BuildingEnvelope

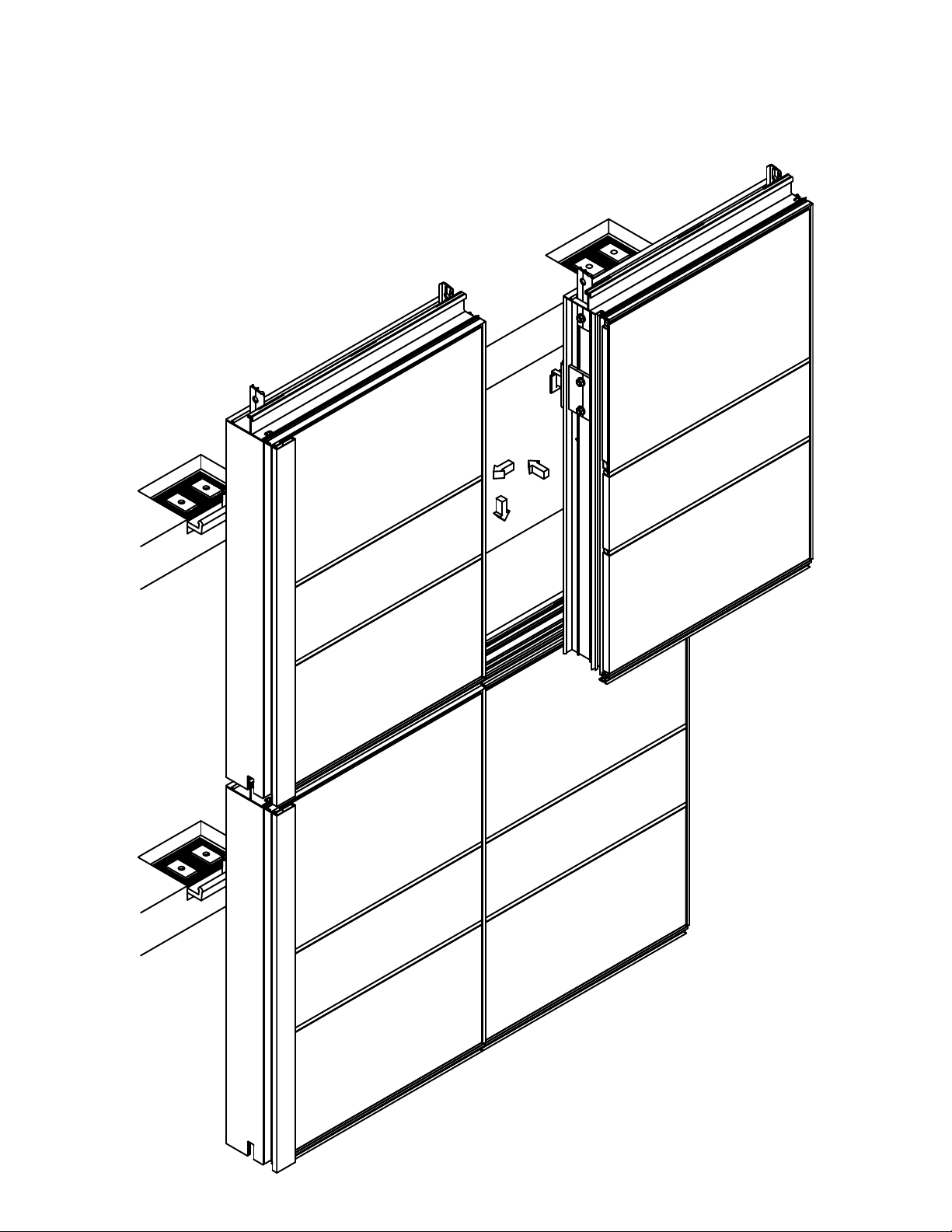

SIGNATURE SERIES UNIT WALL

INSTALLATION MANUAL

®

JULY 2013

Note: Installation Manual is product specific:

FOR REFERENCE ONLY

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

July 2013 00-Assembly-Detail 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

