

1.

2.

3.

4.

7.

12.

11.

10.

9.

5.

ESG-400

7.022.211 / ISSUE 4 22 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 23

ESG-400

9.

Contact quality monitor indicator for split neutral electrode

This indicator illuminates green if a split neutral electrode is connected and the contact resistance is

within an acceptable range. The indicator illuminates red if the split neutral electrode is not connected

or not applied properly (e.g. bad contact quality or partly dislocated) or no neutral electrode is

connected (in both cases the activation of monopolar output is disabled).

10.

Contact quality monitor indicator for non-split neutral electrode

This indicator illuminates green if a non-split neutral electrode is connected.

11.

Neutral electrode socket

This socket connects the plug of a neutral electrode for monopolar application.

12.

UNIVERSAL socket

This socket connects the plug of an Olympus HF instrument with HF instrument recognition.

7.022.211 / ISSUE 4 23 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 24

5-3 Rear panel

1.

Footswitch sockets

This socket connects the plug of a single or double pedal footswitch.

2.

Volume control

This knob is used for adjusting the output volume.

3.

Ventilation hole

Holes for air ventilation via a cooling fan; there are also ventilation holes on each side of the

electrosurgical generator.

4.

Equipotential bonding point

To increase electrical safety, this point is used for potential equalization. All equipment housings that

come into contact with the patient are electrically connected in order to prevent low-frequency

electrical currents from endangering the patient in the event of a defect in the conventional protective

conductor system.

5.

AC power socket

This socket serves as a connection to the mains power supply via a power cord

6.

LINK-OUT socket

This socket connects the plug (14-pin) of a cable connected to peripheral equipment.

7.

LINK-IN socket

This socket connects the plug (26-pin) of a cable connected to peripheral equipment.

NOTE

language setting of the electrosurgical generator.

For a detailed explanation of the different types of

sockets, refer to chapter 6 “Connection of neutral

electrode” and chapter 3.7 “Connection of HF

instruments”.

1.

2.

3.

4.

7.

6.

5.

1.

