JULY 2011

Note: Installation and Glazing Manuals are product specific. FOR REVIEW ONLY!

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Material Handling & General Construction Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

HP-1750

Mullion Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mullion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Jamb Fabrication And Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mull Cap Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Perimeter Sealant Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Horizontal Bridge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Glazing Clip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Glazing Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Outside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Inside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Transition Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Anchorage & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

Mullion Reinforcing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

HP-1750 SSG

Mullion Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Mullion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Mull Cap Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Horizontal Bridge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Glazing Clip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

TABLE OF CONTENTS

HP-1750 SCREWSPLINE & GLAZING

INSTRUCTIONS

These instructions are to be used for typical installations. Reference

shop drawings for special notations on installations and glazing.

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

JULY 2011

2

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Glazing Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. . . . . . . . . . . . . 25

Install Face Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. . . . . . . . . . . . 26

Outside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Inside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Transition Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Anchorage & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing Windload Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mullion Reinforcement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

HP-1750 1/4" CAPTURED

HP-1750 1/4" SSG

HP-1750 SSG

Glazing Detail - Intermediate Mullion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Glazing Detail Outside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Glazing Detail Inside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Glazing Detail - Intermediate Mullion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Glazing Detail Outside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Glazing Detail Inside 90 Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

DOOR INFORMATION

Door Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Door Transom Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Reglazing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-42

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

TABLE OF CONTENTS

JULY 2011

3

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

GENERAL INFORMATION

I. MATERIAL HANDLING Protect against damage

A. Shop

1. Cardboard wrapped or paper interleaved

materials must be kept dry.

2. Check arriving materials for quantity and

keep record of where various materials are

stored

B. Jobsite

1. Material at jobsite must be stored in a safe

place well removed from possible damage by

other trades.

2. Cardboard wrapped or paper interleaved

materials must be kept dry.

3. Keep record of where various materials are

stored.

4. Protect materials after erection. Cement,

plaster, and other alkaline solutions are very

harmful to the finish.

C. Cleaning

Aluminum shall be cleaned with plain water

containing a mild detergent, or a petroleum

product such as white gasoline, kerosene, or

distillate. No abrasive agent shall be used.

E. Protect all aluminum to be placed directly in

contact with uncured masonry or incompatible

materials with a heavy coat of Zinc chromate or

bituminous paint.

F. Follow installation and glazing instructions.

G. Check arriving materials for quantity.

H. Be sure you have all the materials needed to

begin the installation:

1. Approved shop drawings.

2. Framing and accessories.

3. Sealant

4. Glazing materials.

I I I. GENERAL INSTALLATION NOTES Outside Glazing

The HP-1750 system is designed for the following:

1. Shop fabrication

2. Shop or field assembly

3. Installed as an assembled unit into opening

JULY 2011

I I. GENERAL CONSTRUCTION NOTES Standard Practice

A. Study these instructions, shop drawings,

erection drawings and architectural drawings

before starting any work.

B. All materials are to be installed plumb and level.

C. All work should start from an established

benchmark and column centerlines established by

the architectural drawings and the general

contractor.

D. Completely check construction which will

receive your materials against contract

documents. Notify the general contractor by letter

of any discrepancies before proceeding with your

work since this constitutes acceptance of work by

other trades.

4. Anchored in place behind the glazing plane.

5. Face glazed

The framing system is designed for the vertical

gutter members to run through, and the head and

sill gutters square cut between. The face members

are square cut with the verticals running through and

horizontals between. Curtain wall installations are

limited to a maximum of three story construction

with hard splices at either the second or third floor.

Oldcastle BuildingEnvelope's reputation as a product

innovator implies that it reserves the right to change or

modify its products without prior notice.

For further assistance please contact your local

sales representative, regional office or service

center.

Phone: 1-866-OLDCASTLE (653-2278)

4

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

MULLION FABRICATION

HP-10390

TOP OF

HORIZONTAL

1 3/4"

1/4"

1 1/4"

DRILL "F" (.257)

CLEAR HOLES (TYP.)

1/4"

1 1/4"

3/8"

9/32"

HP-10434

1 1/4"

1/4"

DRILL .191 0 HOLE

(#11 BIT)

29/32"

JULY 2011

5

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

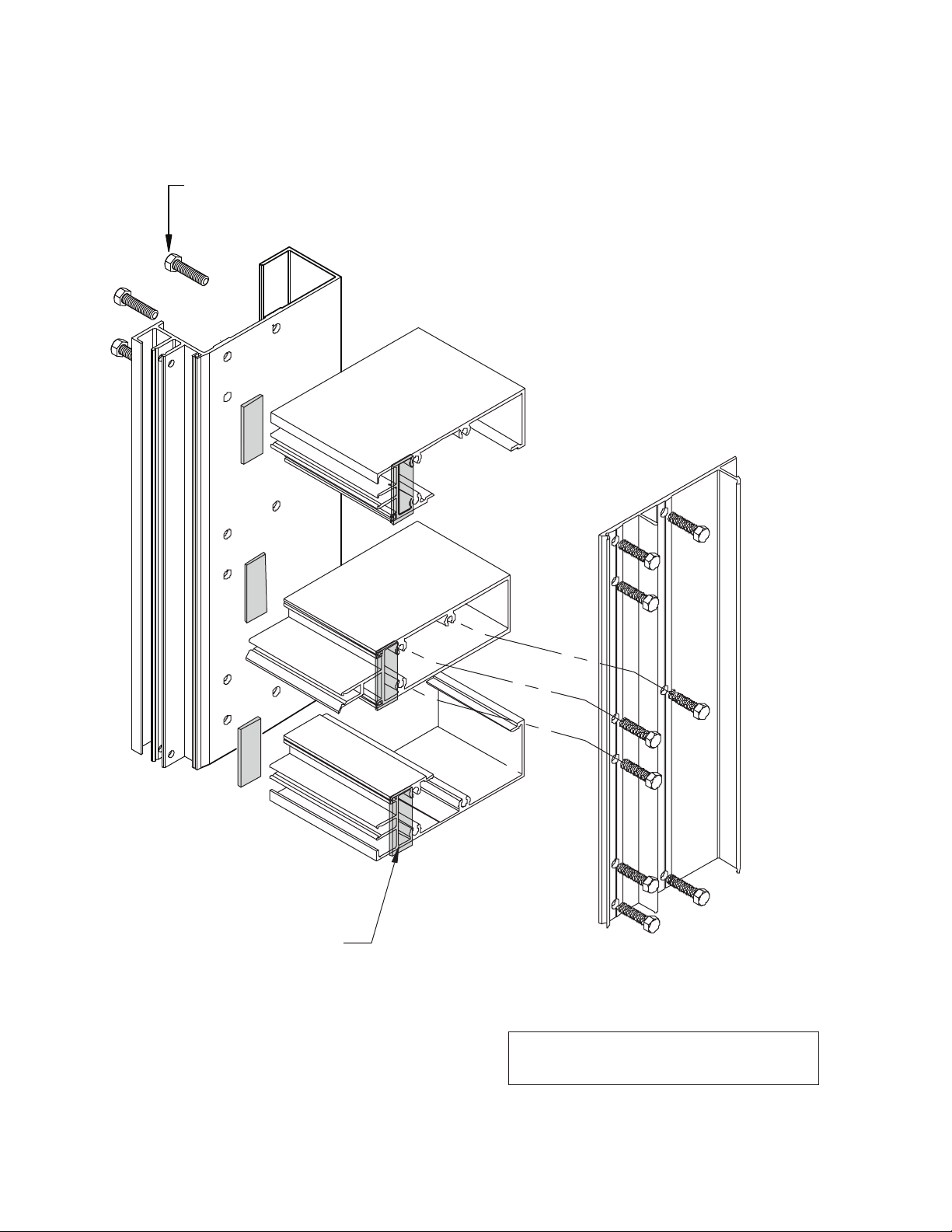

HP-10435

HP-10436

HP-10390

FS-8 (#14 X 1" HHSTS)

3 PER HORIZONTAL

HP-10434

HP-10435

SCHNEE-MOREHEAD SM5601

1/8" X 1/2" TACKY TAPE

VW PART # 4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY

FROM SCREWSPLINES

NOTE:

MULL CAPS REQUIRED

AT HEAD & SILL.

REFERENCE SHEET #8

FOR INSTALLATION.

NOTE: USE RAZOR KNIFE TO TRIM

EXCESS SEALANT TAPE. DO NOT

PULL TAPE TO TRIM.

MULLION ASSEMBLY

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

JULY 2011

6

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

HP-10433

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

JAMB FABRICATION AND ASSEMBLY

FS-8 (#14 X 1" HHSTS)

3 PER HORIZONTAL

HP-10435

HP-10390

SCHNEE-MOREHEAD SM5601

1/8" X 1/2" TACKY TAPE

VW PART # 4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY

FROM SCREWSPLINES

NOTE:

MULL CAPS REQUIRED

AT HEAD & SILL.

REFERENCE SHEET #8

FOR INSTALLATION.

CAPTURED JAMB ALSO USED FOR SSG ASSEMBLY

HP-10436

HP-10435

NOTE: USE RAZOR KNIFE TO TRIM

EXCESS SEALANT TAPE. DO NOT

PULL TAPE TO TRIM.