TABLE OF CONTENTS

SHEET

GENERAL INFORMATION

Product Use

Protection and Storage

Check Material

Field Conditions

Cleaning Materials

Expansion Joints

LAYOUT MULLION AND ANCHOR CENTERLINES

Check Structural Opening

Layout Mullion and Anchor Centerlines

3

3

3

4

4

4

5

5

LOCATE AND INSTALL ANCHORS

INSTALL ANCHOR HOOKS

HOISTING FRAMES

STARTER SILL CONDITION

Install Starter Sill

Check and Properly Locate PVC Spacers

Proper Seal at Starter Sill

Install Horizontal Air Seal Gasket

INSTALL GROUND FLOOR FRAMES

Install the First Frame

Install Adjacent Frames at Ground Floor

INSTALL UPPER LEVEL FRAMES

Seal the Joint

Install Horizontal Air Seal Gasket

Seal Hoisting Holes for Windload Anchor Lug Option

Install First Frame at Upper Level

Install Adjacent Frames at Upper Level

6

7

8-9

10

10

10-11

12

13-14

15-16

17

17

18

19

20-21

JAMB FRAME CONDITION

July 2013 00-Table-of-Contents 1-866-Oldcastle (653-2278) www.oldcastlebe.com

22

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

GENERAL INFORMATION

PRODUCT USE

The unitized curtain wall system is intended for installation by glazing professionals with appropriate

experience. Subcontractors must be qualified to provide field instruction and project management.

Oldcastle BuildingEnvelope does not control the application of its product configurations, sealant or

®

glazing material and assumes no responsibility for the application. It is the responsibility of the owner,

architect and installer to make these selections in strict compliance with applicable laws and building

codes.

Consult silicone sealant manufacturer for review and recommendation of sealant application. Follow

sealant manufacturer's recommendations and literature for proper cleaning, testing and application of

silicone sealant.

The air and water performance of the unitized curtain wall is directly related to the completeness and

integrity of the installation process. To ensure top performance for this system, particular attention

should be given to the following procedures:

1. Surface to be sealed should be cleaned with isopropyl alcohol or solvent and dried as

recommended by sealant manufacturer to remove dirt and cutting oils.

2. Vertical movement of mullion at intermediate floors requires special expansion joints and glazing

materials. The system permit maximum +/-3/4" movement. For designs and applications that may

require greater movement or special considerations, please contact your local Oldcastle

BuildingEnvelope facility.

®

Variations on the details shown may occur, but are not the responsibility of Oldcastle

BuildingEnvelope.

®

PROTECTION AND STORAGE

Handle all material carefully. Do not drop from the truck, stack with adequate separation so the

material will not rub together. Store material off the ground, protecting against the elements and other

construction hazards by using a well ventilated covering. Remove material from package if wet or

located in a damp area. For further guidelines consult AAMA publication "Care And Handling of

Architectural Aluminum From Shop To Site".

CHECK MATERIAL

Check all material upon arrival at job site for quality and to determine any shipping damage. Using the

contract documents, completely check the surrounding conditions that will receive your materials.

Notify the general contractor by letter of any discrepancies before proceeding with the work. Failure to

do so constitutes acceptance of work by other trades.

July 2013 03-General-Info 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

Check shop drawings, installation instructions, architectural drawings and shipping lists to become

familiar with the project. The shop drawings take precedence and include specific details for the

project. The assembly and installation instructions are of a general nature and cover the most

common conditions.

Due to varying job conditions all sealant must be approved by the sealant manufacturer to ensure it

will perform per conditions shown on the instructions and shop drawings. The sealant must be

compatible with all surfaces in which adhesion is required, including other sealant surfaces. Use

primers where directed by sealant manufacturer. Properly store sealant at the recommended

temperatures and check sealant for expiry and shelf life before using.

FIELD CONDITIONS

All material to be installed must be plumb, level and true. Aluminum to be placed in direct contact with

masonry or incompatible material should be isolated with a heavy coat of zinc chromate, bituminous

paint or non-metallic material unless otherwise specified. After sealant is set and a representative

amount of the wall has been glazed (250 sq. ft. or more), perform a water hose test in accordance

with AAMA 501.2 "Field Check of Metal Storefront, Curtain Walls and Slope Glazing Systems for

Water Leakage". On large projects the hose test must be repeated during the glazing operation.