ESG-400

7.022.211 / ISSUE 4 24 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 25

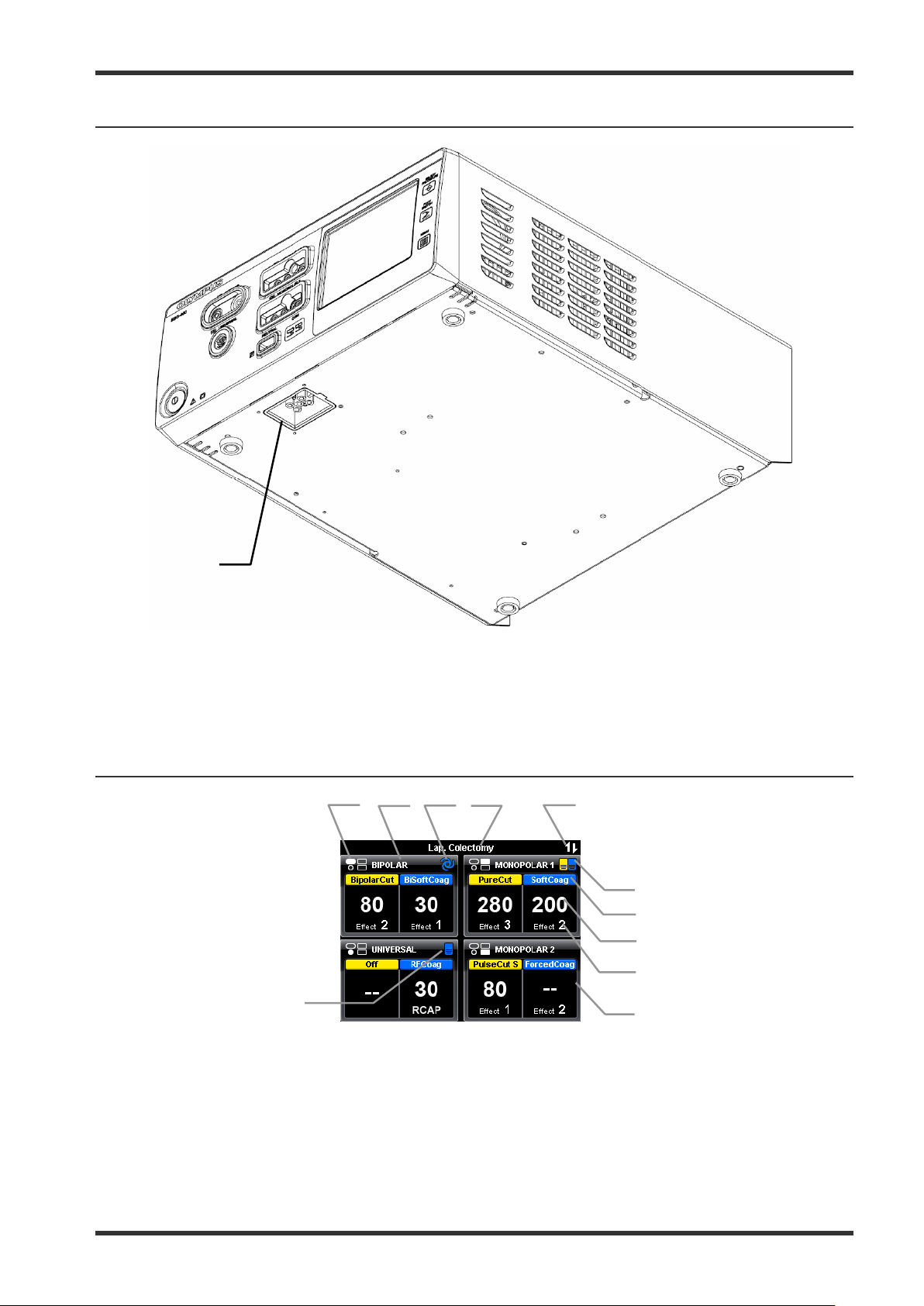

1.

Docking socket

This socket connects the plug (7-pin) of a docking connector to connect peripheral equipment. For

more details, see chapter 1-6-1.

1.

Reference to output sockets indicator

This indicator shows the corresponding output socket where the same symbol is printed on the front

panel.

2.

Output socket name

The name of the corresponding output socket is displayed here.

3.

Autostart indicator

This symbol indicates if the autostart function is assigned to the corresponding output socket. Blank if

1.

1.

2.

3.

4.

5.

8.

6.

11.

7.

9.

10.

5-4 Bottom panel

ESG-400

5-5 All screen

7.022.211 / ISSUE 4 25 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 26

ESG-400

autostart or footswitch is not assigned. Refer to chapter 6.4, “Assign footswitch and autostart function”.

4.

Procedure name

The name of the selected procedure is displayed here. Blank if no procedure is selected.

5.

Communication indicator

This symbol indicates if communication with peripheral equipment connected to the docking socket is

established.

6.

Footswitch indicator (double pedal)

This symbol indicates if a connected double pedal footswitch is assigned to the corresponding output

socket. Blank if autostart or footswitch is not assigned. Refer to chapter 6.4, “Assign footswitch and

autostart function”.

7.

Output mode

The name of the output mode as selected in the “Mode screen” is displayed here. If “Off” is selected,

“--“ will be displayed instead of power level and effect.

8.

Output power level

The number shows the output power level as selected in the “Set screen”. If an output power level is

set to zero, “--” will be displayed instead of numbers.

9.

Effect

The number shows the effect as selected in the “Set screen”. For RFCoag mode the RCAP function

can be selected instead of an effect (refer to chapter 5.3, “Output setting”).

10.

Button area

Each button covers the entire area including all output socket related information as described above

(3. to 10.). Press the button, to switch to the corresponding “Set screen” to select the mode, power

levels and effects for the corresponding output socket.

11.

Footswitch indicator (single pedal)

This symbol indicates if a connected single pedal footswitch is assigned to the corresponding output

socket. Blank if autostart or footswitch is not assigned. Refer to chapter 6.4, “Assign footswitch and

autostart function”.