JULY 2011

7

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

MULLION CAP INSTALLAITON

1) MULL CAPS ARE TO

BE INSTALLED AT

HEAD AND SILL OF

EACH UNIT.

2) CAP SHALL BE

BED IN SEALANT TO

MULLION

3) ATTACH W/ FS-6

4) SEAL FILLER SIDE

JUST PRIOR TO INSTALLATION

OF UNIT INTO OPENING

MODIFY MULL

CAP AT JAMBS.

DRILL #11 (.191)

CLEAR HOLE

HP175-FP-51

11/16"

SEAL FILLER SIDE

OF MULL JUST

PRIOR TO UNIT

INSTALLATION

BED MULL CAP

IN SEALANT

ATTACH MULL CAP

WITH FS-6

(#10 X 3/4" PPH)

JULY 2011

8

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

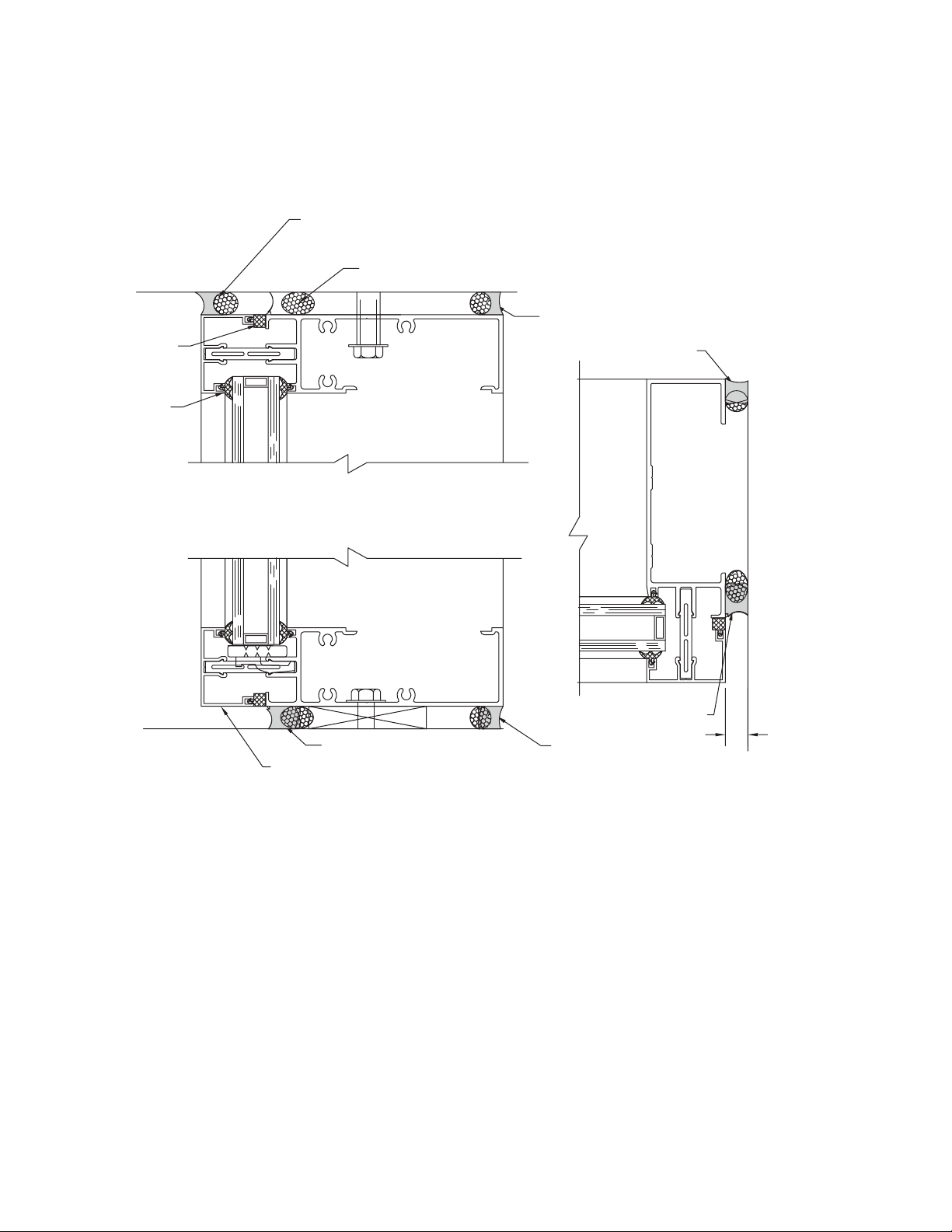

PERIMETER SEALANT

SECONDARY WEATHERSEAL

AT HEAD AND DOWN 2" AT

TOP JAMBS.

PRIMARY WEATHER SEAL

COSMETIC SEAL

HP-10446

COSMETIC SEAL

NHP-6

PRIMARY WEATHER SEAL

3/8"

PRIMARY WEATHER SEAL

KEEP AREA OPEN AT SILL

FOR SYSTEM WEEPAGE.

NOTE:

THE PRIMARY WEATHER SEAL MUST BE APPLIED ALONG THE HEAD, JAMB AND SILL MEMBERS AS SHOWN

ABOVE. THIS IS ESPECIALLY CRITICAL AT THE SILL SO THAT PROPER DRAINAGE OF WATER CAN TAKE PLACE.

FOR EASE OF INSTALLATION IT IS RECOMMENDED THAT THE PRIMARY SEAL BE APPLIED PRIOR TO

INSTALLING GLASS AND FACE CAPS. A MINIMUM 3/8" CAULK JOINT IS RECOMMENDED FOR THE HP-1750

SYSTEM AND IS REQUIRED AT THE JAMBS TO ALLOW PROPER CLEARANCE FOR INSTALLAITON OF FINAL

UNIT.

COSMETIC SEAL

MIN.

JULY 2011

THE SECONDARY WEATHER SEAL MUST BE APPLIED AT THE FACE OF THE COVER AT THE HEAD AND TOP 2"

OF JAMB ONLY. THIS PREVENTS WATER INFILTRATION DIRECTLY INTO THE SYSTEM FROM ABOVE.

FAILURE TO APPLY BOTH THE PRIMARY AND SECONDARY WEATHER SEALS IN THE CORRECT LOCATIONS

WILL GREATLY AFFECT THE PERFORMANCE OF THE SYSTEM.

WHILE NOT REQUIRED FOR PROPER SYSTEM PERFORMANCE, THE COSMETIC SEAL MAY BE APPLIED ALONG

THE INTERIOR IF NEEDED.