Review anchors or embeds in structure as early as possible to confirm that 'as built' building structure

can accommodate anticipated anchor tolerances.

CLEANING MATERIALS

Cement, plaster terrazzo, alkaline and acid based materials used to clean masonry are very harmful

to finishes. Any residue should be removed with water and mild soap immediately or permanent

staining will occur. A spot test is recommended before any cleaning agent is used. Refer to the

architectural finish guide in the detail catalogue.

EXPANSION JOINTS

Expansion joints and perimeter joints shown in these instructions and in the shop drawings are shown

at nominal size. Actual dimensions may vary due to perimeter conditions and/or differences in metal

temperature between the time of fabrication and the time of assembly/installation. For example, a 12

foot unrestrained length of aluminum can expand or contract 3/32" over a temperature change of 50

degrees F. Any movement potential should be accounted for at the time of the assembly and

installation.

July 2013 04-General-Info 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

LAYOUT MULLION AND ANCHOR CENTERLINES

GENERAL NOTE:

FRAMES ARE INTENDED TO BE INSTALLED FROM LEFT TO RIGHT WHEN VIEWED FROM

EXTERIOR.

DETAILING IN THIS INSTALLATION MANUAL MAY VARY FOR SPECIFIC PROJECTS.

1. CHECK STRUCTURAL OPENING

Slab or beam elevation must be within adjustment of anchoring system.

Structural surfaces to receive anchoring system must be level and plumb within the adjustment limits

at head, sill and jamb. See approved shop drawings for allowable adjustment.