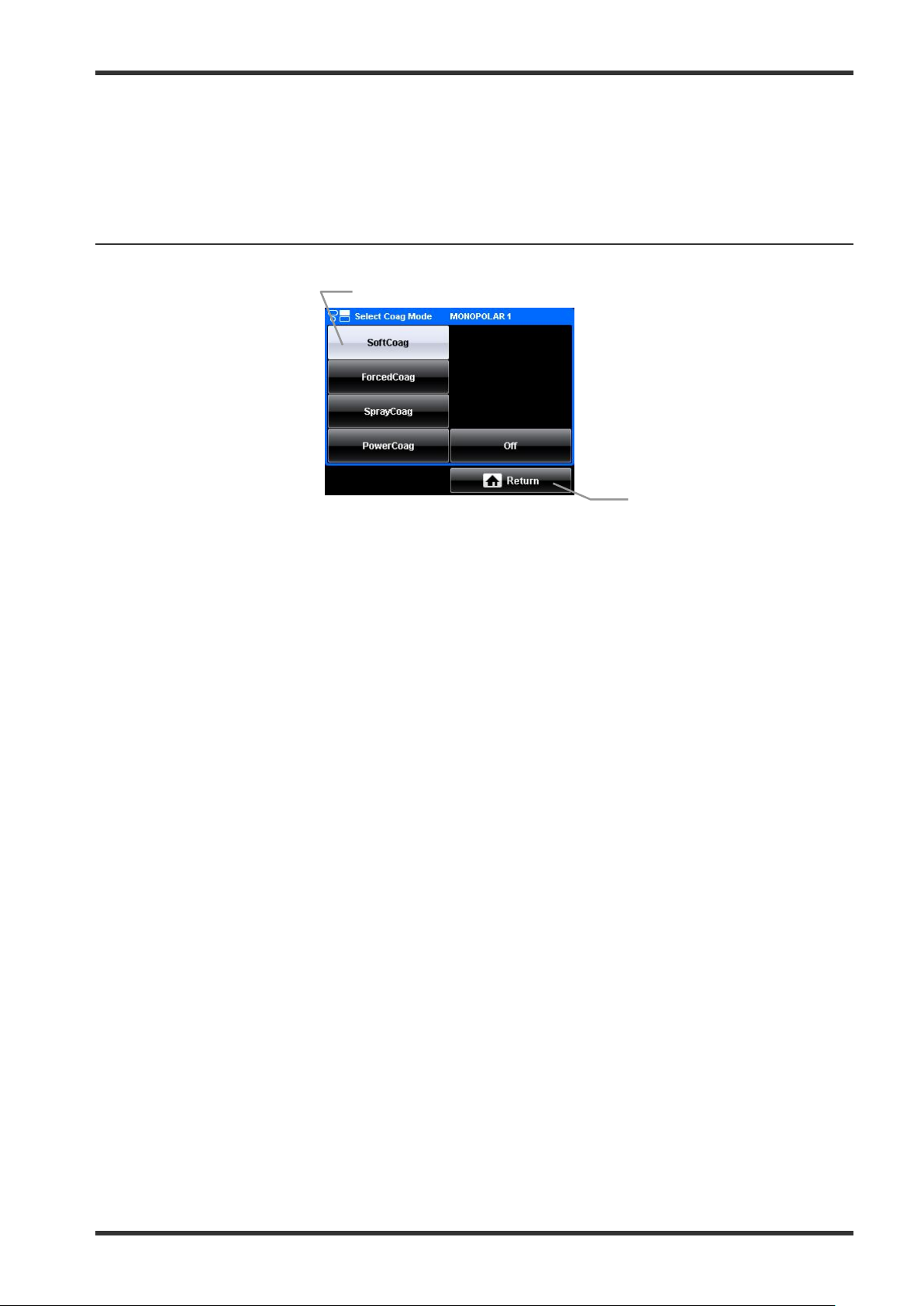

1.

Mode button

The name of the output mode as selected in the “Mode screen” is displayed here. Press this button to

switch to the “Mode screen”. If “Off” is selected,

“--“ will be displayed instead of power level and effect.

2.

Plus button / Minus button

These buttons increase / decrease the output power level.

3.

Toggle button

This button switches to the next effect.

4.

Return button

Press this button to save the settings and to return to the “All screen.”

5.

Output power level

1.

5.

2.

2

6.

3.

4.

5-6 Set screen

7.022.211 / ISSUE 4 26 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 27

The number shows the selected output power level. If an output power level is set to zero, “--” will be

displayed instead of numbers.

6.

Effect

The number shows the selected effect. For RFCoag mode the RCAP function can be selected instead

of an effect (refer to chapter 5.3, “Output setting”)

1.

Mode button

These buttons allow the mode selection for a corresponding output socket as shown in the title line. If

a selection is already activated, this is indicated by a gray button. If no mode shall be selected, press

the “Off button.”

2.

Return button

Press this button to return to the “Set screen.”

1.

2.

5-7 Mode screen

ESG-400

7.022.211 / ISSUE 4 27 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 28

1.

Cut pedal (yellow color)

This pedal is used to activate the selected cutting mode.

2.

Coagulation pedal (blue color)

This pedal is used to activate the selected coagulation mode.

3.

Footswitch plug

Connects the footswitch with the electrosurgical generator on the rear panel.

1.

Coagulation pedal (blue color)

This pedal is used to activate the selected coagulation mode.

2.

Footswitch plug

Connects the footswitch with the electrosurgical generator on the rear panel.

1.

2.

3.

1.

2.

5-8 Footswitch with two pedals

The footswitch with two pedals (Olympus REF: WB50402W) is included in delivery.

ESG-400

5-9 Footswitch with one pedal (optional)

The footswitch with one pedal (Olympus REF: WB50403W) is an optional item which may be purchased

separately.

7.022.211 / ISSUE 4 28 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 29

5-10 Neutral electrode cable “P-cord” (optional)

1.

Lever-locking arm

This arm secures the connector of the neutral electrode with the clamp.

2.

Clamp

This clamp connects the neutral electrode to the “P-cord”.

3.

Plug on the electrosurgical generator side

This plug connects the “P-cord” to the electrosurgical generator.

1.

2.

3.

The neutral electrode cable “P-cord” (Olympus REF: MAJ-814) is an optional item for the connection with a

neutral electrode which may be purchased separately.