9

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

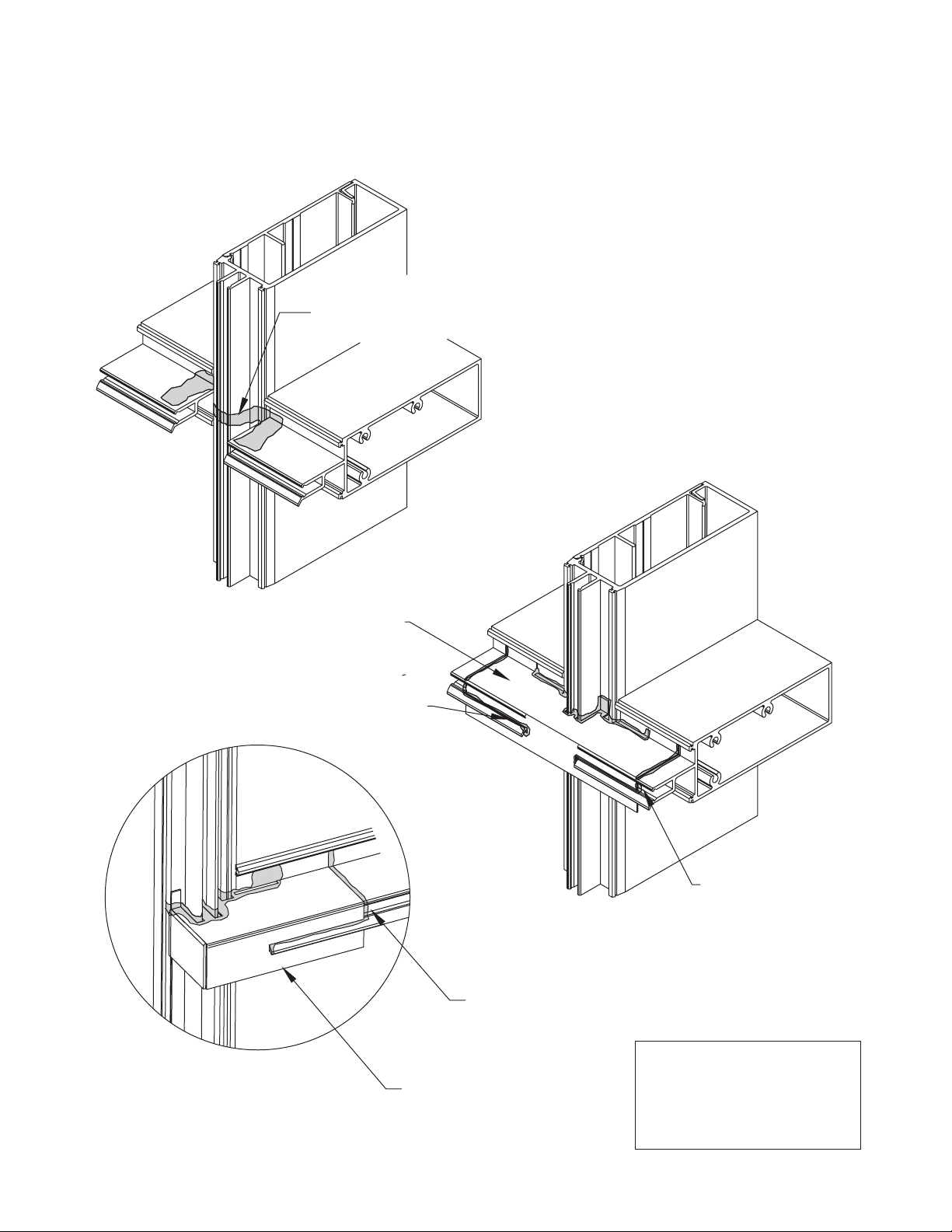

HORIZONTAL BRIDGE INSTALLATION

STEP 1

RUN SEALANT ACROSS

FACE OF MULL AND TOP

OF HORIZONTALS

HP175-FP-43

BRIDGE

1) BED FACE OF MULL

AND TOP OF HORIZONTALS

WITH SEALANT.

2) SET HP175-FP-43 BRIDGE

INTO PLACE. HOOK OVER DRIP LEGS

AND ROTATE INTO PROPER POSITION.

3) SEAL AND TOOL ACROSS

FACE OF MULL AND HORIZONTALS

4) SEAL CLIP POCKET AT EACH END OF BRIDGE

5) SEAL ABOVE AND BELOW DRIP LEG OF

HORIZONTALS

STEP 2

JAMB BRIDGE

SEAL ACROSS FACE

OF BRIDGE AT

DRIP LEG

HP175-FP-44/45

HP225-FP-5/6

BED IN SEALANT

AND SEAL TO MULL

SEAL CLIP

POCKET AT EACH

END OF BRIDGE

FILL GLAZING CLIP TRACK

WITH SEALANT AT DIVERTER

GLAZING NOTE:

GLAZE SYSTEM FROM

BOTTOM TO TOP. INSTALL

BRIDGE TO HORIZONTAL

ABOVE AS YOU PROCEED UP

THE BUILDING.

JULY 2011

10

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

GLAZING CLIP INSTALLATION

HP175-FP-51 MULL CAP

REF SHEET #8 FOR

INSTALLATION & SEALANT

INSTRUCTIONS

STAKE UNDERSIDE

OF VERTICAL CLIPS

TO PREVENT SLIDING

HP175-FP-43

REF SHEET #10

FOR SEALANT

INSTRUCTIONS

LOCATE AT MAXIMUM OF 12" O.C.

(VERTICALS, HEAD & SILL)

HP-8 GLAZING CLIP

LOCATE AT 12" O.C.

(HP-8 @ INT. HORIZ ONLY!)

HP-10 GLAZING CLIPS

JULY 2011

TOWARDS

GUTTER

9/16"

NOTE: CLIPS ARE NOT

SYMMETRICAL, INSTALL AS

SHOWN.

11

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

GLAZING - 1” GLASS

CAUTION:

BE CERTAIN THAT GLASS IS PLACED

FIRMLY AGAINST INTERIOR GASKET

BEFORE SETTING ON BLOCKS. GLASS

BREAKAGE CAN OCCUR AT OR NEAR

SETTING BLOCKS DUE TO THE WEIGHT

OF THE GLASS NOT ALLOWING THE

GLASS TO MOVE TOWARD INTERIOR

GASKET. LUBRICATING THE TOP OF

THE SETTING BLOCK WILL HELP

INSURE PROPER SETTING OF GLASS

(2) HP-17

ING

SETT

BLOCKS

MARK LOCATION OF EACH

GLAZING CLIP PRIOR TO

INSTALLING FACE CAPS.

HP-36 TEMP

CLIPS. SLIDE

GLAZING CL

ORAR

ONTO

IPS.

Y

SEAL BETWEEN VERTICAL

AND HORIZONTAL GASKETS.

TOOL INTERIOR OF JOINT

TO FORM FILLET SEAL.

(2) HP-17

SETTING BLOCKS

SETTING CHAIR

(2) PER DLO

HP-41

NHP-6 GASKETS.

CUT GASKET

+1/4" PER FOO

SEAL CORNE

DETAIL BELOW.

GLAZING NOTE:

GLAZE SYSTEM FROM BOTTOM

TO TOP. INSTALL BRIDGE

TO HORIZONTAL ABOVE AS YOU

PROCEED UP THE BUILDING.

S D.L.O.

RS PER

T.

JULY 2011

12

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

INSTALLING FACE CAPS

WHEN INSTALLING FACE CAPS

USE DEADBLOW HAMMER AND

IMPACT CAPS AT LOCATIONS

OF GLAZING CLIPS ONLY.

FACE CAPS:

HP-10437 @ TYPICAL MULLS &

HORIZONTALS

HP-10438 @ PERIMETER

JAMBS, HEAD & SILL

3/4"

NOTE:

SCREWSPLINE SYSTEM

AVAILABLE WITH 1" OR 1/4"

GLAZING. WHEN INSTALLING

1" SYSTEM AND GLAZING 1/4"

GLASS, ADAPTORS WILL BE

REQUIRED. REFERENCE

SHEET #18.

IF 1/4" GLAZING SYSTEM IS

USED REFERENCE SHEET #38

FOR ADDITIONAL INFORMATION.

INSTALL VERTICAL CAPS

FIRST, THEN HORIZONTALS.

CUT NHP-6 GASKET 3/4" SHORT

ON BOTTOM SIDE OF HORIZONTAL

FACE CAPS.

CAP INSTALLATION NOTE:

TO INSTALL FACE CAPS, LOCATE CAP ONTO

CLIPS AT EACH END. PRESS FIRMLY AGAINST

CAP UNTIL GASKET IS COMPRESSED AGAINST

GLASS AND STRIKE AT PREVIOUSLY MARKED

LOCATIONS OF GASKET CLIPS. WHEN INSTALLED

PROPERLY CAPS SHOULD RESIST ROTATION.

JULY 2011

13

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

O

90 OUTSIDE CORNER

HP-10455

HP-10457

HP-10465

MODIFIED HP175-FP-4

DIVERTER. BED IN SEALANT

& SEAL AS SHOWN

HP175-FP-62

AT MID-SPAN ANCHORS.

ATTACH W/ (2) FS-6

(#10 X 3/4" PPH)

3/8"

HP-10460

JULY 2011

SEAL CONTINUOUS

REFERENCE SHEET #8 FOR

TYPICAL MULL CAP

INSTALLATION

HP175-FP-57

MULL CAP. BED IN

SEALANT & ATTACH

W/ FS-202. LOCATE

AT HEAD & SILL

14

HP-10459

ATTACH W/ FS-55

@ 18" O.C.

DLO +

1 5/16"

MITER DETAIL

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

90 INSIDE CORNER

NOTE:

REFERENCE SHEETS #5 THRU #13

FOR ADDITIONAL INFORMATION.

O

FORMED ALUM. CORNER

COVER. ATTACH W/

FS-6 (#10 X 3/4" PPH)

@ TOP & BOTTOM OF

COVER (MIN.)

HP-10463

ATTACH W/ FS-6

(#10 X 3/4 PPH)

@ 12" O.C.

BED IN SEALANT

A

HP-10464 FACE CAP.

MUST BE INSTALLED PRIOR

TO HORIZONTAL FACE CAPS

MODIFY HORIZONTAL

BRIDGE FOR INSIDE

CORNER AND SEAL AS

SHOWN ON SHEET #10

ATTACH HP175-FP-65

TO CORNER CLOSURE

W/ SEALANT

AT HEAD & SILL

"A"

"A"

HP175-FP-65

END CAP

NOTE:

USE TYPICAL MULL CAPS AND

MODIFY SIMILAR TO JAMB CAPS.

(SEE SHEET #8)

THEN MARRY SEAL ACROSS MULL

CAPS AND ANGLES ATTACHED TO

CORNER CLOSURE.

7 9/16"

JULY 2011

SECT "A-A"

15

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

FABRICATNG & INSTALLING ADAPTORS

HP-10475

BED ADAPTOR IN

SEALANT CONTINUOUS

AND CAP SEAL ALL

FASTENERS

ATTACH W/ FS-23

(#6 X 3/8" PPH)

NOTE:

SEAL GASKET CORNERS

AS SHOWN ON SHEET #12

BED IN SEALANT

AND CAP SEAL

FASTENERS

EQ.

HP-10475

12" O.C.

SEAL CORNERS

OF ADAPTORS

HP-10475

JULY 2011

3/8"

1"

DRILL .173 (#17 BIT)

NOTCH ENDS TO

CLEAR HORIZ. FASTENERS

NOTE: NOTCHES REQUIRED FOR

HORIZONTAL ADAPTORS ONLY!