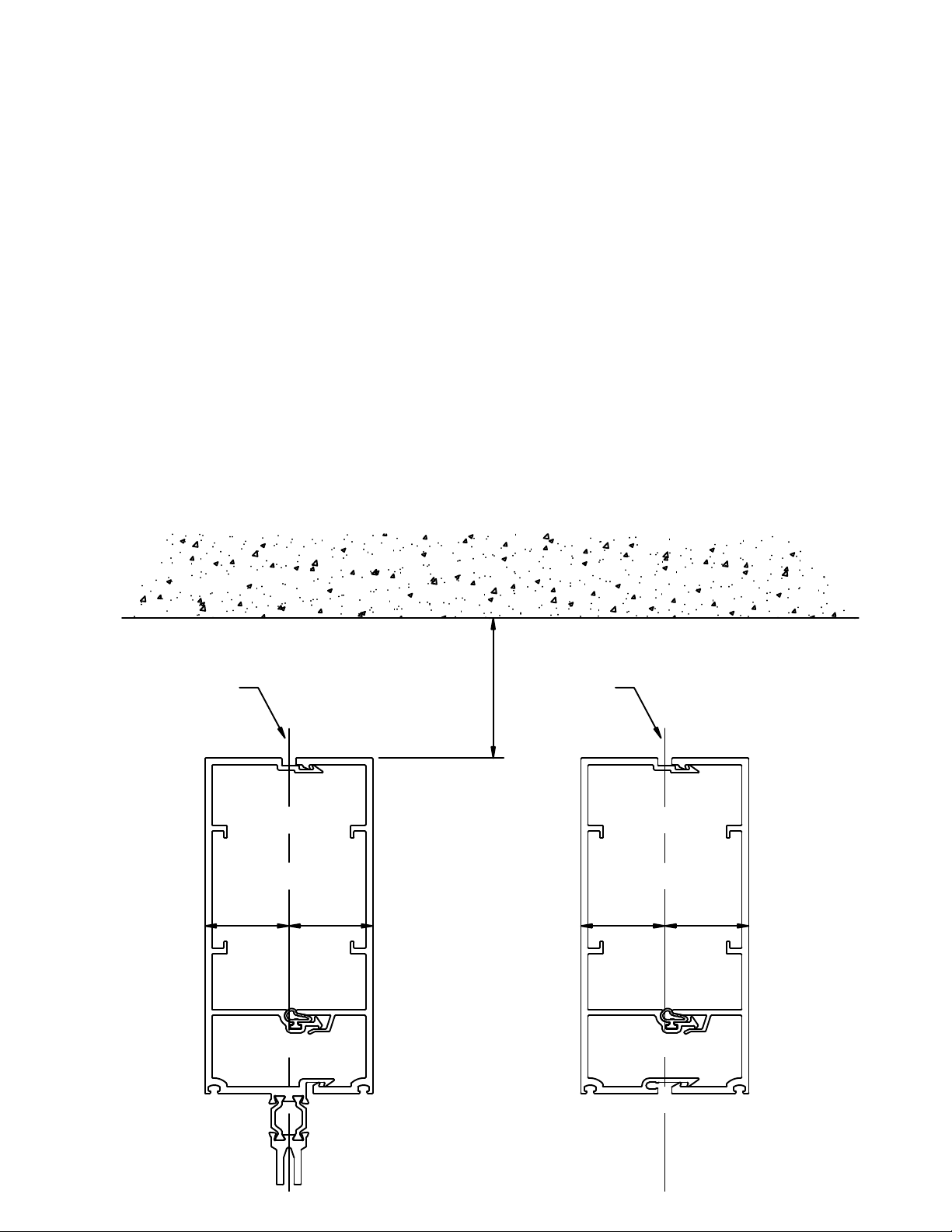

2. LAYOUT MULLION AND ANCHOR CENTERLINES

Centerline of

mullion

±1/32"

1 1/2" 1 1/2" 1 1/2" 1 1/2"

Face of slab/beam

Typical

captured

mullion

2.50"

±1" building

Centerline of

mullion

tolerances

±1/32"

Typical

SSG

mullion

July 2013 05-Mull-Anchor-Layout 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