ESG-400

7.022.211 / ISSUE 4 29 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 30

Pinning of connector 13 Docking

Connector - view of connector side

(bottom view) of ESG-400

1

2 4 3

1 Hand Cut

2 Hand Coag

3 Active electrode

4 Active electrode

1 Hand Cut

2 Hand Coag

3 Active electrode

4 Cut+Coag+Active electrode (top)

1 2 3

4

6 Connector

6-1 Docking Connector

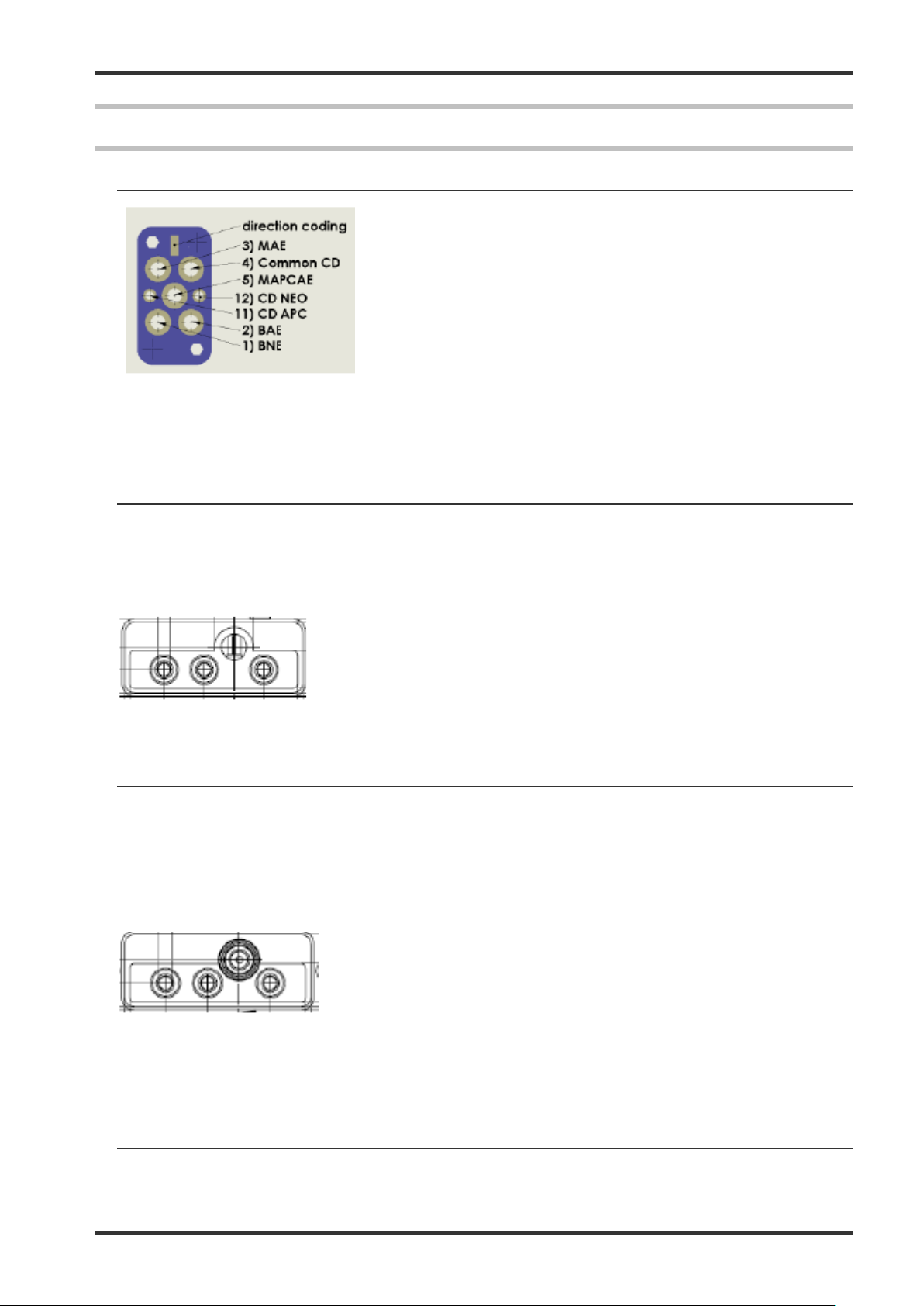

1) BNE – Bipolar Neutral Electrode

2) BAE – Bipolar Active Electrode

3) MAE – Monopolar Active Electrode

4) Common CD – Common ground for connection detection

5) MAPCAE – Monopolar Active Electrode

11) CD APC – Active pin for connection detection

12) CD NEO – Active pin for connection detection

6-2 Monopolar Standard 1

Type: 3 pin Valleylab, pin diameter = 4mm

1 pin BOVIE, pin diameter = 8 mm

Function: Monopolar output

Finger switch input (only for Valleylab: cut and coag)