16

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

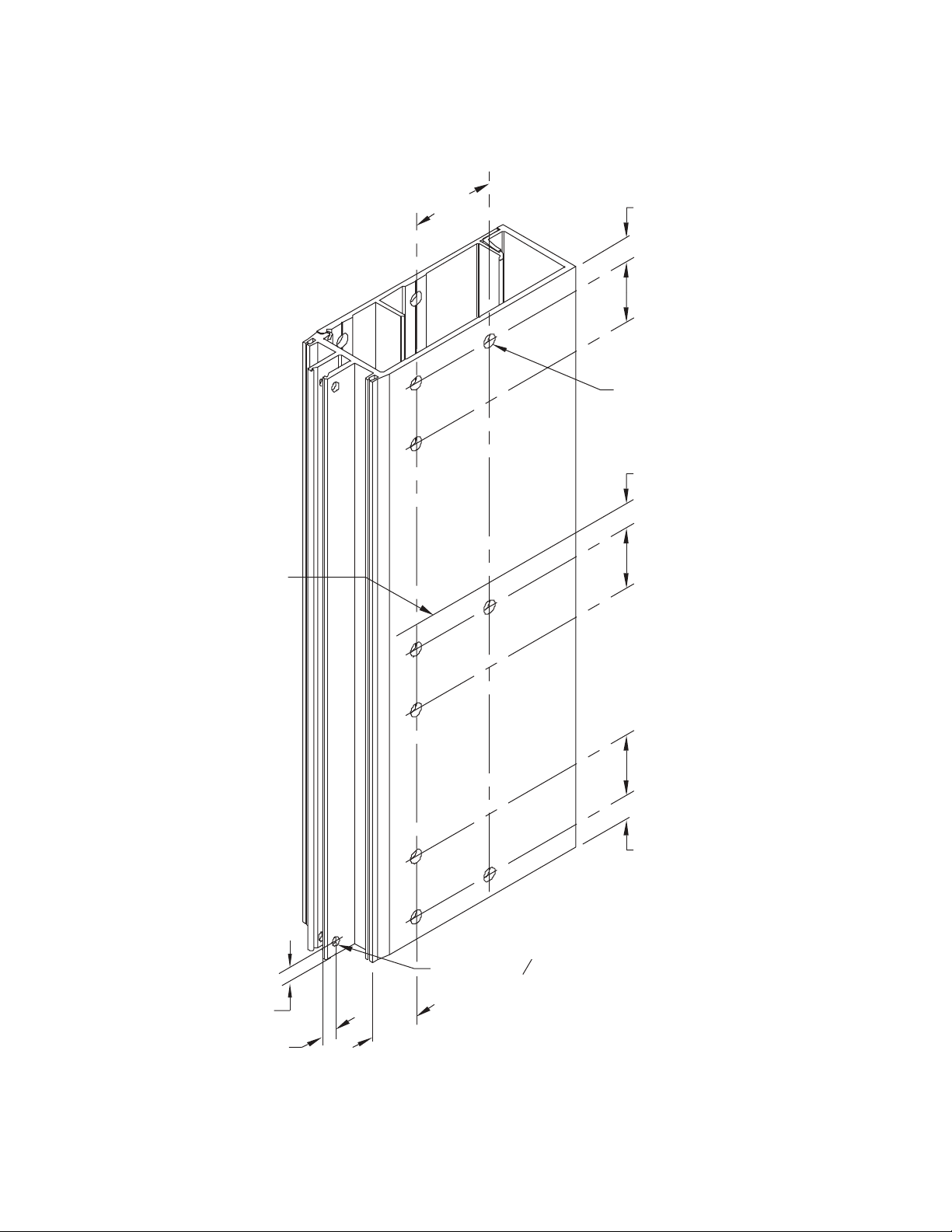

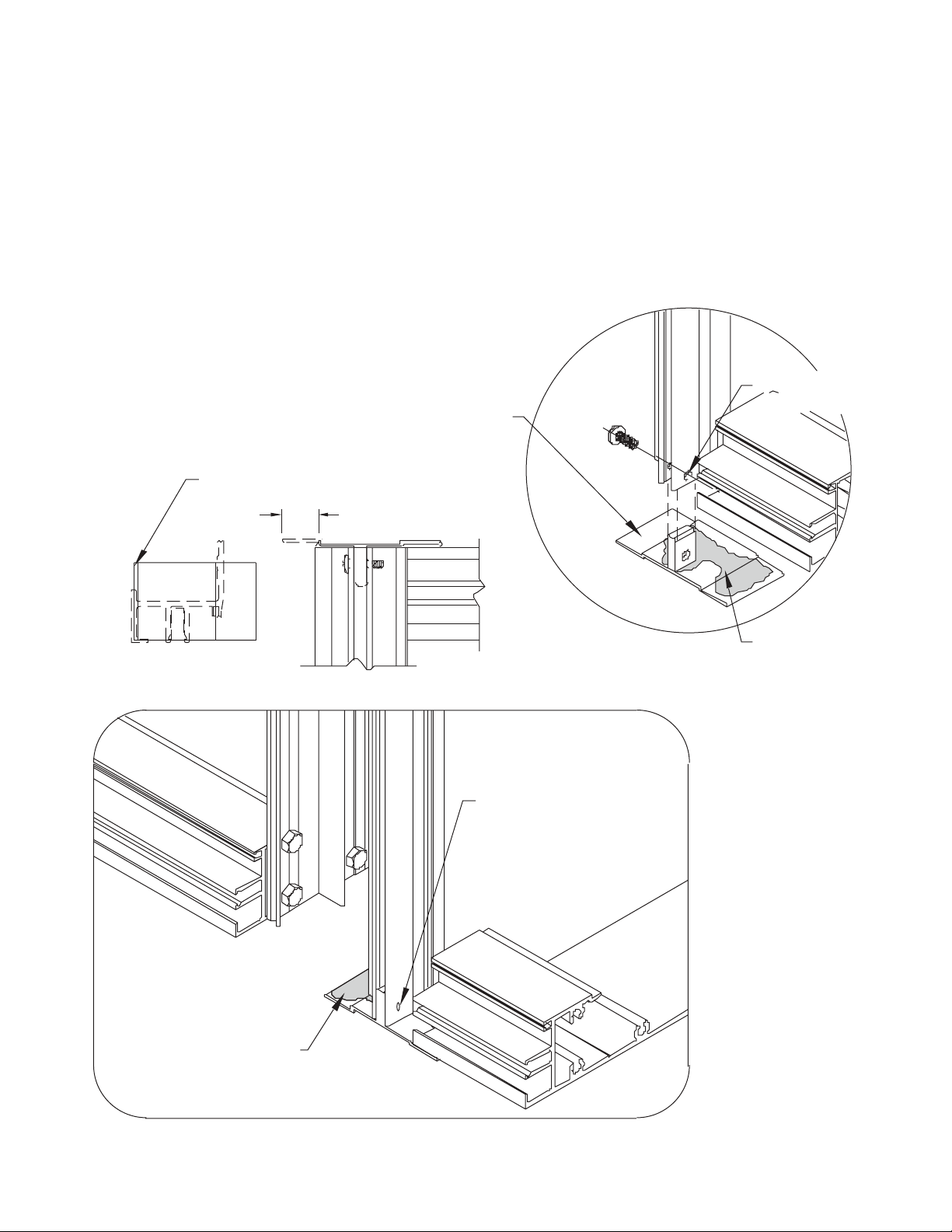

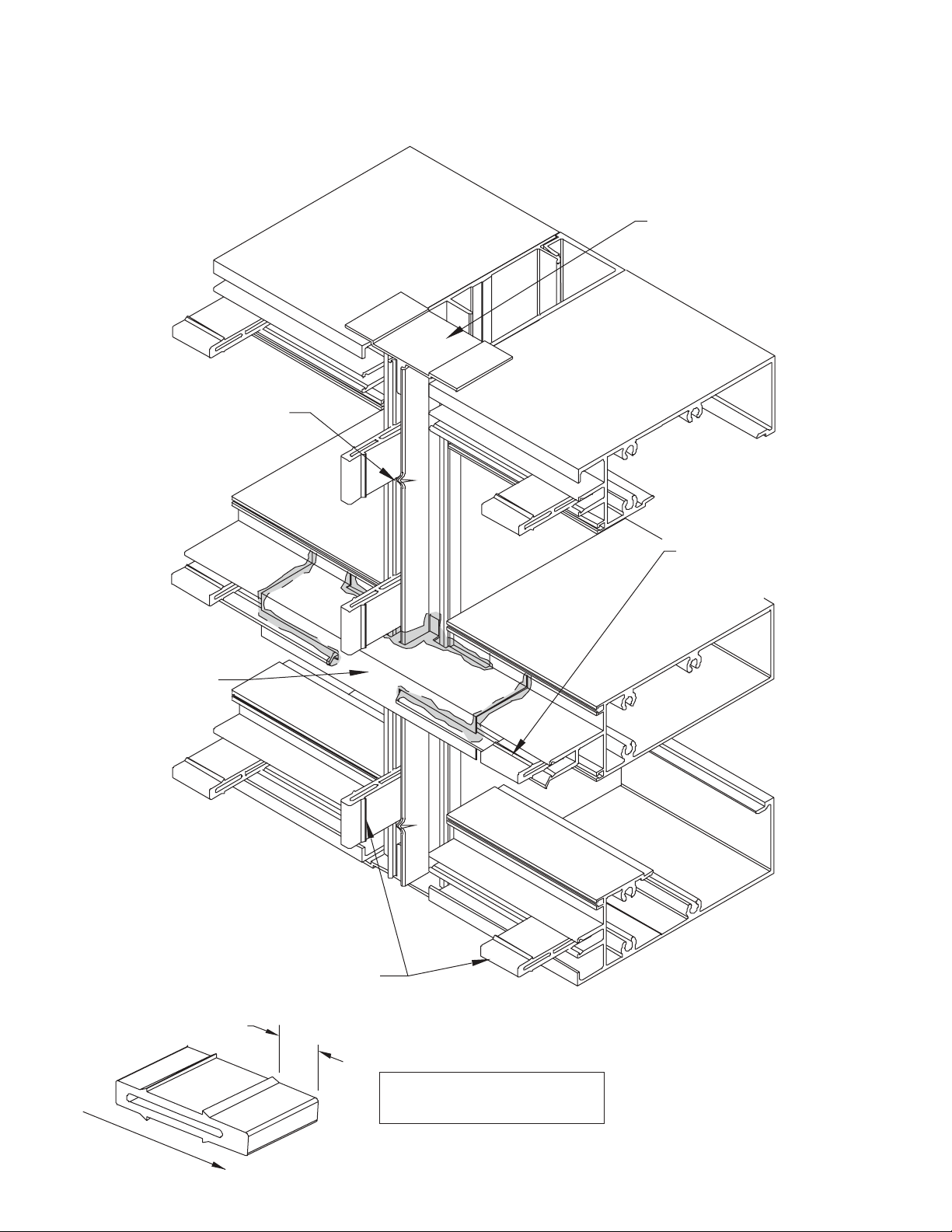

INSTALLING & ANCHORING UNITS

ONCE UNIT IS POSITIONED AS

SHOWN IN DETAIL AT LEFT.

ROTATE AS SHOWN ABOVE

UNTIL FILLER SNAPS INTO

MULLION. THEN SHIM AND

ANCHOR AS SHOWN BELOW.

ANCHOR SIZE DETERMINED

BY STRUCTURAL REQUIREMENTS

NHP-10446

PLACE FRONT HOOK OF

HP-10390 FILLER OVER

LEG OF HP-10434 MULL.

ANCHOR WITH PIPESLEEVE

REQUIRED FOR LIVELOAD ONLY.

HP-10435

HP-10343

NOTE:

1) INSTALL FIRST UNIT, PLUMB,

SQUARE AND ANCHOR.

2) ROTATE NEXT UNIT INTO PLACE

AND ANCHOR.

3) REPEAT ACROSS OPENING.

4) ANCHOR BOLTS REQUIRED AT MAX.

6" OF EACH SIDE OF MULLION.

5) INSTALL HP-10343 SNAP FILLERS

AFTER UNIT HAS BEEN FULLY

INSTALLED AND ANCHORED.

JULY 2011

17

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

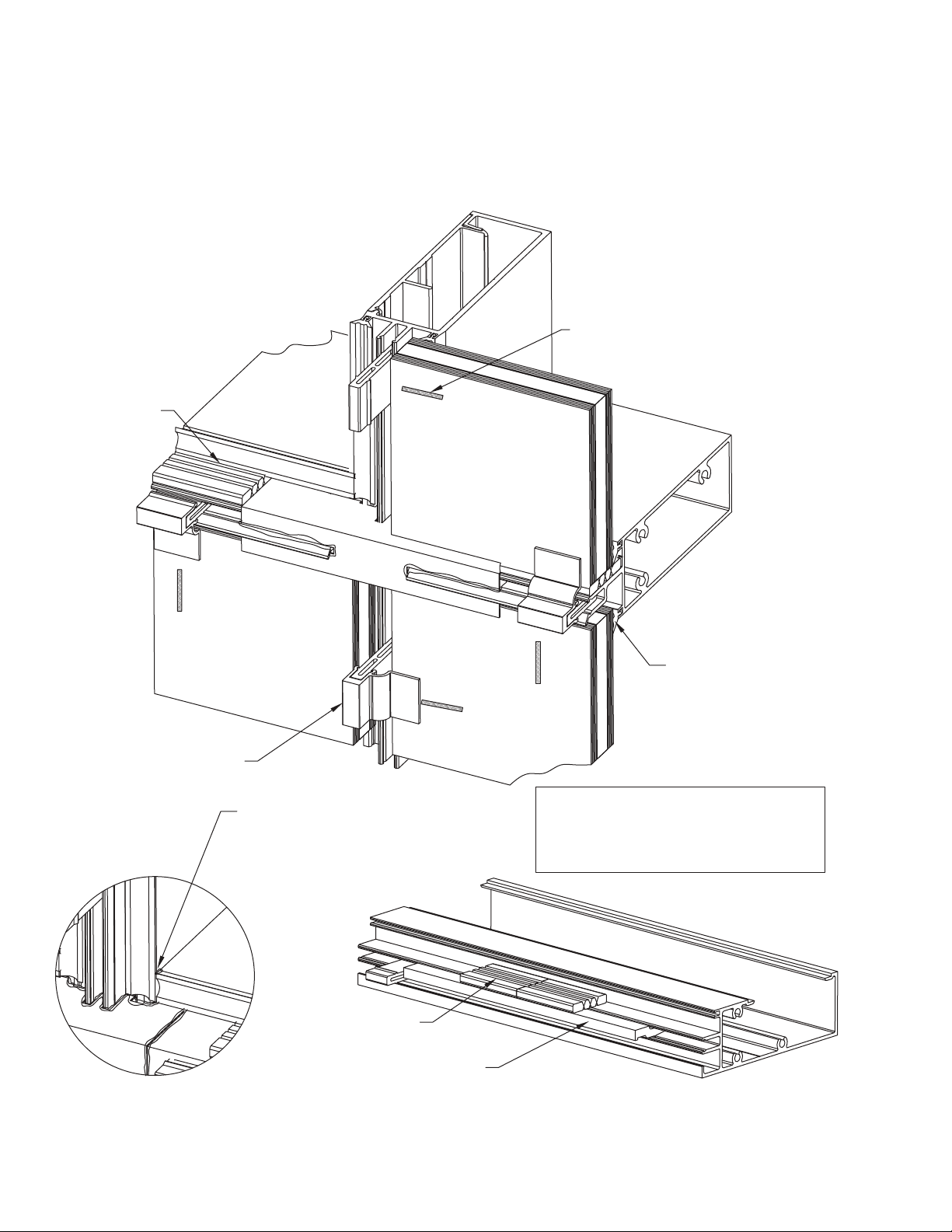

INSTALLING WINDLOAD ANCHOR

ANCHOR REQUIRED AT

MULLS (SIZE BY STRUCTURAL

REQUIREMENTS)

WINDLOAD ANCHOR

SLOT SIZE DETERMINED