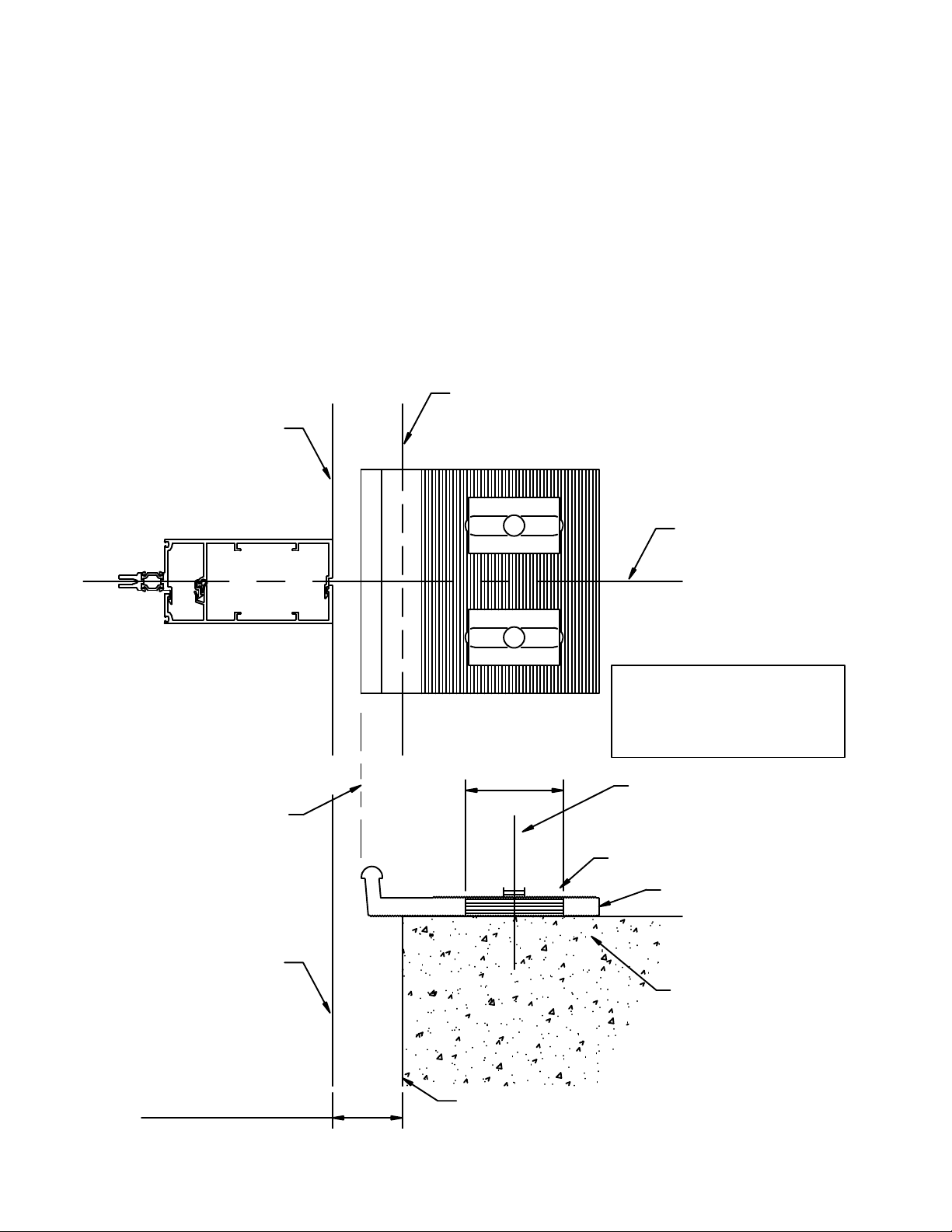

LOCATE AND INSTALL ANCHORS

1. LOCATE AND INSTALL ANCHORS

See approved shop drawings for anchor types and locations.

Locate centerline of aluminum anchor at the mark for centerline of mullion.

Adjust alum anchor bracket for in and out. Apply aluminum serrated washers. Make final in and out

adjustment prior to tightening the anchor bolt in place.

Face of slab/beam

Back of mullion

Location of this point

is CRITICAL! Field survey

may be required

Back of mullion

3 1/2" slot

for in/out adjustments

Mullion/anchor

centerline

Reference shop drawings for

actual anchor configuration

and/or project specific

information.

Anchor bolt (ref. shop drawings

for specific fastener info/torque

requirements)

Alum serrated washer

Alum anchor bracket

2 1/2"

±1" building tolerances

July 2013 06-Locate-Install-Anchors 1-866-Oldcastle (653-2278) www.oldcastlebe.com

Face of slab/beam

Reference field conditions.

Isolator required to prevent

galvanic reaction.

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL ANCHOR HOOKS

1. INSTALL ANCHOR HOOKS

Back off FS-341 stopping screw at the bottom of the anchor bracket, slide in the anchor hook.

Tighten up FS-341, the screw is to prevent anchor hook from sliding out of the anchor bracket during

frame installation.

Slide the anchor hook

into anchor bracket

Tighten up FS-341

stopping screw

after anchor hook

installation

July 2013 07-Install-Anchor-Hooks 1-866-Oldcastle (653-2278) www.oldcastlebe.com

r

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

HOISTING FRAMES

SAFETY PROCEDURES ARE THE SOLE RESPONSIBILITY OF THE INSTALLER. OLDCASTLE

BUILDINGENVELOPE ASSUMES NO RESPONSIBILITY FOR PROJECT SAFETY

®

PROCEDURES.

1. HOISTING FRAMES

Frames can be hoisted either through anchor lugs (shear angle) installed in frame head horizontals o

through sleeves attached to the mullion halves.

Inspect frames prior to hoisting. For illustration purposes only, a spreader bar is shown as a hoisting

device. Other lifting devices can be used. Means & methods are the sole responsibility of the

installler. The spreader bar chains should be spaced the same distance as the distance between

hoisting holes in head horizontal or hoisting holes on sleeves. Maximum frame weight to be less than

1500 pounds.

Handle frame to hoist smoothly and in a controlled manner, no swinging or spinning allowed during

hoisting. Avoid shock loads.

Spreader bar should indicate hoisting configuration depending on frame weight. Ensure hoisting bar

is rated for frame weight configuration as required.

