Olldcastlebe PW-180 User Manual

JULY 2011

Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

P W - 9 0 & P W - 1 8 0 S L I D I N G M A L L F R O N T

I N S T A L L A T I O N I N S T R U C T I O N S

CONTENTS

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 1

PW 90 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 2 – 3

PW 180 Assembly Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

PW 180 Installation Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5 – 6

PW 180 Glass Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

GENERAL INFORMATION:

The Oldcastle BuildingEnvelope PW 90 and PW 180 sliding mall

fronts represent the latest in product development technology

complemented by glazing contractor on-the-job input and

experience. Proper use of these systems will assure optimum

results in erection and long term performance.

Oldcastle BuildingEnvelope does not control the application nor

selection of its product configurations, sealant or glazing materials

and assumes no responsibility thereof. It is the responsibility of

the owner,architect and installer to make these selections in

strict compliance with applicable laws and building codes.

PROTECTION AND STORAGE:

Handle the material carefully. Do not drop from the truck. Stack

with adequate separation so that the material will not rub together. Store material off the ground. Protect against the elements

and other construction hazards by using a well ventilated covering. Remove material from package if it is wet or is located in a

TM

TM

damp area.

CHECK MATERIAL:

Check all material upon arrival for quality and to assure against

shipping damage. Any visible damage must be noted on the

freight bill at the time of receipt. If a claim is required, then the

receiving party must process a claim with the freight company.

Completely check construction which will receive your materials

against contract documents. Notify the general contractor by letter of any discrepancies before proceeding with the work.

Failure to do so constitutes acceptance of work by other trades.

Check shop drawings and installation instructions to become

familiar with the project. The shop drawings take precedence

and include specific details for the project. The installation

instructions are of a general nature and cover the most common

conditions. Due to varying job conditions, all sealants used

should be approved by the sealant manufacturer to insure they

will function for conditions shown on instructions and shop

drawings. They must be compatible with all surfaces in which

adhesion is required including other sealant surfaces. Use

primers where directed by manufacturer of sealants. Be sure to

properly store sealants at recommended temperatures and

check sealant for remainder of shelf life before using.

FIELD CONDITIONS:

• Not recommended for exterior use where door must be watertight.

• All materials to be installed plumb, level, and true. Aluminum to

be placed in direct contact with the masonry or incompatible

materials should be isolated with a heavy coat of zinc-chromate

or bituminous paint.

• Coordinate protection of installed materials with general con-

tractors and other trades.

CLEANING MATERIALS:

Cement, plaster, terrazzo, alkaline and acid based materials used

to clean masonry are very harmful to finishes and should be

removed with water and a mild soap immediately or permanent

staining will occur. A spot test is recommended before any

cleaning agent is used.

MAINTENANCE:

Keep tracks free of debris, including areas where panels stack.

Wax tracks periodically using wax stick. Actual waxing schedule

depends on door use factors, including traffic, season and climate, but once a week in high traffic areas should keep panels

operating smoothly.