BY STRUCTURAL

REQUIREMENTS

ANCHOR SIZE DETERMINED

BY STRUCTURAL REQUIREMENTS

NOTE:

CURTAIN WALL INSTALLATIONS ARE

LIMITED TO A MAXIMUM OF THREE

STORY CONSTRUCTION WITH DEADLOAD

SPLICES AT EITHER THE SECOND OR

THIRD FLOOR. SINCE THE FILLER

SIDE OF THE MULLION ASSEMBLY

SNAP FITS WITH THE MULLION, NO

PROVISION IS MADE TO EITHER

ANCHOR OR SPACE THE MEMBER AT A

SPLICE.

JULY 2011

18

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

INSTALLING MULLION REINFORCING

HP-10434

HP-10390

HP-10414 REINFORCEMENT

ATTACH W/ FS-43

(#12 X 3/4" PPH) @

HEAD & SILL ONLY

POSITION REINFORCEMENT TO

FIT AGAINST WALL OF

MULLION TO PROVIDE MAXIMUM

CLEARANCE FOR MULL FILLER

HP-10390

HP-10434

3/8" X 3 3/4" STEEL

BAR. CUT LENGTH TO BE

MULL LENGTH MINUS 2"

AND INSET 1" FROM EACH

END. ATTACH W/ FS-43

AT EACH END OF STEEL.

SECURE HP-10414 REINFORCING

WITH FS-43 ABOVE AND BELOW

STEEL.

JULY 2011

21

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG MULLION FABRICATION

HP-10390

TOP OF

HORIZONTAL

1 3/4"

1/4"

1 1/4"

DRILL "F" (.257)

CLEAR HOLES (TYP.)