ESG-400

6-3 Monoploar Standard 2 (Erbe)

Type: 3 pin Valleylab, pin diameter = 4mm

Coaxial ERBE, pin diameter = 5 mm (inner) and 9 mm (outer)

Function: Monopolar output

Finger switch input (cut and coag)

6-4 Bipolar Standard 3

Type: 2 pin socket, pin diameter = 4mm / pin distance 28.8 mm

Coaxial socket, pin diameter = 4 mm (inner) and 8 mm (outer)

7.022.211 / ISSUE 4 30 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 31

Function: Bipolar output

1 Neutral electrode

2 Active and neutral electrode

1

2

Pin 3

Pin 2

Pin 4

Pin 5

Pin 6

Pin 1

B (COAG)

A (CUT)

(coding)

Pin 7 - NC

(coding)

Com

ESG-400

6-5 Monopolar Neutral Electrode

Type: 2 pins socket, Pin diameter = 2.5 mm, Pin distance = 10 mm

Function: Monopolar output

CQM input

Principle sketch of connector 5 Neutral Electrode

6-6 Foot switch 1 (SIP/SOP)

Type: Foot switch, 7-pol.

Pinning of foot switch connector

7.022.211 / ISSUE 4 31 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 32

6-7 Foot switch 2 (SIP/SOP)

Left Pedal

Right Pedal

L

Com

L/R

R

M

Type: Foot switch, 7-pol.

ESG-400

Activation detection of foot switch

7.022.211 / ISSUE 4 32 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 33

ESG-400

WARNING

7 System Diagram

The recommended combinations of ancillary equipment and accessories that can be used with the

electrosurgical generator are listed in the system chart below. In addition, new products released after the

introduction of this product may also become compatible with this electrosurgical generator. For further details,

contact Olympus.

7.022.211 / ISSUE 4 33 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 34

8 Cleaning, storage and disposal

WARNING

After cleaning the electrosurgical unit, dry it thoroughly before storage or using

it again. If it is used while still wet, there is a risk of electric shock.

Patient debris and reprocessing chemicals are hazardous. During cleaning

and disinfection, always wear appropriate personal protective equipment, such

as eye wear, face mask, moisture-resistant clothing and chemical-resistant

waterproof gloves that fit properly so that your skin is not exposed. Always

remove contaminated protective clothing before leaving the reprocessing area.

CAUTION

When disconnecting plugs of instruments or power cords, always hold the

plug. Pulling the cable may result in damaging of the wires.

Never immerse the electrosurgical unit in water, clean or disinfect by

immersion, gas sterilization or autoclaving. It may cause equipment damage.

Do not clean the connectors or the alternating current power inlet. Cleaning

them can deform or corrode the contacts, which could damage the

electrosurgical unit.

Do not wipe the external surface with hard or abrasive wiping material. The

surface will be scratched.

The electrosurgical unit may be contaminated with infections materials, therefore, before servicing, perform the

following cleaning procedures. For maintenance and storage of other items than those described below, refer to

the respective instructions for use.

8-1 Cleaning

All surfaces of the unit’s housing can be cleaned and disinfected with the cleaning agents and surface

disinfectants normally used for medical equipment (mild cleaning solution, e.g. 70 % isopropyl alcohol). No

liquid must enter the connector or the unit during cleaning.

1) Switch off the electrosurgical unit and disconnect the power cord from the grounded wall outlet.

2) If the equipment and / or accessories are contaminated with blood or other potentially infectious materials,

first wipe off all gross debris using neutral detergent, and then wipe its surface with a lint-free cloth

moistened with a surface disinfectant.

3) To remove dust, dirt and non-patient debris, wipe the electrosurgical unit and footswitch using a soft,

lint-free cloth moistened with 70 % ethyl or isopropyl alcohol.

ESG-400

7.022.211 / ISSUE 4 34 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 35

8-2 Storage

CAUTION

Do not store the electrosurgical unit in a location exposed to direct sunlight,

x-rays, radioactivity, liquids or strong electromagnetic radiation (e.g. near

microwave medical treatment equipment, short-wave medical treatment

equipment, magnetic resonance imaging equipment, radio or mobile phones).

Damage to the electrosurgical unit may result.

Before storage of the electrosurgical unit, disconnect the power cord and store it properly according to the

environmental conditions described in chapter 1.4 (Technical data).

8-3 Disposal of the unit

When disposing of this electrosurgical unit, or any of its components (such as fuses), follow all applicable

national and local laws and guidelines.

Waste electrical and electronic equipment

In accordance with European Directive 2002/96/EC on waste electrical and electronic equipment (WEEE), the

product must not be disposed of as unsorted municipal waste, but should be collected separately.

ESG-400

Refer to Olympus for return and / or collection systems available in your country.