JULY 2011

1

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

P W - 9 0 S L I D I N G M A L L F R O N T

I N S T A L L A T I O N I N S T R U C T I O N S

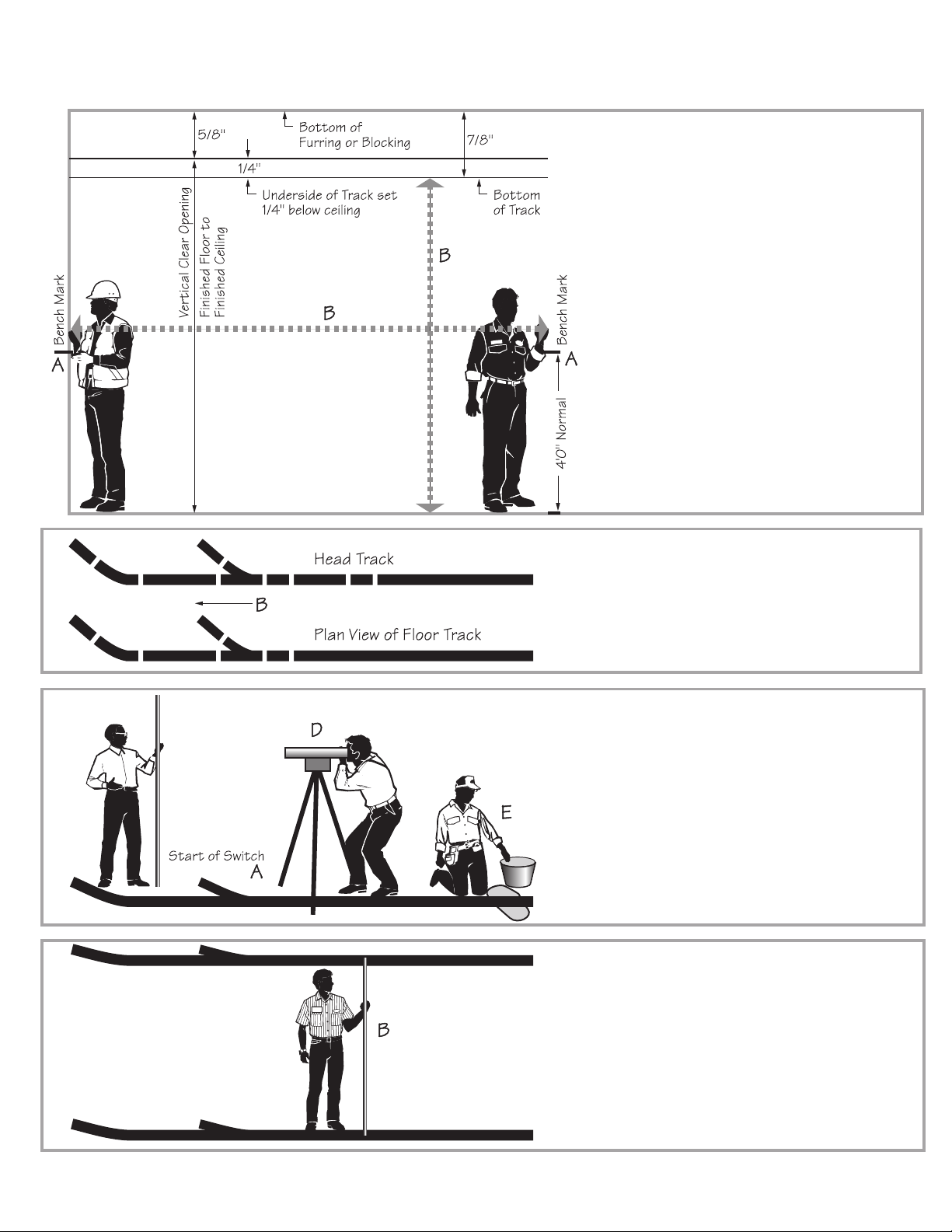

A). OBTAIN BENCH MARKS AT EACH

1.

JAMB (4’0” FROM FINISHED FLOOR)

FROM GENERAL CONTRACTOR.

B). CHECK OPENING FOR WIDTH

AND HEIGHT.

C). CHECK JAMBS FOR PLUMB.

A). DOUBLE CHECK SHIPMENT BY

2. LAYING OUT TRACK & ACCESSORIES

IN ACCORDANCE WITH ASSEMBLY

PRINT AND ACCESSORY LISTS.

B). TAILS OF TOP SWITCH MUST FACE

SAME DIRECTION AS FLOOR SWITCH.

A). LOCATE THE START OF SWITCH ON

SHOP DRAWING OR DATA SHEET.

3.

DRAWINGS OR DATA SHEET. C). INSTALL

FLOOR SWITCH AND TRACKS STARTING AT THE

“START OF SWITCH POINT AND LOCK JAMB. D).

SET TOP OF TRACK WITH FINISHED FLOOR AND

LEVEL WITHIN 1/8” – USE TRANSIT OR WATER

LEVEL AND LEVELING WEDGES. E). PACK

QUICK DRYING CEMENT AROUND ALL TRACK

ANCHOR STRAPS AND SWITCHES. F). DO NOT

SET PANELS UNTIL CEMENT IS HARD.

4.

B). ESTABLISH DIMENSION OF TRACK

CENTER LINE TO LOCK JAMB ON SHOP

A). INSTALL TOP TRACK LEVEL AND

PLUMB WITH BOTTOM TRACK.

JULY 2011 2

B). USE A STORY POLE TO HOLD

VERTICAL OPENING DIMENSION

TO +1/4” TO –0”.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Loading...

Loading...