Adjust the spreader bar

to have chains spaced

the same distance

as the hoisting holes

Sleeve

HOIST THROUGH

SLEEVES

July 2013 08-Hoisting-Frames 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

HOISTING FRAMES

See notes on previous page

Windload anchor lug

HOIST THROUGH

WINDLOAD

ANCHOR LUGS

July 2013 09-Hoisting-Frames 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

STARTER SILL CONDITION

1. INSTALL STARTER SILL

Locate starter sill per approved shop drawings. The starter sill must be level and straight. The starter

sill should run continuously across elevation, whenever the splicing is necessary, a min. 3/16" gap

should be left for proper seal in-between starter sills.

Install windload anchor lug at each mullion location, crimp the windload anchor lug in place on starter

sill. Install starter sill fasteners. Ensure fastener heads will not interfere with frame sill horizontals.

Seal over all fastener heads and tool sealant.

Requires a min. 3/16" gap

at splice joint

for proper seal

Ensure starter sill fixing bolt

will not interfere with frame

sill horizontals

The windload anchor lug

should be crimped in place

at every mullion location

2. CHECK AND PROPERLY LOCATE PVC SPACERS

The 4" long V927 rigid PVC spacers should be pre-assembled on each starter sill. Three pieces of

PVC spacers are required per module. One should be located at center of the module, two other

pieces should be located at each mullion location.

3. PROPER SEAL AT STARTER SILL

Clean and prepare substrates for sealing per sealant manufacturer's recommendations. Apply backer

rod and perimeter seals under starter sill. Tool sealant. Apply sealant at splice joints. All splice joints

should be sealed from the drainage hole on the starter sill to the top of the upturned leg. Connect

sealant at underside of starter sill with sealant at splice joint. See illustration on p.11.

Apply sealant at outer surface for approximately 1" on each side of the joint as shown; set 1-1/2" wide

by 3" long silicone sheet on top of the silicone sealant.

July 2013 10-Install-Starter-Sill 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

STARTER SILL CONDITION

Seal from the drain hole

to the top of the upturned leg

Marry the sealant

at underside of starter sill

with sealant at splice joint

Set the 1-1/2" wide silicone

sheet in silicone sealant

at starter sill joint location

Apply sealant at each end of starter sills

for receiving 1-1/2" wide silicone sheet

tool sealant

July 2013 11-Seal-Starter-Sill 1-866-Oldcastle (653-2278) www.oldcastlebe.com

4. INSTALL HORIZONTAL AIR SEAL GASKET

Clean areas to receive sealant as per sealant manufacturer's recommendations. Install horizontal air

seal gasket GP-50041 into starter sills continuously across elevation. Where splicing is necessary,

locate the joint at mid-point of the module, apply bead of sealant to set the ends of gasket in place.

Tool squeeze out sealant.

Note silicone must adhere to EPDM gasket e.g. Dow 756 silicone sealant. Ensure fingers of

horizontal air seal gaskets are not filled with silicone as this will hamper frame installation.

Tool excess sealant

out of fingers

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

STARTER SILL CONDITION

Locate the joint of

horizontal air seal gasket

at mid-point of the module

V-927 PVC spacers

(3) pieces per module

Set the ends of gasket

in silicone

Set the ends of EPDM gasket

in silicone;

tool squeeze out or add additional

sealant on outer surface

July 2013 12-Horiz-Air-Seal-Gasket 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL GROUND FLOOR FRAMES

1. INSTALL THE FIRST FRAME

Frames are installed from left to right and from bottom to top.

Before proceeding to installing first frame, check all starter sill joints to make sure they are properly

sealed and horizontal air seal gaskets have been applied.

Apply 3" to 6" long silicone sealant towards exterior portion of the horizontal air seal gasket on top of

starter sill at each end, flatten the sealant at top. Do not allow sealant to skin before installing frame.

Tool sealant flat on top

Apply 3" to 6" long of sealant

on top of starter sill

towards the exterior portion

of horizontal air seal gasket

Seal over all fastener

heads and tool sealant

July 2013 13-Install-First-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

r

INSTALL GROUND FLOOR FRAMES

Install the first frame by lifting the frame over starter sill and lower the frame down and rest the ancho

hook on pre-set alum anchor at slab/beam.