7.022.211 / ISSUE 4 35 / 99 Chapter 1: PRODUCT SPECIFICATIONs

Page 36

ESG-400

7.022.211 / ISSUE 4 36 / 99 Chapter 2: Block Description

Page 37

ESG-400

CHAPTER 2: BLOCK DESCRIPTION

1 BLOCK DESCRIPTIONS .............................................................................................. 38

1-1 Motherboard ..................................................................................................................................... 39

1-2 HVPS Board ..................................................................................................................................... 41

1-3 Generator board ............................................................................................................................... 41

1-4 Relay Board ..................................................................................................................................... 41

1-5 Front Panel ....................................................................................................................................... 42

7.022.211 / ISSUE 4 37 / 99 Chapter 2: Block Description

Page 38

ESG-400

Fig. 2.1.1. Block descriptions

1 Block Descriptions

7.022.211 / ISSUE 4 38 / 99 Chapter 2: Block Description

Page 39

1-1 Motherboard

Due to the containing embedded PC the Motherboard is the central unit of the ESG-400. The Motherboard

controls the Relay Board, the HVPS Board and the Generator Board. It contains all input and output interfaces

to the user as well as to other medical devices or computers. Additionally functionalities off the board are the

low voltage supplies for the complete unit, the mains input including filters and the measuring part of the

voltage line selection circuit for switching between 115 and 230 VAC.

Overview:

Embedded PC incl. periphery

Embedded PC with MPC5200 controller (incl. address and data bus, chip selects,

interrupt inputs, I2C, SPI, in-/output ports, uarts, timer)

Watchdog circuit

Chip select decoder

Hardware reset

JTAG interface

Real time clock

ESG-400

POF interface for the spark monitor

Digital input and output circuits

D/A converters for controlling the HVPS

A/D converters for measuring different signals from Relay, HVPS and Generator, temperatures and

watching on important voltages

Connections/Interfaces:

To the PCBs Relay, HVPS and Generator

Push buttons for user inputs on the front panel

Volumeboard for changing the speaker volume

Power Indicator shows power-on of the unit on the front

CQM Indicator shows status of CQM on the front

Controlling and driving the main housing fan

Audio circuit incl. D/A converter and amplifier for sound

Graphic controller with driver and backlight for the front display

Touch controller for the touch display

Ethernet controller and connector for external connections

RS-232 with connector for external connections

USB host with transceiver and connector for external connections

FlexRay controller, transceiver and connector for external connections

Connectors for footswitch incl. detection and analysis circuit

Connectors for handswitches incl. activation detection circuits

Instrument recognition circuit for instruments connected to the universal socket

Detection circuit for devices connected to the docking connector

7.022.211 / ISSUE 4 39 / 99 Chapter 2: Block Description

Page 40

ESG-400

Low voltage supplies

Switching regulators for -12 VDC, +5 VDC and +3,3 VDC (5 V and 3,3 V cascaded)

DC/DC converters for isolated +12 VDC and +5 VDC SIP/SOP voltages

Batteries for a permanent +3 V voltage for RTC and SRAM

Reference voltage of 8,192 V

Mains input

Input filters

Inrush current limiter

Mains voltage measurement and output signal for a selection circuit on the HVPS

7.022.211 / ISSUE 4 40 / 99 Chapter 2: Block Description

Page 41

1-2 HVPS Board

The high voltage power supply (HVPS) is a switching mode power supply with series resonance circuit. It

provides a high DC voltage for the HF Generator. It contains:

voltage line selection circuit, for automatic change between 110/230 VAC

simple rectifier circuit

PWM driving circuit

driving circuits including a digital flip-flop stage for complete cycle driving

power FET half-bridge, a series resonance circuit, output transformer and rectifying stage

current and voltage monitors

discharge circuit

1-3 Generator board

The Generator Board generates the HF output energy from a DC input voltage and contains:

control circuit for generating start and driving pulses of “one cycle” sinus oscillator

ESG-400

driving stage for power FET, parallel resonance circuit and series resonance circuit

relays for switching between different transformer windings

HF output voltage monitor and redundant HF voltage monitor

HF output current monitor and redundant HF current monitor

HF output phase monitor

HF leakage current monitor

spark monitor (SPM) supply circuit

spark monitor for detecting positive and negative DC voltage offset

1-4 Relay Board

The Relay board is used to connect the active output socket to the generator board. It contains:

connectors to every single HF output socket

relays which are separating the non active output terminals from the active output terminals

separating relays are forced guided relays with read-back contact in secondary circuit to control the relay

status

contact quality monitor (CQM)

transient voltage suppression (TVS) diodes in applied part

7.022.211 / ISSUE 4 41 / 99 Chapter 2: Block Description

Page 42

1-5 Front Panel

The Front Panel is the main part of the user interface. It contains:

LCD touch screen

Push Buttons

Contact Quality Monitor

BIPOLAR socket

MONOPOLAR 1 socket Valleylab & Bovie

MONOPOLAR 2 socket Valleylab & Erbe

UNIVERSAL socket

Socket for neutral electrode

ESG-400

7.022.211 / ISSUE 4 42 / 99 Chapter 2: Block Description

Page 43

ESG-400

CHAPTER 3: REPAIR SYSTEM

1 ESG-400 MAIN UNIT .................................................................................................... 44

2 BOARD COMPATIBILITY ............................................................................................. 44

3 OPTIONAL ACCESSORIES ......................................................................................... 44

3-1 WB50402W (Footswitch with two pedals) ....................................................................................... 44

3-2 WB50403W (Footswitch with one pedal) ......................................................................................... 44

3-3 MAJ-814 (Neutral electrode cable “P-cord”) .................................................................................... 44

4 PRECAUTIONS ON FUNCTION AND OPERATION SETTINGS ................................. 44

4-1 General Precautions ........................................................................................................................ 44

7.022.211 / ISSUE 4 43 / 99 Chapter 3: Repair System

Page 44

1 ESG-400 Main Unit

(1) In general, the main unit must be shipped to a service center in the event of a malfunction.

(2) Individual units can be replaced.

2 Board Compatibility

The compatibility of boards and components is dependent on the hardware version of the generator. The

hardware version can be indentified by the serial number of the generator.

The serial number starting with 5 numbers, hardware version with WXX and followed by 3 numbers after the

hyphen.

Example: XXXXXWYY-ZZZ, WYY will show the hardware version.

3 Optional Accessories

3-1 WB50402W (Footswitch with two pedals)

Supplied as a spare part subject to repair services in the event of a malfunction.

3-2 WB50403W (Footswitch with one pedal)

Supplied as a spare part subject to repair services in the event of a malfunction.

3-3 MAJ-814 (Neutral electrode cable “P-cord”)

Supplied as a spare part subject to repair services in the event of a malfunction.

ESG-400

4 Precautions on Function and Operation Settings

4-1 General Precautions

Before repair, it is generally advisable to record the function and operation settings as the basis for restoring

these settings after service.

If the original settings cannot be known due to mechanical problems present at the time the unit was accepted

for repair, apply the factory-set values or the safest settings (such as the lowest output levels). In this case,

inform the user that the settings have been changed.

7.022.211 / ISSUE 4 44 / 99 Chapter 3: Repair System

Page 45

ESG-400

CHAPTER 4: TROUBLESHOOTING

1 GENERAL ..................................................................................................................... 46

2 NEUTRAL ELECTRODE OPERATION ........................................................................ 47

3 ERROR SCREEN, CODES AND MEASURES ............................................................. 48

3-1 What to do when no error code is displayed .................................................................................... 50

3-2 What to do when an error code is displayed .................................................................................... 54

7.022.211 / ISSUE 4 45 / 99 Chapter 4: Troubleshooting

Page 46

ESG-400

DANGER

Never use the electrosurgical unit if an abnormality is suspected.

CAUTION

Repairs must only be carried out by Olympus or a firm authorized by Olympus.

CAUTION

Preventive maintenance (inspection / periodic safety check) must only be

carried out by a qualified person / technician.

1 General

If the electrosurgical unit has visible damage, do not use the electrosurgical unit and contact the legal

manufacturer. If the unit is not functioning properly, use the information in this chapter to identify and correct the

malfunction. If the problem cannot be resolved by the described remedial action, stop using the electrosurgical

unit and contact the legal manufacturer for repair.

7.022.211 / ISSUE 4 46 / 99 Chapter 4: Troubleshooting

Page 47

Contact quality monitor

Mode

Indication

Bipolar application

Standby and activation

A neutral electrode is not required. Contact

quality monitor indicator for split neutral

electrode illuminates red.

Monopolar application

A non-split neutral electrode is

connected. Activation is possible.

Contact quality monitor detects

connection of neutral electrode.

If a split neutral electrode is

connected, it has a short circuit.

Immediately replace the neutral

electrode!

Contact quality monitor indicator for non-split

neutral electrode illuminates green.

A split neutral electrode is connected.

Activation is possible. Contact quality

monitor detects connection of neutral

electrode and contact to patients’ skin.

Contact quality monitor indicator for split

neutral electrode illuminates green.

During standby: A split or a non-split

neutral electrode is not connected or a

split neutral electrode detaches.

Activation is disabled.

During activation: A split or a non-split

neutral electrode has disconnected or a

split neutral electrode detaches. The

activation is stopped.

Contact quality monitor indicator for split

neutral electrode illuminates red.

During activation an alarm signal can be

heard and the touch-screen will display an

error window (E202).

2 Neutral electrode operation

Check the following table, to identify or correct failures regarding the neutral electrode operation.