1/4"

1 1/4"

3/8"

HP-10469

1 1/4"

1/4"

DRILL .173 Ø HOLE

(#17 BIT)

25/32"

JULY 2011

22

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

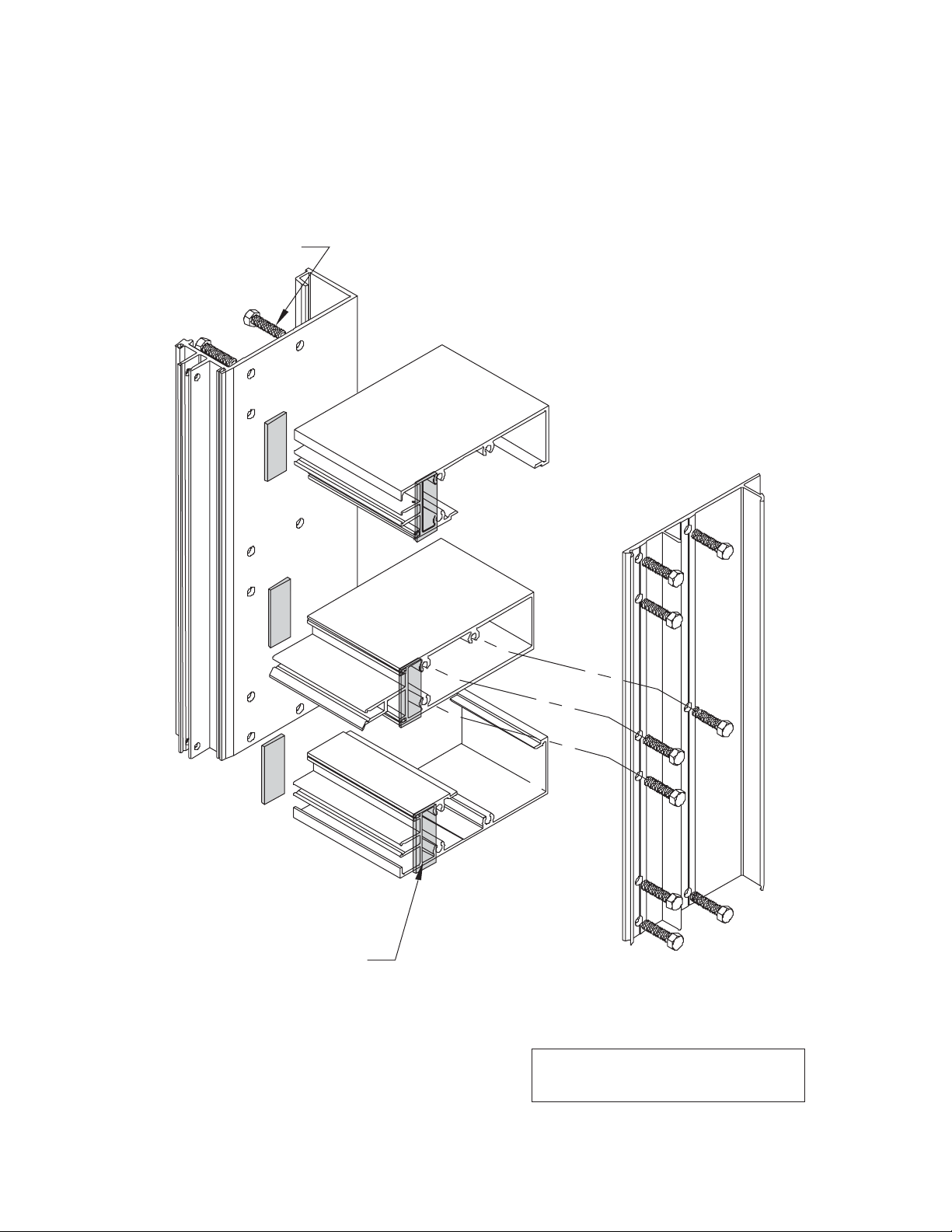

SSG MULLION ASSEMBLY

FS-8 (#14 X 1" HHSTS)

3 PER HORIZONTAL

HP-10469

HP-10435

SCHNEE-MOREHEAD SM5601

1/8" X 1/2" TACKY TAPE

VW PART #4666 (OR EQUAL)

NOTE: KEEP TAPE AWAY

FROM SCREWSPLINES

HP-10390

HP-10436

HP-10435

JULY 2011

NOTE:

MULL CAPS REQUIRED

AT HEAD & SILL.

REFERENCE SHEET #25

FOR INSTALLATION.

23

NOTE: USE RAZOR KNIFE TO TRIM

EXCESS SEALANT TAPE. DO NOT

PULL TAPE TO TRIM.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG MULL CAP INSTALLATION

DRILL #17 (.173)

CLEAR HOLE

1) MULL CAPS ARE TO

BE INSTALLED AT

HEAD AND SILL OF

EACH UNIT.

2) CAP SHALL BE

BED IN SEALANT TO

MULLION

3) ATTACH W/FS-23

4) SEAL FILLER SIDE

JUST PRIOR TO INSTALLATION

OF UNIT INTO OPENING

HP175-FP59 MULL CAP

MODIFY AS SHOWN

AT JAMB

JULY 2011

SEAL FILLER

SIDE OF MULL

DURING UNIT

INSTALLATION

FS-23

(#8 X 1/2" PPH)

CAPSEAL

24

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG BRIDGE INSTALLATION

STEP 1

RUN SEALANT ACROSS

FACE OF MULL AND TOP

OF HORIZONTALS

HP175-FP-61

BRIDGE

1) BED FACE OF MULL

AND TOP OF HORIZONTALS

WITH SEALANT.

2) SET HP175-FP-61 BRIDGE

INTO PLACE. HOOK OVER DRIP

LEGS AND ROTATE INTO

PROPER POSITION.

3) SEAL AND TOOL ACROSS

FACE OF MULL AND HORIZONTALS

4) SEAL CLIP POCKET AT EACH END OF BRIDGE

5) SEAL ABOVE AND BELOW DRIP LEG OF

HORIZONTALS

STEP 2

SEAL ACROSS FACE

OF BRIDGE AT

DRIP LEG

SEAL CLIP

POCKET AT EACH

END OF BRIDGE

GLAZE SYSTEM FROM BOTTOM TO TOP.

INSTALLING DIVERTERS TO HORIZONTAL

ABOVE AS YOU PROCEED UP BUILDING.

JULY 2011

25

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - GLAZING CLIP INSTALLATION

V2110

(5/16" X 5/16"

DSA TAPE)

HP-8 GLAZING CLIP

LOCATE AT 12" O.C.

(HP-8 @ INT. HORIZ ONLY!)

HP175-FP-60 BRIDGE

REF SHEET#26

FOR SEALANT

INSTRUCTIONS

HP175-FP-59 MULL CAP

REF SHEET #25 FOR

INSTALLATION & SEALANT

INSTRUCTIONS

HP-10 GLAZING CLIPS

9/16"

LOCATE AT 12" O.C

(HEAD & SILL)

TOWARDS

GUTTER

JULY 2011

24

NOTE: CLIPS ARE NOT SYMMETRICAL,

INSTALL AS

SHOWN.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - GLAZING 1” GLASS

V2110 SPACER TAPE, ALIGN TAPE

WITH "V" GROOVE IN MULLION

SEE NOTES BELOW FOR

WHEN RUNNING STRUCTURAL

SILICONE, SEAL GAP BETWEEN

GASKET AND TAPE.

HP-17

SETTING

BLOCK

INSTALLATION INFORMATION

STRUCTURAL SILICONE

MARK LOCATION OF EACH

GLAZING CLIP PRIOR TO

INSTALLING FACE CAPS.

WEATHER SEAL,

REFERENCE SHEET #26

FOR ADDITIONAL

INFORMATION

GLAZING NOTE:

GLAZE SYSTEM FROM BOTTOM

TO TOP. INSTALLING BRIDGES

TO HORIZONTAL ABOVE AS YOU

PROCEED UP BUILDING.

HP-36 TEMPORARY

CLIPS. SLIDE ONTO

GLAZING CLIPS.

NHP-6 GASKETS.

CUT GASKETS D.L.O.

+1/4" PER FOOT.

NOTES:

1) PEAL BACK 1" TO 2" OF PROTECTIVE

FILM FROM V2110 AT TOP AND BOTTOM

OF LITE.

2) BE CERTAIN THAT GLASS IS PLACED

FIRMLY AGAINST INTERIOR GASKET AND

TAPE BEFORE SETTING ON BLOCKS.

3) LEAVE PROTECTIVE FILM ON V2110

TAPE BETWEEN ENDS UNTIL GLASS IS

IN POSITION.

4) REMOVE REMAINDER OF PROTECTIVE

FILM FROM SPACER TAPE. (NOTE: GLASS

CAN NOT BE ADJUSTED ONCE IN

CONTACT WITH ADHESIVE OF SPACER

TAPE)

5) INSTALL HP-36 HORIZONTAL

TEMPORARY CLIPS.

JULY 2011

25

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - INSTALLING - FACE CAPS

WHEN INSTALLING FACE CAPS

USE DEADBLOW HAMMER AND

IMPACT CAPS AT LOCATIONS

OF GLAZING CLIPS ONLY.

NOTE: LEAVE 1/4" GAP

IN HORIZONTAL GASKET

AT EACH VERTICAL

JOINT

1/4"

3/8"

MARRY WEATHER SEAL

TO HORIZONTAL GASKET

CAP INSTALLATION NOTE:

TO INSTALL FACE CAPS. LOCATE

CAP ONTO CLIPS AT EACH END. PRESS

FIRMLY AGAINST CAP UNTIL GASKET IS

COMPRESSED AGAINST GLASS AND STRIKE

AT PREVIOUSLY MARKED LOCATIONS OF

GASKET CLIPS. WHEN INSTALLED PROPERLY

CAPS SHOULD RESIST ROTATION.