Use the adjustment bolt on anchor bracket to adjust the elevation of the frame. Adjust the elevation of

the frame to make sure the frame is level, plumb and at the correct height. After adjustment, freeze

the anchor hook for lateral movement by installing FS-339 #10 by 1/2" hex head screw. Use metal

shims if necessary to maintain the nominal distance between bottom of the mullion and top of the

starter sill. Remove shims after adjustment for slip anchor condition at ground floor.

Use the adjustment bolt

to adjust the elevation

of the frame

Install FS-339

to laterally freeze

anchor hook in place

July 2013 14-Install-First-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL GROUND FLOOR FRAMES

2. INSTALL ADJACENT FRAMES AT GROUND FLOOR

Just prior to installing the next frame, apply sealant at the bottom of the first frame up vertical air seal

gasket GP-50001 for approximately 4" long above horizontal air seal gasket. Connect the vertical seal

with the horizontal seal which was previously applied on top of the starter sill. Do not allow sealant to

skin before installing next frame.

Apply 4" long sealant

at the bottom of the mullion

along vertical air seal gasket

Connect vertical seal

with horizontal seal

-

"

3

4"

"

6

Install the next frame by lifting the frame up to clear the starter sill. Move the next frame to the left to

engage the outer mullion hooks; then rotate the next frame towards building to snap inner hooks;

once snapped, slide the next frame down to engage horizontal air seal at stack joint.

Again use the adjustment bolt to level the frame. Check and ensure vertical air seal gasket GP-50001

has not slid down in the gasket raceway in mullion.

Repeat in the same method for installing the rest of the frames at ground floor.

July 2013 15-Install-Adjacent-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL GROUND FLOOR FRAMES

1. Lift the next frame up to clear the starter sill

2. Move to the left to engage the outer hook

3. Rotate the frame towards the building

4. Engage the inner hook

5. Slide the next frame down to engage horizontal air seal

July 2013 16-Install-Adjacent-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL UPPER LEVEL FRAMES

1. SEAL THE JOINTS

Clean and prepare the surfaces of the head horizontal at mullion joints per sealant manufacturer's

commendations. Apply sealant completely along the entire joint between head horizontals; also apply

sealant at front face for approximately 1" on each side of the joint as shown; set 1-1/2" wide by 2-5/8"

long silicone sheet on top of the silicone sealant.

Completely seal the joint

between head horizontals

Neatly seal the joints

between trims

2. INSTALL HORIZONTAL AIR SEAL GASKET

Install horizontal air seal gasket GP-50041 into head horizontals continuously across elevation. Apply

sealant for approximately 3" long on each side of the splice joint, push gasket into raceway, tool

squeeze out sealant. Where splicing is necessary, locate the joint at mid-point of the module and

apply bead of sealant to set the ends of gasket in place. Push in the next piece of gasket, tool

squeeze out sealant and remove excess sealant from outer face.

Apply sealant at outer face

for approximately 1"

on each side of the joint

Set the 1-1/2" wide silicone

sheet in silicone sealant

at mullion joint location;

tool squeeze out

Apply sealant

on each side of splice joint

at gasket raceway

Locate the joint of

horizontal air seal gasket

at mid-point of the module

July 2013 17-Install-Upper-Level-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

Set the ends of the gasket

in silicone in place;

push in the next piece;

tool squeeze out sealant

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL UPPER LEVEL FRAMES

3. SEAL THE HOISTING HOLES FOR WINDLOAD ANCHOR LUG OPTION

For frames with windload anchor lug (shear angle) option, clean and prepare the surfaces of the head

horizontal at mullion joints; apply sealant completely along the entire joint between head horizontals;

also apply sealant at and around hoisting hole, set 2" by 2" alum plate at hoisting hole location.

Similar to frames with sleeve option, apply sealant to outer face for approximately 1" on each side of

the joint as shown; set 1-1/2" wide by 2-5/8" long silicone sheet on top of the silicone sealant.

Then install horizontal air seal gasket GP-50041 into head horizontals continuously across elevation.