ESG-400

Legend: Red illumination of the indicator

Green illumination of the indicator

7.022.211 / ISSUE 4 47 / 99 Chapter 4: Troubleshooting

Page 48

ESG-400

Error category

Error condition priority

Indicator (“caution”)

symbol condition

High priority

Immediate user response

is required

Flashes in red color

Medium priority

Prompt user response

is required

Flashes in yellow color

Low priority

Awareness of the user

is required

Constant on in yellow color

Error code

Remedial actions

Caution symbol

Error title

Error window

(Example: E002 Short circuit)

Fig. 4.3.1. Error Screen

3 Error screen, codes and measures

Follow the troubleshooting advices in this chapter, to identify or correct failures. The error window is configured

as shown in figure below.

If an error occurs (see Fig. 4.3.1):

An error window will appear and an alarm signal is audible.

A short message with the error code, error title and a description of the remedial action will be displayed.

The error code consists of an error number shown under the “caution” symbol.

Depending on the error priority, the condition of the audible signal and the “caution” symbol are different

(see Table 4.1).

Proceed with the described remedial action.

The error window disappears after a few seconds, if the error is cleared.

If the error window is still displayed, the error is not cleared. Proceed with the next remedial action if

available.

Table 4.1: Error priorities and the corresponding indicator symbol condition

7.022.211 / ISSUE 4 48 / 99 Chapter 4: Troubleshooting

Page 49

ESG-400

NOTE

The electrosurgical generator is equipped with an

intelligent alarm system which determines alarm

conditions on the base of multiple variables. Depending

on the risk potential, alarms are classified in “high

priority”, “medium priority” and “low priority” alarms. An

alarm of higher priority overrides an existing alarm of

lower priority. If more than one alarm situation of equal

priority is determined, the one that occurred first is

displayed only. This electrosurgical generator complies

with the IEC 60601-1-8: 2006.

7.022.211 / ISSUE 4 49 / 99 Chapter 4: Troubleshooting

Page 50

3-1 What to do when no error code is displayed

Situation

Possible cause

Remedial action

The electrosurgical

generator does not

respond after

pressing the power

switch.

Improper connection of the power cord to

the AC power socket on the rear panel of

the electrosurgical generator or to the

grounded wall outlet.

Check the power cord and the grounded wall

outlet for correct connection.

The grounded wall outlet has wrong or

not output voltage.

Check the grounded wall outlet or use an

alternative grounded wall outlet.

The power cord is damaged.

Check the power cord for damages and, if

necessary, replace the power cord.

Malfunction of the electrosurgical

generator.

Contact the legal manufacturer.

The touch-screen

remains dark after

switching the

electrosurgical

generator on (sound

is audible after

switching on).

Malfunction of the touch-screen.

Contact the legal manufacturer.

The touch-screen

cannot be controlled.

An object is in contact with the

touch-screen.

Remove the object.

The touch-screen is not properly

calibrated.

Contact the legal manufacturer.

Malfunction of the touch-screen.

Stop using the electrosurgical generator and

press the power switch to turn off the

electrosurgical generator. Contact the legal

manufacturer.

The electrosurgical

generator does not

react when a push

button on the front

panel is pressed

during standby.

A push button is already pressed.

Release the push button.

Malfunction of the electrosurgical

generator.

Contact the legal manufacturer.

The electrosurgical

generator does not

react when a (push)

button on the front

panel is pressed

during activation.

The (push) buttons are not available

during activation.

Release the footswitch or hand switch to stop

the activation.

Perform the indicated remedial actions below. If the problem cannot be resolved by the described remedial

action, contact the legal manufacturer.

ESG-400

7.022.211 / ISSUE 4 50 / 99 Chapter 4: Troubleshooting

Page 51

ESG-400

Situation

Possible cause

Remedial action

No sound is audible

during activation.

The volume is set to an inaudible level

(e.g. due to high environmental noise).

Increase the volume either on the touch-screen

within the “Menu screen” or use the volume

control on the rear panel of the electrosurgical

generator.

Malfunction of the electrosurgical

generator.

Stop using the electrosurgical generator and

press the power switch to turn off the

electrosurgical generator. Contact the legal

manufacturer.

The volume can not

be adjusted via the

volume control within

the “Menu screen” or

at the rear panel.

The volume of the error-related audible

signal is not adjustable.

No action required.

Malfunction of the electrosurgical

generator.

Contact the legal manufacturer.

The electrosurgical

generator does not

respond to footswitch

or handswitch

activation.

Improper connection of the footswitch to

one of the footswitch sockets on the rear

panel of the electrosurgical generator or

the HF instrument to the output socket.

Check the footswitch and the HF instrument for

correct connection.

The footswitch or the handswitch of the

HF instrument and / or the connection

cable are damaged.

Check the footswitch or the handswitch of the