JULY 2011

26

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - 90 OUTSIDE CORNER

0

HP-10466

HP-10465

FS-8

HP-10455

STRUCTURAL

SILICONE

V2110

WEATHERSEAL

SEAL BETWEEN VERTICAL

WEATHERSEAL AND GASKETS

MODIFY HP175-FP-62 BRIDGE

AT CORNER AND SEAL AS SHOWN

HP175-FP-57

MULL CAP. BED IN

SEALANT & ATTACH

W/ FS-202. LOCATE

AT HEAD & SILL

DLO +

1 5/16"

JULY 2011

REFERENCE SHEET #25

FOR TYPICAL MULL CAP

INSTALLATION

27

MITER DETAIL

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - 90 INSIDE CORNER

NOTE:

REFERENCE SHEET #23 THRU #29

FOR ADDITIONAL INFORMATION

0

FORMED ALUM. CORNER

COVER. ATTACH W/

FS-6 (#10 X 3/4" PPH)

@ TOP & BOTTOM OF

COVER (MIN.)

7 9/16"

HP175-FP-66

13/16"

HP-10461 CORNER

CLOSURE. ATTACH W/

FS-6 (#10 X 3/4" PPH)

BED IN SEALANT

ATTACH HP175-FP-66

TO CORNER CLOSURE

W/ SEALANT AT HEAD

& SILL

@ 18" O.C.

SECT "A-A"

"A"

"A"

V2110 DSA TAPE

STRUCTURAL SILICONE

13/16"

NOTE:

USE TYPICAL MULL CAPS AND

MODIFY SIMILAR TO JAMB CAPS.

(SEE SHEET #8)

THEN MARRY SEAL ACROSS MULL

CAPS AND ANGLES ATTACHED TO

CORNER CLOSURE.

HP175-FP-61 DIVERTER BRIDGE

TO BE USED AT HORIZONTALS.

MODIFY AND SEAL.

JULY 2011

28

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - FABRICATING & INSTALLING ADAPTORS

HP-10475

BED ADAPTOR IN

SEALANT CONTINUOUS

ATTACH W/ FS-23

(#6 X 3/8" PPH)

CAP SEAL

SEAL

CONTINUOUS

HP-1047

ATTA

@ 12" O.C

EQ.

6

CH W/ FS-

.

HP-10497 GLAZING

ADAPTOR.

ATTACH W/ FS-23

@ 12" O.C.

BED IN SEALANT

43

12" O.C.

SEAL CORNERS

OF ADAPTORS

HP-10476

JULY 2011

3/8"

1"

DRILL .173 (#17 BIT)

NOTCH ENDS TO

CLEAR HORIZ. FASTENERS

NOTE: NOTCHES REQUIRED FOR

HORIZONTAL ADAPTORS ONLY!

29

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

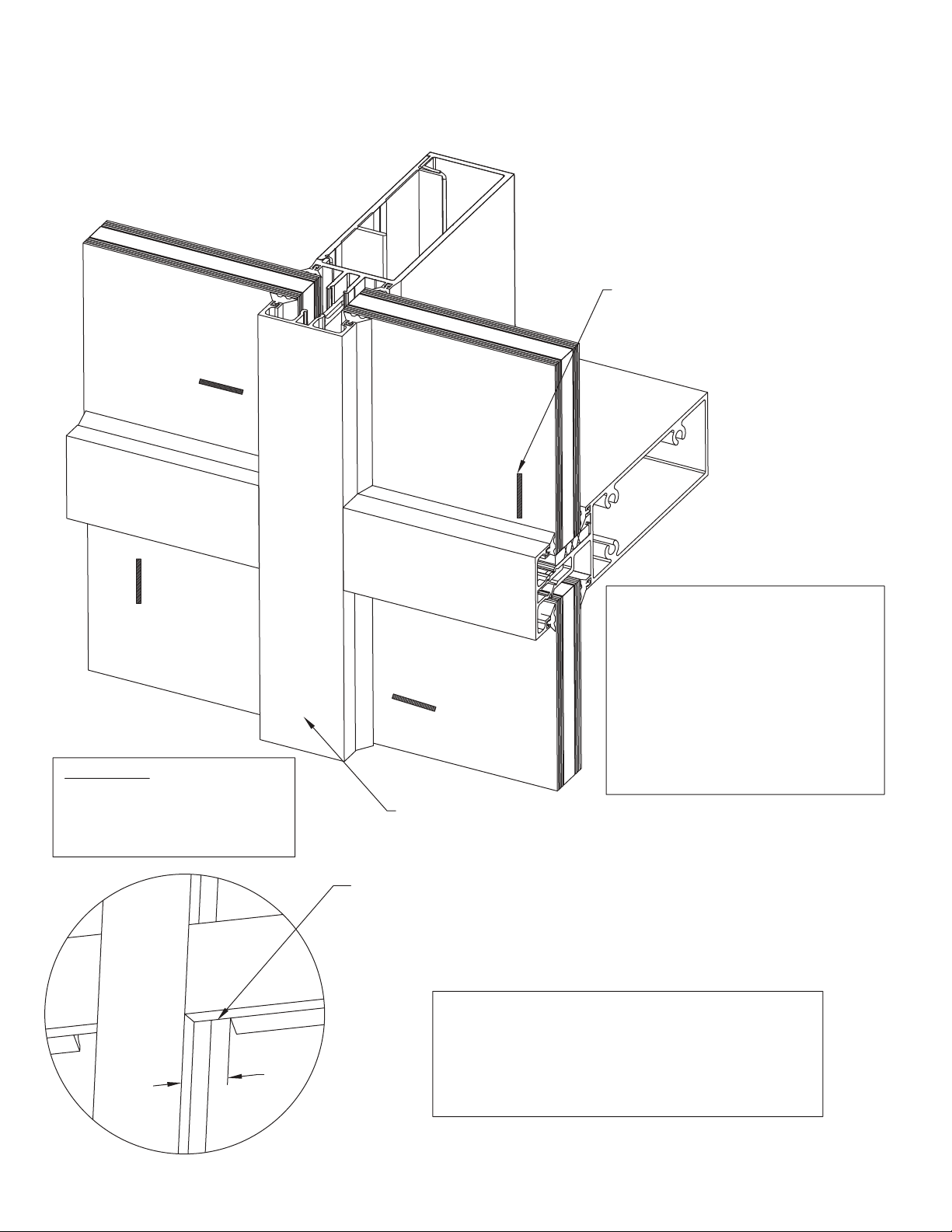

SSG - INSTALLING-ANCHORING UNITS

ONCE UNIT IS POSITIONED AS

SHOWN IN DETAIL AT LEFT.

ROTATE AS SHOWN ABOVE

UNTIL FILLER SNAPS INTO

MULLION. THEN SHIM AND

ANCHOR AS SHOWN BELOW.

ANCHOR SIZE DETERMINED

BY STRUCTURAL REQUIREMENTS

NHP-10446

PLACE FRONT HOOK OF

HP-10390 FILLER OVER

LEG OF HP-10469 MULL.

ANCHOR WITH PIPESLEEVE

REQUIRED FOR LIVELOAD ONLY.

HP-10435

HP-10343

NOTE:

1) INSTALL FIRST UNIT, PLUMB,

SQUARE AND ANCHOR.

2) ROTATE NEXT UNIT INTO PLACE

AND ANCHOR.

3) REPEAT ACROSS OPENING.

4) ANCHOR BOLTS REQUIRED AT

6" OF EACH SIDE OF MULLION.

5) INSTALL HP-10343 SNAP FILLERS

AFTER UNIT HAS BEEN FULLY

INSTALLED AND ANCHORED.

JULY 2011

30

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - INSTALLING - WINDLOAD ANCHOR

ANCHOR REQUIRED AT

MULLS (SIZED BY STRUCTURAL

REQUIREMENTS)

JULY 2011

WINDLOAD ANCHOR

SLOT SIZE DETERMINED

BY STRUCTURAL

REQUIREMENTS

31

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG - MULLION REINFORCING

HP-10469

HP-10390

HP-10414 REINFORCMENT

ATTACH W/ FS-255

(#12 X 3/4" PFH) @

HEAD & SILL ONLY

HP-10390

POSITION REINFORCEMENT TO

FIT AGAINST WALL OF

MULLION TO PROVIDE MAXIMUM

CLEARANCE FOR MULL FILLER

HP-10434

3/8" X 3 3/4" STEEL

BAR. CUT LENGTH TO BE

MULL LENGTH MINUS 2"

AND INSET 1" FROM EACH

END. ATTACH W/ FS-43

AT EACH END OF STEEL.

JULY 2011

SECURE HP-10414 REINFORCING

WITH FS-43 ABOVE AND BELOW

STEEL.

32

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

GLAZING 1/4” GLASS

ERECTION NOTES:

1) WHEN INSTALLING HP-1750

UTILIZING 1/4" GLAZING, PLEASE

REFERENCE DETAILS SHOWN ON

SHEETS 5 THROUGH 21 FOR

STANDARD FABRICATION, ASSEMBLY

AND ERECTION.