Where splicing is necessary, to locate the joint at mid-point of the module and apply bead of sealant

and set the ends of gasket in place. Tool squeeze out sealant.

Apply sealant

at and around hoisting holes

for receiving the alum plates

Set alum plates

at hoisting hole locations

Set the 1-1/2" wide silicone

sheet in silicone sealant

at mullion joint location

Completely seal the joint

between head horizontals

Apply sealant at front face

for approximately 1"

on each side of the joint

For smoke seal condition,

seal the inboards of

splice joint and down

along back of mullion

until anchor locaiton

July 2013 18-Install-Upper-Level-Frame 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL UPPER LEVEL FRAMES

4. INSTALL FIRST FRAME AT UPPER LEVEL

Before proceeding to upper level, check all horizontal joints at lower level to make sure they are

properly sealed and horizontal air seal gaskets have been applied.

Apply a 3" to 6" long bead of silicone sealant towards exterior portion of the horizontal air seal gasket

on top of head horizontal at each end at the frame below, flatten the sealant at top; Install the first

frame at upper level by lifting the frame over head horizontal and lower the frame down.

Use the adjustment bolt on anchor bracket to adjust the elevation of the frame. Use shims if

necessary to maintain the nominal distance between bottom of the mullion and top of the head

horizontal. Remove shims after adjustment.

3" to 6" long

Flatten sealant at top

before lowering the frame

Apply 3" to 6" long of sealant

on top of head horizontal

towards the exterior portion

of horizontal air seal gasket

July 2013 19-Install-First-Frm-Upper-Level 1-866-Oldcastle (653-2278) www.oldcastlebe.com

3" to 6" long

For smoke seal condition,

seal along the back of the

mullion at splice joint

down to anchor

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL UPPER LEVEL FRAMES

5. INSTALL ADJACENT FRAMES AT UPPER LEVEL

Just prior to installing the next frame, apply sealant at the bottom of the first frame up vertical air seal

gasket GP-50001 for approximately 4" long above horizontal air seal gasket. Connect the vertical seal

with the horizontal seal which was previously applied on top of the head horizontal.

Smoke seal

Connect vertical seal

with horizontal seal

Apply 4" long sealant

at the bottom of the mullion

along vertical air seal gasket

4"

"

6

-

"

3

Smoke seal

Install the next frame by lifting the frame 4" to 6" above previous frame to clear the sleeves and head

horizontals. Move the next frame to the left to engage the outer mullion hooks; then rotate the next

frame towards building to snap inner hooks; once snapped, slide the next frame down to engage

horizontal air seal at stack joint.

Again use adjustment bolt on anchor bracket to adjust the elevation of the frame, then freeze the

lateral movement by installing FS-339 screw on anchor hook.

Repeat in the same method for installing the rest of the frames.

July 2013 20-Install-Adjacent-Frm-Upper-Level 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

INSTALL UPPER FLOOR FRAMES

1. Lift the next frame up to clear the sleeve

2. Move to the left to engage the outer hook

3. Rotate the frame towards the building

4. Engage the inner hook

5. Slide the next frame down to engage horizontal air seal

July 2013 21-Install-Adjacent-Frm-Upper-Level 1-866-Oldcastle (653-2278) www.oldcastlebe.com

SIGNATURE SERIES UNIT WALL INSTALLATION MANUAL

JAMB FRAME CONDITION

1. SEAL AT THE NOTCH ON JAMB MULLION

For jamb frames at expansion joints or starter sills, apply sealant at the notch on mullion above and

below the expansion joint. Set 4" wide by 6" long silicone sheet in place.

Set the 4" wide silicone

sheet in silicone sealant

at the notch on jamb mullion

tool sealant

Interior

Make sure to set

the end of the air seal

gasket in silicone

Interior

Make sure to set

the end of the air seal

gasket in silicone

July 2013 22-Jamb-Frame-Condition 1-866-Oldcastle (653-2278) www.oldcastlebe.com

Set the 4" wide silicone sheet

in sealant at the notch on jamb;

marry the sealant to sealant

at underside of starter sill

Loading...

Loading...