2) THE 1/4" SYSTEM WILL USE THE

HP-10486 HORIZONTAL AND HP-8

GLAZING CLIPS TYPICALLY AT ALL

VERTICALS AND HORIZONTALS.

HP-8 @ 12" O.C.

HP-10495

HP-10486

HP-8 @ 12" O.C.

HP-10437

HP-10343

JULY 2011

3) WATER DIVERTERS HP175-FP-47

WILL BE USED AT INTERMEDIATE

VERTICALS AND FIELD MODIFIED

FOR USE AT JAMBS.

33

HP-10435

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

0

90 OUTSIDE CORNER 1/4” GLASS

HP-10455

HP-10457

HP-10465

MODIFIED HP175-FP-47

DIVERTER. BED IN SEALANT

& SEAL AS SHOWN

SEAL CONTINUOUS

HP175-FP-57

MULL CAP. BED IN

SEALANT & ATTACH

W/ FS-202. LOCATE

AT HEAD & SILL

REFERENCE SHEET

# 8 FOR TYPICAL

MULL CAP

INSTALLATION

3/8"

HP-10487

HP-10488

ATTACH W/ FS-55

@ 18" O.C.

DLO +

9/16"

MITER DETAIL

JULY 2011

34

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

90 INSIDE CORNER 1/4” GLASS

NOTE:

REFERENCE SHEETS 5 THRU 12

FOR ADDITIONAL INFORMATION.

0

FORMED ALUM. CORNER

COVER. ATTACH W/

FS-6 (#10 X 3/4" PPH)

@ TOP & BOTTOM OF

COVER (MIN.)

HP-10463

ATTACH W/ FS-6

(#10 X 3/4 PPH)

@ 12" O.C.

BED IN SEALANT

A

HP-10489 FACE CAP.

MUST BE INSTALLED PRIOR

TO HORIZONTAL FACE CAPS

MODIFY HORIZONTAL

BRIDGE FOR INSIDE

CORNER AND SEAL AS

SHOWN ON SHEET #10

ATTACH HP175-FP-65

TO CORNER CLOSURE

W/ SEALANT

AT HEAD & SILL

"A"

A

"A"

NOTE:

USE TYPICAL MULL CAPS AND

MODIFY SIMILAR TO JAMB CAPS.

(SEE SHEET #8)

THEN MARRY SEAL ACROSS MULL

CAPS AND ANGLES ATTACHED TO

CORNER CLOSURE.

HP175-FP-65

END CAP

A

7 9/16"

JULY 2011

SECT "A-A"

35

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

SSG -GLAZING 1/4” GLASS

ERECTION NOTES:

1) WHEN INSTALLING HP-1750 SSG

UTILIZING 1/4" GLAZING, PLEASE

REFERENCE DETAILS SHOWN ON

SHEETS 23 THROUGH 36 FOR

STANDARD FABRICATION, ASSEMBLY

AND ERECTION.

2) THE 1/4" SYSTEM WILL USE THE

HP-10486 HORIZONTAL AND HP-8

GLAZING CLIPS TYPICALLY AT ALL

HORIZONTALS

3) WATER DIVERTERS HP175-FP-68

WILL BE USED AT INTERMEDIATE

VERTICALS AND FIELD MODIFIED

FOR USE AT JAMBS.

HP-8 @ 12" O.C.

HP-10486

HP-8 @ 12" O.C.

HP-10437

HP-10343

HP-10495

HP-10435

JULY 2011

36

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

0

SSG -90 OUTSIDE CORNER 1/4” GLASS

HP-10455

HP-10466

HP-10465

FS-8

STRUCTURAL

SILICONE

V2110

WEATHERSEAL

SEAL BETWEEN VERTICAL

WEAHTERSEAL AND GASKETS

HP175-FP-57

MULL CAP. BED IN

SEALANT & ATTACH

W/ FS-202. LOCATE

AT HEAD & SILL

REFERENCE SHEET

#25 FOR TYPICAL

MULL CAP

INSTALLATION

MODIFY HP175-FP-68

AT CORNER AND SEAL PER

SHEET #30

DLO +

9/16"

MITER DETAIL

JULY 2011

37

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

0

SSG -90 INSIDE CORNER 1/4” GLASS

NOTE:

REFERENCE SHEET #23 THRU #29

FOR ADDITIONAL INFORMATION

1/16"

FORMED ALUM. CORNER

COVER. ATTACH W/

FS-6 (#10 X 3/4" PPH)

@ TOP & BOTTOM OF

COVER (MIN.)

7 9/16"

HP175-FP-66

"A"

"A"

JULY 2011

HP-10461 CORNER

CLOSURE. ATTACH W/

FS-6 (#10 X 3/4" PPH)

@ 18" O.C.

BED IN SEALANT

ATTACH HP175-FP-66

TO CORNER CLOSURE

W/ SEALANT

AT HEAD & SILL

SECT "A-A"

38

V2110 DSA TAPE

STRUCTURAL SILICONE

NOTE:

USE TYPICAL MULL CAPS AND

MODIFY SIMILAR TO JAMB CAPS.

(SEE SHEET #8)

THEN MARRY SEAL ACROSS MULL

CAPS AND ANGLES ATTACHED TO

CORNER CLOSURE.

HP175-FP-68 DIVERTER BRIDGE

TO BE USED AT HORIZONTALS.

MODIFY AND SEAL.

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

DOOR DETAILS

HP-10479

HP-10482

HP-10480

HP-10482

HP-10480

ACCESS HOLES

LOCATED AT ANCHORS

JULY 2011

39

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

HP-10479

ACCESS HOLES

LOCATED AT

HORIZONTAL

FASTENERS

DOOR DETAILS

JULY 2011

ANCHOR JAMB THROUGH

HP-10390 FILLER

LOCATE ANCHORS AT HEAD & SILL

(ADDITIONAL ANCHORS MAY BE

REQUIRED BASED ON PROJECT

CONDITIONS.)

HOLE PLUG REQUIRED

AT VISION AREAS

40

HP-10481

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

REGLAZING INSTRUCTIONS

VERTICAL DEGLAZING INSTRUCTIONS

A. In order to remove a lite of glass, it is necessary to remove one face member.

B. The procedure for removing any vertical face member is shown in Figure D-1.

1. Remove exterior glazing gasket in order to provide access to plastic clips.

2. Insert keyhole saw through the space between the glass and aluminum face until saw blade projects out to other side.

3. Slide the saw blade until it comes in contact with a plastic clip and saw through clip. Repeat process until all clips have

been cut and face can be removed.

4. Remove balance of exterior gaskets on lite to be removed.

5. Remove lite of glass per standard glazing practices.

6. Maximum glass size for replacement litre in HP-175 equals 5/9" over daylite opening and 7/8" over daylite opening in HP-225.

7. If all faces are removed, glass size equals original sizes.

VERTICAL REGLAZING PROCEDURE

1. Remove old clips from face member by sliding out one end.

3. Insert new plastic clips into vertical member and stake as previously outlined.

5. Mark location of plastic clips on glass as shown on glazing details sheet #8.

6. Apply face member without preloading gasket.

7. Roll in glazing gasket HP-10477 on exterior of reglazed lite and bottom side of intermediate horizontal if applicable.

8. For butt glazed mullions it will be necessary to remove old silicone and clean the metal surfaces with isopropyl alcohol.

The adjacent glass edges should also have excess silicon removed and be prepped for new sealant.

After setting new lite, reseal interior structrural joints as well as the exterior weather seal.

JULY 2011

41

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

H P - 1 7 5 0 I N S T A L L A T I O N M A N U A L

REGLAZING INSTRUCTIONS

HORIZONTAL REGLAZING INSTRUCTIONS

A. In order to remove a lite of glass, it is necessary to remove one face member. On the butt

glazed system it will also be necessary to cut and remove the vertical silicone joints at the

interior and exterior of the glass.

B. The procedure for removing any face member is shown in Figure D-2.

1. Remove exterior glazing gasket in order to provide access to plastic clips.

2. Insert thin bladed chisel through the space between the glass and aluminum face.

3. Slide the chisel until it comes in contact with a plastic clip and slide clips to one end of

horizontal. Repeat process until all clips are located at end of cap, then slide face cap

off of clips.

4. Remove balance of exterior gaskets on lite to be removed.

5. Remove lite of glass per standard glazing practices.

6. Maximum glass size for replacement litre in HP-1750 equals 5/8" over daylite opening.

7. If all faces are removed, glass size equals original sizes.

HORIZONTAL REGLAZING PROCEDURE

1. Remove old clips from face member by sliding out one end.

2. On intermediate horizontal gutter members, slide the gutter portion of the old clips sideways

so new clips can be inserted.

3. insert new plastic clips into gutter member.

4. Position setting blocks and jiggle glaze new lite of glass into opening.

5. Mark location of plastic clips on glass as shown on glazing details sheet #8.

6. Apply face member without preloading gasket.

7. Roll in glazing gasket HP-10477 on exterior of reglazed lite and bottom side of intermediate

horizontal if applic

able.

JULY 2011

42

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Loading...

Loading...